Open Access

Open Access

ARTICLE

Numerical Simulation of Hydraulic Fracture Propagation in Deep Elasto-Plastic Reservoirs

1 Natural Gas Research Institute Branch of Shaanxi Yanchang Petroleum (Group) Co., Ltd., Xi’an, 710061, China

2 School of Petroleum Engineering, China University of Petroleum (East China), Qingdao, 266580, China

3 State Key Laboratory of Deep Oil and Gas, China University of Petroleum (East China), Ministry of Education, Qingdao, 266580, China

* Corresponding Author: Tiankui Guo. Email:

(This article belongs to the Special Issue: Integrated Geology-Engineering Simulation and Optimizationfor Unconventional Oil and Gas Reservoirs)

Energy Engineering 2025, 122(8), 3013-3039. https://doi.org/10.32604/ee.2025.066033

Received 27 March 2025; Accepted 27 May 2025; Issue published 24 July 2025

Abstract

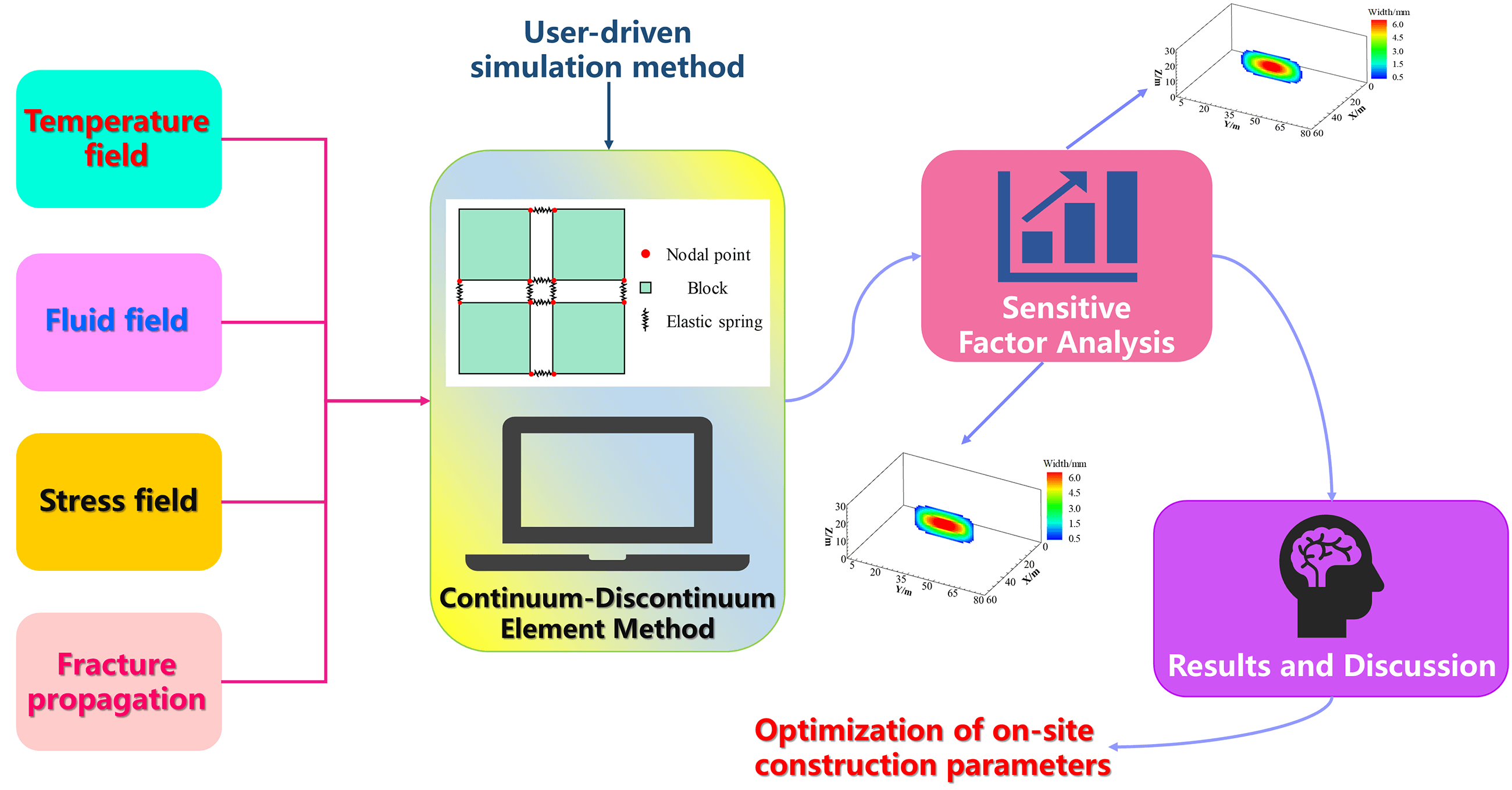

Hydraulic fracturing is a key technology for the efficient development of deep oil and gas reservoirs. However, fracture propagation behavior is influenced by rock elastoplasticity and thermal stress, making it difficult for traditional linear elastic models to accurately describe its dynamic response. To address this, this study employs the Continuum-Discontinuum Element Method (CDEM), incorporating an elastoplastic constitutive model, thermo-hydro-mechanical (THM) coupling effects, and cohesive zone characteristics at the fracture tip to establish a numerical model for hydraulic fracture propagation in deep elastoplastic reservoirs. A systematic investigation was conducted into the effects of fluid viscosity, reservoir temperature, injection rate, elastic modulus, and horizontal stress difference on fracture propagation. The findings show that a larger horizontal stress differential results in a more rectangular fracture geometry, a shorter fracture length, and a wider fracture. An increase in elastic modulus has a negligible impact on fracture length but reduces fracture width, resulting in a rounded rectangular morphology. Elevated reservoir temperature induces thermal tensile stress around the fracture, mitigating in-situ stress effects and reducing both breakdown and propagation pressures. Higher injection rates and fluid viscosity increase fracture initiation difficulty, promoting shorter but wider fractures with enhanced height growth beyond interlayer barriers. Additionally, horizontal stress significantly affects near-fracture plastic deformation: when the stress difference increases from 10 to 25 MPa, the maximum cumulative plastic strain in the surrounding rock rises by 66.67%. By integrating elastoplasticity and thermal stress effects, this study overcomes the limitations of conventional hydraulic fracturing simulations, offering novel insights for optimizing extraction strategies in deep unconventional reservoirs.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools