Open Access

Open Access

ARTICLE

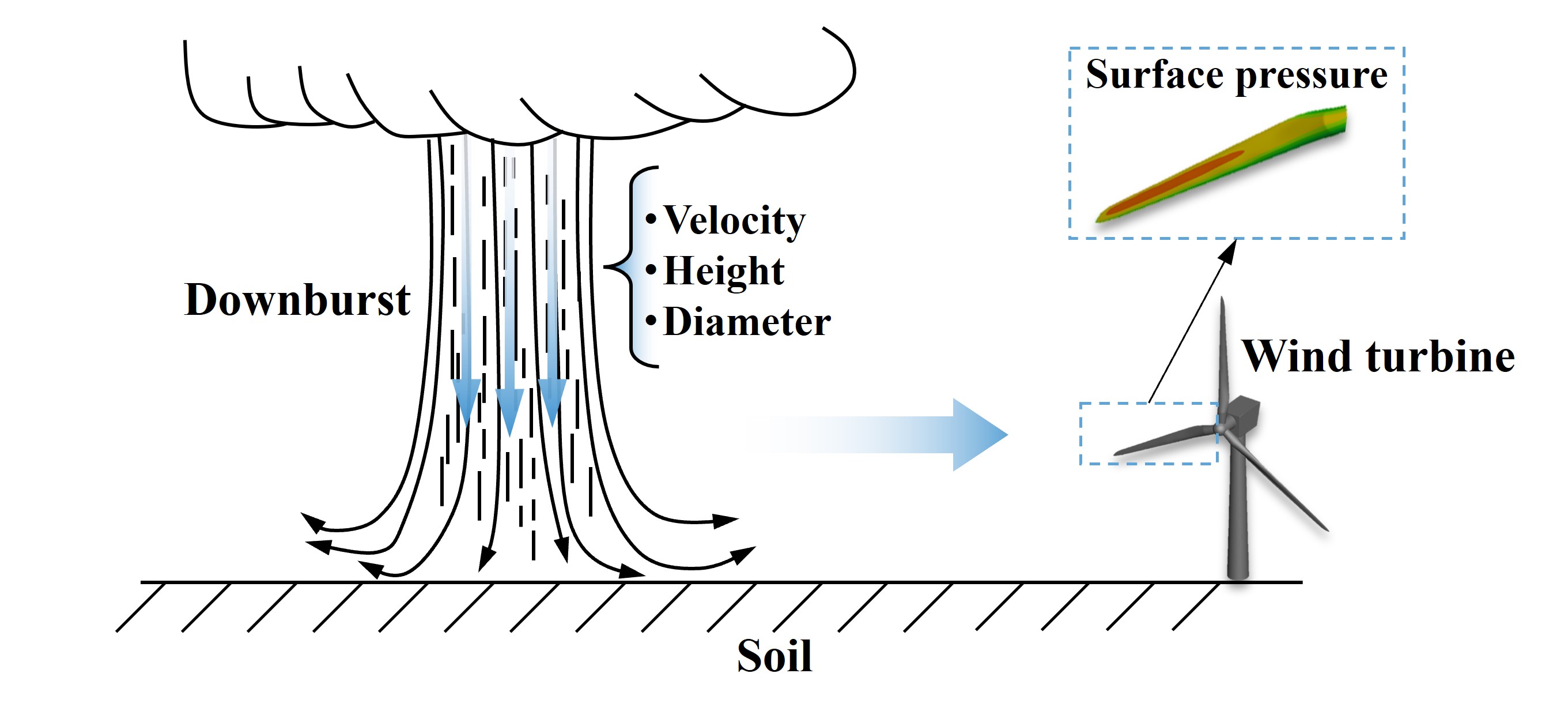

Fluid-Dynamic Loads on Turbine Blades in Downburst Wind Fields

1 School of Green Energy and Storage, Lanzhou University of Technology, Lanzhou, 730050, China

2 Gansu Provincial Technology Centre for Wind Turbines, Lanzhou, 730050, China

3 School of Energy and Power Engineering, Lanzhou University of Technology, Lanzhou, 730050, China

4 Shanghai Key Laboratory of Mechanics in Energy Engineering, Shanghai Institute of Applied Mathematics and Mechanics, School of Mechanics and Engineering Science, Shanghai University, Shanghai, 200072, China

* Corresponding Author: Yan Wang. Email:

(This article belongs to the Special Issue: Fluid Mechanics & Thermodynamics in Renewable Energy and HVAC Systems)

Fluid Dynamics & Materials Processing 2025, 21(11), 2651-2671. https://doi.org/10.32604/fdmp.2025.070122

Received 08 July 2025; Accepted 20 October 2025; Issue published 01 December 2025

Abstract

A downburst is a strong downdraft generated by intense thunderstorm clouds, producing radially divergent and highly destructive winds near the ground. Its characteristic scales are expressed through random variations in jet height, velocity, and diameter during an event. In this study, a reduced-scale parked wind turbine is exposed to downburst wind fields to investigate the resulting extreme wind loads. The analysis emphasizes both the flow structure of downbursts and the variations of surface wind pressure on turbine blades under different jet parameters. Results show that increasing jet velocity markedly enhances the maximum horizontal wind speed, while greater jet height reduces the horizontal wind speed and shifts the peak velocity closer to the jet center. Increasing jet diameter primarily affects the radial position of the maximum horizontal wind speed. For the wind turbine, the maximum equivalent stress and blade displacement increase almost linearly with jet velocity, but exhibit the opposite trend with jet diameter. Specifically, as jet velocity rises from 10 m/s to 20 m/s, the surface pressure coefficient at the blade tip increases by approximately 4.5 times. Changes in jet diameter indirectly alter the turbine’s relative position within the wind field, leading to variations in wind load direction and exposure area. Conversely, increasing jet height extends the dissipation path of the downdraft, thereby reducing the intensity of the airflow acting on the blades. For example, when jet height increases from 0.3 m to 1.2 m, the surface pressure coefficient at the blade tip decreases by nearly 50%.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools