Open Access

Open Access

ARTICLE

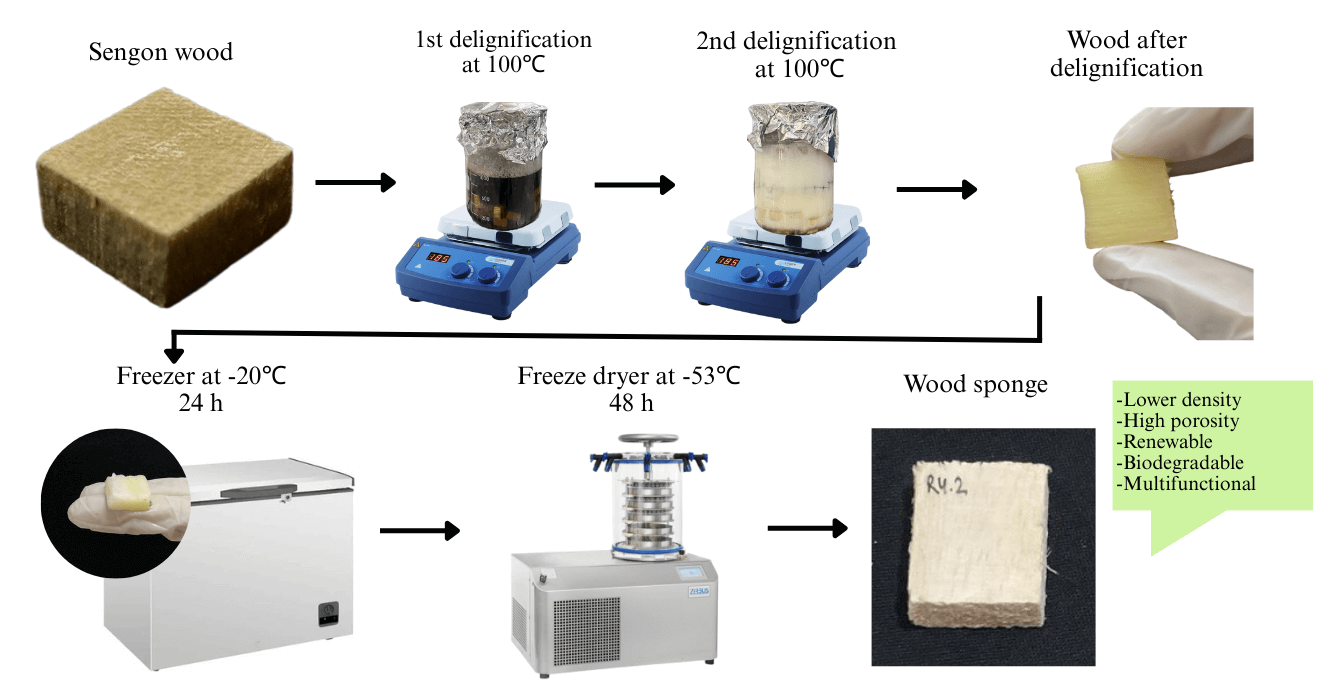

Characteristics of Wood Sponge from Sengon (Falcataria moluccana) Wood Manufacturing through a Multistage Delignification Process

1 Forest Products Department, Faculty of Forestry and Environment, IPB University, Bogor, 16680, Indonesia

2 Research Center for Biomass and Bioproducts, National Research and Innovation Agency, Cibinong, 16911, Indonesia

* Corresponding Authors: Imam Wahyudi. Email: ; Sarah Augustina. Email:

Journal of Renewable Materials 2025, 13(8), 1661-1681. https://doi.org/10.32604/jrm.2025.02024-0081

Received 29 December 2024; Accepted 28 April 2025; Issue published 22 August 2025

Abstract

Adsorbents with three-dimensional porous structures have gained widespread attention due to their unique characteristics, including a large surface area, high porosity, and excellent absorption capacity. One of the products is the wood sponge. The key to successfully producing wood sponges lies in an optimal multistage delignification process, which is particularly influenced by wood species, solvent, time, and temperature. The aim of this research was to analyze the characteristics of wood sponge derived from sengon wood (Falcataria moluccana Miq.) after multistage delignification. The process involved delignification using NaOH and Na2SO3 solutions at 100°C for 8, 9 and 10 h, followed by further delignification in H2O2 solution at 100°C for 1, 2, 3, and 4 h. The samples were then frozen at 20°C for 24 h and freeze-dried at 53°C for 48 h. The results showed that wood sponges treated at 100°C exhibited lower density, larger pore diameters, brighter color, and superior absorption capacity compared to untreated wood and sponges treated at room temperature for 24 h. FTIR analysis confirmed a decrease in wavelength between 1032–1035 cm−1, indicating the degradation of hemicellulose and lignin. XRD analysis revealed that crystallinity increased as amorphous content decreased with prolonged delignification. The wood sponges demonstrated good porosity, with an absorption capacity ranging from 0.65 to 2.24 g/g. The optimal treatment suggested in this research was multistage delignification using NaOH and Na2SO3 solution for 10 h, followed by a 1 h treatment with H2O2 solution.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools