Open Access

Open Access

ARTICLE

Optimization of the Working Cycle Parameters of a Syngas Piston Engine Based on Mathematical Modeling

1 Turbines and Engines Department, Ural Federal University named after the First President of Russia B.N. Yeltsin, Yekaterinburg, 620062, Russia

2 New Energy Technologies Laboratory, Ural Federal University named after the First President of Russia B.N. Yeltsin, Yekaterinburg, 620062, Russia

* Corresponding Author: Leonid Plotnikov. Email:

(This article belongs to the Special Issue: Thermal Engineering Technology Innovation and Sustainable Development)

Energy Engineering 2025, 122(11), 4621-4633. https://doi.org/10.32604/ee.2025.070713

Received 22 July 2025; Accepted 18 September 2025; Issue published 27 October 2025

Abstract

Improving the specific, technical, economic, and environmental characteristics of piston engines (ICE) operating on alternative gaseous fuels is a pressing task for the energy and mechanical engineering industries. The aim of the study was to optimize the parameters of the ICE working cycle after replacing the base fuel (propane-butane blend) with syngas from wood sawdust to improve its technical and economic performance based on mathematical modeling. The modeling results were verified through experimental studies (differences for key parameters did not exceed 4.0%). The object of the study was an electric generator based on a single-cylinder spark ignition engine with a power of 1 kW. The article describes the main approaches to creating a mathematical model of the engine working cycle, a test bench for modeling verification, physicochemical properties of the base fuel (propane-butane blend), and laboratory syngas. It was shown that replacing the fuel from a propane-butane blend to laboratory syngas caused a decrease in engine efficiency to 33% (the efficiency of the base ICE was 0.179 vs. the efficiency of 0.119 for the converted ICE for the 0.59 kW power mode). Engine efficiency was chosen as the key criterion for optimizing the working cycle. As a result of optimization, the efficiency of the converted syngas engine was 6.1% higher than that of the base engine running on the propane-butane blend, and the power drop did not exceed 8.0%. Thus, careful fine-tuning of the working cycle parameters allows increasing the technical and economic characteristics of the syngas engine to the level of ICEs running on traditional types of fuel.Keywords

The internal combustion engine (ICE) is one of the most common energy converters, which is used in a variety of areas of human activity. ICE is used in everyday life (gasoline tools, motorboats, mopeds, cars, etc.), and in high-tech industries (aviation, shipbuilding, energy, etc.). Therefore, improving the specific, technical, economic, and environmental characteristics of engines remains an urgent task for science, engineering and technology.

Efficient use of alternative (renewable) fuels in ICEs is a promising task for ensuring sustainable development of the energy industry [1,2]. Today, scientists are actively introducing the use of various fuels in ICEs: methane [3], propane-butane blend [4], hydrogen [5,6], ammonia [7], methanol [8], syngas [9], biofuel [10], and mixtures of various components [11,12]. Each alternative fuel has its pros and cons when used in an engine. Therefore, the parameters of the ICE working cycle must be adjusted for specific fuel, taking into account its physical and chemical properties. Only in this case is it possible to obtain competitive characteristics of an engine running on alternative fuel.

One of the most promising and environmentally friendly fuels for ICEs is syngas from coal or wood [13]. Syngas is usually a gaseous fuel consisting mainly of hydrogen H2, methane CH4, and carbon monoxide CO. This gas can be obtained from various raw materials such as coal, wood, agricultural waste, food industry waste, seaweed, grass, straw, bagasse, sewage sludge, and tires through gasification, pyrolysis, or reforming processes [14,15]. Syngas is a renewable fuel because it can be produced from wood or waste from wood processing plants.

The current results of research on syngas engines are presented below. Traditional research consisted of obtaining technical and economic characteristics of ICEs on syngas, which was obtained in different ways and from different substances [16,17]. Kandasamy et al. studied the operation of an ICE on syngas obtained from glycerin [16]. It was shown that the engine power on syngas increased by 3.15%, NOx emissions were reduced by 21.22% compared to an ICE running on diesel fuel. Zhou et al. conducted similar studies for syngas obtained from various volatile organic compounds [17]. It was found that there was an economic effect from generating electricity from this syngas.

There are also many studies comparing the technical and economic characteristics of ICEs running on different types of fuel, including syngas [18–21]. Thus, Farkhondeh et al. compared the characteristics of an ICE with compression ignition running on biogas, syngas, and diesel fuel [18]. The maximum positive effect of using syngas is a reduction in CO emissions by 71%, NOx by 25%, and an increase in power by 6% compared to traditional diesel fuel. Dhairiyasamy et al. studied the operation of a dual-fuel engine running on biodiesel with various syngas additives [19]. The addition of syngas allowed to reduce specific fuel consumption by 6.5%, CO emissions decreased by 30%, and CH emissions fell by 25%; however, NOx emissions increased by 2.1%. Kantaroğlu analyzed the characteristics of a spark ignition engine running on syngas, hydrogen, and ammonia [20]. It was found that syngas is a competitive and environmentally friendly fuel and have prospects for use in ICEs with zero emissions.

Converting an ICE to run on syngas requires optimizing its working cycle parameters to obtain the best technical and environmental characteristics [22–24]. Wei et al. tuned the working cycle parameters of a spark ignition engine running on syngas to minimize emissions while maintaining output power based on numerical simulation [22]. The scientists were able to achieve a significant reduction in CO, CH, and NOx emissions from a syngas-powered ICE while maintaining output power compared to a gasoline-powered engine. There are also studies on the use of artificial intelligence algorithms to optimize the parameters of ICEs for operation on syngas of various compositions [23–25]. It has been shown that this approach is effective and leads to significant improvement in the technical and environmental characteristics of the ICE.

A separate area of research is the study of the influence of the syngas composition on the performance of ICEs [26,27]. Jamsran et al. clearly demonstrated the presence of a significant influence of the composition of syngas and its physical and chemical properties on the technical and environmental performance of a compression ignition engine [26]. Enomoto obtained similar data for a spark ignition ICE [27].

An important area of research is also the study of the effect of syngas on the combustion process in different ICEs [28–31]. Ran et al. studied the combustion process of syngas in an extremely lean mixture for a spark ignition engine [28]. The main goal was to obtain a stable combustion process and reduce emissions of harmful substances. Oleksandr et al. improved the combustion process of syngas as applied to a spark ignition engine [29]. Gobbato et al. conducted similar studies, but for a compression ignition ICE [30]. It was shown that the transition to syngas requires careful adjustment of engine parameters to achieve stable and high-quality combustion of the working fluid.

Thus, it must be concluded that there is a limited number of studies related to the study of the characteristics of the working cycle of the engine on synthesis gas and the development of methods for increasing its efficiency and power. This gap is partially closed by this study.

The objective of this study was to optimize the operating cycle parameters of an ICE after replacing the fuel with a propane-butane blend to syngas to improve its technical and economic performance based on mathematical modeling. The modeling results were verified by bench tests of the engine running on both a propane-butane blend and syngas.

The scientific hypothesis of the study was to find an accessible and simple way to improve the power and efficiency of an engine converted to run on syngas by optimizing the operating parameters of the ICE.

The scientific novelty of the study consists in specifying the degree of influence of various engine parameters on its power and efficiency in relation to the syngas ICE based on physical and mathematical modeling of the working cycle. Also, a comparative analysis of the operational characteristics of a gasoline engine and a syngas ICE for various operating modes has scientific value.

The practical significance of the study lies in the description of the method for fine-tuning a syngas engine to improve its performance characteristics based on a verified mathematical model. Engine manufacturers and ICE modernization organizations will find the results mentioned useful and applicable.

The article structure consists of a description of the research methods (mathematical model and laboratory setup), the results of verification of the mathematical model for a gasoline engine and an ICE running on syngas, and an analysis of methods for increasing the efficiency of a syngas engine.

2 Object, Methods and Statement of the Research Problem

The object of the research was the Huter HT1000L electric generator based on a four-stroke, single-cylinder piston engine running on a propane-butane blend. The main technical characteristics of the generator were: rated power Nn = 1.0 kW; crankshaft speed at rated power nn = 3600 min−1; maximum torque Мmax = 4 N m; specific fuel consumption at nominal mode gn = 450 g/(kW·h); cylinder diameter D = 52 mm; piston stroke S = 38 mm; compression ratio ε = 7.7; ignition timing angle φ = 21.5 degrees; excess air coefficient λ = 1.0. These parameters were basic for the created mathematical model and for conducting experimental studies.

The working cycle of this piston engine was simulated using the Diesel-RK program from the Russian University Bauman Moscow State Technical University. A brief description of the mathematical apparatus (calculation methods) for the “Diesel-RK” program is presented below. The parameters of the gas in the engine cylinder and the gas exchange system are determined by the step-by-step solution of the system of difference equations of conservation of energy, mass and the equation of state in the “Diesel-RK” program. These equations are written for open thermodynamic systems. The dependence of the properties of the working fluid on the chemical composition and temperature is considered in the calculations of gas exchange processes. The mathematical apparatus for gas exchange processes takes into account the non-stationary flow of gas in pipelines. The multi-zone model is used to calculate the combustion process in spark-ignition engines. The Vibe method is used to calculate the rate of heat release in the cylinder. The zone model is used to determine temperatures (the method of Professor V. A. Zvonov). Heat exchange in the main engine parts is calculated separately for different surfaces, the temperatures of which are determined by solving the heat conductivity problem. The heat transfer coefficient from gases to the cylinder wall is determined by the Voshni formula. A more detailed description of the mathematical apparatus of the “Diesel-RK” program can be found in [32,33]. The main limitations of the created mathematical models are that they are applicable only to a specific engine with a given power and geometric dimensions, and the models do not describe non-stationary processes in the ICE cylinder in sufficient detail.

The base fuel for use in the studied electric generator was a propane-butane blend. The following chemical composition of this blend was specified in the mathematical model: C3H8—98.7%; H2—1.0%; CO2—0.1%; N2—0.2%. The following main physicochemical properties of the propane-butane blend were also specified: net calorific value Hu = 46.47 MJ/kg; molecular weight M = 44.09 g/mol; density ρ = 1.967 kg/m3. These fuel properties fully corresponded to those for the propane-butane blend used in the bench tests.

The alternative fuel was syngas, which was obtained from sawdust with a moisture content of 10% through continuous gasification in the university laboratory “New Energy Technologies”. The chemical composition of the laboratory syngas was as follows: CH4—3.5%; CO2—14.3%; H2—8.6%; N2—55.9%; CO—17.7%. The laboratory syngas had the following physicochemical properties: net calorific value Hu = 3.58 MJ/kg; density ρ = 1.214 kg/m3. These data were specified in the mathematical model for simulating the working cycle of a piston engine running on syngas. These fuel properties fully corresponded to those for the syngas used in the bench tests.

The production of laboratory synthesis gas was achieved through a full-flow gasification process of wood sawdust in a specially designed apparatus. Two diffusers and two cylindrical sections made up the gasifier. Wood sawdust was fed into the apparatus by means of screws and was raised by means of air supplied from below. Within the apparatus, the following processes were executed: moisture evaporated from the wood sawdust, volatile substances were released, heterogeneous chemical reactions occurred, slag formation and heavy hydrocarbon compounds (resins) were condensed. The gas was captured at the apparatus outlet, cooled, filtered, and resins were separated and fed into the fuel system of the piston engine for the operation of the power plant.

An experimental setup based on an electric generator with a piston engine was created to verify mathematical models (Fig. 1). The main technical characteristics of the setup are presented above. The engine could operate on propane-butane blend (in gaseous state) and syngas. It was possible to obtain engine parameters (fuel and air consumption, efficiency, exhaust gas composition) depending on the power (load) during the experiments. The tests were conducted at a constant crankshaft speed n = 3600 min−1 for different loads (from idle to 0.9 kW). It is known that the state of the power plant battery has a significant impact on the operating characteristics and performance indicators [34]. However, in this case, this factor was excluded, since the internal combustion engine was started by human mechanical force (manual rotation of the crankshaft for starting).

Figure 1: Photograph of the experimental setup for verification of the simulation results: 1—electric generator based on a piston ICE; 2—electric loading device; 3—cylinder with propane-butane blend; 4—gas rotameter; 5—air flow meter

The algorithm for conducting experiments for a gaseous fuel engine was as follows: (1) the gasifier was started to produce synthesis gas or a cylinder with a propane-butane mixture was prepared; (2) the valves for supplying gas to the piston engine were opened; (3) the internal combustion engine as part of an electric generator was manually started; (4) smooth adjustment of the air-fuel ratio (excess air ratio) was performed by means of valves; (5) the engine load was set (electric lamps were turned on/off); (6) a stable engine operating mode was waited for; (7) engine operating parameters were recorded.

Gas consumption (propane-butane blend or syngas) was determined using an RMS gas rotameter from the Russian company Pribor-M. The relative uncertainty of gas consumption determination was 2.5%. Air consumption through the engine was determined using a Meta-215 flow meter from the Russian company Emis. The relative uncertainty of air consumption determination was 1.5%.

The load (resistance) for the electric generator was set by successively switching on/off incandescent lamps with a power of 50 to 100 W. The relative uncertainty in determining the engine power was 5.5%. The series of experiments was carried out at least 2–3 times to confirm the reproducibility of the results.

3 Verification of a Mathematical Model through Experimental Research

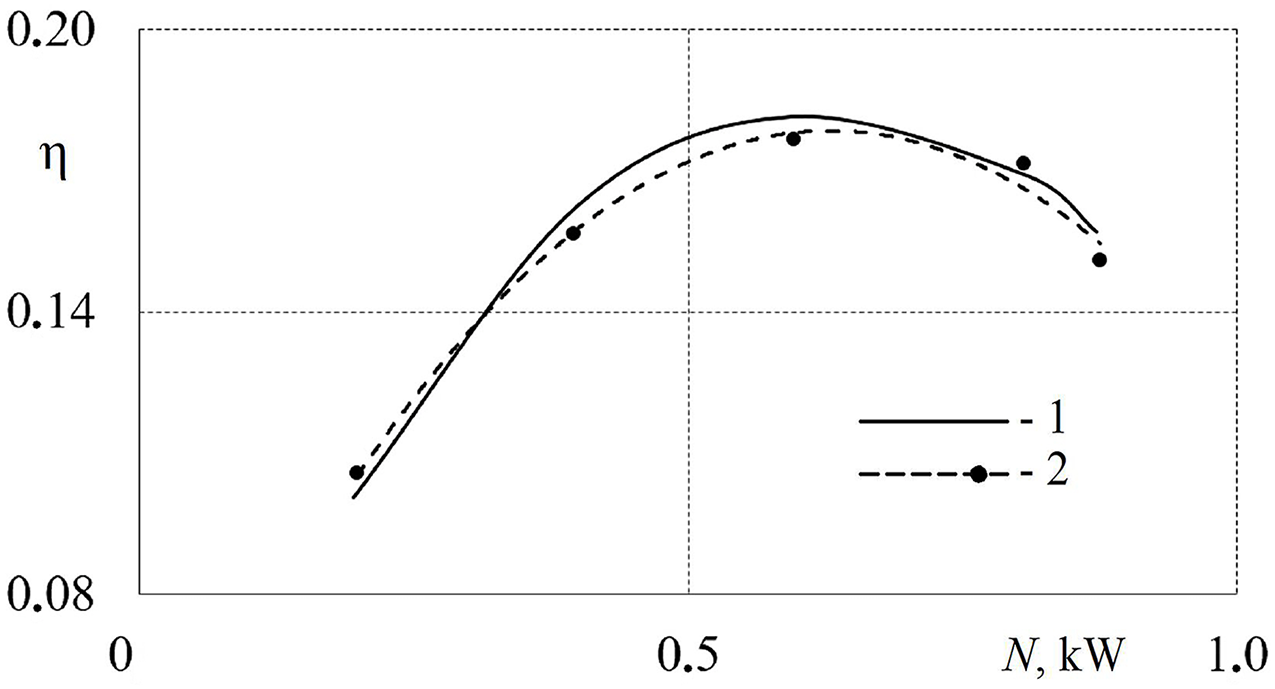

Verification of the modeling results by means of experimental studies for engines running on propane-butane blend and syngas is presented below. A comparison of the efficiency values of an ICE running on a propane-butane blend for the mathematical model and tests is shown in Fig. 2.

Figure 2: Calculated and experimental dependences of the efficiency η on the power N for a piston engine operating on a propane-butane blend: 1—simulation; 2—experiment

The dependence form η = f (N) is identical for modeling and experiments. In particular, the maximum of the function η = f (N) occurs in the region of a power equal to 0.6 kW. The differences in the engine efficiency values for modeling and testing do not exceed 4.1%. A comparison of other engine indicators (operation on a propane-butane blend) for a load of 0.875 kW is summarized in Table 1.

Table 1 shows that the differences in engine power do not exceed 0.3%; the difference in fuel consumption is in the range of 2.7%–3.0%; air flow characteristics are within 3.7%; the maximum differences in efficiency reach 4.1%. It can be concluded from Fig. 1 and the data in Table 1 that the mathematical model reliably simulates the main indicators of the working cycle of an electric generator based on a piston engine running on a propane-butane blend.

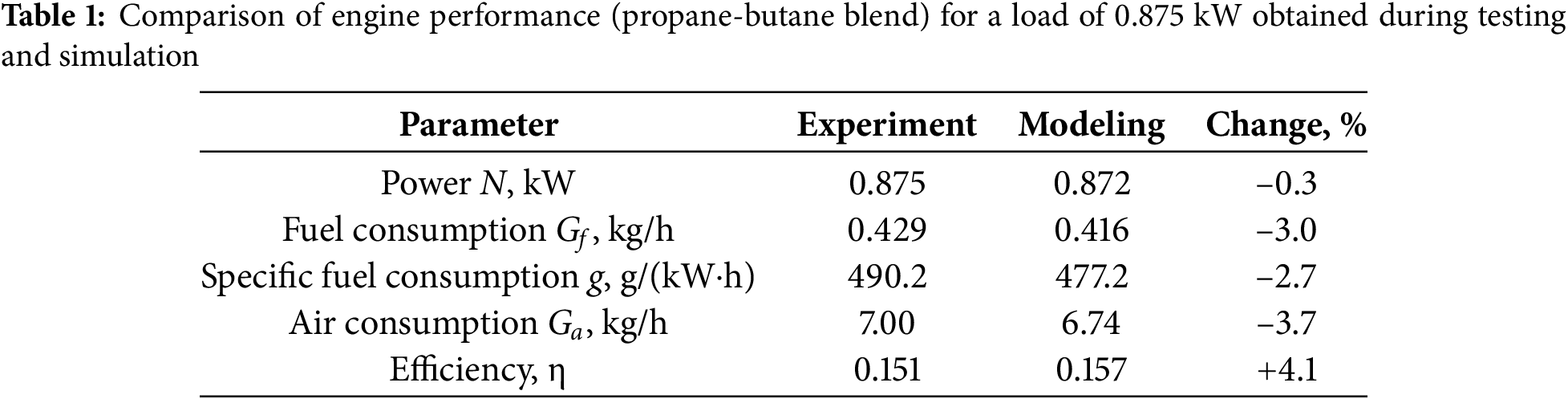

Experimental studies of a piston engine running on syngas were also conducted to verify the mathematical model. Only the fuel was changed (the propane-butane blend was replaced by syngas) in the mathematical model and the operating engine. All other engine operating parameters (compression ratio, ignition advance angle, excess air coefficient, etc.) remained unchanged. A comparison of the efficiency of the engine running on syngas for the mathematical model and tests is shown in Fig. 3.

Figure 3: Calculated and experimental dependences of the efficiency η on the power N for a piston engine running on syngas: 1—simulation; 2—experiment

The form of the η = f (N) dependence is identical for the simulation and experiments. The maximum power developed by the engine decreased from 0.9 to 0.6 kW due to the replacement of gaseous fuel. The maximum of the η = f (N) function is in the region of 0.4 kW for the case of engine operation on syngas. The differences in the engine efficiency values for the simulation and tests also do not exceed 4.0%. A comparison of other ICE parameters (operation on syngas) for a load of 0.58 kW is summarized in Table 2.

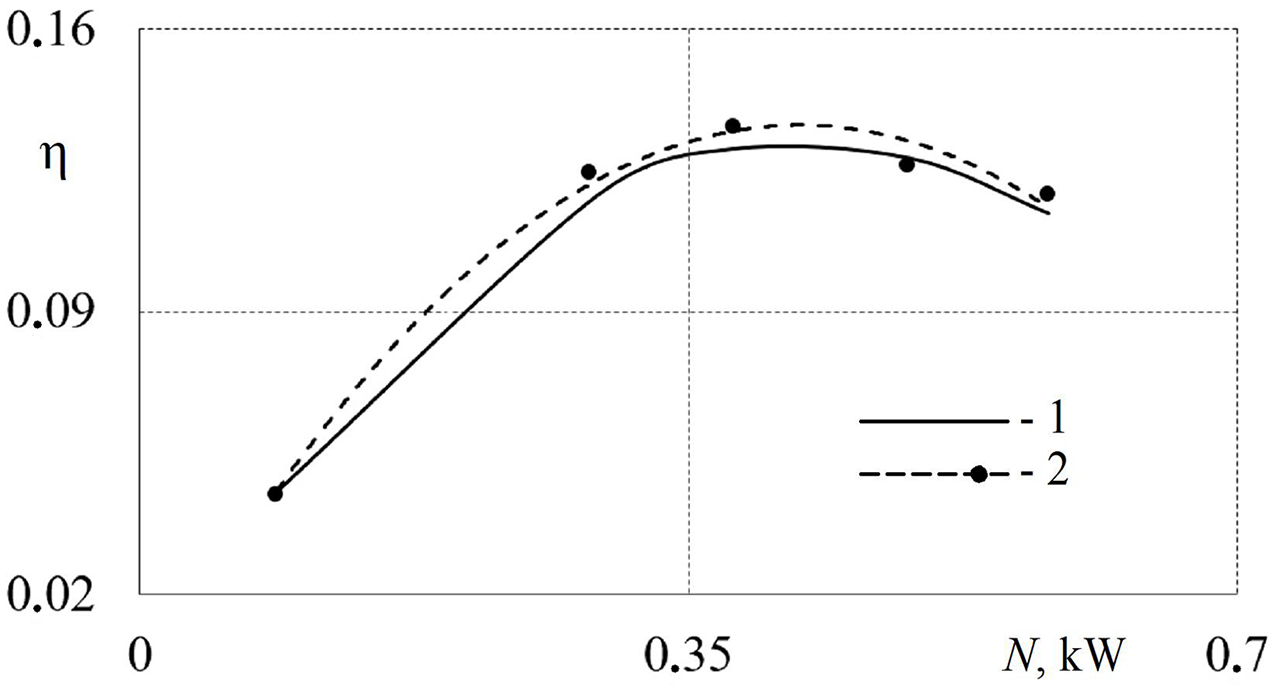

Table 2 shows that there is no difference in the power values when comparing the simulation results and experimental data; the differences in fuel consumption range from 1.8% to 4.3%; the difference in air flow characteristics is within 3.4%; the differences in efficiency do not exceed 4.0%. The change in the mass air consumption Ga through the cylinders of an engine running on a propane-butane blend and syngas, obtained on the basis of modeling and bench tests, are shown in Fig. 4.

Figure 4: Computational and experimental dependences of mass air flow Ga on power N for a piston engine running on propane-butane blend (a) and syngas (b): 1—modeling; 2—experiment

Also, Fig. 4 shows that the air consumption through the synthesis gas engine decreased by an average of 18.5% compared to a gasoline ICE. This indicates a deterioration in the filling of the cylinder with the working fluid (a blend of syngas and air). Therefore, it can be expected that the power of the syngas engine will also drop by a similar amount compared to a gasoline ICE. However, the processes of gas exchange, mixture formation, and combustion were not considered in detail in this study. The differences in the Ga values do not exceed 4% for an ICE running on a propane-butane blend and syngas.

Thus, the created mathematical models reliably simulate the working process of a piston engine operating both on a propane-butane blend and on syngas. Therefore, these mathematical models can be used to optimize and predict the performance of the ICE in question when operating on different types of gaseous fuel.

4 Improving the Performance of a Syngas Engine by Optimizing the Working Cycle Parameters

The simulation results and experimental data showed that the efficiency of the engine on syngas was inferior to the indicators in comparison with the operation on a propane-butane blend. For example, the efficiency drops by 32.8% at a power of 0.59 kW. The efficiency of the base engine was 0.177, and the efficiency of the converted ICE was 0.119. This difference is due to both the energy characteristics of the used fuel and the features of the working process in the engine. Consequently, there is a need to optimize the operating parameters of an ICE converted to run on syngas. The purpose of such optimization is to bring the technical parameters of the syngas engine as close as possible to those when running on the base fuel (propane-butane blend).

It is known that the technical and economic indicators of the engine depend on the energy value of the fuel [35]. The quality of the combustion process of the working fluid in the cylinder also plays an important role. One of the key factors is the combustion rate of various types of gaseous fuel during normal engine operation. The combustion process is greatly delayed in lean combustible mixtures (such as propane-butane blend and syngas) [36]. Therefore, it is necessary to optimize the engine working cycle to improve the technical and economic performance of the ICE in the case of changes in the properties of the used gaseous fuel.

The main optimization criterion was engine efficiency. It is necessary to increase the efficiency of the converted engine for operation on syngas to the level of efficiency on the base fuel (propane-butane blend). The auxiliary criterion was engine power. It is necessary to maintain the power of the converted ICE. The engine was optimized using the following parameters: ignition advance angle φ; excess air coefficient λ; compression ratio ε; intake system resistance рin; exhaust system resistance рex.

The engine optimization was performed based on a verified mathematical model. The results of the engine working cycle optimization for specific parameters are shown in Figs. 5–9.

Figure 5: Calculated dependences of power N (1) and efficiency η (2) on ignition advance angle φ for a syngas engine

Figure 6: Calculated dependences of power N (1) and efficiency η (2) on the excess air coefficient λ for a syngas engine

Figure 7: Calculated dependences of power N (1) and efficiency η (2) on the compression ratio ε for a syngas engine

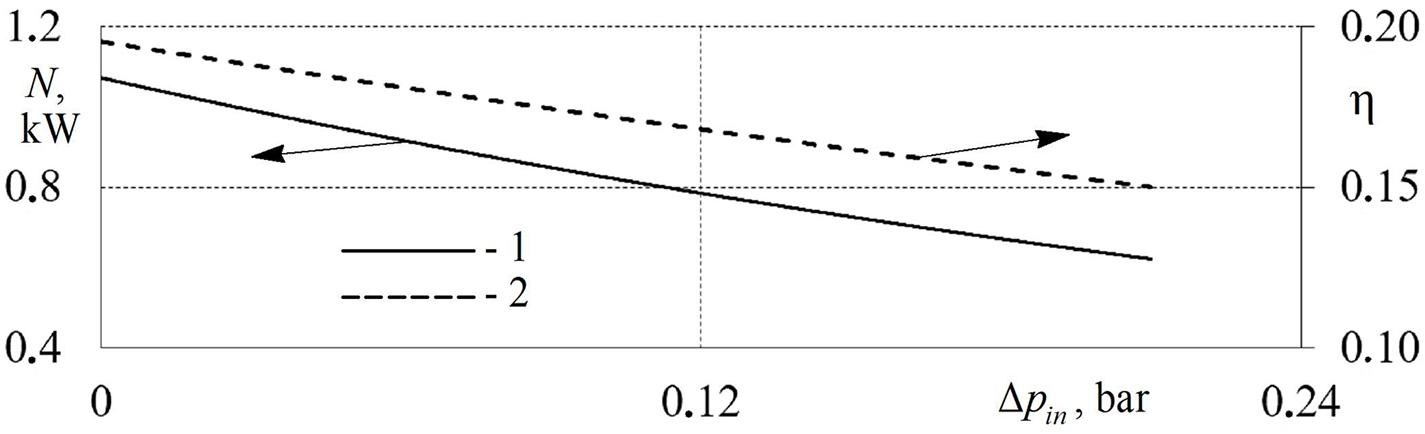

Figure 8: Calculated dependences of power N (1) and efficiency η (2) on resistance in the intake system pin for a syngas engine

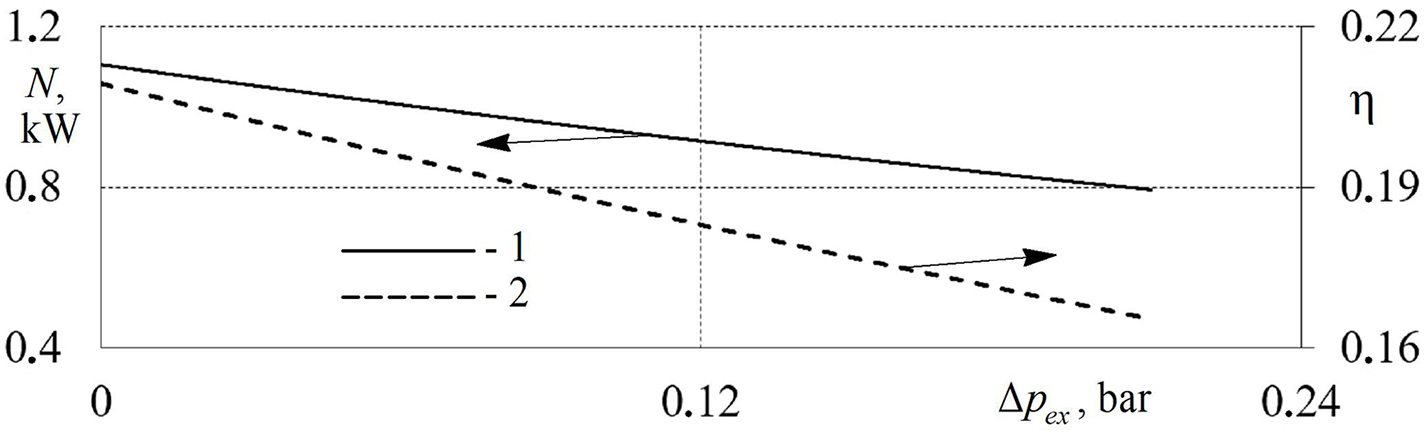

Figure 9: Calculated dependences of power N (1) and efficiency η (2) on resistance in the exhaust system pex for a syngas engine

Fig. 5 demonstrates that the ignition advance angle φ has a significant effect on the change in engine efficiency and power. In this case, the functions η = f (φ) and N = f (φ) have a clearly defined maximum. For example, it is necessary to use φ = 16 degrees to achieve maximum efficiency. The range of variation of the ignition advance angle φ was selected based on statistical data on the value of φ for most engines running on gasoline or gas.

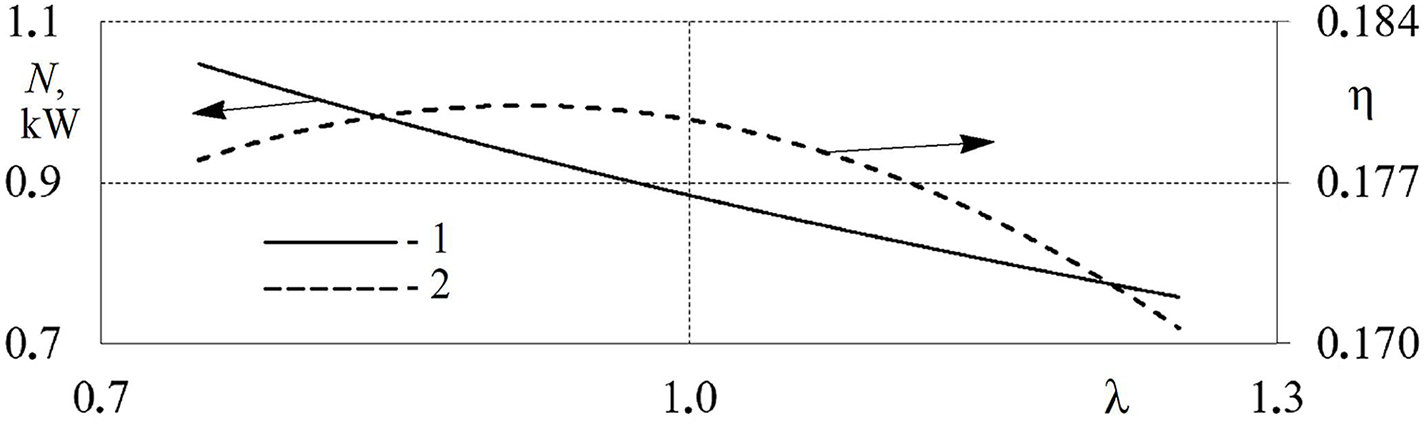

An increase in the excess air coefficient λ causes a linear decrease in the power of the ICE running on syngas (Fig. 6). In this case, the function η = f (λ) is not linear and has a maximum at λ = 0.8 (Fig. 6). Most gas engines operate with λ = 1.0. Therefore, the range of λ variation was chosen to be ±30% relative to the standard value for research purposes.

Fig. 7 shows that increasing the compression ratio ε causes a monotonic increase in engine power and efficiency. Accordingly, it is advisable to increase ε to the maximum possible value for safe operation of the engine on syngas without detonation. The maximum values of ε are determined by avoiding detonation in engines; the minimum values of ε are selected based on acceptable values of the ICE efficiency.

The increase in hydraulic resistance of the intake system causes a rather sharp linear decrease in both the power and efficiency of the engine running on syngas (Fig. 8).

This is explained by a significant deterioration in filling the cylinder with the working fluid during the intake process. The resistance values for the engine intake and exhaust systems were selected based on statistical data and the achievement of acceptable power and efficiency values. The most common resistance values in ICE gas exchange systems were investigated.

The increase in hydraulic resistance of the exhaust system also leads to a sharp decrease in engine power and efficiency. This is due to a significant decrease in the quality of gas exchange processes.

The obtained dependencies allowed us to select new engine parameters to achieve the maximum efficiency value:

– It is necessary to change the ignition advance angle φ from 21.5 to 16 degrees;

– It is necessary to reduce the excess air coefficient λ from 1.0 to 0.8;

– It is necessary to increase the compression ratio ε from 7.7 to 9.6;

– It is necessary to reduce the resistance of the engine intake system рin from 0.08 to 0.02 bar;

– It is necessary to reduce the resistance of the exhaust system рex from 0.14 to 0.02 bar.

Most of the proposed changes can be implemented by tuning (adjusting) the ignition and fuel systems, i.e., without significantly changing the engine design. The most complex and time-consuming change is increasing the compression ratio. It requires modifying the cylinder head, changing the connecting rod length and piston geometry.

A mathematical model of a new (optimized) syngas engine with the parameters specified above was created based on the results obtained. The technical and economic parameters of the optimized ICE were compared with those of the base engine running on a propane-butane blend (the parameters remained unchanged). A comparison of the power and efficiency of these ICEs depending on the crankshaft speed is presented in Fig. 10.

Figure 10: Calculated dependences of power N and efficiency η on crankshaft speed n for an engine running on different types of fuel: 1—propane-butane blend (N); 2—syngas (N); 3—propane-butane blend (η); 4—syngas (η)

Fig. 10 shows that the efficiency of the optimized engine on syngas has increased by 6%–9% compared to the base ICE running on a propane-butane blend. For example, the efficiency of the syngas engine is 0.226, and the efficiency of the ICE on propane-butane blend is 0.213. The power of the optimized engine on syngas has decreased by 0%–8% compared to the base ICE running on a propane-butane blend.

Thus, it can be stated that the optimization results have been achieved: the efficiency of the syngas engine has become higher than that of the base engine. At the same time, the power drop did not exceed 8% compared to the base engine. Accordingly, there are effective ways to improve the technical and economic parameters of syngas engines without significant costs.

The obtained results are applicable only for a given engine (of given power and geometric dimensions). The magnitudes of changes in the values of operational parameters (ignition advance angle, excess air coefficient, compression ratio, etc.) must be specified for each new engine to achieve the maximum effect. Therefore, a linear extension of the obtained data to all piston engines is impossible.

The main conclusions of the study are as follows:

1. Mathematical models of the working cycle of a piston engine running on a propane-butane blend and syngas have been developed;

2. An experimental stand with a loading device and a measuring system for verifying the modeling results has been created;

3. The differences between the modeling results and experimental data were no more than 4.0%; accordingly, the created mathematical models reliably simulated the working cycle of an engine running on a propane-butane blend and syngas;

4. Replacing the fuel with a propane-butane blend with syngas causes a decrease in engine efficiency by up to 32.8%; accordingly, it is necessary to optimize the ICE working parameters for operation on the new fuel (syngas);

5. Engine optimization was carried out based on the following parameters: ignition timing; excess air coefficient; compression ratio; resistance of the intake and exhaust systems; the main optimization criterion was ICE efficiency;

6. The efficiency of the optimized engine running on syngas increased by 6.1% compared to the base ICE running on a propane-butane blend; the power drop did not exceed 8.0%;

7. Syngas can be considered as an alternative fuel for an ICE.

The direction of further research may be related to experimental tests of an engine with optimized parameters and the study of ICEs of different sizes and power.

Acknowledgement: Not applicable.

Funding Statement: The research funding from the Ministry of Science and Higher Education of the Russian Federation (Ural Federal University Program of Development within the Priority-2030 Program) is gratefully acknowledged.

Author Contributions: The authors confirm contribution to the paper as follows: Study conception and design, Leonid Plotnikov; data collection, Danil Davydov, Dmitry Krasilnikov; analysis and interpretation of results, Leonid Plotnikov, Alexander Ryzhkov; draft manuscript preparation, Leonid Plotnikov, Alexander Ryzhkov. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data that supports the findings of this study are available from the authors upon reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Longwic R. Diesel engine operations with alternative fuels. Boca Raton, FL, USA: CRC Press; 2024. 86 p. [Google Scholar]

2. Pesonen J, Prinz R, Ovaskainen H, Kauranen P, Poikela A, Kärhä K. Alternative powertrains and fuels in heavy non-road mobile machinery and their future expectations—a review. Curr For Rep. 2025;11(1):10. doi:10.1007/s40725-024-00244-2. [Google Scholar] [CrossRef]

3. De Oliveira Gonçalves F, Lopes MS, Lopes ES, Maciel Filho R. Techno-economic and environmental analysis of decarbonization pathways for road freight transportation in Brazil. Renew Sustain Energy Rev. 2025;222:115991. doi:10.1016/j.rser.2025.115991. [Google Scholar] [CrossRef]

4. Gonca G, Genc I. Effects of ternary mixtures of propane-butane-hydrogen and different liquid fuels on the performance specifications of a spark ignition engine. Energy Sources Part A Recovery Util Environ Eff. 2022;44(4):8890–907. doi:10.1080/15567036.2021.1974982. [Google Scholar] [CrossRef]

5. Marjani SR, Motaman S, Varasteh H, Yang Z, Clementson J. Assessing hydrogen as an alternative fuel for rail transport—a case study. Sci Rep. 2025;15(1):6449. doi:10.1038/s41598-025-90887-3. [Google Scholar] [PubMed] [CrossRef]

6. Plotnikov LV, Ulman NV. Computational and analytical evaluation of the efficiency of using hydrogen as a fuel in an internal combustion engine. IOP Conf Ser Earth Environ Sci. 2021;723(5):052018. doi:10.1088/1755-1315/723/5/052018. [Google Scholar] [CrossRef]

7. Zhou X, Li T, Wang N, Wang X, Wu Z, Li Z, et al. Scaled model experiments for ammonia engines under the high-pressure direct-injection mode. Appl Therm Eng. 2025;277(2):127170. doi:10.1016/j.applthermaleng.2025.127170. [Google Scholar] [CrossRef]

8. Rao X, Yuan C, Guo Z, Xu Y, Sheng C. Methanol as an alternative fuel for marine engines: a comprehensive review of current state, opportunities, and challenges. Renew Energy. 2025;252(5):123562. doi:10.1016/j.renene.2025.123562. [Google Scholar] [CrossRef]

9. Enomoto H, Saito K. Effects of the hydrogen and methane fractions in biosyngas on the stability of a small reciprocated internal combustion engine. Energy. 2020;213:118518. doi:10.1016/j.energy.2020.118518. [Google Scholar] [CrossRef]

10. Abebe FF, Nallamothu RB, Ancha VR, Teklehaimanot H, Tefera NT. Optimized biodiesel production from Maesa lanceolata seeds and its emission analysis: a sustainable non-edible feedstock for renewable energy. Biomass Bioenergy. 2025;200(6):108045. doi:10.1016/j.biombioe.2025.108045. [Google Scholar] [CrossRef]

11. Hürpekli M, Özsezen AN. Combustion characteristics in a diesel engine running on a diesel fuel produced by the Fischer-Tropsch synthesis process from lignite. J Energy Inst. 2025;120:102115. doi:10.1016/j.joei.2025.102115. [Google Scholar] [CrossRef]

12. Khujamberdiev R, Cho HM. Hybrid fuels for CI engines with biofuel hydrogen ammonia and synthetic fuel blends. Energies. 2025;18(11):2758. doi:10.3390/en18112758. [Google Scholar] [CrossRef]

13. Christopher Selvam D, Devarajan Y, Nagappan B, Arora A, Madhan Kumar G, Pradhan D. Sustainable fuel solutions: a comprehensive review of syngas in internal combustion engines. Chem Pap. 2025;79(7):4019–27. doi:10.1007/s11696-025-04069-6. [Google Scholar] [CrossRef]

14. Kong G, Wang K, Zhang X, Li J, Han L, Zhang X. Torrefaction/carbonization-enhanced gasification-steam reforming of biomass for promoting hydrogen-enriched syngas production and tar elimination over gasification biochars. Bioresour Technol. 2022;363(1):127960. doi:10.1016/j.biortech.2022.127960. [Google Scholar] [PubMed] [CrossRef]

15. Morrone B, Bracciano P, Cirillo D, La Villetta M, Caputo C. Exergy and economic analysis of a micro-cogeneration system coupled with a biomass gasifier. Renew Energy. 2025;244:122574. doi:10.1016/j.renene.2025.122574. [Google Scholar] [CrossRef]

16. Kandasamy VK, Munimathan A, Rajendran S, Dhairiyasamy R. Syngas production from aqueous phase reforming of glycerol-water mixture for compression ignition engine. Energy Environ. 2024;35(7):3803–32. doi:10.1177/0958305X231204028. [Google Scholar] [CrossRef]

17. Zhou Y, Ma X, Chen Z, Gong H, Chen L, Yu H. Study on the feasibility of converting the recovered volatile organic compounds to syngas via catalytic steam reforming for gas-fueled power generation. Energy. 2023;263:125761. doi:10.1016/j.energy.2022.125761. [Google Scholar] [CrossRef]

18. Farkhondeh SA, Abbaspour-Fard MH, Zareei J. Investigation of the effects of syngas-biogas blends on RCCI engine with direct diesel injection: a computational study of performance, knock, and emissions. Energy Convers Manag. 2025;26:101021. doi:10.1016/j.ecmx.2025.101021. [Google Scholar] [CrossRef]

19. Dhairiyasamy R, Dixit S, Varshney D, Gabiriel D. Renewable syngas and biodiesel dual fuel applications for enhanced engine performance and emission control. Ind Crops Prod. 2025;225(9):120509. doi:10.1016/j.indcrop.2025.120509. [Google Scholar] [CrossRef]

20. Kantaroğlu E. CFD-based analysis of performance and emissions in an i-DSI engine using various e-fuels and syngas. Flow Turbul Combust. 2025:1–47. doi:10.1007/s10494-025-00660-9. [Google Scholar] [CrossRef]

21. Tucki K, Mruk R, Botwinska K. Impact of syngas on maximal spark ignition engine power. Eng Rural Dev. 2020;19:1787–94. doi:10.22616/ERDev.2020.19.TF475. [Google Scholar] [CrossRef]

22. Wei L, Li X, Yang W, Dai Y, Wang CH. Optimization of operation strategies of a syngas-fueled engine in a distributed gasifier-generator system driven by horticulture waste. Energy Convers Manag. 2020;208:112580. doi:10.1016/j.enconman.2020.112580. [Google Scholar] [CrossRef]

23. Das S, Tamang SK. Multi-objective optimization of a dual fuel CI engine powered with syngas and pilot diesel using TLBO algorithm: a metaheuristic approach. IOP Conf Ser Earth Environ Sci. 2024;1372(1):012097. doi:10.1088/1755-1315/1372/1/012097. [Google Scholar] [CrossRef]

24. Xu Z, Jia M, Xu G, Chang Y. Computational optimization of syngas/diesel RCCI combustion at low load in different engine size. SAE Tech Pap. 2019 Apr. doi:10.4271/2019-01-0573. [Google Scholar] [CrossRef]

25. Ahmed MM, Hasan MK, Shafiq M, Qays MO, Gadekallu TR, Nebhen J, et al. A peer-to-peer blockchain based interconnected power system. Energy Rep. 2021;7(4):7890–905. doi:10.1016/j.egyr.2021.08.071. [Google Scholar] [CrossRef]

26. Jamsran N, Park H, Lee J, Oh S, Kim C, Lee Y, et al. Syngas composition for improving thermal efficiency in boosted homogeneous charge compression ignition engines. Fuel. 2022;321:124130. doi:10.1016/j.fuel.2022.124130. [Google Scholar] [CrossRef]

27. Enomoto H. Gas component effect on energy loss of reciprocated engine operated by bio-syngas from wood gasifier. Biomass Convers Biorefin. 2025;15(7):11027–43. doi:10.1007/s13399-024-05915-5. [Google Scholar] [CrossRef]

28. Ran Z, Hariharan D, Lawler B, Mamalis S. Experimental study of lean spark ignition combustion using gasoline, ethanol, natural gas, and syngas. Fuel. 2019;235(2):530–7. doi:10.1016/j.fuel.2018.08.054. [Google Scholar] [CrossRef]

29. Mytrofanov O, Proskurin A, Kong W. Analysis of syngas combustion process in piston engines. Probl Energetics Reg. 2024;4(64):118–26. doi:10.52254/1857-0070.2024.4-64.10. [Google Scholar] [CrossRef]

30. Gobbato P, Masi M, De Simio L, Iannaccone S. A method for determining hydrogen-methane–nitrogen mixtures for laboratory tests of syngas-fuelled internal combustion engines. Int J Engine Res. 2021;22(8):2533–47. doi:10.1177/1468087420946134. [Google Scholar] [CrossRef]

31. Chen Y, Jiang Y, Wen X, Liu H. An investigation of the kinetic modeling and ignition delay time of methanol—syngas fuel. Front Energy Res. 2022;9:812522. doi:10.3389/fenrg.2021.812522. [Google Scholar] [CrossRef]

32. Kuleshov AS. Multi-zone DI diesel spray combustion model for thermodynamic simulation of engine with PCCI and high EGR level. SAE Int J Engines. 2009;2(1):1811–34. doi:10.4271/2009-01-1956. [Google Scholar] [CrossRef]

33. Plotnikov LV. Preparation and analysis of experimental findings on the thermal and mechanical characteristics of pulsating gas flows in the intake system of a piston engine for modelling and machine learning. Mathematics. 2023;11(8):1967. doi:10.3390/math11081967. [Google Scholar] [CrossRef]

34. Qays MO, Buswig Y, Basri H, Hossain ML, Abu-Siada A, Rahman MM, et al. An intelligent controlling method for battery lifetime increment using state of charge estimation in PV-battery hybrid system. Appl Sci Switz. 2020;10(24):8799. doi:10.3390/app10248799. [Google Scholar] [CrossRef]

35. Hafis M, Balaji K, Tamilarasan N, Senthilkumar D, Sakthivel R. A review on alternative fuels: spray characteristics, engine performance and emissions effect. Sustain Futures. 2025;9(2):100456. doi:10.1016/j.sftr.2025.100456. [Google Scholar] [CrossRef]

36. Patil R, Sreedhara S. A detailed analysis of mixture stratification on flame displacement speed for syngas combustion. Flow Turbul Combust. 2024;112(4):1105–26. doi:10.1007/s10494-024-00530-w. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools