Open Access

Open Access

ARTICLE

Impact of Injection Strategies and Jatropha Biodiesel-Diesel Blends on Soot and Emissions

1 Energy and Renewable Energies Technology Center, University of Technology-Iraq, Karada, Baghdad, 35050, Iraq

2 Department of Applied Sciences, University of Technology-Iraq, Baghdad, 35050, Iraq

* Corresponding Author: Mohammed A. Fayad. Email:

(This article belongs to the Special Issue: Advancements in Energy Resources, Processes, Systems, and Materials-(ICSSD2024))

Energy Engineering 2025, 122(3), 929-941. https://doi.org/10.32604/ee.2025.061612

Received 28 November 2024; Accepted 23 January 2025; Issue published 07 March 2025

Abstract

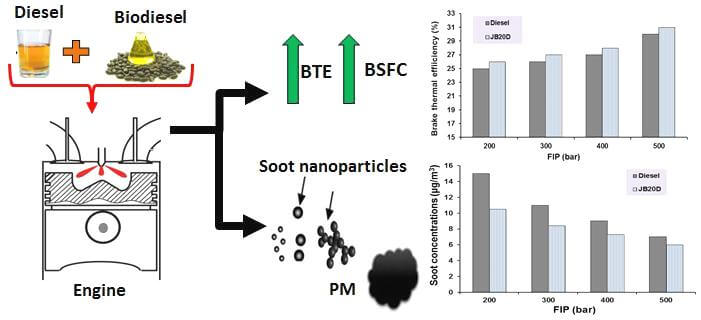

Oxygenated fuels can reduce harmful emissions without affecting engine performance, meeting the big challenge in the transportation industry, which keeps the environment safe and reduces global warming. This study investigates the impact of biodiesel injection strategies and fuel injection pressures (FIP) on diesel engine exhaust emission characteristics. The engine is fuelled with 20% Jatropha biodiesel (JB) and 80% diesel, named JB20D. The ratios of fuel injection pressures started with injecting the fuel (diesel and JB20D) from 200 bar to 500 bar. The experimental outcomes indicate that the engine performance of brake-specific fuel consumption increased by 21.36% from the burning of JB20D compared with diesel, while brake thermal efficiency improved by 6.54% for low and high FIP compared to the diesel. The high fuel injection pressures slightly decrease the nitrogen oxide (NOX) emissions for both diesel and biodiesel. The emissions of NOX decreased from the combustion of JB20D by 18.7% under high fuel injection pressures compared to diesel. The concentration of soot particulate decreased by 20.4% form JB20D combustion than those combusted from diesel fuel.Graphic Abstract

Keywords

Abbreviations

| BSFC | Brake-specific fuel consumption |

| BTE | Brake thermal efficiency |

| CO | Carbon monoxide |

| DI | Direct injection |

| FIP | Fuel injection pressure |

| SMPS | Scanning mobility particle-sizer |

| HC | Hydrocarbon |

| JB20D | 20% Jatropha biodiesel and 80% diesel |

| NOX | Nitrogen oxides |

| PM | Particulate matter |

| SDG | Sustainable Development Goal |

In recent years, many researchers have increased awareness about the negative effects of pollution on the environment and the depletion of petroleum sources, which requires that new sustainable and low-emission fuels be developed, in line with global net-zero targets and the United Nations Sustainable Development Goals (SDG 7: Bio-diesel as promised with the worldwide goal of affordable and clean energy, SDG 12: Responsible Consumption and Production, and SDG 13: Climate action). Through trans-esterification, biodiesel can be extracted from renewable sources, including vegetable oils and animal fats [1,2]. It is reported that biodiesel has numerous benefits to the environment. It offers all the valuable properties: renewable, oxygenated, biodegradable and environmentally friendly, thus becoming a potential solution to decrease emissions of greenhouse gases and air pollutants. It has been a well-documented fact that biodiesel leads to enhanced reduction of exhaust emission of hazardous pollutants, including polycyclic aromatic hydrocarbons (PAH), hydrocarbons (HC), particulate matter (PM) and carbon monoxide (CO), and a slight increase in NOx emission. In the same context, the results confirm measures towards increasing energy density and minimizing the greenhouse impact of the transport and energy industries. Moreover, the influences of biodiesel combustion on the performance and emission levels have been observed to be a critical factor leading to conversion towards sustainable energy systems [3].

The adverse impacts of soot emissions from diesel engines on human health and the environment have received attention. Due to environmental concerns, compression-ignition engines must use biodiesel and exhaust catalysts [4,5]. The use of biodiesel is a good solution in diesel engines to decline the CO, HC, NOX, and emissions of soot, which produces a lower level of emissions in the exhaust compared with the fossil fuel. Jatropha biodiesel is a good substitute for diesel fuel in the transport sector based on the previous literature review. Biodiesel blends can affect soot emissions and engine performance, as mentioned in work by Boehman et al. [6]. They found that the B20 (20% biodiesel and 80% diesel) combustion decreased the soot concentration in the exhaust. The molecular structure of chemical oxygen-bonded in biodiesel promotes the soot formation reduction and enhances the combustion process. The blend of biodiesel into diesel fuel has been extensively examined in engines operated with diesel fuel [7,8]. It is reported that the NOX concentration slightly increased from the oxygenated fuels that contained high oxygen-bond, which resulted in better fuel combustion [9].

Most of documents refers that the brake specific fuel consumption (BSFC) increased due to lower heating value. Devan et al. [10] studied the influence of the addition of 15% biodiesel with 75% diesel fuel on smoke emissions and engine performance. They obtained that the brake thermal efficiency (BTE) improved and showed a good reduction in smoke emissions from the biodiesel blend combustion under high engine load conditions. Also, the soot emissions decreased from biodiesel blends under different engine conditions due to the oxygen content in the biodiesel properties, which improves the soot oxidation rate. The blends of rapeseed methyl ester (10%, 20%, and 30%) by weight with diesel fuel were tested under various fuel injection pressures (FIPs) in diesel engines. The combustion of these blends raised the BTE by 1.5% and 2.3%, respectively, and BSFC increased by 6.4%, 11.3% and 14.6%, respectively.

Injection strategies such as FIP contribute to enhancing both the process of combustion and exhaust emissions [11]. Besides, it is stated that the particulate soot significantly decreased with high FIP in diesel engines operated with biodiesel blends. The presence of high FIP leads to a faster rate of combustion because of the high in-cylinder temperatures. Zhang et al. [12] stated that the high FIP improves the mixing ratio of air-fuel, which results in better combustion and lower formation of exhaust emissions. The value of viscosity in biodiesel can be enhanced by presenting high FIP, which improves the atomization process and fuel spray [13]. To improve the combustion efficiency, the spray characteristics (distributions of droplet, spray structure, and angle) should be enhanced to decrease the exhaust emissions. Smaller fuel droplets can be produced under high FIP, while larger fuel droplets can be produced during low FIP. The injection pressures between 200 and 300 MPa lead to a significant reduction in the rate of soot formation [14,15].

The literature demonstrates that research work on the injection pressure effect during the combustion of diesel-biodiesel blends in a diesel engine on the concentration of particulate matter in the soot has been conducted by limited studies [16–18]. Most studies mentioned that the engine used a single injection strategy. At the same time, there is little understanding of the optimal multi-stage injection strategy based on biodiesel blends, especially with Jatropha blends [19,20], and [21]. Different engine operating conditions can also be used to compare various forms of advanced injection, such as split injection and pilot injection, and balance the efficiency and emissions of biodiesel blends [22,23]. However, the nature and distribution of diesel-jatropha mixture particles and their relationship to injection timing or injection pressure have not been covered by studies in the literature. Given that Jatropha biodiesel is chemically different from conventional diesel, it may be essential to understand how the particles differ from traditional combustion of diesel for emission control [24,25]. Moreover, most studies do not consider the variation of the model across operating conditions such as ambient temperature and relative humidity. Further understanding of how diesel-Jatropha biofuel blends perform under different conditions would provide real-world information on how to improve performance and reduce emissions [26]. Recently, there have been a few studies published on the behavior of Jatropha biofuel blends on engine performance and life. Research could also compare potential biofuel deposits, corrosion, injector clogging, and critical life cycle emissions from an environmental perspective. However, no study has been conducted on the compatibility of Jatropha biofuel blends with advanced techniques such as diesel particulate filters (DPF) or selective catalytic reduction (SCR), which is another research gap in the literature. It would also be useful to expand our knowledge of how these technologies affect emissions and performance when using biofuel blends.

Therefore, this work is focused on investigate the effect of Jatropha-biodiesel blends (JB20D) and injection strategy on exhaust pollutants and soot particles’ properties in a diesel engine. The effect of JB20D on the engine performance of BTE and BSFC is also highlighted. Furthermore, this study also investigates the influence of biodiesel injection strategies and fuel injection pressure (FIP) on the diesel engine exhaust pollutants properties that have been examined. Evaluating the benefits of using engines with higher fuel injection pressures was one of the main motivations for this study. Proving this property and its success in reducing pollutants, especially PM emission, with tested biodiesel will enable it to be recommended to engine manufacturers. The test engine was fuelled with 20% Jatropha biodiesel and 80% diesel blend, named JB20D. The ratios of FIP started to inject the fuel (diesel and JB20D) from 200 bar to 500 bar.

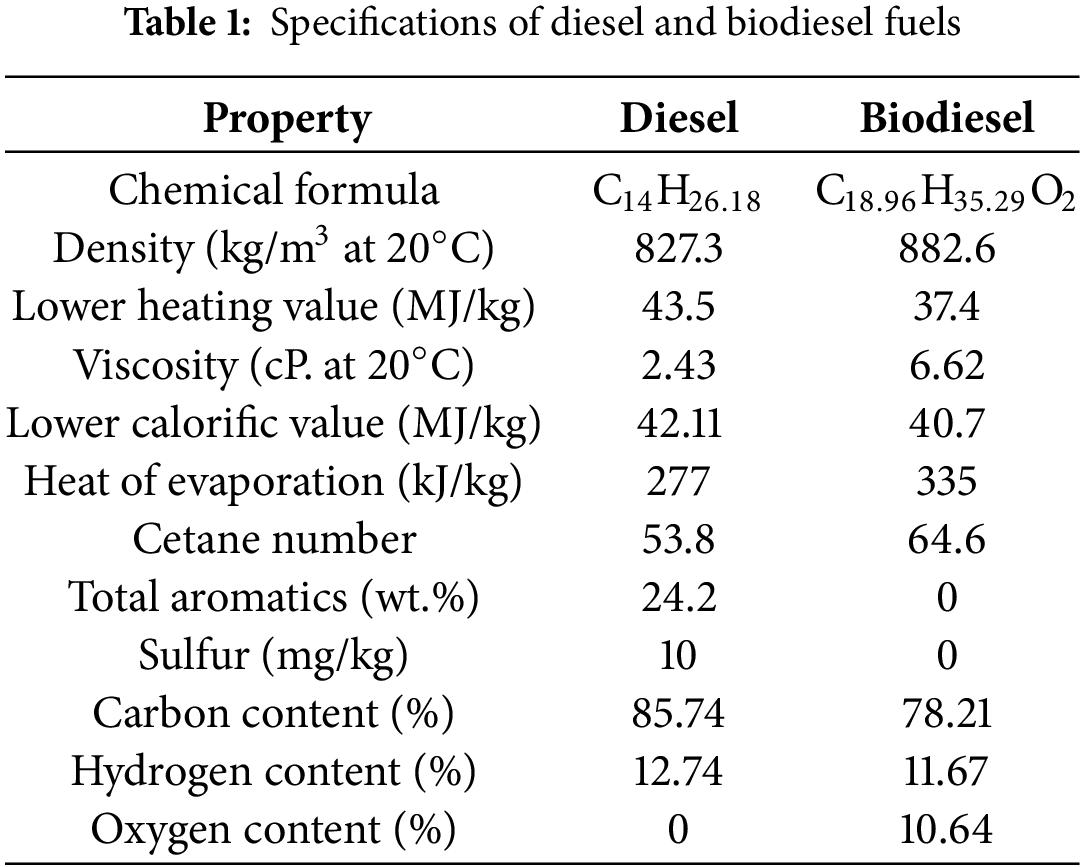

The fuel used in the present work is a blend of diesel and biodiesel which when burned produces a variety of pollutants in the exhaust pipe. Biodiesel produced from Jatropha using stratification process. The product as an alternative fuel was blended with diesel fuel to prepare the final blend. The blend of biodiesel can be used in the engine by mixing 20% of Jatropha biodiesel with 80% of diesel, known as JB20D. The blends of JB20D are produced from Jatropha oil as renewable sources and environmentally friendly. Table 1 describes the tested fuels specifications during the experiments. These properties were tested in the Fuel Technology Laboratory at the Dora Refinery, Baghdad, which is a very reliable specialized laboratory in Iraq in the oil and gas industry. The temperature of the diesel-biodiesel blend was controlled using a water-cooling system.

2.2 Setup of Equipment and Engine

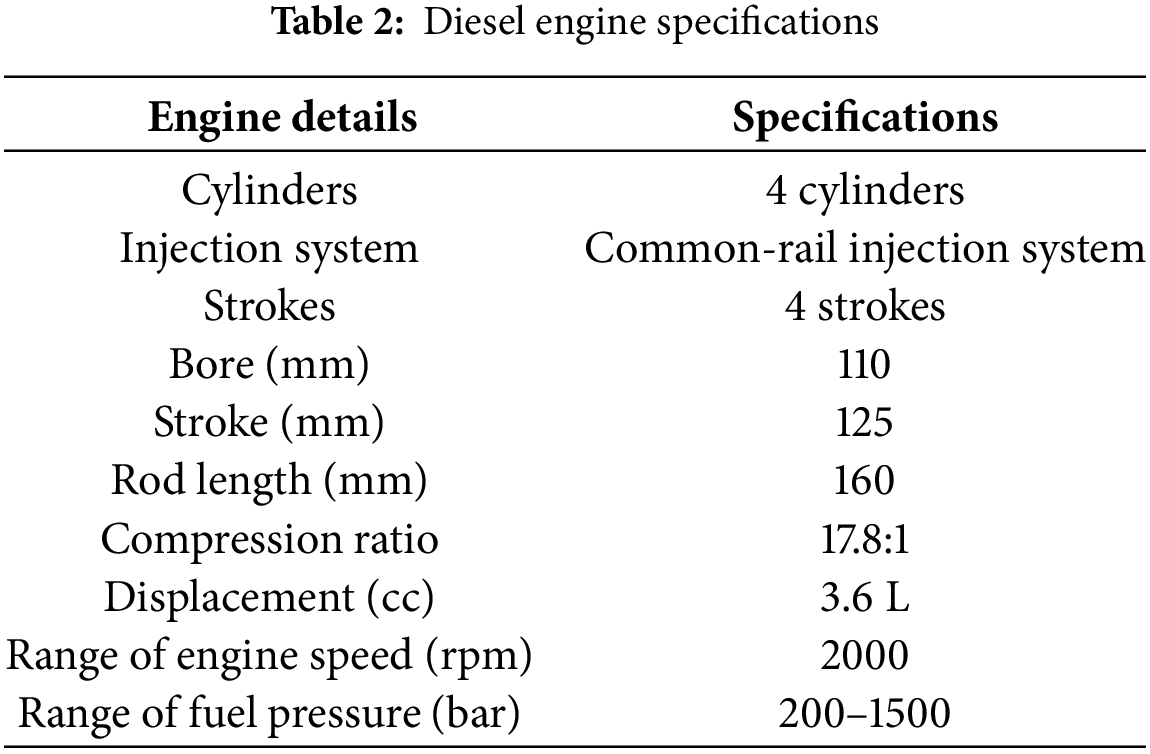

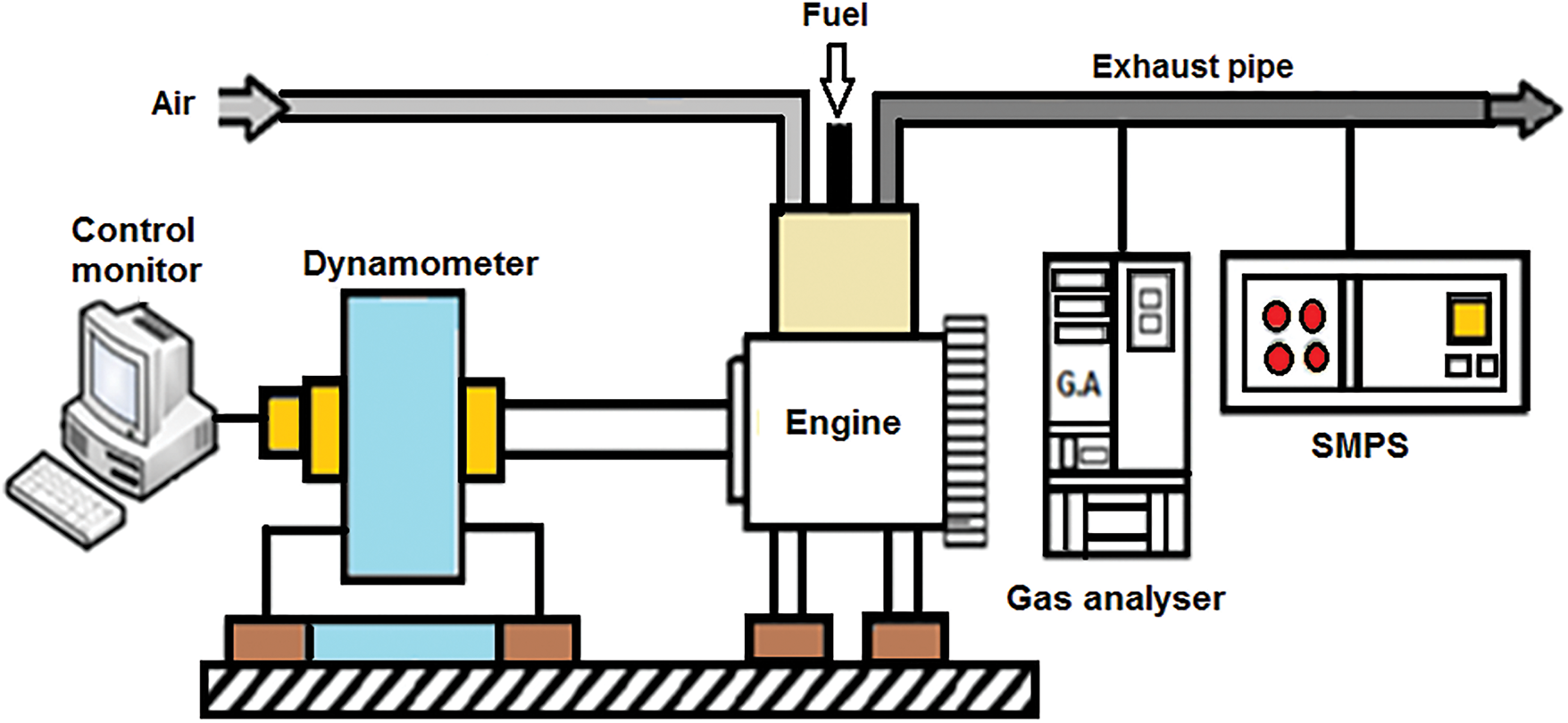

The research was conducted by a direct injection (DI) diesel engine to evaluate the different pollutants emitted by different fuels and operation conditions. Table 2 illustrates the used engine specifications. This engine has an advanced injection system that controls the fuel injection pressure, duration, quantity and the fuel injection timing. The setup of the engine tools used in experiments is depicted in Fig. 1 (schematic diagram). Different positions of the engine are linked with thermocouples K-type to measure and record all temperatures. The equipment of scanning mobility particle sizer (SMPS) and exhaust gas analyzer (type of Multigas mode 4880) was used to measure the soot nanoparticles and engine emissions. The system of volumetric flow measurement was utilized to measure fuel consumption.

Figure 1: Engine setup and tools

2.3 Measuring Instruments and Uncertainty Analysis

A coupled hydraulic dynamometer was employed to apply load to the engine and increase torque. The inlet air flow rate was measured using an orifice plate mounted on a 200 L air tank, which helped minimize pressure fluctuations in the intake manifold. The fuel flow rate was determined by recording the time required to consume 200 mL of fuel. Diesel or biodiesel was supplied to the fuel system from the fuel tank. Soot nanoparticles and engine emissions were measured using a scanning mobility particle sizer (SMPS) and an exhaust gas analyzer (Multigas Model 4880). Multigas 4880 was used to measure standard emissions, including NOx, HC, CO, and carbon dioxide (CO2).

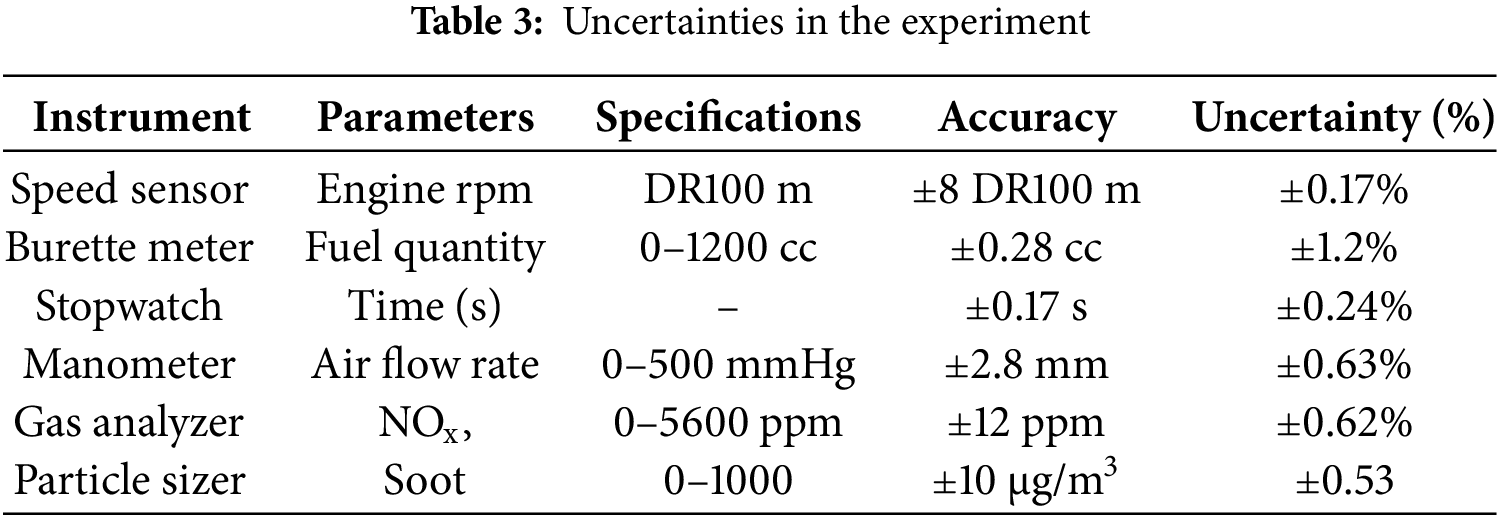

For the purpose of making a critical comparison between the statistical accuracy of the study and the experimental results, uncertainty analysis was used. The use of this analysis identifies potential anomalies observed during the calibration of measuring devices. This analysis makes it possible to predict the errors of available measurements and whether they are within acceptable engineering limits. The uncertainty prediction procedure used by Al-Kayiem et al. [27], Eq. (1), was adopted for the experiments using the data of instruments specification, shown in Table 3.

The maximum uncertainty achieved in the study was 3.05, which is reasonable and accepted as indicated by Ref. [27].

The aim of this experimental study is to determine the advantages effect of using high fuel injection pressure on engine performance and emissions, especially soot emissions. Several articles have shown that CO and smoke emissions are consistently reduced with increasing fuel injection pressure [28–30]. The injection strategy used in this study was based on operating the engine at the optimum injection timing for each fuel. The engine was started with diesel fuel and allowed to settle at a constant speed with medium load (IMEP = 3 kN/m2). The fuel injection pressure was increased to the desired pressure: four pressures were used: 200, 300, 400, and 500 bar. The engine speed was fixed during the test’s measurements at 2000 rpm. As the engine speed increases, the intake air flow rate is increased to maintain a constant intake pressure. After the engine is allowed to run at a constant speed, the fuel consumption, torque, NOx, and PM from the combustion of each fuel were measured.

The performance parameters were calculated utilizing the following equations [31]:

– The brake power:

The brake mean effective pressure:

The fuel mass flow rate:

The air mass flow rate:

The brake-specific fuel consumption:

The total fuel heat:

The brake thermal efficiency:

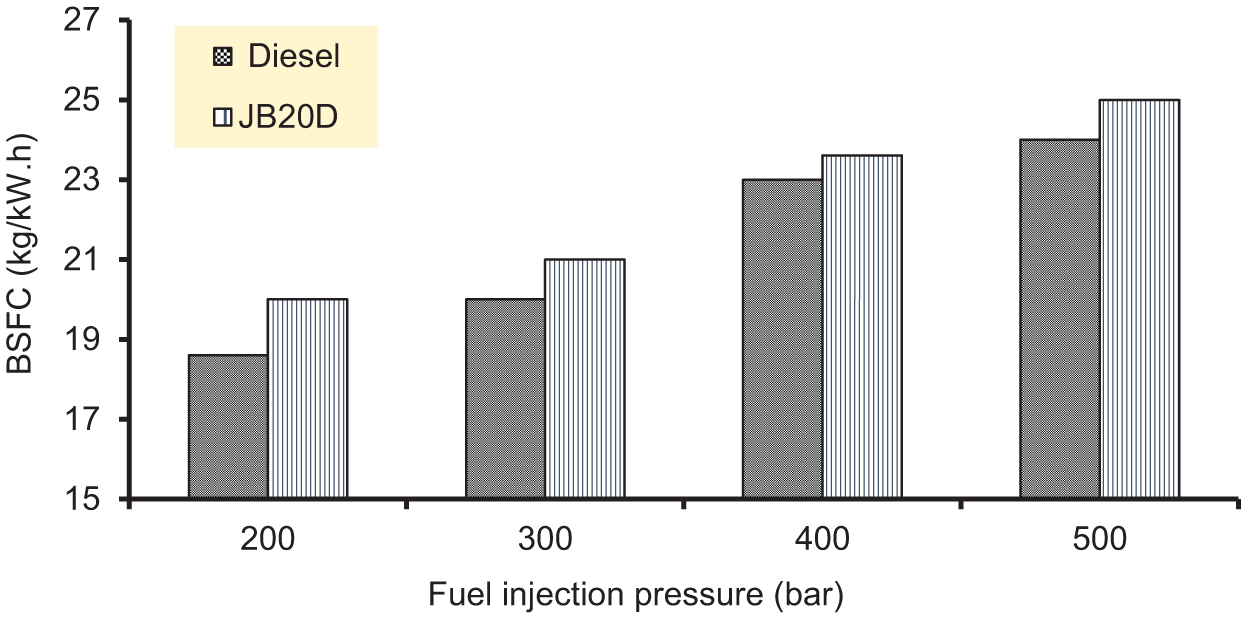

3.1 Brake-Specific Fuel Consumption

The effects of fuel injection pressure (FIP) and Jatropha biodiesel on values of BSFC are shown in Fig. 2. Notably, the highest BSFC was obtained from JB20D combustion and 500 bar of fuel injection pressure. The results indicated that the low amount of FIP decreased the fuel consumption from JB20D and diesel. The BSFC increased during JB20D combustion when compared with the diesel. This trend of results was found in other previous studies of [8,16], which they justified that the lower calorific value of biodiesel enhances the slight increase in fuel consumption. Prior works also stated that the oxygenated fuel produces higher fuel consumption than the base fuel [17,18]. Low heating values of JB20D contribute to more biodiesel needed for consumption inside the combustion chamber to reach the same diesel power. Biodiesel burning produces 21.36% of BSFC in comparison with diesel for various FIPs.

Figure 2: Effect of different fuel injection pressures on the brake-specific fuel consumption (BSFC) for Jatropha biodiesel and diesel

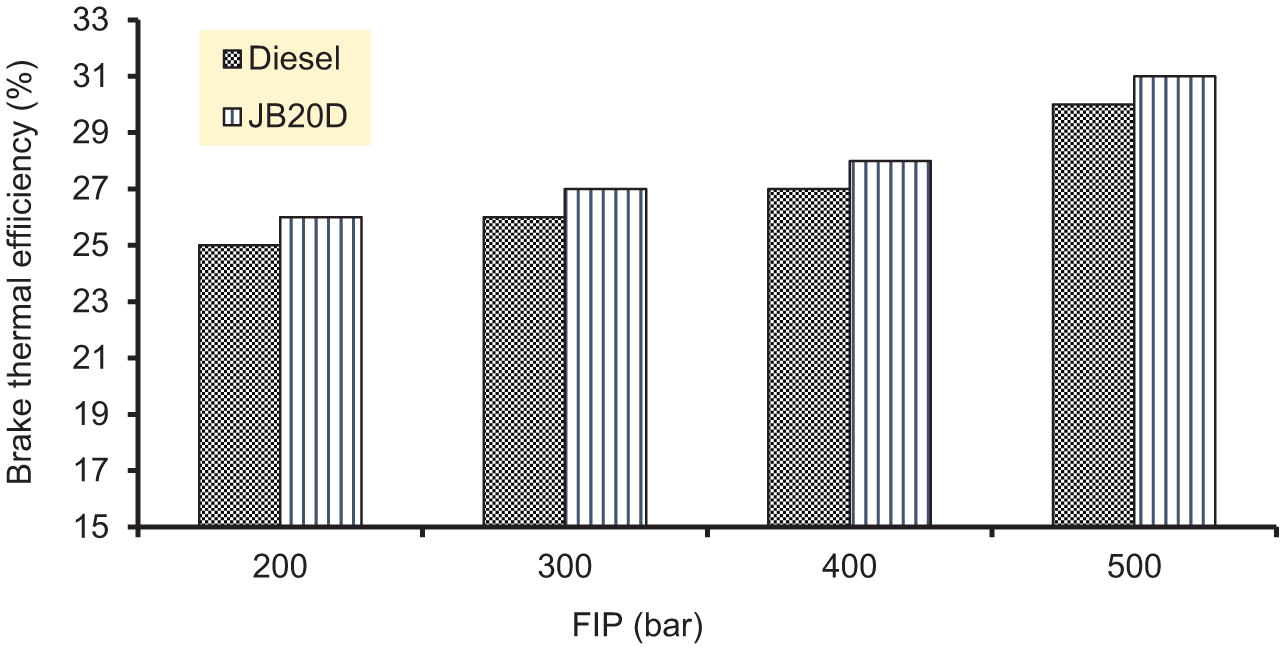

The values of BTE from biodiesel and diesel are depicted in Fig. 3 under various FIPs. The BTE enhanced with increasing FIP for JB20D and diesel. This could be referred to fuel better atomization, which is caused by growing FIP, thus enhancing the process of combustion and leading to higher BTE. The thermal efficiency was improved from the combustion of diesel-biodiesel blend combustion compared to neat diesel [32]. The blend of JB20D combustion gives the highest BTE with respect to the regular diesel, as described in Fig. 3. The blends of JB20D increase the BTE by 6.54% for different FIPs, as depicted in the results of Fig. 3. The good properties of the JB20D blend (oxygen-bond) lead to improved combustion efficiency and enhanced the engine total thermal efficiency.

Figure 3: Different FIP impact on the BTE for Jatropha biodiesel and diesel

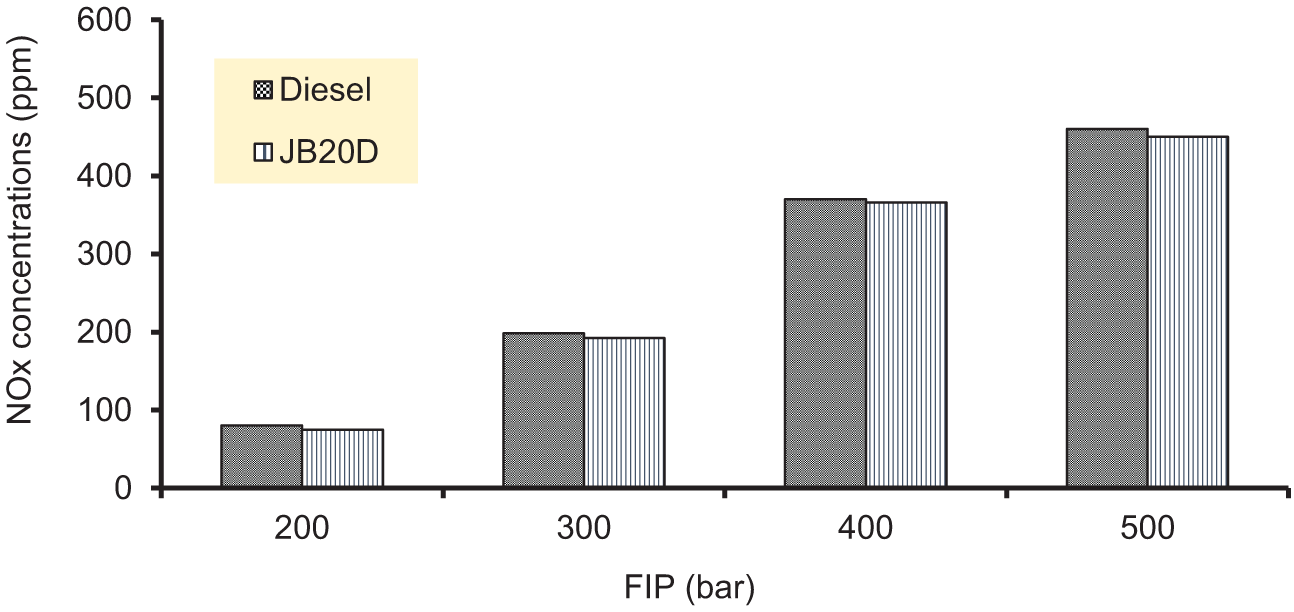

The values of NOX emissions from JB20D combustion and diesel are presented in the trends of Fig. 4 under different FIPs. The JB20D combustion emitted slightly lower NOX pollutants compared to the reference fuel (diesel). Moreover, the results trend indicated that increasing the FIP increases the NOX while it is decreasing from the burning of JB20D compared with diesel. This could be due to the enhanced mixing inside the combustion chamber between biodiesel and air, thereby lower NOX emissions produced [3,20]. Notably there was a reduction in NOX with increasing the FIP to 500 bars for both fuels than to the low FIP. Many studies mentioned that good improvement can occur with high fuel injection pressure [21–23]. For various FIP, the trends show that the NOX decreased by 6.5% at low FIP (200 bar) and about 2.17% at high FIP (500 bar) when JB20D used compared to diesel. Increasing FIP enhances the fuel atomization for both diesel and JB20D that led to this result.

Figure 4: Different FIP impact on NOX emissions for Jatropha biodiesel and diesel

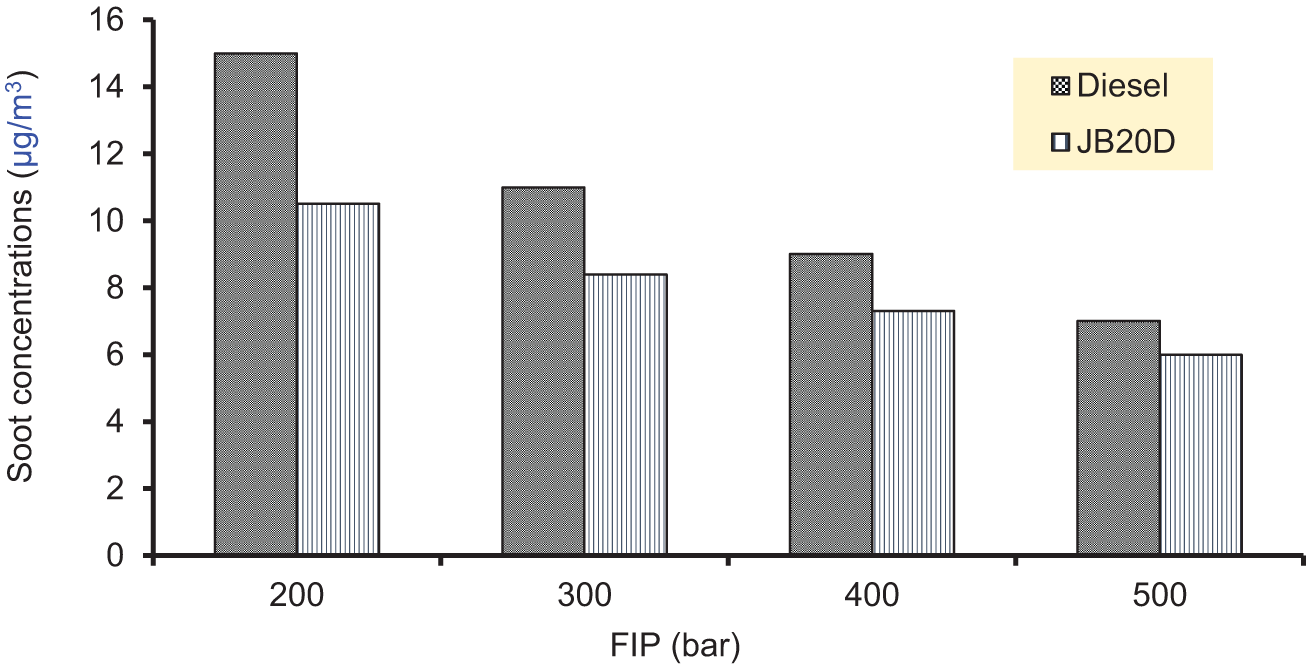

3.4 Soot Nanoparticles Emissions

The variation of soot concentrations from the effects of FIP and JB20D is shown in Fig. 5. The soot emission in exhaust decreased when FIP reached to 500 bar due to high rate of soot oxidation with increasing injection pressure. Also, the improved fuel atomization, good air, and fuel mixing result in a decline in the total soot concentrations during the combustion [24]. Previous work documented that increasing FIP to 600 bar contributes decrease in soot formation [32]. The JB20D combustion emitted lower soot emission by 32.8% compared to the diesel for low FIP and 14.28% at high FIP, as shown in Fig. 5.

Figure 5: Effect of different FIP on the soot concentrations for Jatropha biodiesel and diesel

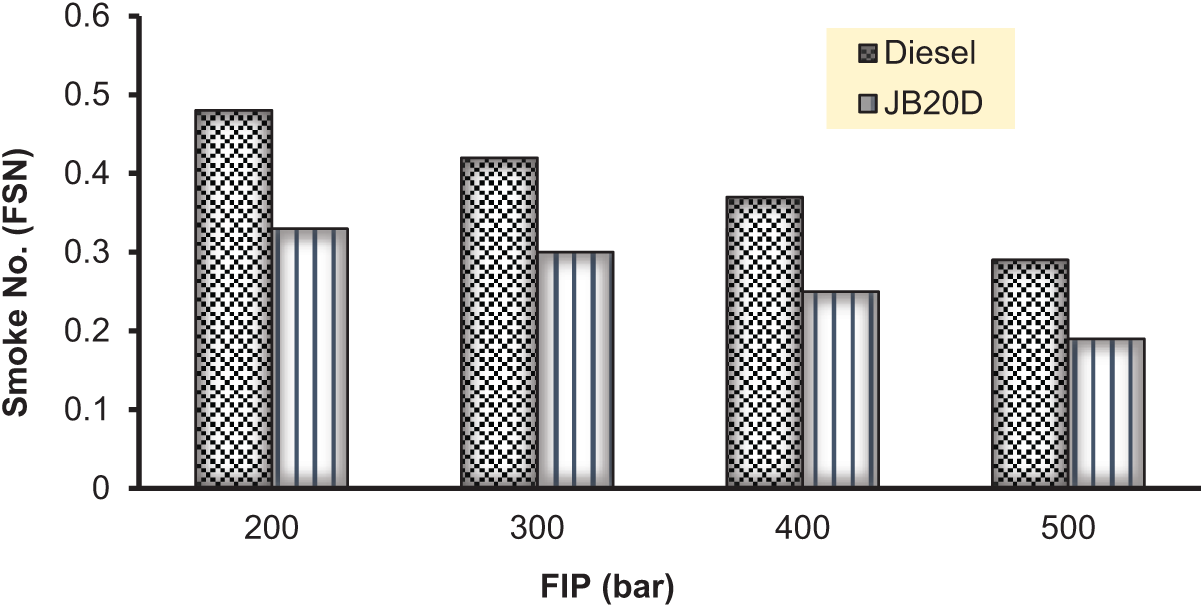

Fig. 6 illustrates the impact of various injection timings and types on Smoke Number (SN) under variable injection pressure conditions. Smoke emissions emitted from the exhaust can arise from two main mechanisms: either from a diffusion flame or from fuel-air mixtures that are too rich or too lean to ignite spontaneously. Under high cylinder pressures and temperatures, the soot is primarily generated in fuel-air rich zones [33]. Regarding the effect of fuel type and injection pressure, SN decreases as injection pressure increases since higher initial injection pressure leads to greater heat generation inside the combustion chamber. The current findings are compatible with findings by Ren et al. [34]. For neat diesel fuel, the average SN achieved were 24.14% higher than JB20D fuel. Fig. 6 also demonstrates that the mean SN decreased with JB20D combustion relative to diesel combustion as injection pressure rose. The reduction in results from more complete combustion is due to the JB20D oxygen content, which enhances the already-formed soot particles oxidation [35,36].

Figure 6: Effect of different FIP on the smoke number for Jatropha biodiesel and diesel

3.6 Comparison with the Literature

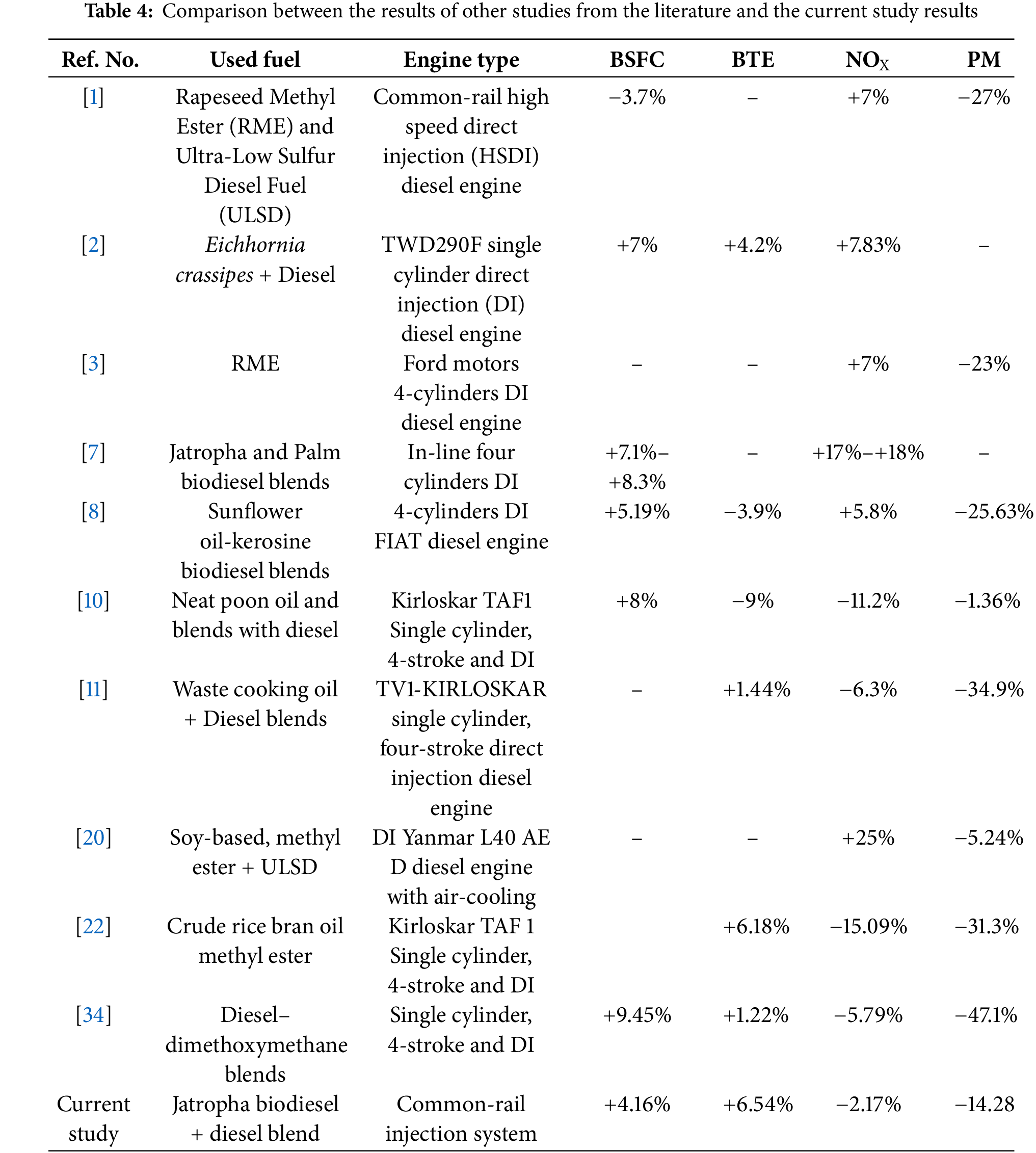

It is difficult to compare the current study with studies in the literature due to the many differences between them. For example, several studies, as shown in Table 4, used single-cylinder engines ( [2,10,11,22]), while others used four-cylinder engines ( [1,3,7,8]). Previous study [20] used an air-cooled engine. However, the table gives general trends that can be relied upon and built upon. Among these trends is that the use of biodiesel of all types causes a decrease in the concentrations of PM emitted in different rates depending on the type of biofuel used and engine operating conditions. The results of the current study were consistent with this trend. As for the concentrations of NOx, they increased in [3,7,8,20] by varying rates depending on the type of fuel and the test method. Studies [10,11,22,34] included a decrease in these concentrations and attributed the reason to the low viscosity of biofuel and its blends with diesel and to the operating and injection methods. The results of the current study were consistent with the results of the second group for the same reasons above and in addition to the use of high fuel injection pressure. As for BTE and BSFC, it is possible to divide the results listed in the table into two groups: First group, with an increase in BSFC, BTE increases, as is the case for references [2,34], which is consistent with the results of the current study. The second group, with an increase in BSFC, BTE decreases, as in references [8,10]. This discrepancy is due to the difference in examination and testing methods, the type of fuel and its specifications, and the design of the injection system, whether in terms of fuel injection pressure, spray distribution, engine compression ratio, and other important factors. However, in all studies in the table, BSFC increased using biofuel, except for reference [1], where it decreased. The researchers in this study used a common-rail high speed direct injection (HSDI) diesel engine, which enabled them to control the fuel injection pressure and timing and dealt with it in a complex but wise manner that led to such a result.

The effect of Jatropha biodiesel and FIPs on the performance and emissions characteristics in diesel engines was studied. The main conclusions from the current results are summarized below:

• Engine performance improved with higher FIP and JB20D based on base diesel results. BTE improved by 6.54% for the JB20D case, while BSFC increased somewhat. This result is due to the oxygen-bond into the JB20D, which leads to high thermal efficiency for the tested FIP.

• The main point obtained was the NOX emissions slightly decreased from JB20D and low FIP by 18.64%, while high FIP increased the NOX.

• It was obtained that the soot emission decreased from the JB20D compared to the base diesel. At high FIP, the reduction in soot emission compared to the low FIP for JB20D and diesel was about 32.8%.

It is highly important and is recommended, in the future, to study the impact of injection timing, the percentage of fuel injected, the injection angle, and the effect of all of this on the concentrations of soot emitted from the engine.

Acknowledgement: The authors gratefully thank the University of Technology-Iraq and Energy and Renewable Energies Technology Center for supporting this research.

Funding Statement: This research was not funded by any institute or organization and all costs were paid by the authors.

Author Contributions: All authors contributed to the study conception and design. Mohammed A. Fayad and Amera A. Radhi: data curation, conceptualization, supervision, methodology, writing—original draft preparation. Marwa K. Abood: methodology, writing—original draft preparation. Hind A. AL Salihi: investigation and writing—reviewing and editing; Miqdam T. Chaichan: investigation, writing—reviewing, editing and methodology. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

Ethics Approval: The study does not include human or animal subjects.

Conflicts of Interest: The authors declare no affiliations with or involvement in any organization or entity with any financial interest (such as honoraria; educational grants; participation in speakers’ bureaus; membership, employment, consultancies, stock ownership, or other equity interest; and expert testimony or patent licensing arrangements), or non-financial interest (such as personal or professional relationships, affiliations, knowledge or beliefs) in the subject matter or materials discussed in this manuscript.

References

1. Al Ezzi A, Fayad MA, Al Jubori AM, Jaber AA, Alsadawi LA, Dhahad HA, et al. Influence of fuel injection pressure and RME on combustion, NOx emissions and soot nanoparticles characteristics in common-rail HSDI diesel engine. Int J Thermofluids. 2022;15:100173. doi:10.1016/j.ijft.2022.100173. [Google Scholar] [CrossRef]

2. Abdul Wahhab HA, Al-Kayiem HH. Environmental risk mitigation by biodiesel blending from Eichhornia crassipes: performance and emission assessment. Sustainability. 2021;13(15):8274. doi:10.3390/su13158274. [Google Scholar] [CrossRef]

3. Dhahad HA, Fayad MA, Chaichan MT, Abdulhady Jaber A, Megaritis T. Influence of fuel injection timing strategies on performance, combustion, emissions and particulate matter characteristics fueled with rapeseed methyl ester in modern diesel engine. Fuel. 2021;306:121589. doi:10.1016/j.fuel.2021.121589. [Google Scholar] [CrossRef]

4. Liu J, Wu P, Sun P, Ji Q, Zhang Q, Wang P. Effects of iron-based fuel borne catalyst addition on combustion, in-cylinder soot distribution and exhaust emission characteristics in a common-rail diesel engine. Fuel. 2021;290:120096. doi:10.1016/j.fuel.2020.120096. [Google Scholar] [CrossRef]

5. Barik D, Bora BJ, Sharma P, Medhi BJ, Balasubramanian D, Krupakaran RL, et al. Exploration of the dual fuel combustion mode on a direct injection diesel engine powered with hydrogen as gaseous fuel in port injection and diesel-diethyl ether blend as liquid fuel. Int J Hydrog Energy. 2024;52:827–40. doi:10.1016/j.ijhydene.2023.06.083. [Google Scholar] [CrossRef]

6. Boehman AL, Song J, Alam M. Impact of biodiesel blending on diesel soot and the regeneration of particulate filters. Energy Fuels. 2005;19(5):1857–64. doi:10.1021/ef0500585. [Google Scholar] [CrossRef]

7. Ashrafur Rahman SM, Masjuki HH, Kalam MA, Abedin MJ, Sanjid A, Rahman MM. Assessing idling effects on a compression ignition engine fueled with Jatropha and Palm biodiesel blends. Renew Energy. 2014;68:644–50. doi:10.1016/j.renene.2014.02.050. [Google Scholar] [CrossRef]

8. Ekaab NS, Hamza NH, Chaichan MT. Performance and emitted pollutants assessment of diesel engine fuelled with biokerosene. Case Stud Therm Eng. 2019;13:100381. doi:10.1016/j.csite.2018.100381. [Google Scholar] [CrossRef]

9. Rajak U, Nashine P, Verma TN. Assessment of diesel engine performance using Spirulina microalgae biodiesel. Energy. 2019;166:1025–36. doi:10.1016/j.energy.2018.10.098. [Google Scholar] [CrossRef]

10. Devan PK, Mahalakshmi NV. Performance, emission and combustion characteristics of poon oil and its diesel blends in a DI diesel engine. Fuel. 2009;88(5):861–7. doi:10.1016/j.fuel.2008.11.005. [Google Scholar] [CrossRef]

11. Kannan GR, Anand R. Effect of injection pressure and injection timing on DI diesel engine fuelled with biodiesel from waste cooking oil. Biomass Bioenergy. 2012;46:343–52. doi:10.1016/j.biombioe.2012.08.006. [Google Scholar] [CrossRef]

12. Zhang M, Hong W, Xie F, Su Y, Han L, Wu B. Experimental investigation of impacts of injection timing and pressure on combustion and particulate matter emission in a spray-guided GDI engine. Int J Automot Technol. 2018;19(3):393–404. doi:10.1007/s12239-018-0038-8. [Google Scholar] [CrossRef]

13. Ejim CE, Fleck BA, Amirfazli A. Analytical study for atomization of biodiesels and their blends in a typical injector: surface tension and viscosity effects. Fuel. 2007;86(10–11):1534–44. doi:10.1016/j.fuel.2006.11.006. [Google Scholar] [CrossRef]

14. Xiao H, Guo F, Wang R, Yang X, Li S, Ruan J. Combustion performance and emission characteristics of diesel engine fueled with Iso-butanol/biodiesel blends. Fuel. 2020;268:117387. doi:10.1016/j.fuel.2020.117387. [Google Scholar] [CrossRef]

15. Wang X, Gao J, Chen H, Chen Z, Zhang P, Chen Z. Diesel/methanol dual-fuel combustion: an assessment of soot nanostructure and oxidation reactivity. Fuel Process Technol. 2022;237:107464. doi:10.1016/j.fuproc.2022.107464. [Google Scholar] [CrossRef]

16. Sharma P, Chhillar A, Said Z, Huang Z, Nguyen VN, Nguyen PQP, et al. Experimental investigations on efficiency and instability of combustion process in a diesel engine fueled with ternary blends of hydrogen peroxide additive/biodiesel/diesel. Energy Sources Part A Recov Util Environ Eff. 2022;44(3):5929–50. doi:10.1080/15567036.2022.2091692. [Google Scholar] [CrossRef]

17. Fayad MA, Tsolakis A, Martos FJ, Bogarra M, Lefort I, Dearn KD. Investigation the effect of fuel injection strategies on combustion and morphology characteristics of PM in modern diesel engine operated with oxygenate fuel blending. Therm Sci Eng Prog. 2022;35:101476. doi:10.1016/j.tsep.2022.101476. [Google Scholar] [CrossRef]

18. Tan YR, Zhu Q, Zong Y, Lai J, Salamanca M, Akroyd J, et al. The influence of alcohol, carbonate and polyethers as oxygenated fuels on the soot characteristics from a CI engine. Fuel. 2023;338:127296. doi:10.1016/j.fuel.2022.127296. [Google Scholar] [CrossRef]

19. Singh G, Sharma S, Singh J, Kumar S, Singh Y, Ahmadi MH, et al. Optimization of performance, combustion and emission characteristics of acetylene aspirated diesel engine with oxygenated fuels: an experimental approach. Energy Rep. 2021;7:1857–74. doi:10.1016/j.egyr.2021.03.022. [Google Scholar] [CrossRef]

20. Szybist JP, Song J, Alam M, Boehman AL. Biodiesel combustion, emissions and emission control. Fuel Process Technol. 2007;88(7):679–91. doi:10.1016/j.fuproc.2006.12.008. [Google Scholar] [CrossRef]

21. Li Z, Mi S, Zhang Y, Qian Y, Lu X. Characterizing the role of fuel injection strategies on performance, combustion, and emissions in intelligent charge compression ignition (ICCI) mode. Appl Therm Eng. 2022;207:118169. doi:10.1016/j.applthermaleng.2022.118169. [Google Scholar] [CrossRef]

22. Saravanan S, Nagarajan G, Sampath S. Combined effect of injection timing, EGR and injection pressure in NOx control of a stationary diesel engine fuelled with crude rice bran oil methyl ester. Fuel. 2013;104:409–16. doi:10.1016/j.fuel.2012.10.038. [Google Scholar] [CrossRef]

23. Li Y, Wang P, Wang S, Liu J, Xie Y, Li W. Quantitative investigation of the effects of CR, EGR and spark timing strategies on performance, combustion and NOx emissions characteristics of a heavy-duty natural gas engine fueled with 99% methane content. Fuel. 2019;255:115803. doi:10.1016/j.fuel.2019.115803. [Google Scholar] [CrossRef]

24. Fayad MA. Investigation of the impact of injection timing and pressure on emissions characteristics and smoke/soot emissions in diesel engine fuelling with soybean fuel. J Eng Res. 2021;9(2):296–307. doi:10.36909/jer.v9i2.9683. [Google Scholar] [CrossRef]

25. Wang X, Huang Z, Zhang W, Kuti OA, Nishida K. Effects of ultra-high injection pressure and micro-hole nozzle on flame structure and soot formation of impinging diesel spray. Appl Energy. 2011;88(5):1620–8. doi:10.1016/j.apenergy.2010.11.035. [Google Scholar] [CrossRef]

26. Kalil Rahiman M, Santhoshkumar S, Subramaniam D, Avinash A, Pugazhendhi A. Effects of oxygenated fuel pertaining to fuel analysis on diesel engine combustion and emission characteristics. Energy. 2022;239:122373. doi:10.1016/j.energy.2021.122373. [Google Scholar] [CrossRef]

27. Al-Kayiem HH, Tukkee AM, See YK. Experimental assessment of a solar Vortex engine integrated with sensible TES at different collector configurations. Renew Energy. 2024;227:120539. doi:10.1016/j.renene.2024.120539. [Google Scholar] [CrossRef]

28. An Y, Zhang Y, Chen T, Shi M, Wang Y, Su Z, et al. Numerical study of ducted fuel injection strategy for soot emissions reduction in a heavy-duty diesel engine. Appl Therm Eng. 2025;260:125066. doi:10.1016/j.applthermaleng.2024.125066. [Google Scholar] [CrossRef]

29. Pachiannan T, Zhong W, Balasubramanian D, Ali Alshehri M, Pugazhendhi A, He Z. Enhancing engine performance, combustion, and emission characteristics through hydrogen enrichment in n-pentanol/diesel blends: a study on advanced combustion strategies for reduced emissions. Int J Hydrog Energy. 2025;98:741–50. doi:10.1016/j.ijhydene.2024.12.005. [Google Scholar] [CrossRef]

30. Lu Y, Wei M, Wang X, Wu P, Zhao W, Ji Q, et al. Numerical study of nozzle hole number and pre-injection timing effect on combustion and emissions of methanol/diesel dual-fuel engine. Int Commun Heat Mass Transf. 2025;161:108512. doi:10.1016/j.icheatmasstransfer.2024.108512. [Google Scholar] [CrossRef]

31. Ekab NS, Salam AQ, Abd AO, Chaichan MT. Effect of Al2O3 nanoparticles on the compression ignition performances and emitted pollutants of a diesel engine. Fluid Dyn Mater Process. 2023;19(11):2847–61. doi:10.32604/fdmp.2023.028874. [Google Scholar] [CrossRef]

32. Pickett LM, Siebers DL. Soot in diesel fuel jets: effects of ambient temperature, ambient density, and injection pressure. Combust Flame. 2004;138(1–2):114–35. doi:10.1016/j.combustflame.2004.04.006. [Google Scholar] [CrossRef]

33. Shi L, Xiao W, Li M, Lou L, Deng KY. Research on the effects of injection strategy on LTC combustion based on two-stage fuel injection. Energy. 2017;121:21–31. doi:10.1016/j.energy.2016.12.128. [Google Scholar] [CrossRef]

34. Ren Y, Huang Z, Jiang D, Liu L, Zeng K, Liu B, et al. Combustion characteristics of a compression-ignition engine fuelled with diesel-dimethoxy methane blends under various fuel injection advance angles. Appl Therm Eng. 2006;26(4):327–37. doi:10.1016/j.applthermaleng.2005.07.009. [Google Scholar] [CrossRef]

35. Man XJ, Cheung CS, Ning Z. Effect of diesel engine operating conditions on the particulate size, nanostructure and oxidation properties when using wasting cooking oil biodiesel. Energy Proc. 2015;66:37–40. doi:10.1016/j.egypro.2015.02.020. [Google Scholar] [CrossRef]

36. Li X, Guan C, Luo Y, Huang Z. Effect of multiple-injection strategies on diesel engine exhaust particle size and nanostructure. J Aerosol Sci. 2015;89:69–76. doi:10.1016/j.jaerosci.2015.07.008. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools