Open Access

Open Access

REVIEW

Sustainable Biocomposites from Renewable Resources in West Africa: A Review

1 UPR BioWooEB, CIRAD, Montpellier, F-34398, France

2 BioWooEB, CIRAD, University of Montpellier, Montpellier, F-34398, France

* Corresponding Authors: Souha Mansour. Email: ; Marie-France Thevenon. Email:

Journal of Renewable Materials 2025, 13(8), 1547-1586. https://doi.org/10.32604/jrm.2025.02024-0078

Received 27 December 2024; Accepted 28 March 2025; Issue published 22 August 2025

Abstract

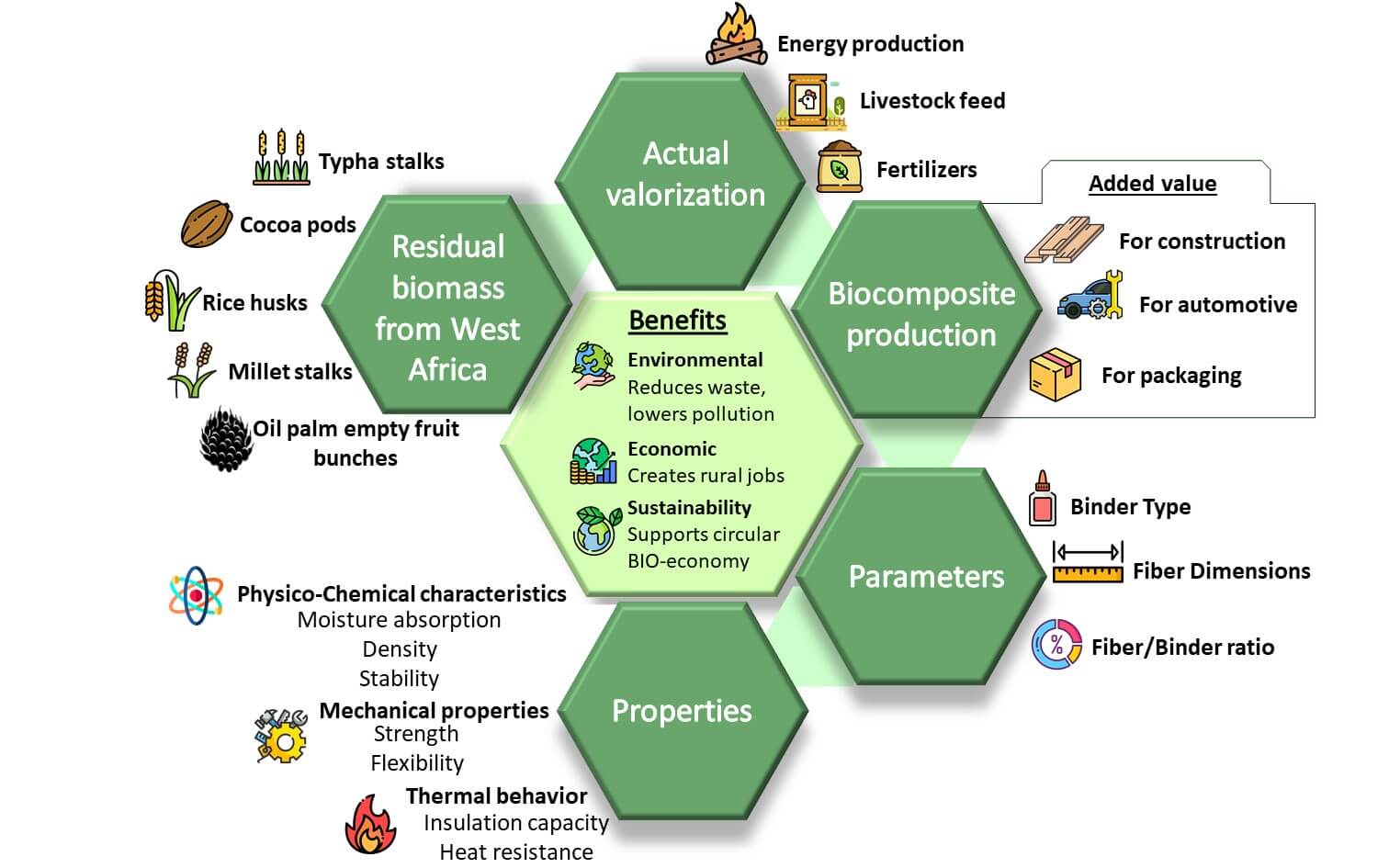

The use of agricultural residues in biocomposite production has gained increasing attention, driven by several benefits. Converting agricultural by-products into bio-based materials within a circular economy represents a sustainable strategy to mitigate lignocellulosic waste, reduce reliance on fossil resources, and lower environmental pollution. This approach also creates economic opportunities for rural African communities by generating diverse income sources for workers in collection, processing, and manufacturing. As a result, the integration of agricultural residues into biocomposites production not only addresses environmental concerns but also fosters economic growth and supports rural development. In this review, five biomasses from West Africa are examined, focusing on their production, chemical composition, physical and mechanical properties, and potential applications in biocomposites. The five biomasses listed are cocoa pod husks, oil palm empty fruit bunches, rice husks, millet stalks, and typha stalks. Key parameters, such as the type of binder, fiber dimensions, fiber-to-binder ratio, and the strength of fiber-binder adhesion, are systematically studied to assess their influence on the overall performance of the resulting composites. Special attention is given to understanding how these factors affect mechanical properties (e.g., strength and flexibility), thermal behavior (e.g., insulation capacity and heat resistance), and physico-chemical characteristics (e.g., moisture absorption, density, and chemical stability). This comprehensive analysis provides insights into optimizing composite formulations for enhanced functionality and sustainability. This study is essential to optimize the use of agricultural residues in West Africa for biocomposites, tackling waste issues, promoting sustainability, and filling research gaps on their properties.Graphic Abstract

Keywords

The search for alternatives to petroleum-based composites has gained significant attention due to their inherent drawbacks. These materials exhibit a high carbon footprint, contributing to greenhouse gas emissions, and are non-biodegradable, leading to long-term environmental persistence. For example, it is estimated that a single plastic bag could take as much as 500 years to break down [1]. Driven by growing environmental and sustainability concerns, biocomposites have emerged as a promising solution to mitigate these issues [2]. A biocomposite is a material in which at least one component, either the polymer matrix or the reinforcing fibers, originates from renewable biological sources. These materials provide notable environmental benefits and mark progress toward a more sustainable approach to material design compared to petroleum-based alternatives [3]. The use of natural fibers in composite materials has gained scientific interest due to their environmental and functional advantages.

Natural fibers, particularly those sourced from agricultural residues, offer a sustainable alternative to synthetic fibers. These fibers are biodegradable, reducing the environmental impact associated with plastic waste. Agro-waste fibers also support the principles of a circular economy by providing a renewable source of materials, thereby reducing dependence on petrochemical-based materials. The use of agro-waste not only addresses waste disposal issues but also contributes to the development of sustainable, high-performance materials with a lower carbon footprint [4]. The carbon footprint difference between glass fibers and lignocellulosic fibers is well-established; glass fibers have a carbon footprint of 1.8 t CO2-equivalent, whereas hemp fibers range bundles promoting the dispersion between 364 and 406 kg CO2-equivalent per tonne of hemp, and flax fibers had an average of 349 kg CO2-equivalent per tonne of flax [5]. Hemp fiber composites reduce greenhouse gas emissions by 10%–50% compared to their functionally equivalent fossil-based counterparts. Accounting for carbon uptake, these reductions increase further to 30%–70% [5]. The use of cellulose fibers in composites for automotive applications reduced greenhouse gas emissions by around 16% while also causing energy savings between 6.5% and 7.4% [6]. They pose lower health risks to workers compared to synthetic fibers, particularly concerning inhalation hazards. A report emphasized that natural fibers offer friendly processing, resulting in no tool wear and no skin irritation, which implies a safer working environment compared to synthetic fibers [7]. Moreover, it was reported that natural fibers can be incinerated efficiently with minimal residue. While glass fiber composites can leave behind up to 30% ash, natural fiber composites typically result in only 1%–2% ash. This reduction in residue reduces the environmental burden of incineration and simplifies disposal, making natural fibers a more eco-friendly option [8]. Finally, their lower cost and reduced specific weight compared to synthetic fibers contribute to lighter composite materials, leading to decreased transportation costs and energy consumption during production. Lotfi et al. [9] showed that the unit price of most natural fibers is also by far lower than that of glass and carbon fibers (natural fibers values are between 0.5 and 2.5 $/kg-while carbon fibers prices between 8 and 11 $/kg and glass fibers between 2 and 3.5 $/kg). For example, Joshi et al. [10] stated that natural fibers presented up to 30% weight reduction compared to glass fiber composites.

Functionally, natural fibers provide excellent thermal and acoustic insulation, making them highly suitable for use in applications such as construction and automotive manufacturing. A study has shown that jute and pineapple fibers offer thermal conductivity values between 0.038 and 0.055 W/m · K, and 0.035 to 0.041 W/m · K, respectively, making their thermal insulation performance comparable to that of synthetic materials [11]. Despite their advantages, natural fiber-based composites exhibit certain limitations that restrict their range of applications. A key limitation is that, with few exceptions, most natural fibers do not match the mechanical performance of synthetic fibers like glass fibers. For instance, glass fibers exhibit tensile strength values ranging from 2000 to 3000 MPa, whereas most natural fibers (flax, hemp, jute, sisal, etc.) fall within the range of 50 to 1000 MPa [12]. Additionally, they are susceptible to degradation, although this can be mitigated through appropriate treatments. Another challenge is their tendency to absorb water, leading to swelling and potential dimensional instability [12]. Le Bourhis et al. [13] reported tensile strength values of 0.7 GPa for hemp fibers and 3 GPa for glass fibers, also noting that hemp fibers are hydrophilic, unlike glass fibers.

There are three classes of natural fibers: i) plant-based, which are the most abundant, like ramie, cotton, and flax, ii) animal-based like wool and silk, and iii) mineral-based fibers like asbestos. Various classification systems exist for plant-based fibers. Depending on their primary use, fiber-producing plants are categorized into two types: i) primary plants that are cultivated for their fiber content (e.g., jute, hemp, flax, and sisal), and ii) secondary plants where the fibers are a by-product (e.g., pineapple, oil palm, and coir). Classified by the plant part from which they originate, plant-based fibers fall into six categories: bast fibers (e.g., jute, flax, hemp, ramie, and kenaf), leaf fibers (e.g., abaca, sisal, and pineapple), seed fibers (e.g., coir, cotton, and kapok), core fibers (e.g., kenaf, hemp, and jute), grass and reed fibers (e.g., wheat, rice, and corn), and other fibers derived from wood [14].

The chemical composition of natural fibers varies depending on the plant part from which the fibers are derived, the specific plant species, and external factors such as soil characteristics, climatic conditions, and the developmental stage of the plant cells [15]. The lignocellulosic composition is well-documented and widely studied in the literature [14,16,17]. The main components of lignocellulosic fibers are carbohydrates (cellulose, hemicelluloses, and pectins) in combination with lignin and lower amounts of extractives and mineral elements. The interactions between hemicelluloses, cellulose, and lignin in plant cell walls contribute to the cell wall structure’s overall stability and integrity, creating a supramolecular network that affects the material’s mechanical strength and water interaction behavior.

Cellulose (Fig. 1) is the most ubiquitous and abundant polymer on the planet, consisting of a linear hydrophilic glucan polymer with D-glucopyranose units (C6H11O5) which are linked by β-(1-4)-glycosidic bonds [17–20]. The degree of polymerization (DP) depends on the origin and the treatment of the raw material, which consists of 100 to 30,000 units per chain [19]. A large number of hydroxyl groups along the chain (3 hydroxyl groups per unit) confers hydrophilic properties and also induces the formation of intra- and inter-molecular hydrogen bonds which are crucial in guiding the crystalline packing that determines the material’s physical properties [18] with areas of high order (crystalline) and low order (amorphous) [19]. The hydrogen bonds and Van der Waals interactions give cellulose a supramolecular structure, primarily composed of nanofibrils.

Figure 1: Cellobiose structure, monomer of cellulose

Hemicelluloses are complex and abundant polysaccharides found in plant cell walls, consisting of branched, heteropolymer chains made up of various sugar units, including xylose, mannose, galactose, arabinose, and glucuronic acid, linked by β-(1-4)-glycosidic bonds and additional linkages, as illustrated in Fig. 2. Hemicelluloses accounts for 15%–35% of the dry mass in both annual and perennial plants [21]. The degree of polymerization (DP) of hemicelluloses is much lower than that of cellulose, typically ranging from 50 to 300 sugar units per chain, depending on the plant source and the processing conditions. The hemicelluloses’ structure is highly branched, distinguishing it from the more linear cellulose structure. This branching contributes to its lower crystallinity and higher amorphous structure than cellulose [18]. Hemicelluloses are very hydrophilic, soluble in alkaline solutions, and easily hydrolyzed in acid [17].

Figure 2: The monomers of hemicelluloses

Lignin is a complex, three-dimensional, highly cross-linked, and amorphous macromolecule. It consists of both aromatic and aliphatic components and is hydrophobic, insoluble in most solvents, and resistant to acid hydrolysis. Lignin’s primary role in plants is to provide rigidity and structural support by binding cellulose and hemicellulose fibers within cell walls. Its synthesis occurs alongside cellulose, filling spaces between the polysaccharides. Lignin is made up of phenylpropane units and has functional groups such as hydroxyl and methoxy, however, its precise structure is not fully understood, and no method currently exists to isolate it in its native state. While lignin is resistant to microbial degradation, it becomes more susceptible to enzymatic breakdown after pretreatment. Its molecular weight varies between 1000 and 20,000 g/mol, but the degree of polymerization is difficult to measure due to its fragmentation during extraction [17]. Lignin’s structure originates from three monolignols: p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol, upon polymerization, these alcohols form p-hydroxyphenyl (H unit), guaiacyl (G unit), and syringyl (S unit), respectively (Fig. 3). The structure and bonding of lignin units vary significantly based on plant species, age, type, and growing conditions [22].

Figure 3: Lignin unit molecular structure

In addition to the three main components, minor constituents such as pectins, extractives, and inorganic compounds are also present. Pectins refer to a group of heteropolysaccharides found in the middle lamella, primarily composed of polygalacturonic acid. Pectins contribute to plant flexibility and become water-soluble only after partial neutralization with alkali or ammonium hydroxide [17]. Extractives are classified based on their solubility in specific solvents and are categorized into three groups: water-soluble, toluene-ethanol-soluble, and ether-soluble extractives. Although present in small quantities, the amount of extractives varies significantly depending on plant species, age, storage conditions, and extraction method. Inorganic compounds include silica, metal oxides, phosphates, and other trace elements [23].

The mechanical properties of natural fibers are affected by the cellulose content, the degree of polymerization of cellulose and the microfibrillar angle. For example, high cellulose content and cellulose microfibrils that are more aligned in the fiber direction lead to higher mechanical performances. Table 1 resumes the physical and mechanical properties of some natural fibers [12].

As illustrated in the table above, the mechanical properties exhibit substantial variation among the different types of biomasses. These variations have a significant impact on the overall properties of the composite material. In composite materials, fibers primarily bear the mechanical load, contributing to the composite’s stiffness and strength. The polymer resin holds the fibers in place and facilitates load transfer from fractured or weaker fibers to intact ones, helping maintain the composite’s structural integrity. A third crucial factor affecting the properties and behavior of the composite is the fiber/matrix interface. When working with natural fibers, compatibility with the matrix is often lacking due to the presence of numerous hydroxyl and carboxyl groups in key components such as cellulose, hemicelluloses, and pectins, which render the fibers hydrophilic and polar. These fibers are typically combined with polymer matrix which are mainly non-polar and hydrophobic. This non-compatibility causes poor interfacial bonding that plays an important role in the mechanical properties of the composites [3]. In order to overcome this problem, different treatments have been developed to improve the fiber/matrix interface and they are classified into two categories. The first category includes the pre-treatments that aim to enhance the wetting and the mechanical interlocking between the composite constituents. Pre-treatments modify the roughness and the surface physico-chemistry of the fibers by extracting non-cellulosic compounds from the plant cell walls. This extraction alters inter-cellular cohesion within the fiber bundles, promoting the dispersion of fibers within the matrix. As for the second category, it consists of the functionalization of natural fibers which can be done by chemical or physical treatments. The aim of functionalization is to establish a chemical and/or physico-chemical coupling between the fibers and the matrix [15]. Table 2 shows some of the most important treatments used for natural fibers with the details that characterize each treatment.

This review focuses on the utilization of residual biomasses from major agricultural sectors in West Africa to develop high-value-added products. Five prevalent residual biomasses in West Africa have been identified as, cocoa pod husks, oil palm empty fruit bunches, rice husks, millet stalks and typha fibers. These biomasses are chosen for their significant local abundance and limited current utilization, as they primarily exist as agricultural residues, with the exception of typha which is an invasive plant present in large quantities. The disposal of these materials poses significant challenges, as they are often burned or left to accumulate on agricultural sites. In West Africa, open-field burning remains a common practice for managing crop residues. This practice leads to air quality impairment, smog, haze, and various health issues. The most common health problems affecting locals include coughing, eye irritations, headaches, nausea and skin irritation. The high prevalence of respiratory allergies indicates severe air pollution in the region [25]. From another perspective, in West Africa, the improper management of agricultural residues such as their removal or open-field burning, contributes to soil nutrient depletion and erosion, which in turn adversely affects soil fertility and agricultural productivity. This issue highlights the need for sustainable agricultural practices that not only enhance productivity but also promote environmental conservation. By repurposing these by-products in composite production, this work not only addresses waste management issues but also contributes to sustainable development in the region. This approach supports environmental conservation while creating economic opportunities for farmers and workers, fostering a transition toward circular economy practices in West Africa. Apart from rice husks, these agricultural residues are not well-documented, particularly in the context of biocomposites. Therefore, this study aims to explore their properties and current applications, shedding light on existing gaps in the research and highlighting areas that remain underexplored. By addressing these gaps, this work may pave the way for further studies and innovations in the use of these materials in biocomposite production. Most reviews either focus on a single biomass, exploring its properties and applications in detail, or they examine a specific property across different biomasses, comparing how each material performs with respect to that property. This research focuses on understanding these agricultural residues’ mechanical, thermal, and chemical properties and how they contribute to biocomposite properties, and environmental benefits, emphasizing reducing waste and enhancing eco-friendly production processes in various industries. This review highlights the potential of these agricultural residues as sustainable raw materials for high-value products while addressing the environmental and economic challenges arising from their underutilization. By examining the transformation of these residues into biocomposites, this work supports the development of eco-friendly alternatives to conventional materials, which is crucial for reducing reliance on petrochemicals and minimizing waste. Additionally, the review provides a comprehensive analysis of the processing techniques, mechanical properties, and potential applications of these agro-waste-based materials. It offers valuable insights for future research directions and industrial applications in sectors such as packaging, automotive, and construction, where there is a growing demand for renewable and biodegradable alternatives.

This review is structured into three main sections: i) the first section focuses on outlining the research methodology employed to develop this review, ii) the second section focuses on the biomasses, comprising an overview of the biomass (plant characteristics and production quantities, an analysis on the chemical composition, the physical and mechanical properties of the residual fibers, and a final section covering the current valorization., and iii) the third section examines the use of these biomasses in composites, with the composites categorized based on the binder used. This section concludes with a summary of findings, offering insights into the potential and limitations of biomass-based composites.

This work presents a literature review, following a methodology comprised of four sequential steps: formulation of research questions, study identification, selection and evaluation, and, finally, analysis and synthesis. Each of these steps is examined in detail as follows:

In order to start this work, the following questions are asked:

• What are the most abundant agricultural biomasses in West Africa that cause environmental or management challenges due to their excessive presence, and how can these be valorized in biocomposite production?

• How do the chemical compositions and morphological properties of these biomasses impact their potential applications and the characteristics of the biocomposites they produce?

• What parameters are studied in biocomposite fabrication? And how do these parameters affect the properties of the product?

• What are the gaps in the current research regarding the properties and applications of agricultural residues in biocomposites, and what areas need further investigation to optimize their use?

For this review article, a comprehensive search of relevant studies is conducted to gather information on the use of agricultural residues in biocomposite production, specifically focusing on West African biomasses. The following steps are followed for study identification:

• Databases and Information Sources: A wide range of scholarly sources is searched to ensure comprehensive coverage of the topic. These sources include: Academic databases (Google Scholar, Web of Science, and ScienceDirect). Government reports and technical papers (Reports from relevant agricultural, environmental, and industrial bodies that focus on waste management, and biomass utilization), and finally, conference proceedings.

• Search Strategy: A structured search strategy is applied to locate articles related to the conversion of agricultural residues into biocomposites. The following keywords and phrases are used: “agricultural residues”, “West Africa”, “biocomposites”, “biomass valorization”, “cocoa pod husks biocomposites”, “oil palm empty fruit bunch”, “millet stalks composites”, “typha fibers biocomposites”, “bio-sourced materials”, “sustainable development Africa”, “mechanical properties composites”. Boolean operators (AND, OR) are used to combine search terms, for example, “West Africa AND biocomposites AND agricultural residues” or “biomass valorization AND environmental sustainability”.

• Inclusion and Exclusion Criteria: The following criteria are applied to select the most relevant studies: Inclusion Criteria (Studies published in peer-reviewed journals, conference papers, and technical reports, articles focused on the use of agricultural residues in biocomposites, their properties (chemical, physical, and mechanical), environmental applications, and research articles that investigate the potential for utilizing specific West African biomasses, such as cocoa pod husks, oil palm empty fruit bunches, rice husks, millet stalks, and typha fibers). As for the exclusion criteria (articles not directly related to the use of agricultural residues in biocomposites, studies focusing on biocomposites using non-agricultural fibers or synthetic materials, and publications with limited data on the physical, mechanical, or chemical properties of the materials discussed.

• Title and Abstract Screening: The initial screening involved evaluating titles and abstracts to ensure the study’s relevance to the research questions. Studies that appear to focus on unrelated materials or lacked relevant data are excluded at this stage.

• Full-Text Evaluation: After initial screening, the full texts of the remaining articles are reviewed to assess the quality and relevance of the study. Studies are selected if they provided valuable data on the properties of agricultural residues and their use in biocomposites.

• Data Extraction: Key data points are extracted from each study, including information on the type of biomass, its chemical composition, mechanical and thermal properties, treatment methods, and its applications in biocomposites.

For study identification, a total of 136 articles were selected after a comprehensive database search, while numerous others were excluded due to a lack of relevant information. Studies are included if they i) focus on West African agricultural residues in biocomposites and ii) provide data on chemical composition of biomass and mechanical, or thermal properties of biocomposites. Studies are excluded if they i) focus on synthetic composites or irrelevant biomass types and/or ii) lack key data. The quality of selected articles was assessed based on methodological rigor, reproducibility, and data consistency. As for data extraction, only data on biomass types, properties, and applications and on composites fabricated by these materials and the parameters studied and properties are extracted and compared across studies.

Each study included in the review is analyzed for key findings on the selected biomasses (cocoa pod husks, oil palm empty fruit bunches, rice husks, millet stalks, and typha fibers). The analysis focus on: i) chemical composition by comparing the cellulose, hemicelluloses, lignin and extractives content across biomasses, ii) mechanical properties by assessing tensile strength, impact resistance, and flexibility to determine suitability for various applications, iii) thermal properties by evaluating heat resistance and insulation performance of the composites.

The studies are synthesized by identifying patterns and inconsistencies in the reported data. For example, it is found that oil palm empty fruit bunches tend to result in stronger composites, while rice husks excel in thermal properties. Common factors such as binder types and fiber treatments are also compared to see their impact on composite performance.

Finally, gaps are identified. For example, a synthesis of the studies revealed that while significant progress has been made, there are gaps in understanding the long-term performance and scalability of these biocomposites. The need for further optimization of fiber treatments and binder formulations is identified. Additionally, exploring underutilized agricultural residues could open new opportunities for waste valorization and sustainable material development.

3 Focus on Five Residual Biomasses from West Africa

The cocoa plant, from the Malvaceae family and Theobroma genus, is globally recognized as the key ingredient in chocolate production. Indigenous to the Amazon basin in tropical America, it thrives in the lush rainforests of the region. In the 1800s, it was brought to West Africa, where the tropical climate proved ideal for its cultivation, leading to widespread production in the area. The cocoa tree is classified into two primary groups: Criollo and Forastero, each distinguished by its geographic distribution, as well as unique fruit and seed characteristics. Criollo, typically cultivated on a limited scale due to its low productivity, has large red or green fruits and seeds with white or pale violet interiors, and is highly disease-prone. Forastero, which accounts for the bulk of global cocoa production, has green fruits that turn yellow when ripe and seeds with dark violet or blackish interiors, and it is much more disease-resistant. Additionally, there is a third group, Trinitario, which is a hybrid of Criollo and Forastero, combining the best traits of both [26,27].

The cocoa tree reaches 5 to 8 m in height under cultivation with a diameter of 4 to 6 m of the crown. In some cases, and under forest conditions, it can reach up to 20 m due to competition for light with other species [26]. Cocoa has a dimorphic growth pattern, meaning it develops two distinct types of growth forms. Specifically, it produces vegetative shoots, which support leaf and stem growth, and reproductive shoots, which generate flowers and fruit. This duality allows the plant to allocate resources and energy to growth and reproduction, adapting its growth strategy to environmental conditions and developmental stages. Though cocoa is typically considered shallow-rooted, its roots can reach depths of 1.5–2.0 m, with 80% located in the top 0.2–0.4 m of soil. While roots can extend laterally over considerable distances (more than 5 m), most are found within 0.5 m of the stem. The soil’s nature (structure, texture, and consistency) affects this plant’s root system [27]. The cocoa fruit is protected by the cocoa pod husk (CPH) which consists of three layers, arranged from outermost to innermost as follows: the epicarp, the mesocarp, and the endocarp (Fig. 4). The epicarp is the exterior part of the fruit, it has an oval shape with a rough and thick appearance which protects the fruit against the climate, plagues, and damage done by impact. The mesocarp is a hard-composite structure that holds the beans in place under severe conditions. And finally, the endocarp is the innermost part and it is a soft whitish tissue that protects the beans in a lubricated environment [28].

Figure 4: Cocoa tree and parts of the cocoa pod

In 2022, global cocoa bean production reached 5,875,000 t, with the Côte d’Ivoire contributing nearly 40% of this total, amounting to 2,230,000 t of cocoa beans [29]. The husk of the cocoa pod makes up 70% to 80% of the fruit’s dry weight. As an estimation, every ton of dry cocoa bean generates 10 t of CPH as waste and Côte d’Ivoire presents approximately 6,500,000 t of CPH to valorize [28].

Many researchers have studied the chemical composition of the CPH for possible uses as shown in Table 3.

In addition to cellulose, hemicelluloses, and lignin, other elements are present in smaller amounts. Fidelis et al. [38] reported that nitrogen constitutes 1.6% of the total solids, phosphorus 0.3%, potassium 2.5%, and magnesium 0.3%. Similarly, Vasquez et al. [34] analyzed the minor elements in the chemical composition of CPH, finding 2.77% of potassium, 0.01% of sodium, 0.11% of magnesium, 0.25% of calcium, 0.04% of manganese, 0.04% of zinc, and 0.006% of iron. Additionally, other studies have indicated small percentages of these elements, such as approximately 0.45% phosphorus, 7.2% potassium, 0.7% magnesium, 0.85% calcium, and trace amounts of manganese and iron [39,40].

The cocoa fruit is used in producing chocolate, which utilizes only about 33% of the fruit’s total weight, leaving approximately 70% of the fruit, in the form of CPH, discarded without proper treatment. While some farmers repurpose CPH as natural fertilizer, most of it goes to waste [41]. If left untreated on the soil surface, these CPH can become a source of inoculum for plant diseases, notably black pod rot. This is due to the presence of Phytophthora spp., a pathogen responsible for significant yield losses, accounting for nearly 25% of global cocoa production [42]. Leaving CPH waste on the ground significantly contributes to its carbon footprint due to anaerobic decomposition, generating methane and nitrous oxide, which account for over 85% of emissions [43]. Utilizing CPH in value-added products offers both economic and environmental benefits, enhancing the sustainability of cocoa production.

CPH can be repurposed in various industries, including soap production, papermaking, biofuel generation, and dietary fiber extraction, as detailed below [28,41,42]. CPH’s chemical composition indicates that it contains many minerals, including potassium. West African nations are benefiting from its presence by using it to produce natural soap rather than potentially carcinogenic chemical-based soaps. Every ton of fresh CPH yields six kilograms of potash, which can be concentrated and filtered for use in oil saponification to produce soap. Potash soaps made from CPH are more soluble and have greater cleaning and foaming power than chemical soaps based on potassium hydroxide. Because it gives farmers a new source of income and frees them from the quantities of waste they produce, the use of CPH in producing soap is important [44].

Numerous researchers have explored the potential of substituting wood fibers with plant-based fibers in paper production to reduce deforestation, a major driver of climate change. For biomass to be suitable for this application, it must exhibit specific characteristics. Two key factors determine its suitability: i) chemical composition—ideal biomass should have high cellulose content, contain no more than 30% lignin, and have low ash content ii) Fiber morphology—the diameter and length of the fibers are critical, as they affect paper properties such as tear resistance and strength. Depending on fiber morphology, the paper’s application varies. Shorter and thinner fibers produce pulp suitable for porous tissues, while longer fibers manufacture high-tear resistance paper. CPH meets the criteria by exhibiting both the recommended chemical composition and fiber morphology suitable for paper production. Studies have shown that CPH can be a viable alternative to wood fibers, presenting a promising solution to reduce deforestation and its associated climate impacts [28,31,42].

In light of the expanding global energy demand, efforts are being made to find inexpensive, environmentally friendly, renewable energy sources that can replace fossil fuels. Studies have been conducted to explore the properties and potential applications of CPH in bioenergy production. Amongst these researches, Mancini et al. [45] found that it is possible to use CPH to produce biogas with accumulated methane yields. Bio-oil production is also possible via a rapid pyrolysis process from this residue. Thermogravimetric analysis confirmed that CPH can serve as a viable raw material for pyrolysis [46]. Thompson et al. [47] estimated the production of bioethanol from cocoa pod husk to be around 0.28 L ethanol (kg TS)−1 which was lower than other biomasses and that is due to its high lignin content which demands additional delignification steps.

CPH contain between 52% to 74% of insoluble dietary fibers consisting of cellulose, hemicelluloses, and lignin. The insoluble dietary fibers have the ability to absorb water within its fibrous matrix. There are also the soluble dietary fibers, mainly pectin, β-glucan, and oligosaccharides. Pectin is the predominant soluble dietary fibers present in CPH. The development of soluble dietary fibers-enriched food is beneficial for weight management and dietary fiber intake deficiency since they can retain water, increase satisfaction after eating, and decrease glucose absorption in the intestines. Not many studies have investigated the role of total dietary fibers from CPH as an ingredient in food products even though CPH could contribute to the fight against hunger and malnutrition [42].

3.2 Oil Palm Empty Fruit Bunch

Oil palm, also known as Elaeis guineensis from the family Arecaceae, is a diploid monoecious perennial crop. Elaeis derives from elaion which is Greek meaning oil, as for guineensis it is attributed to the guinea coast [48,49]. The oil palm tree reaches about 7 to 13 m in height and between 45 to 65 cm in diameter at 1.5 m above the ground, with leaves of about five meters long. It takes five years for this tree to bear fruit, with a life expectancy of around 25 years [50]. Oil palms grow in tropical regions around the equator, prospering in the presence of sun and humidity; therefore, cultivated between ten degrees north and south from the equator and spread over 42 countries. During their lifespan, oil palms mainly produce oil, fruits, and large lignocellulosic agricultural wastes. In 2022, the world production of oil palm fruit is estimated to be 425 million tons with 21 million tons originating from West Africa [29]. Given that each tree yields 12 to 14 bunches weighing 120–350 kg, it is estimated that between 1 and 3 billion oil palm trees are cultivated worldwide. On average, a single oil palm tree produces about 231 kg of biomass annually, including approximately 40 kg of oil and 191 kg of lignocellulosic material [51–53]. Consequently, West Africa alone generates between 14 and 40 million tons of oil and lignocellulosic materials. There are two ways to obtain the different wastes from this plant. The first is the plantation routines such as pruning and replantation and the second is from the oil extraction mills [54]. The different fibers obtained from oil palm (Fig. 5) are as follows: oil palm trunks fibers (OPT), oil palm fronds fibers (OPF), oil palm mesocarp fibers (OPM), oil palm kernel shell (OPKS), and oil palm empty fruit bunch (OPEFB) [55]. Oil palm fronds (OPF) accounts for 70% of the total oil palm biomass, while oil palm empty fruit bunches (OPEFB) make up 10%, equivalent to approximately 12.4 million tons, and oil palm trunks (OPT) contribute just 5%.

Figure 5: Different types of fibers obtained from an oil palm tree

With almost 15 million tons produced per year, the OPEFB fibers are gaining more interest due to their abundance, renewability, non-toxicity, and low cost [56].

3.2.2 Chemical Composition of Oil Palm Empty Fruit Bunch

Similar to other lignocellulosic biomasses, oil palm empty fruit bunch (OPEFB) is primarily composed of cellulose, hemicelluloses, lignin, ash, and extractives. Several factors influence the composition of these components in OPEFB. For instance, the geographical region significantly impacts the chemical composition, as soil characteristics and environmental conditions vary. Plus, the plant maturity, the species, and the extraction process are all factors that affect the proportions of the listed components inside the OPEFB fibers [51]. Generally, the proportions in OPEFB fibers are as follows: 40%–50% for cellulose, 20%–30% for hemicelluloses, and 10%–15% for lignin with 10% to 15% moisture content. These quantities are detailed in Table 4 based on different studies. In addition to cellulose, hemicelluloses, and lignin, there are other components in minor percentages like arabinose, xylose, mannose, galactose, silica, copper, calcium, manganese, iron, and sodium [57].

3.2.3 Physical and Mechanical Properties of Oil Palm Empty Fruit Bunch

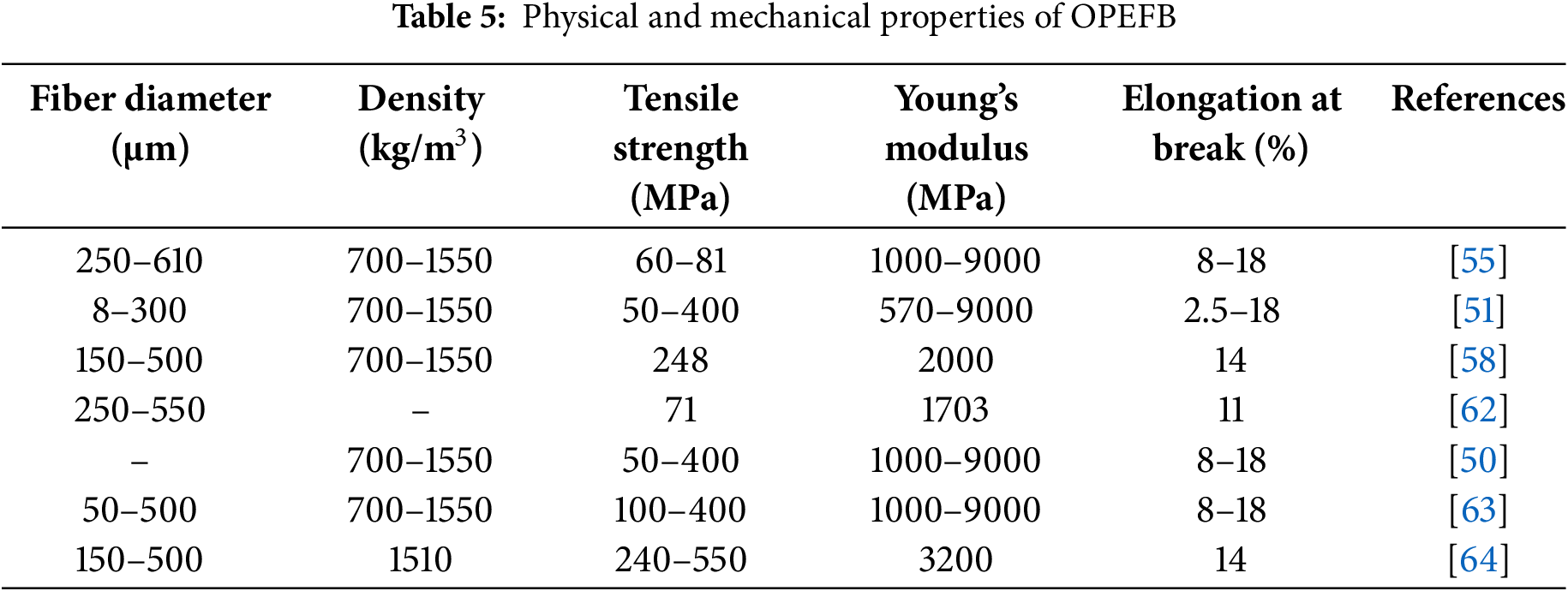

Just like the chemical composition, physical and mechanical properties of the fibers are also affected by the same factors since this composition impairs in mechanical properties. Other factors are also important, such as microfibril angle, cell dimensions and defects, cellulose and crystalline organization, and fiber cell structure’s crystal/amorphous nature [51,57]. Table 5 lists the different values obtained for the different physical and mechanical properties of OPEFB.

OPEFB fibers vary in length from 0.9 to 280 mm, comprising a mix of both short and long fibers [65]. Danso et al. [66] reported a fiber length of 38 mm. Ramlee et al. [67] mentioned that the value is somewhere between 10 and 20 mm. On the other hand, Abdul Khalil et al. [51] stated that OPEFB fibers can stand between short and long fibers with values going from 0.89 to 142 mm. OPEFB fibers have an average diameter of approximately 300 µm, with density values remaining consistent across studies. Regarding mechanical properties, reported values for Young’s modulus range from 1000 to 9000 MPa. Studies show significant variability in the physical and mechanical properties of OPEFB fibers. These discrepancies can be attributed to variations in fiber extraction methods, testing techniques, and environmental conditions. While some properties, such as density, remain relatively consistent, others, like tensile strength and Young’s modulus, show significant variation, emphasizing the need for standardized characterization methods.

The vast amount of waste generated by the oil palm industry poses significant disposal challenges. Generally, oil palm biomass is used as fuel, mulch, and fertilizer by burning it into ash. Traditionally, OPEFB was primarily disposed of through incineration at palm oil mills, with the resulting ash recycled as fertilizer for plantations. However, this method has largely been abandoned due to its detrimental environmental effects, especially air pollution [68]. In recent years, alternative methods such as using OPEFB as a soil improver and for co-composting have gained traction in Indonesia. Despite these developments, fully converting OPEFB remains essential to protect the environment and ensure the sustainability of the palm oil industry.

The structural composition of OPEFB fibers comprises a complex matrix of cellulose, hemicelluloses, and lignin, collectively forming lignocellulosic material. This material is an excellent source of fermentable sugars, making it highly suitable for conversion into valuable products. Cellulose and hemicelluloses can be broken down through acid or enzymatic hydrolysis, producing glucose along with various pentose and hexose sugars. These sugars can then undergo fermentation to produce bioethanol [69]. Bioethanol produced from OPEFB had higher values (0.41 L ethanol (kg TS)−1) than that of CPH (0.28 L ethanol (kg TS)−1) [47].

Rice originates from the Germineae family and the Oryzae genus. Among nearly twenty species, only two are widely cultivated: Oryza sativa L. the Asian rice, and Oryza glaberrima Steud., which is African rice [70]. O. sativa is now cultivated globally, as for O. glaberrima, it is limited to the West African region. To benefit from the best qualities of these two species, breeding of the two was realized which gave birth to new varieties entitled NERICA rice (new rice for Africa) that are well spreading in many regions in Africa. Given the widespread distribution of Oryza species, geographic origin alone is not a reliable criterion for species identification. Consequently, the distinction between Oryza sativa and Oryza glaberrima is characterized by the latter’s more strictly annual growth habit, in contrast to the former, which exhibits greater flexibility in its life cycle. Additionally, O. glaberrima lacks secondary branching on the primary branches of the panicle, a feature present in O. sativa. Furthermore, the ligule length differs between the species, with O. sativa typically having a longer ligule, whereas O. glaberrima has a shorter, more rounded ligule [71]. These differences in species also influence rice husk characteristics. For example, species with higher silica content makes them more suitable for industrial applications such as silica extraction, cement additives, and insulation materials [71]. In contrast, other species may contain slightly higher levels of lignin and cellulose, which can make them more useful for biofuel production, biodegradable packaging, or animal feed. The structure and density of rice husks can impact their combustion efficiency and thermal insulation properties, which are important factors in energy applications. Optimizing rice husk utilization across industries requires understanding variations in panicle length, grain length, and width, as these factors influence the physical and chemical properties that determine their potential applications. Rice varieties with longer and wider grains tend to have thicker husks, which can contribute to higher silica content, making them more suitable for industrial uses such as silica extraction and cement additives. Rice varieties with smaller grains often produce thinner husks with greater surface area, enhancing their efficiency in biofuel combustion and insulation. Husk thickness and density also impact mechanical properties, determining their suitability for applications such as biodegradable materials, animal bedding, and agricultural mulching. Grain morphology influences husk composition and is a crucial factor for optimizing its utilization across various industries.

A typical rice plant averages around 1.2 m in height, although notable exceptions exist. Dwarf mutants, for instance, reach only 0.3 to 0.4 m, while certain floating varieties can attain heights exceeding 7 m. The plant consists of round and hollow stems, flat leaves, roots, and panicles made up of spikelets (Fig. 6). The roots are fibrous and relatively shallow helping the plant to absorb water and nutrients. The stem, or culm, comprises a series of nodes and internodes. The node bears a leaf and a bud that might give rise to a tiller. The internodes are hollow with a smooth surface, their length varies along the culm typically increasing the length from the base of the plant upwards. As for the leaves, they grow one on each node, and the last leaf wrapping the panicle is called the flag leaf. Eventually, the panicle is carried on the previous internode and it carries the spikelets, and based on its length, shape, and angle the variety can be identified [70].

Figure 6: Rice plant

Rice has historically been the primary food source for nearly half of the global population, playing a crucial role in the sustenance of billions of people. Covering approximately 1% of the Earth’s surface, rice cultivation is a significant agricultural activity worldwide. In terms of production volume, rice ranks as the third most produced agricultural commodity globally, after sugarcane and maize. In 2022, global rice production reached nearly 780 million tons, underscoring its importance not only as a staple food but also as a vital component of global food security and agricultural economies. Asia is the dominant contributor to global rice production, accounting for 90% of the total, while Africa contributes 5.1%. Within Africa, West Africa is the most productive region, generating approximately 22 million tons of rice in 2022. The principal rice-producing countries in this region include Nigeria, Mali, Guinea, Senegal, and Côte d’Ivoire [29]. The rice kernel is composed of endosperm, husk, bran, and germ. The endosperm makes up 70% of the whole seed weight, rice husk accounts for 20%, rice bran for 6% to 8%, and rice germ for 1% [72]. This means for every 1000 kg of rice paddy there are 200 kg of husk. So, for a global estimation of the quantity produced in 2021, there are almost 158 million tons of rice husk. Rice husk, also known as rice hull, is the tough, protective outer layer of the rice grain, which is removed during the milling process. This by-product is generated in large quantities annually, in rice-producing countries. While rice husk is often considered agricultural waste, its improper disposal, particularly through burning, poses significant environmental concerns. Disposing of rice husk results in the release of harmful gases, such as carbon dioxide while burning, and methane if landfilling was applied, which contribute to air pollution and exacerbate global warming. Additionally, the combustion process generates ash, which can contain silica and other particulate matter that further contaminates the air and contributes to respiratory problems in humans and animals [73]. Given these environmental risks, it is crucial to explore sustainable alternatives for rice husk management.

3.3.2 Chemical and Physical Properties

Rice husk (RH) is tough, has abrasive resistance behavior, and silica-cellulose structure. The length of RH typically ranges from 8 to 10 mm and the bulk density was found to be between 100 to 160 kg/m3. The chemical composition of RH varies depending on factors such as paddy variety, crop year, climate, geographical conditions, soil chemistry, and fertilizer use during cultivation. RH is made of 80% organic matter and 20% ash. The inorganic part is composed mainly of amorphous silica and contains traces of some alkali oxides, earth metals, aluminum, and iron. RH is generally composed of 25% to 35% of cellulose, 18% to 21% hemicelluloses, 26% to 31% lignin, and 15%–17% of ash [74–76]. RH ash is a porous, lightweight material with a high external surface area, making it valuable for diverse industrial applications. Its significance lies in its high silica content, which constitutes 87%–97% of the ash. The remaining composition includes minor amounts of other oxides, such as potassium oxide (K2O), aluminum oxide (Al2O3), calcium oxide (CaO), magnesium oxide (MgO), sodium oxide (Na2O), and iron oxide (Fe2O3). This combination of properties and composition enables RH ash to be used effectively in fields like construction, ceramics, and environmental management [77].

RH has gained significant attention due to its unique properties, including high silica content, lightweight structure, and porous nature making it valuable for a range of industrial applications. RH and its derivatives, such as RH ash are now utilized in energy production, construction, environmental remediation, and materials science fields. Its sustainable potential in creating eco-friendly alternatives has made rice husk a valuable resource for reducing waste and contributing to green technologies [78].

In wastewater treatment, RH has proven to be an effective, low-cost adsorbent for removing contaminants such as azo dyes and heave metals. A study on citric acid-treated RH shows that the acid significantly improved dye adsorption capacity, making it an effective solution for environmental cleanup [79]. For example, this research on the removal of Direct Red-23 dye has demonstrated that adsorption onto treated RH follows the Langmuir isotherm model, indicating monolayer adsorption. Kinetic analysis further showed alignments with Lagergren’s first-order model, with film diffusion as the primary rate-controlling step. The findings highlight the potential of RH as an abundant and inexpensive biomaterial for sustainable wastewater treatment [79]. In another case study in wastewater treatment, rice husk has been effectively utilized as a low-cost adsorbent for the removal of hexavalent chromium (Cr(VI)) from aqueous solutions [80]. The study shows that both boiled RH and formaldehyde-treated RH exhibit strong adsorption capacities, with maximum Cr(VI) removal occurring at pH 2.0. The authors also demonstrated that boiled RH and formaldehyde-treated RH achieve removal efficiencies of 71.0% and 76.5%, respectively, at an adsorbent dose of 20 g/L. Given its abundance and cost-effectiveness, untreated boiled RH offers a practical and sustainable solution for small-scale industries in rural areas where conventional materials like activated carbon may not be readily available.

The high cellulose and lignin content, coupled with the naturally porous structure of RH, makes it an excellent material for producing activated carbon. These characteristics enhance its adsorption capacity, making it suitable for diverse applications, including filtration, purification, and environmental remediation [81]. The lignin content in RH makes it an excellent candidate for fertilizer applications, as its slow decomposition rate allows for a gradual release of nutrients into the soil. This extended breakdown process improves soil structure and contributes to long-term soil fertility, making RH a valuable organic amendment in agricultural practices [82].

Its porous nature plays a key role in enhancing the thermal insulation properties of the manufactured bricks. Beyond bricks manufacturing, RH is applied in other materials production, such as cement, and particleboards. Its combination of a lightweight, fibrous structure and high silica content makes it particularly suitable for improving construction materials’ durability, insulation, and sustainability [83]. Additionally, RH-based materials offer thermal and acoustic insulation, contributing to energy efficiency and reducing the environmental impact of construction projects. The higher the porosity of the RH, the more effective the bricks are at reducing heat transfer, making them ideal for energy-efficient construction. This enhances insulation performance, promoting stable indoor temperatures and lowering energy consumption in buildings. Zeolites are also produced from rice husk due to their content of silica (20%) [84]. In India, RH ash has been effectively utilized as a pozzolanic material in concrete, enhancing its durability and strength. The study has demonstrated that incorporating RH ash into cement mixtures improves compressive strength and resistance to sulfate attacks. Taiwo et al. [85], examined the effects of partially substituting ordinary Portland cement with RH ash on concrete durability against sulfate attack. The results indicated that RH ash concrete significantly reduced deterioration when subjected to sulfate attack, highlighting its effectiveness in enhancing concrete durability.

The millet plant encompasses a diversity of species, including, most notably, Pearl millet (Pennisetum glaucum (L.) R. Br.), Finger millet (Eleusine coracana (L.) Gaertn), Foxtail millet (Setaria italica (L.) Beauv), and Proso millet (Panicum miliaceum (L.)). Pearl millet is the most widely cultivated millet species [86], it belongs to the family Poaceae, the genus Pennisetum, and the species glaucum. It originated in West Africa and later spread to Eastern Africa and India [87]. In 2021, global millet production was estimated at 29.5 million tons, cultivated across approximately 30 million hectares. Africa emerged as a major contributor, producing nearly 40% of the total global millet yield. Within this total, pearl millet is the predominant species, accounting for more than half of the global millet production. Pearl millet’s significance lies in its adaptability to arid and semi-arid climates. Its exceptional drought and heat tolerance distinguish it from other cereals, making it a staple in regions like Africa and India, where growing conditions are particularly challenging [88]. Other millet species, including finger millet, foxtail millet, and proso millet, make up the remaining share of millet production, contributing to the crop’s global diversity [29]. Pearl millet ranks as the sixth most important cereal crop globally, following maize, rice, wheat, barley, and sorghum. It is an annual, warm-season crop cultivated primarily between late May and September. Pearl millet (Fig. 7) can grow to heights ranging from 1.5 to 4 m, characterized by a leafy structure. Its leaf blades measure between 20 to 100 cm in length and 1 to 7 cm in width. The plant’s inflorescence presents a spike that is typically 0.1 to 0.5 m long. The cylindrical fruit comes in various colors, including white, pearl, yellow, brown, and occasionally purple [89].

Figure 7: Pearl millet plant parts

Pearl millet grains are primarily harvested for food consumption, while the residual biomass, including the cob, stalk, and husk, is typically utilized as fodder for livestock. In cases where it is not used as animal feed, these residues are often burned on site, with minimal utilization for other valuable applications. According to Bhuyan et al. [90], the Residue-to-Product Ratio (RPR), a metric used to quantify the amount of crop residue remaining after harvest, is 0.33 for the cob, 0.3 for the husk, and 2 for the stalk of pearl millet. This means that for every kilogram of grain harvested, 2 kg of stalk are produced. Using these ratios, estimates suggest that in 2022, global pearl millet stalk production reached approximately 60 million tons, with West Africa contributing 20 million tons of husk—one-third of the world’s total. This substantial quantity of biomass, often regarded as waste, holds significant potential for alternative, beneficial applications [90]. Pearl millet grains can be processed into various food products. Known as “nutri-cereals,” they are valued for their rich nutritional profile, which includes high levels of protein, dietary fiber, essential minerals, and fatty acids, as well as notable antioxidant properties. Additionally, pearl millet is a suitable option for individuals with celiac disease or gluten sensitivity, as it is naturally gluten-free [91].

3.4.2 Chemical and Physical Properties

The chemical composition of pearl millet stalks has been relatively understudied, as research has largely concentrated on major crops such as maize and wheat.

Consequently, pearl millet stalks have received less scientific attention. However, Yadav et al. [88] highlighted that the chemical composition varies significantly between different parts of the stalk, which include the core, sheath, and outer dry leaves. They stated that the cellulose content in the sheath and the leaves are 39.7% and 44.2%, respectively. Hemicelluloses levels were found to be 19.1% in the sheath, and 26.02% in the leaves. Lignin was of 29.5% in the sheath and 9.87% in the leaves and finally for the ash content it was found to be 11.42% and 13.26% for the sheath and leaves, respectively [88]. The core values by Yadav et al. are presented in Table 6 alongside the values obtained by other researchers.

The same goes for the physical properties, where not many studies are found on this subject. Babé et al. [94] found that the bulk density of millet waste fibers is 0.38 g/cm3, with fiber lengths between 2 and 5 mm and a natural water content of 8.8%. As for the rest, it consists mainly of the millet cobs or husk and not the stalk. Saeed et al. [92] worked with millet fibers with a length of 0.41 mm, a diameter of 27.1 mm, a lumen diameter of 13.31 mm, and a cell wall thickness of 7.4 mm.

In regions like Africa and India, the whole plant can be fed directly to livestock, particularly in regions where high-quality forage is scarce. Ground pearl millet biomass serves as suitable poultry feed, whereas milling the grain is typically necessary for cattle and swine to enhance digestion and nutrient absorption [95]. In addition to its role in livestock nutrition, pearl millet residues—such as stalks and husks—are commonly used as fodder, especially in dryland areas where fresh forage is limited. These residues are a vital resource, helping to sustain livestock during dry seasons [96].

In many rural communities, these by-products are repurposed for building materials, including thatching roofs and fencing, owing to their availability and insulating properties. They also serve as a source of fuel for cooking, commonly burned in traditional stoves. This production capacity makes pearl millet a viable feedstock for bioethanol, with efficiency comparable to other widely used cereal grains. With its high starch content, pearl millet is well-suited for ethanol production, supporting renewable energy initiatives, particularly in regions where it is widely cultivated and can serve as an alternative to traditional biofuel crops like corn [93].

Unlike the plants described in previous sections of this review, typha is not an agricultural residue. Typha is a perennial aquatic plant that goes by many names such as reedmace, bulrush, cattail, or corn dog grass [97]. The Typha genus in the Typhaceae family consists of almost 30 species of monocotyledonous flowering plants. Among these species, three are most common: Typha latifolia (broadleaf cattail), Typha angustifolia (narrow-leaf cattail), and Typha domingensis (tall cattail) [98]. This work will be focused on Typha australis, a variety of Typha domingensis also referred to as Typha domingensis Pers. Var. ß. Australis [99]. This genus was selected because of its high distribution volume in West Africa, where it thrives in the warm climates and wetland ecosystems characteristic of subtropical and tropical regions [100]. This plant can reach 1.5 to 2.7 m in height, and it differs from narrow-leaf cattail by having a greater number of broader, more flattened leaves. All typha species are monoecious unisexual plants with wind-pollinated flowers, which develop in dense spikes (female and male spikes). The female spike is dark or pale brown with gray dots. This spike is 16 cm long and 3 cm wide. As for the male spike, it’s narrower, longer, and situated above the female spike [98,100,101]. Up to 80% of the plant’s weight is occupied by the ribbon-like leaves which are formed by a spongy tissue that gives the plant its insulating ability [102]. Typha australis (Fig. 8) has a fibrous root system with rhizomes nearly 3.5 m long, capable of producing oxygen to sustain the plant for up to six days [103]. Typha australis reproduces through two mechanisms: (i) sexual reproduction via seed dispersal, where thousands of seeds are released from the spikes and carried by the wind, enabling long-distance propagation, and (ii) vegetative reproduction through rhizome multiplication, which facilitates rapid and extensive colonization [99].

Figure 8: The different parts of the typha plant

Typha australis is a species with a worldwide distribution, found in diverse regions and countries including Greece, Hawaii, Egypt, South Sudan, West Africa, Southern Africa, Syria, Lebanon, Palestine, Japan, and Northern India [100]. In Senegal, 150,000 T are collected per year. Cluet et al. [104] mentioned that between 300,000 to 500,000 t can be extracted per year from the Senegal river. Typha australis grows on the banks of the Senegal river and its tributaries, also in cultivated plots, and irrigation channels [102]. It grows on the banks of gently agitating streams and stagnant water up to almost one meter deep and in brackish water. In Senegal, Typha australis tolerates a high degree of soil salinity despite generally having low tolerance for saline soils. The rapid spread of Typha australis disrupts irrigation and drainage by slowing water flow and raising water levels, heightening the risk of flooding during the rainy season. Its growth obstructs canoe navigation and fishing, reducing the open water surface area. Additionally, typha has health impacts, as it promotes Bilharzia (Schistosomiasis) by creating year-round stagnant water that fosters parasite growth. It also affects livestock health, as aquatic plants like typha harbor liver fluke parasites, increasing infection risks for animals.

Given the large quantities of typha produced and its associated drawbacks, identifying beneficial applications for this biomass is crucial. There are many applications for different parts of the plant in different fields. As with many plants, various parts of typha serve as a food source, each yielding distinct products. The tender inner part of the plant can be eaten raw or boiled. In Africa, it can also be used to produce salt obtained from the ashes of burned typha. Flour and starch are made from the rhizomes of cattail, and edible oil is extracted from the seeds [99].

In France, an experiment explored converting typha leaves into ethanol, with the remaining residue repurposed for cellulose fiber and fertilizer production [99,100].

Moreover, in medicine, typha’s pollen was used as an absorbent instead of cotton, for surgeries and childbirths and also as an astringent and diuretic substance. A decoction made from typha leaves is traditionally used to treat uterine hemorrhages and bloody diarrhea. Cattail flowers are used in treating burns, wounds, and ulcers [100].

In textile applications, compared to cotton, there are almost 9 to 16 times more quantities produced per hectare per year. With these quantities, its use in textiles is more beneficial than cotton to produce clothing like jackets, hats, gloves, and in ropes, sandals, baskets, rugs, and other materials [99].

In Europe, they are used to stuff chairs and make plant coverings. In Guatemala, typha leaves are crafted into fans used for stoking charcoal fires. In New Zealand, they are manufactured into the interior walls of houses for thermal insulation purposes. In Bermuda, bedding for domestic animals is obtained from the leaves [32].

4 Biomaterials Issued from These Residual Biomasses

Agricultural residues, such as crop stalks, husks, and other plant-based by-products, are increasingly recognized for their potential as sustainable reinforcements in biocomposite materials. Often regarded as waste, these by-products present a viable alternative to synthetic fibers, promoting more sustainable manufacturing practices. Research has delved into the mechanical, thermal, and chemical properties of these agricultural residues, seeking to understand how their unique characteristics enhance the performance of biocomposites. These residues enhance composite strength and functionality while also providing environmental benefits, such as waste reduction and support for circular economy practices. As industries increasingly prioritize sustainability, incorporating agricultural residues into composite materials represents a significant step forward. This section will explore the application of the previously discussed agricultural residues, highlighting their roles as fiber reinforcements in biocomposites and their potential to support more eco-conscious production methods.

CPH is mainly used in bio-based composites for packaging [105], furnishing [106], building [107], and automotive applications [108]. The different biocomposite materials developed from CPH are presented in this section according to the used matrix.

Sanyang et al. [109] studied CPH used in a poly(lactic acid) (PLA) matrix to develop biocomposite films by solvent casting method. CPH was ground in fine particles of 250 µm, and varying fiber contents up to 15% were incorporated into the PLA matrix. The study exclusively examined the mechanical properties of biocomposite films, conducting tensile tests to assess performance. The results showed that the tensile strengths ranged from 8.9 to 10 MPa. The authors noted that “CPH/PLA films with 10% CPH loading exhibited the highest tensile strength, increasing by 12.55% compared to 0% CPH film” however no standard deviations are reported. A more balanced interpretation is warranted, as the recorded tensile strength values remained relatively stable at 8.9, 9.3, 10, and 9.6 MPa for 0%, 5%, 10%, and 15% fiber content, respectively. The stabilization of tensile strength around 9–10 MPa could be attributed to a good dispersion of the fibers in the PLA matrix helping the effective transfer of applied stress from the polymer to the fiber. The corresponding Young’s modulus values were 1.5, 3.2, 7.8, and 10.4 MPa for 0%, 5%, 10%, and 15% fiber content, respectively. These significant increases indicate that CPH provided a genuine reinforcement effect in the PLA matrix, with fiber dispersion remaining effective even at 15% content.

4.1.2 Poly (Vinyl) Alcohol (PVA)

Pua et al. [105] also studied the utilization of CPH in a new green composite film with poly (vinyl) alcohol (PVA) for packaging applications. In this study, the authors have evaluated the effect of chemical modification of CPH (through alkalization treatment), the fiber loading of CPH (up to 15%) with neat CPH and modified CPH, and the presence or absence of a plasticizer (glycerol) in PVA-based biocomposites obtained by solvent casting method. CPH fibers were crushed to approximately 250 µm in size to facilitate their incorporation in PVA-based films. The different obtained PVA-based biocomposite films were mainly characterized in terms of mechanical properties and biodegradability in soil. Regarding the tensile properties, the addition of CPH in PVA-based biocomposite decreases the tensile strength and the elongation at break, with an increase in fiber content of up to 15%. These values were better for modified CPH fibers but a similar decrease is observed with an increase in fiber content. The addition of plasticizer significantly reduced the tensile strength of the biocomposite. The authors interpreted this as the “inability of fiber and the irregularity shape of fiber to support stress which moved from the polymer to fiber”. Concerning the biodegradability of CPH/PVA composite films, it was assessed using a soil burial test, showing a 53.8% reduction in film mass after 15 days. The composite films significantly diminished in size and became fragile and brittle after 7–15 days in soil. A higher fiber content led to greater weight loss, suggesting an accelerated degradation rate. However, weight changes may be underestimated due to soil debris adhering to the film. Additionally, modified CPH fibers improved the degradation rate compared to unmodified fibers.

Imoisili et al. [110] evaluated the use of CPH in polymer composite production within an epoxy matrix, incorporating different fiber contents of 5%, 10%, 20%, and 30%. To prepare epoxy-based biocomposites, the CPH was ground to a particle size of 38 µm, and the epoxy resin was mixed with an amine-class hardener in a 2:1 weight ratio. The authors focused on the mechanical properties of the composites (tensile strength, Young’s modulus, elongation at break, and flexural strength), the micro-hardness, and the morphology. They demonstrated that tensile strength significantly decreased from 55 to 13 MPa as the CPH content increased from 0% to 30%. In terms of Young’s modulus, a slight decrease was observed between 0% and 5% CPH content, where it declined from 615 to 610 MPa. However, beyond 5%, Young’s modulus increased, reaching 639 MPa at 30% fiber content. For elongation at break, a substantial decrease was reported, from 12.5% to 4.7%. Regarding flexural properties, flexural strength declined significantly from 51 to 25 MPa as the CPH content increased, whereas the flexural modulus increased from 1460 to 1740 MPa. The micro-hardness showed an increase from near 15 to 18 HV when the filler content went from 0% to 30%. Finally, the dispersion of CPH in the matrix was shown using scanning electronic microscopy (SEM) micrographs where it was observed that a 5% filler loading exhibited the best dispersion, while higher filler contents led to poorer dispersion.

4.1.4 Thermoplastic Polyurethane (TPU)

El-Shekeil et al. [111] investigated the effect of three CPH filler contents (20%, 30%, and 40%) in a thermoplastic polyurethane (TPU) matrix to understand their effect on the mechanical and morphological properties of the composite. The different CPH/TPU formulations were blended using an internal mixer at 190°C and the biocomposites plates were shaped using a hot press technique. Results showed that for increasing fiber content from 20% to 40%, tensile strength increased (from 18.5 to 21 MPa), Young’s Modulus increased (from 212.5 to 327.9 MPa), tensile strain decreased (from 31% to 14%), flexural strength increased (from 13 to 18 MPa), flexural modulus increased (from 565 to 867 MPa), and finally impact strength decreased (from 12.6 to 6.1 kJ/m2). SEM analysis confirmed strong interfacial bonding, as indicated by the absence of fiber pullouts and gaps between the fibers and the matrix.

Chun et al. [112] studied the use of CPH in polypropylene-based biocomposites as a solution to replace wooden fittings, fixtures and furniture, reducing the forest consumption in cutting trees. They investigated the effect of maleated polypropylene (MAPP) addition in polypropylene (PP) matrix, where MAPP acts as a coupling agent to enhance biocomposite properties. They focused on mechanical, thermal, and morphological properties of polypropylene-based composites obtained by melt blending process. CPH was ground in powder with an average particle size of 22 µm prior to their use in PP matrix by melt blend process. The authors fabricated composites with varying filler contents of 10, 20, 30, and 40 phr (parts per hundred resin), both with and without MAPP. As expected, they found that the increase in CPH content decreased tensile strength (from 20 to 15 MPa) and the elongation at break (from 30% to 12%) while increasing the tensile modulus (from 800 to 1100 MPa). For composites with 10 phr of CPH, they found that the addition of MAPP improved significantly tensile strength (24.5 vs. 20 MPa without MAPP) and modulus (950 vs. 800 MPa without MAPP) values than the composites without MAPP. Concerning the thermal stability, CPH induced an early onset of thermal decomposition (Tonset5%, temperature at 5% weight loss) whatever the CPH content, but demonstrated increased thermal stability at higher temperatures and that was proven by the higher residue % at 700°C (2.69% for 20 phr of CPH without MAPP vs. 1.22% for neat PP). Additionally, they found that the incorporation of MAPP enhanced the thermal stability of the composites, for example for PP/20CPH as indicated by higher Tonset5% (Tonset5% = 283°C with MAPP vs. Tonset5% = 272°C without MAPP), Tdegmax (decomposition temperature at maximum rate) for the same composite (Tdmax = 443°C vs. Tdmax = 422 without MAPP), and increased residue content at 700°C (3.7% vs. 2.69% without MAPP). SEM micrographs revealed poor dispersion and agglomeration of CPH particles in the PP matrix, indicating the incompatibility between hydrophilic CPH and hydrophobic PP, whereas PP/CPH biocomposites with MAPP displayed CPH particles embedded and coated by the PP matrix. This improvement was attributed to the incorporation of MAPP, which enhanced interfacial interaction between the CPH particles and the PP matrix.

The same authors presented another study [113] for PP/CPH composites without MAPP, and instead used fiber treatment: mercaptopropyltrimethoxysilane (MPS) and sodium dodecyl sulfate (SDS). Therefore, the purpose of the study was to compare the effect of the two different filler treatments on torque development, tensile properties, water absorption, thermal properties, and morphological properties of the composites. Similar composites with varying filler contents of 10, 20, 30, and 40 phr (parts per hundred resin), both treated and untreated CPH fibers. As in the previous study, the tensile strength and elongation at break of PP/CPH composites decreased with increasing CPH content, while processing torque, tensile modulus, water absorption, and crystallinity increased. Thermal decomposition was also influenced by CPH content. MPS or SDS presence improved the processing torque, tensile strength, tensile modulus, water resistance, crystallinity, and thermal stability of the PP/CPH composites, due to enhanced filler–matrix adhesion achieved through filler treatment. SEM analysis confirmed that CPH treated with MPS or SDS exhibited improved filler dispersion and interfacial adhesion with the PP matrix. Notably, SDS treatment showed superior performance in tensile properties and water absorption compared to MPS, though both treatments resulted in similar improvements in thermal properties.

Veloso et al. [108] aimed to investigate the effects of incorporating varying levels of CPH particles into composites with a recycled low-density polyethylene (LDPE) matrix. The study analyzes the physical and mechanical properties of these composites to evaluate their suitability for construction applications. The fibers were ground using a hammer mill, and the fibers used were 0.841 mm. Five compositions were prepared, replacing LDPE with cocoa waste at 0%, 10%, 20%, 30%, and 40% by weight. The materials were mixed using a twin-screw extruder, and samples were molded in a thermal press. Density decreased from 0.81 to 0.61 g/cm³ with increased CPH content (from 0% to 40%), resulting in lighter materials, which are well-suited for construction applications. Moisture content increased but remained at low levels (0.03% for 0% CPH to 0.60% for 40%). Water absorption rose (0.17% at 0% CPH to 2.68% at 40% CPH) but was still lower compared to wood-based materials. As for the mechanical properties, the modulus of elasticity (MOE) values slightly increased with added CPH. Tensile strength dropped from 13 MPa (neat LDPE) to 3.5 MPa (40% CPH), indicating increased stiffness. Specific elongation and tenacity decreased as a result of CPH incorporation. SEM analysis revealed a non-uniform particle distribution and the formation of agglomerates, which contributed to the decline in mechanical properties. The inclusion of CPH in recycled LDPE composites results in lighter, more rigid materials with some loss of tensile strength and flexibility. These changes are attributed to the chemical properties of CPH, including its extractive and lignin content, as well as the inconsistent interaction between the matrix and reinforcement.

4.2 Oil Palm Empty Fruit Bunch

OPEFB is the interest of many researchers whether alone or mixed with other fibers to develop composite materials [55,114,115] due to its low price and its large availability. OPEFB fibers are also recognized for their excellent mechanical properties. Researchers have explored their compatibility with various types of binders, including natural, and synthetic matrices. Additionally, efforts have been made to combine OPEFB fibers with other natural or synthetic fibers, creating hybrid composites. This approach leverages the complementary properties of different fibers to achieve improved mechanical, thermal, or functional characteristics, tailoring the material for specific applications such as construction [55], automotive [116], and packaging [117] industries.

4.2.1 High-Density Polyethylene (HDPE)

Rozman et al. [118] investigated the effect of different filler loadings and the particle size of OPEFB fibers with high-density polyethylene (HDPE) composites on their mechanical properties. The OPEFB fibers were ground in three sizes (270–500 µm, 180–270 µm, and 75–180 µm), and then incorporated into the HDPE matrix using a single-screw extruder before being shaped into composite plates via compression molding. The results showed that MOE (modulus of elasticity) increased with higher filler loading, indicating improved stiffness, especially for smaller particle sizes. However, MOR (modulus of rupture) and tensile strength decreased with increasing filler content, attributed to weak interfacial adhesion between the fibers and the polymer matrix. Similarly, impact strength and elongation at break diminished as filler levels rose, due to poor wetting and fiber agglomeration. SEM micrographs revealed extensive fiber pullout and debonding, underscoring the challenges of achieving strong filler-matrix bonding. The authors concluded that smaller particle sizes are preferable for enhancing certain mechanical properties, particularly stiffness and stress resistance. Filler loading had a negative effect on properties such as tensile strength, impact strength, MOR, and elongation at break, while positively influencing stiffness and MOE. Still, further work is needed to improve interfacial adhesion, potentially through chemical treatments or compatibilizers. The findings highlight OPEFB’s potential as a low-cost reinforcement material, though optimization is required for broader applications.