Open Access

Open Access

ARTICLE

Experimental Investigation of a Loop Heat Pipe with a Flat Evaporator

National Key Laboratory of Spacecraft Thermal Control, Beijing Institute of Spacecraft System Engineering, China Academy of Space Technology, Beijing, 100094, China

* Corresponding Author: Hongxing Zhang. Email:

(This article belongs to the Special Issue: Recent Advances in Loop Heat Pipe)

Frontiers in Heat and Mass Transfer 2025, 23(2), 651-662. https://doi.org/10.32604/fhmt.2025.062191

Received 12 December 2024; Accepted 19 February 2025; Issue published 25 April 2025

Abstract

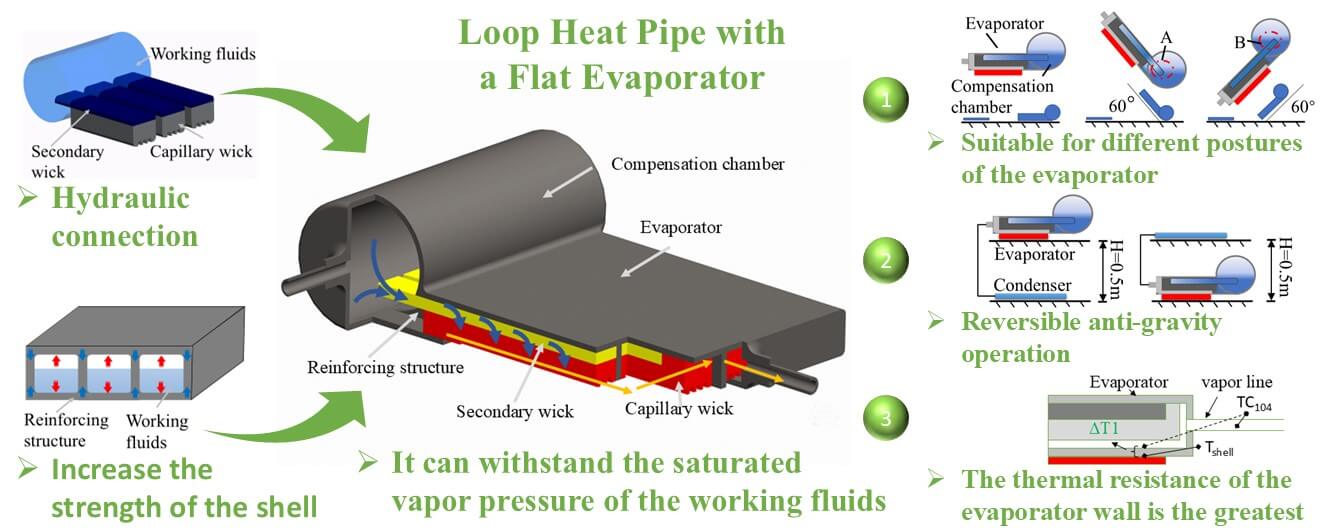

The loop heat pipe with a flat evaporator is mainly divided into two forms: rectangular evaporator and disk-shaped evaporator. The rectangular evaporator has advantages such as low heat leakage, a thin shell, and a large contact area compared to the disk-shaped evaporator. However, most of the research on rectangular evaporators focuses on working fluids such as water, methanol, and acetone, when these working fluids are in operation, the internal pressure of the evaporator is less than atmospheric pressure. Ammonia, propylene, and other working fluids can also be utilized in the loop heat pipe, these working fluids demonstrate better performance when operating within other temperature intervals, for example, the operating temperature range of ammonia is −20°C to 50°C, however, in an atmospheric pressure environment, it is very difficult for the shell of the rectangular evaporator to withstand the saturated vapor pressure of the working fluid. This paper designs a rectangular flat plate loop heat pipe that can use ammonia as the working fluid. The internal reinforcing structure is used to improve the pressure strength of the shell. The secondary wick connects the compensation chamber and the capillary wick hydraulically. The experiment indicates that this kind of rectangular evaporator is unaffected by the position, and the secondary wick can effectively supply liquid under different angles. The thermal resistance of the evaporator wall was analyzed, and it was found that the thermal resistance of the evaporator wall was the main component of the thermal resistance of the system. The heat transfer capacities of 460 W@0.5 m and 200 W@10 m were tested. The test results indicate that by setting a reinforcing structure inside the flat plate evaporator, the evaporator can withstand internal pressure. Combined with the design of the secondary wick, the flat plate evaporator can use working fluids with different pressures, expanding the range of available working fluids.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools