Open Access

Open Access

ARTICLE

Modelling and Analysis of Enhanced Power Generation by Recovering Waste Heat from Fallujah White Cement Factory for Clean Energy Sustainability

1 Department of Mechanical Engineering, Faculty of Engineering, Karabük University, Karabük, 78050, Türkiye

2 Mechanical Engineering Department, University of Technology-Iraq, Baghdad, 10066, Iraq

3 Training and Workshop Center, University of Technology-Iraq, Baghdad, 10066, Iraq

4 Energy and Renewable Energies Technology Center, University of Technology-Iraq, Baghdad, 10066, Iraq

* Corresponding Author: Hasanain A. Abdul Wahhab. Email:

(This article belongs to the Special Issue: Advancements in Energy Resources and Their Processes, Systems, Materials and Policies for Affordable Energy Sustainability)

Energy Engineering 2026, 123(2), 22 https://doi.org/10.32604/ee.2025.073702

Received 23 September 2025; Accepted 20 November 2025; Issue published 27 January 2026

Abstract

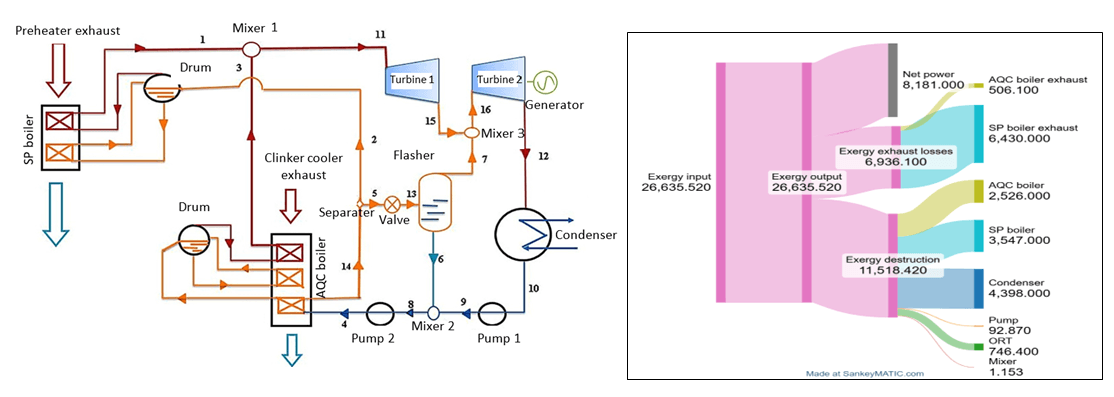

Improving energy efficiency and lowering negative environmental impact through waste heat recovery (WHR) is a critical step toward sustainable cement manufacturing. This study analyzes advanced cogeneration systems for recovering waste heat from the Fallujah White Cement Plant in Iraq. The novelty of this work lies in its direct application and comparative thermodynamic analysis of three distinct cogeneration cycles—the Organic Rankine Cycle, the Single-Flash Steam Cycle, and the Dual-Pressure Steam Cycle—within the Iraqi cement industry, a context that has not been widely studied. The main objective is to evaluate and compare these models to determine the most effective approach for enhancing energy and exergy efficiencies. The methodology involved detailed thermodynamic and exergy analyses of each system, supported by mathematical modelling and simulation using data from plant operations. The results reveal that the Dual-Pressure Steam Cycle emerged as the most effective system, delivering 13.76 MW of net power with a thermal efficiency of 32.8% and an exergy efficiency of 51%. This significantly outperformed the baseline Organic Rankine Cycle (8.18 MW, 18.8% thermal efficiency, 30.7% exergy efficiency). These findings confirm that multi-pressure steam cycles offer a robust and practical solution for the Fallujah plant. This application provides a clear, high-impact pathway to enhance national industrial energy efficiency, significantly reduce CO2 emissions, and promote clean energy sustainability in Iraq. Future work should consider economic feasibility and potential integration with renewable energy sources to further enhance sustainability.Graphic Abstract

Keywords

Cite This Article

Copyright © 2026 The Author(s). Published by Tech Science Press.

Copyright © 2026 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools