Open Access

Open Access

ARTICLE

Pushing the Boundaries of Starch Foams: Novel Laminar Composites with Paper Reinforcement

Department of Tool and Materials Engineering, Faculty of Engineering, King Mongkut’s University of Technology Thonburi, Bangkok, 10140, Thailand

* Corresponding Author: Manisara Phiriyawirut. Email:

Journal of Renewable Materials 2025, 13(1), 101-114. https://doi.org/10.32604/jrm.2024.056830

Received 31 July 2024; Accepted 11 October 2024; Issue published 20 January 2025

Abstract

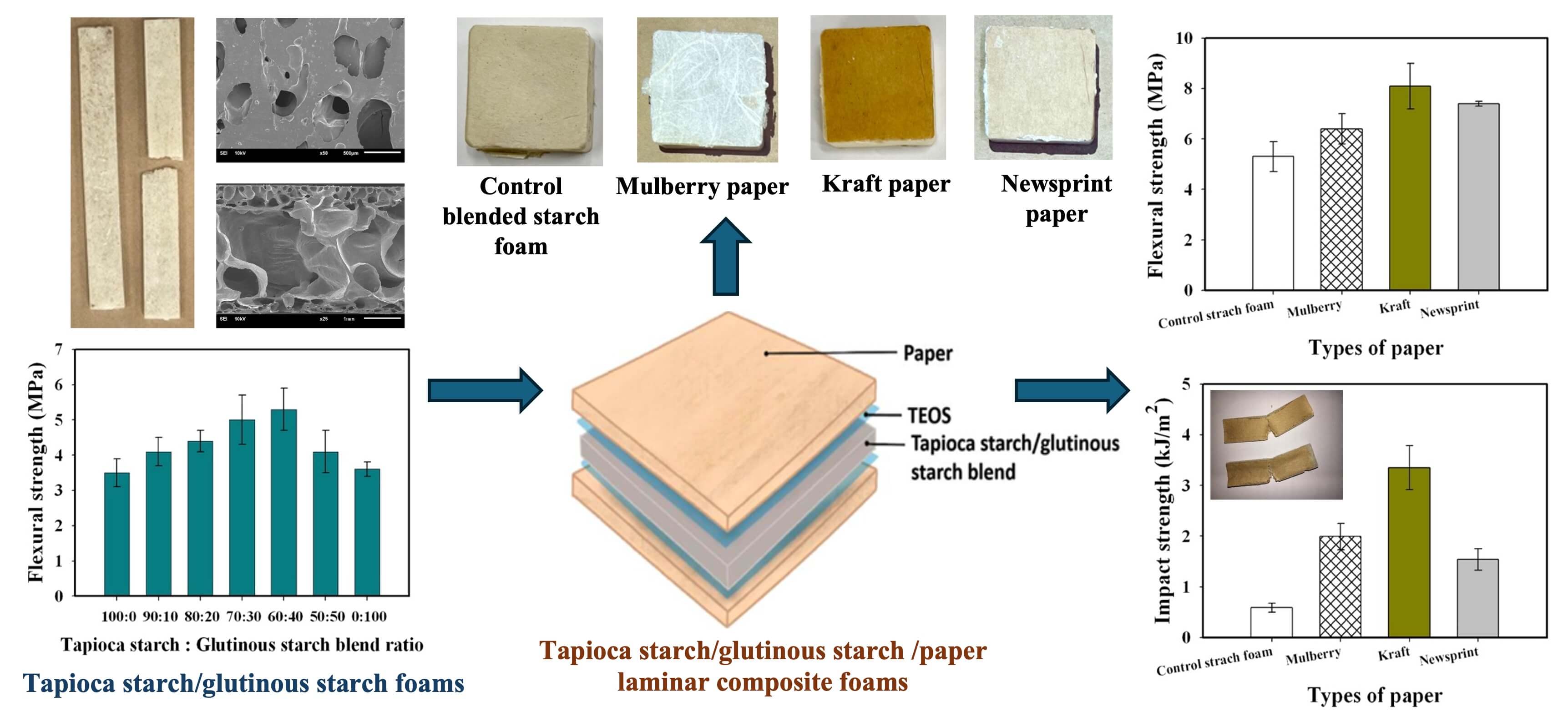

This work explores the development of biodegradable laminar composite foams for cushioning applications. The focus lies on overcoming the inherent brittleness of starch foams by incorporating various paper types as reinforcement. Tapioca starch and glutinous starch were blended in varying ratios (100:0–0:100) to optimize the base material’s properties. The morphology, density, flexural strength, and impact strength of these starch blends were evaluated. The results revealed a trade-off between impact strength and density, with increasing glutinous starch content favoring impact resistance but also leading to higher density. The optimal ratio of tapioca to glutinous starch for achieving maximum flexural strength and modulus was determined to be 60:40. The flexural strength of the composite material at this ratio reached a peak value of 5.3 ± 0.6 MPa, significantly surpassing the flexural strength of pure tapioca foam, which was measured to be 3.5 ± 0.4 MPa. Building on this foundation, novel laminar composite foams were fabricated using the 60:40 starch blend reinforced with mulberry paper, kraft paper, and newsprint paper. To enhance the interfacial adhesion between the starch matrix and paper reinforcement, a silane coupling agent was employed at a 10 wt% loading on the paper. The incorporation of paper reinforcement into starch foams was found to enhance their mechanical properties. Specifically, flexural strength values increased from 5.3 ± 0.6 MPa for the unreinforced starch foam to 6.8 ± 0.6 MPa, 8.1 ± 0.9 MPa, and 7.4 ± 0.1 MPa when reinforced with mulberry paper, kraft paper, and newsprint paper, respectively. Notably, kraft paper reinforcement led to the most enhancements in flexural strength, flexural modulus, and impact strength. This research paves the way for developing sustainable cushioning materials with competitive mechanical properties using bio-based resources like starch and paper.Graphic Abstract

Keywords

The ever-growing e-commerce industry, particularly amplified by the COVID-19 pandemic, has led to a dramatic increase in the demand for packaging materials. While foam cushioning remains popular due to its lightweight nature, flexibility, and shock absorption properties, its dependence on non-biodegradable materials raises significant environmental concerns. Starch, a renewable and biodegradable biopolymer derived from abundant crops such as tapioca, corn, and rice, offers a promising alternative to petroleum-based packaging materials [1–3]. It is readily available, affordable, and possesses biodegradability, aligning perfectly with the growing demand for eco-friendly materials. Various starches, including tapioca, corn, and glutinous rice, can be used to produce biodegradable foams [4–6]. Their properties vary based on amylose, amylopectin, and lipid content. Tapioca starch is commonly used due to its availability and cost-effectiveness [7–9], but it often lacks flexibility and water resistance. Blending glutinous rice starch, known for its superior flexibility and toughness [4], with tapioca starch can enhance the mechanical properties of starch foams, making them more suitable for impact-resistant applications, by optimizing the blend ratio.

To enhance the mechanical properties of starch foams, especially for impact-resistant applications, biodegradable reinforcements like natural fibers can be incorporated [10–12]. Laminar composites, formed by layering these fibers, offer advantages such as low density, lightweight, and versatility [13]. Natural sheet-like materials, such as corn husks [14], plant leaves [15], and papers [16], can be used as reinforcements in starch foams. By strategically aligning these materials within the foam structure, the mechanical properties can be tailored to meet specific requirements.

Paper, a readily available and a product of renewable resource, can effectively reinforce starch foams [17–19]. Its high cellulose content provides strength and stiffness, addressing the brittleness of starch. The porous structure of paper facilitates strong adhesion with the starch matrix. Surface treatments can further enhance interfacial compatibility [20]. Mulberry paper, known for its strength and tear resistance, is a promising reinforcement option [21]. Kraft paper offers superior strength, toughness, and water resistance [22]. Newsprint paper, although less resistant to moisture and tearing, can still improve mechanical properties when used as a reinforcement [23]. Both kraft paper and newsprint paper benefit from a more ordered fiber alignment due to their machine production, enhancing their overall mechanical properties.

Laminar composites of starch foams and paper offer enhanced water resistance due to several mechanisms. Paper acts as a physical barrier, limiting water penetration. Additionally, improved interfacial adhesion between starch and paper and reduced porosity contribute to moisture resistance [14,24]. The lignin content of paper, a natural antimicrobial agent, further enhances resistance to mold and insects [25]. These combined properties make starch-paper composites suitable for applications requiring durability and resistance to biological degradation.

To push the boundaries of starch foams and develop novel laminar composites with paper reinforcement, this research comprehensively investigates two critical factors: the blending ratio of tapioca starch and glutinous starch, and the type of paper reinforcement employed. These two components are determined to play pivotal roles in determining the overall mechanical properties and performance of the composite material. By carefully adjusting the blend ratio of tapioca and glutinous starches, a balance between processability, strength, and flexibility is sought. Additionally, the selection of appropriate paper reinforcements is crucial. Three distinct paper types—mulberry, kraft, and newsprint—were chosen for their varying properties. By comparing the performance of these three paper types, the most effective reinforcement option for achieving the desired mechanical properties in the starch-paper composite is identified, ultimately pushing the boundaries of starch foam technology and creating innovative sustainable cushioning material solutions.

Tapioca starch and glutinous starch were obtained from commercial sources in Thailand. Gaur gum and magnesium stearate were purchased from Chemipan Corporation Co., Ltd. (Bangkok, Thailand). Tetraethoxysilane (TEOS) was obtained from Merck. Analytical reagent grade (AR) acetic acid, chloroform, and ethanol were procured from RCI Labscan Co. Ltd. (Bangkok, Thailand). Mulberry paper, kraft paper, and newsprint paper with thicknesses of 0.22, 0.09, and 0.14 mm, respectively, were purchased from a local vendor in Thailand.

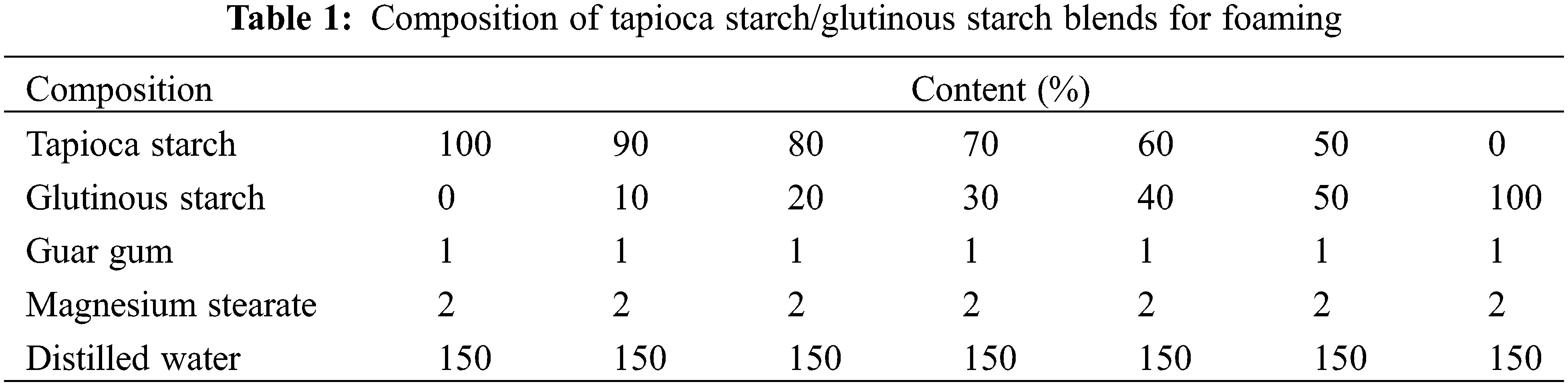

2.2 Preparation of Tapioca Starch/Glutinous Starch Blend Foams

Tapioca starch and glutinous starch were dried at 105°C for 24 h before use. Tapioca starch, glutinous starch, guar gum (1 wt% based on dry starch weight), and magnesium stearate (2 wt% based on dry starch weight) were first thoroughly dry-blended using a kitchen-aid mixer [14]. Distilled water was then gradually added to the dry mixture, and the entire composition was mixed for an additional 20 min to ensure homogeneity. The specific formulations for each sample are presented in Table 1. For the preparation of tapioca starch/glutinous starch blend foams, a hot-press molding technique was employed. The mixed starch composition was placed in a mold cavity and subjected to a pressing force of 100 kgf/cm2 at a temperature of 160°C on the upper platen and 165°C on the lower platen for a holding time of 5 min. This process facilitates the formation of the desired starch blend foams.

2.3 Preparation of Blended Starch/Paper Laminate Composite Foams

Tapioca starch, glutinous starch, guar gum (1 wt%), and magnesium stearate (2 wt%) were dry-blended and mixed with water for homogeneity. The tapioca/glutinous starch ratio was optimized based on mechanical properties for cushioning applications.

The investigated papers, including mulberry paper, kraft paper, and newsprint paper, were used in their as-received condition. To enhance interfacial adhesion between the paper and starch matrix, some paper samples were subjected to a silane coupling agent treatment. These TEOS-treated papers were prepared by coating them with a 10 wt% TEOS solution prepared by dissolving TEOS in a 30% ethanol solution. Following the coating process, the TEOS-treated papers were air-dried for 24 h before further use.

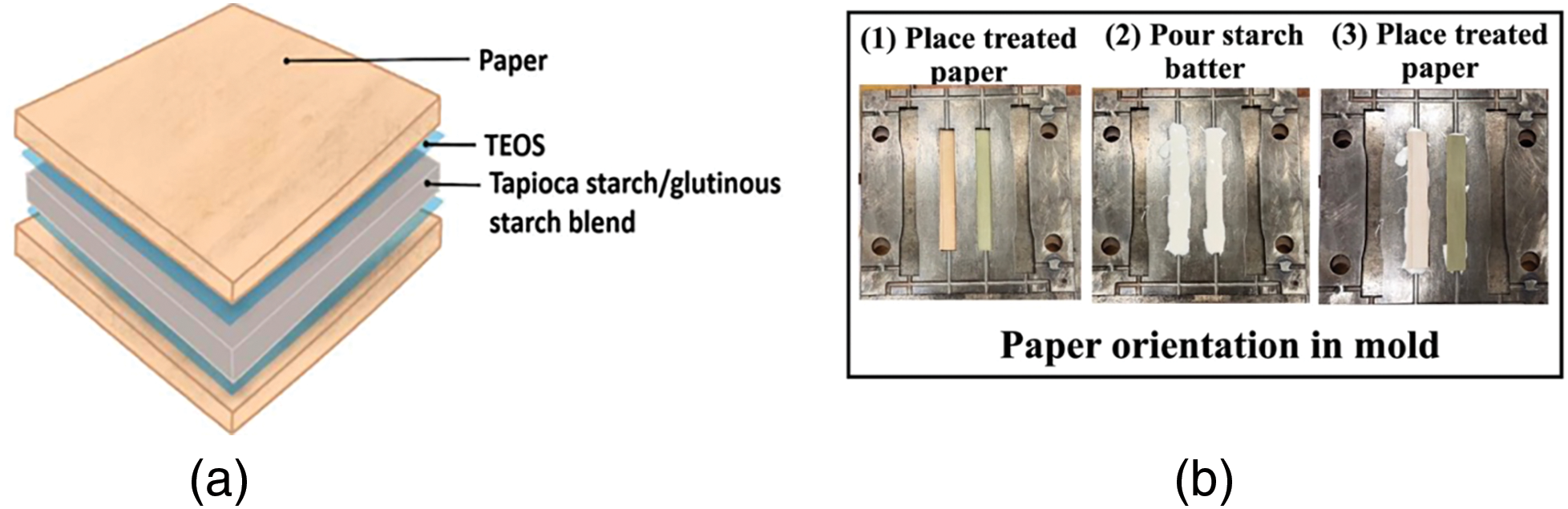

The composite starch foams were fabricated using a compression molding technique. Molds conforming to ASTM D790-03 standards for flexural property and impact testing were employed. These molds possessed dimensions of 14.5 mm in width and 120 mm in length. The specific construction details of these composite foams are illustrated in Fig. 1a. The starch batter was sandwiched between layers of TEOS-treated paper as see in Fig. 1b. The mold was then subjected to a temperature of 160°C, a pressure of 100 bar, and a holding time of 5 min. This process facilitated the formation of the desired starch/paper laminate composite foams.

Figure 1: (a) The construction of blended starch/paper laminate composite foams and (b) Paper orientation in mold

2.4 Characterization of Starch Blends and Composite Foams

The viscosity of tapioca starch/glutinous starch blend batters was measured using a rotational viscometer (TA.XT Plus) at room temperature. The density of both the starch blend foams and the final starch/paper laminate composites were determined using a Density Determination Kit with chloroform at room temperature. To characterize the morphological features of the foams and composites, scanning electron microscopy (SEM) was employed using a JEOL JSM-6610 LV instrument. Samples were prepared by coating their surfaces and fractured cross-sections (obtained after flexural testing) with a thin layer of gold to enhance electrical conductivity and improve image quality. SEM analysis was conducted at an accelerating voltage of 10 kV to obtain high-resolution images of the microstructure.

To establish a baseline for mechanical testing, starch foam samples and their composites were conditioned in a desiccator for 24 h. Flexural strength was measured using a three-point bending method on a Universal testing machine (LLOYD Instruments LR50K) according to ASTM D 790-03 standards, with a maximum load of 5 kN and a crosshead speed of 2 mm/min. The impact strength of notched composite foams was evaluated using cantilever beam (Izod-type) impact machine following the ASTM D256 standard. A milling machine was employed to create notches in the cross-section of each starch foam specimen. These notches adhered to the specifications outlined in ASTM D256, with a depth of 4.8 mm and a radius of 0.25 mm. Each sample was tested three times to obtain an average value.

3.1 Tapioca Starch/Glutinous Starch Blend Foams

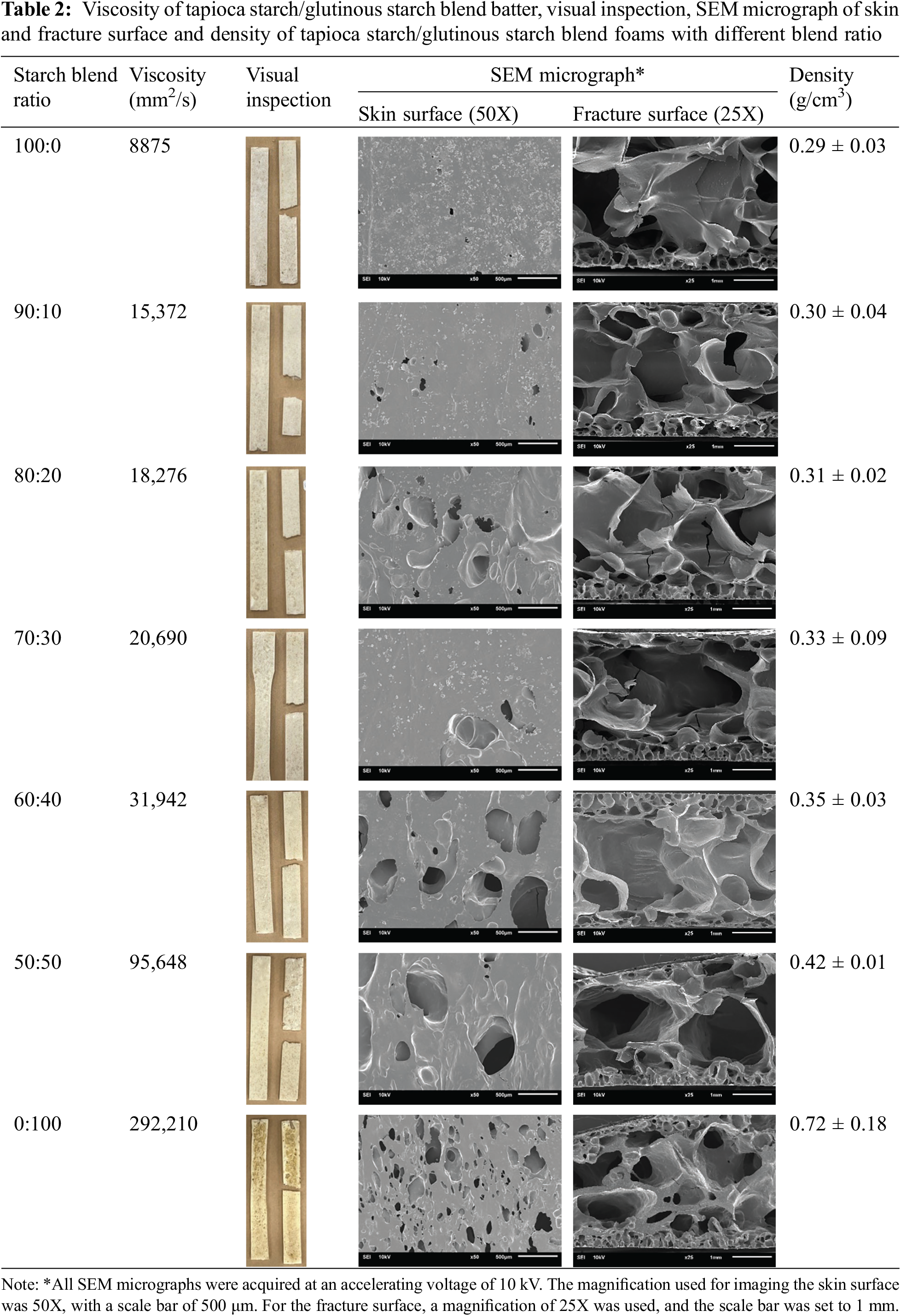

Table 2 presents the viscosity of the tapioca starch/glutinous starch blend batters, along with observations from visual inspection, SEM micrographs of the skin and fracture surfaces, and density of the foams prepared with different blend ratios.

The impact of varying tapioca starch/glutinous starch ratios on starch batter viscosity was investigated. Tapioca starch (100:0) exhibited a significantly lower viscosity (8874.9 mm2/s) compared to glutinous starch (0:100) (292, 210.0 mm2/s). This difference can be ascribed to the lower amylose content (17%) and higher amylopectin content (83%) in tapioca starch compared to the 100% amylopectin content in glutinous starch. As a result, tapioca starch has a lower molecular weight, aligning with the principle that amylopectin, with a molecular weight approximately 100 times that of amylose [13], contributes to higher viscosity. Introducing glutinous starch into the blends (90:10, 80:20, 70:30, 60:40, and 50:50) progressively increased viscosity, corroborating the findings of Saeleaw et al. [4], who observed a similar viscosity increase with increasing glutinous starch content. The significant increase in viscosity observed when tapioca starch is blended with glutinous starch, even at ambient temperature, can be attributed to the unique structural properties of amylopectin, a major component of starch. Amylopectin molecules have a highly branched structure, forming a three-dimensional network when dispersed in water. This network structure effectively traps water molecules, resulting in increased viscosity. Glutinous starch is particularly rich in amylopectin compared to tapioca starch. Consequently, when glutinous starch is added to a tapioca starch slurry, the amylopectin molecules from both starches interact to form an even more extensive and robust network. This denser network enhances the ability of the slurry to trap water, leading to a substantial increase in viscosity. The formation of this three-dimensional network is facilitated by the numerous hydroxyl groups present in amylopectin molecules. These hydroxyl groups can form hydrogen bonds with water molecules and with each other, contributing to the stability and strength of the network. Additionally, the degree of polymerization and the distribution of branch points in amylopectin molecules can influence the extent of network formation and, consequently, the viscosity of the slurry.

Tapioca starch foams (100:0), glutinous starch foam (0:100) and starch/glutinous starch blends (90:10, 80:20, 70:30, 60:40, and 50:50) were prepared using hot compression molding at 160°C, 100 bar for 5 min. As shown in Table 2, tapioca starch foams (100:0) and blends up to 50:50 exhibited aesthetically pleasing, smooth, and glossy surfaces with minimal collapse. However, increasing glutinous starch content beyond 50% led to a more yellowish hue, increased collapse, and a rougher surface texture. This can be attributed to the high amylopectin content [26] and inherent viscosity of glutinous starch, which hinders foam cell expansion and results in thicker cell walls and potential collapse.

The formation of pores on the foam skin surface in contact with the mold during compression molding is influenced by various factors. These factors include non-uniform water evaporation, mold pressure, adhesion between the foam and mold, and mold properties. The viscosity of the starch slurry significantly affects pore formation, with higher viscosity leading to smaller and more numerous pores. Additionally, the shrinkage of the foam during cooling can cause non-uniform pore sizes due to uneven contraction. Other factors such as temperature, pressure, type of starch, and additives can also impact pore size and distribution. The skin surface morphology of starch foams, as characterized by pore structure, is significantly influenced by the starch composition. The pore structure of foams produced from tapioca starch, glutinous starch, and their blends exhibits distinct characteristics. Tapioca starch foams (100:0) generally possess a fine and shallow pore structure, while glutinous starch foams (0:100) tend to have larger and deeper pores. Glutinous starch, with its higher amylopectin content, forms a weaker gel network during cooling, leading to more significant foam collapse and larger pore formation. Conversely, tapioca starch, having a higher amylose content, forms a stronger gel network, resulting in smaller and shallower pores. As the proportion of glutinous starch in the blends increases, the foam’s pore structure gradually shifts from a fine and shallow pore network (characteristic of tapioca starch) to a larger and deeper pore network (characteristic of glutinous starch), suggesting a greater degree of foam collapse during cooling.

Cross-sectional analysis (Table 2) revealed distinct cell morphologies across core and edge regions. The core of tapioca starch foam (100:0) displayed a dominant open-cell structure with large, interconnected voids and thin cell walls, facilitating air passage and indicating good expansion. In contrast, glutinous starch foam (0:100) exhibited a less expansive core with a similar open-cell structure but thicker cell walls. The edge regions of both foams displayed a combination of closed-cell and open-cell structures. These closed cells had denser walls and a compressed appearance, suggesting limited airflow. Interestingly, the open cells in the edge regions exhibited thinner walls compared to those in the core. As the glutinous starch content in the blends increased (from 0% to 50%), a gradual shift occurred. The thickness of the closed-cell region at the edges progressively increased, while the open-cell core became thinner. This transition reflects the reduced foam expansion and potential collapse associated with higher glutinous starch content, likely due to its influence on starch-water interactions during foaming. The increased viscosity of the starch slurry with higher glutinous starch content also played a significant role in shaping the foam structure. A more viscous slurry may have hindered bubble nucleation and growth, leading to fewer and larger cells, especially in the core region. Additionally, the higher viscosity could have reduced the mobility of the starch molecules, limiting their ability to form a continuous network and resulting in thicker cell walls [26].

The density of starch foams composed of various ratios of tapioca starch and glutinous starch is presented in Table 2. It was found that the tapioca starch foam (100:0) exhibited the lowest density at 0.291 g/cm3, while the glutinous starch foam (0:100) had the highest density at 0.724 g/cm3. The density of the blended foams increased proportionally with the increasing content of glutinous starch. This observation is consistent with the morphological analysis. As the content of glutinous starch increased, the cell walls of the foam cells became thicker, particularly in the glutinous starch foam, which exhibited the thickest cell walls and a denser cellular structure. Consequently, the blended foams demonstrated higher densities with increasing amounts of glutinous starch.

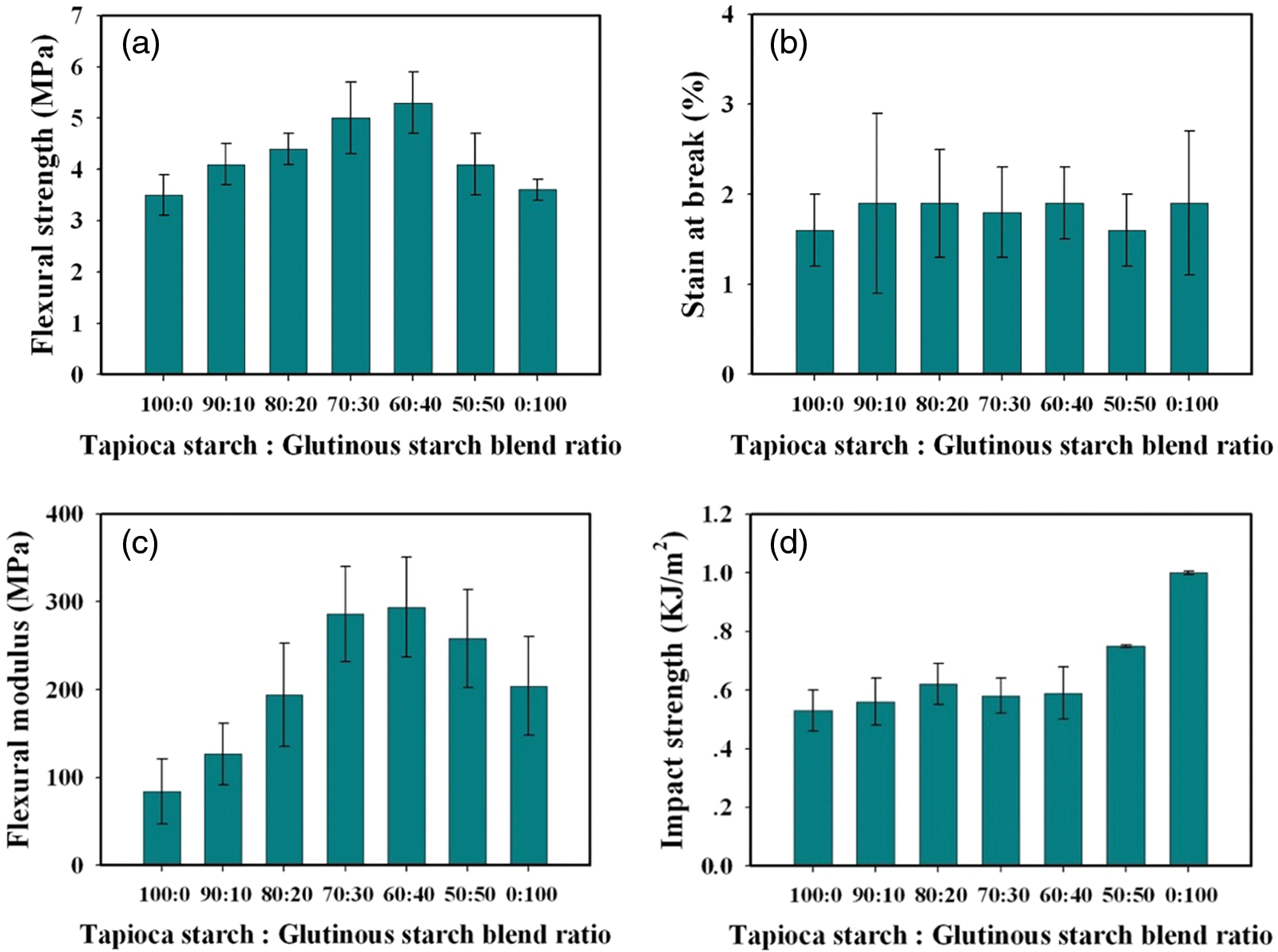

The impact of blending tapioca starch with glutinous starch on the mechanical properties of the resulting foams was investigated. Fig. 2 presents the data on flexural strength, flexural modulus, strain at break, and impact strength.

Figure 2: Flexural properties and impact strength of tapioca starch/glutinous starch blend foams with different blend ratio, (a) Flexural strength (b) Strain at break (c) Flexural modulus, and (d) Impact strength

The mechanical properties of starch foams, particularly flexural modulus and impact strength are influenced by their cellular structure and amylopectin content. Glutinous starch, with its higher amylopectin content, exhibits superior mechanical properties compared to tapioca starch. The amylopectin molecules likely form a stronger network within the foam matrix, enhancing its flexibility and toughness [27], leading to improved performance. These findings highlight the importance of starch composition in tailoring the mechanical properties of starch-based foams.

The incorporation of glutinous starch into tapioca starch foam (10%–40% glutinous starch) significantly enhanced its flexural strength and modulus. This improvement can be attributed to both structural changes and increased molecular interactions. The addition of glutinous starch led to a denser foam with thicker cell walls, providing greater resistance to bending and improving overall structural integrity. Additionally, the higher amylopectin content in glutinous starch facilitated stronger intermolecular interactions within the foam matrix, creating a more robust network. This enhanced network structure contributed to increased flexural strength and modulus, while the relatively constant flexural strain suggests that the foam’s ability to absorb energy and dissipate stress remained largely unchanged. However, further increases in glutinous starch content beyond 40% led to a decline in these mechanical properties. The excessive viscosity of the blend may have hindered the formation of a uniform and well-connected cellular structure, potentially resulting in defects such as larger pores and uneven cell wall thickness. Moreover, the high amylopectin content might have led to excessive crosslinking, reducing the flexibility of the foam matrix and compromising its mechanical performance.

The Izod impact test revealed a clear dependence of impact resistance on starch type. Tapioca starch, with its open structure, resulted in foams with lower resistance due to easier energy propagation. Conversely, glutinous starch formed denser foams with superior impact resistance. The denser amylopectin network effectively absorbs and dissipates impact energy, aligning with previous research by Machado et al. [28] and Salgado et al. [29] who reported a positive correlation between foam density and impact resistance (80% original). Interestingly, blending tapioca and glutinous starches (10%–50% glutinous starch) resulted in a gradual increase in impact resistance, mirroring the behavior of pure starches. This aligns with Saeleaw and Schleining’s work [4] on crackers, where higher glutinous starch content increased impact resistance.

Among various blend ratios, tapioca starch-glutinous starch foam with a 60:40 ratio emerged as the most promising candidate for composite material development. This blend exhibited superior flexural strength and modulus compared to other ratios, despite having a lower impact strength than pure glutinous starch foam and 50:50 blend foam. Its superior shape retention, resistance to collapse, and lower density compared to the 50:50 blend makes it ideal for packaging applications. Therefore, the 60:40 blend was deemed the most suitable for further development.

3.2 Tapioca Starch/Glutinous Starch Blended Starch/Paper Laminate Composite Foams

This research is centered on developing tapioca starch/glutinous starch blended starch/paper laminate composite foams as cushioning materials. Since water resistance is not a primary concern for this application, the focus of this study will be on the composite morphology and mechanical properties. However, given previous research indicating that laminating starch foams with sheet-like materials can enhance water resistance [24], we will pay close attention to the composite structure to potentially achieve unexpected improvements in this area, while prioritizing the desired cushioning properties.

To enhance the interfacial adhesion between starch and corn husk layers in composite foams, tetraethoxysilane (TEOS) can be used as a coupling agent. Previous studies have shown that TEOS treatment can significantly improve the mechanical properties of starch/corn husk laminate composites [30]. In this study, TEOS was applied to paper layers used as reinforcements in tapioca starch/glutinous starch blended foam composites. This treatment aims to strengthen the bond between the starch matrix and the paper reinforcement, potentially improving the overall mechanical performance of the composite foams.

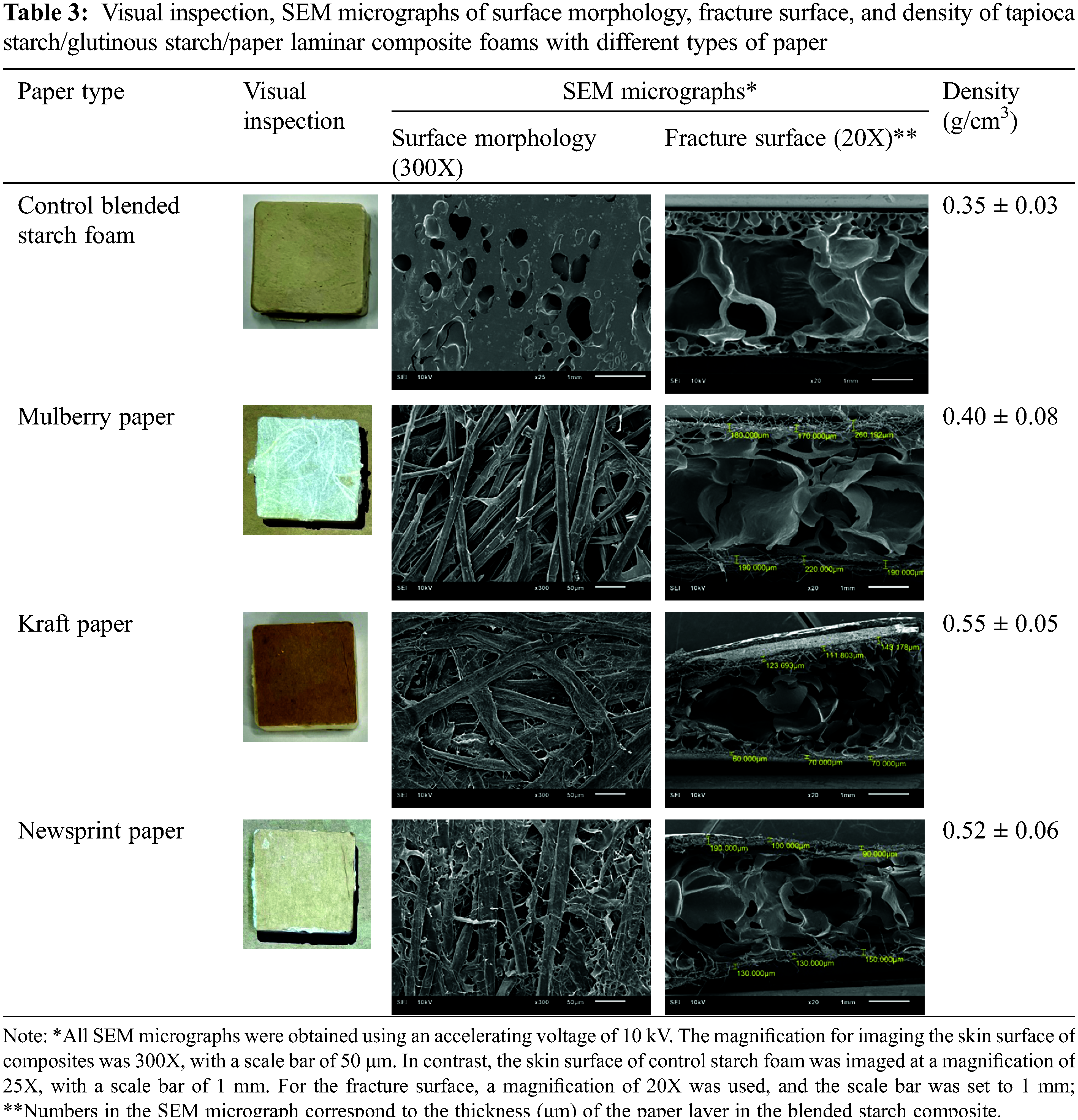

Table 3 presents visual inspection, SEM micrographs of surface morphology and fracture surfaces, and the density data for these composites. Visual inspection revealed excellent color retention for all paper types during molding. Notably, mulberry paper retained its white color, ideal for aesthetics. Kraft and newsprint papers also showed minimal degradation (brown and gray, respectively). Formability varied: thicker mulberry paper (0.22 mm) with loose fibers displayed excellent formability but a textured surface. Thinner kraft (0.09 mm) and newsprint (0.14 mm) papers, with denser fibers, showed good formability with slight collapse due to their flexibility under molding pressure.

SEM analysis (details in Table 3) revealed distinct surface characteristics for the composites compared to the control starch foam. The control foam displayed a smooth surface with small holes, while the composites mirrored the paper types used. Mulberry paper composites exhibited a textured surface due to their loose, randomly arranged fibers with significant inter-fiber space. Kraft and newsprint papers, despite a similar fiber orientation pattern, had denser networks with smaller, fused fibers due to their manufacturing processes.

Both the control foam and composites displayed a gradient in cell morphology across the cross-section. Smaller closed cells were observed near the surface, transitioning to larger open cells towards the center. Paper reinforcement significantly impacted this structure. Mulberry paper composites, with their loose fiber arrangement, allowed for greater vapor permeation and foam expansion, resulting in larger, more open cells throughout. Conversely, the denser fiber networks of kraft and newsprint papers hindered vapor diffusion, leading to lower expansion and smaller cells within the composite [14].

As expected for lightweight applications, the un-reinforced starch foam exhibited the lowest density (0.35 g/cm3). Paper reinforcement increased density: 0.40 g/cm3 for mulberry paper, 0.55 g/cm3 for kraft paper, and 0.52 g/cm3 for newsprint paper. This aligns with findings by Kaisangsri et al. [12] on starch composites with fiber reinforcements. Notably, mulberry paper, observed via SEM to have a more open cell structure, resulted in the lowest density composite due to its ability to facilitate better foam blowing. Conversely, kraft and newsprint paper, with denser fiber packing (as seen in SEM analysis), led to higher-density composites.

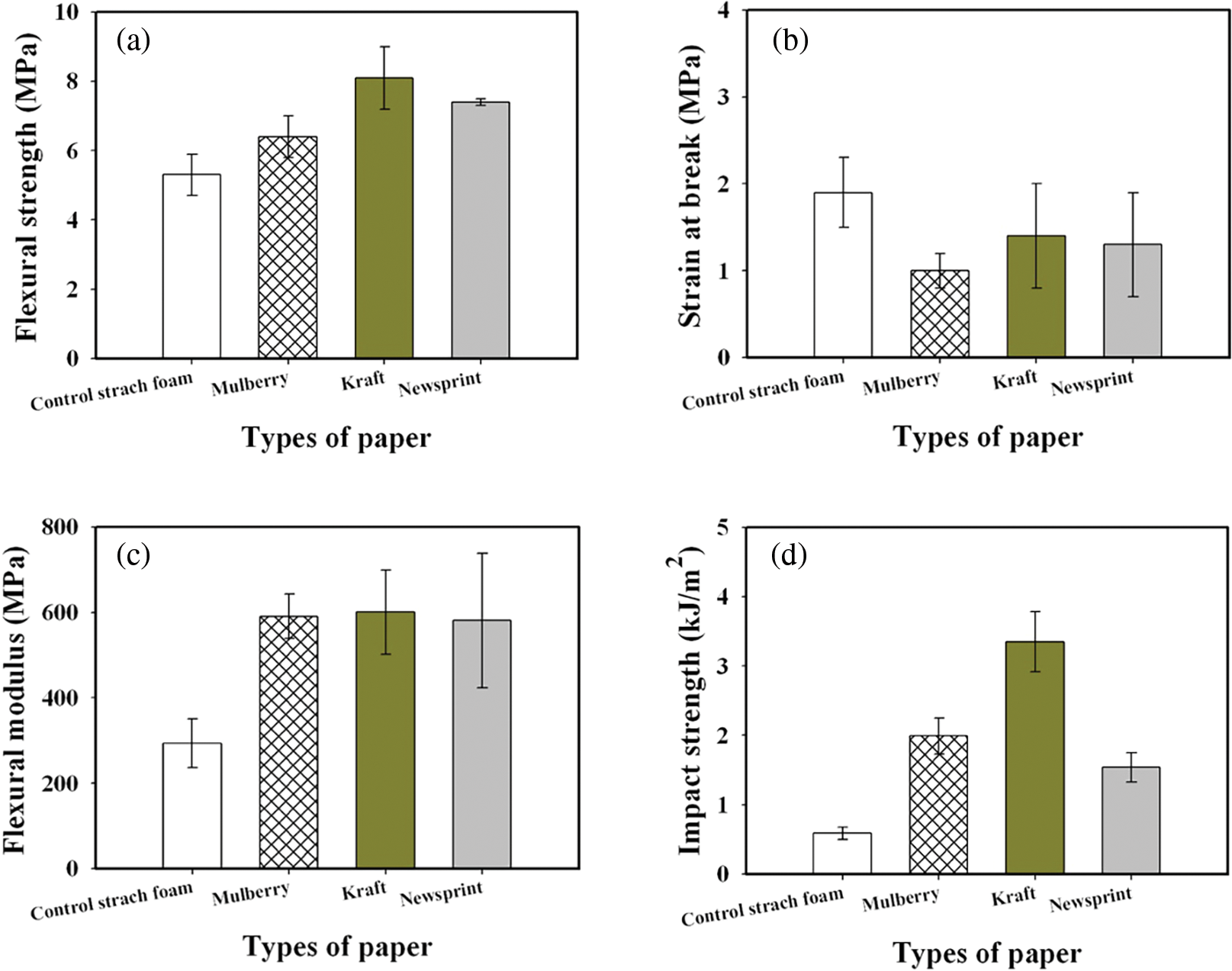

The mechanical properties of the blended starch/paper laminar composite foams reinforced with different types of paper are presented in Fig. 3. Fig. 3a–c focuses on the flexural properties, while Fig. 3d depicts the impact strength.

Figure 3: Flexural properties and impact strength of tapioca starch/glutinous starch/paper laminar composite foams with different types of paper, (a) Flexural strength (b) Strain at break (c) Flexural modulus, and (d) Impact strength

Reinforcement with various paper types significantly enhanced the flexural strength, flexural modulus, and Izod impact strength of layered composite foams made from a 60:40 blend of tapioca and glutinous starches. The superior mechanical properties of these laminar composites can be attributed to several mechanisms. First, the layered structure of the composites allows for effective stress distribution, preventing catastrophic failure under bending or impact loads. Second, the controlled orientation of fibers within the paper layers, when aligned with the direction of applied forces, provides enhanced resistance to bending and impact stresses. Third, the strong interfacial adhesion between the starch matrix and the paper reinforcements contributes to the overall structural integrity of the composite, preventing delamination and improving impact resistance. Finally, the synergistic interaction between the starch matrix and the paper fibers further enhances the mechanical properties, resulting in improved flexural strength, flexural modulus, and impact strength [31].

This aligns with previous research on starch foam reinforcement using natural materials [12]. All reinforced composites demonstrated higher impact resistance compared to the unreinforced foam. This improvement can be attributed to the increased density and smaller cell size of the reinforced foams, which enhance their ability to absorb energy upon impact. Additionally, the layered structure of the composites, with paper reinforcements acting as barriers to crack propagation, contributes to the improved impact resistance. Among the tested papers (mulberry, kraft, and newsprint), kraft paper proved to be the most effective reinforcement, providing the highest flexural strength, flexural modulus, and impact strength. This can be attributed to the long, continuous fibers and uniform structure of kraft paper, resulting from the kraft pulping process [32]. The higher density of the kraft paper reinforcement also contributed to the improved impact resistance. Interestingly, in flexural properties mulberry paper exhibited the lowest values, while newsprint paper showed intermediate results. Additionally, the machine-produced nature of kraft and newsprint papers leads to a better bonding of fibers compared to handmade mulberry paper. On the other hand, for impact strength mulberry paper exhibited the second-highest impact strength, followed by newsprint paper. The lower impact strength of newsprint paper can be attributed to its shorter fiber length and lower density compared to kraft paper. The addition of paper reinforcement also decreased the flexural strain of the composite foams. This reduction in strain is likely due to the constraints imposed by the paper layers on the underlying starch foam, limiting its ability to deform under load.

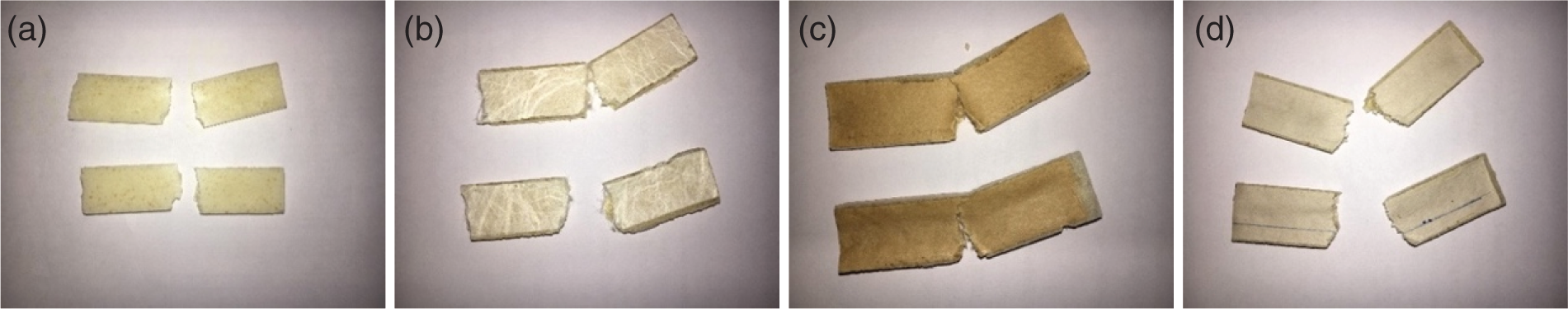

Fig. 4 showcases the impact behavior of the composites. Newsprint paper composites experienced complete separation, while kraft paper displayed hinge breaking due to its strong fibers. Mulberry paper exhibited partial separation potentially due to a combination of fiber resistance and non-uniform distribution. This aligns with studies on fiber orientation in composites [33], suggesting that fibers perpendicular to stress contribute more significantly to strength.

Figure 4: Impact behavior of tapioca starch/glutinous starch/paper laminar composite foams with papers (a) Control blended starch foam, blended starch composite foam with different types of paper. (b) Mulberry papers, (c) Kraft papers, and (d) Newsprint papers

Kraft paper reinforcement offered the most significant improvement in mechanical properties, likely due to its high fiber strength and dense structure. The dense arrangement of fibers in kraft paper provides a strong and continuous network, effectively resisting the propagation of cracks and enhancing the overall structural integrity of the composite. Conversely, mulberry paper, despite having larger fibers, exhibited lower improvements. This may be attributed to a non-uniform distribution of fibers within the paper, which could hinder crack propagation and reduce the reinforcement efficiency. Newsprint paper, characterized by lower strength and potentially weaker adhesion to the starch matrix, showed minimal improvement in mechanical properties.

The smooth paper surface and low density of tapioca starch/glutinous starch/paper laminate composite foams make them promising candidates for cushioning electronic devices. Starch-based foams have static-prevention properties, which is important for protecting electronic devices that are sensitive to static electricity. The starch foam component provides a soft, shock-absorbing layer, while the paper laminate offers a smooth, protective surface. The smooth paper surface of these composite foams can help prevent scratches on delicate electronic components, while the low density can contribute to lighter packaging and reduced shipping costs. Although these materials may not yet match the performance of traditional cushioning materials like PE or PS foams, they offer a more sustainable and potentially biodegradable alternative.

In an effort to push the boundaries of renewable starch foams for cushioning applications, this research investigated the influence of two key factors on novel laminar composite foams: blending ratios of tapioca and glutinous starch (100:0 to 0:100) and the type of paper reinforcement (mulberry paper, kraft paper, and newsprint paper). The findings revealed a trade-off between properties, with the 60:40 tapioca starch-glutinous starch blend identified as the optimal base material for its superior formability, flexural strength, and modulus. While increasing glutinous starch content enhanced impact resistance, it compromised formability. Reinforcement with various paper types led to significant improvements in the mechanical performance of the resulting composites compared to the unreinforced starch foam. Notably, kraft paper reinforcement yielded the most impressive results, achieving the highest impact resistance and flexural strength while maintaining cost-effectiveness. Mulberry paper offered the advantage of the lowest density, while newsprint paper presented the most economical option with comparable properties. Based on these findings, the 60:40 tapioca starch-glutinous starch blend reinforced with kraft paper emerged as the most promising candidate for developing a commercially viable shock-absorbing foam. This novel laminar composite successfully pushes the boundaries of starch foams, offering a sustainable and high-performance alternative for packaging applications.

Acknowledgement: The experimental results reported in this study are part of the undergrad senior project, Department of Tool and Materials Engineering, Faculty of Engineering, King Mongkut’s University of Technology Thonburi (KMUTT).

Funding Statement: This research was funded by the Thailand Science Research and Innovation (TSRI) under Fundamental Fund 2023 (Project: Advanced Materials and Manufacturing for Applications in New S-Curve Industries).

Author Contributions: Study conception and design: Manisara Phiriyawirut; data collection: Pukrapee Rodprasert, Peerapat Kulvorakulpitak, Ratiwan Cothsila; analysis and interpretation of results: Manisara Phiriyawirut, Pukrapee Rodprasert, Peerapat Kulvorakulpitak, Ratiwan Cothsila, Nattarat Kengkla; draft manuscript preparation: Manisara Phiriyawirut. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data from this study can be obtained from the corresponding author (Manisara Phiriyawirut) upon reasonable request.

Ethics Approval: This study does not include human or animal subjects.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Tapia-Blácido DR, Aguilar GJ, Teixeira de Andrade M, Rodrigues-Júnior MF, Guareschi-Martins FC. Trends and challenges of starch-based foams for use as food packaging and food container. Trends Food Sci. 2022;119(10):257–71. doi:10.1016/j.tifs.2021.12.005. [Google Scholar] [CrossRef]

2. Phiriyawirut M, Duangsuwan T, Uenghuab N, Meena C. Effect of octenyl succinate starch on properties of tapioca thermoplastic starch blends. Key Eng Mater. 2017;751:290–5. doi:10.4028/www.scientific.net/KEM.751.290. [Google Scholar] [CrossRef]

3. Jiang T, Duan Q, Zhu J, Liu H, Yu L. Starch-based biodegradable materials: challenges and opportunities. Adv Ind Eng Polym Res. 2020;3(1):8–18. doi:10.1016/j.aiepr.2019.11.003. [Google Scholar] [CrossRef]

4. Saeleaw M, Schleining G. Effect of blending cassava starch, rice, waxy rice and wheat flour on physico-chemical properties of flour mixtures and mechanical and sound emission properties of cassava crackers. J Food Eng. 2010;100(1):12–24. doi:10.1016/j.jfoodeng.2010.03.020. [Google Scholar] [CrossRef]

5. Yun SM, Kang M, Park SY, Eun JB, Chun HH. Characterization of biodegradable corn starch-based foam container incorporating kimchi cabbage (Brassica rapa L. pekinensis) by-product. LWT. 2023;188(10):115432. doi:10.1016/j.lwt.2023.115432. [Google Scholar] [CrossRef]

6. Aygün A, Uslu KM, Polat S. Effects of starch sources and supplementary materials on starch based foam trays. J Polym Environ. 2017;25(4):1163–74. doi:10.1007/s10924-016-0886-0. [Google Scholar] [CrossRef]

7. Matheus JRV, de Farias PM, Satoriva JM, de Andrade CJ, Fai AEC. Cassava starch films for food packaging: Trends over the last decade and future research. Int J Biol Macromol. 2023;225:658–72. doi:10.1016/j.ijbiomac.2022.11.129. [Google Scholar] [PubMed] [CrossRef]

8. Wang Z, Mhaske P, Farahnaky A, Kasapis S, Majzoobi M. Cassava starch: chemical modification and its impact on functional properties and digestibility, a review. Food Hydrocoll. 2022;129(6):107542. doi:10.1016/j.foodhyd.2022.107542. [Google Scholar] [CrossRef]

9. Engel JB, Luchese CL, Tessaro IC. How are the properties of biocomposite foams influenced by the substitution of cassava starch for its residual sources? Food Hydrocoll. 2021;118(2):106790. doi:10.1016/j.foodhyd.2021.106790. [Google Scholar] [CrossRef]

10. Bergel BF, Araujo LL, Santana RMC. Effects of the addition of cotton fibers and cotton microfibers on the structure and mechanical properties of starch foams made from potato starch. Carbohydr Polym Technol Appl. 2021;2(1):100167. doi:10.1016/j.carpta.2021.100167. [Google Scholar] [CrossRef]

11. Zhang J, Zou F, Tao H, Gao W, Guo L, Cui B, et al. Effects of different sources of cellulose on mechanical and barrier properties of thermoplastic sweet potato starch films. Ind Crop Prod. 2023;194(6):116358. doi:10.1016/j.indcrop.2023.116358. [Google Scholar] [CrossRef]

12. Kaisangsri N, Kerdchoechuen O, Laohakunjit N. Biodegradable foam tray from cassava starch blend with natural fiber and chitosan. Ind Crop Prod. 2012;37(1):542–46. doi:10.1016/j.indcrop.2011.07.034. [Google Scholar] [CrossRef]

13. Liew KM, Pan ZZ, Zhang LW. An overview of layerwise theories for composite laminates and structures: Development, numerical implementation and application. Compos Struct. 2019;216:240–59. doi:10.1016/j.compstruct.2019.02.074. [Google Scholar] [CrossRef]

14. Phiriyawirut M, Chaikaew K, Phontaisong N, Sakuldeemeekiat P, Kengkla N. Polybutylene succinate thermo-coated corn husk as laminar reinforcement for crosslinked tapioca starch composite foams. Mater Today: Proc. 2022;52(5):2455–9. doi:10.1016/j.matpr.2021.10.428. [Google Scholar] [CrossRef]

15. Arsyad M, Zakaria Umar M, Umar M. Physical test of energy saving composite board from nipah leaves nypa fruticans. In: Proceeding of Marine Safety and Maritime Installation (MSMI 2018), 2018; Bali, Indonesia; p. 97–103. doi:10.23977/msmi.2018.82611. [Google Scholar] [CrossRef]

16. Shivyari NY, Tajvidi M, Bousfield DW, Gardner DJ. Production and characterization of laminates of paper and cellulose nanofibrils. ACS Appl Mater Interf. 2016;8(38):25520–8. doi:10.1021/acsami.6b07655. [Google Scholar] [PubMed] [CrossRef]

17. Khankham P, Nhuapeng W, Thamjaree W. Fabrication and mechanical properties of the biocomposites between water hyacinth fiber and paper mulberry. Key Eng Mater. 2017;757:73–7. doi:10.4028/www.scientific.net/KEM.757.73. [Google Scholar] [CrossRef]

18. Wattanakornsiri A, Tongnunui S, Jamnongkan T, Migliaresi C. Biocomposites based on thermoplastic starch reinforced with recycled paper cellulose fibers. Appl Mech Mater. 2016;855:126–30. doi:10.4028/www.scientific.net/amm.855.126. [Google Scholar] [CrossRef]

19. Shanmugasundaram N, Rajendran I. Characterization of raw and alkali-treated mulberry fibers as potential reinforcement in polymer composites. J Reinf Plast Compos. 2016;35(7):601–14. doi:10.1177/0731684415625822. [Google Scholar] [CrossRef]

20. Lee CH, Khalina A, Lee SH. Importance of interfacial adhesion condition on characterization of plant-fiber-reinforced polymer composites: a review. Polymers. 2021;13(3):438. doi:10.3390/polym13030438. [Google Scholar] [PubMed] [CrossRef]

21. Srinivas K, Naidu AL, Bahubalendruni MR. A review on chemical and mechanical properties of natural fiber reinforced polymer composites. Int J Performability Eng. 2017;13:189–200. doi:10.23940/ijpe.17.02.p8.189200. [Google Scholar] [CrossRef]

22. Lim GY, Kuek RJX, Teo J, Seetoh IP, Lai CQ. Mechanical properties of additively manufactured kraft paper lattices and paper-epoxy interpenetrating phase composites for polymer foam replacement. Addit Manuf. 2023;77(20):103816. doi:10.1016/j.addma.2023.103816. [Google Scholar] [CrossRef]

23. Ali MA, El-Nemr KF, Hassan MM. Waste newsprint fibers for reinforcement of radiation-cured styrene butadiene rubber-based composites-part I: mechanical and physical properties. J Reinf Plast Compos. 2011;30(8):721–37. doi:10.1177/0731684411407949. [Google Scholar] [CrossRef]

24. Zhang C, Zhang P, Li Y, Sandeep SN, Li J, Ji M, et al. Fully biodegradable, hydrophobic, enhanced barrier starch bio-composites with sandwich structure by simulating wood. Ind Crops Prod. 2023;197(32):116603. doi:10.1016/j.indcrop.2023.116603. [Google Scholar] [CrossRef]

25. Chen M, Li Y, Liu H, Zhang D, Shi Q-S, Zhong X-Q, et al. High value valorization of lignin as environmental benign antimicrobial. Mater Today Bio. 2023;18(26):100520. doi:10.1016/j.mtbio.2022.100520. [Google Scholar] [PubMed] [CrossRef]

26. Zhang CW, Li FY, Li JF, Lu HY, Wang G. Bubble wall rupture model for open cell structure in starch/fiber heterogeneous composites. J Biobased Mater Bioenergy. 2020;14(2):169–77. doi:10.1166/jbmb.2020.1955. [Google Scholar] [CrossRef]

27. Wang B, Xu J, Guo D, Long C, Zhang Z, Cheng Y, et al. Research on the relationship between the amylopectin structure and the physicochemical properties of starch extracted from glutinous rice. Foods. 2023;12(3):460. doi:10.3390/foods12030460. [Google Scholar] [PubMed] [CrossRef]

28. Machado CM, Benelli P, Tessaro IC. Sesame cake incorporation on cassava starch foams for packaging use. Ind Crop Prod. 2017;102:115–21. doi:10.1016/j.indcrop.2017.03.007. [Google Scholar] [CrossRef]

29. Salgado PR, Schmidt VC, Molina Ortiz SE, Mauri AN, Laurindo JB. Biodegradable foams based on cassava starch, sunflower proteins and cellulose fibers obtained by a baking process. J Food Eng. 2008;85(3):435–43. doi:10.1016/j.jfoodeng.2007.08.005. [Google Scholar] [CrossRef]

30. Phiriyawirut M, Reungdech W, Chongsakul J, Makpum C, Kengkla N. Potential of tetraethoxy silane treated corn husk as reinforcement for crosslinked tapioca starch laminate composite foams. In: Proceeding of The International Polymer Conference of Thailand, 2020 Aug 6–7; Bangkok, Thailand; p. 151–6. [Google Scholar]

31. Gibson RF. Principles of composite material mechanics. 4thed. Boca Raton, CRC Press; 2016. doi:10.1201/b19626. [Google Scholar] [CrossRef]

32. Hawanis HSN, Ilyas RA, Jalil R, Ibrahim R, Majid R, Hamid NHA. Insights into lignocellulosic fiber feedstock and its impact on pulp and paper manufacturing: a comprehensive review. Sustain Mater Technol. 2024;40(3):e00922. doi:10.1016/j.susmat.2024.e00922. [Google Scholar] [CrossRef]

33. Soykeabkaew N, Supaphol P, Rujiravanit R. Preparation and characterization of jute and flax-reinforced starch-based composite foams. Carbohydr Polym. 2007;58(1):53–63. doi:10.1016/j.carbpol.2004.06.037. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools