Open Access

Open Access

ARTICLE

Experimental Study on Properties of Nano-Silicon Modified Microencapsulated Phase Change Materials Mortar

1 Fujian Academy of Building Research Co., Ltd., Fuzhou, 350025, China

2 Fujian Key Laboratory of Green Building Technology, Fuzhou, 350025, China

3 College of Civil Engineering, Fujian University of Technology, Fuzhou, 350118, China

* Corresponding Author: Wei Zhang. Email:

(This article belongs to the Special Issue: Sustainable and Durable Construction Materials)

Structural Durability & Health Monitoring 2025, 19(6), 1489-1506. https://doi.org/10.32604/sdhm.2025.065997

Received 27 March 2025; Accepted 03 July 2025; Issue published 17 November 2025

Abstract

Incorporating microencapsulated phase change materials (MPCM) into mortar enhances building thermal energy storage for energy savings but severely degrades compressive strength by replacing sand and creating pores. This study innovatively addresses this critical limitation by introducing nano-silicon (NS) as a modifier to fill pores and promote hydration in MPCM mortar. Twenty-five mixes with varying NS content from 0 to 4 weight percent and different MPCM contents were comprehensively tested for flowability, compressive strength, thermal conductivity, thermal energy storage via Differential Scanning Calorimetry, and microstructure via Scanning Electron Microscopy. Key quantitative results showed MPCM reduced mortar consistency while NS had minimal effect. Crucially, although MPCM decreased compressive strength, NS addition significantly counteracted this loss. Increasing NS content from 0 percent to 4 percent enhanced compressive strength by 12.53%, 14.21%, 25.49%, 21.70%, and 40.70%, respectively, across the tested MPCM levels. Thermal conductivity was primarily reduced by higher MPCM content leading to lower conductivity, with NS showing negligible and inconsistent influence. The phase change temperature of the modified mortar matched that of pure MPCM, although its relative latent heat slightly decreased. This work conclusively demonstrates the novel and effective use of nano-silicon, achieving up to a 40.7 percent strength recovery in MPCM mortar while preserving its essential phase change temperature and thermal conductivity reduction capability. This strategy presents a feasible pathway for developing high-performance, energy-efficient building composites.Keywords

The construction industry is one of the three major sectors for energy consumption and CO2 emissions in China. In addition to the significant CO2 emissions generated during construction, temperature regulation in buildings during operation also demands substantial energy consumption and produces considerable CO2 emissions.

The concept of green building has gained increasing attention in recent years. Its primary goal is to reduce energy consumption and carbon emissions. During the building operation, strategies such as thermal insulation for the enclosure structure can be implemented to lower energy usage. For example, by adding materials such as vitrified microbeads into the mortar to form thermal insulation mortar [1], or using thermal insulation brick and block [2] or thermal insulation composite walls [3], the basic idea of these strategies is to reduce the thermal conductivity of the enclosure wall and reduce indoor and outdoor temperature transfer.

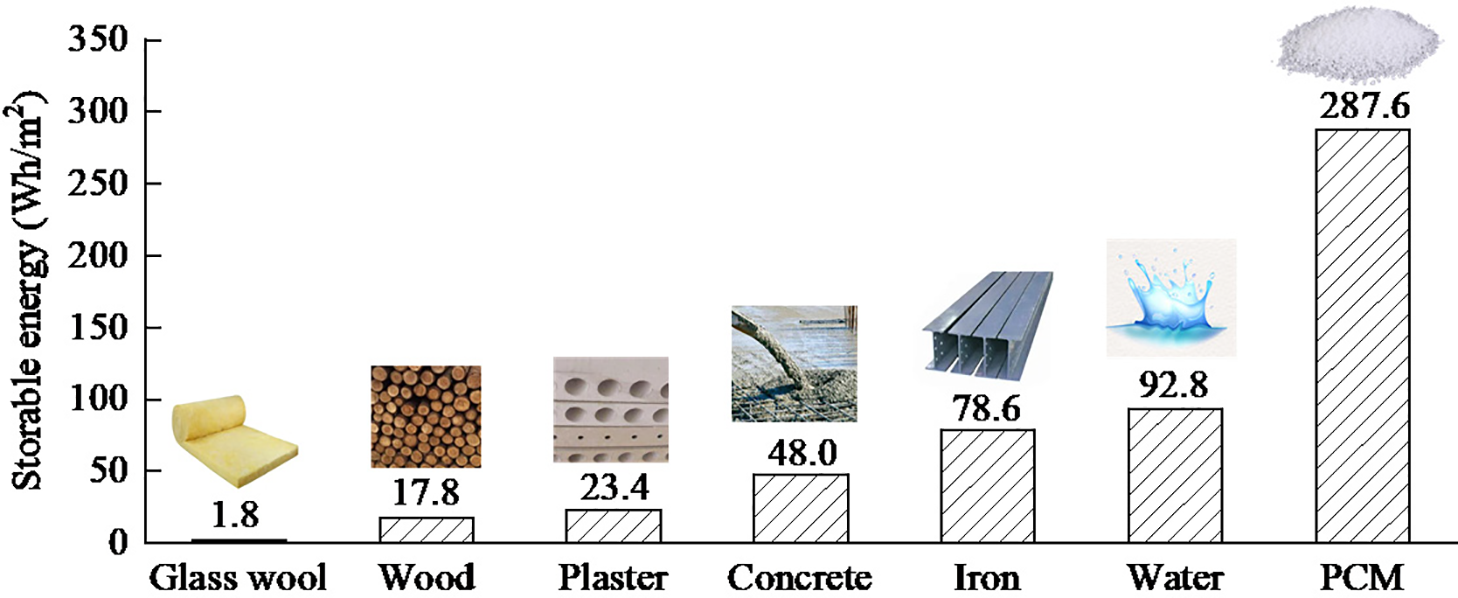

In general, materials have the ability to store and release heat, while different materials have different storable energy. Aridi and Yehya [4] sorted out the storable energy of commonly used construction materials, as shown in Fig. 1. The phase change materials (PCM) for construction have a storable energy of 287.6 Wh/m2, while concrete has 48.0 Wh/m2, and the storable energy of PCM is about six times that of concrete [4,5].

Figure 1: Storable energy of common construction materials

In the phase transition process, phase change materials will store or release energy. This property can be used to store energy and regulate the ambient temperature. If it can be applied to construction materials, a “smart” temperature regulation technology will be formed according to the design needs [6,7]. At present, this strategy has been proven to be feasible by many studies.

Concrete possesses high load-bearing capacity, and incorporating phase change materials (PCMs) can enhance its thermal energy storage capabilities. Al-Yasiri and Szabo [8] investigated large encapsulated PCMs within concrete bricks under various capsule designs. They fabricated eight concrete bricks (including one reference brick without PCM) and evaluated their thermal performance under hot summer conditions in Al Amarah, Iraq. Alsaadawi et al. [9] added varying amounts of microencapsulated fossil wax to different concrete types, examining their setting, hardening, and thermal properties. Their results indicated that increasing PCM content reduced the concrete’s thermal conductivity, increased its heat capacity, and consequently improved its overall thermal performance. However, microstructure analysis revealed that many capsules were damaged during mixing, releasing the paraffin filler into the surrounding matrix and leading to significant strength reduction. Kocyigit et al. [10] developed a novel, environmentally friendly foam concrete incorporating a composite PCM made from saturated capric acid and waste basalt powder. They conducted a comprehensive evaluation of the foam concrete’s morphological, mechanical, physical, and thermal properties. The findings demonstrated that PCM addition reduced the concrete’s dry weight, compressive strength, and flexural strength.

Whether applied to concrete or block walls, plastering with mortar is typically required. Consequently, incorporating phase change materials (PCMs) into the mortar itself is also a viable consideration. Gencel et al. [11] developed a novel cement-based energy storage mortar by replacing 15%, 30%, and 45% of the sand volume with shape-stabilized slag/capric acid PCM. When 45% of the sand was replaced by PCM, the mortar exhibited reductions of 28.57% in bulk density, 85.37% in compressive strength, and 41.25% in thermal conductivity, respectively. Their test results demonstrated that the developed mortar could significantly lower indoor temperatures.

Guo et al. [12] investigated the thermal performance of cement-based mortar blocks incorporating microencapsulated phase change materials (MPCM). Their findings revealed that the distribution of the PCM significantly influenced the blocks’ heat storage and heating properties. Under single heating conditions, the PCM-containing blocks increased heating power consumption by 11.4% to 18% compared to pure mortar blocks.

Whether incorporated into concrete or mortar, PCM must be encapsulated to prevent leakage through the material’s pores and cracks during its liquid phase transition [13–15]. A more significant challenge lies in the inherent properties of the encapsulation materials: their strength and stiffness are typically lower than those of sand, and their hydrophilic nature leads to significant water absorption. This absorption consequently reduces the flowability (workability) of the mortar or concrete mix [16,17]. Moreover, the encapsulating materials will be connected to each other and form an agglomeration phenomenon. These factors will lead to insufficient hydration heat of mortar or concrete and increase porosity, and further result in the deterioration of the strength of the concrete [18–20].

The mechanical properties of MPCM are poor, so it is of great significance for their popularization and application if the properties can be improved. There are some main methods to improve concrete or mortar properties, like adding fiber materials [21], adding auxiliary materials and adding nanomaterials [22,23], etc. Among them, nanomaterials have small particle size, which can fill the pores and micro cracks in MPCM construction materials, and at the same time, nanomaterials can play a lubricating role, and it can improve the flowability of construction mortar, thereby improving the degree of hydration [24–26], for examples, Qian et al. [27] fabricated tantalum-silica biohybrid nanoparticles by coating silica nanoparticles with a layer of tantalum. This tantalum coating not only prevented nanoparticle aggregation but also delayed the pozzolanic reaction between nano-silica and calcium hydroxide in concrete, enabling the particles to effectively fill nanopores within the hydrated cement paste, resulting in a denser microstructure. Khan et al. [28] conducted optimization studies on the dosage and particle size of colloidal nano-silica to develop high-performance, sustainable cement mortar. Their research showed that mortar mixes containing medium and high dosages of NS80 exhibited lower embodied energy per MPa and lower CO2 equivalent strength per MPa, indicating a significant contribution to producing greener concrete with lower environmental impact.

Zhang et al. [29] demonstrated that nano-silica (NS) significantly improves the microstructure, mechanical properties, and durability of metakaolin/fly ash-based geopolymer mortar (GPM). Gao et al. [30] found that adding nano-silica to geopolymer mortar effectively enhanced its bonding performance, with the optimal effect observed at a 2% dosage. Najeeb and Ali Mosaberpanah [31] produced sustainable high-performance mortar using cenospheres (CS) and nano-silica (NS), evaluating the performance of CS and NS in mortar in terms of mechanical properties, durability, and microstructure. The study reported that NS particles increased the drying shrinkage at all ages due to their high pozzolanic activity, and concluded that incorporating 1% NS represented the optimal dosage level for improving the overall performance (mechanical, durability, microstructure).

Collectively, the aforementioned research demonstrates that optimal nano-silica incorporation effectively enhances mortar mechanical properties. However, MPCM mortar exhibits poor fluidity and is prone to agglomeration. Consequently, the potential of nano-silica to improve MPCM-mortar performance, as well as the specific influence of nano-silica content, remains unclear. To address these uncertainties, nano-silica was employed in this study to fill mortar pores, leveraging its characteristic properties. Furthermore, the impact of nano-silica on other critical mortar properties was still unknown. Therefore, an experimental study was conducted on the performance of nano-silica-modified MPCM mortar (termed NS-MPCM mortar). Through microscopic analysis, flowability testing, compressive strength testing, thermal conductivity testing, and DSC testing, this research analyzes the influence mechanism of nano-silica and MPCM addition on the key properties of mortar.

The raw materials of the NS-MPCM mortar include cement, nano-silicon, river sand, microencapsulated phase change materials (MPCM) and water, as shown in Fig. 2.

Figure 2: Raw materials

The P.O. 42.5 Portland cement was used as the cementitious material in NS-MPCM mortar, and the chemical composition of the cement can be found in Table 1. The apparent density of cement was 3.22 g/cm3.

Nano-silicon was provided by Hebei Badu Metal Materials Co., Ltd., with an average particle size of 20 nm.

The natural river sand was used as fine aggregate, and the apparent density of the river sand was 2.50 g/cm3.

2.1.4 Microencapsulated Phase Change Materials (MPCM)

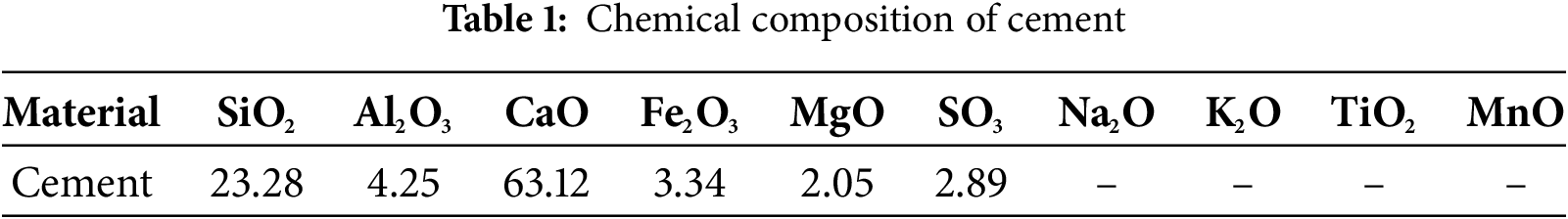

The MPCM used in this study came from Hefei Xinneng Phase Change New Material Co., Ltd., and the apparent density of MPCM was 0.80 g/cm3. This particular MPCM consisted of noctadecane and was encased in a melamine-formaldehyde resin shell. Fig. 3 shows the SEM images of MPCM. It can be seen that MPCM was irregularly spherical and had different particle sizes, ranging from 5 to 25 µm. In addition, it is observed that MPCM presented aggregation, which was due to the cross-linking effect of the shell during the production process.

Figure 3: SEM images of MPCM: (a) ×500; (b) ×1000; (c) ×2000

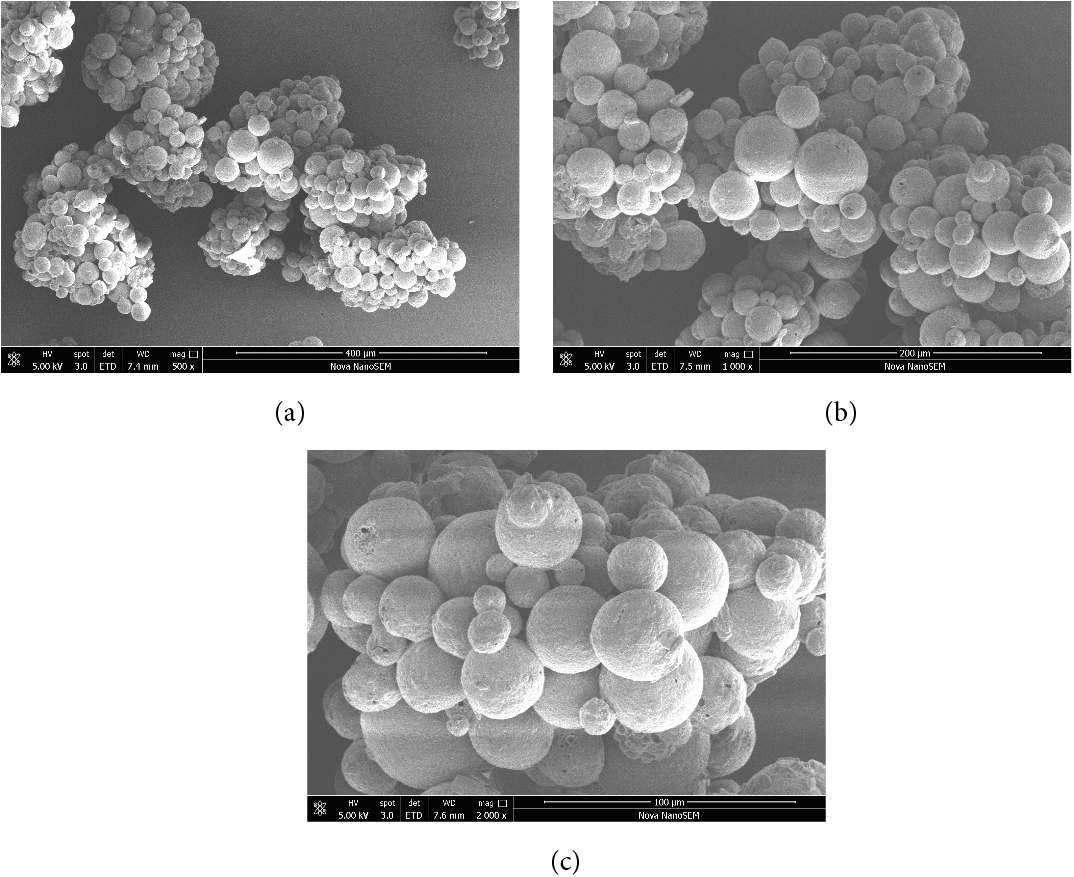

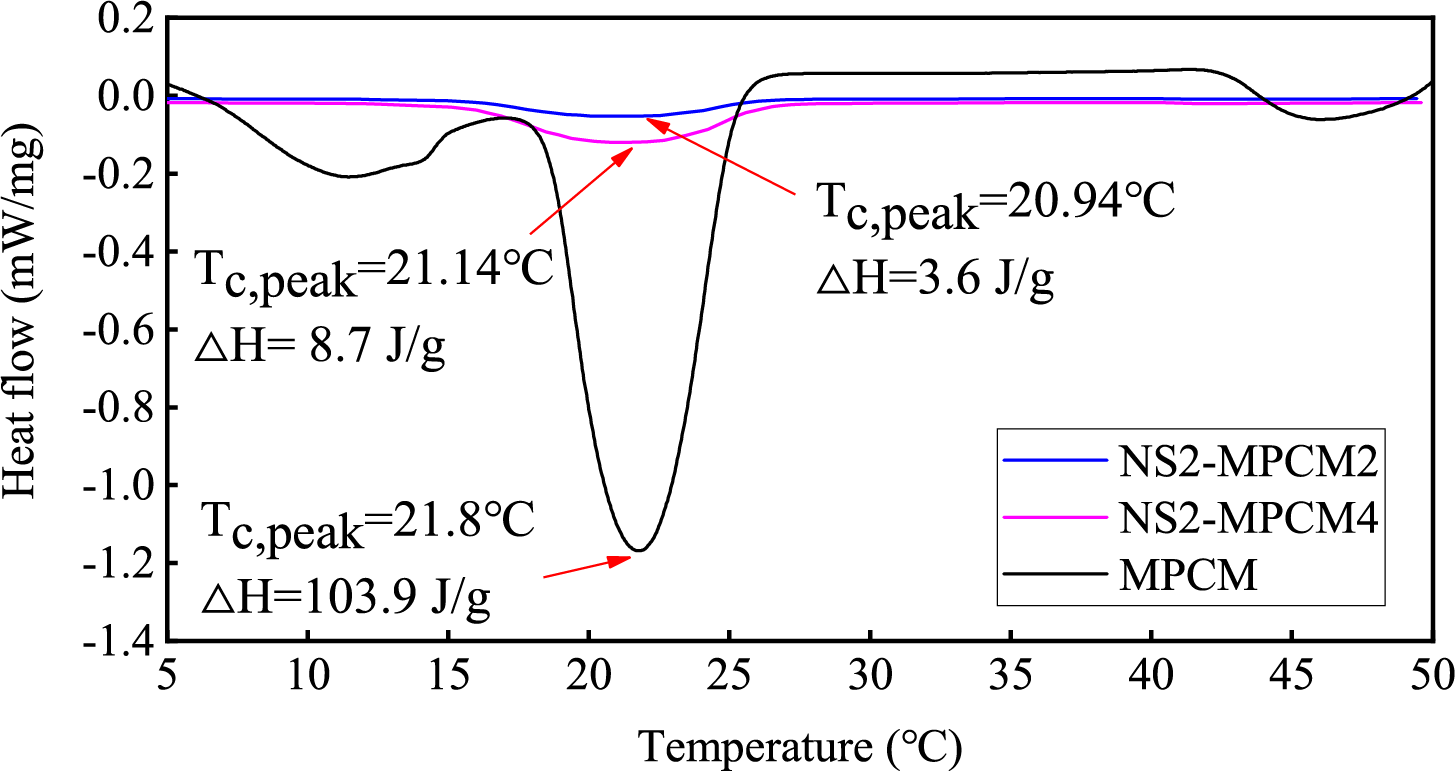

The basic thermal properties of MPCM were characterized using differential scanning calorimetry (DSC) over a temperature range of 5°C–50°C at heating/cooling rates of 3°C/min. The DSC results for MPCM are presented in Fig. 4. The phase transition occurred within the ranges of 24.52°C–31.2°C (melting) and 25.18°C–18.4°C (freezing), with peak temperatures of 28.75°C and 21.8°C, respectively. The corresponding latent heats were 147.4 J/g for melting and 103.9 J/g for freezing. It should be noted that incorporating MPCM into cementitious materials may cause some degree of shell breakage and latent heat loss. Therefore, the focus for building applications lies on the comprehensive latent heat and thermal conductivity of the final cement-based composite, and additional testing of the encapsulated material post-mixing is not typically conducted.

Figure 4: Heat flow of MPCM

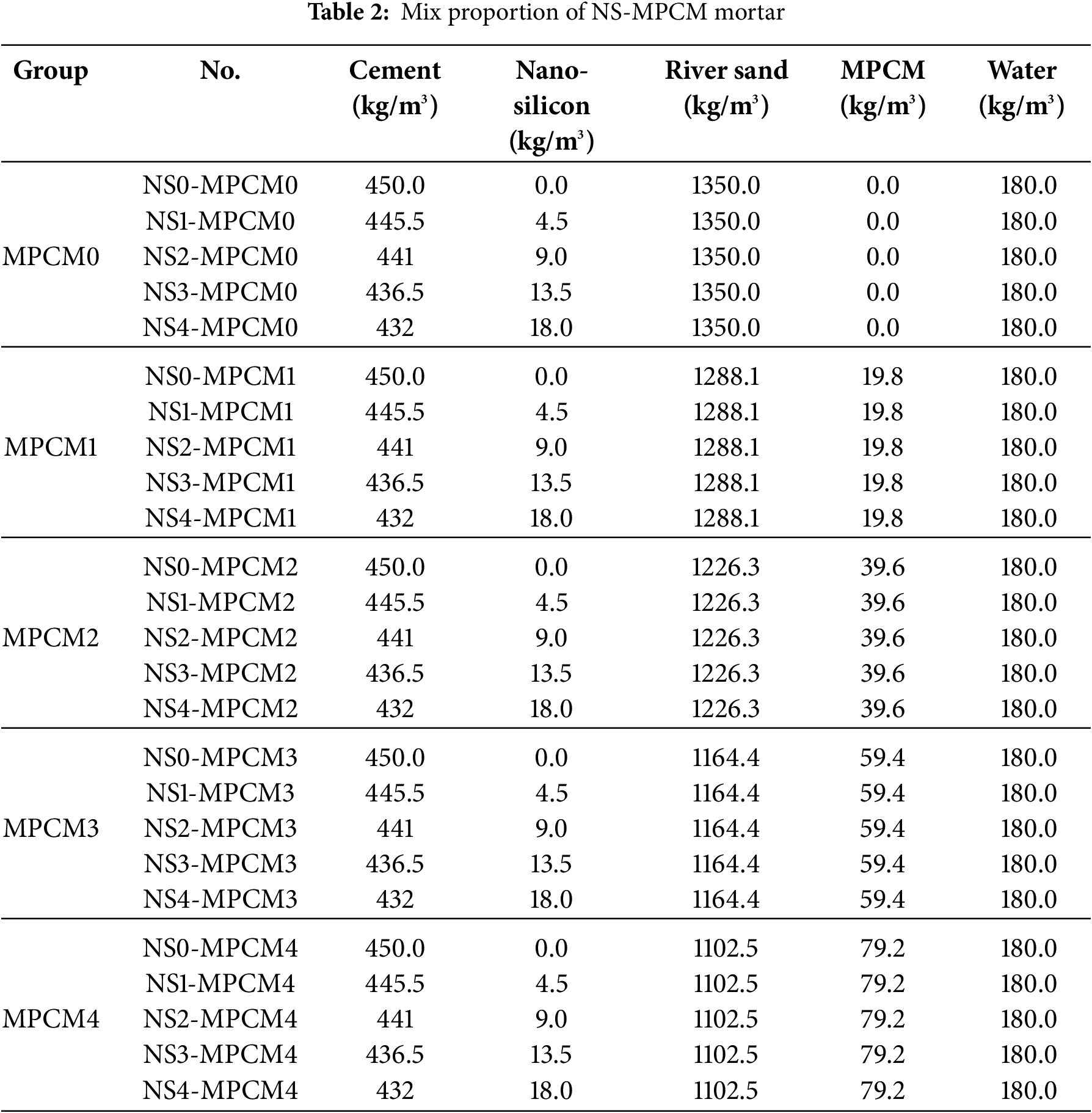

The water-binder ratio of mortar was 3. The main discussion parameters were the contents of nano silicon and MPCM. A total of 25 mixtures were designed, including 5 kinds of nano-silicon content and 5 kinds of MPCM content. The nano-silicon was added into the mixture of mortar by replacing the Portland cement according to the corresponding mass ratio of cement, and the mass ratios were 0%, 1%, 2%, 3% and 4%, respectively. The MPCM was added into the mixture of mortar according to the corresponding mass ratio of mortar, and the mass ratio was 0%, 1%, 2%, 3% and 4%, respectively, and in order to preserve the consistency of the volume, the equal volume of fine aggregate was replaced with MPCM. The mix proportion of NS-MPCM mortar is shown in Table 2, where the number behind NS denotes the percent of NS content, and the number behind MPCM denotes the percent of MPCM content.

Prior to specimen fabrication, all constituent materials were weighed and prepared. The main fabrication procedure involved first dry-mixing sand, Portland cement, and nano-silica (NS) in a mixer for 3 min. Microencapsulated phase change material (MPCM) was then added and mixed for a further 3 min. Following this, water was incorporated and mixing continued for an additional 3 min to achieve homogeneity. The fresh mortar was subsequently placed into molds and compacted by vibration; compression test specimens used 70.7 mm cubic molds, while specimens for thermal performance testing employed molds sized 200 mm × 200 mm × 20 mm. Finally, the molded specimens were moist-cured under natural room temperature conditions for 28 days, with surfaces kept moist through daily water spraying to ensure sufficient water for hydration.

2.3.1 Scanning Electron Microscopy

The microstructure of MPCM and NS-MPCM mortar was obtained by scanning electron microscopy (SEM).

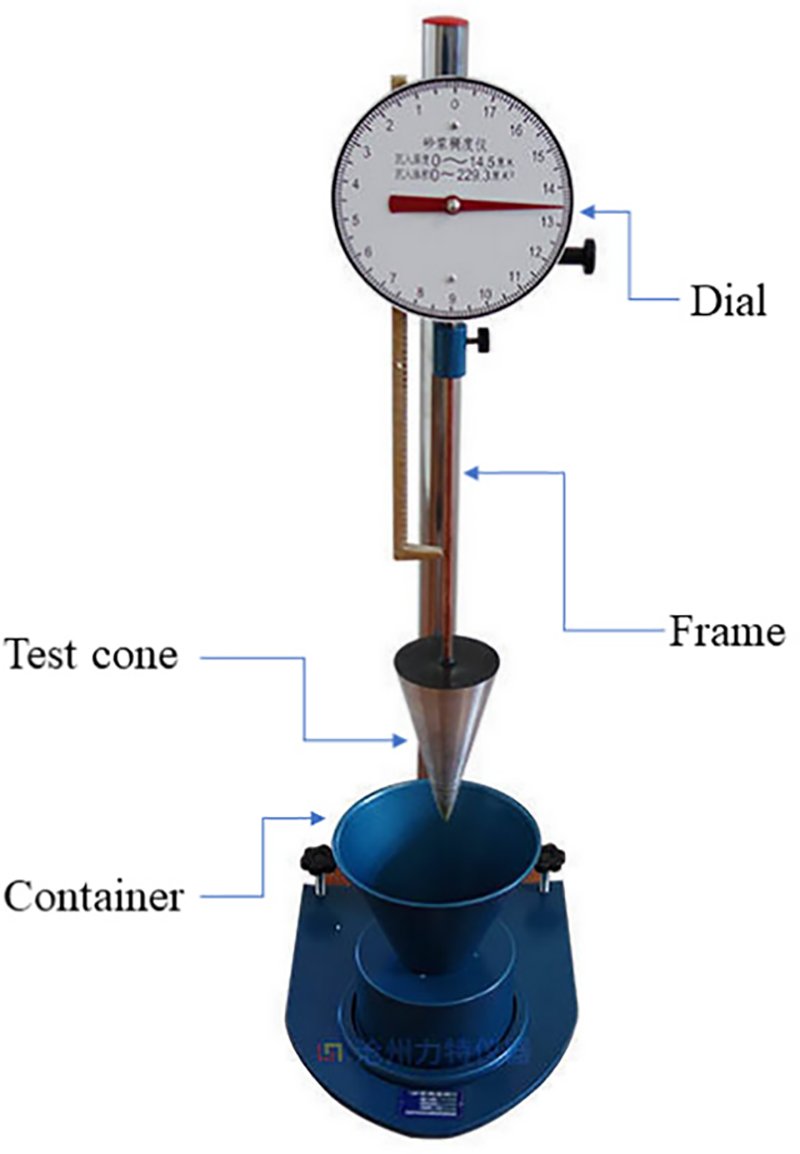

According to guideline JGJ/T 70-2009 [32], a mortar consistency meter (see Fig. 5) was used to test the flowability of NS-MPCM mortar. The mortar consistency-meter consists of three parts: test cone, container, dial, and frame. After the test cone was inserted into the mortar in the container under the action of gravity, the data on the dial could be read to obtain the corresponding consistency. The larger the consistency value, the greater the flowability. The average value of two test results of the same mortar was taken as the measurement value.

Figure 5: Mortar consistency-meter

The compressive strength of the NS-MPCM mortar was tested by 2000 kN electro-hydraulic servo universal testing machine, as shown in Fig. 6. According to the guideline JGJ/T 70-2009 [32], the size of the mortar test block was 70.7 mm cube, each mix ratio contained three test blocks, and the final compressive strength was the average value of the strength of the three test blocks.

Figure 6: Compressive strength test

The thermal conductivities of the MPCM in the solid and liquid states were tested by considering the influence of MPCM phase change on the test results. The left and right heat exchanger temperatures were set to 10°C and 15°C, respectively. After setting the temperature, it was maintained constant for one hour until the heat flux density no longer fluctuated, after which the data were read. The calculation method for thermal conductivity is shown in the following formula [33,34]:

where λ denotes the thermal conductivity, W/m·°C. qave represents the average value of heat flux on both sides of the specimen, W/m2. d denotes the specimen thickness, m. Tr denotes the temperature on the right side of the specimen, °C. Tl denotes the temperature on the left side of the specimen, °C. Because nano silica has little impact on the thermal storage performance of NS-MPCM mortar, and the thermal storage performances of the samples before and after thermal cycling were investigated in the previous works [35], so aspect of performance would no longer be tested. In addition, our previous research results show that the MPCM are difficult to react with cement, but they do crack, which is mainly due to the mechanical effect in the mixing process, and we mainly study the modification of nano silicon on mechanical properties of mortar, therefore, the macroscopic test results were used to characterize the performance of mortar with added MPCM and nano silicon.

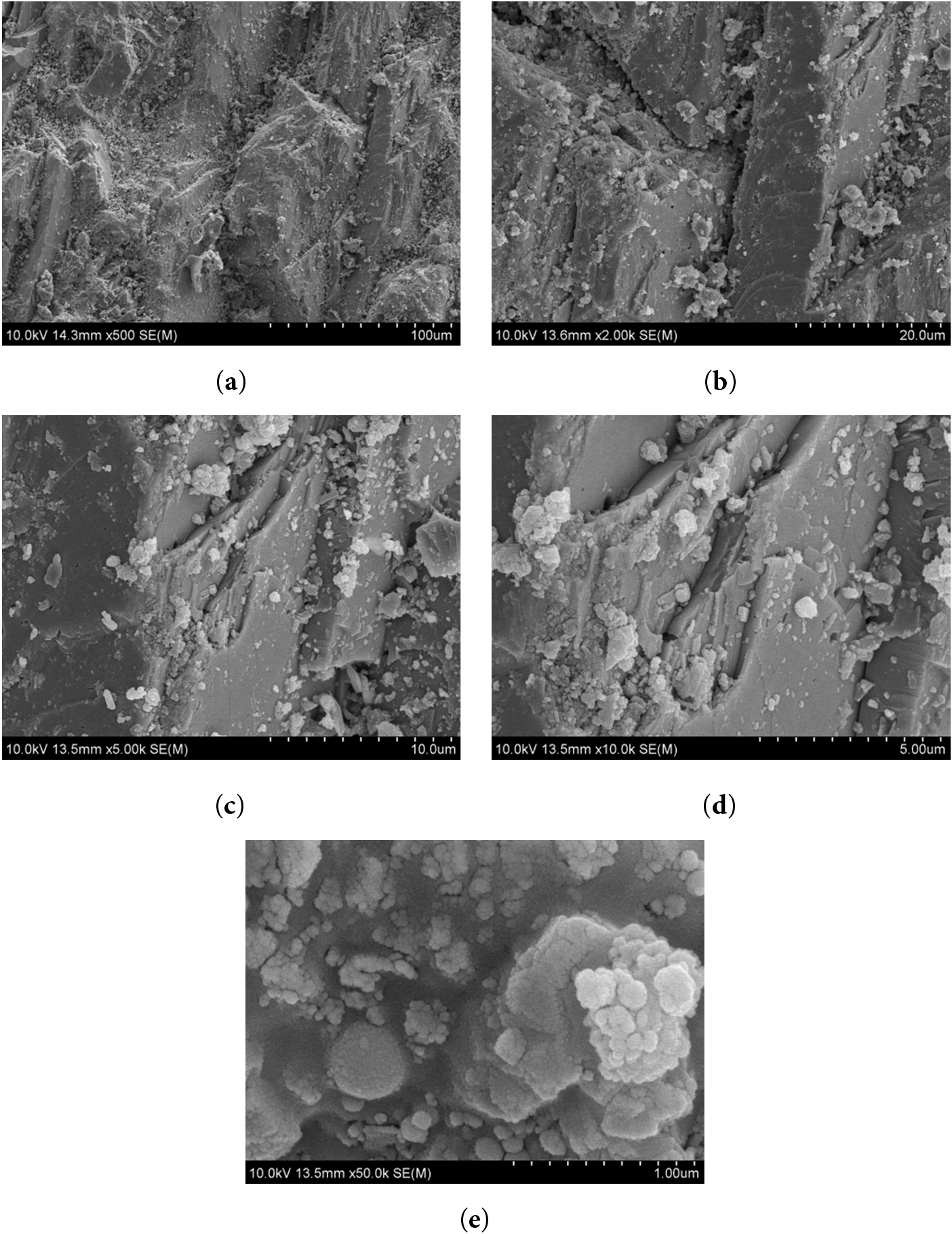

The NS2-MPCM2 mortar specimen was selected for scanning electron microscopy (SEM) analysis, with the results presented in Fig. 7. The micrograph reveals significant C-S-H formation adhering to the fine aggregate, alongside the presence of some cracks within the mortar matrix. Overall, the microstructure of the NS2-MPCM2 mortar showed minimal difference compared to conventional MPCM mortar. Notably, discrete nano-silica particles were not observable in the SEM images. This absence is attributed to two primary factors: firstly, the chemical composition of nano-silica is similar to certain cementitious components, causing it to blend indistinguishably with other hydration products; secondly, any partially hydrated nano-silica particles present may have been below the detection limit due to their extremely small size relative to the surrounding matrix.

Figure 7: SEM images of NS-MPCM mortar: (a) ×500; (b) ×2k; (c) ×5k; (d) ×10k; (e) ×50k

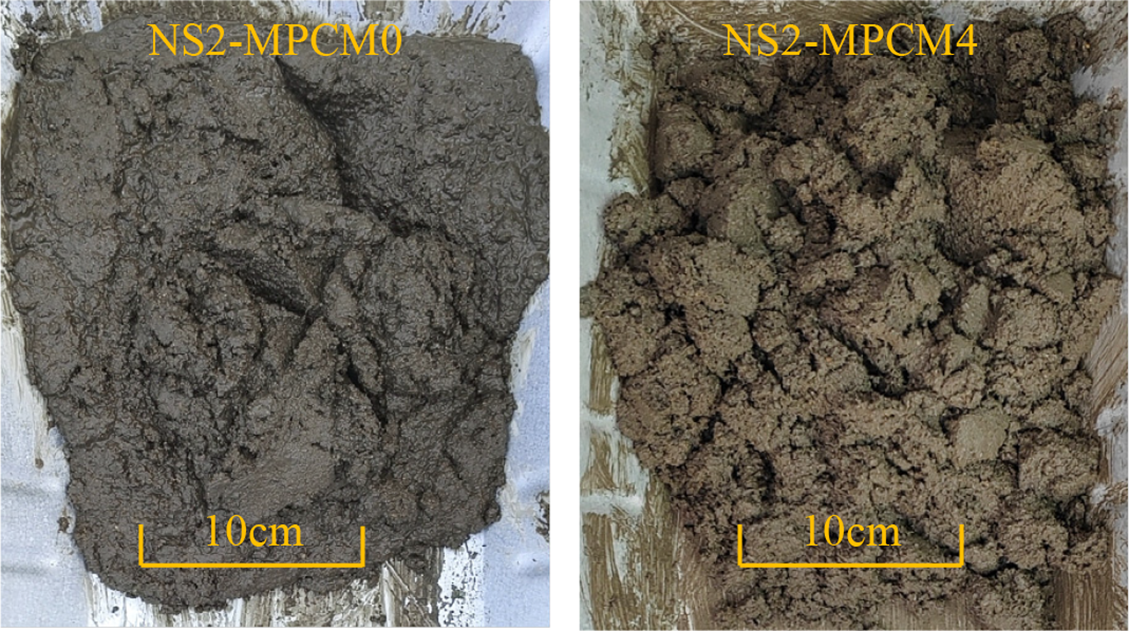

During the preparation of NS-MPCM mortar, increasing the nano-silica (NS) content was observed to have minimal impact on mortar flowability. In contrast, a significant reduction in flowability was observed with increasing microencapsulated phase change material (MPCM) content. Fig. 8 illustrates the contrasting states of mortar corresponding to 0% and 4% MPCM content (both with 2% NS). The NS2-MPCM0 mortar exhibited a thinner consistency with apparent free water visible, whereas the NS2-MPCM4 mortar appeared significantly thicker with no discernible free water.

Figure 8: The state of NS-MPCM mortars

3.2.1 Influence of MPCM Content

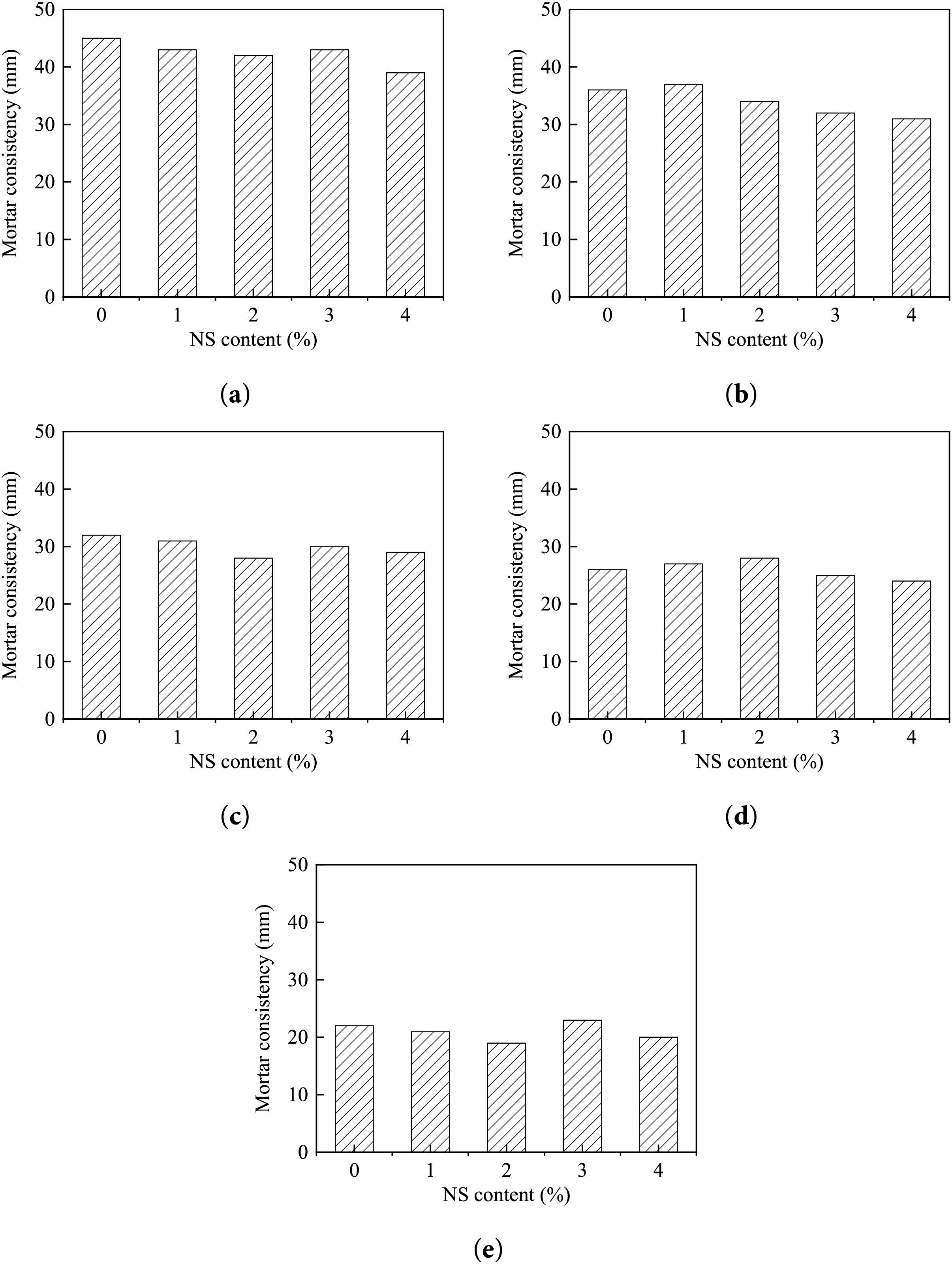

Fig. 9 presents the flow table test results (consistency) for the NS-MPCM mortars. The influence of nano-silica (NS) content on mortar consistency was marginal. In contrast, MPCM content significantly affected consistency. The measured consistency values for mortars with 0%, 1%, 2%, 3%, and 4% MPCM content (by mass) were 39–45 mm, 31–36 mm, 29–32 mm, 24–26 mm, and 20–22 mm, respectively. Compared to the mortar with 0% MPCM, increasing the MPCM content resulted in consistency reductions of 19.82%, 29.20%, 38.62%, and 50.45%, respectively.

Figure 9: Mortar consistency of NS-MPCM mortar: (a) 0% MPCM; (b) 1% MPCM; (c) 2% MPCM; (d) 3% MPCM; (e) 4% MPCM

Unlike the pronounced effect of MPCM dosage, variations in nano-silica (NS) dosage did not exhibit a consistent pattern on mortar fluidity. For example, at MPCM dosages of 1% and 3%, fluidity initially increased, then decreased with increasing NS dosage. Conversely, at MPCM dosages of 2% and 4%, fluidity initially decreased before rising at higher NS dosages. Overall, the incorporation of NS had a minimal effect on the fluidity of MPCM mortar.

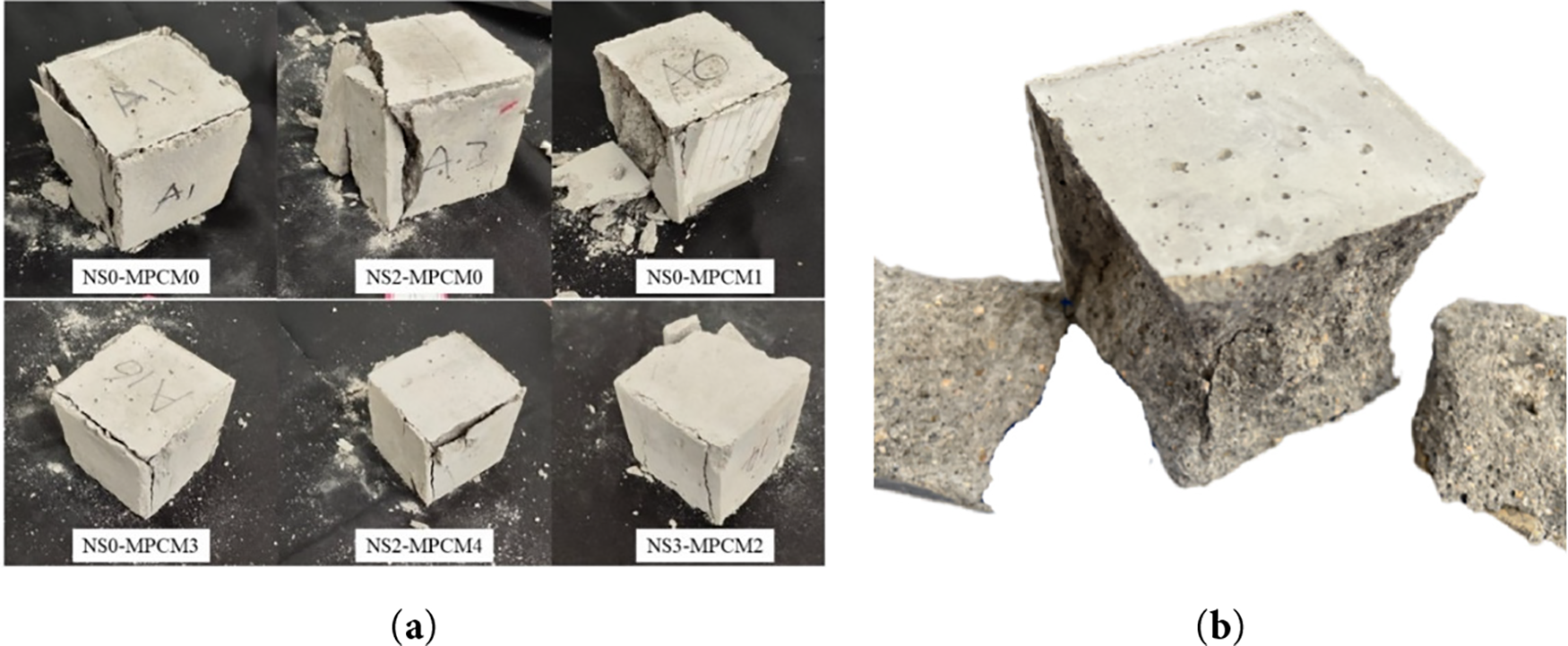

Fig. 10a shows the failure modes of several typical test blocks of NS-MPCM mortar. Compared with conventional mortar (NS0-MPCM0), the compression failure modes of NS-MPCM mortar were similar, all of which show that the mortar was crushed inside, and the surface layer of the mortar test block falls off, as shown in Fig. 10b.

Figure 10: Failure mode of NS-MPCM mortar: (a) failure model of typical test block; (b) the inside of the failure test block

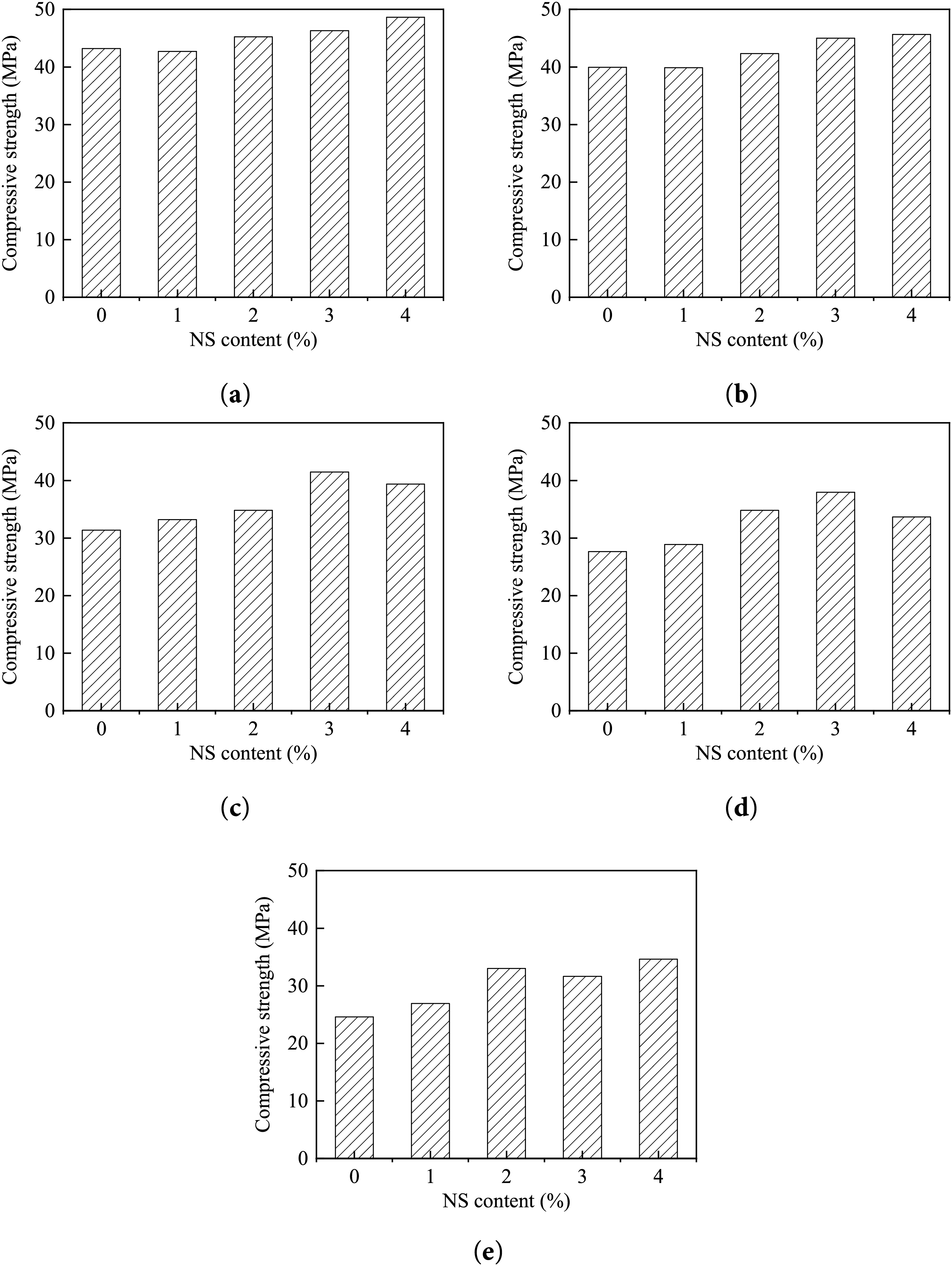

Fig. 11 presents the 28-day compressive strength of NS-MPCM mortar specimens across varying MPCM and nano-silica (NS) contents. Overall, the compressive strength of the MPCM mortar initially increased, then decreased with increasing NS content. For instance, at 2% MPCM content, increasing NS content from 0% to 4% raised compressive strength by 5.8%, 10.9%, 32.2%, and 25.5%, respectively. Similarly, at 3% MPCM content, the corresponding strength increases were 4.5%, 25.9%, 37.3%, and 21.7%. The peak compressive strength consistently occurred at 3% NS content. This enhancement is attributed to NS promoting a more complete hydration reaction and effectively filling pores created by MPCM agglomeration, thereby forming a denser microstructure [34].

Figure 11: Compressive strength of NS-MPCM mortar: (a) 0% MPCM; (b) 1% MPCM; (c) 2% MPCM; (d) 3% MPCM; (e) 4% MPCM

3.3.2 Influence of MPCM Content

Consistent with previous research [30–33], increasing the MPCM content significantly reduced the compressive strength of NS-MPCM mortar. For instance, as the MPCM content increased from 0% to 4%, compressive strength decreased by 43.06%, 37.00%, 27.05%, 31.71%, and 28.81%, respectively. This decline is primarily due to two key factors: firstly, the replacement of harder, stiffer river sand volume with softer, weaker MPCM particles directly diminished the mortar’s strength; secondly, the hydrophilicity of the MPCM shell promoted agglomeration, creating numerous pores and impairing mortar flowability, which led to inadequate hydration and consequently further reduced compressive strength [21,34].

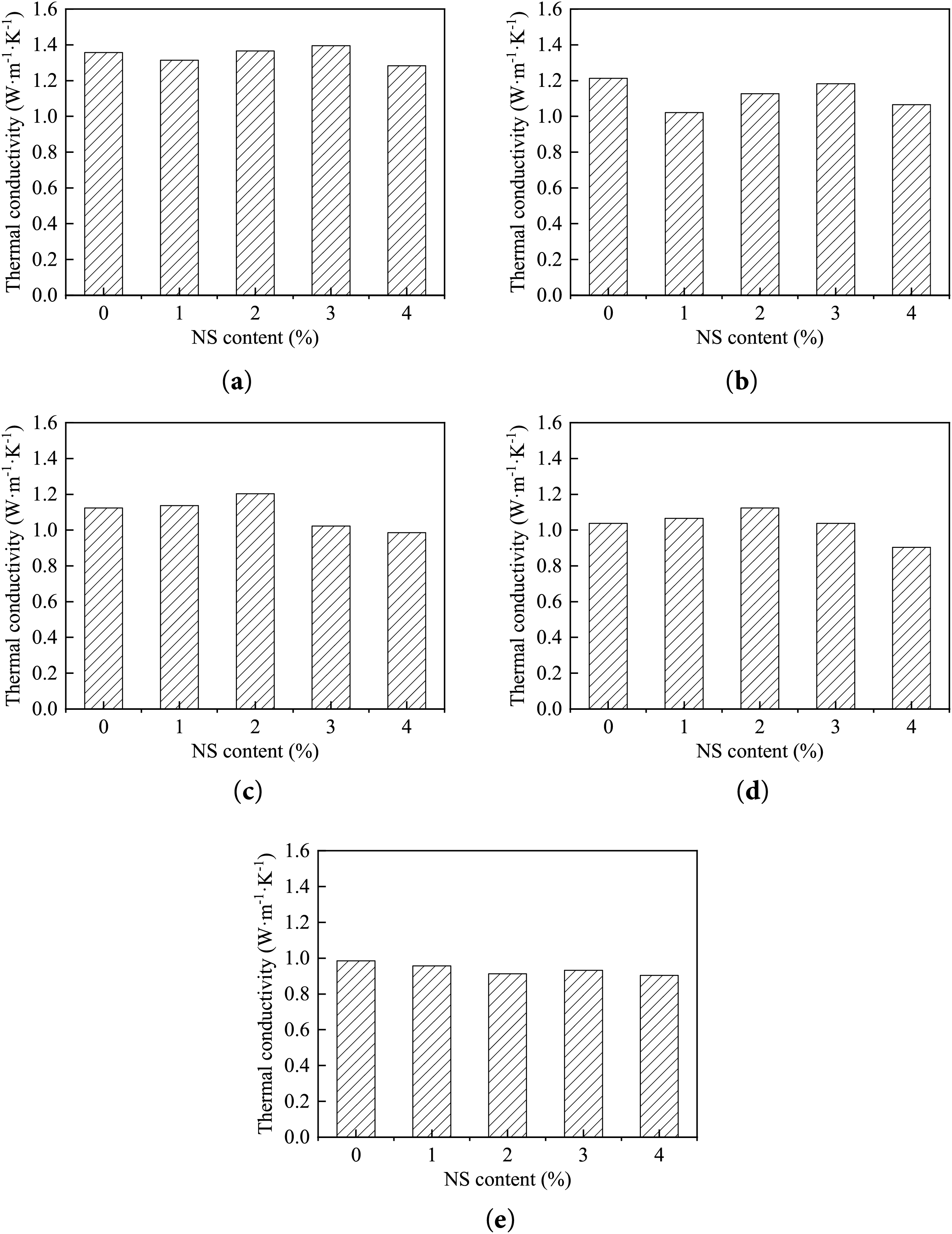

Fig. 12 shows the thermal conductivity of NS-MPCM mortar, which ranged from 0.95 to 1.40 W·m−1·K−1. Comprehensive observation under different MPCM contents reveals that the addition of nano-silicon had a negligible effect on the mortar’s thermal conductivity. These variations could even be attributed to specimen performance dispersion. Although literature suggests thermal conductivity is closely related to porosity [35] and that nano-silicon can effectively fill mortar pores [36], the nano-silicon content was low and primarily filled small cracks, resulting in minimal influence on thermal conductivity.

Figure 12: Thermal conductivity of NS-MPCM mortar: (a) 0% MPCM; (b) 1% MPCM; (c) 2% MPCM; (d) 3% MPCM; (e) 4% MPCM

3.4.2 Influence of MPCM Content

Compared with different MPCM contents, MPCM content significantly affected the thermal conductivity of NS-MPCM mortar. Without nano-silicon, as MPCM content increased from 0% to 4%, thermal conductivity decreased by 10.50%, 17.15%, 23.56%, and 27.35%, respectively. With 1% nano-silicon, thermal conductivity decreased by 22.24%, 13.47%, 18.88%, and 27.19%, respectively. With 2% nano-silicon, thermal conductivity decreased by 17.49%, 11.88%, 17.71%, and 33.18%, respectively. With 3% nano-silicon, thermal conductivity decreased by 15.26%, 26.80%, 25.72%, and 33.17%, respectively. With 4% nano-silicon, thermal conductivity decreased by 16.98%, 23.21%, 29.59%, and 29.43%, respectively.

Although some exceptions existed in the relationship between MPCM content and thermal conductivity, the thermal conductivity of mortar generally decreased as MPCM content increased. This occurred because the hydrophilic shell of MPCM adsorbed substantial water during polymerization, increasing voids within the mortar—a phenomenon also observed by Wang et al. [21]—thereby reducing thermal conductivity.

The DSC curves of MPCM powder, NS2-MPMC2 mortar, and NS2-MPMC4 mortar are shown in Fig. 13. It can be seen that the peak phase transition temperatures of NS2-MPMC2 mortar and NS2-MPMC4 mortar were 20.94°C and 21.14°C, which were very close to that of MPCM powder. Although there were cement, nano-silicon and other materials, they had little influence on the phase change temperature of NS-MPMC mortar, which provides an important guarantee for the feasibility of application of MPMC in building materials.

Figure 13: DSC of MPCM and NS-MPCM mortar

Since the addition of MPCM in the study was based on mass ratio, and the equivalent volume of river sand was replaced by MPCM, and the volume ratio of NS2-MPMC2 and NS2-MPMC4 was about 5.0% and 9.9%, respectively. The latent heats of NS2-MPMC2 mortar and NS2-MPMC4 mortar were 3.6 J/g (3.5% of MPCM) and 8.7 J/g (8.4% of MPCM), respectively, indicating that the latent heat of NS-MPMC mortar will be lost because MPCM may be damaged during the mortar mixing process.

To enhance the mechanical properties of MPCM mortar, nano-silicon was employed as a modifying agent, and a comprehensive series of tests were conducted. NS-MPCM mortars incorporating five different nano-silicon contents and five MPCM dosages were designed and prepared, with subsequent evaluation of their microscopic characteristics, flowability, compressive strength, thermal conductivity, and DSC performance. The principal findings are as follows:

1. The nano-silicon content exhibited minimal impact on the flowability of NS-MPCM mortar. The measured consistencies for mortars containing 0%, 1%, 2%, 3%, and 4% MPCM were 39–45 mm, 31–36 mm, 29–32 mm, 24–26 mm, and 20–22 mm, respectively. Relative to the 0% MPCM reference, the consistency reductions for increasing MPCM contents were 19.82%, 29.20%, 38.62%, and 50.45%, respectively.

2. The compressive failure mode of NS-MPCM mortar specimens closely resembled that of conventional mortar. While higher MPCM content resulted in diminished compressive strength, nano-silicon demonstrated a strengthening effect. As the nano-silicon content increased from 0% to 4%, the corresponding compressive strength improvements were 12.53%, 14.21%, 25.49%, 21.70%, and 40.70%. Maximum strength enhancement was achieved at 3% NS content.

3. The thermal conductivity of NS-MPCM mortar ranged between 0.95 and 1.45 W·m−1·K−1. Nano-silicon content showed negligible influence on thermal conductivity, whereas MPCM incorporation effectively reduced this parameter. Across all nano-silicon variants, increasing MPCM content from 0% to 4% yielded an average thermal conductivity reduction of approximately 30.74%.

4. The phase change temperature characteristics of NS-MPMC mortar remained consistent with those of pure MPCM. At MPCM volume fractions of approximately 5.0% and 9.9% in mortar, the measured latent heat values were about 3.5% and 8.4% of pure MPCM, indicating partial latent heat loss during the mixing process.

This study constitutes fundamental research on phase change mortar material modification, with potential applications in building exterior walls or structures requiring specialized temperature control, thereby improving occupant comfort while reducing energy consumption. Future investigations will focus on NS-MPMC’s comprehensive cost analysis, environmental impact assessment, and material durability evaluation.

Acknowledgement: Specially thanks the professional technical support to the study by the members of our research group, who have provided a stimulating and collaborative environment.

Funding Statement: The work described in this paper is supported by the Fujian Provincial Department of Science and Technology Industrial University Industry-Education Cooperation Project (2022H6009) and the Fujian Province Key Project of Science and Technology Innovation (2022G02025).

Author Contributions: The authors confirm contribution to the paper as follows: study conception: Jian Xia, Xianzhong Hu, Yan Li, Wei Zhang; data collection: Jian Xia, Xianzhong Hu, Yan Li; analysis and interpretation of results: Jian Xia, Xianzhong Hu, Wei Zhang; draft manuscript preparation: Jian Xia, Xianzhong Hu, Yan Li, Wei Zhang. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Data available on request from the authors.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Liu S, Li Q, Zhang J, Zhao K, Wang LA, Zhang Z. Research on mechanical properties of high-strength thermal insulation mortar. Constr Build Mater. 2024;420(5):135260. doi:10.1016/j.conbuildmat.2024.135260. [Google Scholar] [CrossRef]

2. Vijayan DS, Mohan A, Revathy J, Parthiban D, Varatharajan R. Evaluation of the impact of thermal performance on various building bricks and blocks: a review. Environ Technol Innov. 2021;23(5):101577. doi:10.1016/j.eti.2021.101577. [Google Scholar] [CrossRef]

3. Ziapour BM, Rahimi M, Yousefi Gendeshmin M. Thermoeconomic analysis for determining optimal insulation thickness for new composite prefabricated wall block as an external wall member in buildings. J Build Eng. 2020;31(6):101354. doi:10.1016/j.jobe.2020.101354. [Google Scholar] [CrossRef]

4. Aridi R, Yehya A. Review on the sustainability of phase-change materials used in buildings. Energy Convers Manag X. 2022;15(18):100237. doi:10.1016/j.ecmx.2022.100237. [Google Scholar] [CrossRef]

5. Lachheb M, Younsi Z, Youssef N, Bouadila S. Enhancing building energy efficiency and thermal performance with PCM-integrated brick walls: a comprehensive review. Build Environ. 2024;256:111476. doi:10.1016/j.buildenv.2024.111476. [Google Scholar] [CrossRef]

6. da Cunha SRL, de Aguiar JLB. Phase change materials and energy efficiency of buildings: a review of knowledge. J Energy Storage. 2020;27:101083. doi:10.1016/j.est.2019.101083. [Google Scholar] [CrossRef]

7. Faraj K, Khaled M, Faraj J, Hachem F, Castelain C. Phase change material thermal energy storage systems for cooling applications in buildings: a review. Renew Sustain Energy Rev. 2020;119:109579. doi:10.1016/j.rser.2019.109579. [Google Scholar] [CrossRef]

8. Al-Yasiri Q, Szabó M. Thermal performance of concrete bricks based phase change material encapsulated by various aluminium containers: an experimental study under Iraqi hot climate conditions. J Energy Storage. 2021;40:102710. doi:10.1016/j.est.2021.102710. [Google Scholar] [CrossRef]

9. Alsaadawi MM, Amin M, Tahwia AM. Thermal, mechanical and microstructural properties of sustainable concrete incorporating phase change materials. Constr Build Mater. 2022;356:129300. doi:10.1016/j.conbuildmat.2022.129300. [Google Scholar] [CrossRef]

10. Kocyigit F, Bayram M, Hekimoglu G, Cay VV, Gencel O, Ustaoglu A, et al. Thermal energy saving and physico-mechanical properties of foam concrete incorporating form-stabilized basalt powder/capric acid based composite phase change material. J Clean Prod. 2023;414(9):137617. doi:10.1016/j.jclepro.2023.137617. [Google Scholar] [CrossRef]

11. Gencel O, Yaras A, Hekimoğlu G, Ustaoglu A, Erdogmus E, Sutcu M, et al. Cement based-thermal energy storage mortar including blast furnace slag/capric acid shape-stabilized phase change material: physical, mechanical, thermal properties and solar thermoregulation performance. Energy Build. 2022;258(1):111849. doi:10.1016/j.enbuild.2022.111849. [Google Scholar] [CrossRef]

12. Guo J, Jiang Y, Wang Y, Zou B. Thermal storage and thermal management properties of a novel ventilated mortar block integrated with phase change material for floor heating: an experimental study. Energy Convers Manag. 2020;205(10):112288. doi:10.1016/j.enconman.2019.112288. [Google Scholar] [CrossRef]

13. Brooks AL, Fang Y, Shen Z, Wang J, Zhou H. Enabling high-strength cement-based materials for thermal energy storage via fly-ash cenosphere encapsulated phase change materials. Cem Concr Compos. 2021;120:104033. doi:10.1016/j.cemconcomp.2021.104033. [Google Scholar] [CrossRef]

14. Rahi MF, Arıcı M, Abdulateef AM, Niyas H. Numerical investigation and optimization of macro-encapsulated phase change material capsules in building roof slab. J Energy Storage. 2023;68:107806. doi:10.1016/j.est.2023.107806. [Google Scholar] [CrossRef]

15. Kumar D, Alam M, Sanjayan J, Haris M. Comparative analysis of form-stable phase change material integrated concrete panels for building envelopes. Case Stud Constr Mater. 2023;18(5):e01737. doi:10.1016/j.cscm.2022.e01737. [Google Scholar] [CrossRef]

16. Gencel O, Hekimoğlu G, Sarı A, Sutcu M, Er Y, Ustaoglu A. A novel energy-effective and carbon-emission reducing mortars with bottom ash and phase change material: physico-mechanical and thermal energy storage characteristics. J Energy Storage. 2021;44:103325. doi:10.1016/j.est.2021.103325. [Google Scholar] [CrossRef]

17. Qu Y, Chen J, Liu L, Xu T, Wu H, Zhou X. Study on properties of phase change foam concrete block mixed with paraffin/fumed silica composite phase change material. Renew Energy. 2020;150:1127–35. doi:10.1016/j.renene.2019.10.073. [Google Scholar] [CrossRef]

18. Rebelo F, Figueiredo A, Vicente R, Ferreira VM. Study of a thermally enhanced mortar incorporating phase change materials for overheating reduction in buildings. J Energy Storage. 2022;46:103876. doi:10.1016/j.est.2021.103876. [Google Scholar] [CrossRef]

19. Ren M, Liu Y, Gao X. Incorporation of phase change material and carbon nanofibers into lightweight aggregate concrete for thermal energy regulation in buildings. Energy. 2020;197(3):117262. doi:10.1016/j.energy.2020.117262. [Google Scholar] [CrossRef]

20. Sharshir SW, Joseph A, Elsharkawy M, Hamada MA, Kandeal AW, Elkadeem MR, et al. Thermal energy storage using phase change materials in building applications: a review of the recent development. Energy Build. 2023;285(1):112908. doi:10.1016/j.enbuild.2023.112908. [Google Scholar] [CrossRef]

21. Wang Y, Li L, Feng X, Zheng X, Wu Q. Sustainable utilization of fly ash for phase-change geopolymer mortar reinforced by fibers. Constr Build Mater. 2024;412(9-10):134814. doi:10.1016/j.conbuildmat.2023.134814. [Google Scholar] [CrossRef]

22. Raheem AA, Abdulwahab R, Kareem MA. Incorporation of metakaolin and nanosilica in blended cement mortar and concrete—a review. J Clean Prod. 2021;290(5):125852. doi:10.1016/j.jclepro.2021.125852. [Google Scholar] [CrossRef]

23. Gencel O, Subasi S, Ustaoglu A, Sarı A, Marasli M, Hekimoğlu G, et al. Development, characterization and thermo-regulative performance of microencapsulated phase change material included-glass fiber reinforced foam concrete as novel thermal energy effective-building material. Energy. 2022;257(8):124786. doi:10.1016/j.energy.2022.124786. [Google Scholar] [CrossRef]

24. Wang X, Li W, Luo Z, Wang K, Shah SP. A critical review on phase change materials (PCM) for sustainable and energy efficient building: design, characteristic, performance and application. Energy Build. 2022;260(1):111923. doi:10.1016/j.enbuild.2022.111923. [Google Scholar] [CrossRef]

25. Garg R, Garg R, Bansal M, Aggarwal Y. Experimental study on strength and microstructure of mortar in presence of micro and nano-silica. Mater Today Proc. 2021;43:769–77. doi:10.1016/j.matpr.2020.06.167. [Google Scholar] [CrossRef]

26. Shah KW, Ong PJ, Chua MH, Toh SHG, Lee JJC, Soo XYD, et al. Application of phase change materials in building components and the use of nanotechnology for its improvement. Energy Build. 2022;262(2):112018. doi:10.1016/j.enbuild.2022.112018. [Google Scholar] [CrossRef]

27. Qian X, Wang J, Wang L, Fang Y, Chen P, Li M. A clean dispersant for nano-silica to enhance the performance of cement mortars. J Clean Prod. 2022;371(4):133647. doi:10.1016/j.jclepro.2022.133647. [Google Scholar] [CrossRef]

28. Khan K, Johari MAM, Amin MN, Iqbal M. Evaluation of the mechanical properties, microstructure, and environmental impact of mortar incorporating metakaolin, micro and nano-silica. Case Stud Constr Mater. 2024;20(3–4):e02699. doi:10.1016/j.cscm.2023.e02699. [Google Scholar] [CrossRef]

29. Zhang P, Han X, Guo J, Hu S. High-temperature behavior of geopolymer mortar containing nano-silica. Constr Build Mater. 2023;364(6):129983. doi:10.1016/j.conbuildmat.2022.129983. [Google Scholar] [CrossRef]

30. Gao Z, Zhang P, Wang J, Wang K, Zhang T. Interfacial properties of geopolymer mortar and concrete substrate: effect of polyvinyl alcohol fiber and nano-SiO2 contents. Constr Build Mater. 2022;315(13):125735. doi:10.1016/j.conbuildmat.2021.125735. [Google Scholar] [CrossRef]

31. Najeeb Z, Ali Mosaberpanah M. Mechanical and durability properties of modified high-performance mortar by using cenospheres and nano-silica. Constr Build Mater. 2023;362(3):129782. doi:10.1016/j.conbuildmat.2022.129782. [Google Scholar] [CrossRef]

32. JGJ/T 70-2009. Standard for test method of performance on building mortar. Beijing, China: Ministry of Housing and Urban-Rural Development of the Pepople’s Republic of China; 2009. (In Chinese). [Google Scholar]

33. Pilehvar S, Szczotok AM, Rodríguez JF, Valentini L, Lanzón M, Pamies R, et al. Effect of freeze-thaw cycles on the mechanical behavior of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Constr Build Mater. 2019;200(7):94–103. doi:10.1016/j.conbuildmat.2018.12.057. [Google Scholar] [CrossRef]

34. Zhan PM, He ZH, Ma ZM, Liang CF, Zhang XX, Abreham AA, et al. Utilization of nano-metakaolin in concrete: a review. J Build Eng. 2020;30(6):101259. doi:10.1016/j.jobe.2020.101259. [Google Scholar] [CrossRef]

35. Wei J, Zhang H, Zhang W, Liu X, Yang Y. Enhancing thermal performance of energy storage concrete through MPCM integration: an experimental study. J Build Eng. 2024;91:109533. doi:10.1016/j.jobe.2024.109533. [Google Scholar] [CrossRef]

36. Djamai ZI, Salvatore F, Si Larbi A, Cai G, El Mankibi M. Multiphysics analysis of effects of encapsulated phase change materials (PCMs) in cement mortars. Cem Concr Res. 2019;119(5):51–63. doi:10.1016/j.cemconres.2019.02.002. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools