Open Access

Open Access

ARTICLE

Improvement of Surface Electrical Properties of Silicone Rubber Based on Fluorination

Guangxi Key Laboratory of Power System Optimization and Energy Technology, Guangxi University, Nanning, 530004, China

* Corresponding Author: Yi Li. Email:

(This article belongs to the Special Issue: Advanced Modification Methods for Polymers)

Journal of Polymer Materials 2025, 42(2), 549-568. https://doi.org/10.32604/jpm.2025.064866

Received 25 February 2025; Accepted 05 June 2025; Issue published 14 July 2025

Abstract

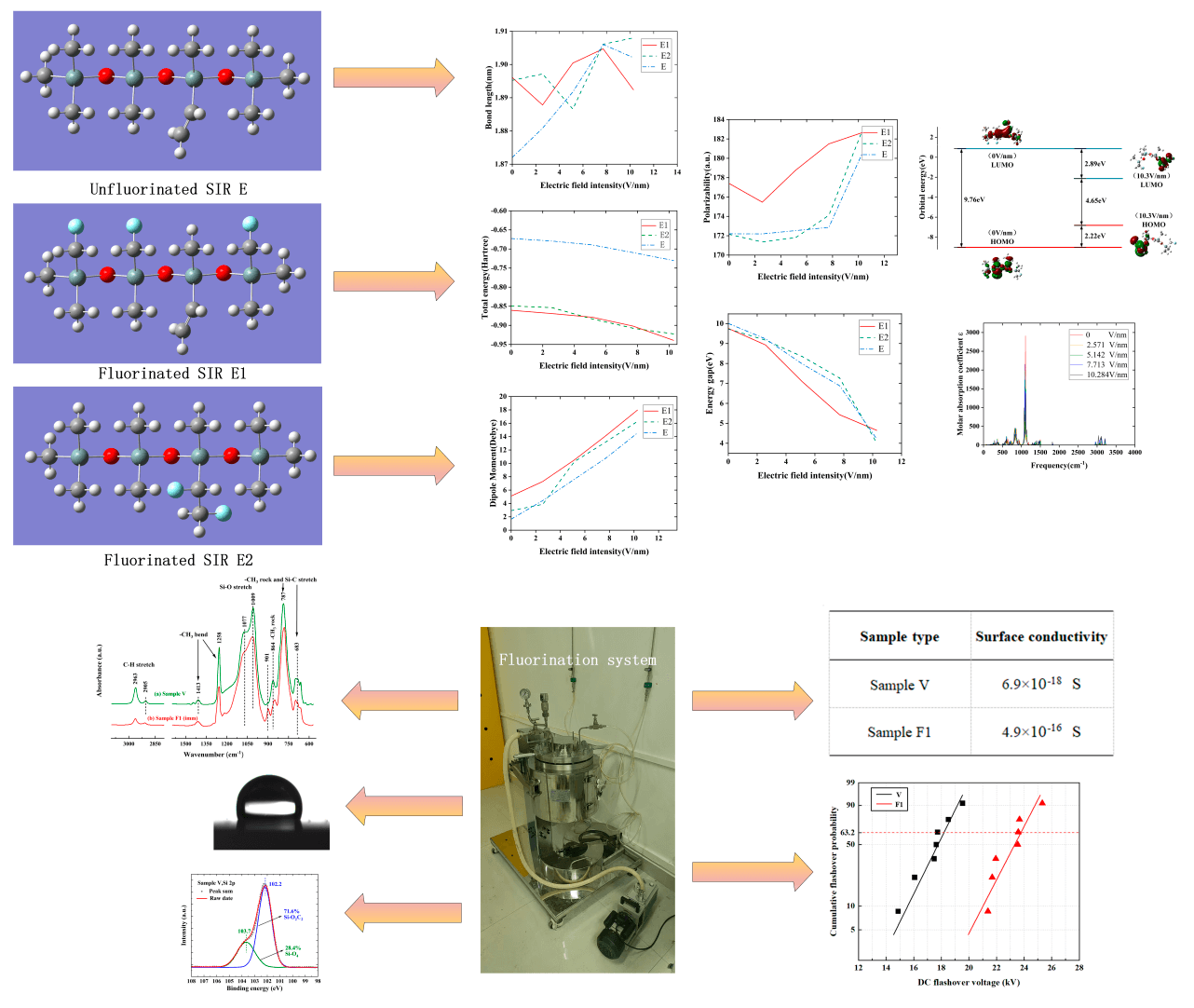

Fluorination is a critical surface modification technique for enhancing the electrical performance of composite insulators. This study employs molecular simulations to examine the microstructure and space charge behavior of fluorinated and non-fluorinated silicone rubber under an electric field, with experimental validation. The results show that fluorinated silicone rubber exhibits lower total energy, higher polarization, and stronger dipole moments compared to its non-fluorinated counterpart, shifting the material from an insulating to a conductive state. Under lower electric field strengths, the carbon-silicon bonds in fluorinated silicone rubber are longer, but it maintains geometric stability under higher fields. The energy gap changes across different fluorination modes and varies with electric field strength, indicating that fluorination affects conductivity differently at various field intensities. Both fluorination methods improve conductivity in the 0–3.8 V/nm range, with substitutional fluorination showing superior performance between 3.8 and 8.9 V/nm. Above 9.1 V/nm, fluorination maximizes conductivity. The fluorinated samples exhibit a greater redshift at higher electric fields, resulting in enhanced conductivity and improved surface charge distribution. These findings offer insights into the microscopic effects of fluorination on silicone rubber’s electrical properties, while experiments confirm that fluorination increases hydrophobicity and boosts DC flashover voltage, further enhancing the material’s performance.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools