Open Access

Open Access

ARTICLE

Eco-Friendly Particleboards Produced with Banana Tree (Musa paradisiaca) Pseudostem Fibers Bonded with Cassava Starch and Urea-Formaldehyde Adhesives

1 Wood Industry and Utilisation Division, Council for Scientific and Industrial Research-CSIR, Forestry Research Institute of Ghana-FORIG, Kumasi, P.O. Box UP63, Ghana

2 Department of Agronomic and Forestry Sciences-DCAF, Federal University of Semiarid Region-UFERSA, Av. Francisco Mota, 572, Costa e Silva, Mossoró, 59625-900, Brazil

3 Jundiaí Agricultural School-EAJ, Federal University of Rio Grande do Norte-UFRN, RN 160, km 03, s/n, Distrito de Jundiaí, Macaíba, 59280-000, Brazil

* Corresponding Author: Fernando Rusch. Email:

Journal of Renewable Materials 2025, 13(7), 1475-1489. https://doi.org/10.32604/jrm.2025.02025-0047

Received 06 March 2025; Accepted 12 May 2025; Issue published 22 July 2025

Abstract

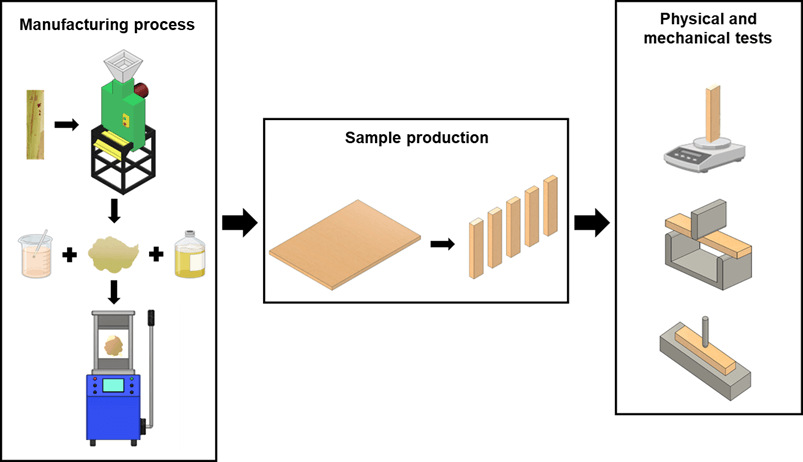

The increase in wood and wood-based products in the construction and furniture sectors has grown exponentially, generating severe environmental and socioeconomic impacts. Particleboard panels have been the main cost-benefit option on the market due to their lightness and lower cost compared to solid wood. However, the synthetic adhesives used in producing traditional particleboard panels cause serious harm to human health. Developing particleboard panels with fibrous waste and natural adhesives could be a sustainable alternative for these sectors. The work aimed to create particleboards with fibrous wastes from the pseudostem of the banana tree (Musa paradisiaca) and different proportions of the natural adhesive cassava starch-CS in replacement of synthetic adhesive urea-formaldehyde-UF. Five experimental groups were manufactured with banana trees and different percentages of UF and CS adhesives, namely (100 UF–0% CS), (50% UF–50% CS), (30% UF–70% CS), (10% UF–90% CS) and (0% UF–100% CS). The particleboards had their physical-mechanical properties determined. The apparent density values did not show significant variation between the assessed treatments. Regarding the water absorption and thickness swelling, the best performances were observed for the panels made without the addition of CS (100% UF). For the mechanical properties of static bending strength and Janka hardness, it was identified that adding up to 50% CS did not interfere with the quality of the panels. These analyses show that the particleboard panels produced with wastes of the banana tree bonded with natural CS adhesive may be an economically viable and environmentally correct alternative, positively strengthening the development of sustainable strategies.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools