Open Access

Open Access

REVIEW

A Decade of Digital Twins in Materials Science and Engineering

Technology, Instruction and Design in Engineering and Education Research Group (TiDEE.rg), Catholic University of Ávila, C/Canteros s/n, Ávila, 05005, Spain

* Corresponding Author: Diego Vergara. Email:

Computers, Materials & Continua 2025, 85(1), 41-64. https://doi.org/10.32604/cmc.2025.067881

Received 15 May 2025; Accepted 21 July 2025; Issue published 29 August 2025

Abstract

Digital twins (DTs) are rapidly emerging as transformative tools in materials science and engineering, enabling real-time data integration, predictive modeling, and virtual testing. This study presents a systematic bibliometric review of 1106 peer-reviewed articles published in the last decade in Scopus and Web of Science. Using a five-stage methodology, the review examines publication trends, thematic areas, citation metrics, and keyword patterns. The results reveal exponential growth in scientific output, with Materials Theory, Computation, and Data Science as the most represented area. A thematic analysis of the most cited documents identifies four major research streams: foundational frameworks, DTs in additive manufacturing, sector-specific applications, and intelligent production systems. Keyword co-occurrence and strategic mapping show a strong foundation in modeling, simulation, and optimization, with growing links to machine learning and sustainability. The review highlights current challenges and proposes future research directions for advancing DTs in materials science.Keywords

Supplementary Material

Supplementary Material FileIn recent years, virtual reality (VR) has expanded the possibilities of teaching in technical careers, where there is a heavy load of practical classes taught in laboratories. In fact, there seems to be a growing trend towards the use of virtual laboratories by educational institutions. One of the most developed knowledge areas in this aspect is engineering, where there is evidence of the implementation of virtual reality applications in different fields: architecture, construction engineering, mining engineering, automotive engineering, chemical engineering, mechanical engineering, engineering education, and materials science [1–5]. While VR has enhanced experiential learning in engineering disciplines, digital twins (DTs) represent a more comprehensive and intelligent integration of physical systems and digital technologies. Unlike VR, which emphasizes visualization, DTs focus on simulation, optimization, and autonomous control, making them a foundational pillar of Industry 4.0.

On the other hand, within this virtual world of training, DTs have emerged as one of the key technologies of Industry 4.0 [6]. However, there seems to be no clear definition, being recognized, for example, as a multi-scale, multiphysics, probabilistic, ultra-fidelity integrated simulation that replicates the behavior of its physical counterpart [7] and, in other cases, a distinction is made between digital models, digital shadows and DTs depending on the level of integration between physical and digital entities [8]. In this regard, DTs consist of three core components: (i) a physical entity or system; (ii) a virtual representation developed through simulation and computational modeling; and (iii) a real-time data link enabling synchronization between the physical and digital realms. This architecture supports continuous monitoring, predictive analysis, and autonomous decision-making. Key operational processes in DT systems include sensor-based data acquisition, real-time analytics, multiphysics simulations, and feedback mechanisms, that often enhanced through artificial intelligence and cloud computing platforms. Nowadays, it seems to be recognized that a DT must have the ability to quickly interpret contextual data in real time and modify their behavior accordingly when abrupt changes occur in their surroundings [9].

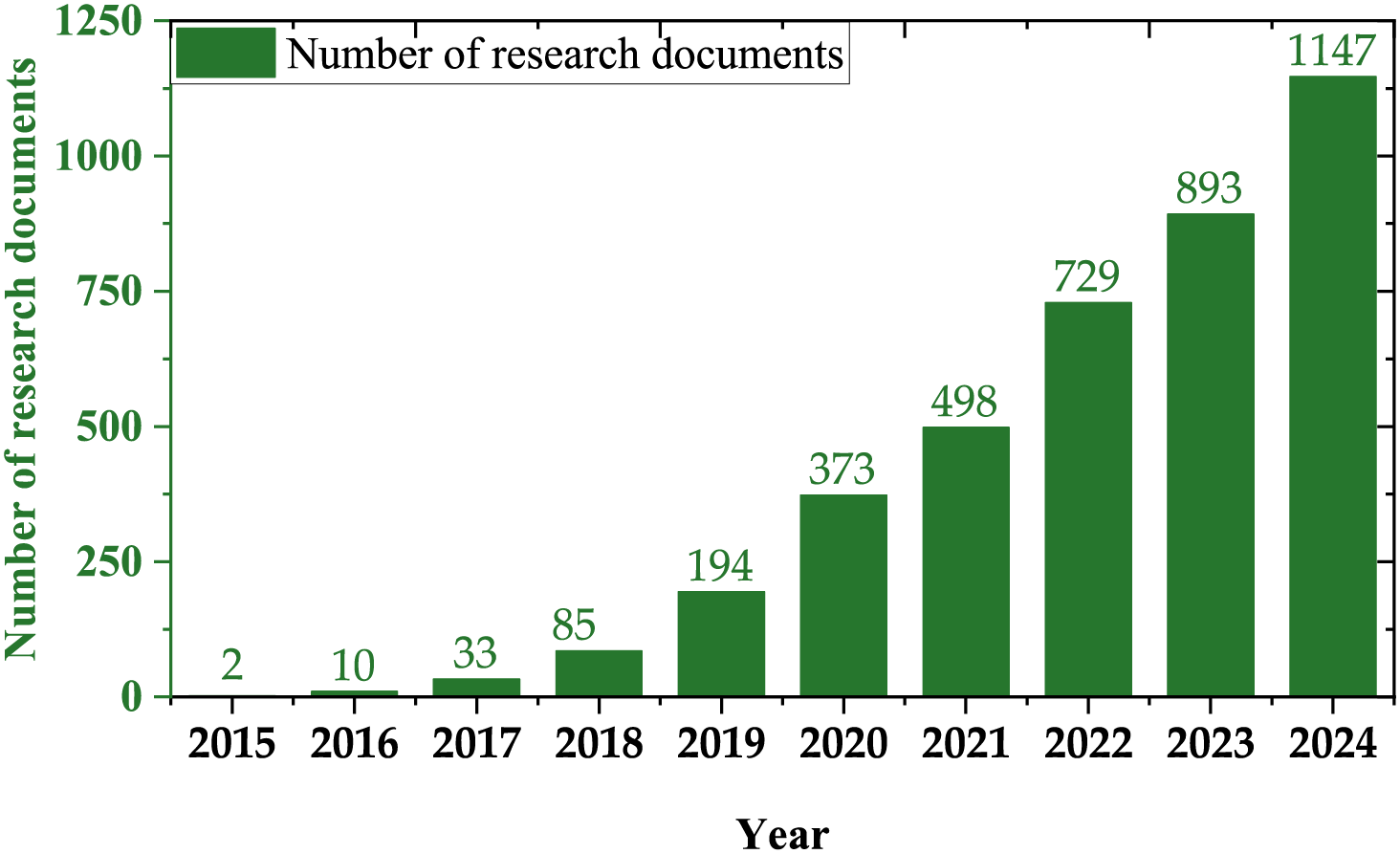

There are numerous case studies on the use of DTs in the field of engineering, with a notable increase in the last decade, as shown in Fig. 1. Thus, there are examples in various fields of engineering, such as in the field of construction, electric unmanned autonomous vehicles, manufacturing process, architecture, civil engineering, robotics, marine engineering, materials engineering, software engineering, aerospace engineering, etc. [10–14]. All these studies agree on the usefulness of using DTs for technical training and engineering instruction.

Figure 1: Trend of DT research in engineering over the last 10 years. Data obtained from the Scopus database with the query: “DTs” and “engineering”

In the context of materials science and engineering, DT systems are defined as dynamic, data-driven virtual replicas of physical materials, components, or processes, designed to monitor, predict, and optimize their behavior in real time. These systems typically integrate a high-fidelity virtual model—based on finite element analysis, phase-field modeling, or molecular dynamics simulations—with real-time data collected through embedded sensors or IoT devices. The synchronization between the physical and virtual entities is enabled through low-latency communication protocols (e.g., MQTT, OPC-UA) and may include edge computing to manage data processing efficiently [15,16]. Methodologically, DTs can be built using physics-based simulations, data-driven machine learning models, or hybrid approaches, allowing them to capture complex relationships such as processing–structure–property correlations or microstructural evolution under operational loads [17,18]. In materials science and engineering, these systems are increasingly applied to areas such as fatigue prediction in composites, optimization of additive manufacturing parameters, and corrosion monitoring in structural metals, offering a powerful tool for accelerating material development and enhancing performance assessment across the lifecycle [13,19,20].

Specifically, this paper deals with the use of DTs in the field of materials science and engineering, separating the analysis into the subareas set out in the North American academic environment and by the Materials Research Society [21]: (i) characterization; (ii) electronics, optics and photonics; (iii) energy and sustainability; (iv) general interest; (v) manufacturing; (vi) materials for quantum information technologies and topological systems; (vii) materials theory, computation and data science; (viii) nanomaterials; (ix) soft materials and biomaterials; and (x) structural and functional materials. To better understand the trend in the design and use of DTs in the field of materials science and engineering, a bibliometric analysis of Scopus and Web of Science has been developed in this study, covering publications from the last decade. This paper is divided into several sections: (i) Introduction; (ii) Methods; (iii) Results; (iv) Discussion; and (v) Conclusions.

The methodological approach for this bibliometric review adheres to a structured five-stage process that ensures both breadth and depth in data collection, screening, analysis, and synthesis. The workflow is visually summarized in Fig. 2, which illustrates the following core phases: (i) literature identification, locating all potentially relevant studies through comprehensive database querying; (ii) data collection, retrieving and organizing metadata for bibliometric processing; (iii) data analysis, applying statistical and bibliometric techniques to evaluate publication trends, sources, and citation networks; (iv) data visualization, using graphical methods to represent key findings and patterns; and (v) draw conclusions, synthesizing insights and identifying research gaps and future directions.

Figure 2: Stages of the research process

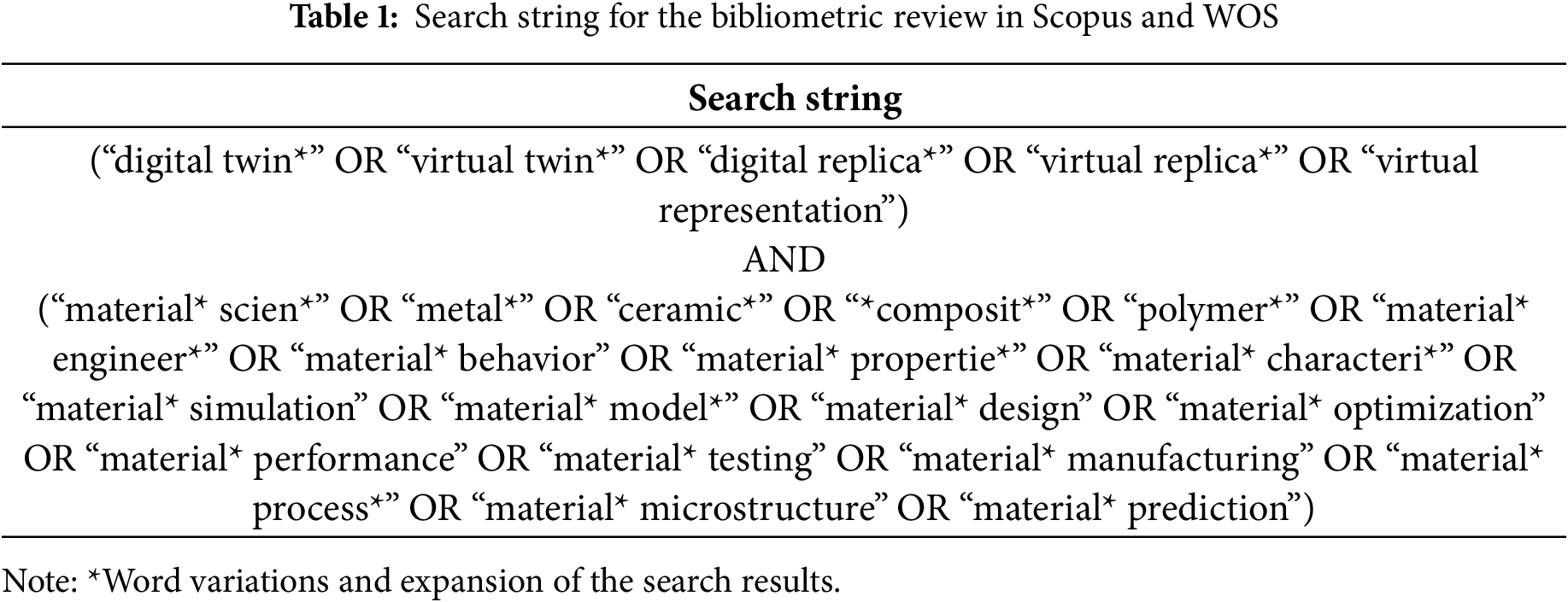

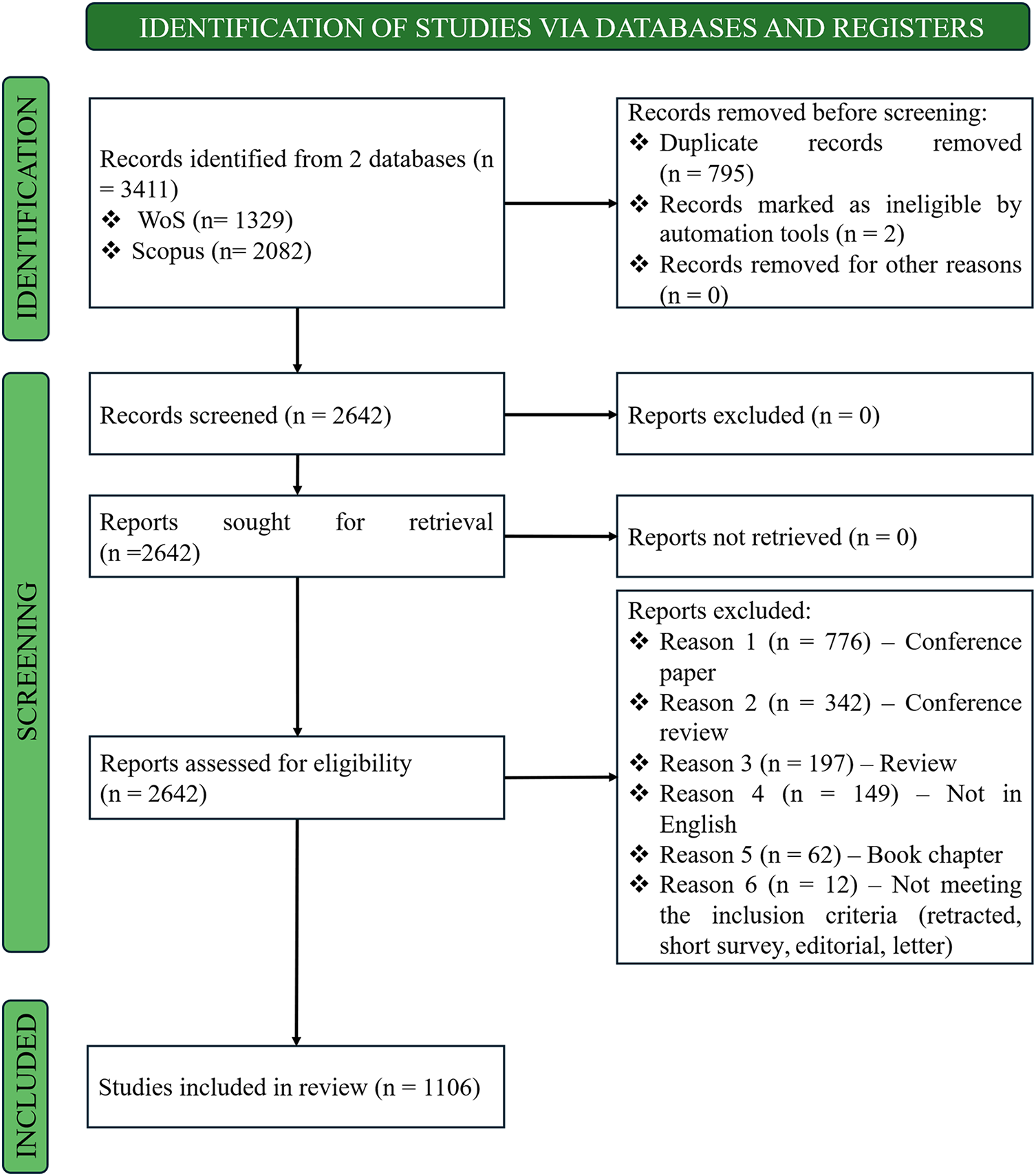

Starting with the procedure of the research, the Stage I involved the formulation of a robust search strategy. To identify relevant publications, a bibliometric search was conducted in the two most reputable academic databases, Scopus and Web of Science (WOS). The search strategy, executed in April 2025, targeted scientific articles published between 1 January 2015, and 30 April 2025. A Boolean search string was constructed to capture a comprehensive set of digital twin (DT)–related terms in conjunction with a broad spectrum of materials science and engineering topics. To validate the Boolean search string, an iterative refinement process was carried out. This included trial searches and benchmark testing using a curated list of known, high-impact publications on DTs in materials science. Adjustments were made to maximize the retrieval of relevant articles while minimizing false positives. The final query was confirmed to retrieve all key reference works considered representative of the field. As detailed in Table 1, this included terms like “digital twin*,” “virtual replica*,” “material* scien*,” “polymer*,” “simulation,” and “manufacturing,” among others. The inclusion of both wildcards and logical operators enhanced the scope of the search, enabling the identification of word variants and thematic expansions within the dataset.

As part of the methodological procedure, Stage II focused on the data collection of the records retrieved during the initial database search, as stated in Fig. 3. To ensure a robust and transparent selection process, the PRISMA 2020 methodology was applied. Widely used in bibliometric and systematic reviews, this framework provides a clear, step-by-step outline of how studies are filtered, allowing for reproducibility and methodological clarity [22,23]. The identification stage began with the extraction of 3411 records from the combined databases: 2082 from Scopus and 1329 from WOS. Following this, 795 duplicate entries were removed, along with 2 records deemed ineligible by automated filtering tools. Duplicate records were identified and removed using the duplicateMatching() function in the Bibliometrix R package, which relies on DOI matching as the primary criterion and exact title string matching as a secondary criterion when DOIs are unavailable. This resulted in a working dataset of 2642 unique studies moving forward. During the screening stage, all remaining records were retained for evaluation, as none were excluded based solely on title or abstract. The eligibility stage introduced more stringent filters, just considering scientific paper written in English, as they are considered the source with the highest impact in the scientific community. Here, a total of 1536 records were excluded at this stage for not meeting the inclusion criteria: 776 were classified as conference papers, 342 as conference reviews, 197 as review articles (non-bibliometric), 149 were not written in English, 62 were book chapters, and 12 were either retracted, short communications, or editorial content. As depicted in Fig. 2, this process culminated in the inclusion of 1106 peer-reviewed journal articles, which constituted the final dataset for the bibliometric analysis, as extracted in Table S1.

Figure 3: PRISMA 2020 flow diagram for the review on the use of digital twins in materials science and engineering

In Stage III (Data Analysis), the bibliographic data extracted from the selected studies—such as titles, abstracts, keywords, publication years, journals, citation counts and affiliations—were systematically processed using the Bibliometrix R package (version 4.4.2) and its companion web interface, Biblioshiny. Bibliometrix played a critical role in data cleaning, standardization and the extraction of key bibliometric indicators. These included citation metrics (total citations, citations per year, and normalized impact), collaboration structures (e.g., co-authorship networks at the author, institution, and country levels), and thematic patterns derived from keyword co-occurrence and clustering algorithms. Here, the clustering algorithm employed is based on the Louvain method for community detection. In parallel, Biblioshiny facilitated interactive data visualization, enabling the generation of a wide range of graphical outputs.

Moving into Stage IV (Data Visualization), the most relevant results were organized and presented using charts and diagrams designed to enhance interpretability. These visualizations included network graphs of co-authorship and keyword associations, histograms showing publication and citation trends over time, and scatter plots mapping the performance of influential journals and documents.

Finally, in Stage V (Synthesis and Interpretation), the analytical results were integrated into a cohesive narrative. This narrative aims to describe the current landscape of DT research in materials science and engineering and identify conceptual gaps, underexplored application domains, and emerging interdisciplinary intersections. Particular emphasis was placed on the evolution of research themes, the concentration of scholarly output in specific geographic and institutional hubs, and the increasing prominence of data-driven and simulation-based methodologies. The findings were framed to inform future investigations and strategic decision-making for researchers and stakeholders interested in leveraging DTs to advance the field of materials science.

3.1 General Bibliometric Data and Progress of Publications

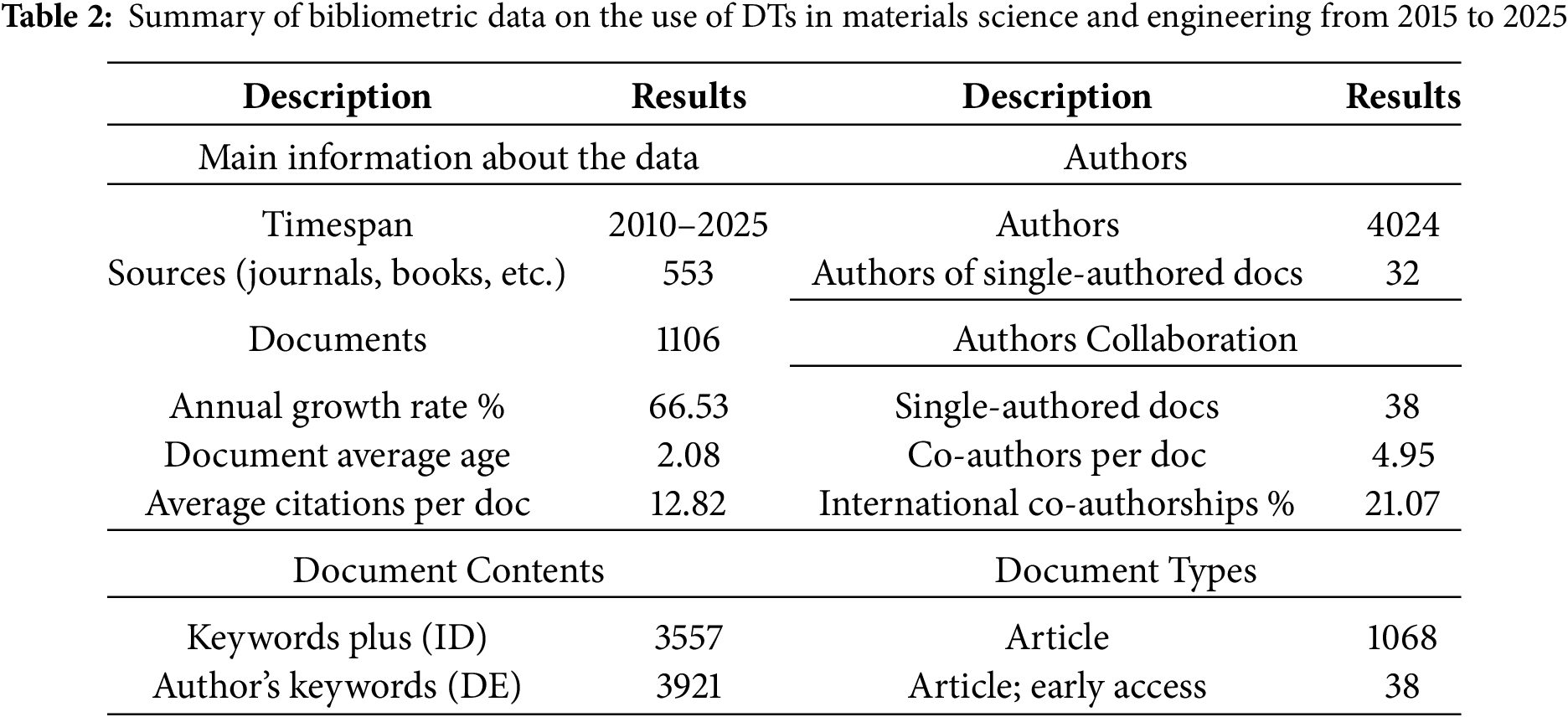

Table 2 summarizes the main bibliometric indicators regarding the use of digital twins (DTs) in materials science and engineering over the period 2015–2025. A total of 1106 documents were analyzed, derived from 553 distinct sources, which correspond exclusively to peer-review scientific journals, as described in the Methods section. The annual growth rate of publications is remarkably high at 66.53%, highlighting the rapid development and increasing attention this topic has received in recent years in comparison with other hot topics in the state of the art as carbon fiber-based batteries (24.08%) [24], titanium additive manufacturing (14.87%) [25] or nanocomposites for multifunctional sensors (22.94%) [26]. Moreover, the average age of documents is 2.08 years, consistent with a recently established and rapidly evolving domain. The average number of citations per document is 11.62, indicating a moderate yet meaningful impact. Regarding content indicators, the dataset includes 3557 keywords plus and 3921 author’s keywords. These descriptors reflect the thematic diversity and the strong integration of digital methodologies into materials research.

In terms of authorship, the dataset includes 4024 unique authors. However, only 32 single-authored documents were identified, which underscores the highly collaborative nature of research in this field. On average, each paper has 4.95 co-authors, and 21.07% of the publications involve international collaboration, demonstrating growing global interest and cooperative research frameworks. The distribution by document type shows a clear dominance of peer-reviewed journal articles (1068), accompanied by a smaller number of early access articles (38), likely representing papers accepted and available online ahead of print.

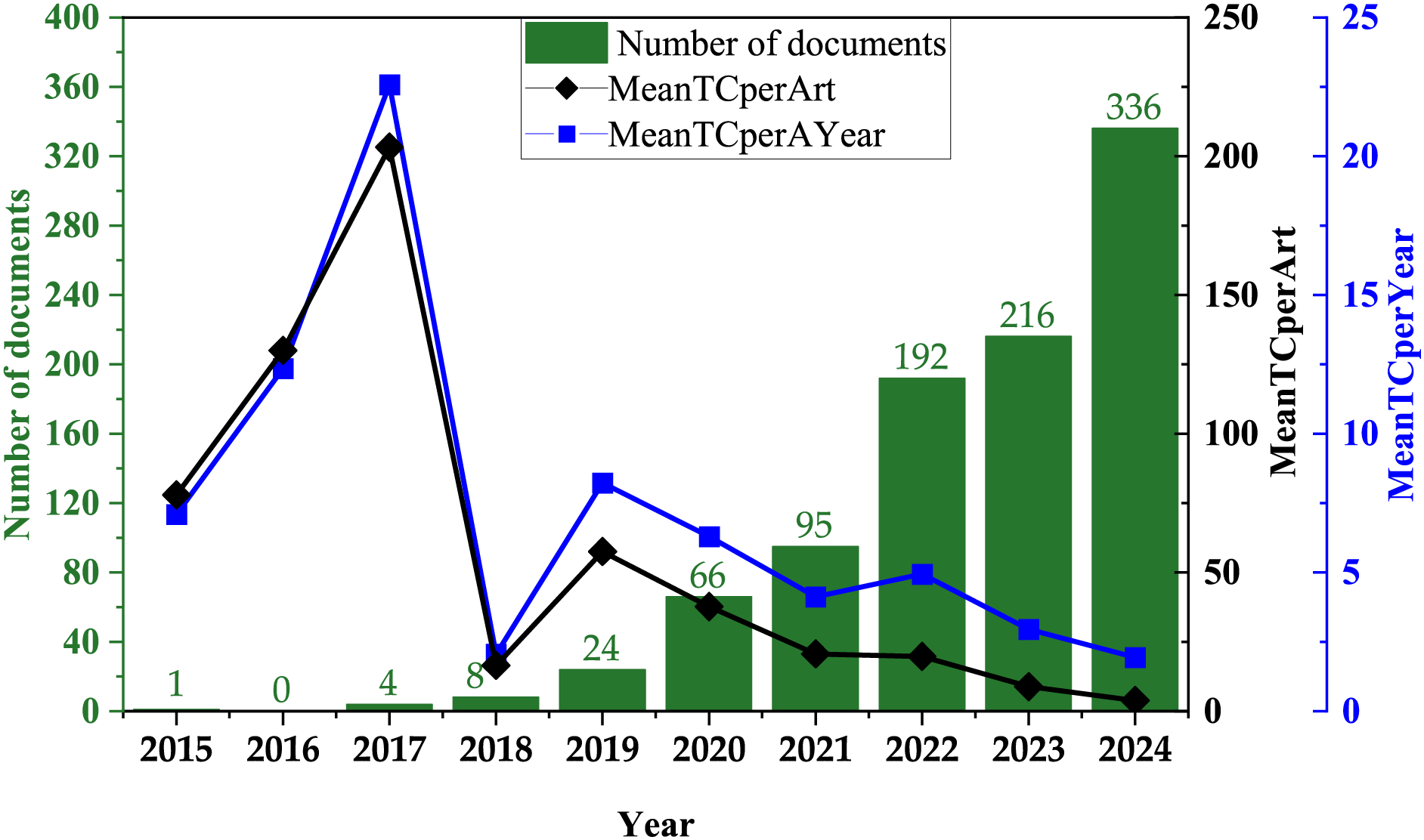

Fig. 4 presents the evolution of annual scientific production and citation metrics from 2015 to 2024. The number of publications increased steadily from 1 in 2015 to a peak of 336 documents in 2024. A particularly sharp rise was observed between 2021 and 2024, which may be attributed to the convergence of digitalization efforts and data-driven material design strategies. Despite a dip in 2020, likely influenced by disruptions caused by the COVID-19 pandemic, the field regained momentum rapidly. In this regard, citation metrics reveal that the Mean TCperArt (mean total citations per article) and Mean TCperYear (mean total citations per year) peaked in 2018, indicating the publication of highly cited foundational papers during that year. In subsequent years, although the number of publications rose, citation averages per article showed a gradual decline, a trend commonly associated with the recency of newer publications which have had less time to accumulate citations. This pattern reinforces the presence of influential early works and a continuous influx of newer studies sustaining the field’s growth.

Figure 4: Annual scientific production and citation evolution from 2015 to 2024 (MeanTCperArt: mean total citations per article; MeanTCperYear: mean total citations per year)

3.2 Leading Scientific Journals

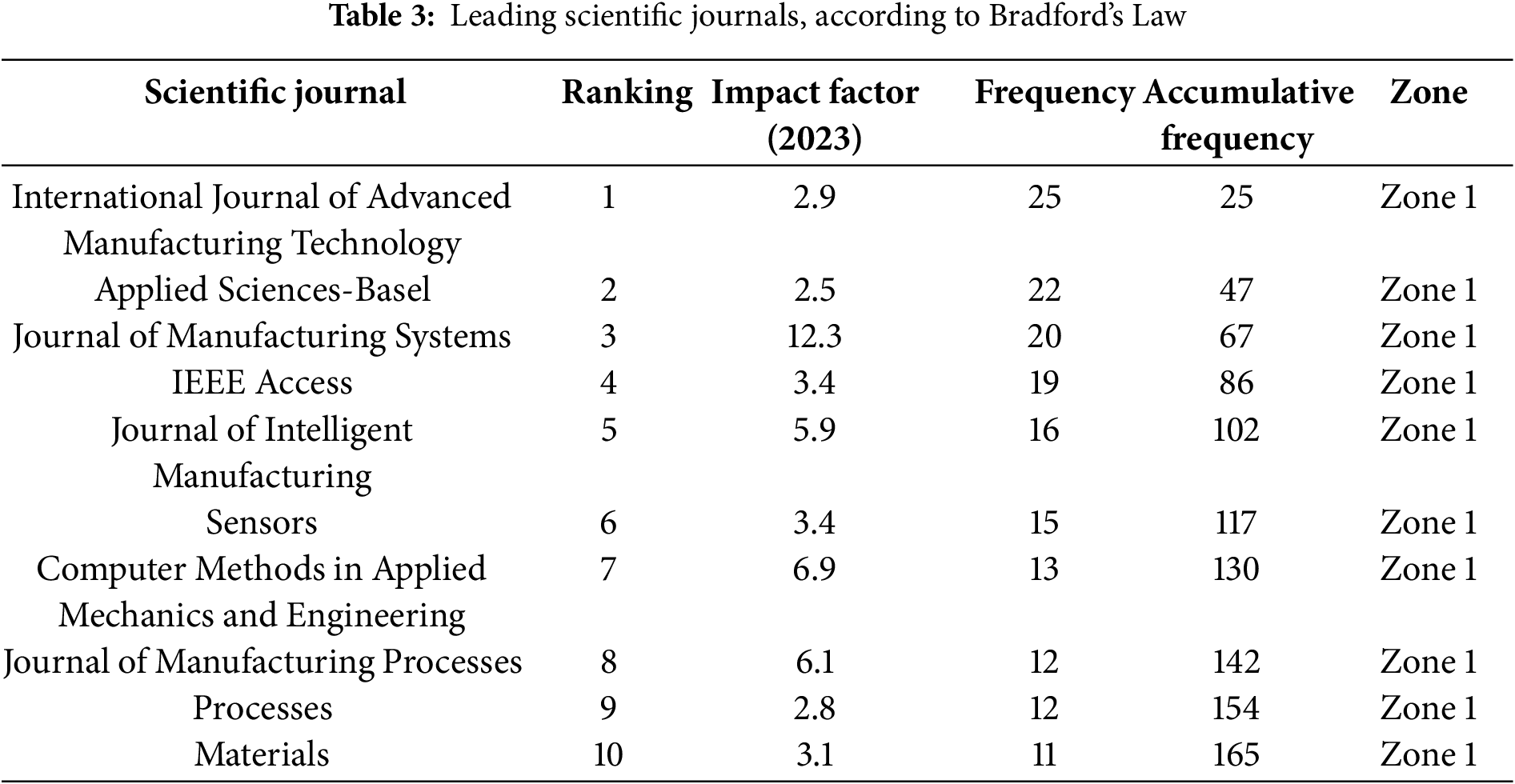

Table 3 presents the ranking of the most relevant scientific journals publishing research on DTs in materials science and engineering, according to Bradford’s Law. This law is a bibliometric principle that classifies journals into “zones” based on their productivity on a specific subject. According to Bradford, if journals are arranged in order of decreasing productivity, they can be divided into a core (Zone 1) and subsequent concentric zones, each producing approximately the same number of articles, but with an increasing number of journals in each zone. The first zone contains the most prolific journals and constitutes the essential core for the studied field.

In this case, all the top-10 journals identified fall within Zone 1, indicating a concentrated core of publication activity. These journals account for a total of 165 documents. The International Journal of Advanced Manufacturing Technology leads the list with 25 documents, followed by Applied Sciences-Basel (22) and the Journal of Manufacturing Systems (20). Other prominent journals include IEEE Access and the Journal of Intelligent Manufacturing, each with 19 and 16 documents, respectively. These outlets are closely aligned with advanced manufacturing, automation, and intelligent systems, reinforcing the interdisciplinary nature of DTs within materials research.

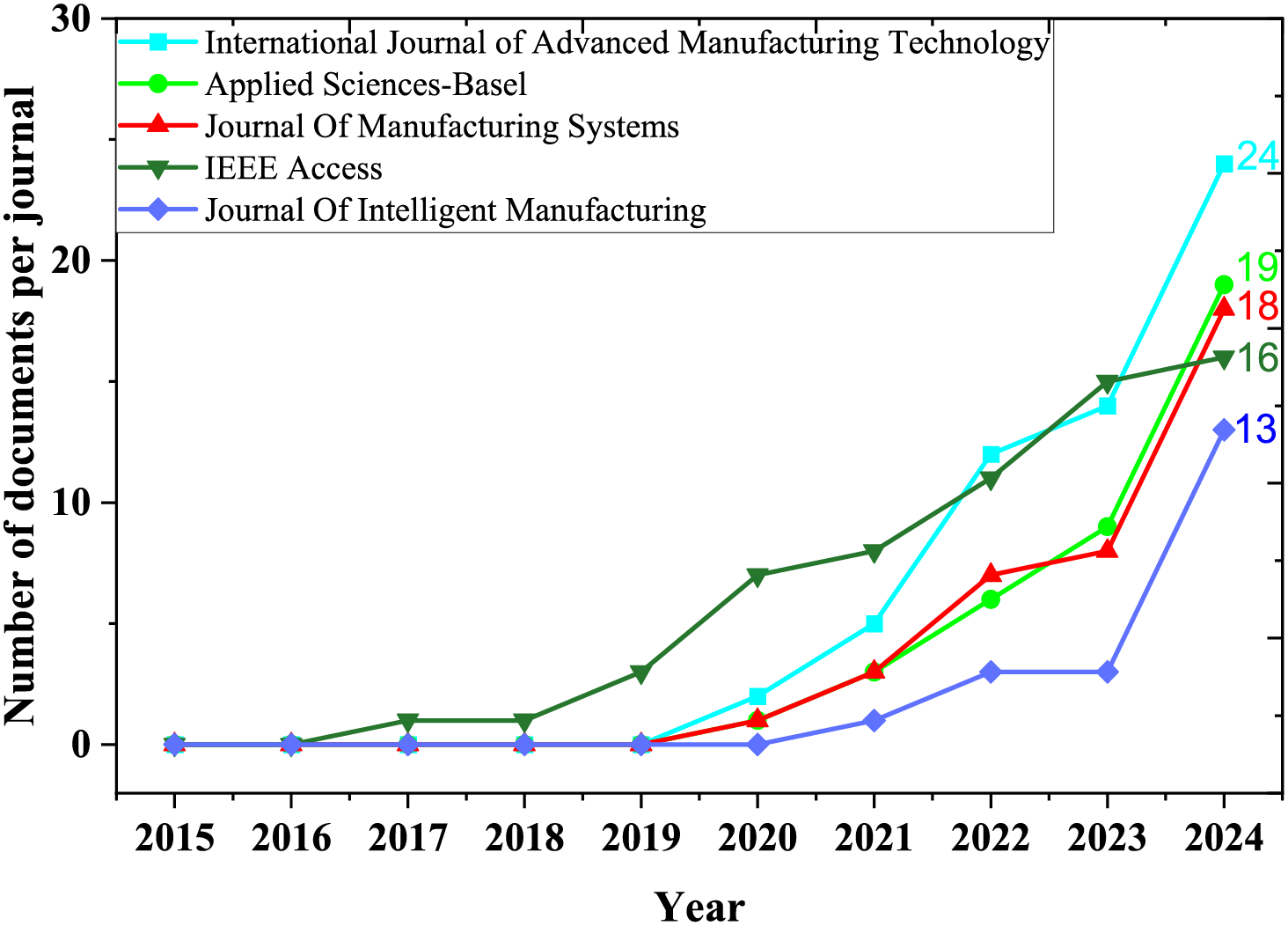

Fig. 5 provides a temporal visualization of the scientific output from the top-5 journals between 2015 and 2024. A significant growth trend is evident, particularly from 2019 onward, which correlates with the overall expansion of the field discussed earlier. The International Journal of Advanced Manufacturing Technology shows the most pronounced increase, reaching 24 documents by 2024. Applied Sciences-Basel and the Journal of Manufacturing Systems also show sustained growth, with 19 and 18 documents, respectively, in the same year. Notably, IEEE Access and the Journal of Intelligent Manufacturing follow closely, with 16 and 13 documents.

Figure 5: Top-5 scientific journal production from 2015 to 2024

These trends highlight the growing interest in DTs within established journals of manufacturing and materials science and the responsiveness of these platforms to emerging research topics. The predominance of these journals in Zone 1 suggests that future work in this area will continue to consolidate within these high-output venues, facilitating visibility and knowledge exchange.

3.3 Institutional and Regional Contributions to Scientific Research

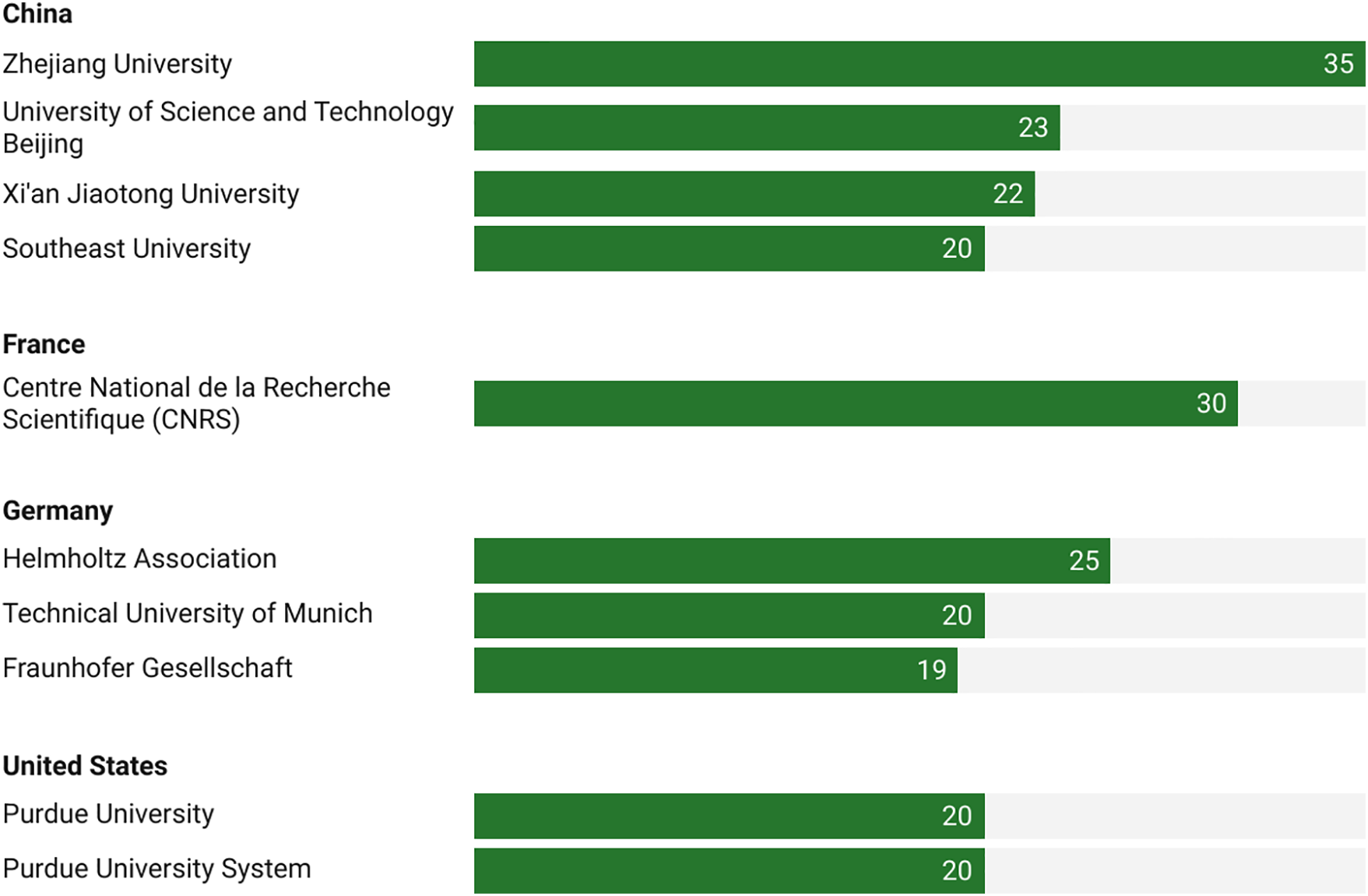

Fig. 6 illustrates the leading contributing affiliations by country, providing a detailed overview of the most productive institutions and their publication dynamics within the studied domain. Here, China emerges as the dominant contributor, with Zhejiang University (35 publications), University of Science and Technology Beijing (23), Xi’an Jiaotong University (20), and Southeast University (20) occupying leading positions. In Europe, the Centre National de la Recherche Scientifique (CNRS) in France stands out with 30 publications, while Germany is represented by the Helmholtz Association (25), the Technical University of Munich (21), and the Fraunhofer Gesellschaft (19). In the United States, the Purdue University system leads with 20 documents. These figures suggest a strong institutional engagement from technologically advanced nations, particularly those investing heavily in smart manufacturing and advanced simulations. The central role of Chinese institutions reflects national strategic priorities in digital innovation and industrial automation, while the visibility of the CNRS and Helmholtz highlights the relevance of interdisciplinary research platforms in Europe.

Figure 6: Top contributing affiliations by country and number of publications

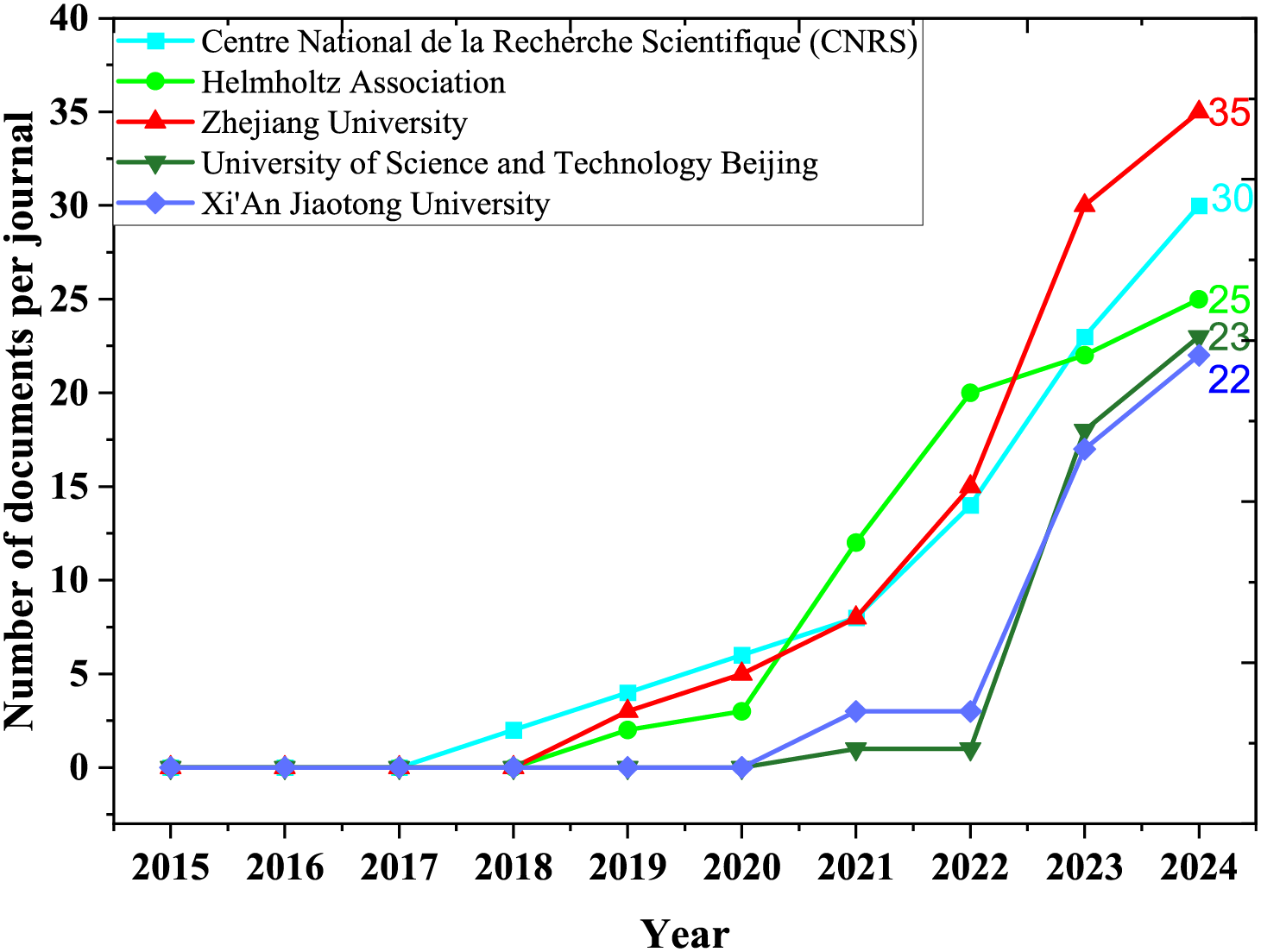

Fig. 7 traces the annual publication output of the top five institutions between 2015 and 2024. The CNRS shows the most pronounced growth, peaking at 35 publications in 2024, followed by the Helmholtz Association (33), Zhejiang University (28), University of Science and Technology Beijing (25), and Xi’an Jiaotong University (22). The rapid increase observed from 2021 onward aligns with the post-pandemic acceleration of digitalization across scientific domains, as commented before. The presence of CNRS and Helmholtz at the top of the list reflects their structured support for collaborative, high-performance computing initiatives and the development of cyber-physical systems, which are closely tied to the DT paradigm. Meanwhile, the consistent upward trajectory in China’s universities reflects robust investment in digital infrastructure and computational modeling, essential components for DT implementation in materials research.

Figure 7: Top-5 affiliations’ production from 2015 to 2024

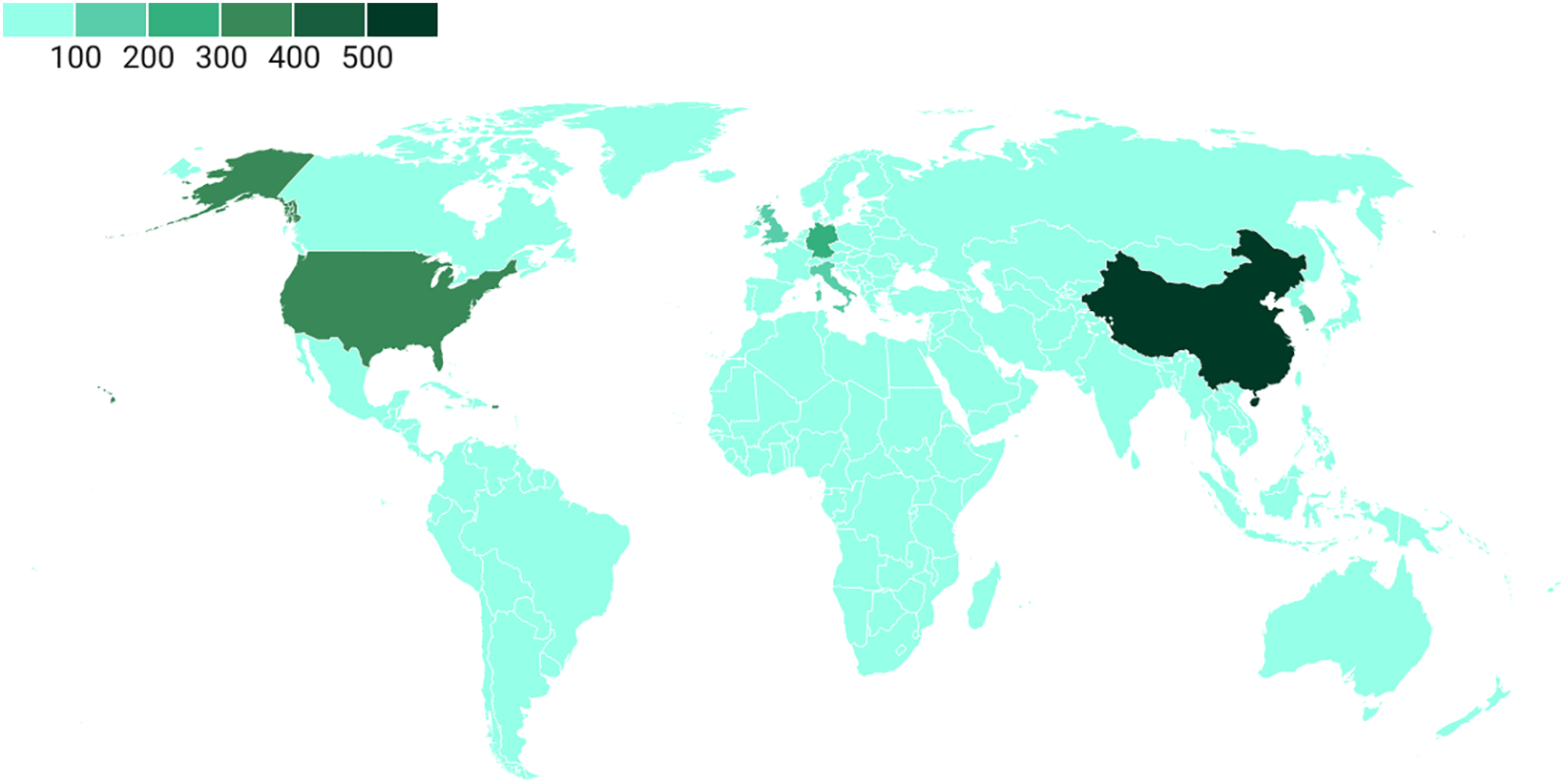

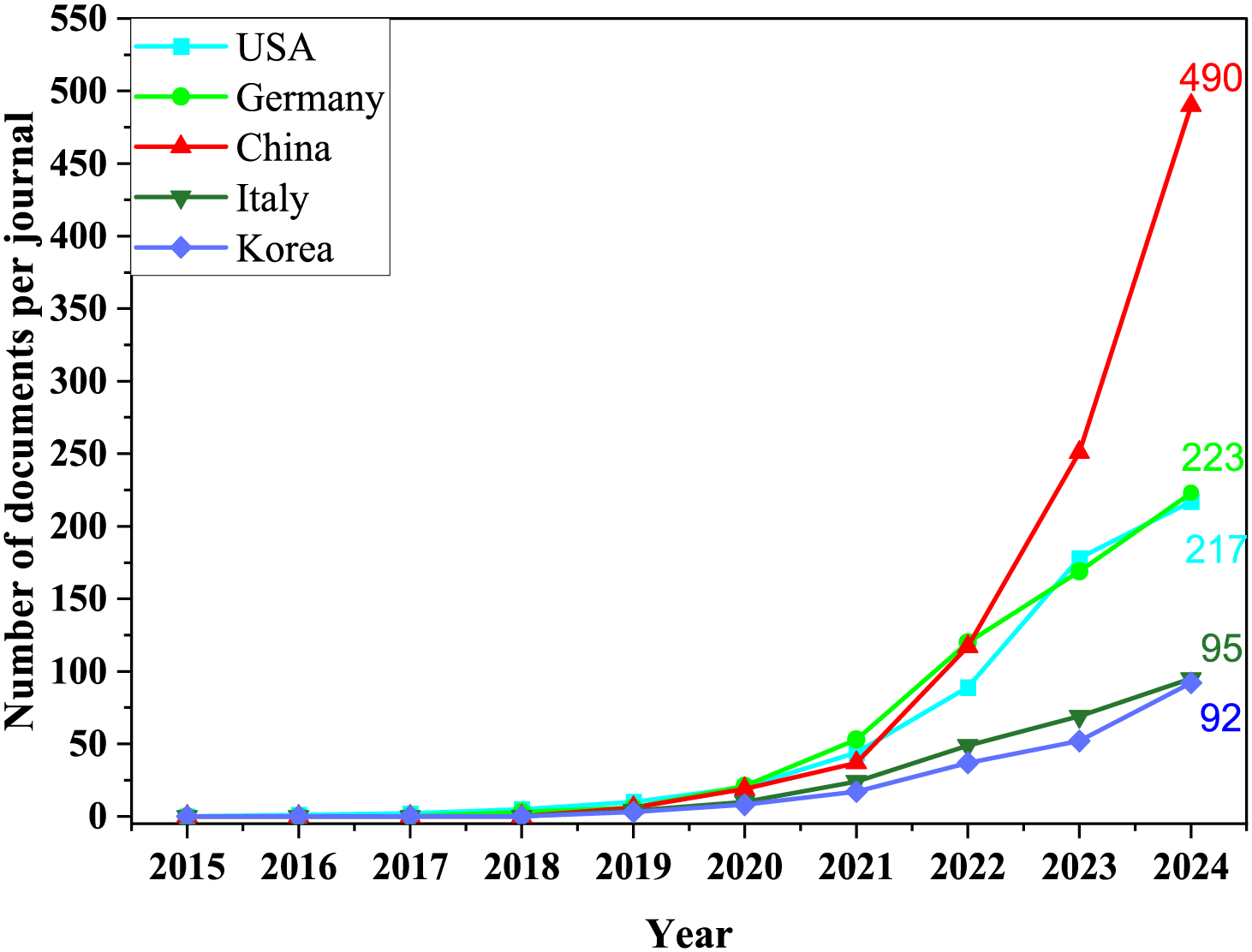

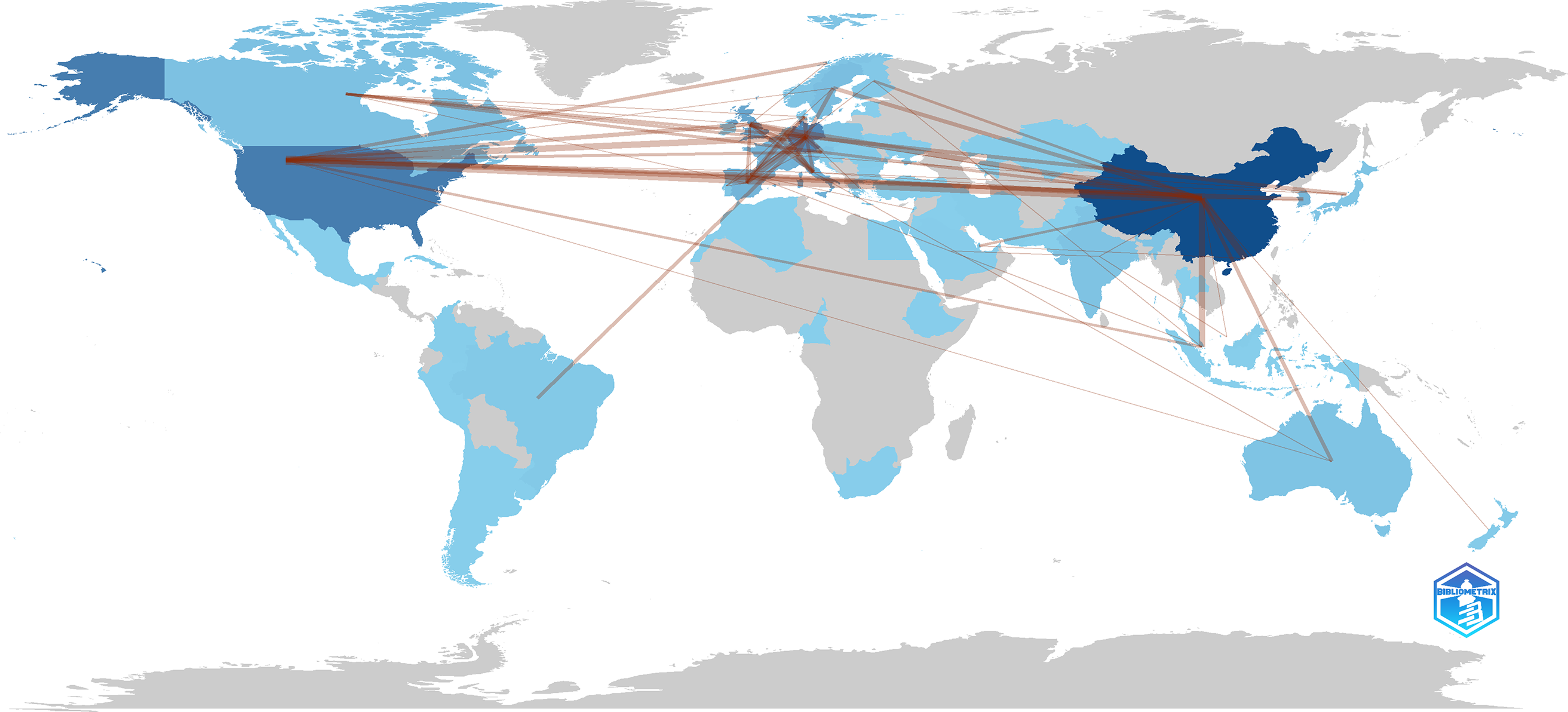

Turning to the geographical distribution, Figs. 8 and 9 offer complementary views of national-level contributions. Fig. 8 provides a global heat map of country-level scientific production, underscoring China’s dominant role, followed by notable activity in the United States, Germany, the United Kingdom, and Italy. This spatial representation confirms the centrality of East Asia, North America, and Western Europe in driving research in this emerging field. In Fig. 9, the temporal evolution of the top five countries’ output reveals exponential growth for China, reaching 490 publications in 2024. Germany and the United States follow closely with 225 and 217 publications, respectively. Italy (95) and South Korea (52) round out the group. These results suggest a sharp increase in scientific output worldwide, with China accelerating at a particularly fast pace. This growth may be attributed to its national-level programs such as “Made in China 2025” and increased focus on artificial intelligence and advanced materials.

Figure 8: Countries’ scientific production from 2015 to 2024

Figure 9: Top-5 countries’ scientific production from 2015 to 2024

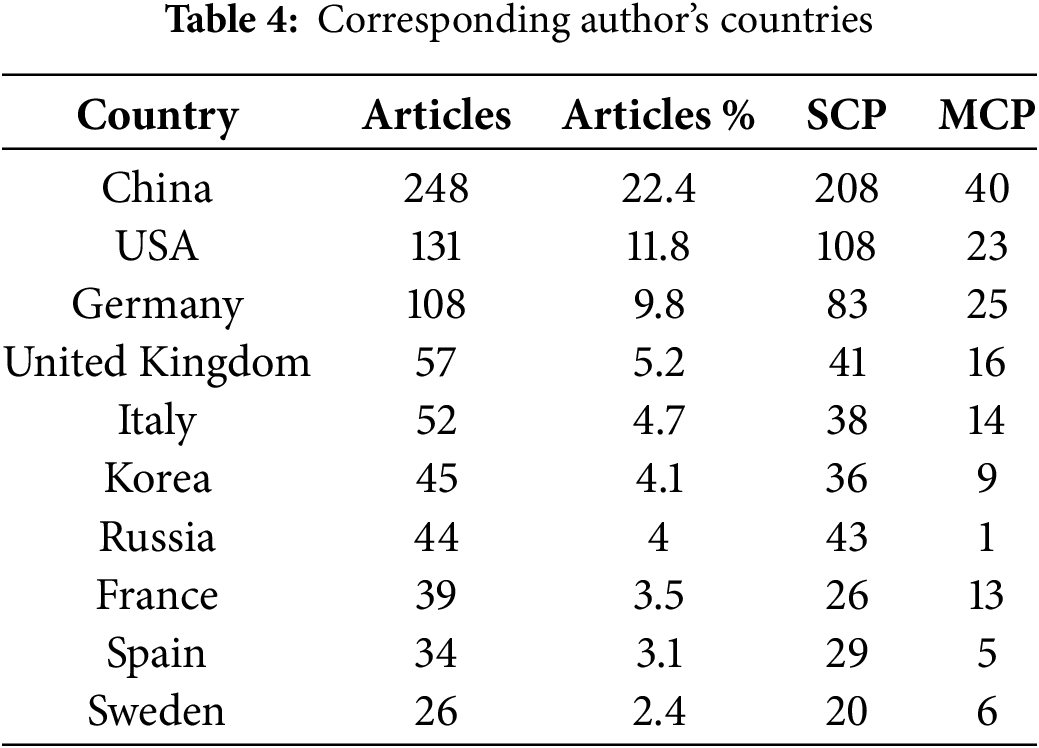

Table 4 analyzes the country affiliation of corresponding authors, distinguishing between single-country publications (SCP) and multi-country collaborations (MCP). China again leads with 248 articles (22.4% of the total), of which 208 are SCPs and 40 MCPs. The United States follows with 131 documents (108 SCP, 23 MCP), and Germany with 108 (83 SCP, 25 MCP). The data indicate a strong national concentration of research output in China, suggesting internal research capacity and limited reliance on international collaborations. In contrast, countries such as Germany and the United Kingdom exhibit a more balanced pattern, combining domestic leadership with active engagement in cross-border research. These findings reflect differing models of scientific production: while China emphasizes rapid domestic expansion and capacity building, European countries and the USA continue to foster international collaborations that may enhance diversity in approaches and broader applicability of results.

Although this study presents absolute publication counts by country, it is important to recognize that such metrics inherently favor countries with larger populations or more extensive R&D infrastructures. For example, China’s dominant position in publication volume may partially reflect the scale of its research ecosystem. However, smaller countries with high research intensity (e.g., Germany, Italy, France or Spain) may demonstrate significant contributions when metrics are normalized by GDP, population, or R&D spending. While normalization was not conducted in this review due to data scope constraints, we acknowledge its importance for a more equitable representation of national scientific productivity.

Fig. 10 shows the collaboration world map. Here, the most active international links include China–USA (18 co-authored articles), China–Singapore (9), Germany–Switzerland (6), and France–Spain (3), among many others. These data confirm the existence of a robust international research network, though they also reveal regional concentration patterns, with China, the USA, and Germany forming the core of the collaboration network.

Figure 10: Countries’ collaboration world map

In summary, a robust and geographically diverse research scene is confirmed by institutional and national analyses. China’s leadership is clear in its significant institutional output and national productivity, reflecting a strategic drive in digital manufacturing and material informatics. Complementarily, European and North American institutions show strong, sustained engagement, particularly leveraging collaborative structures to embed DT technologies across numerous disciplines.

3.4 Quantitative Impact of the Most Cited Publications

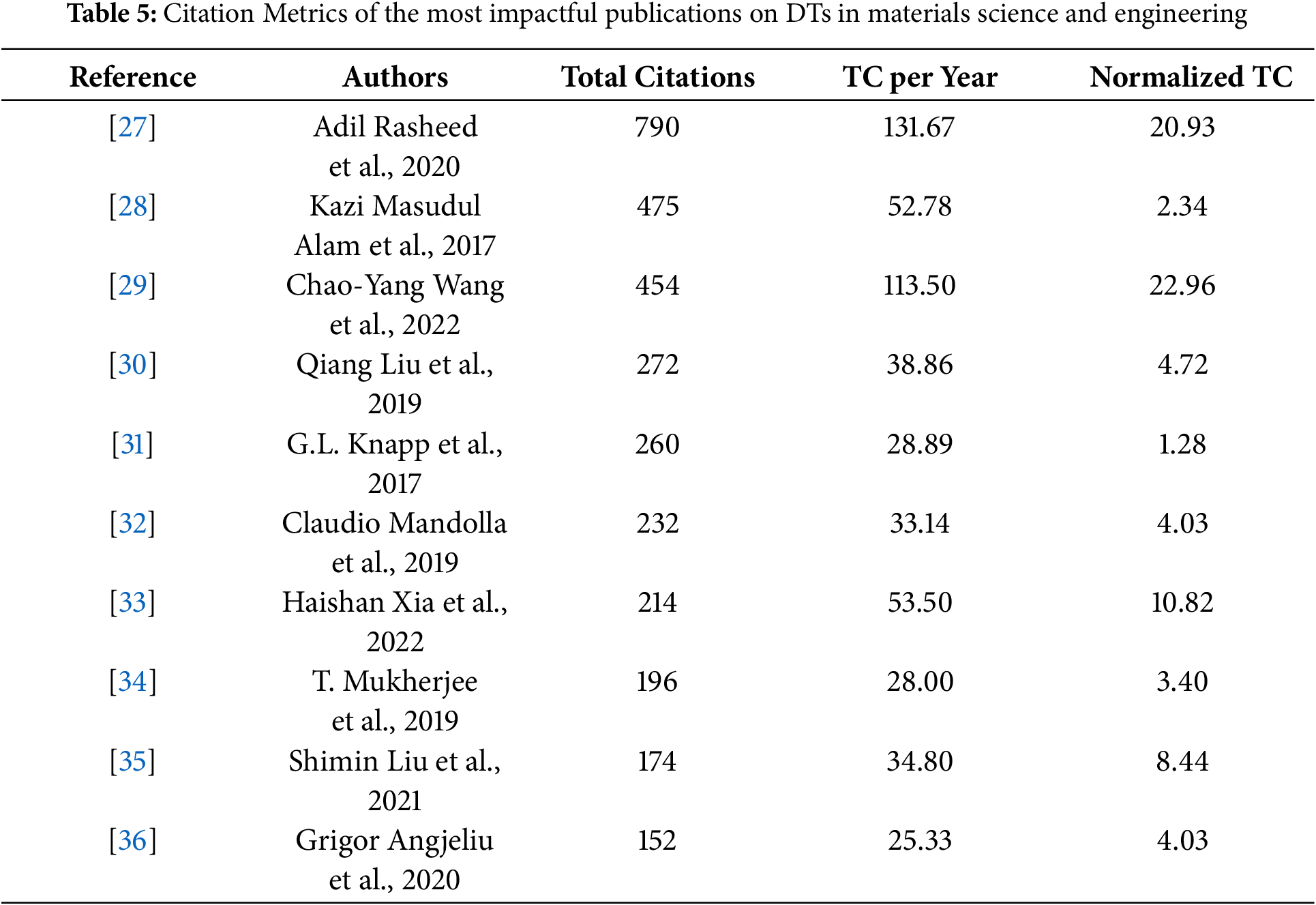

Table 5 presents the citation metrics of the most impactful publications related to the field. To enable fair comparison across publications from different years, a normalized citation metric (Normalized TC) was included. This was calculated by dividing the total citations of each article by the average number of citations for all articles published in the same year within the dataset. This year-based normalization mitigates bias arising from publication age and varying exposure times in citation accumulation. Among them, the paper by Adil Rasheed et al. (2020) stands out with 790 total citations, achieving 131.67 citations per year and a normalized citation score of 20.93, highlighting its pivotal role in shaping the field. Similarly, Chao-Yang Wang et al. (2022), despite being a more recent contribution, has already garnered 454 citations and exhibits the highest normalized impact (22.96), indicating both its rapid recognition and relevance. Other influential works include Kazi Masudul Alam et al. (2017) with 475 citations and a strong yearly citation rate (52.78), as well as Qiang Liu et al. (2019) and G.L. Knapp et al. (2017), which maintain steady influence over time. Notably, while some studies exhibit high total citations, their normalized citation scores suggest a more moderate influence when adjusted for publication year, as seen in G.L. Knapp et al. and T. Mukherjee et al.

4.1 Analysis of the Most Impactful Documents and Citation Trends

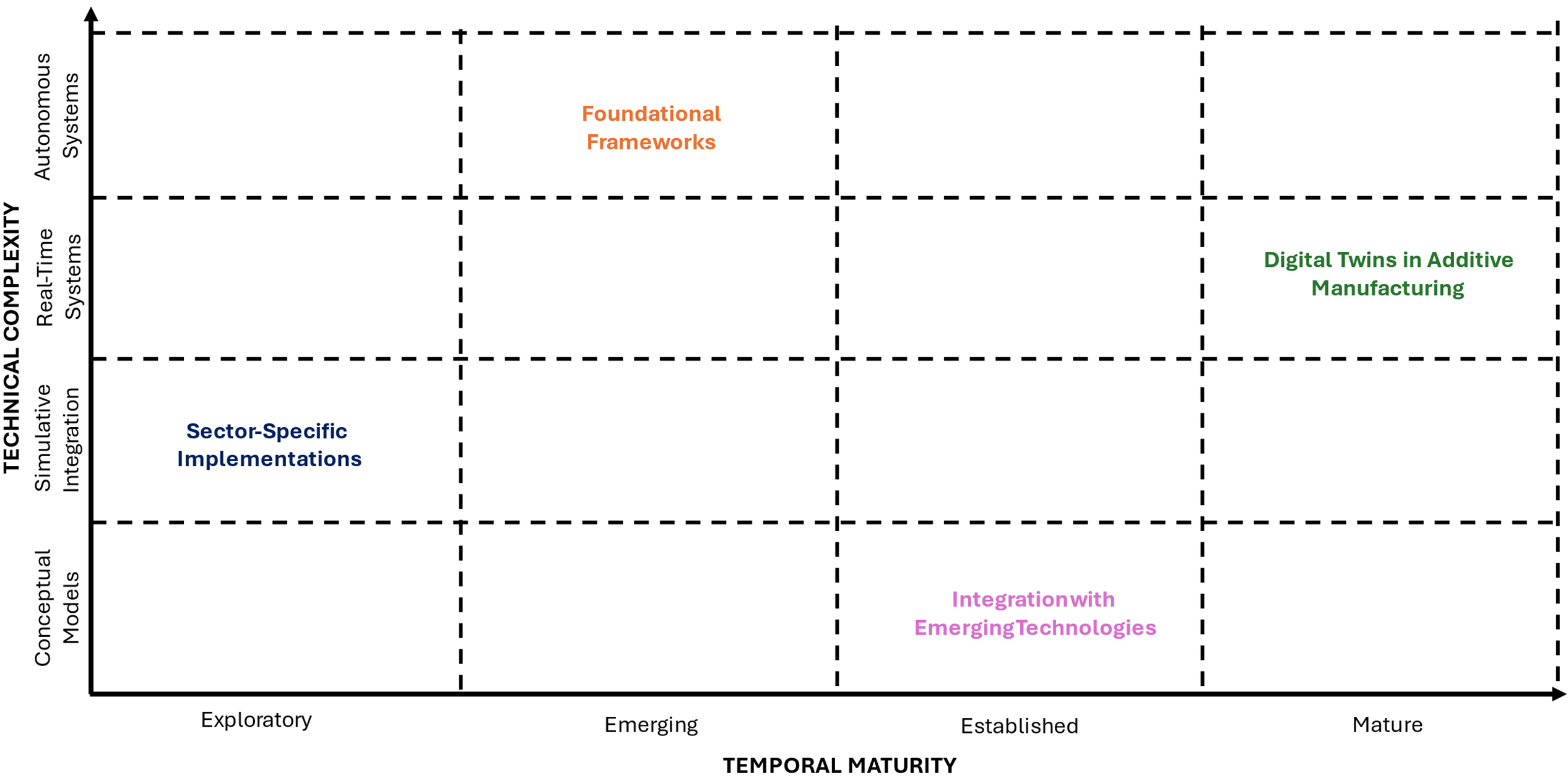

The quantitative and thematic analysis of the ten most cited publications in the field of DTs applied to materials science and engineering reveals four dominant research streams. These categories reflect the diversity and maturity of research topics and demonstrate how the concept of DTs has evolved across different application domains, methodologies, and technological enablers. The publications were grouped based on shared themes, objectives, or application sectors: (i) conceptual frameworks and modeling foundations, (ii) DTs in additive manufacturing (AM), (iii) sector-specific implementations, and (iv) integration with emerging technologies for sustainability.

The first group, conceptual frameworks and modeling foundations, includes two highly cited papers [27,28] that lay the theoretical and architectural groundwork for DT technologies. These works do not aim for a specific industrial application, but instead focus on defining core principles, system structures, and technological enablers that contribute to DT development. Rasheed et al. (2020) [27] provide a comprehensive exploration of the values, challenges, and enabling technologies associated with DTs, from a modeling and simulation standpoint. Their work is pivotal in establishing a shared language and research agenda for DT development. Similarly, Alam and El Saddik (2017) [28] propose C2PS, a cloud-based cyber-physical systems reference model, emphasizing architectural principles and system interoperability. These works do not focus on specific applications but rather outline the structural and functional dimensions that support DT implementation in various sectors.

The second group, focused on DTs in AM, highlights that AM as one of the earliest and most dynamic domains for the application of DT technologies, as demonstrated by four seminal contributions in this area [31,32,34,35]. Knapp et al. (2017) [31] define a modular framework to construct DTs in AM, with emphasis on materials behavior and real-time data integration. Mandolla et al. (2019) [32] extend the discourse by integrating blockchain technology into the DT of the aircraft industry, addressing traceability and trust in the AM lifecycle. Mukherjee (2019) [34] focus on the qualification process of 3D-printed metallic components, proposing a DT framework to enhance quality control and reduce development time. Liu et al. (2021) [35], in turn, incorporate biomimicry principles in the digital modeling of machining processes for aerospace parts, showcasing how biologically inspired strategies can enhance the adaptability and precision of virtual replicas. Collectively, these works illustrate the convergence of data-driven modeling, real-time monitoring, and quality assurance in the evolving landscape of AM.

The third group, sector-specific implementations, comprises three studies that investigate DTs as targeted solutions for distinct application domains, demonstrating the versatility and cross-sectoral adaptability of the concept beyond traditional manufacturing settings [29,33,36]. Wang et al. (2022) [29] present a breakthrough in the battery industry, combining DTs with electrochemical modeling to achieve fast charging in high-energy lithium-ion batteries. This article, published in Nature, exemplifies the increasing role of DTs in materials-centric energy applications. Xia et al. (2022) [33] provide a bibliometric and technological review of DT applications in smart cities, emphasizing the integration of GIS (Geographic Information Systems) and BIM (Building Information Modeling) technologies. Their work underlines the potential of DTs in urban planning, environmental monitoring, and infrastructure sustainability. Angjeliu et al. (2020) [36] address a unique heritage context, developing DTs for historical masonry buildings by integrating numerical simulation and experimental data, thus bridging cultural heritage preservation and modern computational methods.

Finally, the fourth group, rapid design and smart manufacturing systems, is represented by the work of Liu et al. (2019) [30], who propose a DT-driven approach for rapid and individualized design in flow-shop manufacturing environments. Their work demonstrates how smart manufacturing can leverage DTs for real-time decision-making, system optimization, and mass customization. The proposed model emphasizes flexibility and responsiveness in production systems, showing how DT technology can enable adaptive control and synchronization in highly dynamic environments.

When comparing the four thematic clusters, a methodological evolution becomes apparent. Initial efforts were centered on defining the foundational architecture of DT systems, focusing on interoperability, modularity, and conceptual clarity. These early models served as flexible blueprints for diverse applications but remained largely theoretical. The next stage in the evolution introduced domain-specific implementations, particularly in additive manufacturing, where digital twins began to incorporate sensor-driven data acquisition, multi-scale simulation, and feedback loops to support process monitoring and control. As the field matured, research extended into complex application domains such as energy systems and infrastructure, requiring hybrid approaches that fused data from heterogeneous sources—ranging from electrochemical modeling to geospatial analysis—into unified virtual environments. More recent developments point to a convergence with artificial intelligence and biomimetic strategies, enabling adaptive, self-optimizing systems capable of real-time decision-making. This trajectory reflects a shift from descriptive virtual replicas toward autonomous and predictive digital ecosystems, signaling a maturing research landscape driven by integration, scalability, and operational relevance.

To further contextualize the four identified research streams, Fig. 11 presents a conceptual taxonomy that maps them across two dimensions: technical complexity (from conceptual models to autonomous systems) and temporal maturity (from exploratory to mature deployment). This classification highlights how each theme aligns with the technological and developmental progression of digital twins. In this regard, foundational frameworks exhibit high systemic complexity but remain largely theoretical or emerging in application. Digital twins in additive manufacturing are both technically advanced and industrially mature. In contrast, sector-specific implementations are still in early, low-complexity stages. Integration with emerging technologies (e.g., AI, blockchain, e-learning) is gaining traction, though it remains conceptually grounded and at a moderate level of maturity.

Figure 11: Taxonomy of the four thematic research clusters in DT studies applied to materials science and engineering, positioned according to technical complexity and temporal maturity

4.2 Classification of Materials Science Research Areas

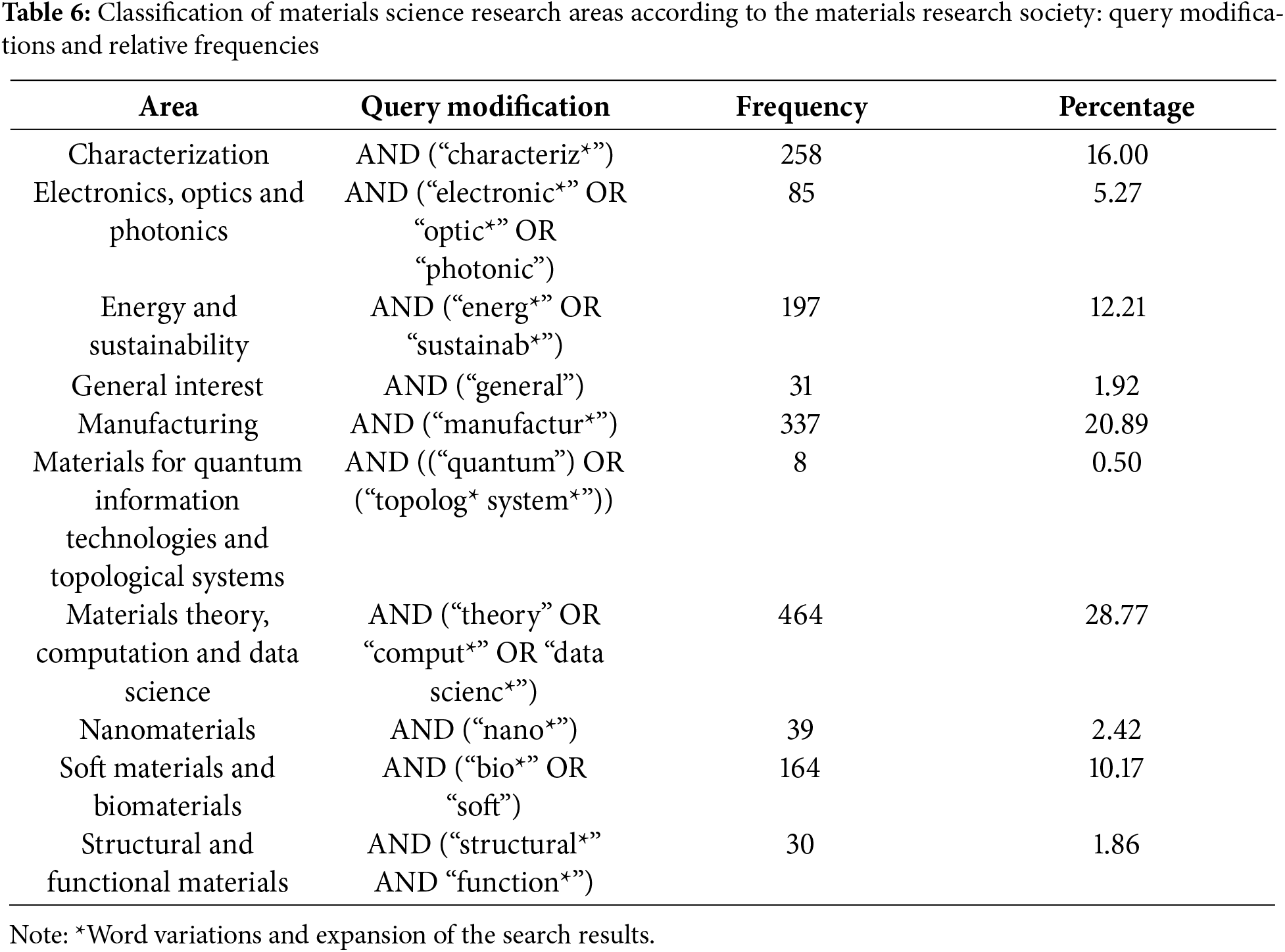

Table 6 provides a thematic breakdown of research areas in materials science, following the classification scheme proposed by the Materials Research Society (MRS) [21] and considering in other studies [37,38], along with the specific Boolean search strategies used to retrieve relevant literature. It allows us to identify which subfields are most actively engaging with computational modeling, data-driven techniques, and simulation-based methods—core components of DTs. Among the ten thematic categories, Materials Theory, Computation, and Data Science stands out as the most frequently represented, accounting for 28.77% of the total query results. This finding is highly significant within the scope of this review. The prominence of this area underscores the foundational role that computational models, simulation environments, and data analytics play in the development and implementation of DTs in materials engineering. DTs rely heavily on the continuous interaction between physical systems and their digital counterparts through real-time data acquisition, model updating, and predictive analytics. These capabilities are made possible through advancements in computational materials science, high-throughput simulations, artificial intelligence, and cloud-based platforms—all of which are encompassed by this research category [39–42].

Following this, the Manufacturing category accounts for 20.89% of the results, reinforcing the relevance of DTs in process optimization and digital control systems. DTs are particularly impactful in advanced manufacturing processes, including additive manufacturing (AM), where they enable real-time feedback loops, defect detection, and lifecycle simulation. These capabilities are central to the push for “smart factories” and Industry 4.0 applications. Characterization (16.00%) and Energy and Sustainability (12.21%) also exhibit significant activity. In material characterization, DTs support predictive insights into material responses, optimize experimental protocols, and enhance reliability through digital replicas of test environments [17,43–45]. In the energy sector, DTs are used to simulate battery aging, monitor thermal material performance, and improve sustainability through predictive maintenance and system diagnostics [46–49]. The category Soft Materials and Biomaterials follows with 10.17%, suggesting growing interest in applying DTs to biomedical and flexible materials contexts. Applications include tissue modeling, personalized biomaterial design, and smart prosthetic development—fields where DTs can simulate complex biological interactions in real-time [50].

Moderate representation is found in Electronics, Optics, and Photonics (5.27%), and Nanomaterials (2.42%). In these areas, DTs contribute primarily through nanoscale process simulations, optoelectronic device modeling, and adaptive design of smart nanocomposites [51,52]. Structural and Functional Materials (1.86%) and Materials for Quantum Information and Topological Systems (0.50%) are the least represented, which may reflect narrower query scopes or their inclusion under broader categories such as theory or electronics. Nonetheless, these areas also offer fertile ground for DT deployment, particularly in smart sensing, multifunctional composites, and structural health monitoring systems [53,54].

In summary, the analysis of thematic frequency confirms that the most prominent and enabling field for DTs within materials science are Materials Theory, Computation, and Data Science. This domain provides the methodological backbone that allows DTs to function as intelligent, adaptive systems capable of enhancing materials discovery, performance prediction, and lifecycle optimization. Its dominance reinforces the idea that the advancement of DTs is inseparable from progress in computational infrastructure, modeling accuracy, and data integration which are at the heart of this thematic cluster. Other research subareas that have made substantial contributions to the implementation of digital twins is Manufacturing and Material characterization. Considering that these domains have also seen extensive exploration of virtual reality technologies [37] and artificial intelligence [38], such subareas arguably represent the most advanced application of immersive technologies within the field of materials science and engineering.

4.3 Conceptual Structure and Thematic Evolution of DT Research in Materials Science

To provide a deeper understanding of the conceptual landscape and evolution of DT research in materials science and engineering, this section presents a keyword co-occurrence network, a strategic thematic map based on centrality and density metrics and trend topics analysis.

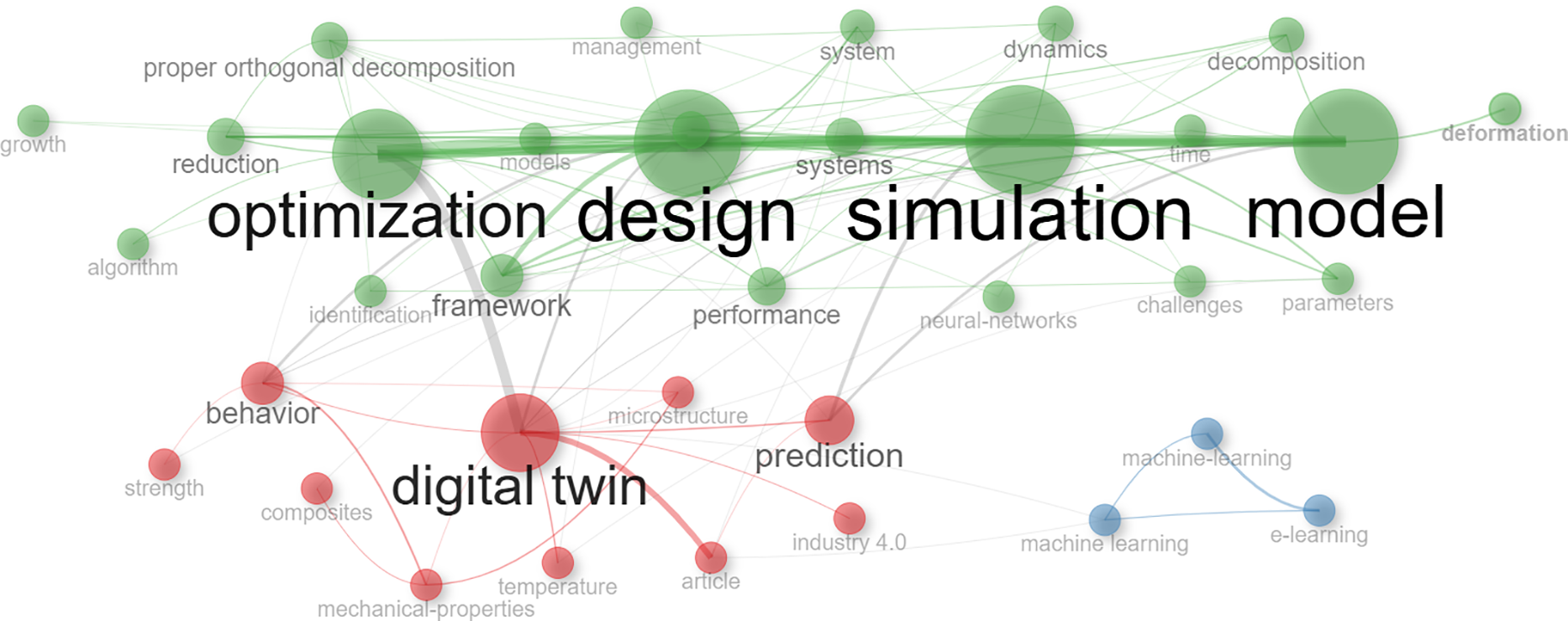

Fig. 12 presents the co-occurrence network of keywords extracted from the bibliographic data. The nodes represent keywords, and their size reflects frequency of occurrence, while the connecting lines denote co-occurrence relationships. Two main thematic clusters are clearly distinguishable. On the one hand, the first cluster, shown in green, comprises keywords such as optimization, design, simulation, and model, which are closely linked and represent the methodological foundation of DT implementations. These terms highlight the computational modeling and system engineering aspects that are crucial for building virtual replicas capable of predicting the behavior of complex material systems. The strong interconnectivity suggests a well-established subdomain that emphasizes simulation-driven optimization processes. On the other hand, the second cluster, depicted in red, revolves around the term digital twin and includes keywords such as prediction, microstructure, mechanical-properties, behavior, and temperature. This cluster emphasizes the materials-specific dimension of DT, particularly its use in simulating and predicting material responses under various physical conditions. The close association with microstructural and behavioral descriptors indicates the application of DTs at finer scales, reflecting a growing interest in integrating virtual representations with real-time material data. Additional clusters, such as the blue cluster associated with machine-learning and e-learning, indicate peripheral but increasingly relevant intersections between DT and artificial intelligence. These suggest the development of smart, adaptive systems for materials research and education.

Figure 12: Co-occurrence network of keywords in DT in materials science research

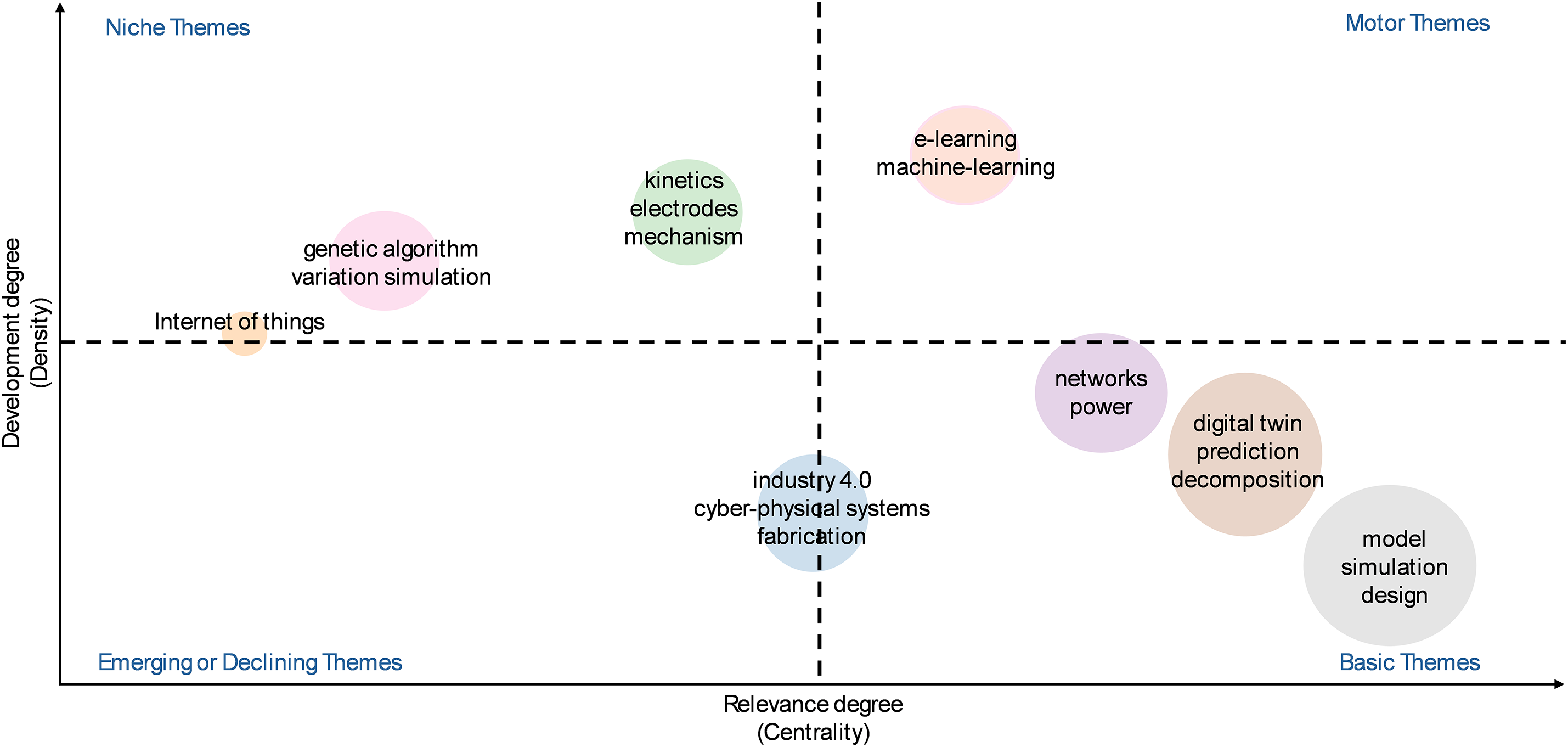

Fig. 13 presents a strategic thematic map that classifies research themes into four quadrants based on their development (density) and relevance (centrality). This map reveals that themes such as machine-learning (betweenness centrality: 408.18; density proxy via closeness: 0.002) and e-learning (280.83; 0.002) fall within the upper-right quadrant (Motor Themes), indicating that these areas are both well-developed and central to current DT research. Their prominent position highlights the growing integration of intelligent technologies in DT environments, which may contribute significantly to real-time analysis and decision-making capabilities. In contrast, the lower-right quadrant (Basic Themes) includes fundamental concepts such as digital twin (3007.18; 0.002), prediction (1163.51; 0.002), decomposition (622.65; 0.002), simulation (2829.27; 0.002), design (2290.95; 0.002), and model (2388.32; 0.002). These keywords constitute the conceptual backbone of the field. Despite their high relevance, the relatively lower density indicates that while these topics are central, there is still room for further methodological refinement and interdisciplinary articulation, particularly concerning their application in materials-specific contexts. The top-left quadrant (Niche Themes) contains more specialized terms such as genetic algorithm (59.86; 0.002), variation simulation (31.36; 0.002), electrodes (65.83; 0.002), and mechanism (107.70; 0.002), which are densely developed yet marginal in relevance. These topics reflect focused investigations that, although technically advanced, are not yet fully integrated into the core DT research landscape. Finally, the lower-left quadrant (Emerging or Declining Themes) includes keywords such as Internet of Things (101.49; 0.002), Industry 4.0 (117.12; 0.002), cyber-physical systems (135.95; 0.002), and fabrication (458.55; 0.002). Their presence in this quadrant may suggest a reduced centrality in the current literature, possibly due to the maturation of these concepts or a shift in focus toward more application-specific domains within DT.

Figure 13: Strategic thematic map of DT in materials science research

In this regard, the role of machine learning is increasingly pivotal across several functional layers. In materials science, machine learning models are commonly used as surrogates for computationally expensive simulations, enabling rapid approximation of complex behaviors such as stress–strain responses, thermal gradients, or microstructural evolution. Furthermore, machine learning facilitates real-time model updating by integrating sensor data streams into predictive models, ensuring that the digital replica remains synchronized with the physical system. In adaptive control applications, reinforcement learning and Bayesian optimization are employed to dynamically adjust process parameters—such as in AM or thermal treatment—based on feedback from both simulated and physical environments.

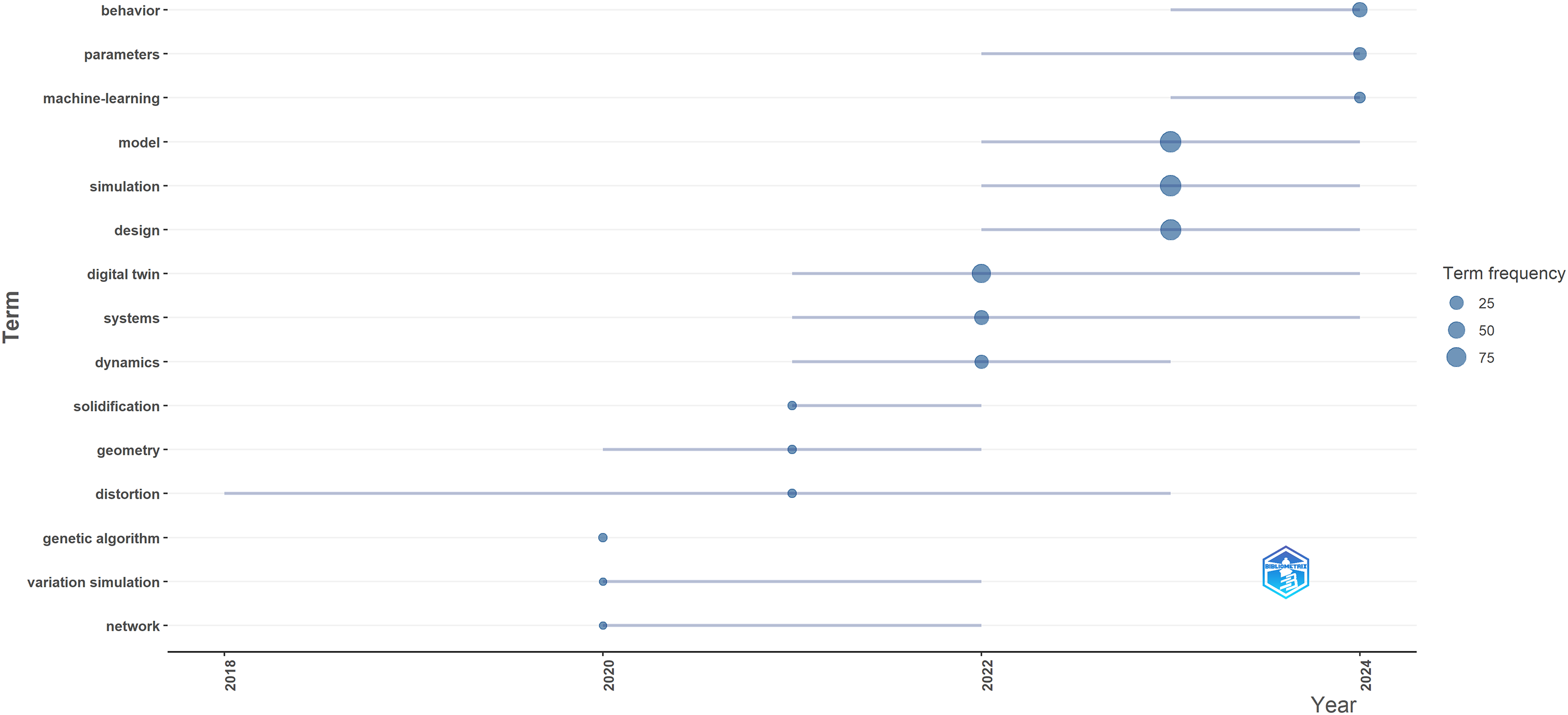

In order to gain additional insights into the temporal evolution of key themes in the field, Fig. 14 presents a trend topics analysis based on term frequency and time of emergence. This figure highlights both persistent and emergent concepts extracted from the bibliographic dataset. Notably, terms such as digital twin, simulation, model, and design have been present since the early stages of the field’s development and continue to exhibit strong presence through 2024. In contrast, more recent topics such as machine learning, parameters, and behavior have shown significant momentum in the last two years, suggesting a growing shift toward data-driven, predictive, and adaptive systems. The emergence of specialized terms such as solidification, distortion, and genetic algorithms further illustrates the increasing technical granularity and modeling depth in DT research applied to materials science. This temporal perspective complements the structural mapping presented earlier and helps identify high-impact research directions and upcoming subfields within the community.

Figure 14: Trend topics analysis based on the temporal evolution and frequency of keywords

In summary, the combined interpretation of Figs. 12–14 indicates that the DT field in materials science is structured around two dominant pillars: computational simulation and system optimization, and materials-level prediction and behavior modeling. This trial characterization confirms that, in this field, DT research is prominent and central to the convergence of engineering simulation, intelligent systems, and materials behavior prediction.

4.4 Industrial Impact and Strategic Direction

In parallel with academic research, the industrial sector has become a driving force in the development and deployment of DT technologies within the area. Several global companies have established dedicated platforms and solutions to apply DTs across the materials lifecycle, from design and processing to performance monitoring and maintenance. Among them, Siemens, General Electric, Dassault Systèmes, PTC, and Ansys have emerged as leading contributors [55–57]. Siemens’ Xcelerator platform, for instance, offers an integrated DT environment that combines sensor data, simulation, and analytics for predictive material behavior and manufacturing optimization, especially in aerospace and industrial machinery. Similarly, GE’s Predix platform focuses on digital twins of critical components in power generation and aviation, enabling real-time monitoring and failure prediction based on material fatigue models and thermal stress simulations. Dassault Systèmes’ 3DEXPERIENCE platform is heavily oriented toward collaborative virtual prototyping, providing a unified digital environment where engineers can model, simulate, and test material systems under varying conditions. PTC’s ThingWorx and Ansys’ Twin Builder also contribute significantly to digital transformation by enabling scalable DT solutions based on physics-based models, embedded analytics, and machine learning.

These industrial platforms serve as both technological tools and strategic assets, aligned with broader corporate digitalization roadmaps. Many of these companies have published clear long-term visions that position DTs as core enablers of Industry 4.0, smart manufacturing, and sustainability transitions. For example, Siemens and General Electric have committed to expanding the capabilities of their DT solutions to include multiscale materials modeling, integration with AI-driven optimization algorithms, and support for decentralized edge/cloud architectures. Dassault Systèmes, through its strategic alliances with materials innovation centers, has emphasized DT-based virtual material design environments, particularly in sectors like aerospace, biomedical, and electronics. These initiatives reflect a shift toward closed-loop material development, where the interaction between real-time data and predictive simulation accelerates innovation cycles and supports circular economy principles. Furthermore, many of these platforms are increasingly adopting open standards and promoting interoperability with public research institutions, indicating a growing convergence between industrial and academic DT ecosystems. This industrial engagement highlights the transformative potential of DTs to enhance operational efficiency and drive more intelligent, adaptive, and sustainable materials technologies.

This review has examined the role of digital twins (DTs) in materials science and engineering through a systematic bibliometric analysis of 1106 peer-reviewed scientific articles indexed in Scopus and Web of Science from 2015 to 2025. The study employed a five-phase methodology to retrieve, classify, and evaluate scientific production, thematic areas, citation impact, and keyword patterns. The documents were analyzed both quantitatively—through citation metrics, source and country performance—and qualitatively—via thematic clustering and strategic keyword mapping. The review was structured around ten subareas established by the Materials Research Society (MRS), providing a comprehensive view of the conceptual and application-driven evolution of DTs in materials science and engineering.

The results show a remarkable increase in scientific output on DTs, with an average annual growth rate of 66.53%, especially accelerating from 2020 onward. The most prominent thematic category identified was Materials Theory, Computation, and Data Science, representing 28.77% of the indexed publications. This underscores the foundational importance of simulation environments, computational modeling, and data-driven strategies in enabling DT functionality. The Manufacturing category followed closely with 20.89%, highlighting the relevance of DTs in process optimization, production control, and digital integration within advanced manufacturing systems. Other notably active subfields included Characterization (16.00%) and Energy and Sustainability (12.21%), both of which reflect the increasing role of DTs in predictive testing, real-time system diagnostics, and performance monitoring across experimental and application-oriented material research. Additionally, co-occurrence networks and strategic maps revealed that DTs are conceptually anchored in modeling, optimization, and simulation, while increasingly integrating with peripheral themes such as machine learning, cyber-physical systems, and e-learning.

The thematic discussion based on the most cited documents highlighted four dominant streams of DT research: (i) conceptual frameworks and modeling foundations, (ii) DTs in additive manufacturing (iii) sector-specific implementations, and (iv) integration with emerging technologies for sustainability. These clusters underscore the versatility of DTs as both a modeling paradigm and a practical tool for improving process efficiency, quality assurance, and material innovation. While additive manufacturing has emerged as a leading application domain, recent studies also demonstrate the potential of DTs in sustainable battery design, biomedical materials, and smart cities—thus broadening the scope of future implementations.

To sum up, this review contributes to a clearer understanding of the DT research landscape in material science and engineering, offering insights into both established and emerging trends. The findings are valuable for researchers and practitioners aiming to deploy DTs in areas such as process optimization, predictive maintenance, and digital material testing. However, several challenges remain, including data interoperability, real-time integration, and multiscale model validation. Future research should focus on enhancing the fidelity and adaptability of DTs, promoting open data standards, and exploring interdisciplinary synergies—particularly with artificial intelligence, biomimetic design, and sustainable engineering—to fully exploit the transformative potential of DTs in materials science.

Acknowledgement: Not applicable.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm contribution to the paper as follows: Conceptualization, Diego Vergara, Antonio del Bosque and Pablo Fernández-Arias; methodology, Diego Vergara and Antonio del Bosque; software, Antonio del Bosque; validation, Diego Vergara and Pablo Fernández-Arias; formal analysis, Antonio del Bosque and Pablo Fernández-Arias; investigation, Diego Vergara, Antonio del Bosque and Pablo Fernández-Arias; data curation, Diego Vergara and Antonio del Bosque; writing—original draft preparation, Diego Vergara and Antonio del Bosque; writing—review and editing, Diego Vergara, Antonio del Bosque and Pablo Fernández-Arias; supervision, Diego Vergara, Antonio del Bosque and Pablo Fernández-Arias. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The authors confirm that the data supporting the findings of this study are available within the article.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

Supplementary Material: The supplementary material is available online at https://www.techscience.com/doi/10.32604/cmc.2025.067881/s1.

References

1. Zhu Z, Liu C, Xu X. Visualisation of the Digital Twin data in manufacturing by using Augmented Reality. Procedia CIRP. 2019;81(2):898–903. doi:10.1016/J.PROCIR.2019.03.223. [Google Scholar] [CrossRef]

2. Vergara D, Rubio MP, Lorenzo M. Interactive virtual platform for simulating a concrete compression test. Key Eng Mater. 2014;572:582–5. doi:10.4028/WWW.SCIENTIFIC.NET/KEM.572.582. [Google Scholar] [CrossRef]

3. Tuhaise TahVV, Abanda JHM, Abanda FH. Technologies for digital twin applications in construction. Autom Constr. 2023;152(1–2):104931. doi:10.1016/J.AUTCON.2023.104931. [Google Scholar] [CrossRef]

4. Galeazzi A, Marenghi P, Duò L, Galardo M, Rota R, Sancassani S, et al. Virtual reality and digital twins for enhanced learning in chemical engineering. Comput Aid Chem Eng. 2024;53:3535–40. doi:10.1016/B978-0-443-28824-1.50590-1. [Google Scholar] [CrossRef]

5. Vergara D, Extremera J, Rubio MP, Dávila LP. The technological obsolescence of virtual reality learning environments. Appl Sci. 2020;10(3):915. doi:10.3390/APP10030915. [Google Scholar] [CrossRef]

6. Crepory A, De Oliveira A, Alves Borges R. A categorization of digital twin and model-based system engineering interactions. Appl Sci. 2025;15(10):5333. doi:10.3390/APP15105333. [Google Scholar] [CrossRef]

7. Glaessgen EH, Stargel DS. The digital twin paradigm for future NASA and U.S. Air force vehicles. In: AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference; Honolulu, HI, USA; 2012. doi:10.2514/6.2012-1818. [Google Scholar] [CrossRef]

8. Kritzinger W, Karner M, Traar G, Henjes J, Sihn W. Digital Twin in manufacturing: a categorical literature review and classification. IFAC-PapersOnLine. 2018;51(11):1016–22. doi:10.1016/J.IFACOL.2018.08.474. [Google Scholar] [CrossRef]

9. Hribernik K, Cabri G, Mandreoli F, Mentzas G. Autonomous, context-aware, adaptive Digital Twins—state of the art and roadmap. Comput Ind. 2021;133(3):103508. doi:10.1016/J.COMPIND.2021.103508. [Google Scholar] [CrossRef]

10. Zech P, Jäger A, Schneiderbauer L, Exenberger H, Fröch G, Flora M. Agile construction digital twin engineering. Buildings. 2025;15(3):386. doi:10.3390/BUILDINGS15030386. [Google Scholar] [CrossRef]

11. Wang G, Zheng X, Psarommatis F, Ramirez CA, Agrawal P, Thompson AE. An approach integrating model-based systems engineering, IoT, and digital twin for the design of electric unmanned autonomous vehicles. Systems. 2025;13(2):73. doi:10.3390/SYSTEMS13020073. [Google Scholar] [CrossRef]

12. Bado MF, Tonelli D, Poli F, Zonta D, Casas JR. Digital twin for civil engineering systems: an exploratory review for distributed sensing updating. Sensors. 2022;22(9):3168. doi:10.3390/S22093168. [Google Scholar] [PubMed] [CrossRef]

13. Li X, Li G, Bi Z. Digital twins to predict crack propagation of sustainable engineering materials under different loads. Machines. 2024;12(2):125. doi:10.3390/MACHINES12020125. [Google Scholar] [CrossRef]

14. Guinea-Cabrera MA, Holgado-Terriza JA. Digital twins in software engineering—a systematic literature review and vision. Appl Sci. 2024;14(3):977. doi:10.3390/APP14030977. [Google Scholar] [CrossRef]

15. Perzylo A, Profanter S, Rickert M, Knoll A. OPC UA NodeSet ontologies as a pillar of representing semantic digital twins of manufacturing resources. In: IEEE International Conference on Emerging Technologies and Factory Automation, ETFA; Zaragoza, Spain; 2019. p. 1085–92. doi:10.1109/ETFA.2019.8868954. [Google Scholar] [CrossRef]

16. Müller M, Mielke J, Pavlovskyi Y, Pape A, Masik S, Reggelin T, et al. Real-time combination of material flow simulation, digital twins of manufacturing cells, an AGV and a mixed-reality application. Procedia CIRP. 2021;104:1607–12. doi:10.1016/J.PROCIR.2021.11.271. [Google Scholar] [CrossRef]

17. Song J, Ihuaenyi RC, Lim J, Wang Z, Li W, Fang R, et al. A microstructural electrochemo-mechanical model of high-nickel composite electrodes towards digital twins to bridge the particle and electrode-level characterizations. Energy Environ Sci. 2025;18(7):3129–47. doi:10.1039/D4EE04856C. [Google Scholar] [CrossRef]

18. Niu Z, Pinfield VJ, Wu B, Wang H, Jiao K, Leung DYC, et al. Towards the digitalisation of porous energy materials: evolution of digital approaches for microstructural design. Energy Environ Sci. 2021;14(5):2549–76. doi:10.1039/D1EE00398D. [Google Scholar] [CrossRef]

19. He Y, Ma Y, Huang K, Wang L, Zhang J. Digital twin Bayesian entropy framework for corrosion fatigue life prediction and calibration of bridge suspender. Reliab Eng Syst Saf. 2024;252(5):110456. doi:10.1016/J.RESS.2024.110456. [Google Scholar] [CrossRef]

20. Heng J, Dong Y, Lai L, Zhou Z, Frangopol DM. Digital twins-boosted intelligent maintenance of ageing bridge hangers exposed to coupled corrosion-fatigue deterioration. Autom Constr. 2024;167(2):105697. doi:10.1016/J.AUTCON.2024.105697. [Google Scholar] [CrossRef]

21. Materials Research Society—2025 MRS Fall Meeting & Exhibit n.d. [cited 2025 May 11]. Available from: https://www.mrs.org/meetings-events/annual-meetings/2025-mrs-fall-meeting. [Google Scholar]

22. Page MJ, McKenzie JE, Bossuyt PM, Boutron I, Hoffmann TC, Mulrow CD, et al. The PRISMA, 2020 statement: an updated guideline for reporting systematic reviews. Int J Surg. 2021;88:105906. doi:10.1016/J.IJSU.2021.105906. [Google Scholar] [PubMed] [CrossRef]

23. Haddaway NR, Page MJ, Pritchard CC, McGuinness LA. PRISMA2020: an R package and Shiny app for producing PRISMA 2020-compliant flow diagrams, with interactivity for optimised digital transparency and Open Synthesis. Campbell System Rev. 2022;18(2):e1230. doi:10.1002/CL2.1230. [Google Scholar] [PubMed] [CrossRef]

24. del Bosque A, Vergara D, Lampropoulos G, Fernández-Arias P. Energy storage in carbon fiber-based batteries: trends and future perspectives. Appl Sci. 2024;14(21):10034. doi:10.3390/APP142110034. [Google Scholar] [CrossRef]

25. del Bosque A, Fernández-Arias P, Vergara D. Titanium additive manufacturing with powder bed fusion: a bibliometric perspective. Appl Sci. 2024;14(22):10543. doi:10.3390/APP142210543. [Google Scholar] [CrossRef]

26. del Bosque A, Lampropoulos G, Vergara D. Nanocomposites for multifunctional sensors: a comprehensive bibliometric exploration. Nanomaterials. 2024;15(1):34. doi:10.3390/NANO15010034. [Google Scholar] [PubMed] [CrossRef]

27. Rasheed A, San O, Kvamsdal T. Digital twin: values, challenges and enablers from a modeling perspective. IEEE Access. 2020;8:21980–2012. doi:10.1109/ACCESS.2020.2970143. [Google Scholar] [CrossRef]

28. Alam KM, El Saddik A. C2PS: a digital twin architecture reference model for the cloud-based cyber-physical systems. IEEE Access. 2017;5:2050–62. doi:10.1109/ACCESS.2017.2657006. [Google Scholar] [CrossRef]

29. Wang CY, Liu T, Yang XG, Ge S, Stanley NV, Rountree ES, et al. Fast charging of energy-dense lithium-ion batteries. Nature. 2022;611(7936):485–90. doi:10.1038/S41586-022-05281-0. [Google Scholar] [PubMed] [CrossRef]

30. Liu Q, Zhang H, Leng J, Chen X. Digital twin-driven rapid individualised designing of automated flow-shop manufacturing system. Int J Prod Res. 2019;57(12):3903–19. doi:10.1080/00207543.2018.1471243. [Google Scholar] [CrossRef]

31. Knapp GL, Mukherjee T, Zuback JS, Wei HL, Palmer TA, De A, et al. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017;135(3):390–9. doi:10.1016/J.ACTAMAT.2017.06.039. [Google Scholar] [CrossRef]

32. Mandolla C, Petruzzelli AM, Percoco G, Urbinati A. Building a digital twin for additive manufacturing through the exploitation of blockchain: a case analysis of the aircraft industry. Comput Ind. 2019;109(2):134–52. doi:10.1016/J.COMPIND.2019.04.011. [Google Scholar] [CrossRef]

33. Xia H, Liu Z, Efremochkina M, Liu X, Lin C. Study on city digital twin technologies for sustainable smart city design: a review and bibliometric analysis of geographic information system and building information modeling integration. Sustain Cities Soc. 2022;84(19):104009. doi:10.1016/J.SCS.2022.104009. [Google Scholar] [CrossRef]

34. Mukherjee T, DebRoy T. A digital twin for rapid qualification of 3D printed metallic components. Appl Mater Today. 2019;14:59–65. doi:10.1016/J.APMT.2018.11.003. [Google Scholar] [CrossRef]

35. Liu S, Bao J, Lu Y, Li J, Lu S, Sun X. Digital twin modeling method based on biomimicry for machining aerospace components. J Manuf Syst. 2021;58(12):180–95. doi:10.1016/J.JMSY.2020.04.014. [Google Scholar] [CrossRef]

36. Angjeliu G, Coronelli D, Cardani G. Development of the simulation model for Digital Twin applications in historical masonry buildings: the integration between numerical and experimental reality. Comput Struct. 2020;238(3):106282. doi:10.1016/J.COMPSTRUC.2020.106282. [Google Scholar] [CrossRef]

37. Extremera J, Vergara D, Rodríguez S, Dávila LP. Reality-virtuality technologies in the field of materials science and engineering. Appl Sci. 2022;12(10):4968. doi:10.3390/APP12104968. [Google Scholar] [CrossRef]

38. Vergara D, Lampropoulos G, Fernández-Arias P, Antón-Sancho Á. Artificial intelligence reinventing materials engineering: a bibliometric review. Appl Sci. 2024;14(18):8143. doi:10.3390/APP14188143. [Google Scholar] [CrossRef]

39. Antonini L, Berti F, Isella B, Hossain D, Mandelli L, Pennati G, et al. From the real device to the digital twin: a coupled experimental-numerical strategy to investigate a novel bioresorbable vascular scaffold. PLoS One. 2021;16(6):e0252788. doi:10.1371/JOURNAL.PONE.0252788. [Google Scholar] [PubMed] [CrossRef]

40. Nguyen PCH, Vlassis NN, Bahmani B, Sun WC, Udaykumar HS, Baek SS. Synthesizing controlled microstructures of porous media using generative adversarial networks and reinforcement learning. Sci Rep. 2022;12(1):1–16. doi:10.1038/S41598-022-12845-7. [Google Scholar] [PubMed] [CrossRef]

41. Yağcı T, Cöcen Ü, Çulha O. Aluminum alloy development for wheel production by low pressure die casting with new generation computational materials engineering approaches. Arch Foundry Eng. 2021;21:35–46. doi:10.24425/AFE.2021.138677. [Google Scholar] [CrossRef]

42. Gopalakrishnan S, Hartman NW, Sangid MD. Integrating materials model-based definitions into design, manufacturing, and sustainment: a digital twin demonstration of incorporating residual stresses in the lifecycle analysis of a turbine disk. J Comput Inf Sci Eng. 2021;21. doi:10.1115/1.4048426/1086979. [Google Scholar] [CrossRef]

43. Ghanem R, Soize C, Mehrez L, Aitharaju V. Probabilistic learning and updating of a digital twin for composite material systems. Int J Numer Methods Eng. 2022;123(13):3004–20. doi:10.1002/NME.6430. [Google Scholar] [CrossRef]

44. Hu E, Choo HH, Zhang W, Sumboja A, Anggraningrum IT, Syahrial AZ, et al. Integrating machine learning and characterization in battery research: toward cognitive digital twins with physics and knowledge. Adv Funct Mater. 2025;2025(25):2422601. doi:10.1002/ADFM.202422601. [Google Scholar] [CrossRef]

45. Sweat R, Park JG, Liang R. A digital twin approach to a quantitative microstructure-property study of carbon fibers through HRTEM characterization and multiscale FEA. Materials. 2020;13(19):4231. doi:10.3390/MA13194231. [Google Scholar] [PubMed] [CrossRef]

46. Vorozhtsov AB, D’yachenko NN. Digital twin of a high-energy system using aluminum hydride as a fuel. J Eng Phys Thermophys. 2021;94(4):972–6. doi:10.1007/S10891-021-02374-X. [Google Scholar] [CrossRef]

47. Meshalkin VP. Current theoretical and applied research on energy- and resource-saving highly reliable chemical process systems engineering. Theor Found Chem Eng. 2021;55(4):563–87. doi:10.1134/S004057952104031X. [Google Scholar] [CrossRef]

48. Olayiwola O, Cali U, Elsden M, Yadav P. Enhanced solar photovoltaic system management and integration: the digital twin concept. Solar. 2025;5(1):7. doi:10.3390/SOLAR5010007. [Google Scholar] [CrossRef]

49. Tan J, Radhi RM, Shirini K, Gharehveran SS, Parisooz Z, Khosravi M, et al. Innovative framework for fault detection and system resilience in hydropower operations using digital twins and deep learning. Sci Rep. 2025;15(1):1–28. doi:10.1038/S41598-025-98235-1. [Google Scholar] [PubMed] [CrossRef]

50. Mikołajewska E, Mikołajewski D, Mikołajczyk T, Paczkowski T. A breakthrough in producing personalized solutions for rehabilitation and physiotherapy thanks to the introduction of AI to additive manufacturing. Appl Sci. 2025;15:2219. doi:10.3390/APP15042219/S1. [Google Scholar] [CrossRef]

51. Beuerlein KU, Shojaati M, Ansari M, Panzer H, Shahabad SI, Keshavarz MK, et al. Microstructure simulation of maraging steel 1.2709 processed by powder bed fusion of metals using a laser beam: a cellular automata approach with varying process parameters. Results Mater. 2025;25:100667. doi:10.1016/J.RINMA.2025.100667. [Google Scholar] [CrossRef]

52. Dede EM, Zhou F, Zhou Y, Lohan DJ, Asheghi M, Goodson KE, et al. Applications, design methods, and challenges for additive manufacturing of thermal solutions for heterogeneous integration of electronics. J Electron Packag. 2025;147:021009. doi:10.1115/1.4067649/1211362. [Google Scholar] [CrossRef]

53. Sánchez-Romate XF, Bosque AD, Artigas-Arnaudas J, Muñoz BK, Sánchez M, Ureña A. A proof of concept of a structural supercapacitor made of graphene coated woven carbon fibers: EIS study and mechanical performance. Electrochim Acta. 2021;370:137746. doi:10.1016/J.ELECTACTA.2021.137746. [Google Scholar] [CrossRef]

54. Bosque A, Sánchez-Romate XF, Sánchez M, Ureña A. Ultrasensitive and highly stretchable sensors for human motion monitoring made of graphene reinforced polydimethylsiloxane: electromechanical and complex impedance sensing performance. Carbon. 2022;192(3):234–48. doi:10.1016/J.CARBON.2022.02.043. [Google Scholar] [CrossRef]

55. Zorchenko NV, Tyupina TG, Parshutin ME. Technologies used by general electric to create digital twins for energy industry. Power Technol Eng. 2024;58(3):521–6. doi:10.1007/S10749-024-01839-2. [Google Scholar] [CrossRef]

56. Tao F, Zhang H, Zhang C. Advancements and challenges of digital twins in industry. Nat Comput Sci. 2024;4(3):169–77. doi:10.1038/S43588-024-00603-W. [Google Scholar] [PubMed] [CrossRef]

57. Ameli A, Makelainen M, Huttunen J, Frigerio D, Rydin A, Qin K. Digital twin in manufacturing: transient thermo-mechanical simulations. In: 2024 23rd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm); Aurora, CO, USA; 2024. p. 1–7. doi:10.1109/ITHERM55375.2024.10709618. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools