Open Access

Open Access

REVIEW

3D Printed Hydrogels for Soft Robotic Applications

School of Mechanical and Aerospace Engineering, Nanyang Technological University, 50 Nanyang Avenue, Singapore, 639798, Singapore

* Corresponding Author: Yifan Wang. Email:

Journal of Polymer Materials 2025, 42(2), 277-305. https://doi.org/10.32604/jpm.2025.065269

Received 08 March 2025; Accepted 23 June 2025; Issue published 14 July 2025

Abstract

The integration of 3D-printed hydrogels in soft robotics enables the creation of flexible, adaptable, and biocompatible systems. Hydrogels, with their high-water content and responsiveness to stimuli, are suitable for actuators, sensors, and robotic systems that require safe interaction and precise manipulation. Unlike traditional techniques, 3D printing offers enhanced capabilities in tailoring structural complexity, resolution, and integrated functionality, enabling the direct fabrication of hydrogel systems with programmed mechanical and functional properties. In this perspective, we explore the evolving role of 3D-printed hydrogels in soft robotics, covering their material composition, fabrication techniques, and diverse applications. We highlight advancements in hydrogel-based actuators, sensors, and robots, emphasizing their ability to perform intricate motions. In addition, we discuss challenges like mechanical robustness, scalability, and integration as well as the potential of hydrogels in soft robotics and explore future directions for their development.Keywords

With the growing demand for flexibility and adaptability, soft robotics has attracted increasing research attention in recent years [1–3]. Unlike traditional rigid robotics, which largely depend on mechanics or electronics, material properties play the key role in soft robotics. Silicone-based elastomers, such as polydimethylsiloxane (PDMS), are most used in actuation for their advantages in stability, ease of processing, and excellent mechanical properties [4–6]. However, current trends are shifting towards intelligent soft materials to enable smaller, more capable robots with integrated functions, thus reducing dependence on complex design and control strategies [7–9].

Owing to their distinctive properties, such as softness, elasticity, biocompatibility, and multifunctionality, hydrogels have recently emerged as promising smart materials for soft robotic systems [10–16]. Moreover, unlike conventional soft materials used in robotics, hydrogels mimic the properties of soft biological tissues, including flexibility, high water content, and responsiveness to a variety of stimuli. These unique features make hydrogels highly suitable for soft robotic applications, enabling safe human interaction, precise manipulation, and adaptive functionalities [17–21]. Currently, most hydrogel parts are fabricated through molding, and then solidified by UV curing or heat curing, which limits the complexity and manufacturing speed.

Additive manufacturing, also known as 3D printing, is an emerging technique that utilizes a layer-by-layer strategy to fabricate complex structures. Compared to subtractive manufacturing, 3D printing enables complex designs, accelerates prototyping, and reduces costs for low-volume production. In recent years, breakthroughs in 3D printing technologies have unlocked new possibilities for hydrogel applications by allowing the fabrication of intricate, customized structures with high printing resolution [22–25]. Unlike conventional methods, 3D printing facilitates spatial control over material distribution, internal architecture, and mechanical gradients, enabling functionalities such as anisotropic swelling, programmable actuation, and embedded sensing within a single structure. For example, digital light processing allows micron-level resolution, while extrusion-based methods enable multimaterial integration. These advancements not only enable fine-tuning of hydrogel properties—such as stiffness gradients, swelling behavior, and anisotropic responsiveness—but also support the seamless integration of multiple functions within a single construct. Such integrated capabilities are difficult to achieve using non-printed hydrogels, which typically require manual assembly and suffer from limited design flexibility. For instance, 3D-printed hydrogels can combine sensing, actuation, and self-healing capabilities, paving the way for robotic systems with enhanced autonomy and embodied intelligence [26–30].

Despite their promise, several challenges remain in realizing the full potential of 3D-printed hydrogels in robotic applications. Firstly, from a materials perspective, developing high-performance hydrogels for printing is still needed. Additionally, for the printing aspect, issues such as achieving faster actuation, optimizing printing resolution for 3D hydrogel structures remain challenging. Moreover, interdisciplinary approaches that combine bioinspired designs, computational modeling, and advanced printing techniques are critical for overcoming these barriers.

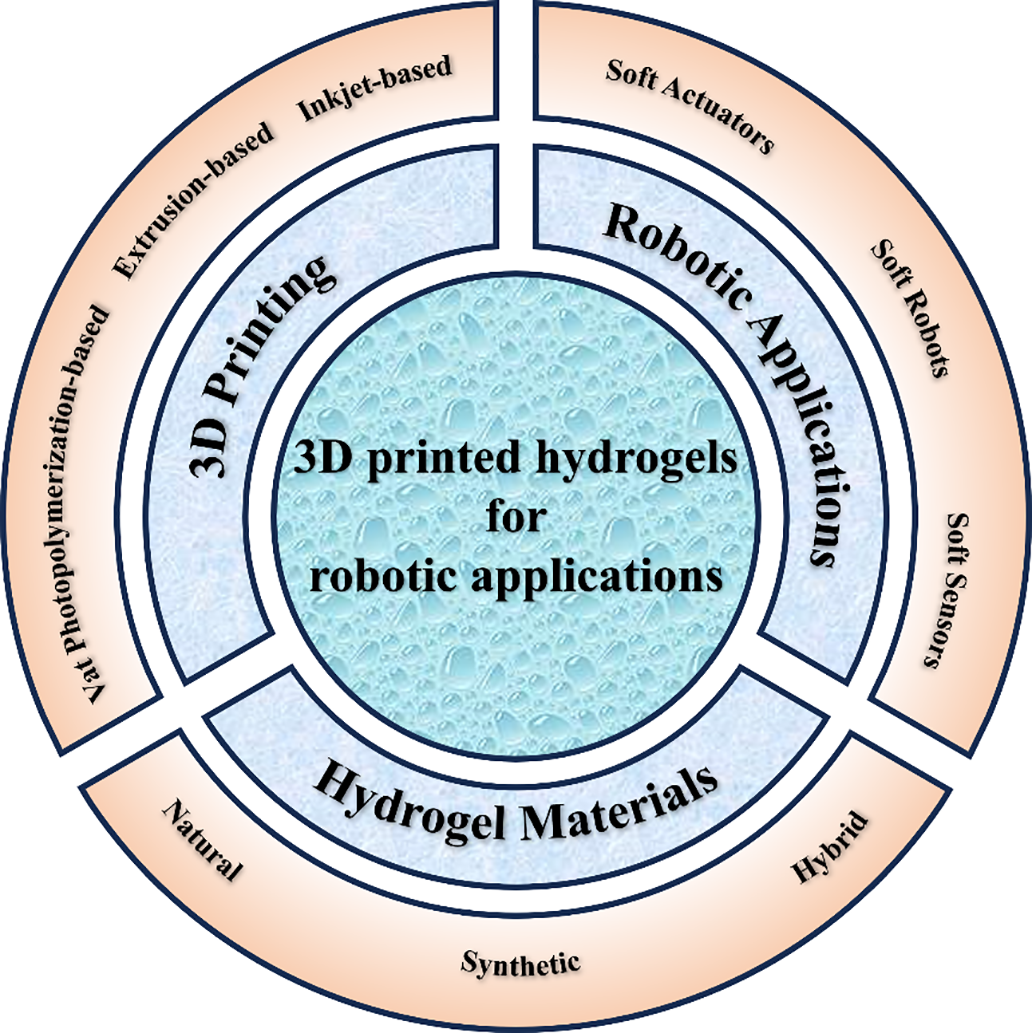

In this perspective, we systematically describe the evolving role of 3D-printed hydrogels in robotics, examining their material characteristics, fabrication methods, and application domains (Fig. 1). We firstly introduce the classification, properties, and relevance of hydrogels for robotic applications. The additive manufacturing methods for these hydrogels are then introduced and summarized. Then, we discuss the development of hydrogel-based soft robotic systems, focusing on actuation, sensing, and integrated functionalities. Finally, we address the remaining challenges and outline future prospects for broader adoption and innovation of 3D-printed hydrogels in soft robotics.

Figure 1: Summary of 3D printed hydrogels for soft robotic applications

By systematically categorizing natural, synthetic, and hybrid hydrogels alongside a detailed discussion of diverse additive manufacturing techniques, we provide a comprehensive framework that bridges material science with advanced processing strategies. This integrated approach not only emphasizes the multifunctional potential of hydrogels in soft robotics but also highlights how careful modulation of both composition and printing parameters can yield sophisticated actuators, sensors, and robotic systems.

Furthermore, we introduce a comparative analysis framework that directly correlates hydrogel properties with their performance in soft actuators, sensors, and integrated robotic functionalities. By contrasting traditional and 3D-printed hydrogel systems, we demonstrate how additive manufacturing enables new levels of architectural complexity, functional integration, and spatial programmability. This approach addresses current technological challenges, such as water retention, mechanical robustness, and printing resolution, by figuring out the interplay between material design and processing techniques. By outlining emerging research directions that incorporate biomimetic design, nanocomposite reinforcement, and machine learning-assisted optimization, our review sets the stage for the development of next-generation intelligent and adaptive soft robotic systems. This dual focus on material innovation and process integration not only fills critical knowledge gaps but also provides a valuable roadmap for future advancements in the field.

2 3D Printable Hydrogel Materials

2.1 Classification of Hydrogels

The selection of hydrogel plays a crucial role in determining the printability, biocompatibility, and mechanical properties of 3D-printed constructs. Hydrogels can be categorized by their composition into natural, synthetic, or hybrid types (Table 1).

Natural hydrogels are soft, water-rich materials derived from natural polymers such as alginate, collagen, chitosan, and hyaluronic acid [31–33]. Known for their inherent bioactivity and biocompatibility, these hydrogels are highly suitable for biomedical applications [34–36]. However, the rheological complexity of natural hydrogels, such as high viscosity and slow gelation, can still pose challenges for 3D printing [37,38]. While shear-thinning behavior is generally advantageous, insufficient structural recovery after shear may compromise printing resolution in some cases [39]. To enhance the printability of natural hydrogels, approaches such as tuning rheological properties, optimizing crosslinking mechanisms, and incorporating additives to adjust composition are commonly applied [40].

Cai et al. used extrusion-based 3D printing to fabricate oxidized alginate–gelatin composite hydrogels containing Laponite [41]. This work highlights the importance of natural hydrogels in advancing 3D printing technology and demonstrates their integration into sophisticated manufacturing processes. Xu et al. investigated high-strength chitosan-based supramolecular hydrogels designed for 3D bioprinting, emphasizing their potential as bioink materials and contributing to advancements in the bioprinting field [42]. However, 3D printed natural hydrogels face limitations in robotic applications due to their insufficient mechanical strength, slow actuation, environmental sensitivity, and lack of electrical or thermal conductivity, which hinder their performance in dynamic and complex systems [43]. To overcome these challenges, hybrid approaches combining natural hydrogels with synthetic materials or nanocomposites are often employed to enhance their properties and expand their functionality [44–46].

Synthetic hydrogels, made from polymers such as polyethylene glycol (PEG), polyacrylamide (PAAm), poly(acrylic acid) (PAAc), and polyvinyl alcohol (PVA), are particularly well-suited for robotics due to their tunable mechanical properties and predictable behavior during 3D printing [47–52]. Their properties, such as viscosity, flow characteristics, and responsiveness to external stimuli, can be precisely adjusted to meet the demands of different robotic applications. These hydrogels offer exceptional control over mechanical strength and elasticity, which is crucial for designing soft actuators and sensors in robotics. Additionally, their ability to be engineered for specific functions, such as mimicking tissue stiffness or responding to environmental stimuli, makes them ideal for bio-inspired robotics and soft robotic systems [53,54]. Modifications can further enhance their durability, mechanical performance, and integration with electronic components, allowing for the development of more versatile and adaptive robotic systems.

Wang et al. developed cross-linked PAA hydrogels via DLP 3D printing, enabling precise control over actuator geometry and composition [55]. By tuning the acrylic acid and cross-linker content, the printed hydrogels exhibited programmable ionic exchange capacity, water uptake, and mechanical stiffness. Under low applied voltages (4–6 V), the resulting actuators demonstrated rapid and reversible bending with a maximum deformation angle up to 43°, highlighting their potential for use in soft robotics. Liu et al. developed an injectable PEG-based synthetic hydrogel crosslinked via Ag+–thiol coordination, where Ag+ acted as both the chemical crosslinker and antibacterial agent [56]. Adhesive liposomes loaded with BMP-2 were incorporated into the hydrogel matrix as drug carriers, providing sustained release and enhanced tissue adhesion. The resulting system exhibited self-healing, antibacterial properties, and promoted bone regeneration in osteoporotic models.

Nevertheless, synthetic hydrogels still face challenges in achieving multifunctional integration, such as combining actuation, sensing, and structural roles within a single material system. To address these limitations, hybrid strategies are increasingly employed to enhance performance and expand the capabilities of hydrogel-based robotic components.

Hybrid hydrogels, formed by combining natural and synthetic components, offer a unique balance of biocompatibility, mechanical strength, and functional versatility, making them particularly promising for applications in robotics [57,58]. By leveraging the biocompatibility and biodegradability of natural materials alongside the enhanced mechanical properties and stability provided by synthetic elements, hybrid hydrogels can improve printability and structural integrity. This balance is especially advantageous in soft robotics, where materials need to mimic biological tissues while maintaining durability and responsiveness. Hybrid hydrogels enable the creation of complex, adaptable robotic structures that combine natural-like flexibility and synthetic robustness, paving the way for advancements in robotic systems and biomedical devices.

Cheng et al. developed a direct ink writing 3D printing technique to fabricate biomimetic soft robots using a variety of functional hydrogel materials, including PAAm, PVA, and PNIPAm [59]. By introducing alginate as a biocompatible rheological modifier, the hydrogels exhibited enhanced mechanical toughness while retaining their intrinsic properties such as stretchability, permeability, and stimuli-responsiveness. This method enabled the creation of complex and functional designs, including a hydraulically actuated PAAm-based artificial tentacle, a PVA-based bioengineered robotic heart capable of material transport, and a PNIPAm-based phototropic artificial tendril.

Wang et al. developed a hydrogel 3D printing technique using the capacitor edge effect, enabling the fabrication of hybrid alginate-polyacrylamide hydrogels with precise geometries and multifunctional properties. This method facilitated the creation of hydrogel scaffolds and ionic devices, demonstrating potential applications in soft robotics [60].

To expand the functionality of hydrogels beyond their intrinsic material properties, various functional fillers such as magnetic particles, photothermal agents, and other environmentally responsive additives are often incorporated into the polymer network. Jiang et al. developed a hybrid hydrogel actuator by in situ forming Fe3O4 microparticles within an alginate/PNIPAm–PAAc network through UV-induced photo-reduction and hydrolysis [61]. The magnetic particle distribution was spatially controlled by adjusting irradiation time, enabling programmable responses to magnetic fields, temperature, and near-infrared (NIR) light. This approach demonstrates the potential of hybrid hydrogels for multi-responsive actuation in soft robotics.

Kim et al. developed a hybrid hydrogel-based adhesive actuator inspired by octopus suction cups [62]. The system, called the Plasmonic AdPatch, integrates a thermoresponsive PNIPAm hydrogel with plasmonic gold nanostars (GNSs) on a nanohole-patterned PDMS substrate. The PNIPAm hydrogel enables volumetric changes in response to temperature, while GNSs convert NIR light into heat, providing a secondary photoresponsive trigger. This dual-responsive hydrogel enables reversible, switchable adhesion with high precision under both thermal and photothermal stimuli, demonstrating potential for soft robotic systems requiring remote and controllable actuation.

Chen et al. developed a hybrid hydrogel actuator by integrating thermoresponsive PNIPAm/nigrosine hydrogel and pH-responsive PAAc hydrogel into a sandwich structure with an anisotropic bamboo sheet as the passive layer [63]. The PNIPAm component provided temperature and NIR-light responsiveness, while the PAAc layer enabled pH-induced swelling and shrinking. This dual-active-layer design allowed bidirectional and programmable bending under single or combined stimuli. The actuator exhibited strong deformation, good durability, and was demonstrated in biomimetic tasks such as simulated predation and stimulus-controlled release, highlighting the promise of hybrid hydrogels for multifunctional and multi-responsive robotic systems.

Hybrid hydrogels offer a powerful strategy for integrating multiple functionalities into soft robotic systems by combining material components with complementary properties. Through compositional and structural design, these materials can achieve complex, multi-responsive behaviors that are difficult to realize with conventional hydrogels [64–66]. Continued innovation in hybrid hydrogel systems is expected to drive further advancements in the development of intelligent, adaptable, and task-specific soft robotic platforms.

Hydrogels exhibit a diverse range of properties that position them as highly promising materials for applications in robotics. Their high water content, which can reach up to 90%, imparts a soft and flexible structure that closely mimics the mechanical characteristics of biological tissues [67,68]. This biomimetic behavior allows hydrogels to undergo significant deformation under external forces while maintaining their structural integrity, making them suitable for soft robotic components requiring elasticity and adaptability.

In particular, hydrogels with high water content often exhibit superior compliance, low interfacial friction, and excellent compatibility with aqueous environments [69,70]. These features not only enhance their deformability and adaptability but also make them especially suitable for underwater robotic applications such as swimming, where soft hydrodynamic propulsion and rapid response are essential. For instance, a jelly-like artificial muscle based on a hydrogel–dielectric elastomer hybrid was recently demonstrated to achieve fast, untethered swimming through electro-driven actuation, highlighting the advantages of water-rich hydrogel systems for dynamic and self-contained robotic motion [71].

High water content also significantly influences the physical behavior and application performance of hydrogels. It contributes to their softness, high deformability, and effective ion transport, which are essential for many robotic functions such as actuation and sensing. However, maintaining this water content is critical, as evaporation can lead to performance degradation over time. The permeability and hydration-retention characteristics of hydrogels further enhance their usability in robotics. Hydrogels can facilitate the diffusion of ions or small molecules, enabling their integration into systems requiring ionic conduction. Their ability to retain water under diverse environmental conditions ensures consistent performance, making them reliable for prolonged operational scenarios. For instance, Wang et al. demonstrated that by incorporating glycerol into a conductive hydrogel system, water retention was substantially improved, enabling the hydrogel to retain its structure and sensing functionality over 8 days under ambient conditions [72].

Furthermore, the mechanical properties of hydrogels, including stiffness, toughness, and resilience, can be precisely tailored by varying polymer composition, crosslinking density, and the incorporation of reinforcing agents, such as nanoparticles or fibers [73–75]. For example, Liang et al. developed a nanoconfined hydrogel system based on polyacrylamide and high-aspect-ratio hectorite nanosheets, in which high polymer entanglement was achieved under co-planar nanoconfinement while maintaining a water content of 62 wt% [76]. This approach led to a tenfold increase in Young’s modulus (up to 50 MPa) compared to the non-confined control, without sacrificing flexibility or hydration. The work demonstrates how mechanical reinforcement can be realized even in water-rich hydrogels by optimizing nanoscale architecture and polymer density, offering new possibilities for soft robotic applications requiring both high stiffness and compliance. Such tunability offers the flexibility needed to design robotic systems for applications ranging from delicate manipulation to high-load operations.

A key attribute of hydrogels in the context of robotics is their stimuli-responsive behavior. Many hydrogels exhibit reversible swelling or deswelling when exposed to external stimuli such as temperature, pH, light, or electric fields [4]. This property is particularly advantageous for actuators and sensors in soft robotics, enabling controlled, programmable, and reversible deformations. For instance, thermos-responsive hydrogels can contract or expand in response to temperature fluctuations, providing actuation capabilities without complex mechanical components [77]. Similarly, electrically conductive hydrogels can act as responsive materials for electrically driven actuators, facilitating precise motion control in robotic systems. For instance, Yang et al. developed a hybrid hydrogel composed of agar and poly(sulfobetaine methacrylate) (PSBMA), which combines thermos-responsive and electro-responsive functionalities within a single material [78]. The hydrogel demonstrates rapid and reversible bending under both high and low voltage electric fields, while also exhibiting temperature-dependent optical transitions for self-sensing. These multi-responsive capabilities, enabled by its zwitterionic and physically crosslinked network structure, make it a promising actuator material for soft robotics.

Hydrogels provide a way to mimic the movement and function of natural tissues. Their softness and adaptability enable their use in applications such as artificial muscles, grippers, and sensors capable of handling fragile objects or conforming to irregular surfaces [79,80]. The development of hybrid hydrogels, combining natural and synthetic polymers, allows for the optimization of mechanical strength and flexibility, enabling complex robotic designs that balance robustness and adaptability. Reinforcing hydrogels with nanoscale fillers or fibers further extends their applicability to repetitive and dynamic motions required in actuators while maintaining the desired pliability for smooth operations. They provide a foundation for designing innovative robotic systems capable of dynamic adaptability and functional integration, mirroring the capabilities of natural organisms and fostering progress in bio-inspired and adaptive robotics.

3 3D Printing Techniques for Hydrogels

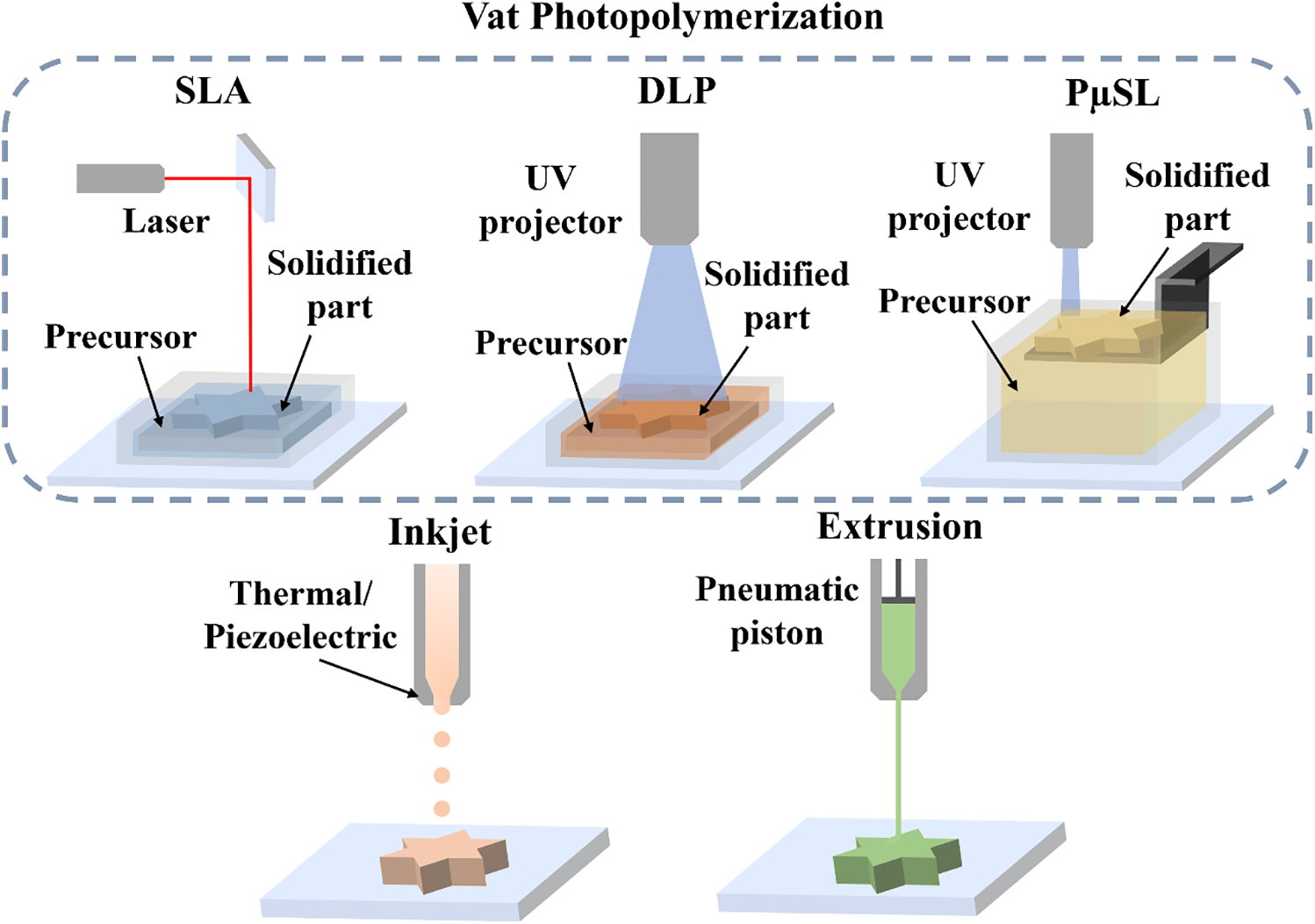

Several 3D printing techniques are widely employed in the fabrication of hydrogel-based structures, each offering unique advantages and limitations, making them suitable for different applications. Technologies such as extrusion-based printing, inkjet-based printing, and vat photopolymerization-based printing have been extensively explored for hydrogel printing [11,81,82] (Fig. 2). These methods vary in their capabilities regarding resolution, printing speed, and material compatibility, which are critical factors in determining their suitability for specific applications (Table 2). The selection of an appropriate 3D printing technique depends on the desired structural complexity, mechanical properties, and functional requirements of the hydrogel. Carefully balancing these trade-offs has driven progress in hydrogel-based technologies for robotics, highlighting the versatility and adaptability of 3D printing in hydrogel fabrication.

Figure 2: Schematic of diverse 3D printing techniques: Vat Photopolymerization-based (SLA, DLP, PµSL), Inkjet-based, Extrusion-based

3.1 Vat Photopolymerization-Based 3D Printing

Vat photopolymerization-based 3D printing encompasses a family of light-driven printing techniques that selectively solidify photosensitive hydrogel precursors in a liquid vat. By tuning resin chemistry and exposure parameters, these methods can produce finely detailed hydrogel components with programmable mechanics, which are critical for actuators, sensors, and soft robots. In the sections that follow, we examines various vat photopolymerization-based approaches, highlighting how each leverages photopolymerization kinetics and light-material interactions to address the unique demands of hydrogel fabrication for robotics.

Stereolithography has emerged as a highly precise 3D printing technique for fabricating hydrogel-based structures, offering fine resolution and intricate detailing suitable for robotic applications. The process utilizes a photocurable hydrogel resin containing photo-initiators, crosslinkers, and other functional additives, which is selectively solidified layer-by-layer using a controlled light source, such as a laser or projector. This method enables the creation of complex 3D architectures with high precision, essential for developing soft robotic components like actuators, sensors, and bio-inspired grippers. SLA’s capability to produce hydrogels with programmable mechanical properties and stimuli-responsiveness further enhances its utility in robotics, allowing the fabrication of adaptable systems that can mimic biological movements or respond dynamically to environmental changes. Anandakrishnan et al. introduced the fast hydrogel stereolithography (FLOAT) printing method, enabling rapid fabrication of centimeter-sized, multiscale hydrogel models within minutes [83]. By leveraging low-suction force-driven, high-velocity prepolymer flow and precise photopolymerization control, FLOAT significantly improves print speed, maintains high cellular viability, and supports the creation of complex structures such as vascularized tissues, highlighting its potential for advanced biomedical applications. Although post-rinsing and post-curing are often required to improve structural stability, SLA continues to be a powerful tool for advancing hydrogel-based robotic technologies due to its precision and material multifunctionality.

3.1.2 Digital Light Processing (DLP)

Digital Light Processing is a highly precise 3D printing technique for hydrogel-based robotic applications. By projecting 2D light patterns onto photocurable resin through a spatial light modulating device, DLP enables the fabrication of hydrogel structures with resolution as fine as 1 μm. Its ability to rapidly cure entire layers simultaneously, achieving speeds of 70 to 100 mm/h, makes it an efficient method for fabricating intricate components required in robotic applications [84,85].

The technique’s compatibility with advanced hydrogel formulations, including those reinforced with nanofibers, nanoparticles, and metal ions, further enhances its utility in robotics. These additives significantly improve the mechanical properties of hydrogels, such as flexibility, strength, and elasticity, making them suitable for dynamic systems like soft actuators and robotic grippers. Additionally, conductive fillers like carbon nanotube (CNT) expand the functionality of DLP-printed hydrogels, enabling the development of electro-responsive sensors and actuators. Zhang et al. developed a UV-curable, highly stretchable acrylamide–PEGDA (AP) hydrogel system compatible with DLP 3D printing, achieving high resolution (up to 7 µm) and mechanical stretchability (>1300%) [86]. This innovative hydrogel system supports complex 3D structures, hybrid hydrogel–elastomer devices, and applications such as biostructures, flexible electronics, and tissue engineering.

3.1.3 Projection Micro Stereolithography (PµSL)

Projection micro stereolithography is a high-resolution 3D printing method that uses patterned UV or visible light to selectively cure photocurable hydrogel resins. The process involves projecting light through a reduction lens onto the surface of the hydrogel material, enabling precise layer-by-layer fabrication of intricate microstructures. This exceptional resolution makes PμSL highly suitable for applications in soft robotics, where the ability to create detailed and complex geometries is crucial for functional and adaptive robotic components.

An important feature of PμSL is its ability to fabricate stimuli-responsive hydrogels with high precision. By controlling parameters such as light intensity and exposure time, hydrogels with programmable mechanical and functional properties can be achieved. These properties enable the development of robotic actuators and sensors that can respond to environmental stimuli such as temperature or light, resulting in controlled deformation or actuation. Such capabilities are particularly valuable for applications in bio-inspired and adaptive robotic systems. The high-resolution capabilities of PμSL, combined with its ability to produce stimuli-responsive hydrogels, make it a powerful tool for advancing the field of soft robotics. This technique allows for the fabrication of hydrogel components that exhibit dynamic adaptability and fine control, enabling innovative designs in robotics that mimic the flexibility and responsiveness of natural systems. Using PμSL, Han et al. fabricated high-resolution, temperature-responsive PNIPAm hydrogel microstructures with programmable swelling behavior [87]. As a demonstration, they produced complex 3D structures, including grippers and actuators, by tuning the resin composition and process parameters, achieving precise thermal responsiveness and controlled actuation, showcasing potential applications in soft robotics and biomedical devices.

3.1.4 Emerging Rapid Photopolymerization Techniques

Recent advances have pushed vat photopolymerization beyond the classical time-consuming layer-by-layer paradigm, enabling the rapid printing in which whole parts are created in seconds to minutes rather than hours. The two leading approaches, volumetric curing and dynamic meniscus printing, leverage novel light-delivery schemes and fluid replenishment to overcome the time penalties of conventional vat processes.

Computed Axial Lithography (CAL) cures an entire 3D object in a single, continuous exposure by projecting synchronized light patterns into a rotating hydrogel-filled vial [88]. This volumetric method produces smooth, high-fidelity structures and even permits the embedding of rigid skeletons within a swelling matrix—enabling self-actuating soft robots fabricated in under 20 s.

Dynamic Interface Printing (DIP) harnesses a controllable air–liquid meniscus as a moving cure front [89]. By modulating this meniscus acoustically or pneumatically, fresh resin continuously replenishes the irradiation zone, allowing centimetre-scale, cell-laden constructs to be printed in tens of seconds with minimal shear stress and >90% cell viability.

These rapid photopolymerization advances dramatically reduce build times while maintaining micron-scale resolution and multifunctional integration, paving the way for real-time prototyping and high-throughput manufacturing of hydrogel-based soft robotic systems.

3.2 Extrusion-Based 3D Printing

Extrusion-based 3D printing is a widely utilized method for fabricating hydrogel structures, capitalizing on their viscoelastic properties and water-rich polymer networks. This process involves extruding hydrogel precursors through a nozzle in a continuous filament, depositing them layer by layer to build three-dimensional structures. The hydrogel material, often prepared as a viscous ink, can be customized with various additives, including nanoparticles, reinforcing agents, or conductive materials, to tailor its mechanical and functional properties. Post-extrusion, hydrogels may undergo additional crosslinking processes to stabilize the printed structures and enhance their durability.

The method is particularly effective for high-viscosity hydrogel formulations and composite materials that may not be compatible with other printing techniques, such as light-based methods. Its versatility allows for the creation of complex geometries and functional components while accommodating a wide range of materials. While extrusion-based 3D printing typically offers lower resolution compared to light-based techniques, its ability to produce robust, large-scale structures and handle diverse hydrogel formulations makes it a key technology in applications requiring flexibility and adaptability.

Xia et al. developed a 4D-printed bionic soft robot (SBSR) inspired by starfish, utilizing photothermal-responsive reduced graphene oxide-poly(N-isopropylacrylamide) (rGO-PNH) hydrogels [90]. By employing DIW technology, they fabricated programmable structures with enhanced mechanical properties and rapid NIR light response due to the efficient photothermal conversion of reduced graphene oxide nanosheets. The robot demonstrated complex and precise actuation, including bending, grasping, and lifting, mimicking the predatory behavior of starfish. This research underscores the potential of responsive hydrogel-based actuators for biomimetic devices, artificial muscles, and other advanced robotic systems. Wang et al. developed 3D-printed implantable hydrogel bioelectronics using direct ink writing, featuring high conductivity, mechanical compliance, and bio-adhesion for seamless integration with biological tissues. These devices enable electrophysiological monitoring and electrical modulation, offering significant potential for cardiovascular disease diagnosis and therapeutic interventions [91].

More recently, Li et al. introduced a multimaterial cryogenic printing (MCP) approach in which aqueous hydrogel inks are extruded directly into a cold environment, instantly freezing the deposited filament to “lock in” fine features such as thin walls, overhangs, and hollow channels [92]. During a controlled thawing step, the frozen ink undergoes crosslinking to form robust hydrogel–hydrogel interfaces, yielding architectures with micrometer-scale fidelity that remain stable upon return to ambient temperature. This technique enables the fabrication of soft machines with complex internal geometries—such as vascular networks or embedded actuators—without the need for sacrificial supports or post-processing molds.

Heiden et al. demonstrated a fully biodegradable, gelatin-based biogel extrusion process tailored for soft actuators with integrated optical sensing waveguides [93]. Their fused-deposition method uses a shear-thinning gelatin–microgel composite that prints at room temperature and solidifies via ionic crosslinking upon exposure to a calcium bath. The resulting biogel devices exhibit high stretchability (>300% strain), omnidirectional actuation, and built-in light transmission paths for real-time deformation monitoring, all while allowing zero-waste recycling through simple enzymatic degradation at end of life

These advances push extrusion-based hydrogel printing beyond traditional DIW limits by offering new routes to high-resolution, supportless fabrication and functionally integrated, sustainable soft robotic components.

Inkjet-based 3D printing is an advanced technique that employs controlled droplet deposition to manufacture hydrogel-based parts with high precision and structural complexity. This method involves preparing hydrogel inks tailored for specific applications, often containing crosslinking agents, water, and functional additives. Inkjet-based 3D printing utilizes micro-scale nozzles to dispense precise droplets of hydrogel ink, which are deposited layer by layer and solidified through thermal or UV-induced curing. With its high precision and adaptability, inkjet-based printing is ideal for applications in soft robotics, where complex, responsive hydrogel components are required, as well as in wearable devices and flexible electronics.

Peng et al. introduced an innovative ion inkjet printing (IIP) technique to pattern hydrogel surfaces, enabling programmable and complex shape deformations [94]. By depositing ferric ions onto specific regions of the hydrogel, crosslinking densities were locally altered, resulting in varying swelling and deswelling behaviors. This method allowed for the creation of diverse 3D shapes, such as cylindrical shells and flower-like structures, demonstrating its potential for applications in soft robotics, microfluidics, and bio-inspired devices. Yoon et al. developed a novel inkjet–spray hybrid printing process for fabricating multilayered, cell-laden hydrogel structures with high resolution, speed, and scalability [95]. By combining drop-on-demand inkjet printing with a fine-mist spray-coating technique, this method allows for precise deposition and crosslinking of bioinks, enabling the creation of complex 3D hydrogels with applications in tissue engineering and biomedical devices.

4 3D Printed Hydrogels for Robotic Applications

3D-printed hydrogels have emerged as transformative materials in the field of soft robotics, offering unique properties such as flexibility, biocompatibility, stimuli-responsiveness, and self-healing capabilities. These characteristics enable the creation of soft robotic systems that mimic the adaptability and complex movements of biological organisms. By leveraging the programmable and multifunctional nature of hydrogels, researchers have developed innovative robotic components, including actuators, sensors, and locomotion systems, that expand the frontiers of automation and interaction with diverse environments [1,96]. Table 3 summarizes the hydrogel’s contributions to various soft robotic applications. This section explores the advancements and applications of hydrogel-based soft actuators, robots, and sensors, highlighting their potential to address challenges in robotics and beyond.

4.1 Hydrogel-Based Soft Actuators

Soft actuators utilize flexible structures that can dynamically adapt to their surroundings, enabling them to carry out precise motions and perform specialized tasks. Hydrogel-based soft actuators, in particular, enhance the capabilities of soft robots by allowing the controllable deformation of morphing materials, enabling a wide range of functions and actions across diverse applications.

A typical type of soft actuator is the gripper, designed to grasp or pick up target objects by executing programmed deformations in its actuating components. Hu et al. developed the first hydrogel “hand” [97]. They utilized a pair of bilayer hydrogels that bent towards each other, so that the grasping and releasing processes can be realized through heating and cooling, which laid the foundation for the development of hydrogel-based grippers. Nevertheless, because of the poor mechanical properties of hydrogel, many of the current hydrogel grippers have limited gripping performance. Therefore, using tough hydrogels for manufacturing the grippers is a promising solution to this problem.

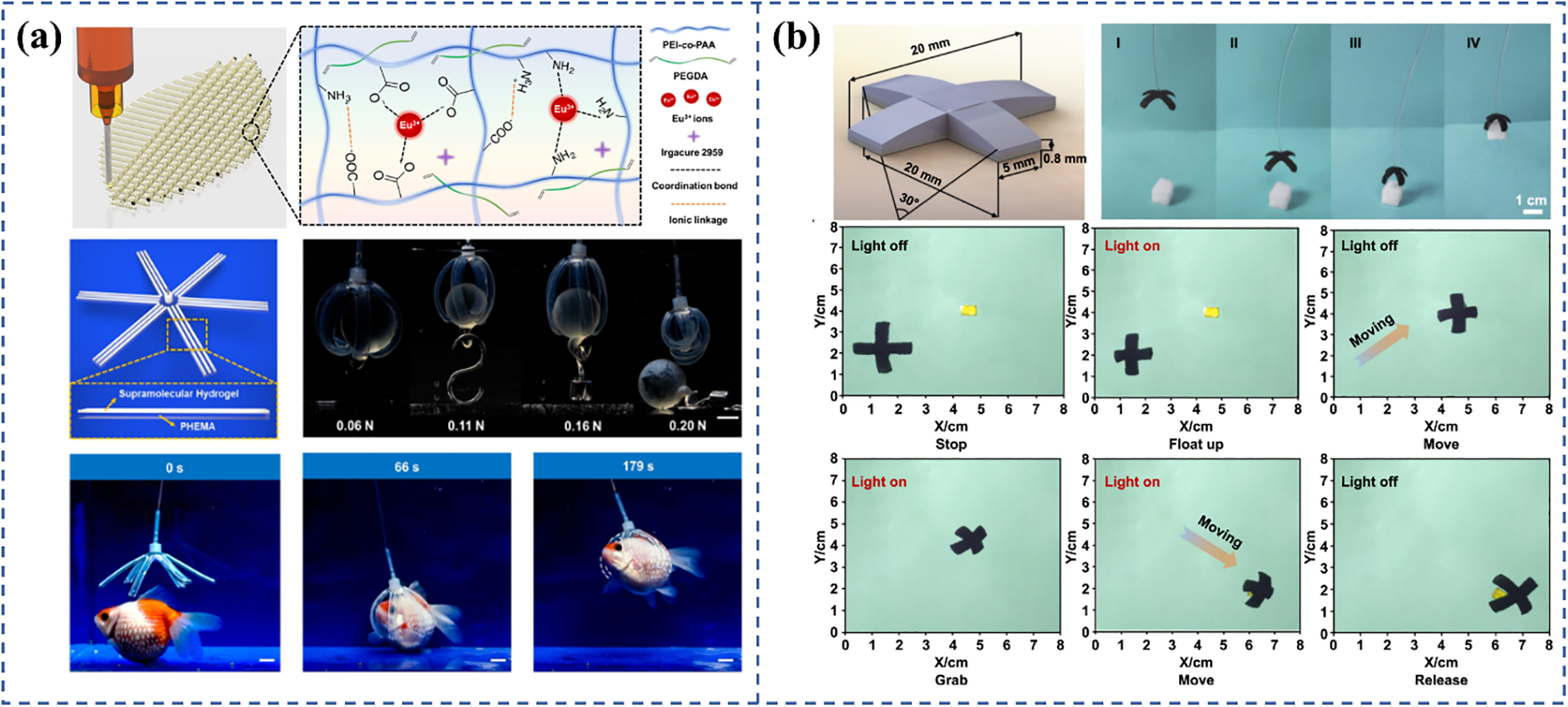

Yao et al. developed a novel 3D-printable lanthanide-ion-coordinated supramolecular hydrogel ink based on a polyethyleneimine (PEI)-co-PAAc copolymer, Eu³+ ions, and PEGDA. Their hydrogel exhibits dynamic, humidity-responsive full-color luminescence and reversible opacity tuning driven by water uptake/release and dynamic coordination bond formation and breakage. This unique ink enabled the fabrication of soft actuators—most notably a camouflageable hydrogel gripper for underwater applications—that simultaneously undergo shape morphing and optical property modulation, offering a promising approach for biomimetic soft robotic systems [98] (Fig. 3a). Zhan et al. developed a dual layer photothermal responsive shape memory hydrogel based on N-isopropylacrylamide with carbon nanoparticles through PµSL 3D printing. By using grayscale printing, they created a microgripper that achieves rapid, reversible deformation under near-infrared light for controlled object manipulation in aqueous environments [99] (Fig. 3b). These hydrogels regulate pore opening and closing within the actuator’s structure in response to temperature changes. Odent et al. demonstrated multi-responsive hydrogel-based actuators that are encoded with anisotropic swelling behavior to provide rapid and controllable motion [100]. Yuk et al. used polyacrylamide-alginate tough hydrogels to fabricate a transparent hydraulic gripper, capable of capturing and releasing live fish in water without harm, highlighting its potential for delicate underwater applications [101]. When pressurized, the gripper exhibited asymmetric inflation, allowing it to bend and successfully capture a fish. Yang et al. developed a programmable single-material 4D printing method using PEGDA hydrogels and a digital micro-mirror device-based light curing system. Through programmable control of water absorption and deformation, they fabricated bioinspired hydrogel structures, including a gripper capable of controlled grasping and releasing, demonstrating potential applications in tissue engineering and bionic systems [102].

Figure 3: Hydrogel-based soft grippers. (a) 3D-printable lanthanide-ion-coordinated supramolecular hydrogel for programmed deformations for gripper application. Adapted with permission from reference [98]. Copyright 2020, American Chemical Society. (b) Photothermal-responsive shape memory hydrogel gripper fabricated via grayscale-controlled PµSL 3D Printing. The gripper operates based on a photothermal-driven shape memory effect, where NIR light irradiation heats the carbon nanoparticle-doped PNIPAm-based hydrogel, causing rapid water loss and structural shrinkage, leading to a gripping motion. When the light is removed, the hydrogel rehydrates and expands, enabling reversible deformation for object manipulation. Adapted with permission from reference [99]. Copyright 2021, IOP Publishing Ltd

Hydrogel actuators are well-suited for manipulators due to their flexibility, responsiveness to multiple stimuli, and biocompatibility, enabling precise control and adaptive motion. These properties make them ideal for applications requiring delicate handling and environmental interaction, such as medical robotics and soft manipulation tasks. Additionally, their lightweight and programmable nature enhance their performance in dynamic, complex environments.

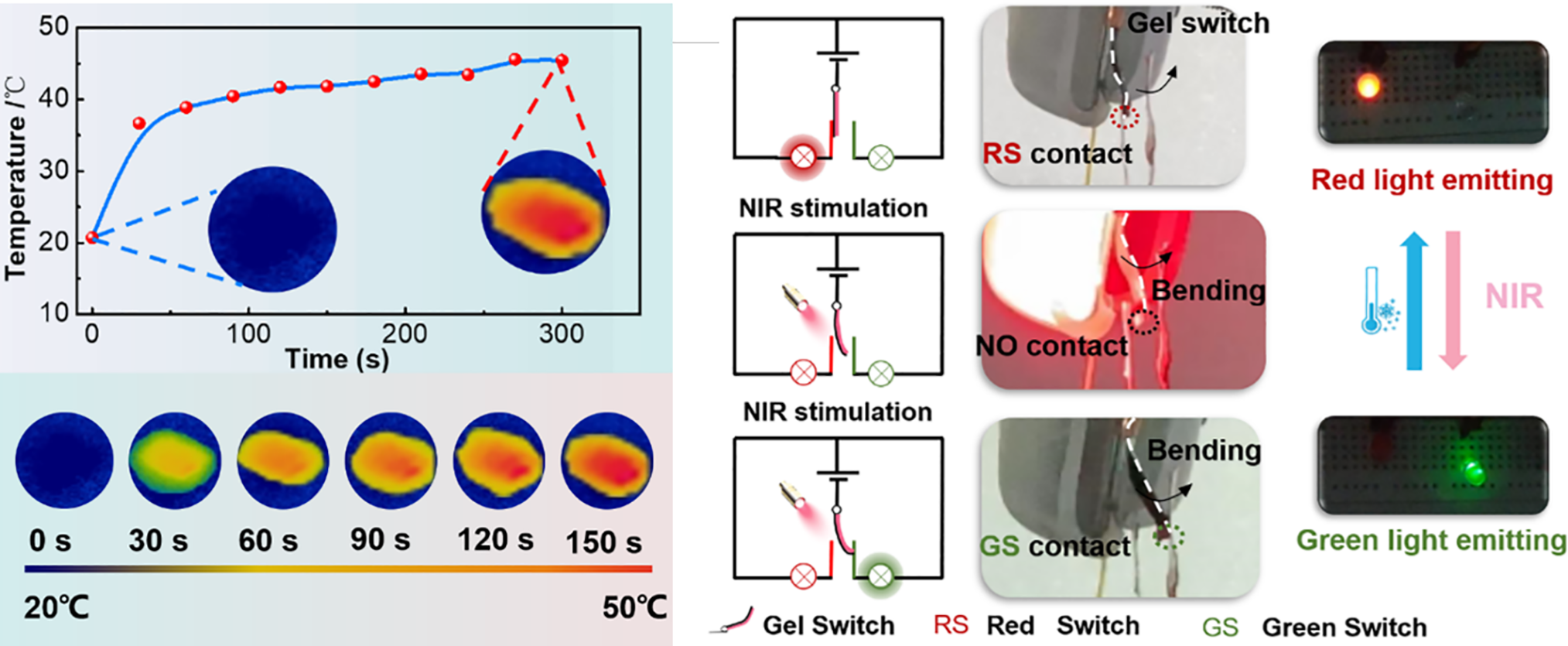

Li et al. developed an asymmetric bilayer actuator combining CNTs-Ecoflex and thermo-responsive PNIPAm hydrogel, utilizing the photothermal effect of CNTs to generate heat under NIR light and PNIPAm’s swelling/shrinking behavior for shape deformation [103]. The device integrates sensing capabilities through the piezoresistive properties of CNTs, enabling real-time feedback. Applications include an intelligent gripper, an artificial iris, and a light switch, where deformation induced by NIR light triggers electrical connections to control on/off states, demonstrating its potential in biomimetic systems and soft robotics (Fig. 4).

Figure 4: Hydrogel manipulator comprising CNTs-Ecoflex and thermo-responsive PNIPAm hydrogel for electric switch via light irradiation. Adapted with permission from reference [103]. Copyright 2021, Elsevier B.V

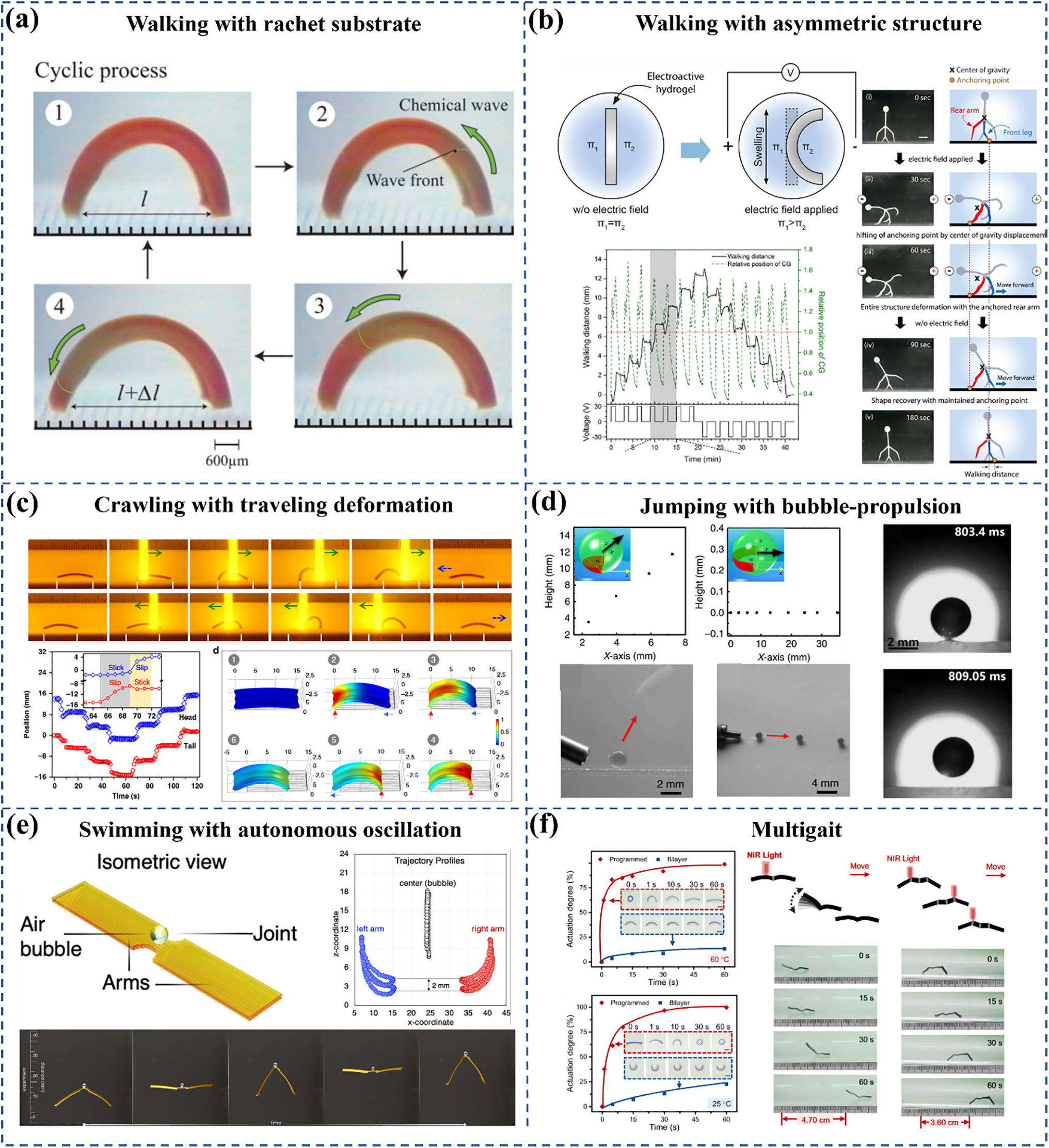

Following the discussion on individual hydrogel-based actuation mechanisms, we now shift focus to soft robotic systems capable of autonomous locomotion in the next section. These platforms leverage the inherent responsiveness and deformability of hydrogels to achieve complex and programmable movements. In the following sections, we categorize these systems based on their primary locomotion modes, such as walking, crawling, jumping, swimming, and multigait, and examine how specific hydrogel properties are tailored to support each functional behavior.

4.2 Hydrogel-Based Soft Robots

Hydrogels can be made into soft robots with motility, which is another significant robotic application for 3D-printed hydrogels. The main principle for the hydrogel-based soft robots is to transform their own shape-changing to controllable directional motions or interactions between the robots and the environment. To achieve this, the hydrogel needs to possess properties such as reversible deformation, flexibility, responsiveness to external stimuli, biocompatibility, self-healing capabilities, programmability, high hydration, and, in some cases, electrical conductivity. The 3D printed hydrogel-based soft robots can be classified according to the gaits, which are: walking robots, crawling robots, jumping robots, and swimming robots.

Walking is a typical gait in animals, where friction control is essential for converting reversible deformations into directional movement. In soft robots, friction can be controlled through two main approaches: (i) employing ratchet substrates to provide directional resistance [104], and (ii) designing asymmetrically shaped hydrogels to enable controlled deformation and movement [105]. Walking hydrogels typically feature two “legs” and can repeatedly bend-unbend or extend-contract in response to cyclic stimuli. Ratchet substrates control friction by permitting movement in one direction and blocking it in the opposite, enabling the creation of diverse walking robots [104]. Walking motion was achieved by inducing periodic deformation in an arched hydrogel, allowing it to move spontaneously on a ratchet substrate (Fig. 5a). Constructing asymmetry structure is another method for walking, which helps create different frictions on two legs. Han et al. designed a 3D-printed electroactive hydrogel (EAH) walker that achieves untethered, bidirectional locomotion through electric-field-driven deformation [106]. When an electric field is applied, ion migration creates an osmotic pressure gradient, causing the hydrogel to bend asymmetrically. This shifts the center of gravity to the rear arm, anchoring it and allowing the front leg to slide forward. Removing the field lets the structure recover, further advancing the front leg. Reversing the electric field mirrors the process, enabling controlled back-and-forth walking (Fig. 5b).

Figure 5: Hydrogel-based soft robots. (a) Hydrogel walking robots designed by permitting movement in one direction and blocking it in the opposite through friction controlled by rachet structure. Adapted with permission from reference [104]. Copyright 2007, WILEY-VCH Verlag GmbH & Co. KGaA. (b) Bio-inspired asymmetric hydrogel walking robot driven by electroactive stimulation. Adapted with permission from reference [106]. Copyright 2020, American Chemical Society. (c) Bidirectional crawling robots of anisotropic hydrogels induced by dynamic light exposure. Adapted from reference [107] under CC BY 4.0. (d) Light-driven hydrogel-based jumping robot that achieves rapid in-air motion via a unique bubble-propulsion mechanism. Adapted from reference [109] under CC BY 4.0. (e) Magnetically and photothermally actuated hydrogel swimming robot with autonomous oscillation and phototactic locomotion. Adapted from reference [110] under CC BY-NC-ND 4.0. (f) Multigait hydrogel robots with thermo-responsive and UV-triggered programming for complex motions. Adapted from reference [111] under CC BY 4.0

Crawling robots are inspired by the locomotion of animals such as snakes, worms, insects, and legless amphibians, which use flexible, wave-like or undulatory movements to navigate through confined or uneven spaces. Crawling robots can easily navigate through narrow or uneven environments, making them ideal for tasks in confined spaces, while they also possess disadvantages, such as lower moving speed and unidirectional motion. Zhu et al. achieved crawling motion in a hydrogel-based soft robot by leveraging light-induced anisotropic deformation and friction modulation. Localized swelling and deswelling, triggered by dynamic light exposure, generated a deformation gradient that, combined with surface friction control, enabled directional crawling [107] (Fig. 5c).

Jumping, a common locomotion mode in animals, relies on the accumulation and rapid release of elastic energy, which can be realized in soft robots through tailored structural designs and external stimuli [10]. Hu et al. developed a light-driven jumping robot using a rolled CNT/hydrogel bilayer actuator, inspired by the flicking finger motion [108]. When exposed to light, the CNT layer absorbs energy and expands, while the polymer layer remains relatively unchanged, creating an internal strain. This strain accumulates at the overlapping ends of the bilayer, which act like a compressed spring. Once the stored energy exceeds the frictional force holding the ends together, the bilayer suddenly unrolls, releasing the strain energy and propelling the robot into the air. The robot can jump up to five times its own height and even perform a somersault. Li et al. introduce a light-driven hydrogel-based jumping robot that achieves rapid in-air motion via a unique bubble-propulsion mechanism [109]. Its performance is powered by the photothermal effect of embedded iron oxide nanoparticles, which induce a swift temperature rise that vaporizes water to form a gas bubble. This rapid bubble formation triggers a fast, localized expansion that propels the robot upward. Notably, the jumping robot can reach heights of up to 15 cm with a take-off speed of 1.6 m/s and a response time of only 800 ms. These findings demonstrate the potential of hydrogel-based systems in developing high-speed, agile jumping robots for soft robotics applications (Fig. 5d).

Swimming is a unique gait for underwater animals, in which hydrodynamic thrust must be generated through dynamic morphing. For autonomous swimming, soft robots need an integrated feedback loop to transition between out-of-equilibrium states and oscillated deformations. Cezan et al. developed a light- and magnetically driven hydrogel swimmer that autonomously exhibits phototactic motion, mimicking biological swimming behaviors [110]. The swimmer is composed of a hybrid bonding polymer hydrogel, integrating photo-responsive supramolecular nanofibers and covalent polymer networks, along with ferromagnetic nickel nanowires. When subjected to an oscillating magnetic field, the swimmer undergoes a flapping motion, generating propulsion. Additionally, light exposure induces asymmetric stiffness changes, altering the swimmer’s deformation dynamics and enabling it to move toward a light source, demonstrating an autonomous positive phototaxis. This mechanism enables controlled propulsion and directional swimming in response to visible light, with potential applications in autonomous soft robotics and underwater systems (Fig. 5e).

Hydrogel-based robots can also achieve multigait locomotion, enabled by the formation of distinct primary structures under defined conditions or through the application of varied dynamic actuation strategies. Ni et al. developed thermo-responsive hydrogel robots crosslinked by dynamic disulfide bonds, enabling spatio-selective anisotropy through UV-triggered programming [111]. By leveraging thermally driven chain conformation changes and photothermal heating, high-speed light-powered hydrogel robots with diverse complex motions were achieved (Fig. 5f). Huang et al. developed a hydrogel-based underwater adhesive using controllable complexation of resilin-like proteins and Keggin-type polyoxometalates [112]. The adhesive hydrogel switches between rigid and adhesive states within a mild temperature range, enabling soft robots functionalized with magnetic nanoparticles to perform switchable adhesion, locomotion, and shape morphing in aqueous environments, with applications in tasks like cargo delivery and artificial blood vessel repair.

While hydrogel-based actuators and locomotion systems enable motion and interaction, sensors are essential for closing the feedback loop in soft robotic systems. Soft sensors based on hydrogels allow robots to perceive mechanical, thermal, or optical stimuli, enabling adaptive behavior and environmental awareness. The following section focuses on recent advances in hydrogel-based sensors and their integration into soft robotic platforms.

4.3 Hydrogel-Based Soft Sensors

A sensor is a device that detects and responds to signals or stimuli from its surroundings. In contrast to conventional sensors made of rigid components, soft sensors rely on the intrinsic properties of the materials such as resistive, piezoresistive, capacitive, and optical characteristics [94]. In particular, hydrogel sensors rely on high water content, flexibility, biocompatibility, stimuli-responsiveness, and ability to transduce chemical or physical inputs into measurable signals.

The sensing mechanism of hydrogel sensors typically involves two stages: first, they detect chemical or physical inputs via chemical diffusion or physical fields; second, they transduce these input signals into measurable outputs. These outputs are expressed in various forms, including geometric, mechanical, optical, electrical, or biological responses [96,113–116]. With their versatile capabilities, hydrogel sensors are increasingly being utilized in practical applications such as healthcare monitoring, wearable devices, and human-machine interfaces.

4.3.1 Resistive Strain Sensors

In recent years, hydrogel-based resistive strain sensors have significantly increased, driven by the simplicity of creating conductive and stretchable hydrogel materials. Hydrogel resistive strain sensors can be achieved by constructing conductive polymer networks, introducing conductive nanoparticles, or incorporating free ions. There are several related applications, including angle detection, pressure sensing, and tactile sensing, which are applicable in rehabilitation systems and motion tracking systems. Wu et al. developed a 3D printable Silk fibroin (SF)-PAAm/PAAc hydrogel system, and prepared a resistive strain sensor system for hand gesture detection [48]. Haghiashtiani et al. demonstrated the first use of 3D printing to fabricate ionic hydrogel-elastomer hybrids for electrically responsive actuators, which also possess self-sensing capabilities, mimicking the signal transmission mechanism found in human skin [117]. Liu et al. reported a biomimetic, hierarchical fabrication strategy to 3D print composite organo-hydrogels with robust mechanical properties. Utilizing direct ink writing, they align ceramic platelets within a PVA matrix and strengthen the interface via silane treatment, yielding hydrogels with high stiffness, strength, and toughness [118]. Notably, the composite hydrogels also exhibit excellent electrical conductivity and strain sensing capabilities, which the authors demonstrate through a smart sensing glove. This work underscores the potential of advanced hydrogel printing techniques for developing multifunctional sensor platforms in flexible electronics and soft robotics (Fig. 6a).

Figure 6: Hydrogel-based soft sensors. (a) Multi-functional hydrogel-based smart sensing gloves for touching screen interaction and robotics control. Adapted from reference [118] under CC BY 4.0. (b) One-Step 3D-Printed Polyaniline–Hydrogel Microgrid for High-Performance Capacitive Sensing. Adapted with permission from reference [120]. Copyright 2022, Elsevier Ltd. (c) Highly stretchable and tough hydrogel-based optical fibers for strain sensing. Adapted with permission from reference [122]. Copyright 2016, WILEY-VCH Verlag GmbH & Co. KGaA

The most common way to develop a hydrogel-based capacitive sensor is to prepare two conductive hydrogels sandwiched on a dielectric soft layer to form a capacitor with variable capacitance. Yin et al. fabricated highly sensitive and flexible capacitive-type pressure sensors with DLP 3D printing [119]. A capacitive sensor capable of detecting static and dynamic pressures, as well as strain, with high sensitivity and a low detection limit, was created by sandwiching a layer of VHB tape dielectric between two structured PAAm-PEGDA hydrogel films. This hydrogel can also be used in the dielectric layer. Yue et al. demonstrate a one-step 3D reactive printing strategy to fabricate interpenetrating polyaniline and hydrogel microgrid structures that seamlessly integrate conductive and dielectric phases in a single printed architecture [120]. The printed sensor exhibits ultra-high mechanical resilience with stretchability exceeding 1500% and excellent fatigue resistance. As a parallel-plate capacitive device, it delivers a sensitivity of 7.10 kPa−1 over the 0 to 0.39 kPa pressure range and maintains stable performance during extended cycling. This work underscores the potential of 3D-printed hydrogel architectures for capacitive sensing in soft robotics applications (Fig. 6b). He et al. proposed that electron double layer (EDL)-based capacitive sensors can be manufactured by carefully designing the geometries of the conductive and stretchable nanostructured (CSN) hydrogel layers [121]. This approach enables the achievement of superior sensing performance, including high sensitivity, excellent linearity, fast dynamic response, remarkable cyclic stability, and a wide operating temperature range. After integrating the sensor into grippers, different combinations of signals while grasping various objects can be detected. Furthermore, high resolution pressure mapping can be achieved with the capacitive sensors array.

Hydrogels are often highly transparent in the visible and near-infrared spectrum, enabling effective light transmission. Meanwhile, hydrogels are highly biocompatible and non-toxic, making them an ideal alternative for traditional glass and inorganic plastic materials. They can interface safely with biological tissues for real-time monitoring of physiological conditions like glucose levels, pH, or temperature. For use in robotic applications, hydrogel-based optical sensors are often used in strain and bending monitoring, pressure and tactile sensing, and temperature and humidity monitoring. The strength of hydrogel is always the research focus for the researchers. Guo et al. designed highly stretchable and tough optical fibers using alginate-polyacrylamide hydrogels in a core/clad structure for strain sensing [122]. These fibers leverage their flexibility, transparency, and optical properties to measure strain with high sensitivity and a large dynamic range, demonstrating potential applications in wearable sensors and biomechanical monitoring (Fig. 6c).

Hydrogel-based soft sensors present a compelling alternative in the field due to their ability to overcome key limitations, such as water loss and mechanical fragility, through strategies like protective coatings and optimized formulations. Their intrinsic multifunctionality, combined with unique properties such as self-healing, biocompatibility, and responsiveness to various stimuli, positions hydrogels as highly versatile and attractive materials for diverse sensing applications. These advantages make hydrogel sensors a promising choice for advancing soft robotics, wearable devices, and biomedical technologies.

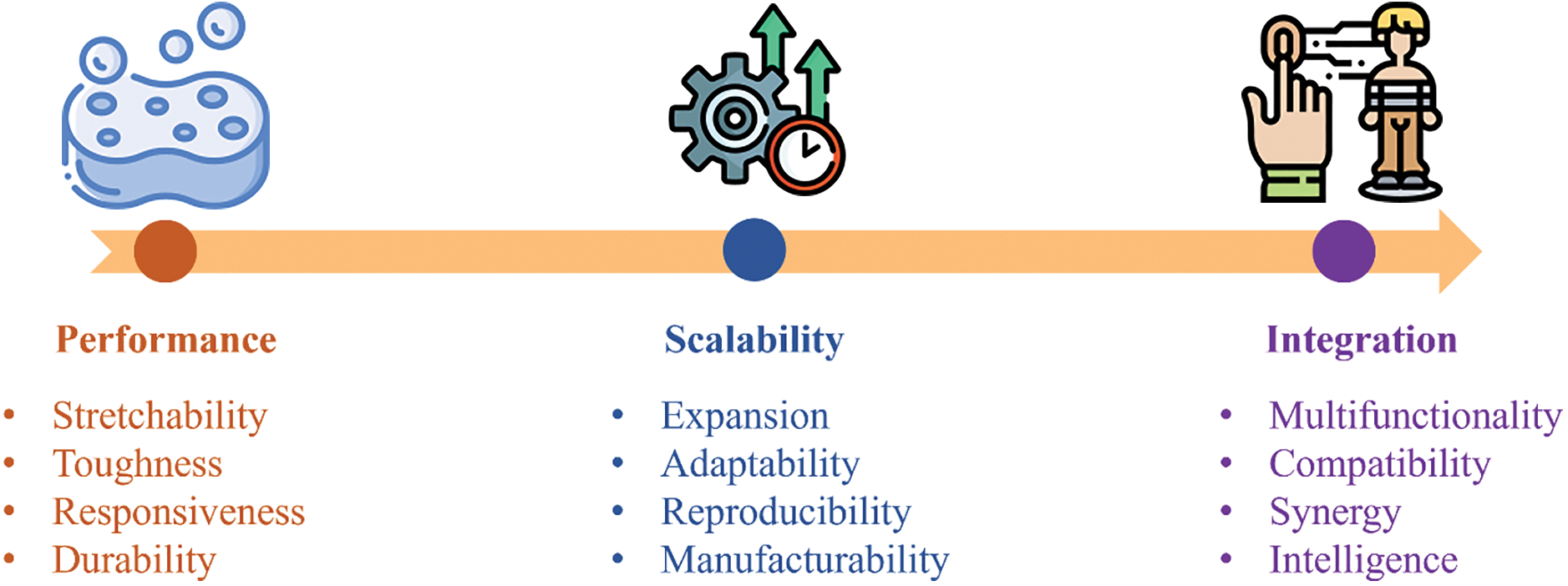

The rapid development of 3D-printed hydrogels has unlocked new possibilities in soft robotics, enabling applications ranging from actuators and sensors to fully integrated robotic systems. However, significant challenges remain in realizing their full potential. This section outlines the key issues and provides a forward looking perspective on advancing this technology for practical deployments (Fig. 7).

Figure 7: Roadmap for future deployments of 3D printed hydrogels for robotic applications. The icons for “Performance”, “Scalability”, and “Integration” are cited from Freepik with permissions.

One of the primary challenges in hydrogel-based robotics is enhancing the performance of printed parts. Hydrogels, while soft and flexible, often lack the mechanical robustness required for dynamic, load-bearing applications in robotics. Achieving a balance between stretchability, toughness, and durability is critical, particularly for applications involving repetitive motion or extreme environmental conditions. Additionally, improving the responsiveness of hydrogels to external stimuli, such as temperature, pH, or light, is essential for achieving faster actuation and more precise control. Innovations in hydrogel composition, such as nanocomposite reinforcement or hybrid material integration, are expected to play a significant role in addressing these limitations.

Furthermore, hydrogel needs to overcome the problem in water evaporation, which can significantly affect the behavior. From the material aspect, regulating the composition of the hydrogel or adding nanoparticles can help enhancing both mechanical strength and the hydrogel’s capacity to bind water through additional hydrophilic sites. Moreover, chemically or physically modifying the surface to form an extra hydrophilic layer can also help reduce water loss.

These material-level enhancements also contribute to improved printability and facilitate stable integration of hydrogels into complex robotic systems, ensuring reliable long-term performance. In parallel, machine learning algorithms are emerging as powerful tools to optimize hydrogel formulations under multi-constraint scenarios, enabling targeted design for specific actuation, sensing, or environmental demands. These models can simulate multi-physics scenarios, allowing researchers to iteratively refine designs and reduce the need for extensive trial-and-error experiment. This integration of artificial intelligence with traditional material science helps pave the way for hydrogels tailored for various robotic systems.

In addition to improving intrinsic material properties, spatial control over hydrogel architecture has emerged as a powerful strategy for enhancing robotic performance. Three-dimensional architected hydrogels, designed through high-resolution printing techniques, enable the encoding of structural and functional gradients directly into the material. By locally tuning parameters such as crosslinking density, filler distribution, or composition, these architectures can achieve region-specific mechanical properties and stimulus responses. This allows for programmable deformation modes, directional or anisotropic actuation, and spatially localized sensing or actuation zones. Architected hydrogels are particularly advantageous for soft robotic tasks involving complex shape morphing, multigait locomotion, self-folding structures, or environment-adaptive mechanisms, where both material functionality and geometric design must be tightly integrated.

Recent advances in grayscale digital light processing (g-DLP) printing further extend this capability by enabling pixel-level control over light exposure, which allows the fabrication of hydrogel structures with spatially varied crosslinking density and stiffness gradients [123,124]. This technique supports seamless integration of soft and stiff domains in a single construct, enabling programmable mechanical behavior, embedded actuation pathways, and complex morphing sequences.

Moreover, the ability to fabricate such heterogeneity in a single manufacturing step reduces the need for post-assembly and enhances the scalability and robustness of soft robotic devices.

Looking ahead, biomimetic design and dynamic adaptability will possibly be the focus of future hydrogel research. By mimicking the complex, responsive behavior of natural tissues, researchers are working towards hydrogels that not only exhibit self-healing and adaptive stiffness but can also dynamically alter their functionalities in response to the environment. In particular, the integration of 3D architected design with stimuli-responsive materials offers a promising route to achieve spatially coordinated responses, such as localized bending, programmable swelling, or multistable actuation. Emerging grayscale DLP techniques may play a central role in realizing such architectures, as they enable continuous, voxel-level modulation of mechanical properties within a single print. This approach allows spatially programmed stiffness gradients, integrated hinge-like zones, and embedded morphing logic without requiring multi-material printing or post-processing. These features are expected to play a critical role in soft robots capable of autonomous reconfiguration, multimodal locomotion, and reversible shape transformation. This can lead to the creation of robotic systems that are truly ‘smart’, capable of real-time self-optimization and fault tolerance. Combining such material-level intelligence with onboard sensing and computational control may ultimately enable soft robotic platforms that adapt in situ to complex and changing environments, supporting robust, multifunctional, and human-compatible robotic systems.

The scalability of 3D printing techniques for hydrogels remains a critical bottleneck. Current methods often excel at fabricating small-scale, high-resolution structures but face challenges when scaled to larger or more complex designs. Ensuring manufacturing uniformity and maintaining resolution across scales are key issues that require advances in printing technologies. Furthermore, efficient and cost-effective production methods are essential to facilitate the transition of hydrogel-based robotic components from laboratory research to widespread industrial applications.

One of the key challenges in scaling up hydrogel 3D printing is increasing production speed while maintaining precision. Traditional methods can be time-consuming, particularly for large-scale or complex structures. Using high-speed printing techniques, such as continuous liquid interface production, can help significantly enhancing fabrication efficiency. Additionally, material consistency and reproducibility remain critical concerns, as slight variations in hydrogel formulation or printing conditions can lead to inconsistencies in mechanical properties. Integrating real-time monitoring and adaptive feedback systems can help ensure print uniformity across different batches, improving consistency and reducing waste.

Furthermore, the integration of multiple materials within a single printing process remains difficult, limiting the functional complexity of printed structures. Hybrid approaches that combine different fabrication techniques may provide a pathway toward more versatile and scalable hydrogel-based systems. For instance, advances in hybrid manufacturing techniques that combine 3D printing with other fabrication methods, such as electrospinning [125], enable the production of robust, high-resolution structures over a wide range of scales.

Advancing scalability, therefore, requires coordinated progress in high-throughput hardware, robust hydrogel formulations, and quality control frameworks that support repeatable and reliable robotic applications.

A significant future direction lies in the integration of multiple functionalities within a single hydrogel device. Multifunctional hydrogels with combined sensing, actuation, and self-healing capabilities hold promise for creating robotic systems with embodied intelligence. However, achieving this level of functional integration requires interdisciplinary efforts in material design, computational modeling, and advanced manufacturing.

Importantly, these integration challenges are not isolated from scalability or performance. For example, complex multifunctional hydrogels require precise deposition and alignment during printing, which in turn depends on print resolution, process control, and consistency. Interfacing hydrogels with external robotic components, whether electronics, power supplies, or control units, also demands mechanical and chemical compatibility.

In addition, the incorporation of machine learning and artificial intelligence into the design and operation of hydrogel-based systems can optimize performance and enable predictive functionality. AI can be used to analyze data from the embedded sensors to predict failure modes or identify opportunities for adaptive behavior. This predictive functionality not only enhances performance but also contributes to the overall resilience of the system, enabling it to adjust its behavior in real time in response to changing environmental conditions or internal states.

Beyond traditional robotic roles such as grippers and manipulators, hydrogel systems may find applications in biologically integrated platforms such as drug-delivery robots and implantable diagnostic devices. Their biocompatibility, biodegradability, and responsiveness make them ideal candidates for this new generation of responsive, multifunctional soft machines.

Overall, 3D-printed hydrogels hold immense potential for soft robotics by enabling the creation of flexible, adaptive, and intelligent systems that seamlessly interact with the environment. These materials are developed for applications not only in traditional robotic domains but also in emerging areas such as wearable devices, medical robotics, and environmental monitoring. By integrating properties such as stimuli-responsiveness, self-healing, and multifunctionality, 3D-printed hydrogels are expected to realize the capabilities of natural tissues. Achieving this will require advancements in material innovation, cutting-edge 3D printing techniques, as well as interdisciplinary collaborations, which pave the way for intelligent and multifunctional robotic systems that address complex challenges and enhance human-robot integration.

In conclusion, this perspective has provided a comprehensive overview of the evolving role of 3D-printed hydrogels in soft robotics. We have discussed the classification of hydrogels—natural, synthetic, and hybrid—and detailed their distinct properties in terms of mechanical behavior, biocompatibility, and printability. By highlighting recent advancements in additive manufacturing techniques, including vat photopolymerization-based printing, extrusion-based printing, and inkjet-based printing, this perspective demonstrates how these innovative methods enable the fabrication of complex, multifunctional hydrogel structures.

The contributions of hydrogels to soft robotic applications have been clearly articulated, from soft actuators and locomotion systems to integrated sensors. Their unique attributes—such as stimuli-responsive behavior and inherent flexibility—are shown to be essential for achieving safe interaction, precise manipulation, and adaptive functionalities in advanced robotic systems.

Despite significant progress, several challenges remain, including the need to enhance mechanical robustness, improve scalability, and integrate multifunctional properties seamlessly. Looking forward, emerging trends such as biomimetic design, nanocomposite reinforcement, and machine-learning-assisted material optimization are poised to drive further innovations in the field.

Overall, this perspective not only consolidates current advancements but also offers valuable insights and future directions, paving the way for the next generation of intelligent, adaptive soft robotic systems based on 3D-printed hydrogels.

Acknowledgement: The authors would like to thank the supported by Singapore MOE Tier-2 Award MOE-T2EP50123-0015. Y.W. acknowledges the NAP award 020482 from Nanyang Technological University Singapore.

Funding Statement: This work was supported by Singapore MOE Tier-2 Award MOE-T2EP50123-0015. Y.W. acknowledges the NAP award 020482 from Nanyang Technological University Singapore.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: Kunlin Wu, Jingcheng Xiao, Yifan Wang; data collection: Kunlin Wu; analysis and interpretation of results: Kunlin Wu, Jinigcheng Xiao, Junwei Li; draft manuscript preparation: Kunlin Wu, Jingcheng Xiao, Junwei Li, Yifan Wang. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data that support the findings of this study are available from the corresponding author, Yifan Wang, upon reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. López-Díaz A, Vázquez AS, Vázquez E. Hydrogels in soft robotics: past, present, and future. ACS Nano. 2024;18(32):20817–26. doi:10.1021/acsnano.3c12200. [Google Scholar] [PubMed] [CrossRef]

2. Sarker A, Ul Islam T, Islam MR. A review on recent trends of bioinspired soft robotics: actuators, control methods, materials selection, sensors, challenges, and future prospects. Adv Intell Syst. 2025;7(3):2400414. doi:10.1002/aisy.202400414. [Google Scholar] [CrossRef]

3. Xiao J, Wu K, Meng Z, Li J, Wang Y. Direct ink writing of coaxial electrostatic fibers with customizable cross-sections and functional properties. Addit Manuf. 2025;100:104679. doi:10.1016/j.addma.2025.104679. [Google Scholar] [CrossRef]

4. Shen Z, Chen F, Zhu X, Yong KT, Gu G. Stimuli-responsive functional materials for soft robotics. J Mater Chem B. 2020;8(39):8972–91. doi:10.1039/D0TB01585G. [Google Scholar] [PubMed] [CrossRef]

5. Kulkarni SS, Bayre NM, Khan KA. Modelling visco-hyperelastic response of Silicone based elastomers for soft robotics and foldable structure applications. Int J Eng Sci. 2025;211(1):104253. doi:10.1016/j.ijengsci.2025.104253. [Google Scholar] [CrossRef]

6. AboZaid YA, Aboelrayat MT, Fahim IS, Radwan AG. Soft robotic grippers: a review on technologies, materials, and applications. Sens Actuators Phys. 2024;372(2022):115380. doi:10.1016/j.sna.2024.115380. [Google Scholar] [CrossRef]

7. Coyle S, Majidi C, LeDuc P, Hsia KJ. Bio-inspired soft robotics: material selection, actuation, and design. Extreme Mech Lett. 2018;22(1):51–9. doi:10.1016/j.eml.2018.05.003. [Google Scholar] [CrossRef]

8. Kortman VG, Mazzolai B, Sakes A, Jovanova J. Perspectives on intelligence in soft robotics. Adv Intell Syst. 2025;7(1):2400294. doi:10.1002/aisy.202400294. [Google Scholar] [CrossRef]

9. Cao Y, Xu B, Li B, Fu H. Advanced design of soft robots with artificial intelligence. Nano-Micro Lett. 2024;16(1):1–48. doi:10.1007/s40820-024-01423-3. [Google Scholar] [PubMed] [CrossRef]

10. Jiao D, Zhu QL, Li CY, Zheng Q, Wu ZL. Programmable morphing hydrogels for soft actuators and robots: from structure designs to active functions. Acc Chem Res. 2022;55(11):1533–45. doi:10.1021/acs.accounts.2c00046. [Google Scholar] [PubMed] [CrossRef]

11. Agrawal A, Hussain CM. 3D-printed hydrogel for diverse applications: a review. Gels. 2023;9(12):960. doi:10.3390/gels9120960. [Google Scholar] [PubMed] [CrossRef]

12. Sachyani Keneth E, Kamyshny A, Totaro M, Beccai L, Magdassi S. 3D printing materials for soft robotics. Adv Mater. 2021;33(19):2003387. doi:10.1002/adma.202003387. [Google Scholar] [PubMed] [CrossRef]

13. Ding H, Wu Z, Wang H, Zhou Z, Wei Y, Tao K, et al. An ultrastretchable, high-performance, and crosstalk-free proximity and pressure bimodal sensor based on ionic hydrogel fibers for human-machine interfaces. Mater Horiz. 2022;9(7):1935–46. doi:10.1039/d2mh00281g. [Google Scholar] [PubMed] [CrossRef]

14. Liu H, Chu H, Yuan H, Li D, Deng W, Fu Z, et al. Bioinspired multifunctional self-sensing actuated gradient hydrogel for soft-hard robot remote interaction. Nano-Micro Lett. 2024;16(1):1–14. doi:10.1007/s40820-023-01287-z. [Google Scholar] [PubMed] [CrossRef]

15. Park CS, Kang YW, Na H, Sun JY. Hydrogels for bioinspired soft robots. Prog Polym Sci. 2024;150:101791. doi:10.1016/j.progpolymsci.2024.101791. [Google Scholar] [CrossRef]

16. Quan MC, Mai DJ. Biomolecular actuators for soft robots. Chem Rev. 2025;125(10):4974–5002. doi:10.1021/acs.chemrev.4c00811. [Google Scholar] [PubMed] [CrossRef]

17. Apsite I, Salehi S, Ionov L. Materials for smart soft actuator systems. Chem Rev. 2022;2022122(1):1349–415. doi:10.1021/acs.chemrev.1c00453. [Google Scholar] [PubMed] [CrossRef]

18. Shen Z, Zhang Z, Zhang N, Li J, Zhou P, Hu F, et al. High-stretchability, ultralow-hysteresis conductingpolymer hydrogel strain sensors for soft machines. Adv Mater. 2022;34(32):2203650. doi:10.1002/adma.202203650. [Google Scholar] [PubMed] [CrossRef]

19. Manjua AC, Alves VD, Crespo JG, Portugal CAM. Magnetic responsive PVA hydrogels for remote modulation of protein sorption. ACS Appl Mater Interfaces. 2019;11(23):21239–49. doi:10.1021/acsami.9b03146. [Google Scholar] [PubMed] [CrossRef]

20. Yao DR, Kim I, Yin S, Gao W. Multimodal soft robotic actuation and locomotion. Adv Mater. 2024;36(19):2308829. doi:10.1002/adma.202308829. [Google Scholar] [PubMed] [CrossRef]

21. Shi X, Lee A, Yang B, Ning H, Liu H, An K, et al. Machine learning assisted electronic/ionic skin recognition of thermal stimuli and mechanical deformation for soft robots. Adv Sci. 2024;11(30):2401123. doi:10.1002/advs.202401123. [Google Scholar] [PubMed] [CrossRef]

22. Tan LJ, Zhu W, Zhou K. Recent progress on polymer materials for additive manufacturing. Adv Funct Mater. 2020;30(43):2003062. doi:10.1002/adfm.202003062. [Google Scholar] [CrossRef]

23. Liu X, Gao M, Chen J, Guo S, Zhu W, Bai L, et al. Recent advances in stimuli-responsive shape-morphing hydrogels. Adv Funct Mater. 2022;32(39):2203323. doi:10.1002/adfm.202203323. [Google Scholar] [CrossRef]

24. Hu M, Wu C, Xie Q, Yu J, Guo Y, Shuai Y, et al. 3D printed degradable hydrogel evaporator for high-efficiency, environmental-friendly solar alkaline-water evaporation. Chem Eng J. 2024;499(6):156132. doi:10.1016/j.cej.2024.156132. [Google Scholar] [CrossRef]

25. Vaghasiya JV, Pumera M. The rise of 3D/4D-printed water harvesting materials. Mater Today. 2024;78:46–74. doi:10.1016/j.mattod.2024.06.007. [Google Scholar] [CrossRef]

26. Li H, Zheng H, Tan YJ, Tor SB, Zhou K. Development of an ultrastretchable double-network hydrogel for flexible strain sensors. ACS Appl Mater Interfaces. 2021;13(11):12814–23. doi:10.1021/acsami.0c19104. [Google Scholar] [PubMed] [CrossRef]

27. Li H, Chng CB, Zheng H, Wu MS, Bartolo PJDS, Qi HJ, et al. Self-healable and 4D printable hydrogel for stretchable electronics. Adv Sci. 2024;11(13):2305702. doi:10.1002/advs.202305702. [Google Scholar] [PubMed] [CrossRef]

28. Wang H, Ding Q, Luo Y, Wu Z, Yu J, Chen H, et al. High-performance hydrogel sensors enabled multimodal and accurate human-machine interaction system for active rehabilitation. Adv Mater. 2024;36(11):2309868. doi:10.1002/adma.202309868. [Google Scholar] [PubMed] [CrossRef]

29. Wang X, Pan C, Xia N, Zhang C, Hao B, Jin D, et al. Fracture-driven power amplification in a hydrogel launcher. Nat Mater. 2024;23(10):1428–35. doi:10.1038/s41563-024-01955-4. [Google Scholar] [PubMed] [CrossRef]

30. Teng X, Xu S, Feng X, Gao Z, Ge Z, Zou B, et al. A dual-paddle soft robot integrated with a bionic elephant nose gripper constructed on the foundation of PNIPAM/MoS2 composite hydrogel. Colloids Surf Physicochem Eng Asp. 2025;717:136825. doi:10.1016/j.colsurfa.2025.136825. [Google Scholar] [CrossRef]

31. Zöller K, To D, Bernkop-Schnürch A. Biomedical applications of functional hydrogels: innovative developments, relevant clinical trials and advanced products. Biomaterials. 2025;312(30):122718. doi:10.1016/j.biomaterials.2024.122718. [Google Scholar] [PubMed] [CrossRef]

32. Guillén-Carvajal K, Valdez-Salas Bín, Beltrán-Partida E, Salomón-Carlos J, Cheng N. Gelatin, and collagen hydrogels for bone regeneration. Polymers. 2023;15(13):2762. doi:10.3390/polym15132762. [Google Scholar] [PubMed] [CrossRef]

33. Dang R, Chen L, Sefat F, Li X, Liu S, Yuan X, et al. A natural hydrogel with prohealing properties enhances tendon regeneration. Small. 2022;18(36):2105255. doi:10.1002/smll.202105255. [Google Scholar] [PubMed] [CrossRef]