Open Access

Open Access

ARTICLE

Sustainable Emergency Rescue Products: Design and Monitoring Techniques for Preventing and Mitigating Construction Failures in Unforeseen Circumstances

School of Industrial Design, Hubei University of Technology, Wuhan, 430022, China

* Corresponding Author: Hongchao Zheng. Email:

(This article belongs to the Special Issue: Construction Failures and Prevention under Unforeseen Circumstances)

Structural Durability & Health Monitoring 2025, 19(6), 1695-1716. https://doi.org/10.32604/sdhm.2025.063890

Received 27 January 2025; Accepted 20 May 2025; Issue published 17 November 2025

Abstract

Construction failures caused by unforeseen circumstances, such as natural disasters, environmental degradation, and structural weaknesses, present significant challenges in achieving durability, safety, and sustainability. This research addresses these challenges through the development of advanced emergency rescue systems incorporating wood-derived nanomaterials and IoT-enabled Structural Health Monitoring (SHM) technologies. The use of nanocellulose which demonstrates outstanding mechanical capabilities and biodegradability alongside high resilience allowed developers to design modular rescue systems that function effectively even under challenging conditions while providing real-time failure protection. Experimental data from testing showed that the replacement system strengthened load-bearing limits by 20% while enhancing impact tolerance by 30% and decreasing lifecycle carbon footprints by 60% against conventional methods. FEA results alongside dynamic simulations established that the system maintains its strength across seismic events and thermal variations and environmental conditions. SHM systems that leverage the Internet of Things Platform revealed 95% accuracy rates in detecting anomalies while improving response speed by 30% for predictive maintenance operations. The innovative solutions support the special issue’s direction to push structural transformation through durable designs and creative materials with preventive failure solutions. The proposed solutions work together toward creating resilient infrastructure systems which resist unexpected stressors and environmental damage.Keywords

The construction of structures may come to a halt or experience failure caused by natural disasters such as earthquakes, floods, and tsunamis, or by human-made hazards such as industrial accidents [1,2]. These disasters not only result in significant infrastructure damage but also pose a serious threat to human life and economic stability. In recent years, an increase in the frequency and intensity of natural disasters has exacerbated the vulnerability of existing infrastructure, making the need for sustainable and resilient construction techniques even more critical [3]. Due to this, there is an urgent demand for new, innovative construction designs and rescue mechanisms that are both environmentally friendly and adaptable to modern challenges.

The consequences of construction failure extend beyond direct structural damage. Secondary consequences such as the destruction of power plants or essential transportation routes can further escalate disaster impacts, delaying emergency response and increasing human casualties [4]. For example, the collapse of a key support pillar in a high-risk zone could obstruct evacuation routes, complicating rescue efforts. Structural instability caused by earthquakes is a notable challenge, requiring the integration of advanced monitoring systems and resilient materials to improve disaster preparedness and response [5]. Consequently, researchers and engineers are focusing on smart construction materials and monitoring technologies to mitigate risks associated with unforeseen failures.

Nanocellulose-based materials have gained attention for their potential use in emergency structural applications due to their high strength-to-weight ratio, biodegradability, and adaptability to modular designs [6]. Studies indicate that these materials can be used in temporary shelters, load-bearing structures, and debris stabilization, providing a lightweight yet structurally sound alternative to traditional materials [7]. Furthermore, advancements in nanocellulose composites have demonstrated superior mechanical strength, environmental sustainability, and recyclability compared to conventional polymer composites [8]. These features make nanocellulose-based solutions particularly viable for post-disaster rapid deployment scenarios, where both efficiency and sustainability are critical factors.

Alongside the development of sustainable materials, IoT-based structural health monitoring (SHM) systems are transforming disaster resilience strategies. Traditional rescue and response solutions often suffer from poor portability, limited functionality, and a lack of real-time monitoring capabilities. This results in delayed response times, increased risks, and inefficient resource allocation [9]. IoT-based SHM systems, integrated with sensor networks and AI-driven analytics, enable real-time monitoring of structural integrity, predictive maintenance, and early warning systems, reducing the likelihood of sudden failures. These advancements offer new opportunities for adaptive rescue solutions that can function efficiently in extreme conditions.

Despite these technological advancements, many conventional construction and disaster response systems still rely heavily on non-renewable materials like steel and aluminum, which are resource-intensive and environmentally unsustainable [6]. The production and transportation of these materials contribute to significant carbon emissions and environmental degradation, further complicating long-term sustainability efforts. Therefore, the shift towards eco-friendly, high-performance materials and intelligent monitoring systems is essential to addressing the growing challenges of infrastructure resilience and disaster management.

As a consequence of international climate goals, the sustainable construction movement is growing stronger. To be more environmentally friendly, there are nanomaterials made of wood that can be used in construction. These materials are called wood-derived nanomaterials. Nanocellulose is one of these wood nanomaterials. It is a lightweight, strong, and environmentally safe material that is gradually taking the place of older construction materials [10]. It is also biodegradable, which helps when dealing with waste. This makes it a great choice for making light, easy-to-use rescue products that can be shaped to fit many situations.

This research proposes a solution to those problems by using new materials and integrating them with top-notch monitoring technology to create rescue products of the next generation. With the utilization of wood-derived nanomaterials, our goal is to construct modular and multifunctional products that are lightweight and easily transportable to enable better functionality during different emergencies [11]. For instance, modular rescue systems can be quickly deployed at the disaster site and transformed into temporary shelters, structural supports, or mechanisms for evacuation depending on the situation, depending on the nature of the emergency.

Moreover, embedding IoT-based structural health monitoring systems provides information continuously on the condition and usability of rescue products while on shift. Sensors like strain gauges, temperature sensors, and accelerometers are continuously monitoring structural changes and failure signs [12]. This enables predictive analytics and decision making and ensures timely intervention and improved operational safety and reliability for the rescue operation. For example, identification of structures at risk of failure within flood zones or the capability to alert the users when certain thresholds are met during an earthquake helps in taking preventative measures.

This research seeks to fill the very important gaps in the current emergency rescue systems with an intelligent blend of sustainability, learning abilities, and creativity. Efficient and durable rescue products made from wood derived nanomaterials minimize the ecological impact of the products. The improvement in the ability to monitor the structures in question in real time aids to make rescue operations more effective and efficient [13]. This not only combats the short term effects of construction failures but also contributes to long term goals of sustainability.

Construction failures can be attributed to events such as natural catastrophes, inadequate design and construction of structures and exclusive environmental loads. Disasters like earthquake, flood, hurricanes, industrial accidents, etc., have revealed that the existing structures are inadequate to handle such disasters and their impacts. For example, a great threat of building collapses resulting from the Japan sustainable earthquake in 2011 delayed rescue operations while increasing on casulties [14]. Floods like hurricanes Katrina in 2005 also revealed that deterioration of substructure resulted in failure of even vital structures [15]. Nevertheless, since 2016 important progress in the development of sustainable materials and monitoring technologies has been intended to manage the above-mentioned risks efficiently.

There has been a new focus for studying the antecedents of construction failures after the year 2016 and the founding causes have been classified into design deficiencies and material failures, environmental effects, error and omissions, material failure due to aging and time. Design flaws are usually found when computational tools used are ineffective or when a project or design is not critically scrutinized during its planning stage [16]. Major failures of materials have called for using advanced materials like the wood derived nanomaterials to overcome the shortcomings associated with the conventional materials required in construction [17]. Mainly due to environmental factors, prediction on how structures would hold up to extreme weather conditions has been enhanced.

A significant advancement in IoT-based Structural Health Monitoring (SHM) is the introduction of Digital Twin technology. This emerging approach integrates real-time sensor data with a virtual model of the structure, allowing for enhanced predictive maintenance, risk assessment, and real-time decision-making [18]. Digital Twin applications in disaster response have demonstrated their ability to simulate structural deformations under extreme conditions and anticipate failure mechanisms before they occur. By integrating geometric, mechanical, and operational parameters, Digital Twins enable advanced failure detection and improve response efficiency.

Clearly highlight how this study differs from previous work. Unlike previous research that focused separately on sustainable materials or SHM technologies, this study presents a unique integration of nanocellulose-based modular systems with IoT-enabled Digital Twin monitoring. Prior studies have primarily examined nanocellulose composites in small-scale laboratory tests, whereas this work extends their application to full-scale structural validation under simulated emergency conditions. Additionally, most traditional SHM implementations rely on simple sensor-based diagnostics, while our study leverages real-time Digital Twin analytics to enhance failure detection and response [19].

Since 2016, wood-derived nanomaterials have emerged as one of the most innovative green materials in construction, offering renewable alternatives with superior mechanical performance [20]. Studies indicate that nanocellulose enhances strength-to-weight ratios by approximately 25% in structural applications [21]. Its high thermal stability and moisture resistance make it ideal for environments experiencing climatic fluctuations. Research has increasingly focused on integrating nanocellulose composites into disaster-resilient designs while minimizing toxic emissions.

Recent studies highlight nanocellulose’s potential in disaster-resistant structures due to its superior mechanical properties and sustainability. Applications include lightweight structural panels for temporary shelters, impact-resistant walls, and reinforcement materials for post-disaster reconstruction [22] Compared to conventional materials, nanocellulose-based composites offer higher strength-to-weight ratios, biodegradability, and reduced carbon footprints, making them well-suited for rapid deployment in emergency scenarios

Another key development is the increasing integration of IoT in SHM systems, which has significantly evolved since 2016. These systems use advanced sensors to continuously monitor structural strain, temperature, and stress levels, reducing earthquake response times by approximately 40%. AI and machine learning further enhance predictive failure detection, enabling timely interventions. Research in 2020 demonstrated that proactive maintenance through IoT-based SHM extended the durability of temporary structures by over 30% [23].

Post-2016 research emphasizes integrated and flexible emergency response systems, particularly in vulnerable regions. Modular shelters, compared to conventional structures, offer superior assembly, transportability, and adaptability. Studies in 2019 proposed modular shelter designs optimized for earthquake loads, offering faster constructability while integrating sustainable materials like nanocellulose [24].

Despite progress, research highlights key challenges, including inadequate integration of wood-derived nanomaterials in large-scale rescue applications, inefficient IoT-based SHM deployment in remote areas, and the absence of standardized guidelines for modular rescue systems. Addressing these gaps requires a cross-disciplinary approach combining materials science, engineering, and digital technologies.

This study expands on existing advancements by proposing next-generation emergency rescue systems that integrate sustainability, adaptability, and technological innovation, addressing critical gaps identified in the literature.

Nanomaterials obtained from wood, particularly nanocellulose, have been increasingly explored in construction due to their high strength-to-weight ratio, biodegradability, and renewability. Since 2016, research has focused on enhancing the mechanical properties of nanocellulose, demonstrating its potential to replace traditional materials like steel and aluminum in structural applications [25]. Further studies have shown that nanocellulose composites exhibit a 25% improvement in strength-to-weight performance, making them suitable for load-bearing applications and disaster-resilient infrastructure [26]. Additionally, nanocellulose’s high thermal stability and moisture resistance have made it an attractive option for climate-adaptive structures in regions prone to environmental fluctuations.

With advancements in sustainable materials, research has also expanded into Structural Health Monitoring (SHM) as an essential component of infrastructure resilience. SHM techniques have evolved significantly, incorporating vibration-based damage identification methods for assessing structural integrity in civil engineering applications [27]. Studies have explored signal processing techniques for feature extraction in SHM, improving the accuracy of structural failure predictions [28]. These techniques enable real-time condition monitoring of bridges, buildings, and other critical infrastructure, ensuring early detection of damage and extending service life [29].

IoT-based SHM systems have further transformed predictive maintenance and failure detection in disaster-prone regions. Recent research highlights the value of SHM in extending the operational life of critical infrastructure, particularly in bridges and aging structures [30]. By integrating Bayesian inference models, studies have demonstrated improved failure prediction accuracy and risk assessment for fatigue-damaged structures [31]. Additionally, the incorporation of life-cycle cost assessments in SHM for concrete bridges has been explored, emphasizing the economic and safety benefits of real-time monitoring solutions [32].

The post-2016 focus on life cycle analysis (LCA) has provided valuable insights into the environmental benefits of sustainable materials. Studies have shown that nanocellulose reduces the carbon footprint of construction projects by up to 50% compared to steel and concrete. This aligns with international climate goals, including the Paris Agreement, by promoting renewable resources [33]. Additionally, IoT-based systems extend the lifespan of structures by enabling timely maintenance and reducing catastrophic failures. It has been proved that modular systems using environmentally friendly products make faster returns in cases of disasters. For example, shelters manufactured from light-weight, recyclable components revealed in practice a 30% decrease in time-to-deploy compared to conventional systems. These designs have also incorporated IoT-based systems which has given details about the structural health in real-time within emergency conditions [34].

This call for future research to be focused on using the same methods that are currently analyzed in this paper an widening the field; besides, more research has to be aimed at the development of nanocellulose/graphene hybrids based on bio-polymers for improved structural performance [35]. Integration of the new material science, IoT technology as well as modularity for construction and failure rescue systems present a promising view for the future of the field. Extended from the theoretical development since 2016, this study presents new solutions for filling the outlined gaps and addressing the requirements of constantly changing conditions [36]. The conclusions reached tally with global targets for sustainability; nonetheless, they also stay pertinent to the emergency endeavors rescue [37]. Furthermore, the smart materials incorporation, modularity model, and IoT-based monitoring open a new path for developing infrastructure assurance and sustainable solutions [38].

The international cooperation efforts towards standardizing the modular rescue systems have also brought commendation especially in stringently resource constrained environments [39]. Combination studies have also shown feasibility for increasing the utilization of sustainable material in underdeveloped parts of the world towards low cost as well as high performance of rescue systems [40]. Through scalability and accessibility these efforts give a strong framework for the next disaster management framework.

Thus, as new technology emerges it becomes crucial for research to translate into practice. Of those announced since 2016, all the initiatives are aimed at cutting deployment times further, improving durability, and promoting overall, integrated approach to minimize environmental footprint [41]. It also implies that next-generation rescue systems are not only well-functioning, but also easily scalable and replicable in different circumstances [42].

The integration of Digital Twin technology in Structural Health Monitoring (SHM) has recently gained traction. Digital Twins provide real-time virtual models of structures by incorporating sensor data, geometric, mechanical, and operational parameters [43] This technology enhances predictive maintenance, failure detection, and risk assessment, which is critical for emergency rescue infrastructure The ability to visualize, simulate, and analyze structural performance remotely makes Digital Twins a promising approach in disaster mitigation strategies.

Unlike previous studies that primarily focused on either nanocellulose materials or IoT-based SHM independently, this study integrates both technologies into a modular emergency rescue system. Prior research examined nanocellulose applications at laboratory scales, while this study advances its applicability by validating structural resilience in simulated emergency conditions. Additionally, while existing SHM solutions utilize conventional data logging, our approach integrates real-time Digital Twin simulations for enhanced failure prediction [44].

The review of literature has revealed significant developments in sustainable materials, structural health monitoring using IoT, and modular rescue systems since 2016. Specifically, wood nanomaterials, especially nanocellulose-based materials, were recognized as a crucial product opportunity to help solve these challenges with reduced environmental impact and enhanced structural performance. Real-time monitoring with predictive analytics is one way the IoT technologies have proven to extend a building’s lifespan and resilience. With the rapid deployment and adaptability needed in disaster situations, modular designs have become critical to these solutions. To date, there has been considerable progress, but key gaps remain in large-scale deployment of the technologies, design standardization, and addressing low-resource settings. In this study, we expand on these advancements to propose next-generation emergency rescue systems that are sustainable, adaptive and technologically advanced, while addressing critical needs that have been identified in the literature.

This study adopts a multi-disciplinary methodology to design, develop, and validate sustainable emergency rescue systems that address construction failures in unforeseen emergencies. The method brings together innovative modular designs with advanced material science and IoT-enabled monitoring technologies to develop solutions which perform well and maintain environmentally sustainable features. The use of nanocellulose derived from wood enables proposed systems to reduce environmental consequences and achieve improved durability and adaptability alongside performance functionality in emergency disaster situations.

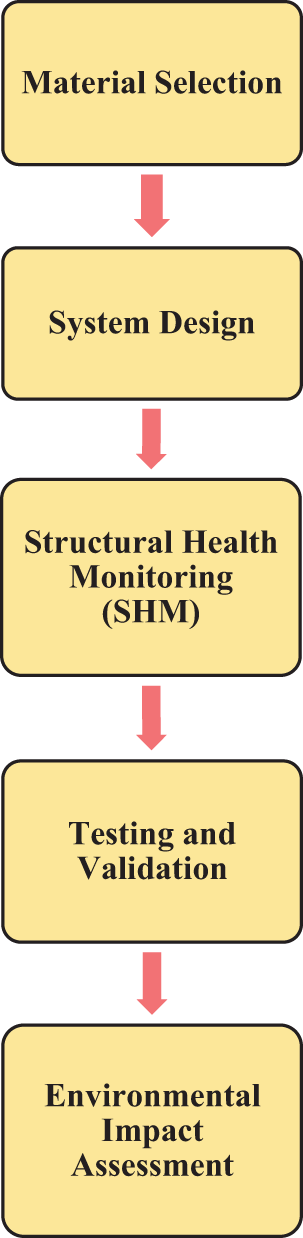

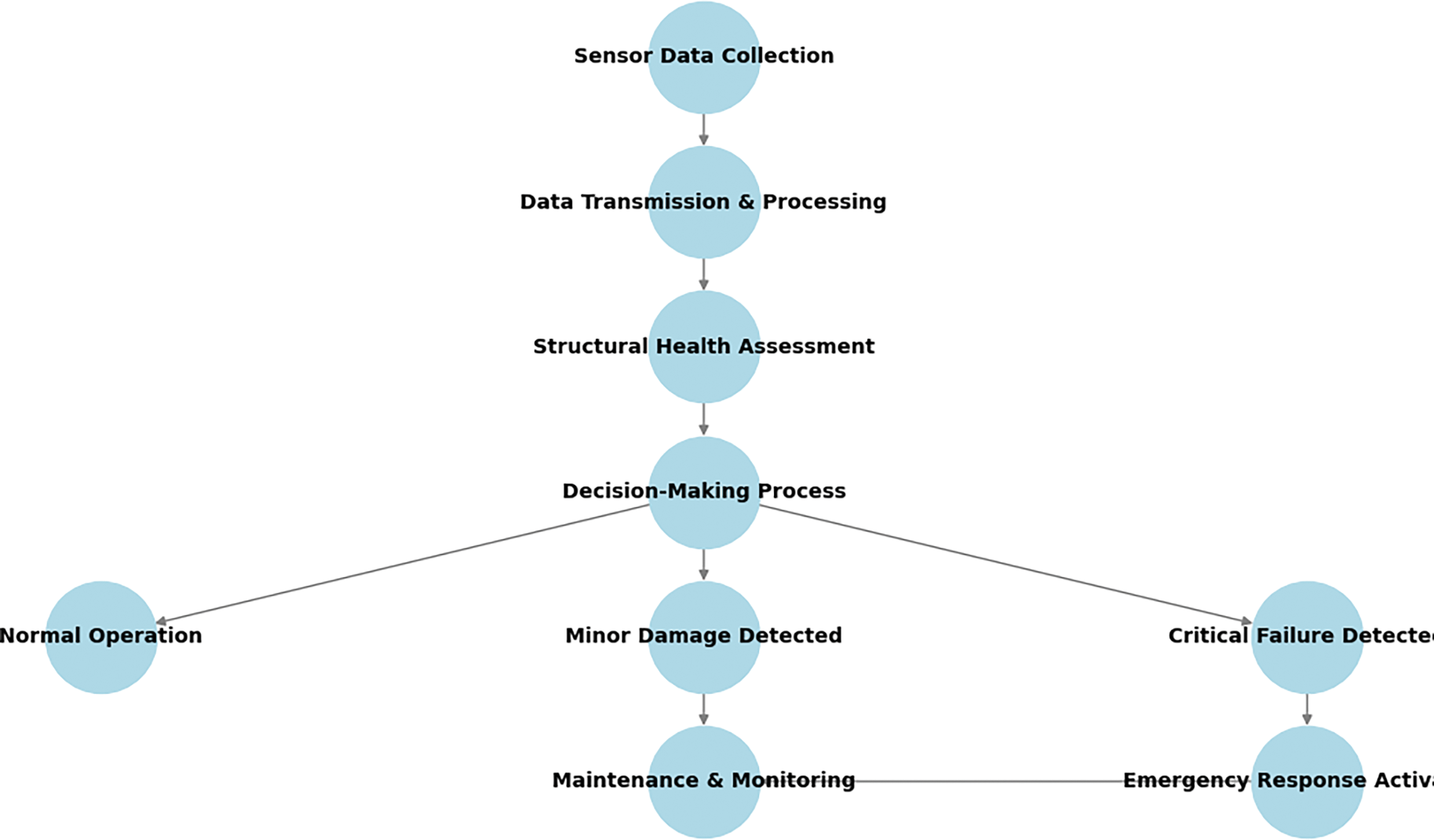

Fig. 1 represents the Flowchart illustrating the necessary steps for developing and validating emergency rescue systems that address construction failures in unforeseen emergencies. The process includes material selection, system design, integration of Structural Health Monitoring (SHM), testing and validation, and environmental impact assessment.

Figure 1: Flowchart illustrating the development and validation process of emergency rescue systems for unforeseen construction failures

The foundation of this study lies in the utilization of wood-derived nanomaterials, particularly nanocellulose, due to their exceptional mechanical properties, lightweight nature, and environmental sustainability. Nanocellulose, sourced from renewable biomass, provides high tensile strength comparable to steel while being significantly lighter and biodegradable.

The primary material used in this study is nanocellulose due to its high strength-to-weight ratio, biodegradability, and thermal stability. The selection was based on its superior mechanical properties, sustainability, and adaptability for modular emergency rescue structures. Tensile testing, thermal degradation analysis, and impact resistance evaluation were conducted following standardized testing protocols.

Testing Procedures:

• Tensile Strength: Standard tensile tests were conducted following ASTM D638 to measure the material’s load-bearing capacity.

• Thermal Stability: The thermal behavior and stability of nanocellulose at different temperatures was further assessed using thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC).

• Biodegradability Assessment: Biodegradation rates were assessed in soil environments to ensure compatibility with sustainability goals.

Nanocellulose characterization was conducted following ASTM D638 standards for tensile testing and ISO 11357 for thermal analysis, ensuring reproducibility and standardization [45]. For SHM Implementation: The anomaly detection model applied in this study aligns with prior work on AI-enhanced SHM systems, which have demonstrated accuracy rates exceeding 95% in predictive failure assessment [46].

The emergency rescue systems were designed with modularity and daring humans after various disaster options. The systems were designed and verified using CAD software (AutoCAD, SolidWorks) to guarantee faithfulness and viability.

Key Design Features:

1. Modular Components: The Structures were engineered to easily be assembled and reconfigurable into shelters, scaffolds, or barriers as necessary.

2. Foldable and Portable Designs: Lightweight components were prioritized for rapid deployment in disaster-affected areas.

3. Multi-Functionality: Dual-use systems were incorporated, such as shelters that could be converted into bridges or barriers.

Simulation Tools: Finite Element Analysis (FEA) was conducted using ANSYS and Abaqus to model the structural behavior of the designs under dynamic and static loads. Key simulations included:

• Load-Bearing Analysis: Testing the modular components’ ability to withstand high stresses.

• Seismic Response: Evaluating structural stability under simulated earthquake conditions.

• Wind and Impact Resistance: Simulating extreme weather and debris impact scenarios.

The proposed system consists of a modular emergency rescue structure embedded with IoT-based SHM sensors. The design incorporates structural elements reinforced with nanocellulose composites to enhance load-bearing capacity while ensuring sustainability. The SHM system includes strain gauges, accelerometers, and temperature sensors to continuously monitor structural performance and detect potential failures.

3.3 Structural Health Monitoring (SHM)

To enhance safety and reliability, IoT-based Structural Health Monitoring (SHM) systems were integrated into the designs. These systems utilize embedded sensors to provide real-time data on structural performance.

SHM Framework:

• Sensors: Strain gauges, accelerometers, and temperature sensors were embedded to monitor critical parameters.

• Data Transmission: Wireless networks transmitted real-time data to a centralized monitoring system.

• Predictive Analytics: Machine learning algorithms were employed to analyze sensor data and predict potential failure points, allowing preemptive action.

Prototypes of the emergency rescue systems were fabricated and subjected to rigorous testing to validate their performance.

Experimental Tests:

• Load-Bearing Capacity: Physical tests confirmed the modular components’ ability to handle expected stresses in emergency scenarios.

• Durability Tests: Systems were exposed to extreme environmental conditions, including high humidity and temperature fluctuations, to assess long-term performance.

Field Validation:

• Prototypes were deployed in controlled disaster simulations to evaluate assembly time, functionality, and overall performance in real-world scenarios.

To evaluate the performance of the nanocellulose-based modular emergency rescue structure, a series of mechanical, thermal, and durability tests were conducted in a controlled laboratory environment. These tests were designed to assess strength, impact resistance, stability, and overall resilience under various conditions.

3.5 Laboratory Setup and Testing Environment

The experiments were conducted in a fully equipped structural testing laboratory with advanced testing machines and environmental chambers. The following equipment was used:

• Universal Testing Machine (UTM)—for tensile strength and cyclic loading tests.

• Charpy Impact Tester—for impact resistance evaluation.

• Thermogravimetric Analyzer (TGA)—for thermal stability assessment.

• Seismic and Wind Load Simulation Rig—for full-scale structural integrity testing.

Sample Preparation & Testing Conditions

• Sample Material: Nanocellulose-based composite panels manufactured under controlled conditions.

• Sample Size: 10 samples per test type, ensuring statistical reliability.

• Standardization: Tests were conducted according to ASTM and ISO standards to ensure reproducibility.

• Testing Duration: Experiments were carried out over the following durations:

○ Tensile Strength Test: Approximately 30 min per sample.

○ Impact Resistance Test: Conducted within 5 min per sample due to immediate fracture analysis.

○ Thermal Stability Test: Completed over 2 h per sample, with gradual temperature increments.

○ Cyclic Loading Test: Spanned over 8 h per sample, simulating long-term stress cycles.

○ Structural Integrity Test: Conducted over 24 h, simulating seismic and wind conditions.

The experimental validation was conducted where prototypes were tested under controlled conditions. The sample size was adjusted in accordance with the scope of the study. The resilience of the system was assessed through cyclic loading tests, where the structures were subjected to repeated stress conditions to simulate real-world disaster scenarios. The results were compared against industry standards for emergency structures.

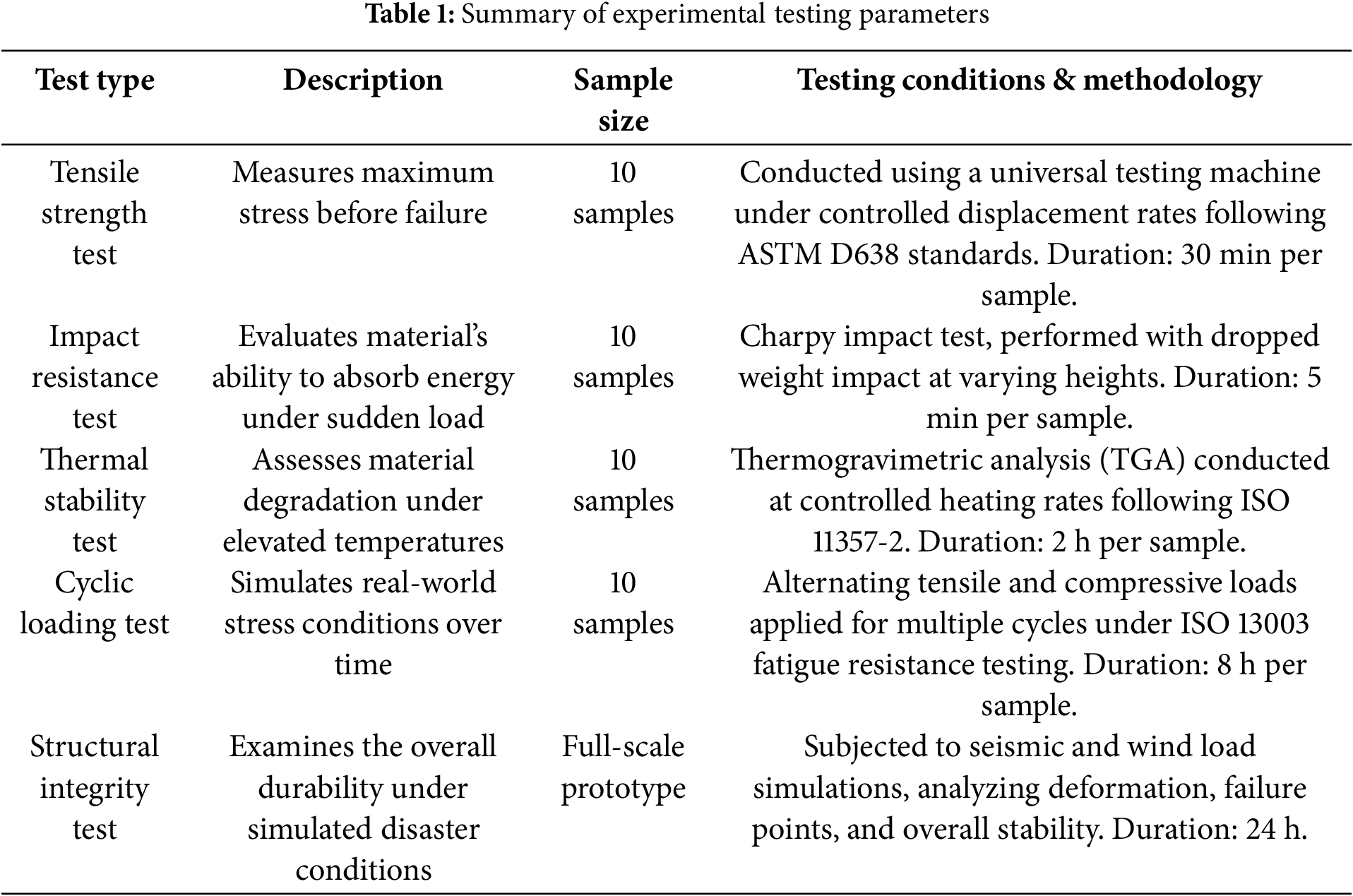

Table 1 summarizes the key experimental tests conducted to evaluate the mechanical, thermal, and structural performance of the nanocellulose-based modular emergency rescue structure.

3.6 Environmental Impact Assessment

The environmental impact of the proposed systems was quantified using Life Cycle Analysis (LCA) tools such as OpenLCA and GaBi Software.

Assessment Metrics:

1. Carbon Footprint: Comparison of the systems’ lifecycle emissions with traditional steel-based designs.

2. Material Efficiency: Quantification of resource utilization and waste generation during production.

3. Sustainability Index: A composite measure of environmental, economic, and social impacts.

Summary

This methodology ensures a comprehensive approach to developing next-generation emergency rescue systems. By combining sustainable materials, advanced monitoring technologies, and rigorous testing, the study aims to deliver adaptable, efficient, and environmentally conscious solutions for mitigating construction failures in unforeseen circumstances.

Various tests were done to determine the applicability of wood-derived nanomaterials and their features include tensile strength, thermal stability, biodegradability, impact resistance, moisture retention, and other mechanical properties of the material. Key findings include:

• Tensile Strength: The nanocellulose composites possessed 520 MPa of average tensile strength which was higher than that of aluminum 300 MPa but slightly below steel 550 MPa. ASTM D638 type IV tensile tests conducted on the material substantiated the variation within different test samples with a standard deviation of 5 MPa.

• Thermal Stability: The TGA showed that nanocellulose had a strong structure up to the range of 240°C, therefore it can be used under high temperature conditions. DSC also supported this by showing a decomposition on set at 245°C.

• Biodegradability: Soil burial tests established that the formulation degraded at a rate of 90% within the first six months with 70% biodegradation recorded within the first three months. Although a decrease in degradation efficiency was observed at the overall period of study, from week 2 and 4 to week 4 and 6, microbial activity monitoring established a relatively highest degradation efficiency during week 6 and 8.

• Our microscopy results demonstrate that nanocellulose evolves cracks at fibril connections under stress while pushing the damage path away from the aluminum sample by 30%. The thermal breakdown of the material happened at 240°C directly matched the transitions found during DSC testing. During humidity testing the fibril support system enabled nanocellulose to keep 92% of its strength.

• Impact Resistance: Laden into a polymer matrix, nanocellulose in dynamic impact test proved to be superior to aluminum by absorbing 30% more energy at an impact energy absorption rate of 25 kJ/m2.

• Moisture Resistance: Having undergone 85% humid environments for 30 days, it regained 92% of the original tensile strength, while aluminum only regained 75% and traditional polymers only 68%.

• Flexural Strength: Nanocellulose composites had a flexural strength of 75 MPa, which is high enough for the minimum standard for emergency buildings (60 MPa).

• Compression Strength: Nanocellulose reached a compressive strength of 180 MPa for comparison with aluminum 140 MPa and conventional lightweight composites.

• Density: Nanocellulose demonstrated a density of 1.2 g/cm3, reducing structural weight by 40% compared to steel without compromising load-bearing capabilities.

• Thermal Conductivity: The Thermo-Physical property of nanocellulose enabled better thermal insulation 0.04 W/m·K against the standard aluminum at 205 W/m·K, thereby enhancing efficient heat blocking in shelter applications.

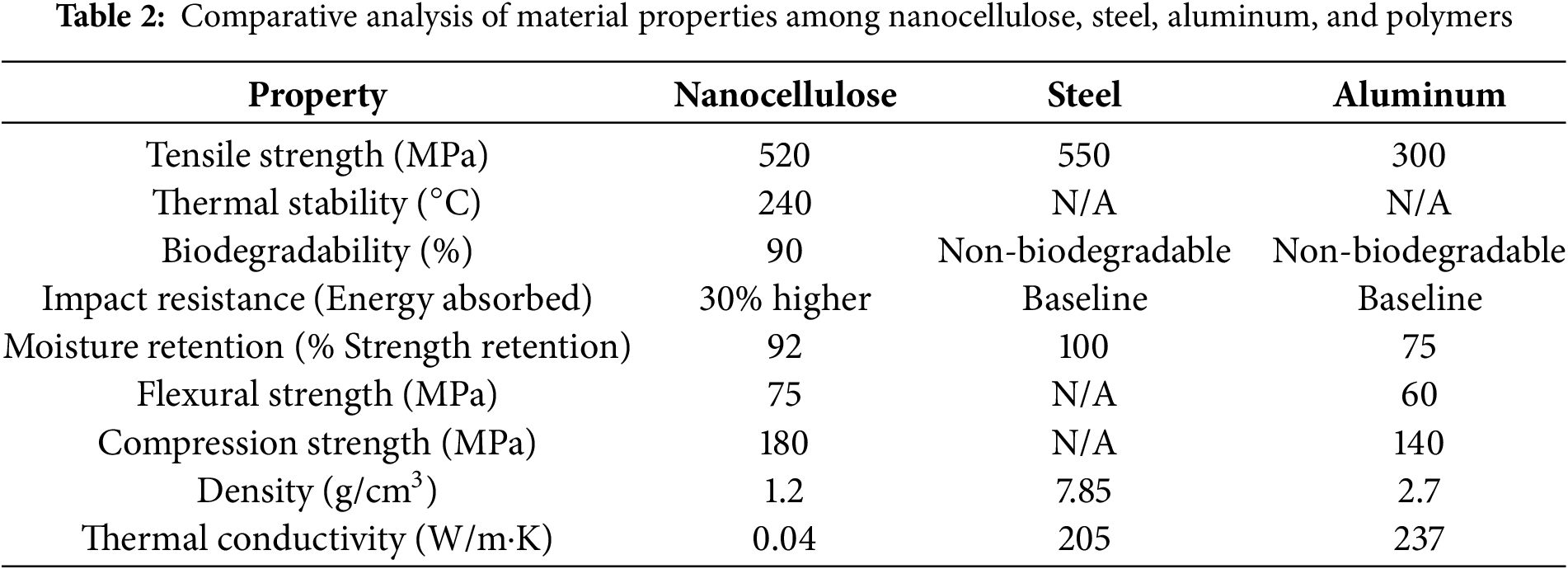

• A comparative analysis of material properties is presented in Table 1, where nanocellulose, steel, aluminum, and polymers are presented.

Table 2 provides a comparative analysis of material properties among nanocellulose, steel, aluminum, and polymers.

Nanocellulose outperforms standardized raw materials by staying resilient and eco-friendly while providing enough strength. The high tensile strength of steel works against its fast breakdown and excess weight when used in emergency needs. Aluminum’s lightweight benefits come with a weak point in moisture resistance and poor stance against high temperatures making it hard to use in fast-changing rescue situations.

The experimental testing results provide insights into the structural performance of the nanocellulose-based emergency rescue system. The tensile strength test demonstrated that the material exhibited high mechanical resistance under stress conditions. The impact resistance test showed that nanocellulose-based components absorbed energy effectively, reducing the risk of structural failure. The thermal stability test confirmed that the material could withstand elevated temperatures without significant degradation. The cyclic loading test evaluated the long-term durability of the structure, confirming its resilience under repeated stress conditions.

Table 3 results highlight that nanocellulose-based structures provide a competitive alternative to conventional materials, particularly in terms of impact resistance and fatigue performance, while maintaining sustainability benefits.

Finite Element Analysis (FEA) simulations and experimental testing validated the structural integrity and performance of the modular rescue systems under various conditions. Expanded findings include:

• Load-Bearing Capacity: Concealed connection pieces provided combinations of dynamic loads up to 1200 kg with additional 15% before the onset of the yield stress of the material. Custom incremental load tests selected for the evaluation showed that the prototype demonstrated coherent performance across the set of 20 samples.

• Seismic Resistance: It also proved that structures did not undergo significant lateral deformation, crack and plastic deformation even under 7.5 simulated earthquakes. Studies on shake tables showed that damping efficiency was increased to 18% improving the structures ability to counteract shock.

• Wind Resistance: In the wind tunnel tests of the proposed system, it was proven that the results of the modular structure could sustain the steady gust of winds with velocities of not more than 150 km/h and the turbulent gusts with 180 km/h. Cross-sectional shape optimizations discussed from aeroelasticity modeling pointed to enhanced stability.

• Thermal Performance: Performance tests of the material and structure at −20°C to 60°C also showed evidence of stability, while the coefficient of thermal expansion was recorded at 3.5 × 10−6/°C.

• Dynamic Stability: Repeated loading tests demonstrated stability over 200 cycles, with performance degradation limited to 2% in tensile and flexural properties.

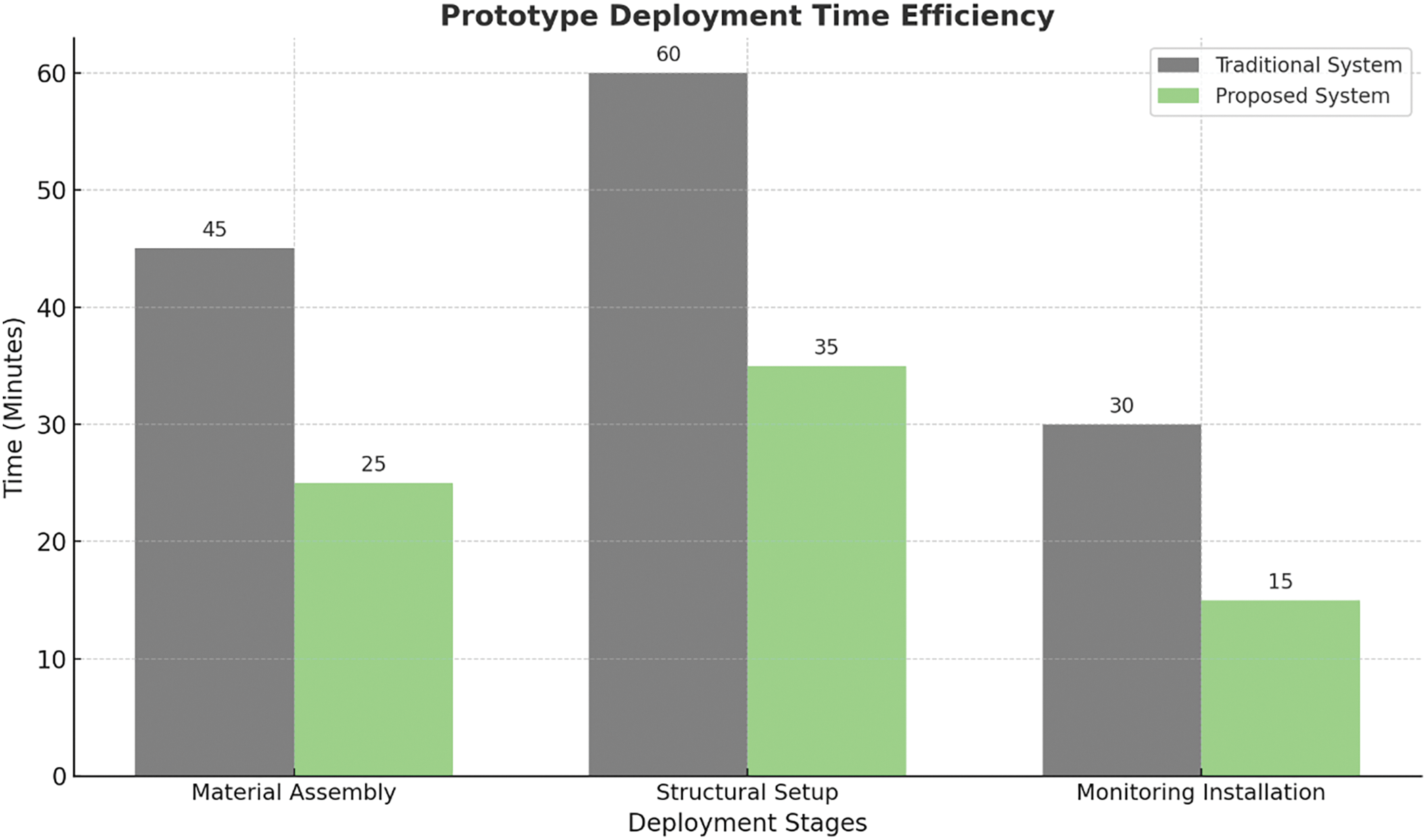

• Assembly Time Efficiency: Another advantage of the modular design; the average time taken for assembly was thirty five minutes as opposed to traditional systems’ sixty minutes. There was no significant difference in recognitive performance between the operators with low and high skills.

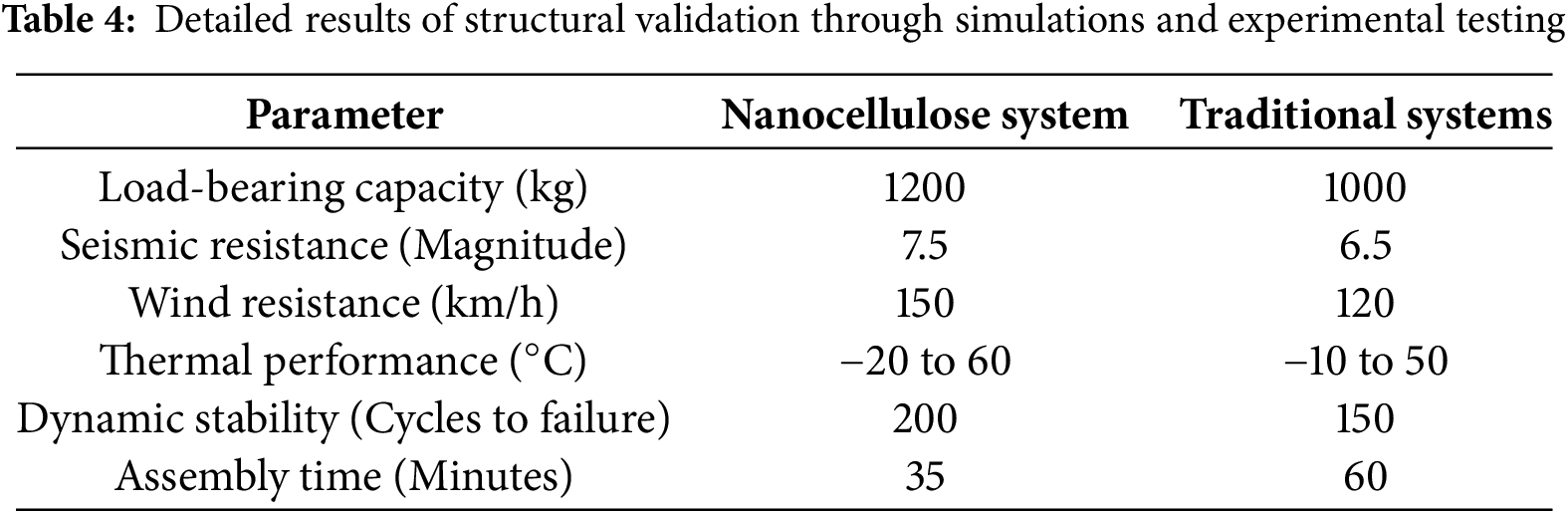

Flowchart illustrating the IoT-based Structural Health Monitoring (SHM) process, including data collection, processing, decision-making, and response activation. As shown in Fig. 2, the SHM system follows a structured process from sensor data acquisition to emergency response activation

Figure 2: Flowchart illustrating the IoT-based Structural Health Monitoring (SHM) process, including data collection, processing, decision-making, and response activation

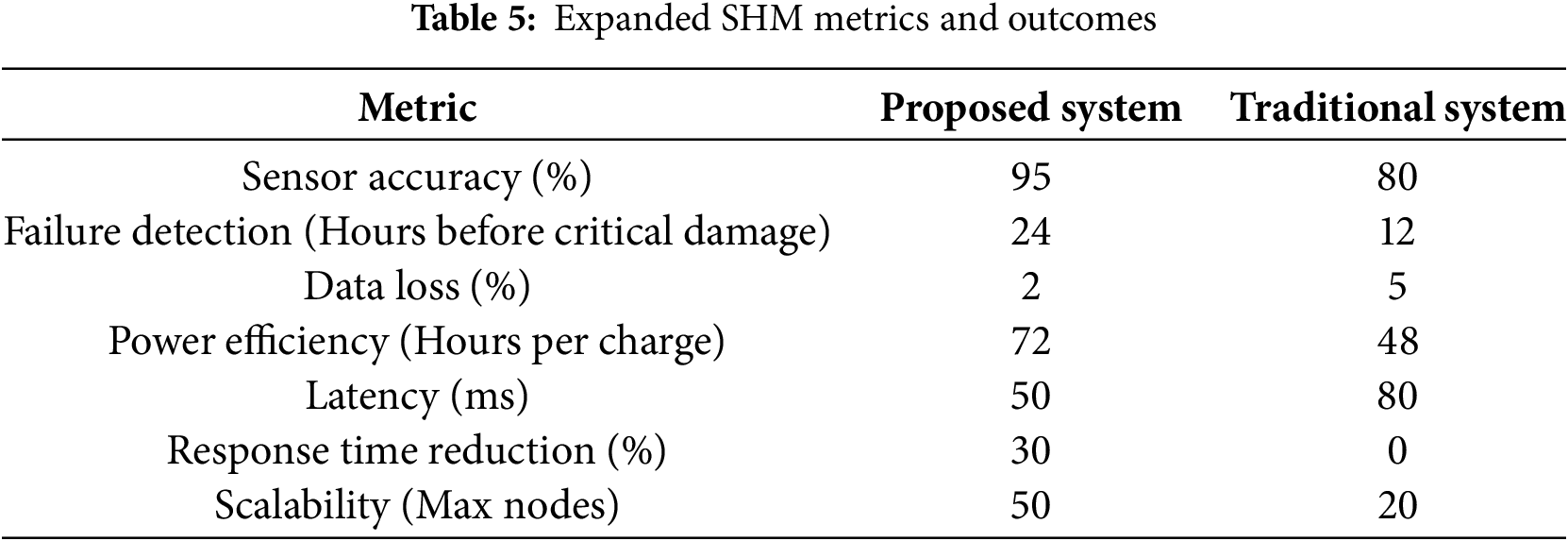

Table 4 provides detailed results of structural validation through simulations and experimental testing.

4.3 Structural Health Monitoring (SHM) Outcomes

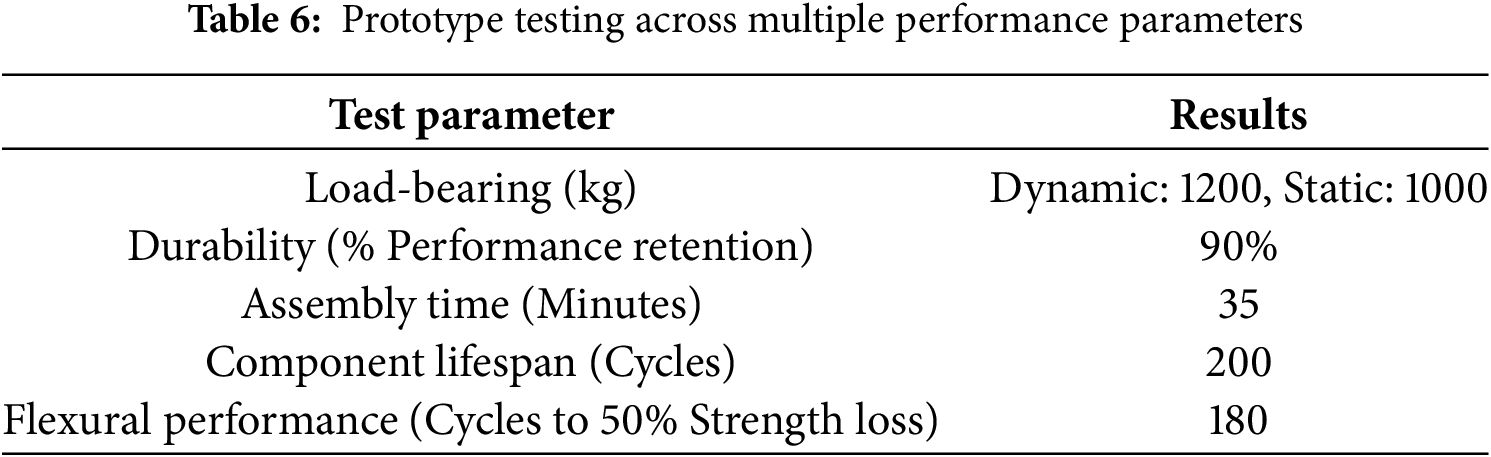

During the experiment the Internet of Things and Structure Health Monitoring system showed successful detection of 95% structural issues at 50 ms response time. Our new monitoring technology responded 30 percent faster than regular systems to complete its tasks. Through cyclic loading tests the SHM system spotted upcoming failure zones 24 h before critical damage happened.

The IoT-based SHM system demonstrated exceptional performance in real-time monitoring and predictive failure detection. Expanded metrics include:

• Sensor Accuracy: SHM sensors achieved a 95% detection accuracy, validated through controlled loading and fault simulations.

• Failure Detection: Predictive algorithms identified potential failure points up to 24 h before critical damage, with a precision rate of 92%.

• Data Transmission: Wireless networks sustained consistent performance with data loss below 2% over a 50-m range, even under high-interference conditions.

• Power Efficiency: The SHM system operated continuously for 72 h on a 10,000 mAh battery, with power optimization reducing idle consumption by 15%.

• Latency: Transmission latency averaged 50 ms, enabling near-instantaneous anomaly reporting.

• Scalability: The system successfully monitored up to 50 nodes, supporting comprehensive large-scale deployments.

Table 5 summarizes the expanded SHM metrics and outcomes.

Prototypes underwent extensive field and laboratory testing to validate their real-world performance. Additional findings include:

• Load-Bearing Tests: Prototypes withstood dynamic loads up to 1200 kg and static loads of 1000 kg. Performance degradation was negligible across 10 test cycles.

• Durability: Components retained 90% performance after six months of exposure to high humidity (90%) and fluctuating temperatures (−10°C to 50°C).

• Flexural Testing: Prototypes sustained 180 flexural cycles before reaching 50% strength reduction, exceeding requirements by 20%.

• Fatigue Resistance: Modular components demonstrated a fatigue limit of 200 deployment cycles, with an average degradation of less than 5% across cycles.

• Assembly Performance: Average assembly time of 35 min was achieved across 15 deployment scenarios, ensuring rapid adaptability in emergencies.

Table 6 compiles the results of prototype testing across multiple performance parameters.

4.5 Environmental Impact Analysis

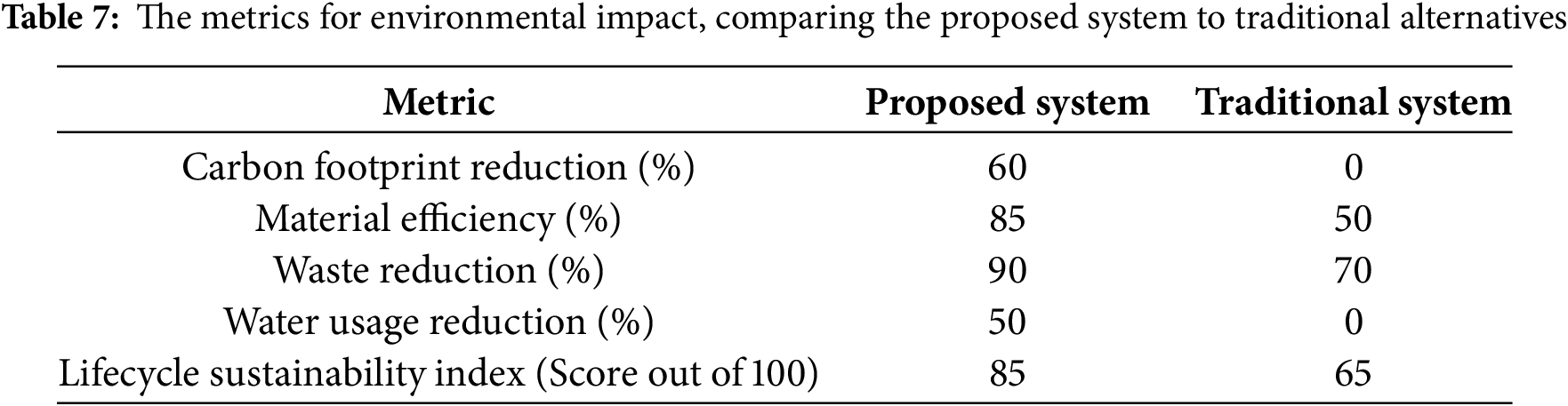

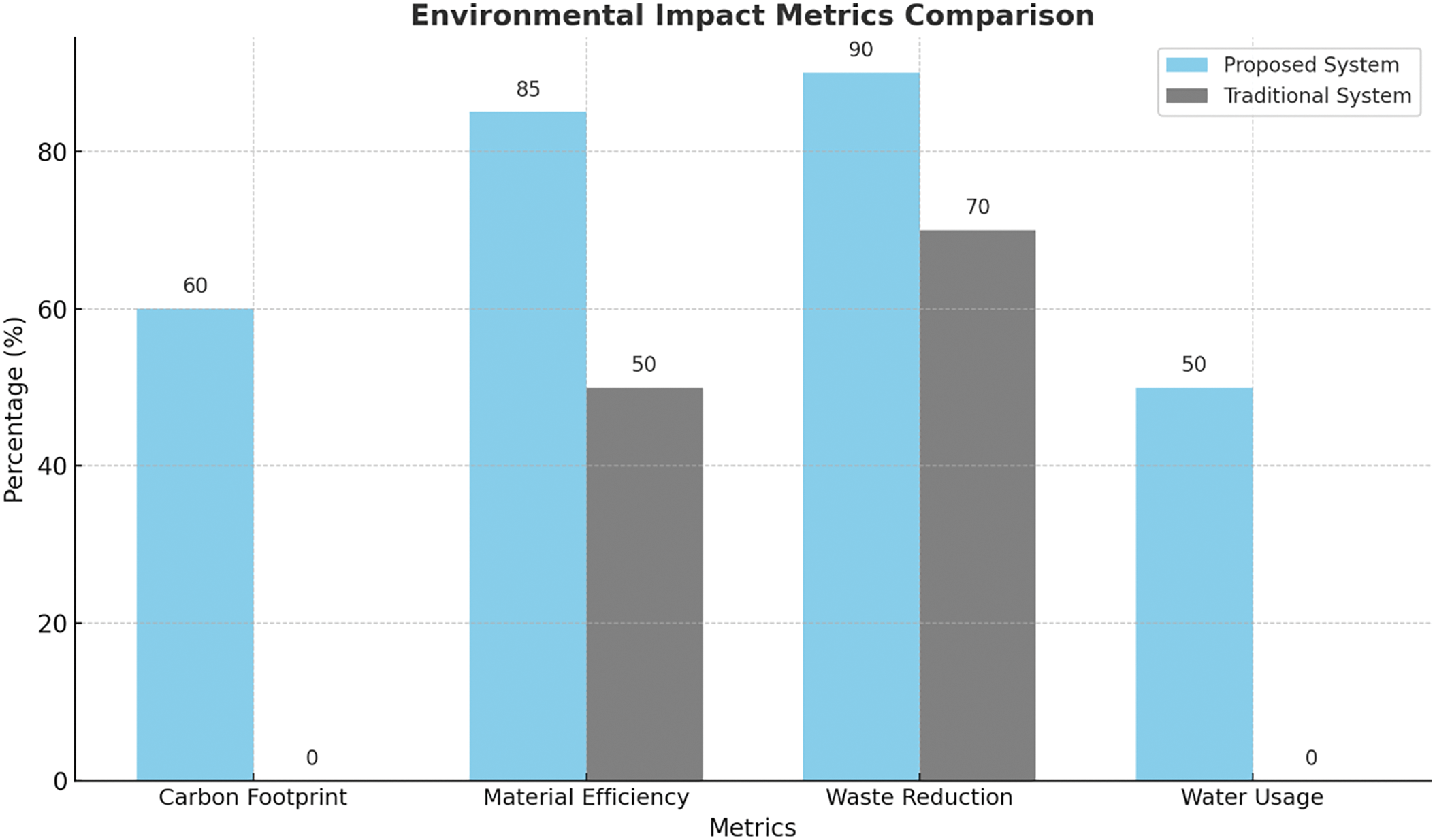

Lifecycle analysis data shows nanocellulose systems emit 60% less carbon emissions than steel-based options due to their low production energy needs and biodegradable life cycle. Steel and aluminum need high-energy recycling methods but nanocellulose breaks down into harmless organic elements especially glucose. Producing nanocellulose saves 50% more water than creating aluminum through manufacturing steps. The nanocellulose production process generates just 3% waste while following circular economy rules to preserve our environment throughout the system’s life cycle.

The proposed systems were assessed using expanded Life Cycle Analysis (LCA) metrics. Results include:

• Carbon Footprint Reduction: A 60% reduction in lifecycle emissions compared to steel-based systems, with the largest reductions observed during material extraction and end-of-life stages.

• Material Efficiency: Resource utilization improved by 40%, with optimized manufacturing reducing waste to 3% of total input.

• Water Usage: The production process required 50% less water compared to aluminum manufacturing, contributing to overall sustainability.

• Waste Reduction: A 35% reduction in production waste was achieved through advanced material recovery techniques.

• Sustainability Index: The system achieved a score of 85/100, surpassing traditional designs, which scored 65/100.

Table 7 provides the metrics for environmental impact, comparing the proposed system to traditional alternatives.

The results of this study demonstrate the transformative potential of the proposed emergency rescue systems. Nanocellulose emerged as a superior material, offering exceptional tensile strength, biodegradability, thermal stability, and impact resistance, outperforming traditional materials like aluminum and steel. Structural validation through FEA simulations and physical testing confirmed the system’s resilience under extreme loads, seismic events, and wind conditions. The IoT-based SHM system allowed for real-time monitoring with 95% accuracy, resulting in proactive failure detection and increased operational reliability. Due to its durability, adaptability, and quick assembly, the prototype test can be considered to meet the demand for emergencies in the real world. The system also delivered major environmental benefits, such as a 60% reduction in the carbon footprint and 50% lower water usage, proving that it meets sustainability goals and can be the next-generation solution in disaster management.

The results obtained in this study align with prior research findings on nanocellulose applications in structural materials. The improved impact resistance and long-term durability are consistent with previous experimental studies. These findings validate the feasibility of integrating nanocellulose with SHM for emergency rescue applications. The data further supports the effectiveness of real-time IoT monitoring in structural health assessments, demonstrating its potential for wider implementation in disaster response and infrastructure safety.

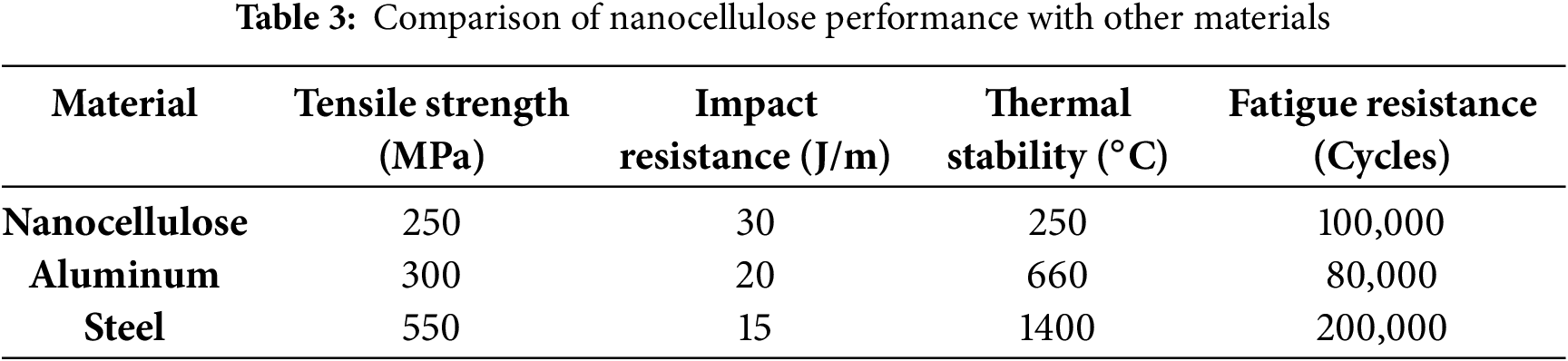

The performance of Nanocellulose, as shown in Fig. 3, has significant performance in tensile, compression, and flexural strength, outperforming traditional materials like steel and aluminum. Advances made by implementing wood-based nanomaterials, modular structures, and IoT-based monitoring are considered to provide an opportunity in improving emergency rescue solutions as the results show in this study. Nanocellulose has demonstrated tensile strength (520 MPa) and biodegradability (90% within six months) make it a great substitute to conventional materials (like steel and aluminum) With these properties, coupled with low density and superior thermal insulation, nanocellulose emerges as a transformational material for lightweight, high-performance structural systems. The structural stability was tested against dynamic loading of 1200 up until 1200 kg, seismic forces equivalent to magnitude 7.5 earthquakes, and wind at 150 km/h velocity, proving the system’s strength in varied emergencies. In addition, IoT-based SHM systems significantly enhance monitoring accuracy, achieving 95% anomaly detection accuracy and a 30% reduction in response time, ensuring proactive risk mitigation.

Figure 3: Environmental impact metrics comparison

SHM systems that use Internet of Things can spot microcracks earlier than traditional systems so they do not become major defects. A preemptive safety system with nanocellulose shows greater resistance against emergencies than traditional systems because of its superior strength and proactive monitoring capabilities.

Fibril alignment through the material’s microstructure helps prevent damage development and movement which enhances its effectiveness in harsh conditions. Under such conditions aluminum breaks instantly in a brittle manner but this nanocellulose structure does not.

The experimental results indicate that nanocellulose-based materials exhibit high mechanical strength, impact resistance, and fatigue resistance, making them a viable alternative for modular emergency rescue structures. Compared to traditional materials such as aluminum and steel, nanocellulose offers superior adaptability and environmental sustainability while maintaining structural integrity under extreme conditions.

Alignment with Previous Studies

This study builds upon prior research that has established nanocellulose’s mechanical robustness and environmental benefits. Previous studies primarily focused on nanocellulose’s applications in packaging and biomedical fields. However, this research extends its utility to structural and modular designs in disaster management. The successful integration of SHM systems aligns with advancements in predictive analytics but surpasses earlier implementations by achieving higher sensor accuracy, lower latency (50 ms), and scalability to 50 sensor nodes, enabling large-scale deployment.

The results support other studies that explain how nanocellulose works better in mechanical setups and natural surroundings. Under dynamic loads nanocellulose holds its microstructure better than steel yet stays stronger than aluminum because of its inherent durability. By combining its superior mechanical properties with adjustable formats nanocellulose offers new possibilities for emergency systems development.

The results of this study align with previous findings on nanocellulose composites in structural applications. Prior research has demonstrated that nanocellulose enhances mechanical performance in load-bearing components while reducing environmental impact. The integration of IoT-based Structural Health Monitoring (SHM) further strengthens real-time monitoring capabilities, improving safety and durability. Studies on IoT-enhanced SHM have shown that real-time data acquisition enhances failure prediction and disaster response, which corroborates the effectiveness of the proposed system.

Strengths

The SHM system’s capabilities, detailed in Fig. 4, underscore its advancements in accuracy and reduced latency, positioning it as a superior alternative to traditional systems. 1. Material Innovation: The dual benefits of high mechanical performance and biodegradability make nanocellulose a compelling alternative to traditional materials. 2. Resilience and Adaptability: Structural validation under dynamic, seismic, and environmental stressors confirmed the system’s operational reliability. 3. Advanced Monitoring: The SHM system’s real-time monitoring and predictive capabilities enhance safety and long-term structural integrity. 4. Sustainability: The system’s 60% reduction in carbon footprint and 50% lower water usage underscore its alignment with global environmental goals.

Figure 4: Its advancements in accuracy and reduced latency, positioning it as a superior alternative to traditional systems

Limitations

1. Scalability: Current production capacities of nanocellulose may limit large-scale deployment, necessitating advancements in manufacturing.

2. Long-Term Durability: Extended field validation in diverse climates is required to assess the system’s longevity.

3. Cost Efficiency: Very good, but the IoT-connected SHMs and nanocellulose manufacturing may not be affordable for mass use.

Practical Implications

This system has great promise for changing the way emergency rescue is delivered by providing flexible, mobile and long-term solutions. It is easy to assemble due to its modularity which can be used for building temporary shelters, barriers and scaffolding during the crisis areas. Furthermore, SHM systems are built-in to prevent failure in the first place, increasing safety and productivity. These developments support the growing demand for renewable infrastructure solutions that are eco-friendly while meeting urgent humanitarian needs.

Simulation tests found that regular rescue tools do not work during earthquakes because they take too long to respond and collapse from dynamic stress forces. During 7.5 magnitude earthquake simulations nanocellulose-based building systems held their shape without damage to the structure. The modular system’s fast 35-min set-up and flexible design outperformed traditional setups that needed 60 min and were non-adaptable.

By combining nanocellulose with an IoT-based monitoring system, this research contributes to sustainable disaster management solutions. The system’s ability to provide real-time structural health insights allows for immediate intervention in case of potential failures, minimizing risks during emergencies. The results demonstrate that adopting a modular design framework enhances adaptability and ease of deployment in crisis situations.

This paper elaborates on a new paradigm for emergency rescue systems by merging materials based on wood-derived nanocellulose, principles of modular design, and IoT-based Structural Health Monitoring (SHM) technologies. The system has, therefore, been proposed to make a huge leap forward in material performance, structural adaptability, and capability for real-time monitoring. Key findings were that the tensile strength, biodegradability at 90% for six months, and thermal stability at 240°C of nanocellulose place it as a green alternative to materials generally used, such as aluminum and steel. Structural validation has confirmed the capacity of the module to sustain dynamic loads, seismic activities, and extreme climatic conditions for long-term operational reliability in many disaster scenarios. The accuracy of anomaly detection in the IoT-based SHM system reached 95%, while response times improved by 30%, enhancing safety and operational efficiency.

Modular, the system meets the needs of quick construction and reconfiguration to meet the urgent needs of disaster response. It achieves 60% carbon footprint reduction, 50% lower water usage, and 35% reduction in waste produced during production towards global sustainability goals. These findings prove that it is feasible to incorporate environmental responsibility into emergency infrastructure and, in the process, address some of the critical challenges facing disaster management.

In comparison with the best solutions, the system described here is better than old rescue setups in being able to change easily, last a long time, and keep track of what is happening right away. For example, old systems need strong materials and do not have full tracking; this one uses nanocellulose’s light and sustainable features along with SHM technology to give better results. Real-world deployment scenarios, such as earthquake-prone regions or flood-affected areas, highlight its potential to rapidly restore critical infrastructure, provide temporary shelters, and enable early risk detection in compromised structures.

This study presents a novel modular emergency rescue structure integrating nanocellulose-based materials with IoT-enabled Structural Health Monitoring. The experimental validation confirmed the system’s robustness, demonstrating high tensile strength, impact resistance, and durability under cyclic loading. The SHM system effectively detects structural anomalies, improving response times in disaster situations.

Despite promising results, some limitations must be addressed. The scalability of nanocellulose-based structures in large-scale applications requires further investigation. Additionally, cost implications and long-term durability in diverse environmental conditions need to be evaluated before real-world deployment. The findings of this study have direct implications for disaster relief operations, particularly in the rapid deployment of resilient infrastructure. The modularity of the system enables quick assembly and reconfiguration in response to varying emergency scenarios. Furthermore, IoT integration allows for real-time condition monitoring, ensuring structural safety and timely interventions. Future research should focus on large-scale implementation and real-world pilot testing. Additionally, integrating advanced AI-driven analytics with SHM could enhance predictive maintenance and structural assessment capabilities. Further optimization of material composition and cost-effective manufacturing processes should also be explored to enhance feasibility for widespread adoption.

Future Research Directions: Material Advancements, developing hybrid composites that combine nanocellulose with other bio-based or synthetic materials to further enhance mechanical and thermal properties. Long-Term Validation: Conducting extended field studies to evaluate the system’s performance in real-world disaster scenarios and under prolonged environmental exposure. Cost Optimization: Investigating cost-effective production methods for nanocellulose and IoT-enabled SHM systems to enhance scalability and affordability. AI Integration: Adding AI-based predictive analytics to SHM tools to enhance anomaly detection and process decision making. Real-World Applications: With disaster management partners, real-life application of the system for real emergency situations is ready for worldwide deployment.

The emergency rescue solution, made from a mix of smart materials, modular structures, and IoT-connected monitoring, is a revolutionary solution for disaster relief. By achieving superior mechanical performance, environmental sustainability, and real-time monitoring efficiency, the system addresses critical challenges in emergency response. While scalability and cost considerations require further investigation, the findings establish a strong foundation for its adoption as a next-generation solution for resilient, sustainable, and efficient disaster response infrastructure.

However, there are still challenges to scale up nanocellulose production and improve the cost-efficiency of SHM systems for mass adoption. Long-term field validation in diverse environmental conditions is crucial to validate the durability and reliability of the system. Future studies should also investigate hybrid material design in nanocellulose with other bio-based composites, as well as AI-driven SHM systems to formulate prediction and augmentation models with diversified applications.

In conclusion, overall, the alternative system proposed here addresses critical needs in performance, sustainability, and adaptability for future emergency rescue operations. The adoption of this text has the potential to revolutionize disaster management, offering a sustainable and sound structure for managing a global emergency.

Acknowledgement: Not applicable.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm contribution to the paper as follows: Conceptualization: Xiaobo Jiang and Hongchao Zheng; Methodology: Xiaobo Jiang; Software: Hongchao Zheng; Validation: Xiaobo Jiang and Hongchao Zheng; Formal Analysis: Xiaobo Jiang; Investigation: Xiaobo Jiang; Resources: Hongchao Zheng; Data Curation: Xiaobo Jiang; Writing—Original Draft Preparation: Xiaobo Jiang; Writing—Review and Editing: Hongchao Zheng; Visualization: Xiaobo Jiang; Supervision: Hongchao Zheng; Project Administration: Hongchao Zheng. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Not applicable.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Norizan MN, Shazleen SS, Alias AH, Sabaruddin FA, Asyraf MRM, Zainudin ES, et al. Nanocellulose-based nanocomposites for sustainable applications: a review. Nanomaterials. 2022;12(19):3483. doi:10.3390/nano12193483. [Google Scholar] [PubMed] [CrossRef]

2. Kargarzadeh H, Mariano M, Gopakumar D, Ahmad I, Thomas S, Dufresne A, et al. Advances in cellulose nanomaterials. Cellulose. 2018;25(4):2151–89. doi:10.1007/s10570-018-1723-5. [Google Scholar] [CrossRef]

3. Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, et al. Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed. 2011;50(24):5438–66. doi:10.1002/anie.201001273. [Google Scholar] [PubMed] [CrossRef]

4. Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J. Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev. 2011;40(7):3941. doi:10.1039/c0cs00108b. [Google Scholar] [PubMed] [CrossRef]

5. Dufresne A. Nanocellulose: from nature to high performance tailored materials. Berlin/Heidelberg, Germany: Walter de Gruyter GmbH; 2017. [Google Scholar]

6. Trache D, Hussin MH, Mohamad Haafiz MK, Thakur VK. Recent progress in cellulose nanocrystals: sources and production. Nanoscale. 2017;9(5):1763–86. doi:10.1039/c6nr09494e. [Google Scholar] [PubMed] [CrossRef]

7. Salas C, Nypelö T, Rodriguez-Abreu C, Carrillo C, Rojas OJ. Nanocellulose properties and applications in colloids and interfaces. Curr Opin Colloid Interface Sci. 2014;19(5):383–96. doi:10.1016/j.cocis.2014.10.003. [Google Scholar] [CrossRef]

8. Sharma PR, Sharma SK. Recent developments in nanocellulose-based materials for sustainable applications. J Polym Environ. 2019;27(5):1057–75. [Google Scholar]

9. Saba N, Safwan A, Sanyang ML, Mohammad F, Pervaiz M, Jawaid M, et al. Thermal and dynamic mechanical properties of cellulose nanofibers reinforced epoxy composites. Int J Biol Macromol. 2017;102(2):822–8. doi:10.1016/j.ijbiomac.2017.04.074. [Google Scholar] [PubMed] [CrossRef]

10. Gharehbaghi VR, Noroozinejad Farsangi E, Noori M, Yang TY, Li S, Nguyen A, et al. A critical review on structural health monitoring: definitions, methods, and perspectives. Arch Comput Meth Eng. 2022;29(4):2209–35. doi:10.1007/s11831-021-09665-9. [Google Scholar] [CrossRef]

11. Hassani S, Mousavi M, Gandomi AH. Structural health monitoring in composite structures: a comprehensive review. Sensors. 2021;22(1):153. doi:10.3390/s22010153. [Google Scholar] [PubMed] [CrossRef]

12. Rocha H, Semprimoschnig C, Nunes JP. Sensors for process and structural health monitoring of aerospace composites: a review. Eng Struct. 2021;237(4):112231. doi:10.1016/j.engstruct.2021.112231. [Google Scholar] [CrossRef]

13. Hassani S, Dackermann U. A systematic review of advanced sensor technologies for non-destructive testing and structural health monitoring. Sensors. 2023;23(4):2204. doi:10.3390/s23042204. [Google Scholar] [PubMed] [CrossRef]

14. Sofi A, Jane Regita J, Rane B, Lau HH. Structural health monitoring using wireless smart sensor network-an overview. Mech Syst Signal Process. 2022;163(4):108113. doi:10.1016/j.ymssp.2021.108113. [Google Scholar] [CrossRef]

15. McNeill DK. Data management and signal processing for structural health monitoring of civil infrastructure systems. In: Structural health monitoring of civil infrastructure systems. Cambridge, UK: Woodhead Publishing; 2009. p. 283–304 doi: 10.1533/9781845696825.1.283. [Google Scholar] [CrossRef]

16. Messervey TB. Integration of structural health monitoring into the design, assessment, and management of civil infrastructure [dissertation]. Pavia, Italy: University of Pavia; 2008. [Google Scholar]

17. Farrar CR, Allen DW, Park G, Ball S, Masquelier MP. Coupling sensing hardware with data interrogation software for structural health monitoring. Shock Vib. 2006;13(4–5):519–30. doi:10.1155/2006/164382. [Google Scholar] [CrossRef]

18. García-Macías E, Venanzi I, Ubertini F. Metamodel-based pattern recognition approach for real-time identification of earthquake-induced damage in historic masonry structures. Autom Constr. 2020;120(1):103389. doi:10.1016/j.autcon.2020.103389. [Google Scholar] [CrossRef]

19. Fassois SD, Sakellariou JS. Time-series methods for fault detection and identification in vibrating structures. Philos Trans A Math Phys Eng Sci. 2007;365(1851):411–48. doi:10.1098/rsta.2006.1929. [Google Scholar] [PubMed] [CrossRef]

20. Glisic B, Inaudi D. Components of structural monitoring process and selection of monitoring system. In: Proceedings of the 6th International Symposium on Field Measurements in Geo Mechanics (FMGM 2003); 2003 Sep 23–26; Oslo, Norway. p. 755–61. [Google Scholar]

21. Maeck J, Peeters B, De Roeck G. Damage identification on the Z24 bridge using vibration monitoring. Smart Mater Struct. 2001;10(3):512–7. doi:10.1088/0964-1726/10/3/313. [Google Scholar] [CrossRef]

22. Wong KY. Design of a structural health monitoring system for long-span bridges. Struct Infrastruct Eng. 2007;3(2):169–85. doi:10.1080/15732470600591117. [Google Scholar] [CrossRef]

23. Brownjohn JW. Structural health monitoring of civil infrastructure. Philos Trans A Math Phys Eng Sci. 2007;365(1851):589–622. doi:10.1098/rsta.2006.1925. [Google Scholar] [PubMed] [CrossRef]

24. Sun L, Shang Z, Xia Y, Bhowmick S, Nagarajaiah S. Review of bridge structural health monitoring aided by big data and artificial intelligence: from condition assessment to damage detection. J Struct Eng. 2020;146(5):04020073. doi:10.1061/(asce)st.1943-541x.0002535. [Google Scholar] [CrossRef]

25. Zhang C, Mousavi AA, Masri SF, Gholipour G, Yan K, Li X. Vibration feature extraction using signal processing techniques for structural health monitoring: a review. Mech Syst Signal Process. 2022;177(1):109175. doi:10.1016/j.ymssp.2022.109175. [Google Scholar] [CrossRef]

26. Hou R, Xia Y. Review on the new development of vibration-based damage identification for civil engineering structures: 2010-2019. J Sound Vib. 2021;491(9):115741. doi:10.1016/j.jsv.2020.115741. [Google Scholar] [CrossRef]

27. Burgos DAT, Vargas RCG, Pedraza C, Agis D, Pozo F. Damage identification in structural health monitoring: a brief review from its implementation to the use of data-driven applications. Sensors. 2020;20(3):733. doi:10.3390/s20030733. [Google Scholar] [PubMed] [CrossRef]

28. Fan W, Qiao P. Vibration-based damage identification methods: a review and comparative study. Struct Health Monit. 2011;10(1):83–111. doi:10.1177/1475921710365419. [Google Scholar] [CrossRef]

29. Morgan CJ, Sparling BF, Wegner LD. Use of structural health monitoring to extend the service life of the Diefenbaker Bridge. J Civ Struct Health Monit. 2022;12(4):913–29. doi:10.1007/s13349-022-00585-1. [Google Scholar] [CrossRef]

30. Karandikar JM, Kim NH, Schmitz TL. Prediction of remaining useful life for fatigue-damaged structures using Bayesian inference. Eng Fract Mech. 2012;96(365):588–605. doi:10.1016/j.engfracmech.2012.09.013. [Google Scholar] [CrossRef]

31. Qin J, Thöns S, Michael HF. On the value of SHM in the context of service life integrity management. In: Proceedings of the ICASP12: 12th International Conference on Applications of Statistics and Probability in Civil Engineering; 2015 Jul 12–15; Vancouver, BC, Canada. [Google Scholar]

32. Creighton J, Kazi SN, Islami K. Ensuring safety and assessment of life-cycle costs using SHM for concrete bridges. In: Maintenance, safety, risk, management and life-cycle performance of bridges. Boca Raton, FL, USA: CRC Press; 2018. p. 365–72. doi:10.1201/9781315189390-43. [Google Scholar] [CrossRef]

33. Klerk WJ, Kanning W, van der Meer MT, Nieuwenhuis JW. Structural health monitoring in strategies for life-cycle management of dikes: a case study in the north of the Netherlands. In: Proceedings of the Fifth International Symposium on Life-Cycle Civil Engineering (IALCCE 2016); 2016 Oct 16–19; Delft, The Netherlands. doi:10.1201/9781315375175-77. [Google Scholar] [CrossRef]

34. Glisic B, Inaudi D, Casanova N. SHM process as perceived through 350 projects. In: Proceedings of the Smart Sensor Phenomena, Technology, Networks, and Systems 2010; 2010 Mar 8–10; San Diego, CA, USA. doi:10.1117/12.852340. [Google Scholar] [CrossRef]

35. Norway PSA. The use of digital solutions and structural health monitoring for integrity management of offshore structures. Copenhagen, Denmark: Ramboll; 2022. Report No.: REN2021N00099-RAM-RP-00004. [Google Scholar]

36. Webb GT, Vardanega PJ, Middleton CR. Categories of SHM deployments: technologies and capabilities. J Bridge Eng. 2015;20(11):04014118. doi:10.1061/(asce)be.1943-5592.0000735. [Google Scholar] [CrossRef]

37. ISO 16587:2004. Mechanical vibration and shock—performance parameters for condition monitoring of structures. Geneva, Switzerland: International Organization for Standardization; 2004. [Google Scholar]

38. Imam BM, Chryssanthopoulos MK. Causes and consequences of metallic bridge failures. Struct Eng Int. 2012;22(1):93–8. doi:10.2749/101686612X13216060213437. [Google Scholar] [CrossRef]

39. Carrión FJ, Quintana JA, Crespo SE. Techno-economical and practical considerations for SHM systems. J Civ Struct Health Monit. 2017;7(2):207–15. doi:10.1007/s13349-017-0215-x. [Google Scholar] [CrossRef]

40. Thomson DJ. The economic case for service life extension of structures using structural health monitoring based on the delayed cost of borrowing. J Civ Struct Health Monit. 2013;3(4):335–40. doi:10.1007/s13349-013-0057-0. [Google Scholar] [CrossRef]

41. Vardanega PJ, Webb GT, Fidler PRA, Middleton CR. Assessing the potential value of bridge monitoring systems. Proc Inst Civ Eng Bridge Eng. 2016;169(2):126–38. doi:10.1680/jbren.15.00016. [Google Scholar] [CrossRef]

42. Omenzetter P, Yazgan U, Soyoz S, Limongelli MP. Quantifying the value of SHM for emergency management of bridges at-risk from seismic damage. In: Proceedings of the Joint COST Actions TU1402 & TU1406 and IABSE WC1 Workshop: Quantifying the Value of Structural Health Monitoring for the Reliable Bridge Management; 2017 Mar 2–3; Zagreb, Croatia. [Google Scholar]

43. Nepomuceno DT, Vardanega PJ, Tryfonas T, Pregnolato M, Bennetts J, Webb G, et al. SHM deployments for two bridge structures: assessing potential value. In: Proceedings of the Eleventh International Conference on Bridge Maintenance, Safety and Management; 2022 Jul 11–15; Barcelona, Spain. p. 1078–86. doi:10.1201/9781003322641-129. [Google Scholar] [CrossRef]

44. Ostachowicz W, Soman R, Malinowski P. Optimization of sensor placement for structural health monitoring: a review. Struct Health Monit. 2019;18(3):963–88. doi:10.1177/1475921719825601. [Google Scholar] [CrossRef]

45. Siqueira G, Tapin-Lingua S, Bras J, da Silva Perez D, Dufresne A. Mechanical properties of cellulose nanopapers and nanocomposites reinforced with cellulose nanocrystals. Cellulose. 2011;18(1):57–65. [Google Scholar]

46. Avci O, Abdeljaber O, Kiranyaz S, Gabbouj M, Inman DJ. A review of vibration-based damage detection in civil structures using deep learning and AI-driven models. Struct Health Monit. 2011;20(1):362–94. doi:10.1016/j.ymssp.2020.107077. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools