Open Access

Open Access

ARTICLE

Distribution Patterns of Deep Shale Reservoirs and Longitudinal Utilization Degree of Horizontal Wells

1 Shunan Division, PetroChina Southwest Oil & Gasfield Company, Luzhou, 646000, China

2 Shale Gas Research Institute of PetroChina Southwest Oil & Gas Field Company, Chengdu, 610051, China

3 Shale Gas Evaluation and Exploitation Key Laboratory of Sichuan Province, Chengdu, 610091, China

4 Development Department, Southwest Oil and Gas Field, PetroChina, Chengdu, 610059, China

* Corresponding Author: Ziqiang Xia. Email:

Energy Engineering 2025, 122(12), 5039-5054. https://doi.org/10.32604/ee.2025.069036

Received 12 June 2025; Accepted 18 August 2025; Issue published 27 November 2025

Abstract

To explore and evaluate the longitudinal utilization degree of marine shale gas horizontal wells in southern Sichuan Basin (hereinafter referred to as “southern Sichuan”), focusing on the shale of Wufeng formation-Longyi1 sub-member in the deep Z block. By using the data from core experiments, well logging, and fracture height detection, a systematic analysis from the perspectives of reservoir distribution, longitudinal utilization height of hydraulic fractures, and longitudinal utilization degree of horizontal wells was conducted. The research results show that: (1) The overall reservoir conditions of the Wufeng formation-Longyi1 sub-member in the study area are relatively favorable, although the quality of Type I reservoir varies significantly among different well blocks; (2) The proppant tracer fracture height detection results show that fractures tend to extend upwards, the average total fracture height of fracture extend is 12.7 m, with the average upward extension height is 2.5 times the downward extension height; (3) The combination of fracture height and gas well productivity analysis suggests that targeting sub-layer ① as the horizontal well target can achieve full production of the continuous thickness of Type I reservoir in Z2 well block, whereas in Z1 well block, due to the significant proportion of the Wufeng formation in the continuous thickness of Type I reservoir, in the areas where the continuous thickness of Type I reservoir in Wufeng formation to middle sub-layer ① is greater than 4 m, horizontal wells cannot achieve full longitudinal utilization of the continuous thickness in top-quality Type I reservoir. The conclusion is that due to the limitations of longitudinal utilization height by artificial fracture networks and the variability in the distribution of continuous thickness of Type I reservoir, Z1 well block can continue to conduct horizontal well target tests and differentiated fracturing designs to further enhance the longitudinal utilization degree of the top-quality Type I reservoir.Graphic Abstract

Keywords

Against the backdrop of increasing human demand for energy and global energy transition, unconventional oil and gas resources, such as shale gas, oil shale, and shale oil have become important alternatives to conventional oil and gas [1,2]. The marine shale of the Wufeng formation-Longmaxi formation in the southern Sichuan has already achieved large-scale, economically viable development in mid-deep blocks (burial depth less than 3500 m) [3–5]. To further intensify oil and gas exploration and development efforts, deep shale blocks, represented by Luzhou and western Chongqing (with burial depths primarily between 3500 and 4500 m), have become the main contributors to production growth [6–8]. Since 2015, the study area has undergone three stages of exploration and development: During the exploration and evaluation stage from 2015 to 2018, Well ZU202-H1 achieved a blowout test production of 45.67 × 104 m3 per day; In the pilot testing stage from 2019 to 2021, the ZU203H1 platform, consisting of three wells, had an average test production of 22.33 × 104 m3 per day; in 2022, the development plan was formulated and implemented, marking the comprehensive initiation of large-scale shale gas production in block Z. Currently, more than 90 wells have been put into production within this area, with a cumulative gas production of 32 × 108 m3, and the average estimated ultimate recovery (EUR) per well reaching 1.1 × 108 m3, indicating a generally favorable development effect.

The development characteristics of high-quality shale reservoirs under sedimentary evolution significantly influence gas well productivity [9,10]. Previous studies deeply investigated paleogeomorphology, lithofacies distribution, and reservoir development characteristics, concluding that relatively low-lying areas of paleogeomorphology are conducive to the deposition and preservation of organic-rich shale [11]; high-carbonaceous siliceous shales exhibit a contiguous distribution of organic matter, with larger pore diameters, and higher porosity and gas content, making them the most favorable reservoirs for shale gas exploration and development [12]. However, previous studies have mainly focused on the plane distribution of reservoirs, and there are few studies on the vertical heterogeneity of reservoirs and the matching relationship with artificial fracture extension height. Therefore, this paper focuses on the heterogeneity of high-quality reservoir distribution within the study area. By integrating data from fracture height detection and production dynamics, the longitudinal utilization degree (refers to the degree of utilization of existing reservoirs vertically by horizontal wells) of high-quality reservoirs in horizontal wells is clarified. This aims to support subsequent production stabilization plans for shale gas fields, horizontal well targeting testing, and differentiated fracturing designs.

2 Regional Geological Overview

The study area is located at the intersection of the gently structured central Sichuan Basin and the low-steep structural belt of southern Sichuan. The structural trend is oriented northeast-southwest, forming a narrow, steep anticline interspersed with broad, gentle synclines. It encompasses two anticlines and two synclines arranged from east to west: the Xiwengquan Anticline, Pulvchang Syncline, Xishan Anticline, and Mituochang Syncline (Fig. 1a,b). The Mituochang Syncline is collectively referred to as the Z1 well block, and the Puluochang Syncline is designated as the Z2 well block. The synclines feature broad, gentle strata with primarily Type III and lower faults, with stratal dips ranging from 0° to 5°, and underdeveloped minor structures.

Figure 1: The structural position of the study area and the comprehensive column diagram of the Wufeng formation-Longmaxi formation in Well Z2

The development strata consist of the Wufeng and Longmaxi formations. The bottom boundary of the Wufeng formation is buried at depths ranging from 2300 to 4500 m (with depths of 2300 to 3800 m in the anticline regions and 3800 to 4500 m in the syncline areas). The syncline regions, characterized as typical deep shale gas blocks, are currently the main focus for development and production. This area predominantly belongs to a semi-deep to deep-water shelf depositional environment. Influenced by the underwater paleo-uplift in central Sichuan to the northwest, the ancient water depth increases from northwest to southeast. Consequently, the thickness of the Wufeng-Longmaxi strata, controlled by the depositional environment, gradually increases from northwest to southeast, ranging between 370 and 530 m.

The target layer for development is the Wufeng-Longyi1 sub-member, with a stratum thickness ranging from 25 to 50 m, of which the Wufeng formation itself is 4 to 9 m thick. According to the subdivision scheme of the Longyi1 sub-member at the base of the Longmaxi formation in southern Sichuan [13], it is divided into seven sub-layers from bottom to top: sub-layers ①, ②, ③, ④, ⑤, ⑥, and ⑦ (Fig. 1c).

3 Reservoir Development Characteristics

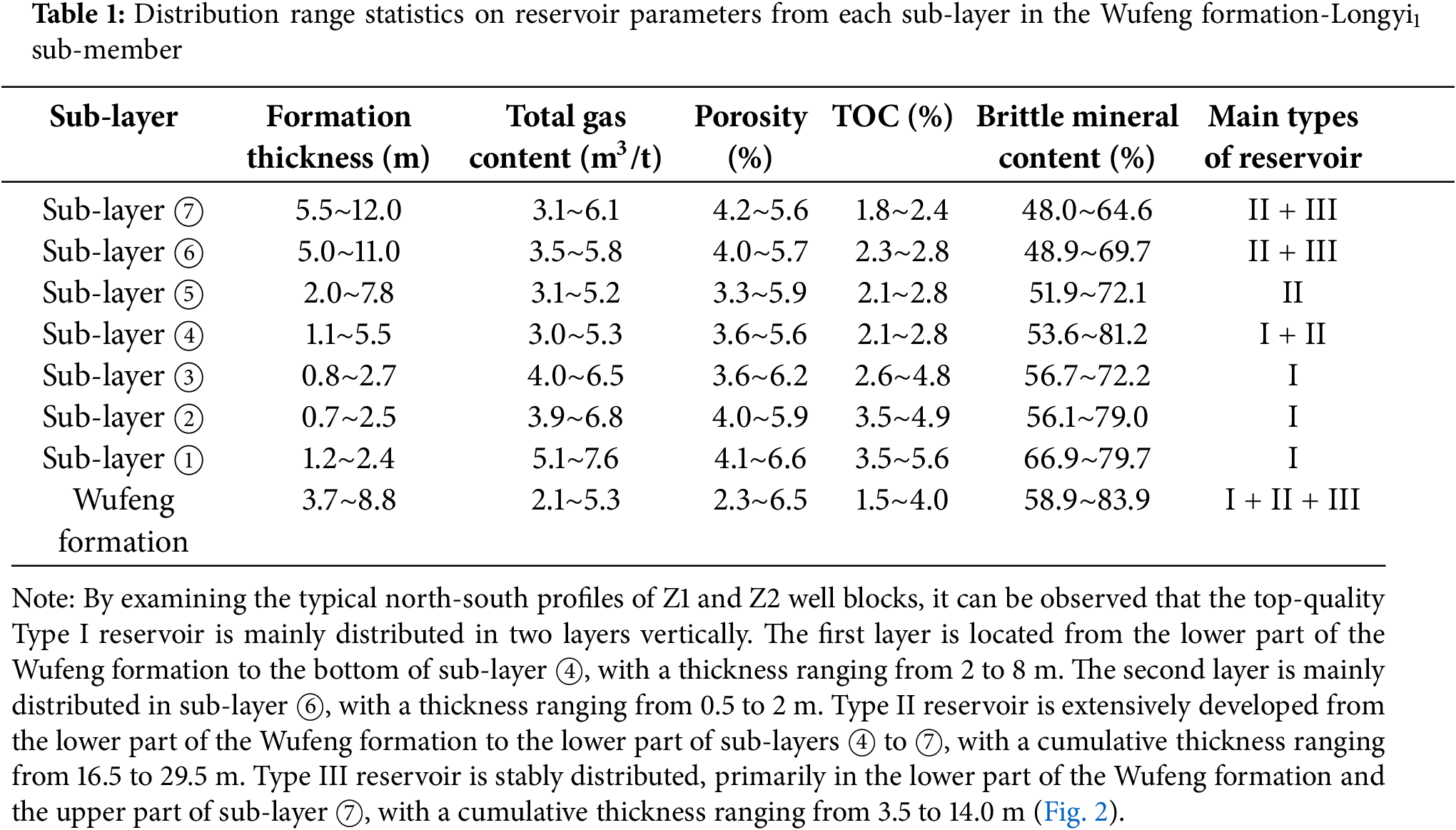

3.1 Vertical Distribution of Reservoirs

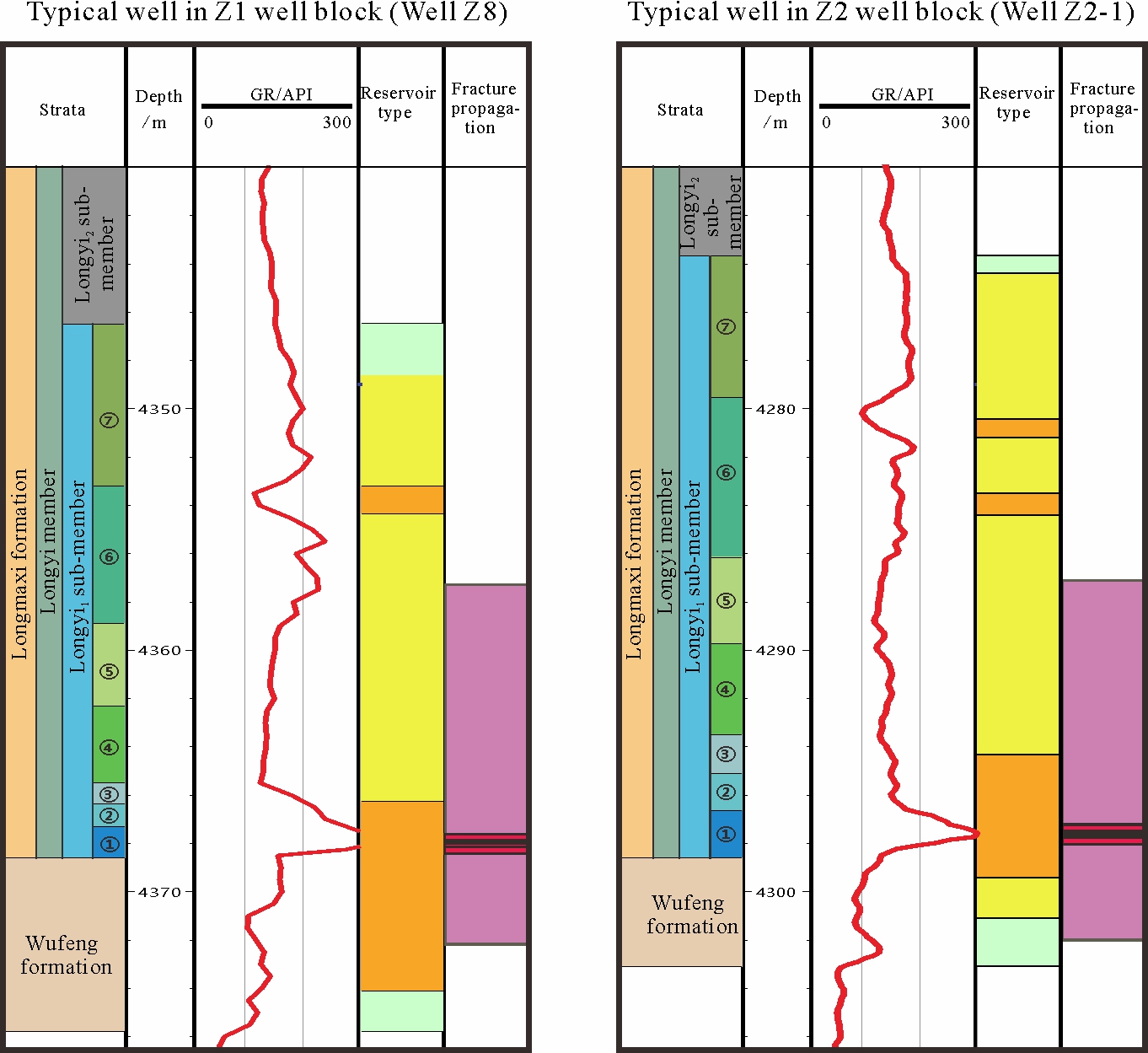

According to the classification and evaluation standards for deep shale reservoirs by PetroChina, the main development layers of the Wufeng-Longyi1 sub-member in the study area are divided into three categories [13]. Analysis of the reservoir parameters from typical wells in the study area shows that there is strong heterogeneity in reservoir quality within sub-layers, with porosity and TOC content being the main parameters influencing the classification of reservoirs (Table 1). Overall, the reservoir quality improves from bottom to top and then deteriorates, with sub-layers ① and ② being the best, meeting the criteria for Type I reservoir (TOC ≥ 3%, porosity ≥ 4%, brittle mineral content ≥ 55%, and gas content ≥ 3 m3/t).

Figure 2: Fine division and comparison of reservoirs in the Wufeng formation-Longyi1 sub-member in the study area

3.2 Planar Distribution of Reservoirs

The reservoir thickness of the Wufeng formation-Longyi1 sub-member generally shows a trend of increasing from the northwest to the southeast (Fig. 3). The combined thickness of Type I and II reservoirs ranges from 20 to 40 m, gradually thickening from the northwest to the southeast, with the high-value area located from Well Z2 to Well R1. The continuous thickness of Type I reservoir (the cumulative thickness of type I reservoir continuously distributed in the vertical direction) ranges from 2 to 8 m, thickening from north to south, with the high-value area located from Well Z2 to Well R2. Compared to the main shale gas demonstration areas in the Sichuan Basin, where the continuous thickness of Type I reservoir ranges from 7 to 15 m (Changning-Weiyuan demonstration area: 5 to 20 m, Zhaotong demonstration area: 3 to 15 m, and Fuling demonstration area: 7 to 15 m), the study area is a shale gas region characterized by typical thin Type I reservoir.

Figure 3: Reservoir thickness distribution map of Wufeng formation-Longyi1 sub-member in the study area. (a) is the combined thickness of Type I and II reservoirs; (b) is the continuous thickness of Type I reservoir

3.3 Variability in Continuous Thickness of Type I Reservoir

Previous studies indicated that in shale gas areas with similar depositional environments, favorable preservation conditions, and comparable fracturing techniques, there is a strong positive correlation between the product of the continuous thickness of Type I reservoir and the length of Type I reservoir encountered by horizontal wells, and the single well productivity [13–15]. Therefore, given the geological characteristics of the thin continuous thickness of Type I reservoir in this area, studying the distribution characteristics of the continuous thickness of Type I reservoir is particularly important.

By comparing the typical wells in the Z1, Z2 well blocks, and the Luzhou block, it is evident that despite the similar reservoir thickness across these wells in the Wufeng formation, there is significant heterogeneity in the vertical distribution of Type I reservoir. The continuous thickness of Type I reservoir and their proportion within the Wufeng formation is notably higher in the Z1 well block compared to the adjacent Z2 well block as well as the Luzhou block which is also a deep shale gas region. Specifically, in the Z1 well block, the continuous thickness of Type I reservoir is primarily developed from the lower part of the Wufeng formation to sub-layer ③. The thickness of the Type I reservoir in the Wufeng formation ranges from 2.5 to 5.1 m, accounting for 45.9% to 70.8% of the total continuous thickness of Type I reservoir. In the Z2 well block, the continuous thickness of Type I reservoir is mainly developed from the middle part of the Wufeng formation to the bottom of sub-layer ④. The thickness of the Type I reservoir in the Wufeng formation ranges from 1.0 to 2.0 m, accounting for 14.9% to 28.5% of the total continuous thickness of Type I reservoir. In the Luzhou block, the continuous thickness of Type I reservoir is primarily developed from the upper part of the Wufeng formation to the middle of sub-layer ④. The thickness of the Type I reservoir in the Wufeng formation ranges from 0.8 to 2.0 m, accounting for 6.8% to 9.0% of the total continuous thickness of Type I reservoir (Fig. 4).

Figure 4: Histogram of reservoir thickness of the Wufeng formation in the study area and adjacent areas, as well as histogram of the proportion of the Wufeng formation in the continuous thickness of Type I reservoir

4 Longitudinal Utilization Height of Hydraulic Fractures

Shale gas reservoirs are classified as artificially modified reservoirs [16–19]. Previous studies suggested that the distribution of artificial hydraulic fractures in shale formations typically exhibits a “star-shaped” pattern [20]. The primary factors that constrain and influence the vertical propagation and extension of hydraulic fractures are the differences in interlayer stress and the characteristics of natural fracture development [21–25].

4.1 Interlayer Stress Differences

A larger value of the minimum horizontal principal stress will result in higher initiation pressure for hydraulic fracturing, making it more challenging to fracture the shale reservoir [17–19]. Additionally, significant interlayer stress differences (i.e., large variations in the minimum horizontal principal stress) will affect the vertical propagation of artificial hydraulic fractures [21]. Currently, the primary target for shale gas development in this area is sub-layer ①. By subtracting the minimum value of the minimum horizontal principal stress of sub-layer ① from the maximum value of the minimum horizontal principal stress of other sub-layers, the interlayer stress differences relative to the target sub-layer can be obtained.

By conducting a statistical analysis of the minimum horizontal principal stress in each sub-layer of two typical wells in the study area, it was found that the stress differences from sub-layers ① to ④ are less than 5 MPa. The high values of stress differences are in the lower part of the Wufeng formation, specifically in sub-layers ⑤ to ⑦. Therefore, the middle part of the Wufeng formation, including sub-layer ⑤, can be produced as a single development interval (Fig. 5).

Figure 5: Stress distribution characteristics of shale reservoirs in the Wufeng formation-Long1 sub-member in the study area. (a) Typical well in Z1 well block; (b) Typical well in Z2 well block

4.2 Development Patterns of Natural Fractures

The mechanical effectiveness of natural fractures with different occurrence varies and has a significant impact on the propagation and extension of hydraulic fractures [22–25]. Detailed descriptions in the cores and imaging logging interpretation of natural fractures from the Wufeng formation-Longyi1 sub-member in the study area revealed that in terms of the vertical development locations, fractures are predominantly concentrated in the Wufeng formation to sub-layer ③, with sub-layers ④ to ⑦ only occasionally showing localized fracture development; in terms of fracture occurrence types, fractures can be classified into three types based on their dip angles: horizontal fractures (0°–15°), oblique fractures (15°–75°), and vertical fractures (75°–90°). The sub-layer with the highest development degree of horizontal fractures is located in the Wufeng formation to sub-layer ②, with a line density reaching up to 18 fractures per meter. The sub-layers with the highest development degree of oblique and vertical fractures are concentrated in the middle to upper parts of the Wufeng formation, with line densities reaching up to 8 fractures per meter and 20 fractures per meter, respectively. The distribution characteristics of natural fractures in the area favor the downward propagation of artificial hydraulic fractures into the middle part of the Wufeng formation, where they intersect with natural fractures at the core scale to form a complex fracture network.

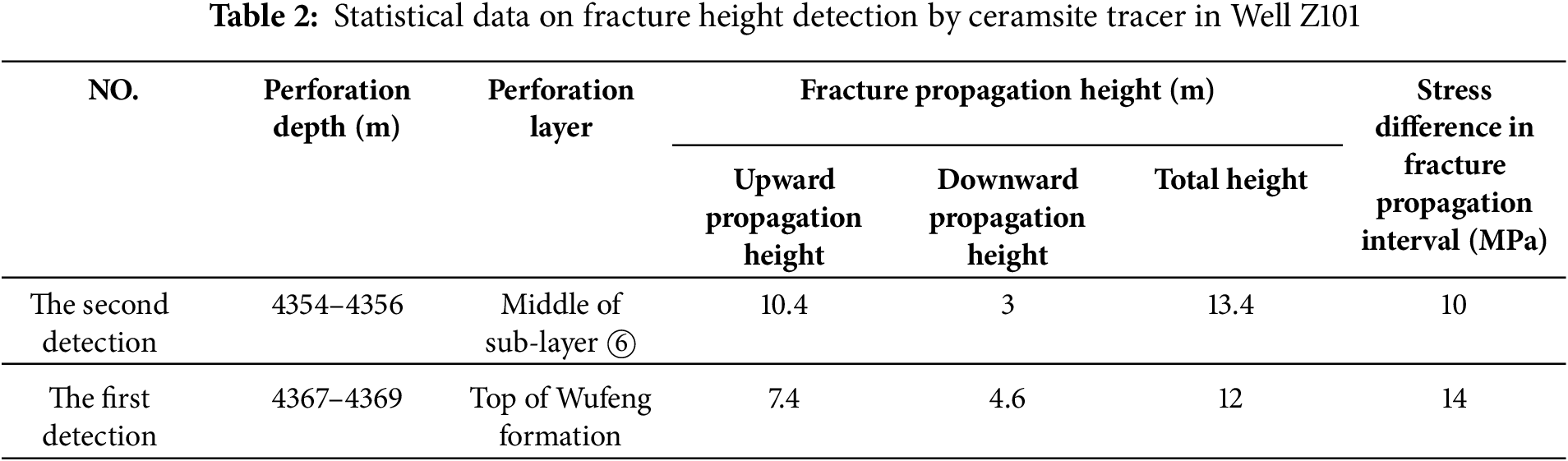

4.3 Fracture Height Monitoring

In the Z1 well block, by using the Schlumberger RST-C pulsed neutron cross-section capture logging instrument, by detecting the capture gamma rays excited by the radiation capture nuclear reaction between neutrons and rocks in the formation, the capture cross-section value of rocks can be obtained. Monitoring process, first measure the baseline before fracturing to obtain the capture cross-section background value curve of the well fluid and formation; Then, non radioactive tracer ceramic proppants are introduced during the fracturing process; Ultimately, the effective height of fractures can be determined by measuring the changes in macroscopic cross-sectional capture values of the formation rock before and after fracturing. The continuous thickness of the Type I reservoir in the Wufeng-Longyi1 sub-member is 3.6 m, with the Wufeng formation having a total thickness of 6.4 m and a Type I reservoir thickness of 2.5 m. A total of two ceramsite tracer fracture height detections were carried out. For the first detection, the fracturing perforation location was at 4360.6 to 4372.6 m (located at the top of the Wufeng formation). The average minimum principal stress value of the perforated interval was 86 MPa, with a total fracture height of 13.4 m. The fracture propagated 10.4 m upwards and 3 m downwards from the middle of the perforated interval, with the upward propagation being 3.5 times the downward propagation. The minimum horizontal principal stress for fracture propagation ranged from 80 to 94 MPa (stress difference of 14 MPa). For the second detection, the fracturing perforation was positioned at 4354 to 4356 m (located in the middle of sub-layer ⑥). The average minimum principal stress value of the perforated interval was 92 MPa, with a total fracture height of 12 m. The fracture propagated 7.4 m upwards and 4.6 m downwards from the middle of the perforated interval, with the upward propagation being 1.6 times the downward propagation. The minimum horizontal principal stress for fracture propagation ranged from 89 to 99 MPa (stress difference of 10 MPa) (Fig. 6, Table 2).

Figure 6: The reservoir in Well Z101 and the comprehensive histogram for fracture height propagation

The detection results show that hydraulic fractures are more likely to propagate upwards. The average height of fracture propagation for the two detections is 12.7 m, with the upward propagation being 2.5 times the downward propagation. As the stress difference decreases, the total height of fracture propagation tends to increase. Specifically, a reduction in stress difference by 4 MPa results in an increase in fracture propagation height by 1.4 m.

5 Longitudinal Utilization Degree of Horizontal Wells

Artificial fracturing stimulation is a crucial method for the efficient development of shale gas [19,21,26–28]. Therefore, this study focuses on the analysis of the propagation height of artificial fracture networks and their matching relationship with the vertical distribution of the continuous thickness of Type I reservoir. By doing so, it aims to evaluate the longitudinal utilization degree of horizontal wells.

The results of fracture height detected by ceramsite tracer show as the stress difference decreases, the total height of fracture propagation increases. This matches the actual stress conditions for longitudinal utilization in the development and production areas, specifically in the Wufeng formation to sub-layer ⑤, where the vertical stress differences typically range from 5 to 8 MPa. Under these conditions, the corresponding fracture heights are between 14 and 15 m. Additionally, based on the fracture propagation pattern (where the upward propagation height is 2.5 times the downward propagation height), the downward propagation height of the fractures in the production areas would be 4 m, while the upward propagation height would be 11 m.

Currently, the primary target horizon for shale gas horizontal wells in the study area is sub-layer ①. Assuming the central part of sub-layer ① is the main trajectory for horizontal wells, and combining this with the distribution segments of the continuous thickness of Type I reservoir, we can then determine the production degree of artificial fractures on Type I reservoir.

Two representative wells were selected from the Z1 and Z2 well blocks, each targeting the sublayer ① as the objective for the horizontal well. The target reservoir of Well Z2-1 is located in the middle of the continuous thickness of Type I reservoir, with the Wufeng formation accounting for only 20.4% of this thickness. Based on a total fracture height of 15 m and a downward propagation height of 4 m, it is calculated that the effective production of 8 m of the continuous thickness of the Type I reservoir can be fully achieved. Conversely, the target reservoir of Well Z8 is situated in the upper part of the continuous thickness of the Type I reservoir, where the Wufeng formation constitutes 70.8% of this thickness. Based on a total fracture height of 15 m and a downward propagation height of 4 m, the effective production of 7.2 m of the continuous thickness of the Type I reservoir cannot be fully realized, and about 1.5 m of Type I reservoir in the lower part of the Wufeng formation cannot be produced (Fig. 7).

Figure 7: The utilization degree of continuous Type I reservoir by fracturing fracture in the study area

The fracture propagation height and the development patterns of Type I reservoir in the development and production area show that while upward production of Type I reservoir can be fully achieved, downward production remains insufficient. Thus, the ideal downward fracture production height is defined as the height at which the target produces the Type I reservoir downward under ideal conditions of complete downward propagation of the artificial fracture network. This is calculated as the sum of half the thickness of sub-layer ① and the thickness of the Type I reservoir in the Wufeng formation. The planar distribution pattern clearly shows that the ideal downward production height in the Z1 well block exceeds that of the Z2 well block. In regions where the isopach thickness exceeds 4 m (the area surrounding Well Z8 to Well Z10), the current propagation height of the artificial fracture network fails to achieve full production of the lower Type I reservoir in the Wufeng formation (Fig. 8).

Figure 8: Continuous thickness of Type I reservoir in Wufeng formation to middle sub-layer ①

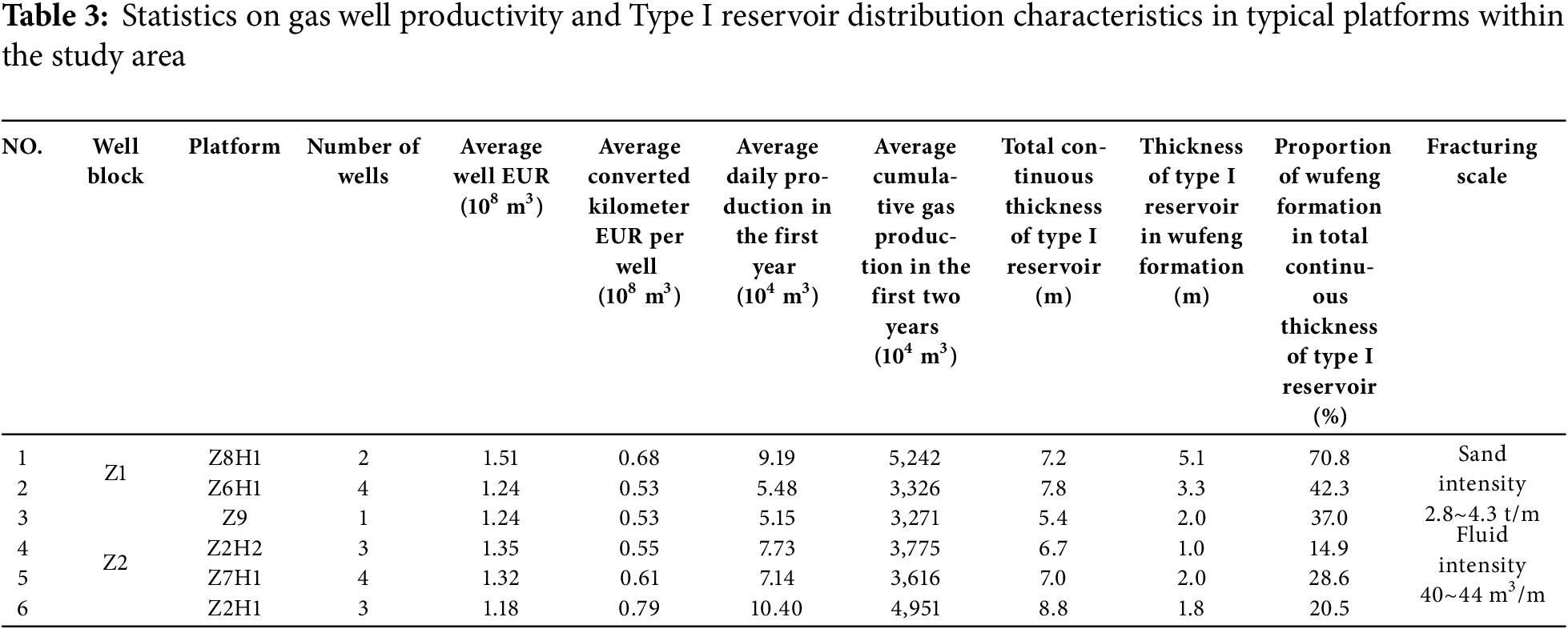

6 Development Effect of Gas Field

An analysis was conducted on six typical platforms within the selected area, encompassing a total of 17 horizontal wells (the drilling target encounter rate is higher than 92.5%, and the fracturing process parameters are relatively high and similar), to examine the relationship between gas well EUR and the thickness of Type I reservoir. The analysis show that in the Z2 well block, where the thickness of Type I reservoir in Wufeng formation is thin and relatively consistent (1.0 to 2.0 m), given a downward fracture propagation height of 4 m, the Type I reservoir in Wufeng formation can be fully produced. There is a significant positive correlation between the converted kilometer EUR of gas wells and the total continuous thickness of Type I reservoir, indirectly indicating that the upward fracture production height from the top boundary of the Wufeng formation exceeds 7 m. Conversely, in the Z1 well block, where the total continuous thickness of Type I reservoir is similar to that in Z2 block (7.2 to 7.8 m), there is a definite positive correlation between the converted kilometer EUR of gas wells and the thickness of the Type I reservoir in Wufeng formation. This indirectly suggests that the downward fracture production height from the top boundary of the Wufeng formation exceeds 3.3 m. Therefore, the current production dynamics indicate that the artificial fracture production height in the study area should exceed 10.3 m (Table 3).

A comprehensive comparative analysis reveals that upon incorporating two sample points from the Z1 well block into the sample dataset of Z2 well block, the correlation between kilometer EUR and the continuous thickness of Type I reservoir significantly decreases, with the determination coefficient (R²) dropping from 0.9 to 0.5. Concurrently, there is no correlation between kilometer EUR and the continuous thickness of the Type I reservoir in Wufeng formation (Fig. 9). This indicates that while the Type I reservoir in the Z2 well block are fully produced, the continuous Type I reservoir in the Z1 well block are not completely exploited, specifically the lower Type I reservoir in the Wufeng formation remain underutilized.

Figure 9: Correlation between the average kilometer EUR per well and the Type I reservoir thickness and proportion in typical platforms. (a) Continuous thickness of Type I reservoir in the Z2 well block; (b) Continuous thickness of Type I reservoir in the Z1 and Z2 well blocks; (c) Continuous thickness of Type I reservoir in Wufeng formation; (d) Proportion of Wufeng formation in the total continuous thickness of Type I reservoir

Through the analysis of typical single well production profile (Fig. 10), the typical well Z2H2-2 well in Z2 well block, the continuous thickness of Type I reservoir is 6.7 m, the drilling rate of target (sub-layers ① to ②) is 93.5%, the length of fracturing section is 2220 m, and adopted high-strength fracturing parameters (sand intensity 4.3 t/m, fluid intensity 41.8 m3/m). It was put into production on 01 September 2022. The RTA calculates that the EUR of the gas well is 1.27 × 108 m3, and the average daily production of the first year is 7.3 × 104 m3. Up to now, the cumulative production is 1039 days and the cumulative gas production is 4909 × 104 m3. Z6H1-1 well is a typical well in the Z1 well block. The continuous thickness of Type I reservoir is 7.8 m, the drilling rate of target (sub-layers ① to ②) is 94.0%, the length of fracturing section is 2370 m, and adopted high-strength fracturing parameters (sand intensity 3.9 t/m, fluid intensity ength 42.6 m3/m). It was put into production on 07 October 2022. The RTA calculates that the EUR of the gas well is 1.14 × 108 m3, the average daily production of the first year is 4.9 × 104 m3, and the cumulative production is 981 days and the cumulative gas production is 3868 × 104 m3. The actual production results of two typical wells show that, under similar target drilling encounter rates and fracturing parameters, the Z6H1-1 well with relatively thicker continuous thickness of Type I reservoir has lower initial gas production capacity and EUR than the Z2H2-2 well with thinner reservoir thickness, indicating that its Type I continuous reservoir may not be fully utilized.

Figure 10: Typical well production curve in the study area. (a) Typical well Z2H2-2 in Z2 well block; (b) Typical well Z6H1-1 in Z1 well block

In summary, the study area is characterized as a thin Type I reservoir shale gas region, where fully producing the top-quality Type I reservoir is essential for achieving high gas well productivity. In the Z1 well block, the continuous thickness of Type I reservoir in the middle part of the Wufeng formation to sub-layer ① generally exceeds 4 m, with the Wufeng formation accounting for 40% to 70% of this continuous thickness. The lower Type I reservoir in the Wufeng formation remain underutilized. Therefore, it is recommended to conduct targeted Wufeng formation tests or fracturing downward directional perforation tests in areas of the Z1 well block where the continuous thickness of the Type I reservoir from the middle part of Wufeng formation to sub-layer ① exceeds 4 m, to achieve more comprehensive production of the Type I reservoir.

(1) The overall reservoir conditions of the Wufeng formation—Longyi1 sub-member in the study area are relatively favorable. However, the continuous thickness of the top-quality Type I reservoir between well blocks varies significantly. When targeting sub-layer ① for horizontal wells, the target in the Z1 well block is located at the upper part of the continuous thickness of Type I reservoir, whereas the target in the Z2 well block is situated in the middle to lower part of the continuous thickness of Type I reservoir.

(2) Results of fracture heights detected by the ceramsite tracer indicate that fractures tend to propagate upward more readily, with an average total fracture propagation height of 12.7 m over two detections. The upward propagation height is 2.5 times the downward propagation height. As the stress difference decreases, the total fracture propagation height tends to increase.

(3) Matching the actual stress conditions in the development and production area, the maximum total fracture propagation height is 15 m, with 4 m downward and 11 m upward. Based on gas well productivity analysis, it is concluded that the continuous thickness of Type I reservoir in the Z2 well block is fully produced, whereas the continuous thickness of Type I reservoir in the Z1 well block is not completely utilized, indicating that the lower Type I reservoir in the Wufeng formation are difficult to be fully produced.

Acknowledgement: Not applicable.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: Ziqiang Xia responsible for data collection, draft manuscript preparation, analysis and interpretation of results; Hai Li, Majia Zheng and Jianlin Li discussed the study and supported a partial financial support; Weiyang Xie and Ruiqi Gao discussed the present study and revised the manuscript; Gaoxiang Wang and Jiangrong Feng participate in data collection and summarization. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The authors confirm that the data supporting the findings of this study are available within the article.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Guo W, Deng S, Sun Y. Recent advances on shale oil and gas exploration and development technologies. Adv Geo-Energy Res. 2024;11(2):81–7. doi:10.46690/ager.2024.02.01. [Google Scholar] [CrossRef]

2. Li H, He S, Radwan AE, Xie J, Qin Q. Quantitative analysis of pore complexity in lacustrine organic-rich shale and comparison to marine shale: insights from experimental tests and fractal theory. Energy Fuels. 2024;38(17):18. doi:10.1021/acs.energyfuels.4c03095. [Google Scholar] [CrossRef]

3. Jin Z, Nie H, Liu Q, Zhao J, Jiang T. Source and seal coupling mechanism for shale gas enrichment in upper Ordovician Wufeng Formation-Lower Silurian Longmaxi Formation in Sichuan Basin and its periphery. Mar Petr Geol. 2018;97(6):78–93. doi:10.1016/j.marpetgeo.2018.06.009. [Google Scholar] [CrossRef]

4. Fan C, Li H, Qin Q, He S, Zhong C. Geological conditions and exploration potential of shale gas reservoir in Wufeng and Longmaxi Formation of southeastern Sichuan Basin, China. J Pet Sci Eng. 2020;191(6):107138. doi:10.1016/j.petrol.2020.107138. [Google Scholar] [CrossRef]

5. Guo X, Wang R, Shen B, Wang G, Wan C, Wang Q. Geological characteristics, resource potential, and development direction of shale gas in China. Pet Explor Dev. 2025;52(1):17–32. doi:10.1016/S1876-3804(25)60002-4. [Google Scholar] [CrossRef]

6. Li Y, Sheng P, Jin L, Liu Y, Zhang X, Shen Y, et al. Deep shale gas lithofacies and reservoir space types of the longmaxi formation in the Hechuan Tongnan area of the Sichuan basin. In: International Field Exploration and Development Conference. Singapore: Springer; 2025. doi:10.1007/978-981-96-2706-6_34. [Google Scholar] [CrossRef]

7. Li S, Zhou Z, Nie H, Zhang L, Song T, Liu W, et al. Distribution characteristics, exploration and development, geological theories research progress and exploration directions of shale gas in China. China Geol. 2022;5(1):110–35. doi:10.31035/cg2021069. [Google Scholar] [CrossRef]

8. Zou C, Dong D, Xiong W, Fu G, Zhao Q, Liu W, et al. Advances, challenges, and countermeasures in shale gas exploration of underexplored plays, sequences and new types in China. Oil Gas Geol. 2024:309–26. doi:10.11743/ogg20240201. [Google Scholar] [CrossRef]

9. Guo T. Evaluation of highly thermally mature shale-gas reservoirs in complex structural parts of the Sichuan Basin. J Earth Sci. 2013;24(6):863–73. doi:10.1007/s12583-013-0384-4. [Google Scholar] [CrossRef]

10. Li Y, Wang X, Wu B, Li G, Wang D. Sedimentary facies of marine shale gas formations in Southern China: the Lower Silurian Longmaxi Formation in the southern Sichuan Basin. J Earth Sci. 2016;27(5):807–22. doi:10.1007/s12583-015-0592-1. [Google Scholar] [CrossRef]

11. Li W, Lei Z, Chen W, Meng S, Chen L, Pu B, et al. Characteristics of sedimentary facies and lithofacies distribution of deep shale of Wufeng Formation-Longmaxi. Spec Oil Gas Res. 2024;31(3):37–44. doi:10.3969/j.issn.1006-6535.2024.03.005. [Google Scholar] [CrossRef]

12. Chen Y, Liu J, Wang N, Zhu Y, Lin W, Cai Q, et al. Microfacies analysis of marine shale: a case study of the shales of the Wufeng-Longmaxi Formation in the western Chongqing, Sichuan Basin, China. Open Geosci. 2024;16(1):14. doi:10.1515/geo-2022-0583. [Google Scholar] [CrossRef]

13. Yang H, Zhao S, Xia Z, Yang X, Zhang C, Zhang D, et al. Target selection of tridimensional development of deep shale gas in the Luzhou region, South Sichuan Basin. Nat Gas Indus. 2022;42(8):162–74. doi:10.3787/j.issn.1000-0976.2022.08.013. [Google Scholar] [CrossRef]

14. Xiao X, Wei Q, Cai H, Li T, Wang M, Pan L, et al. Main controlling factors and enrichment area evaluation of shale gas of the Lower Paleozoic marine strata in south China. Pet Sci. 2015;12(4):573–86. doi:10.1007/s12182-015-0057-2. [Google Scholar] [CrossRef]

15. Wang Z. Reservoir forming conditions and key exploration and development technologies for marine shale gas fields in Fuling area, south China. Petrol Res. 2018;3(3):197–209. doi:10.1016/j.ptlrs.2018.06.008. [Google Scholar] [CrossRef]

16. Altindag R. Assessment of some brittleness indexes in rock-drilling efficiency. Rock Mech Rock Eng. 2010;43(3):361–70. doi:10.1007/s00603-009-0057-x. [Google Scholar] [CrossRef]

17. Zhang Y, Zhang J, Yuan B, Yin S. In-situ stresses controlling hydraulic fracture propagation and fracture breakdown pressure. J Pet Sci Eng. 2018;164:164–73. doi:10.1016/j.petrol.2018.01.050. [Google Scholar] [CrossRef]

18. Rybacki E, Reinicke A, Meier T, Makasi M, Dresen G. What controls the mechanical properties of shale rocks?—Part I: strength and young's modulus. J Pet Sci Eng. 2015;135:702–22. doi:10.1016/j.petrol.2015.10.028. [Google Scholar] [CrossRef]

19. Yang Y, Shi X, Ji C, Yan Y, An N, Zhang T. The hydraulic fracturing optimization for stacked tight gas reservoirs using multilayers and multiwells fracturing strategies. Energy Eng. 2024;12(12):3667–88. doi:10.32604/ee.2024.056266. [Google Scholar] [CrossRef]

20. Jihoon K, George JM. Numerical analysis of fracture propagation during hydraulic fracturing operations in shale gas systems. Int J Rock Mech Min Sci. 2015;76(02):127–37. doi:10.1016/j.ijrmms.2015.02.013. [Google Scholar] [CrossRef]

21. Sun H, Cai X, Hu D, Lu Z, Zhao P, Zheng A, et al. Theory, technology and practice of shale gas three-dimensional development: a case study of Fuling shale gas field in Sichuan Basin, SW China. Pet Explor Dev. 2023;50(03):651–64. doi:10.1016/S1876-3804(23)60417-3. [Google Scholar] [CrossRef]

22. Gale J, Reed R, Holder J. Natural fractures in the Barnett shale and their importance for hydraulic fracture treatments. Am Assoc Pet Geol Bull. 2007;91(4):603–22. doi:10.1306/11010606061. [Google Scholar] [CrossRef]

23. Gale J, Laubach S, Olson J, Eichhubl P, Fall A. Natural fractures in shale: a review and new observations. AAPG Bull. 2014;101(11):2165–216. doi:10.1306/08121413151. [Google Scholar] [CrossRef]

24. Zeng L, Lyu W, Li J, Zhu L, Weng J, Yue F, et al. Natural fractures and their influence on shale gas enrichment in Sichuan Basin, China. J Nat Gas Sci Eng. 2016;30(5):1–9. doi:10.1016/j.jngse.2015.11.048. [Google Scholar] [CrossRef]

25. Ge X, Guo T, Ma Y, Wang G, Li M, Zhao P, et al. Fracture development and inter-well interference for shale gas production from the Wufeng-Longmaxi Formation in a gentle syncline area of weirong shale gas field, southern Sichuan, China. J Pet Sci Eng. 2022;212(11):110207. doi:10.1016/j.petrol.2022.110207. [Google Scholar] [CrossRef]

26. Zhao G, Jin Z, Ding W, Liu G, Yun J, Wang R, et al. Developmental characteristics and formational stages of natural fractures in the Wufeng-Longmaxi Formation in the Sangzhi Block, Hunan Province, China: insights from fracture cements and fluid inclusions studies. J Pet Sci Eng. 2022;208:109407. doi:10.1016/j.petrol.2021.109407. [Google Scholar] [CrossRef]

27. Hao Y, Wang W, Yuan B, Su Y, An J, Shu H. Shale gas simulation considering natural fractures, gas desorption, and slippage flow effects using conventional modified model. J Pet Explor Prod Technol. 2017;8(2):607–15. doi:10.1007/S13202-017-0366-7. [Google Scholar] [CrossRef]

28. Gao S, Yang Y, Chen M, Zheng J, Qin L, Liu X, et al. Hydraulic fracture parameter inversion method for shale gas wells based on transient pressure-drop analysis during hydraulic fracturing shut-in period. Energy Eng. 2024;121(11):3305–29. doi:10.32604/ee.2024.053622. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools