Open Access

Open Access

ARTICLE

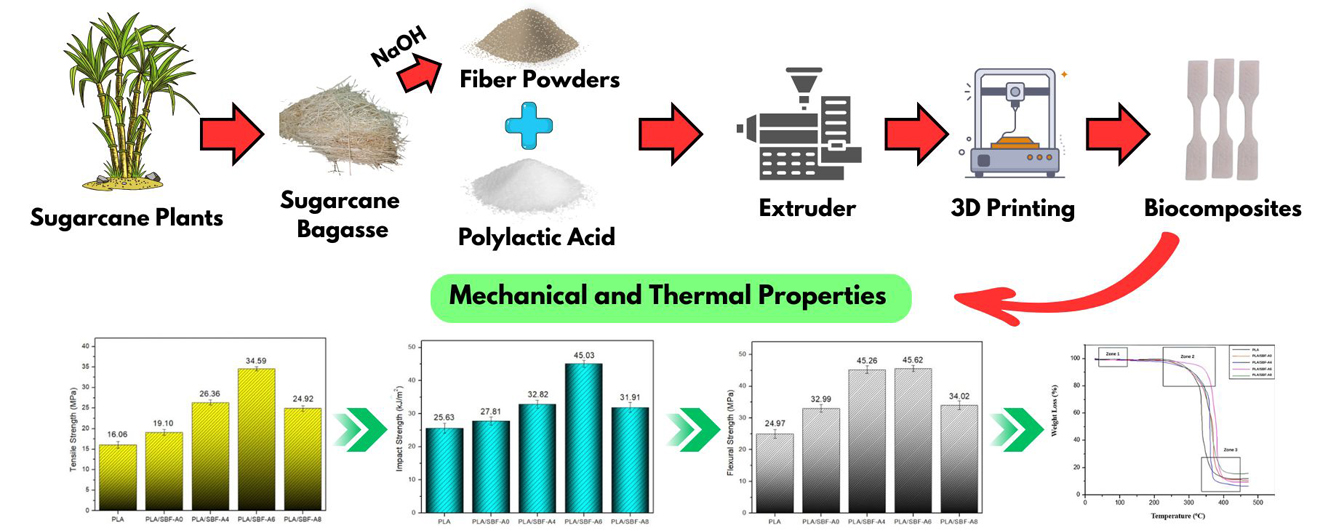

The Effect of Alkalization Fiber on Mechanical, Microstructure, and Thermal Properties of Sugarcane Bagasse Fiber Reinforced PLA Biocomposite

1 Department of Mechanical Engineering, Faculty of Engineering, Universitas Jember, Kampus Tegalboto, Jember, 68121, Indonesia

2 Department of Chemical Engineering, Faculty of Chemical and Energy Engineering, University of Technology Malaysia, Johor Bahru, 81310, Malaysia

3 Centre for Advanced Composite Materials (CACM), Universiti Teknologi Malaysia (UTM), Johor Bahru, 81310, Malaysia

4 Advanced Engineering Materials and Composite Research Centre (AEMC), Department of Mechanical and Manufacturing Engineering, Universiti Putra Malaysia, Serdang, 43400, Malaysia

5 Research Centre for Chemical Defence, Defence Research Institute (DRI), Universiti Pertahanan Nasional Malaysia, Kem Sungai Besi, Kuala Lumpur, 57000, Malaysia

* Corresponding Author: Mochamad Asrofi. Email:

(This article belongs to the Special Issue: Harnessing the Potential of Natural Fiber Composites: A Paradigm Shift Towards Sustainable Materials )

Journal of Renewable Materials 2025, 13(10), 1979-1992. https://doi.org/10.32604/jrm.2025.02025-0033

Received 07 February 2025; Accepted 12 May 2025; Issue published 22 October 2025

Abstract

Biocomposites are one of the environmentally friendly materials as a substitute for synthetic plastics used for various applications in the automotive, household appliances industry, and interiors. In this study, biocomposites from Polylactic Acid (PLA) and sugarcane bagasse fibers (SBF) were made using the 3D Printing method. The effect of alkalization with NaOH of 0 (untreated), 4%, 6%, and 8% of the fibers were studied. The SBF in PLA was kept at 2% v/v from the total biocomposite. The characterization of all biocomposite tested using tensile, flexural, impact, scanning electron microscope (SEM), thermogravimetric analysis (TGA), and Fourier Transform Infrared (FTIR). The tensile test results showed that the 6% NaOH concentration on the fibers had the highest tensile strength of 34.59 MPa compared to pure PLA. The flexural and impact strengths of the biocomposite samples in the treatment also showed the highest results of 45.62 MPa and 45.03 kJ/m2, respectively. SEM imaging also confirmed the presence of good bonding between the matrix and fibers. The thermal stability of biocomposite showed an increase in the degradation point after alkalization. There was a change in the chemical functional group in the biocomposite with fibers treated by 6% NaOH at a wavenumber of 1150–1030 cm−1. These results indicate that PLA biocomposites have competitive properties for application in various industrial sectors.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools