Open Access

Open Access

ARTICLE

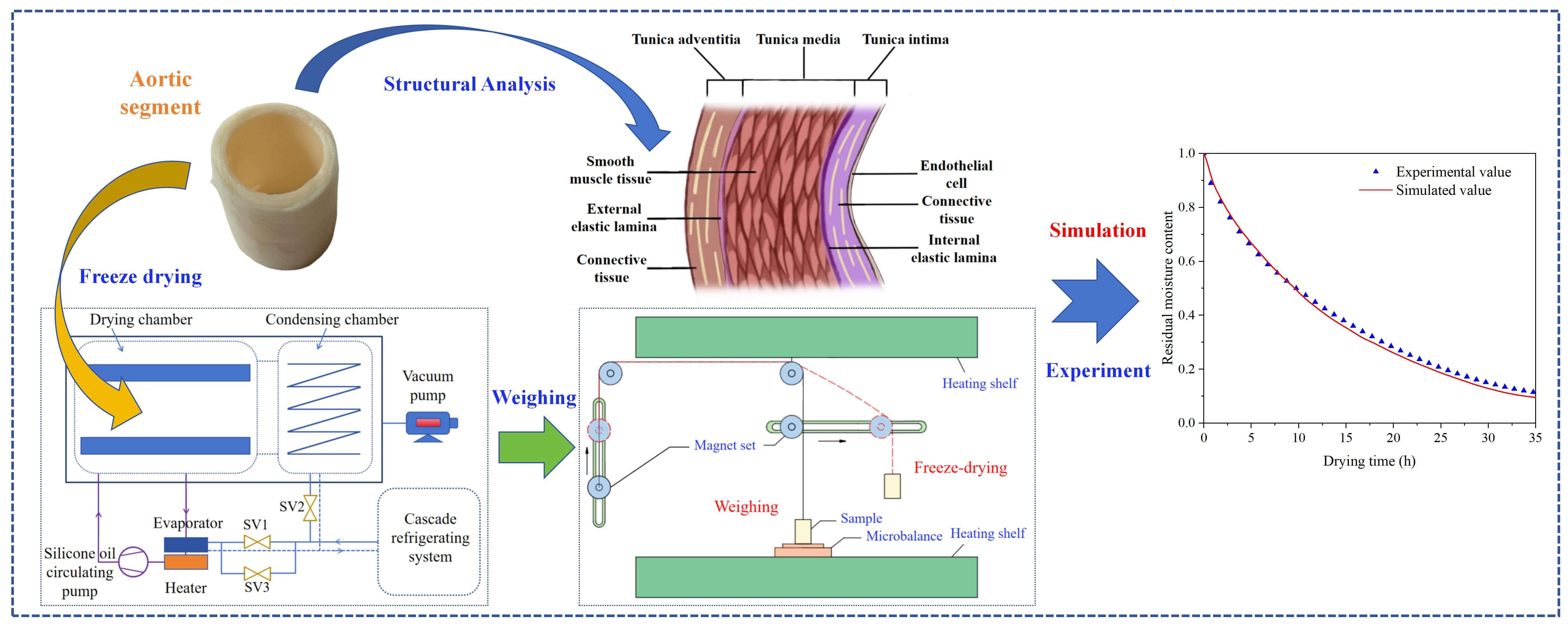

Modeling and Experimental Research of Heat and Mass Transfer during the Freeze-Drying of Porcine Aorta Considering Radially-Layered Tissue Properties

1 School of Civil Engineering and Architecture, Xinxiang University, Xinxiang, 453003, China

2 Postdoctoral Affairs Office, Postdoctoral Research Workstation of Hualan Biological Engineering Incorporated Company, Xinxiang, 453003, China

3 School of Energy and Power Engineering, University of Shanghai for Science and Technology, Shanghai, 200093, China

* Corresponding Author: Yaping Liu. Email:

(This article belongs to the Special Issue: Innovations in Drying Technologies: Bridging Industrial, Environmental, and Energy Efficiency Challenges)

Frontiers in Heat and Mass Transfer 2025, 23(5), 1621-1637. https://doi.org/10.32604/fhmt.2025.072268

Received 23 August 2025; Accepted 11 October 2025; Issue published 31 October 2025

Abstract

Freeze-drying of structurally heterogeneous biomaterials such as porcine aorta presents considerable modeling challenges due to their inherent multilayer composition and moving sublimation interfaces. Conventional models often overlook structural anisotropy and dynamic boundary progression, while experimental determination of key parameters under cryogenic conditions remains difficult. To address these, this study develops a heat and mass transfer model incorporating a dynamic node strategy for the sublimation interface, which effectively handles continuous computational domain deformation. Additionally, specialized fixed nodes were incorporated to adapt to the multilayer structure and its spatially varying thermophysical properties. A novel non-contact gravimetric system was introduced to monitor mass loss in real time without disrupting vacuum, enabling accurate experimental validation. Combined with dehydration data, the model quantified critical parameters including effective thermal conductivity of the dried layer, vapor diffusivity, and sublimation mass transfer resistance. The results show that the migration of the sublimation fronts from both the inner and outer tunics toward the tunica media significantly alters the drying kinetics and heat-mass transfer characteristics. The proposed approach provides an adaptable and predictive framework for simulating freeze-drying processes in structurally heterogeneous systems with spatially varying thermophysical properties.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools