Open Access

Open Access

ARTICLE

Assessment of Nanoparticle-Enriched Solvents for Oil Recovery Enhancement

1

Department of Petroleum Technology, University of Technology-Iraq, Baghdad, Iraq

2

Department of Chemical Engineering, University of Technology-Iraq, Baghdad, Iraq

* Corresponding Author: Muayad M. Hasan. Email:

(This article belongs to the Special Issue: Recent advancements in thermal fluid flow applications)

Fluid Dynamics & Materials Processing 2023, 19(11), 2827-2835. https://doi.org/10.32604/fdmp.2023.027746

Received 13 November 2022; Accepted 20 February 2023; Issue published 18 September 2023

Abstract

Solvents are generally used to reduce the viscosity of heavy crude oil and ultimately enhance oil recovery. Recently, a new method has been introduced where nanoparticles (NPs) are exploited to induce enhanced oil recovery owing to their ability to improve the mobility ratio, dampen the interfacial tension, and alter rock wettability. This study investigated the integration of nano-alumina (Al2O3) NPs with an n-hexane solvent. In particular, a Brookfield viscometer has been used to measure the crude oil viscosity and it has been found that NPs can effectively lead to a significant decrease in the overall oil viscosity (70 cp using the solvent only, 45 cp when NPs are added).Keywords

As a result of the increasing universal demand for energy, fuels, and raw materials, crude oil continues to be the main energy resource in the industry [1]. Crude oil is composed of many hydrocarbon compounds with various functional groups and this diversity gives it different characteristics [2]. Heavy crude oil (HO) constitutes at minimum half of the recoverable oil world sources [3]. According to the US Geological Survey (USGS) and the International Energy Agency (IEA), HO is basically defined as a complex fluid of 10 < API gravity < 20 and viscosity higher than 100 cp that represents about 70% of the total resources of hydrocarbons in the world. These properties may cause many difficulties during the production, refining, and transportation of HO [4,5].

Efficient and economical techniques have been used to reduce the viscosity of HO and improve its production, transport, and separation under reservoir and surface conditions, namely: (i) emulsification of oil-in-water (O/W) emulsions, which can highly decrease the crude oil viscosity and consequently improve its mobility; (ii) reducing the drag force by using of annular flow technique; (iii) deasphalting crude oil by applying CO2, low and high molecular weight-alkanes; (iv) the use of thermal processes that based on the injection of steam and other gases to reduce viscosity; and (v) in-situ upgrading such as the various modes of air injection, e.g., in-situ combustion (ISC), thermal cracking and its catalytic variations [4,6].

Lately, more attention is being paid to dilution methods applied with several solvents at various temperatures to reach a high reduction in the heavy oil viscosity. Using n-hexane in the Athabasca field, which mainly contains bitumen, led to a significant decrease in the viscosity resulting in more mobilicable oil [2].

Light hydrocarbon has been employed as a solvent to blend with heavy oil in a horizontal well as Marin [7] recorded. It was observed that heavy oil viscosity was reduced and allowed to be drained by gravity to the producer.

Fortenberry et al. [8] investigated the effect of mixing low concentrations of a certain economical solvent with alkaline-polymer solutions, one of the chemical techniques, which was noticed that the performance of alkaline-polymer used in enhanced oil recovery has been substantially improved.

Hawbash Mahmood et al. [9] studied the addition of solvents such as methanol, toluene, and gas condensate to the heavy oil. It was found that blending such solvents with the heavy oil obtained from Sheikhan oilfield yielded a good decrease in the viscosity of the heavy crude oil.

An experimental study and modeling with Back Feed Forward Artificial Neural Network (BFF-ANN) was investigated to discover the effect of utilizing toluene and heptane, as solvents, on enhanced oil recovery by reducing the viscosity of the heavy oil. The practical results showed that a higher viscosity reduction was obtained when the toluene/heptane (75/25 vol. %) was mixed, in which, the heavy oil viscosity decreased from 135.6 to 26.33 cP [10].

Moreover, the solvent can be integrated with steam in Steam-Assisted Gravity Drainage (SAGD) method used for enhanced oil recovery. The findings revealed that injecting the solvent with steam in SAGD technique results in higher oil recovery than that obtained from the conventional SAGD method [11].

In recent years, the application of nanotechnology in the oil industry has been accepted and employed as enhanced oil recovery (EOR) agents to their unique features and availability in large quantities [12]. Nanotechnology is a new method that uses nanosized materials for producing applicable systems, matters, and devices, in addition to new phenomena and properties at the nanoscale (1–100 nanometers).

Many researchers have used nanomaterials to reduce the viscosity of bitumen, heavy crude oil, and semi-heavy crude oil. The results of experimental studies showed that NPs concentration, size and type are different parameters that affect the viscosity mechanism of heavy oil [13]. There have been numerous reported studies in the literature witnessing the application of nanoparticles for EOR purposes.

Nanomaterials can be integrated with polymer to formulate polymeric nanofluid used for chemically enhanced oil recovery. This combination leads to improving the characteristics of the developed polymer solution which could be used for severe reservoir conditions. The promoted solution can be applied to the thermal conductivity, reduce oil viscosity and interfacial tension, and the tendency of the rock wettability [14].

An experimental study was conducted by Clint [15] to make a comparison between oil mobilization in oil reservoirs using two nanoparticles named Chemically Derived Graphene (CDG) and silica. The recovery factor started to increase achieving a reasonable enhancement after the concentration of the nano-silica reached 600 ppm which was considered a threshold concentration. However, the findings revealed that when the CGD nanoparticles were applied, for all concentrations, the enhanced recovery factor was substantially improved in comparison with the baseline.

Ogolo et al. [16] tested several nanoparticles to figure out the impact of these nanomaterials on enhanced oil recovery. The EOR experiments were conducted under surface conditions. Besides the nanoparticles, various solutions were employed as the dispersing media for the nano-particles. It was found that among the various nanomaterials used in the experiments, alumina and silica were the best agents to achieve high oil recovery.

Another practical flooding examined the effect of silica nanoparticles on oil production. The results concluded that the productivity improvement was enhanced by 15% of the ultimate recovery factor [17].

Simulation and practical study were conducted on reservoir sandstone to reduce oil viscosity using dielectric and magnetic nanofluids. The viscosity of the oil was measured over a range of temperatures (25°C–120°C) and various shear rates (100–200 s−1). Findings revealed that the crude oil viscosity was considerably high at a low temperature and low shear rate, and steadily the viscosity decreased at the reservoir conditions [18].

Recently, experimental work investigated the impact of ZnO/SiO NPs on several parameters such as rheology, IFT, and rock wettability for enhanced oil recovery. It was found that these parameters were substantially improved when a high concentration of NPs was applied [19].

Moreover, using silica nanofluids has a significant influence on the wettability of the carbonate oil reservoir under the reservoir conditions. The results detected that the rock wettability of the carbonate reservoir was effectively modified to neutral wet and water wet from strongly oil wet [20].

Nevertheless, the stability of the nanofluid is considered the main challenge in chemical flooding for enhanced oil recovery. Lashari et al. [21] studied blending many types of NPs into the polymer to investigate the stability of the developed nanofluid. They have improved nano-compounds based on Hydrolyzed polyacrylamide (HPAM)-graphene oxide (GO) and HPAM–SiO2 to form polymeric solutions for illustrating their properties. It was found that the characteristics of HPAM were substantially enhanced by silica NPs, especially in the saline brines and high temperatures, while, the presence of GO at high temperatures resulted in enhanced viscosity and stability of the applied polymer solution [22].

Another research was conducted on an oil reservoir in harsh conditions with high salinity and high temperatures to illustrate the performance of PAM/sGO composites on the enhanced oil recovery process. In this study, many factors such as, resistance of high temperature, shear stability and the degree of salinity were evaluated. In addition, the developed fluid was characterized by several analyses to examine its ability to increase oil recovery at harsh reservoir conditions. The results revealed that maintaining the viscosity of the developed liquid at high temperatures indicated for best thermal stability compared to the base polymer [23].

Usually, polymer flooding, a chemical technique used for enhanced oil recovery, is applied to improve the mobility ratio of the displacing fluid, which in turn enhances the sweep efficiency and leads to a higher rate of crude oil extraction. However, the presence of harsh reservoir conditions can lead to lower performance efficiency of such polymer solutions. Therefore, to overcome this problem, ZrO2 NPs were combined with the polymer (ZrO2 NPs−PAM) to formulate a novel nano-fluid injection solution for EOR techniques. The results showed that the integration of ZrO2 NPs−PAM decreased the impact of excess salinity on the viscosity [24,25].

In this work, integrating NPs called nano-alumina (Al2O3) NPs with n-hexane as an organic solvent in different concentrations was conducted to investigate their effect on the oil recovery by reducing the viscosity of crude heavy oil. Alumina was chosen for this study because it is very effective to extract oil from reservoirs in comparison with other NPs [26,27], in addition, to its economic reason for being low cost. Another effective reason of using alumina was it is inert and there is not any chemical reaction with the rocks.

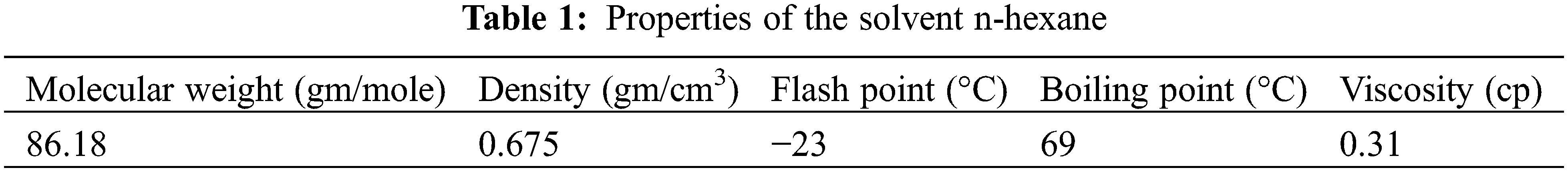

In this study, the sample of the heavy crude oil used was collected from the Amara oil field, south of Iraq, with API, density, and viscosity of 16, 0.979 g/cm3 and 135.6 cp respectively at 25°C. The solvent employed was hexane for diluting the heavy oil which was supplied by the local storage and the properties of this solvent are listed in Table 1.

The nano-particle applied in this project was alumina (Al2O3) which was purchased from the local markets with physical specifications as recorded in Table 2.

Several samples were utilized in this experiment, starting with crude heavy oil alone, and then, the heavy oil was mixed with different concentrations of hexane (5, 10, and 15 wt. %). After that, the mixture of the crude oil and the 15 wt. % of hexane was taken and integrated with various concentrations of alumina nano-particles (10, 50, 100, and 200 ppm). In each preparation process, the sample was prepared a beaker sized 125 ml. The sample was then stirred on a magnetic stirrer for one hour to obtain a homogeneous blending. The viscosity of the samples was measured under a wide range of shear rates of (2 to 42 s−1), using a viscometer type Brookfield (USA) model DV-11, which is a programmable viscometer supplied with a temperature sensor and connected to the computer. Priority to the experiments, the measurements of the rheological parameters were conducted at 25°C. Moreover, different temperatures of 298.15, 308.15, and 318.15 K were taken into account to verify their effect on reducing the viscosity of heavy oil.

The extraction of heavy oil faces a lot of challenges due to the high viscosity of the crude oil. One of the main challenges is that oil cannot easily come out to the surface under standard reservoir conditions. Therefore, the reduction in viscosity is the major target to increase heavy oil recovery. In this work, the crude oil sample was treated with different concentrations of various solvents at different temperatures and nano-alumina particles to investigate the impact of these parameters on the heavy oil recovery. Alumina was chosen for this study because it is very effective to extract oil from reservoirs in comparison with other NPs [26,27], in addition, to its economic reason of being low cost. Another effective reason for using alumina was it is inert and there is not any chemical reaction with the rocks.

Integrating NPs with solvents may improve several parameters such as interfacial tension rock wettability and lead to a high reduction in the crude viscosity resulting in more oil production.

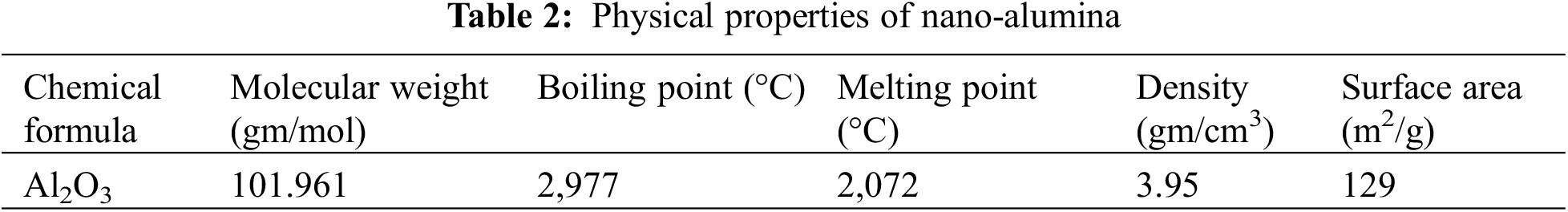

Fig. 1 illustrates the behavior of the heavy oil in terms of the viscosity and shear rate after using hexane as a solvent. From Fig. 1, it can be seen that the viscosity of the crude oil without using solvent slightly decreased over the shearing rate, in which, the viscosity just declined from about 135 to 111 cp. In contrast, adding solvents in different concentrations leads to a higher reduction in the oil viscosity. It is apparent that the reduction in the viscosity increased by increasing the concentration of the solvent along with the shear rate. According to Fig. 1, the viscosity of the heavy oil reduced from about 130 to 95 cp when crude oil was mixed with a concentration of 5 wt. % hexane, while using 10 wt. % hexane resulted in a reduction in the viscosity reaching around 37%. Further lowering in the oil viscosity was gained by blending crude oil with 15 wt. % hexane to reduce the viscosity from almost 115 to 68 cp, which represents about a 40% reduction in the viscosity. The reason behind that is because heavy crude oil has high contents of resin and asphaltene, adding solvents into heavy components can increase the light oil content and in turn reduce the viscosity of the heavy crude oil.

Figure 1: The behavior of the heavy oil at a different weight fraction of hexane

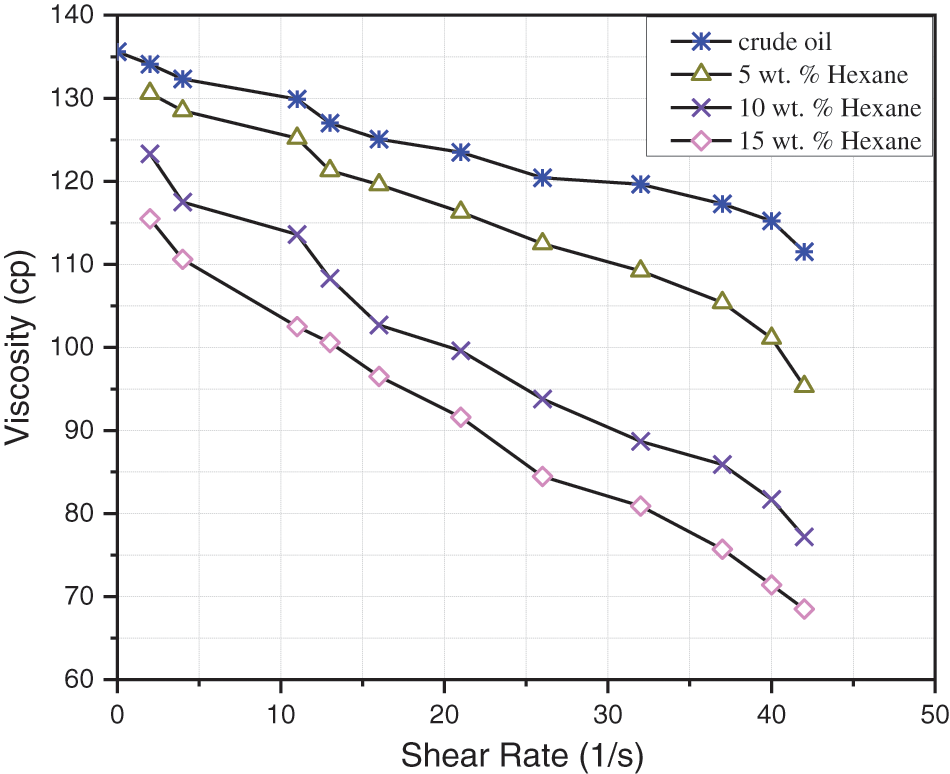

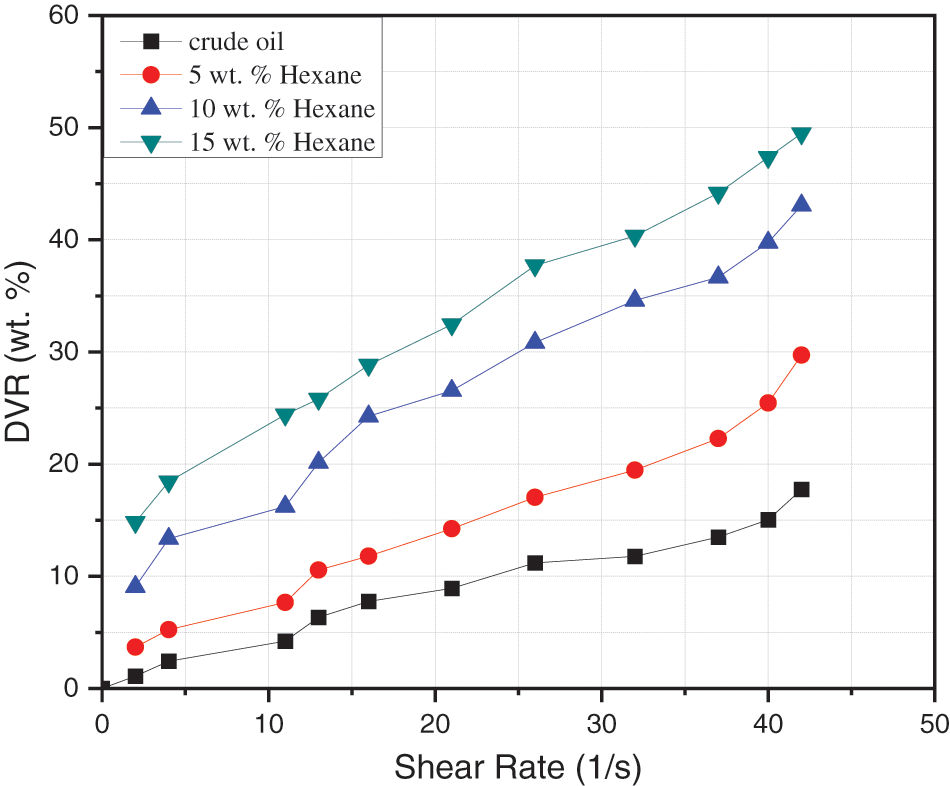

In terms of the degree of viscosity reduction (DVR%), Fig. 2 shows how it was improved by the change in the concentration of the solvent within a certain range of shear rate. The experimental results revealed that DVR% was enhanced to reach its maximum value at the highest weight percent of diluent. So, the extreme reduction in the heavy hydrocarbon viscosity occurred at 15 wt. % of solvent in comparison with using crude oil alone. With an increase in the weight fraction of diluents, the maximum change in viscosity happened at 15 wt. % for all shear rates. The highest value of DVR% was about 52% for 15 wt. % of solvent at a shear rate of 42 s−1, constant temperature, and pressure. The reduction in viscosity is attributed to the formation of structure within the diluents under a shear rate.

Figure 2: Viscosity reduction of heavy oil at different weight fractions of n-hexane

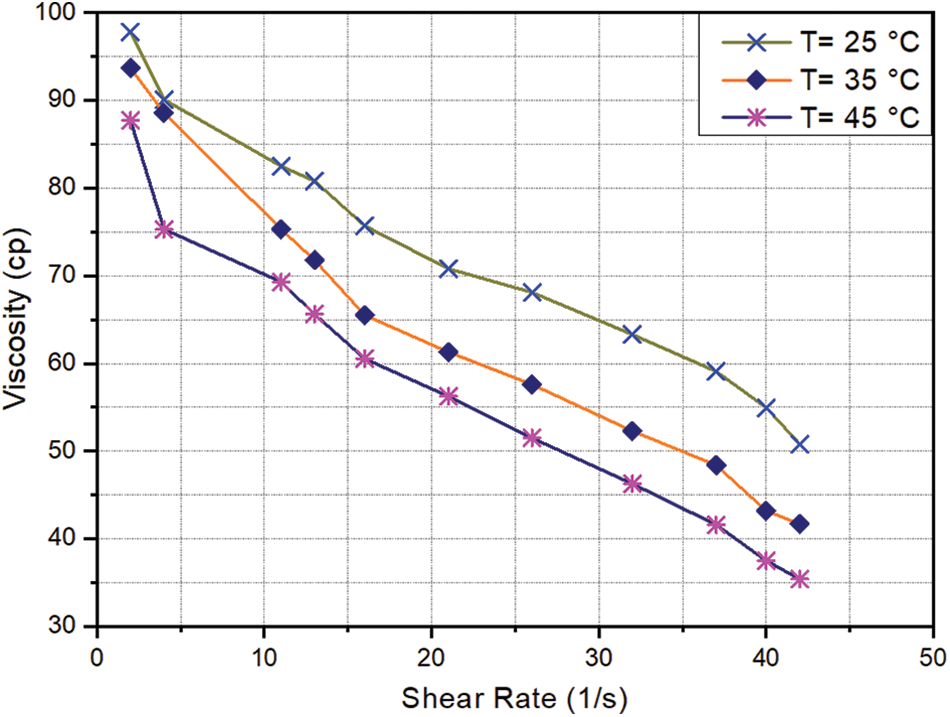

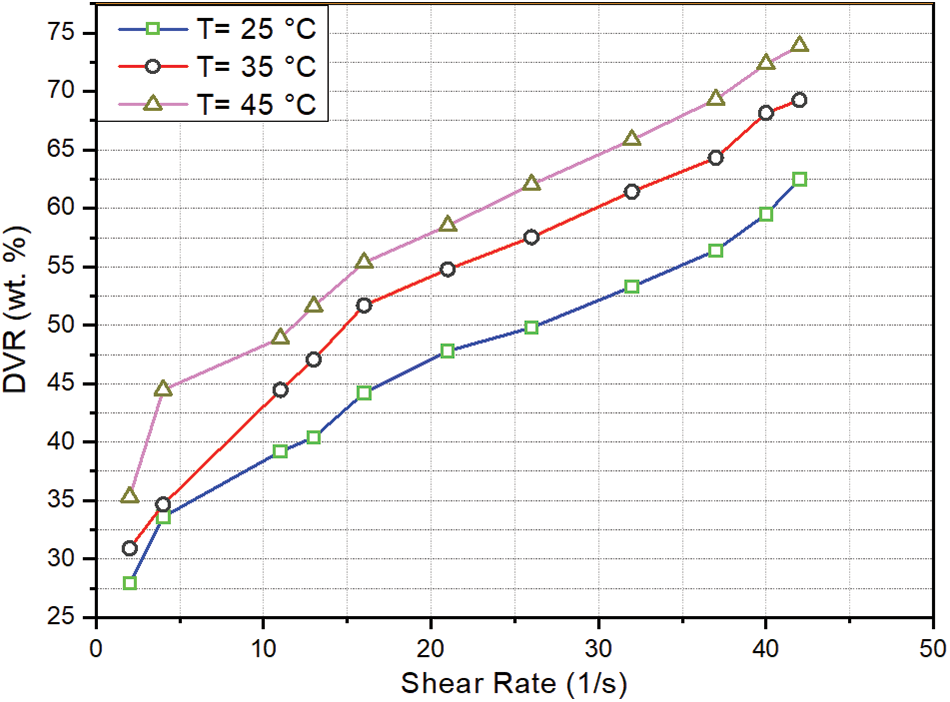

Moreover, the oil sample was tested through a range of shear rates from (2 to 42 s−1) to study the impact of different temperatures on the viscosity reduction of the heavy oil. Fig. 3 displays the viscosity as a function of the shear rate at various temperatures. From Fig. 3, it can be distinctly seen that viscosity was substantially affected by the temperature where the increase in the temperature from 25°C to 45°C has led to a high reduction in the heavy oil viscosity.

Figure 3: Viscosity reduction of heavy oil at various temperatures

Furthermore, the effect of the temperature on the viscosity reduction degree (DVR%) plotted as a function of shear rate is presented in Fig. 4. From Fig. 4, it can be noticed that the degree of the oil viscosity reduction dramatically rose with the increase in the temperature, where the degree reduction of the viscosity climbed up from about 35 wt. % to around 75 wt. % at the highest temperature.

Figure 4: The reduction degree in the viscosity at different temperatures

In addition, the influence of the concentration of nanoparticles (NPs) on the oil viscosity using alumina particles (Al2O3) at various shear rates and at a temperature of 25°C was examined. Four alumina samples in different concentrations were blended with 15 wt. % hexane to study the behavior of the crude oil viscosity and compare it with pure crude oil. Fig. 5 shows the effect of nano-material concentrations on viscosity of the heavy crude oil in the presence of a certain concentration of solvent. The difference in the viscosity reduction of the crude oil mixed with solvent and nanoparticles compared to the pure crude oil alone can be obviously seen in Fig. 5.

Figure 5: The oil viscosity behavior at different nanoparticles concentrations

Where the viscosity of the oil was lowered from about 115 cp to around 75 cp when 10 wt. % of nano-alumina was added to the heavy oil and an increase in the concentration of the blended nano-material significantly reduced the oil viscosity to around 45 cp. According to Hashemi et al. 2014, for crude heavy oil, subjected to thermal cracking due to the high temperature, nano-particles enhance the properties of the crude oil by decreasing oil viscosity, upgrading heavy oil, and removing contaminants present in the oil. This feature of the nano-materials could lead to the same effect for the low temperature.

Also, in the same context, Fig. 6 illustrates the impact of the nano-particles on the weight percent of oil reduction along with the shear rate. From this, it can be noted that the reduction in the viscosity increased with an increase in the concentration of the nano-alumina to about 65 wt. % (DVR) compared to around 15 wt. % of the viscosity reduction for pure crude oil.

Figure 6: The weight percent of the oil viscosity reduction

This experimental work revealed the effect of different concentrations of a certain solvent on the heavy oil viscosity, which is considered the major factor to make crude oil mor movable. This experimental work revealed the effect of different concentrations of a certain solvent on the heavy oil viscosity, which was considered as the major factor to that makes crude oil more movable to increase the oil production recovery.

Moreover, the study has taken into account the influence of integrating different concentrations of NPs with a certain concentration of solvent on the heavy oil viscosity, and as a consequence, leading to extra oil recovery. In comparison with only hexane as a solvent used in this project, mixing various concentrations of nano-materials, in such alumina, can substantially reduce the viscosity of crude heavy oil to increase the amount of oil production. Where the oil viscosity, using only n-hexane with high weight percent, lowered to around 70 cp while when NPs blended with the solvent, it was clearly noticed the rise in the oil viscosity reduction, and the viscosity reached around 45 cp.

Acknowledgement: The authors would like to express their gratitude to the staff of the Petroleum Technology Department, University of Technology-Iraq for supporting this work.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Olaya-Escobar, D. R., Quintana-Jiménez, L. A., González-Jiménez, E. E., Olaya-Escobar, E. S. (2020). Ultrasound applied in the reduction of viscosity of heavy crude oil. Revista Facultad de Ingeniería, 29(54), e11528. [Google Scholar]

2. Azeez, R. A., Al-Zuhairia, F. K., Al-Adilia, A. (2020). A comparative investigation on viscosity reduction of heavy crude oil using organic solvents. International Journal Advanced Science Engineering Information Technology, 10(4), 1675–1681. [Google Scholar]

3. Hasan, M. M. (2018). Enhanced recovery of heavy oil using a catalytic process (Doctoral Dissertation). University of Nottingham. [Google Scholar]

4. Alomair, O. A., Almusallam, A. S. (2013). Heavy crude oil viscosity reduction and the impact of asphaltene precipitation. Energy & Fuels, 27(12), 7267–7276. [Google Scholar]

5. Zhao, F., Liu, Y., Lu, N., Xu, T., Zhu, G. et al. (2021). A review on upgrading and viscosity reduction of heavy oil and bitumen by underground catalytic cracking. Energy Reports, 7(10), 4249–4272. [Google Scholar]

6. Taborda, E. A., Franco, C. A., Lopera, S. H., Alvarado, V., Cortés, F. B. (2016). Effect of nanoparticles/nanofluids on the rheology of heavy crude oil and its mobility on porous media at reservoir conditions. Fuel, 184, 222–232. [Google Scholar]

7. Marin Sr, R. J. (2015). Hydrocarbon solvent injection study for heavy oil recovery in the Colombian oil sands. Search Discover, 41528. [Google Scholar]

8. Fortenberry, R., Kim, D. H., Nizamidin, N., Adkins, S., Pinnawala Arachchilage, G. W. et al. (2015). Use of cosolvents to improve alkaline/polymer flooding. SPE Journal, 20(2), 255–266. [Google Scholar]

9. Hawbash Mahmood, A. A. (2019). To what extent could methanol, toluene and gas condensate effect on heavy crude oil viscosity, Sheikhan oil field, Kurdistan, Iraq. International Journal of Energy Engineering, 9(1), 7–11. [Google Scholar]

10. Al-Zuhairi, F. K., Azeez, R. A., Jassim, M. K. (2020). Artificial neural network (ANN) for prediction of viscosity reduction of heavy crude oil using different organic solvents. Journal of Engineering, 26(6), 35–49. [Google Scholar]

11. Mohan, V., Su, Y., Wang, J., Gates, I. D. (2022). Rich solvent-steam assisted gravity drainage (RS-SAGDAn option for clean oil sands recovery processes. Cleaner Engineering and Technology, 8, 100463. [Google Scholar]

12. Gbadamosi, A. O., Junin, R., Manan, M. A., Agi, A., Oseh, J. O. et al. (2019). Synergistic application of aluminium oxide nanoparticles and oilfield polyacrylamide for enhanced oil recovery. Journal of Petroleum Science and Engineering, 182, 106345. [Google Scholar]

13. Cheraghian, G., Rostami, S., Afrand, M. (2020). Nanotechnology in enhanced oil recovery. Processes, 8(9), 1073. [Google Scholar]

14. Lashari, N., Ganat, T. (2020). Emerging applications of nanomaterials in chemical enhanced oil recovery: Progress and perspective. Chinese Journal of Chemical Engineering, 28(8), 1995–2009. [Google Scholar]

15. Clint, J. H. (2012). Surfactant aggregation. New Delhi: Springer Science & Business Media, Thomson Press Limited. [Google Scholar]

16. Ogolo, N. A., Olafuyi, O. A., Onyekonwu, M. O. (2012). Enhanced oil recovery using nanoparticles. SPE Saudi Arabia Section Technical Symposium and Exhibition, Saudi Arabia. [Google Scholar]

17. Zhang, H., Ramakrishnan, T. S., Nikolov, A., Wasan, D. (2016). Enhanced oil recovery driven by nanofilm structural disjoining pressure: Flooding experiments and microvisualization. Energy & Fuels, 30(4), 2771–2779. [Google Scholar]

18. Sikiru, S., Soleimani, H., Shafie, A., Kozlowski, G. (2022). Simulation and experimental investigation of dielectric and magnetic nanofluids in reduction of oil viscosity in reservoir sandstone. Journal of Petroleum Science and Engineering, 209, 109828. [Google Scholar]

19. Hassan, Y. M., Guan, B. H., Chuan, L. K., Hamza, M. F., Khandaker, M. U. et al. (2022). The influence of ZnO/SiO2 nanocomposite concentration on rheology, interfacial tension, and wettability for enhanced oil recovery. Chemical Engineering Research and Design, 179, 452–461. [Google Scholar]

20. Jang, H., Lee, W., Lee, J. (2018). Nanoparticle dispersion with surface-modified silica nanoparticles and its effect on the wettability alteration of carbonate rocks. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 554, 261–271. [Google Scholar]

21. Lashari, N., Ganat, T. (2021). Synthesized graphene oxide and fumed aerosil 380 dispersion stability and characterization with partially hydrolyzed polyacrylamide. Chinese Journal of Chemical Engineering, 34, 307–322. [Google Scholar]

22. Aliabadian, E., Sadeghi, S., Moghaddam, A. R., Maini, B., Chen, Z. et al. (2020). Application of graphene oxide nanosheets and HPAM aqueous dispersion for improving heavy oil recovery: Effect of localized functionalization. Fuel, 265, 116918. [Google Scholar]

23. Lyu, Y., Gu, C., Tao, J., Yao, X., Zhao, G. et al. (2019). Thermal-resistant, shear-stable and salt-tolerant polyacrylamide/surface-modified graphene oxide composite. Journal of Materials Science, 54(24), 14752–14762. [Google Scholar]

24. Al-Anssari, S., Ali, M., Alajmi, M., Akhondzadeh, H., Khaksar Manshad, A. et al. (2021). Synergistic effect of nanoparticles and polymers on the rheological properties of injection fluids: Implications for enhanced oil recovery. Energy & Fuels, 35(7), 6125–6135. [Google Scholar]

25. Hasan, M. M. (2022). Various techniques for enhanced oil recovery: A review. Iraqi Journal of Oil and Gas Research, 2(1), 83–97. [Google Scholar]

26. Samba, M. A., Hassan, H. A., Munayr, M. S., Yusef, M., Eschweido, A. et al. (2019). Nanoparticles EOR aluminum oxide (Al2O3) used as a spontaneous imbibition test for sandstone core. ASME International Mechanical Engineering Congress and Exposition, vol. 59438, V006T06A054. Salt Lake City, Utah, USA, American Society of Mechanical Engineers. [Google Scholar]

27. Emeka, O. J., Ifeanyi, O., Chikwe, A., Nwachukwu, A., Ndubuisi, O. et al. (2021). Effect of application of aluminium oxide on recovery in enhanced oil recovery. Engineering and Applied Science, 6(2), 41–48. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools