Open Access

Open Access

ARTICLE

A Machine-Learning Approach for the Prediction of Fly-Ash Concrete Strength

1

College of Water Conservancy, Yunnan Agricultural University, Kunming, 650201, China

2

Institute of International Rivers and Eco-Security, Yunnan University, Kunming, 650500, China

3

Southwest Survey and Planning Institute of National Forestry and Grassland Administration, Kunming, 650031, China

* Corresponding Authors: Fulai Wang. Email: ; Feipeng Liu. Email:

(This article belongs to the Special Issue: Advances in Solid Waste Processing and Recycling Technologies for Civil Engineering Materials)

Fluid Dynamics & Materials Processing 2023, 19(12), 3007-3019. https://doi.org/10.32604/fdmp.2023.029545

Received 25 February 2023; Accepted 18 April 2023; Issue published 27 October 2023

Abstract

The composite exciter and the CaO to Na2SO4 dosing ratios are known to have a strong impact on the mechanical strength of fly-ash concrete. In the present study a hybrid approach relying on experiments and a machine-learning technique has been used to tackle this problem. The tests have shown that the optimal admixture of CaO and Na2SO4 alone is 8%. The best 3D mechanical strength of fly-ash concrete is achieved at 8% of the compound activator; If the 28-day mechanical strength is considered, then, the best performances are obtained at 4% of the compound activator. Moreover, the 3D mechanical strength of fly-ash concrete is better when the dosing ratio of CaO to Na2SO4 in the compound activator is 1:1; the maximum strength of fly-ash concrete at 28-day can be achieved for a 1:1 ratio of CaO to Na2SO4 by considering a 4% compound activator. In this case, the compressive and flexural strengths are 260 MPa and 53.6 MPa, respectively; the mechanical strength of fly-ash concrete at 28-day can be improved by a 4:1 ratio of CaO to Na2SO4 by considering 8% and 12% compound excitants. It is shown that the predictions based on the aforementioned machine-learning approach are accurate and reliable.Keywords

Currently, the main form of power generation around the world comes from coal-fired thermal power generation. Today this form of power generation now brings a series of resource and environmental problems, one of the important pollutants is fly ash, which is formed in the high temperature environment of coal-fired power plants and is mainly composed of aluminium oxide, silica and calcium oxide [1]. Fly ash has a low utilisation rate and can occupy a large amount of land space. At the same time, fly ash is an important material that can improve the compatibility and durability of plain concrete [2,3]. Due to its unique physical and chemical properties, fly ash can be used as a new engineering material, mainly as concrete fillers, ground polymers and to replace a certain amount of cement [4,5]. Fly ash is difficult to get chemically active due to its strong glassy shell activity, so there are limitations to its application in engineering. Stimulating the activity of fly ash is the key to improving the utilization of fly ash.

Currently more research is being conducted on alkali-excited fly ash cementitious materials, which is an emerging green cementitious material [6] with higher compressive strength [7], high temperature resistance [8,9] and corrosion resistance [10,11,12] compared to common silicate materials. However, subsequent studies have found that the early strength of fly ash concrete mixed with alkaline exciter alone at ambient temperature and pressure does not improve, limiting its usefulness for practical engineering applications. The activity of fly ash is limited by having a single means of excitation [13], and the composite excitation method is more effective in stimulating the activity of fly ash. On this basis a composite excitation approach to fly ash is proposed. Yi et al. [14] studied the effect of a compound excitant on the strength of fly ash cement and the hydration mechanism, which showed that the use of a compound excitant can improve the cementitious activity of fly ash, and the prepared fly ash cement can be used for engineering purposes. Wu et al. [15] investigated the effect of excitation agents on the early mechanical properties of large dose fly ash cement mortars. The results show that the early mechanical properties of fly ash cement mortar become better with the increase of compound activator, while the early mechanical properties become worse with the increase of fly ash content. At present, there are relatively few studies on composite activated fly ash, which is in the theoretical stage, where there are relatively few effects on the mechanical properties of fly ash cementitious materials by the ratio of different excitants in the composite excitant.

In recent years, experts and scholars at home and abroad have researched and discussed the prediction of the performance of concrete, with artificial neural network algorithms being more prominent in the prediction of concrete performance. Artificial neural network (ANN) is an algorithm established to simulate the biological system of the human brain [16,17]; ANN has the function of self-learning and self-improvement, and can use fuzzy functional relationship conditions to solve some problems, so ANN can better deal with complex functional relationship between some key factors and concrete performance, so as to improve the efficiency of the experiment. There are more methods of ANNs, and they are widely used in engineering, have simpler and easier to understand principles, and faster convergence [18–20]. Currently it is more common to use ANNs to predict some mechanical properties of concrete as well as durability indexes [21–32]. Liu et al. [33] used random forest models, Gaussian progression regression models, and other independent ANN models to predict the depth of carbonation of recycled aggregate concrete, and the results showed that the random forest models showed better performance. However, there is little research on composite activated fly ash strength models based on machine learning.

This paper investigates the effect of single and combined excitants (sodium sulphate and calcium oxide) on the strength of fly ash concrete (7-day and 28-day) at different dosing levels based on indoor tests, and calcium oxide content in the compound excitants on the strength of fly ash concrete was investigated based on indoor tests. A random forest ANN, decision tree ANN and support vector machine ANN based on python software were written to predict the strength of composite activated fly ash concrete from indoor tests, and the best model for composite activated fly ash concrete was screened with software scoring values, which can provide a basis for similar tests.

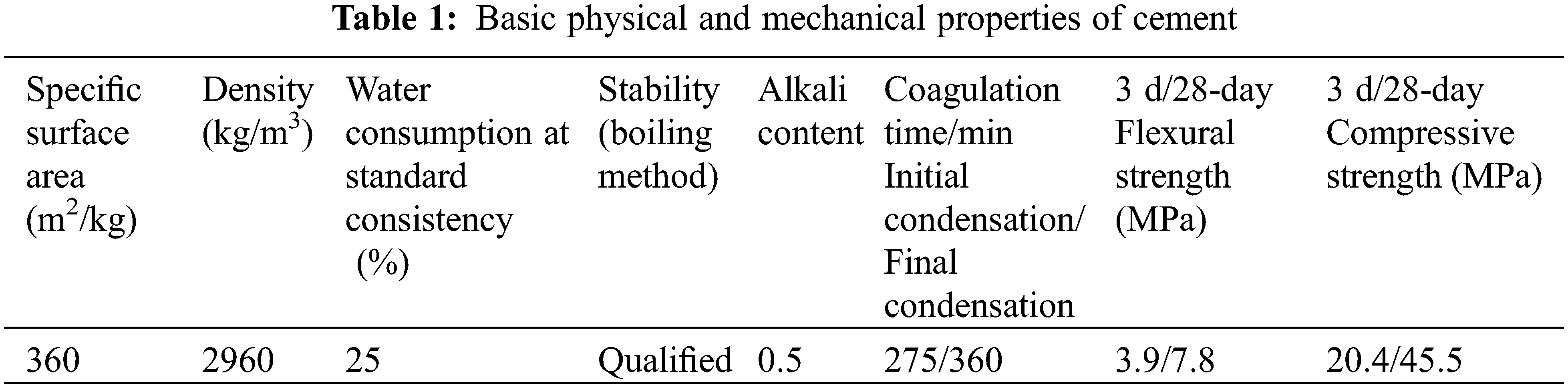

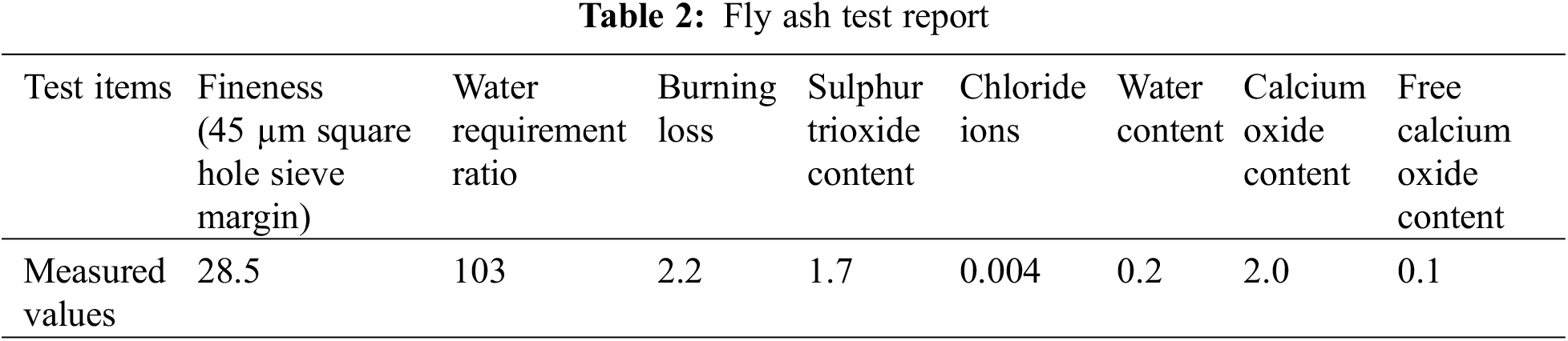

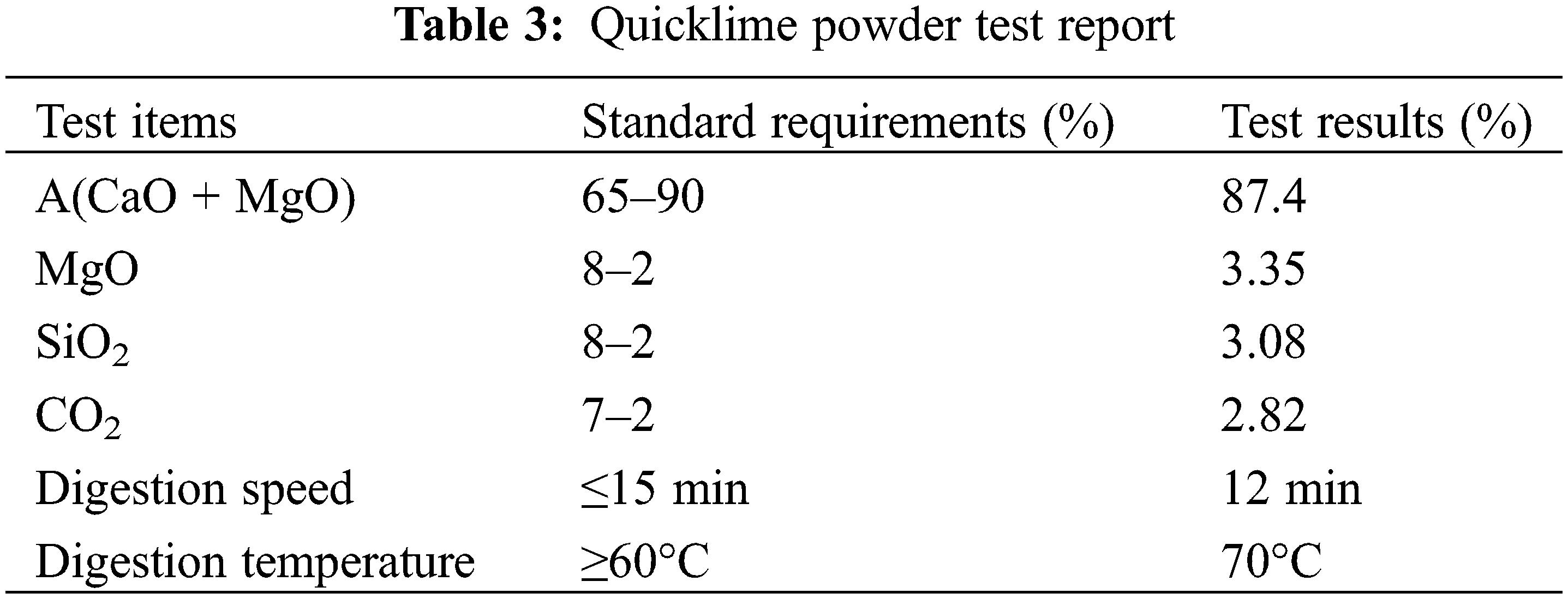

PO42.5 silicate cement was used in the indoor test and its physical properties and indexes are presented in Table 1. The fly ash was Grade II fly ash and its test report is presented in Table 2. The calcium oxide was produced using quicklime powder from a lime factory, whose test report is presented in Table 3. The sodium sulphate content was 98%.

The fine aggregate was laboratory fine river sand with a fineness modulus of 1.94, apparent density of 2660 kg/m3, bulk density of 1380 kg/m3 and saturated surface dry water absorption of 4.6%.

The coarse aggregates were natural granite aggregates with a continuous gradation of 5–20 mm, apparent density of 2746 kg/m3, bulk density of 1510 kg/m3, and a saturated surface dry water absorption rate of 0.6%; the mixing water used for the experiments was laboratory tap water.

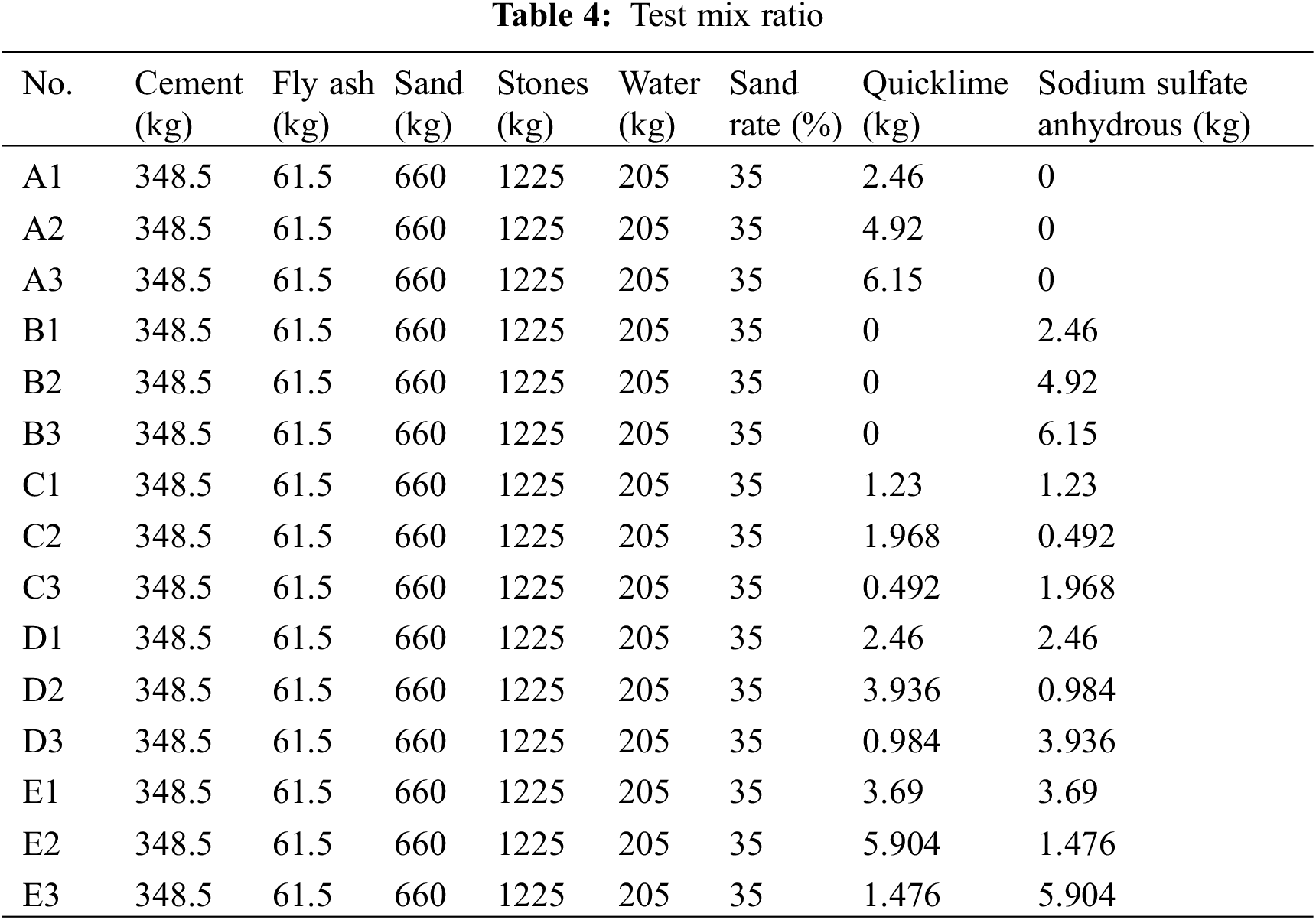

The test water-cement ratio was fixed at 0.5, fly ash dosing was 15%, with excitation agent dosing according to the proportion of fly ash outside the mix. The exciter was first dissolved in water, then mixed with the concrete and cured at standard temperature after mixing. The compressive strength test was carried out on the WA-1000B electro-hydraulic universal testing machine. Fig. 1 shows the condition of the specimen when it was vibrated for 120 s. Fig. 2 shows the 28-day compressive strength testing of a specimen with 8% compound exciter. The test was divided into 15 test groups, including those with CaO alone (4%, 8%, and 10%) and Na2SO4 alone (4%, 8%, 10%), the test groups with the dose of compound excitant (4%, 8%, 12%) and the test groups with different ratios (1:1, 4:1, 1:4) of CaO and Na2SO4 in each compound excitant. These are presented in Table 4.

Figure 1: Condition of specimen pounded for 120 s

Figure 2: 28-day specimen compressive strength test

The test mold was fitted with a standard mold of 100 mm × 100 mm × 100 mm, the mix was loaded into the molds at one time and pounded along the inner wall, shaken on a vibrating table and left to stand indoors for 24 h. For demolding and maintenance; the solidified specimens are demolded and placed in a maintenance room at a temperature of 20 ± 2°C and a relative humidity of 95% or more. After reaching the specified age, the specimens were taken out, dried, and subjected to the corresponding mechanical tests.

2.3.2 Mechanical Properties Test Procedure

After reaching the desired curing age, the concrete specimens were removed and dried to the surface and tested for cubic compressive and flexural strengths. The mechanical properties test process was carried out in strict accordance with the specifications of GB/T50081-2019 “Standard for Mechanical Properties Test Methods for Ordinary Concrete”, and the experimental results were comprehensively collated and analyzed.

2.4 Artificial Neural Networks (ANN)

ANN is now widely used in various fields and has solved several challenging problems in the areas of classification problems, function approximation problems, prediction problems, optimization problems, etc. The ANN approach simulates the structure of neurons in the human brain, which receive and process external information, thus achieving an intelligent solution similar to that of the human brain. It is the model that plays an important role in the activity of ANNs [34].

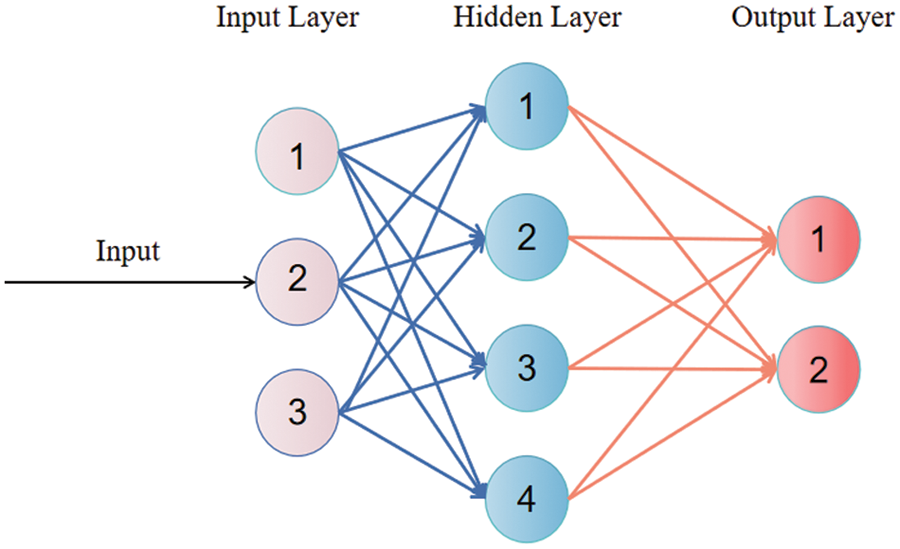

Theoretically, an ANN consists of a set of computational units and a set of unidirectional data connection units. The input, hidden, and output layers form the basic structure of the ANN model. ANN models all have at least one input layer, a hidden layer, and an output layer, and there can be more than one hidden layer. For very complex problems, multiple hidden layers can be very helpful. The mathematical operations performed in neurons are carried out in the hidden and output layers as shown in Eq. (1).

where y = results for representative neurons, w = inter-neuron weights, x = input from the upper level, f = a transfer function, b = representation bias, and i = number of neurons.

The ANN consists of two processing phases, training and testing, which are applied to analyze different moments at different operating times. The modification of the weights relies on the choice of training method, and currently, the commonly used one is the supervised learning method, also called back propagation method. The backpropagation method is a gradient-decreasing method that minimizes the error of a particular training by micro-adjusting the weights one gradient at a time [35]. Fig. 3 shows the principle of a simple ANN model.

Figure 3: A simple artificial neural network model

Decision trees are a commonly applied machine learning method. Decision tree models can summarize and accurately classify and describe the attributes that data exhibits, and they can classify data that is unpredictable. The decision tree classification algorithm is an inductive learning method based on a given sample of data. The top-down recursive method is used to generate a tree structure given a data set with known class labels. The topmost node of the tree is called the root node and the bottom node is called the leaf node, with each leaf node representing the class of the sample. The nodes between the root and leaf nodes are called internal nodes. The decision tree classification algorithm first selects the descriptive attribute with the highest information gain as branch attributes for a given data set, thus creating nodes in the decision tree, and then recursively calls the above method for each subset of samples in each branch to create each child node of the node. When all the data samples on the branch belong to the same class, the division stops, and a leaf node is formed. Alternatively, a leaf node is formed when samples on a branch do not belong to the same class, but there are no remaining descriptive attributes to further divide the dataset, and this leaf node is labelled using the class to which most samples belong. When classifying data samples with unknown class labels, the class labels of the data samples are obtained by judging from the root node downwards, layer by layer, to the leaf nodes.

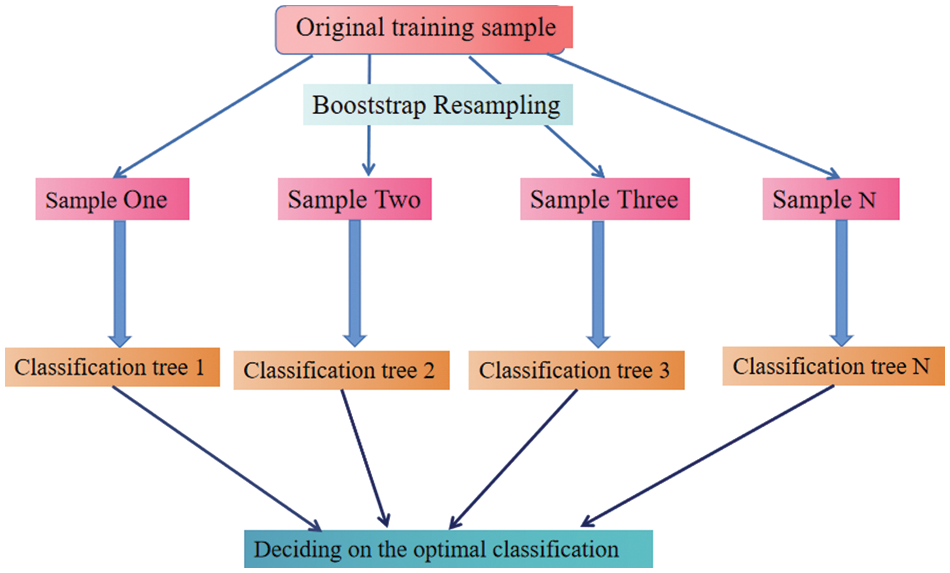

Random Forest (RF) is a comprehensive algorithm combining CART tree and Bagging, which was first proposed by Breiman and is now widely used in problems such as prediction and feature selection [36], and contains two important ideas, the idea of bagging and the idea of random subspace, based on which the two ideas can be implemented to achieve random sample extraction and random feature.

The RF algorithm consists of two algorithms, a regression algorithm and a classification algorithm. The regression algorithm uses a bootstrap resampling method to draw a number of samples from the original sample, and models a decision tree for each bootstrap sample, thus forming a combinatorial model consisting of a set of decision subtrees

Figure 4: Schematic diagram of the principle of random forest

One of the advantages of the support vector machines, which are intelligent algorithms, is that they can learn the relationship between input and output parameters very well [37]. In solving the non-linear regression problem, the support vector machine introduces a non-linear mapping function

3.1 Effect of Compound Activator Dosing on the Mechanical Strength of Fly Ash Concrete

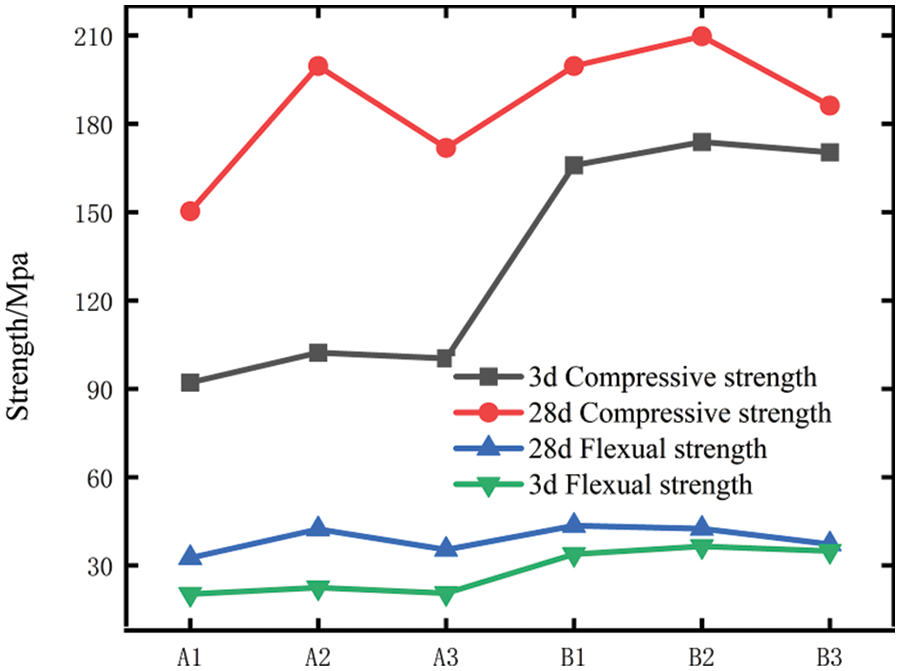

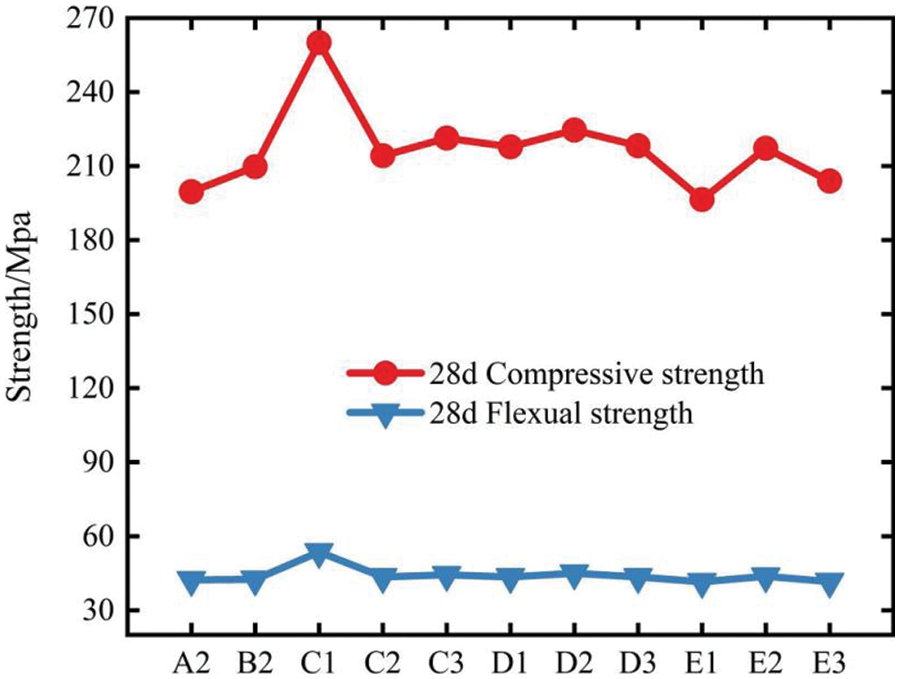

As shown in Fig. 5, the optimum admixture of CaO and Na2SO4 alone is 8%, at which point the mechanical strength of the fly ash concrete at 3- and 28-day is maximum.

Figure 5: CaO alone and Na2SO4 alone affects the mechanical strength of fly-ash concrete at 3-day and 28-day aging

It is clear from Fig. 6 that the 3-day compressive and flexural strengths of fly ash concrete mixed with 8% CaO alone is the lowest, and the compressive and flexural strengths of fly ash concrete mixed with 8% Na2SO4 alone are higher than those of 8% CaO alone at the age of 3 days.

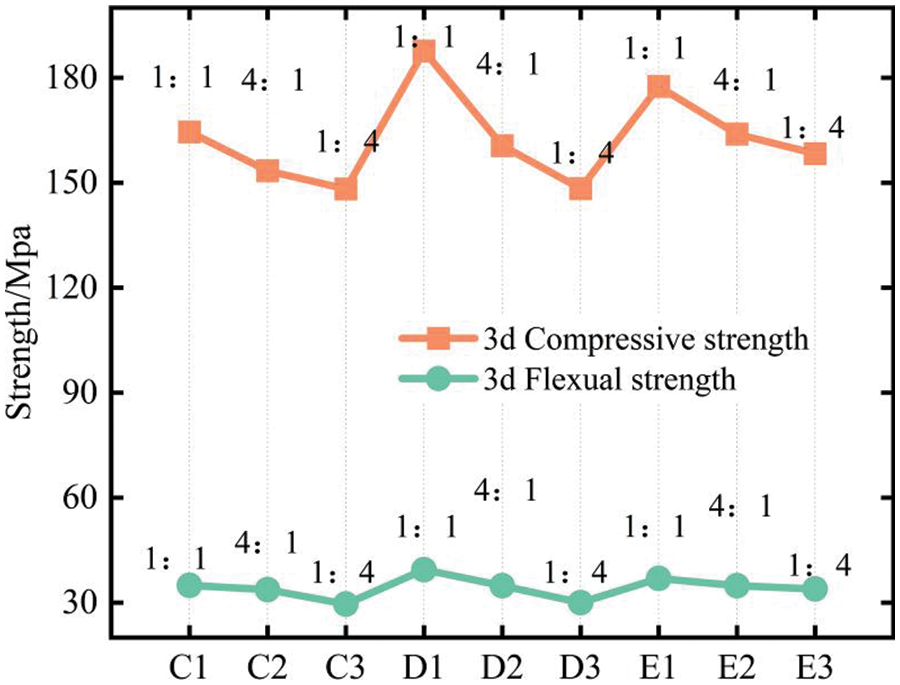

Figure 6: Mechanical strength of 3-day fly ash concrete as influenced by compound activator dosing

The 3-day mechanical strength of fly ash concrete mixed with the compound activator is generally higher than that of fly ash concrete mixed with exciter alone. Comparing (C1, D1, E1), (C2, D2, E2), and (C3, D3, E3), respectively, it can be seen that the 3-day compressive and flexural strengths show a trend of increasing and then decreasing as the dosing of the compound activator increases from 4% to 8% and finally to 12%. The greatest compressive and flexural strength of 3-day fly ash concrete was achieved when 8% compound activator was mixed in.

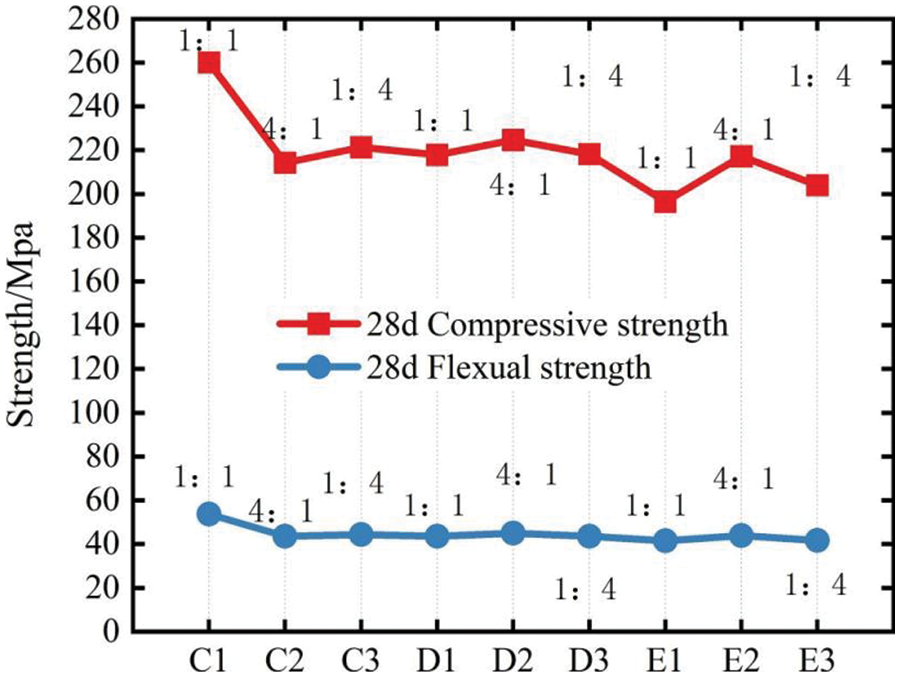

As shown in Fig. 7, the 28-day mechanical strength of fly ash concrete mixed with 8% of CaO alone and 8% Na2SO4 alone was lower than the 3-day mechanical strength. Comparing (C1, D1, E1), (C2, D2, E2), and (C3, D3, E3), it can be seen that the 28-day compressive and flexural strength of fly ash concrete was greatest at this point when the amount of compound activator is 4%.

Figure 7: Effect of compound activator dosing on the mechanical strength of 28-day fly ash concrete

From the apparent pattern, Na2SO4 has a greater effect on the early strength of fly ash concrete, when CaO and Na2SO4 are used as a compound activator than when mixed alone. The best strength of fly ash concrete aged for 3 days was achieved at 8% of the compound activator, while the best strength of fly ash concrete at 28-day was achieved at 4% of the compound activator. The degree of fracture of the internal structure of fly ash is determined by the concentration of hydroxide ions in the system, so the higher the concentration of hydroxide ions, the higher the degree of fracture. In-depth studies have revealed that sodium ions also influence the activity of fly ash in the same way as hydroxide ions, with sodium ions having a smaller ionic radius and easily migrating into the gelling network to balance the charge, thus facilitating the release of active substances. Na2SO4, therefore, has a relatively large effect on the early strength of fly ash concrete. As the curing time increases, the calcium-silica system gradually forms, an effective structure is generated, and the mechanical strength of fly ash concrete is increased [38].

3.2 Effect of Different Ratios of Cao and Na2SO4 Composite Activator on the Mechanical Strength of Fly Ash Concrete

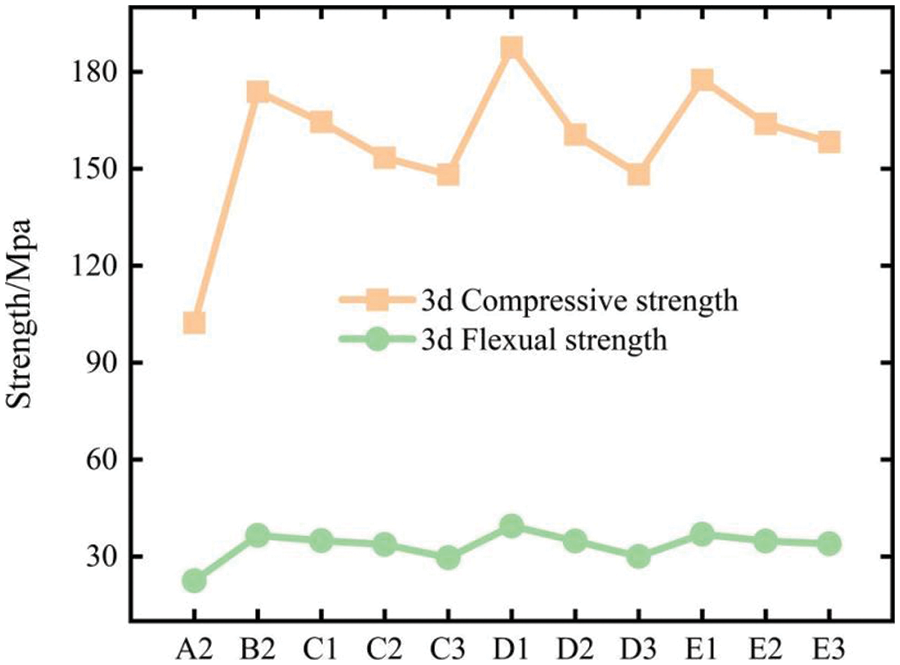

As shown in Fig. 8, ratios of 1:1, 4:1, and 1:4 in Fig. 9 represent the ratio of CaO to Na2SO4 doping. The strength at 3 days age of fly ash concrete with different doses of compound activator was better in compressive and flexural strength for the CaO to Na2SO4 dosing ratio of 1:1 than for the CaO to Na2SO4 dosing ratio of 4:1 and 1:4. And the deduction from Fig. 9 is that the 28-day compressive and flexural strength of CaO to Na2SO4 at a dosing ratio of 1:1 was better than the CaO to Na2SO4 dosing ratio of 4:1 and 1:4 when the compound activator was dosed at 4%. The 28-day compressive and flexural strength of the CaO to Na2SO4 dosing ratio of 4:1 was better than the CaO to Na2SO4 dosing ratio of 1:1 and 1:4 when the compound activator was dosed at 8% and 12%.

Figure 8: Mechanical strength of 3-day fly ash concrete affected by different CaO to Na2SO4 dosing ratios

Figure 9: Effect of different CaO to Na2SO4 dosing ratios on the mechanical strength of 28-day fly ash concrete

The analysis suggests that the pre-sodium ions can effectively stimulate the release of active substances within the fly ash, thus increasing the pre-strength. When calcium hydroxide is present in the system, the active alumina in the fly ash particles react with gypsum to produce hydrated calcium sulphate aluminate, which consumes more aluminum ions but accelerates the hydration reaction. The reaction proceeds as follows; sulphate ions react with activated alumina in the system in the presence of calcium ions to form calcium alumina (Aft):

Al2O3 + Ca2+ + OH− + SO42− = 3CaO·Al2O3·3CaSO4·32H2O

Gypsum also reacts with partially hydrated calcium aluminate and forms calcium alumina (Aft):

3CaO·Al2O3·3CaSO4·6H2O + 3(CaSO4·2H2O) + 20H2O = 3CaO·Al2O3·3CaSO4·32H2O

Sulphate and calcium alumina (Aft), on the other hand, has a certain degree of swelling of their own, and in excess may cause volumetric instability with increasing age, leading to a reduction in strength.

3.3 Analysis of Intensity Based on Machine Learning

In this paper, based on machine learning, we use python to write random forest ANN, decision tree ANN, and support vector machine ANN models to predict and estimate the strength of composite excited fly ash concrete, and compare the predictive results of the three models to filter out the best model.

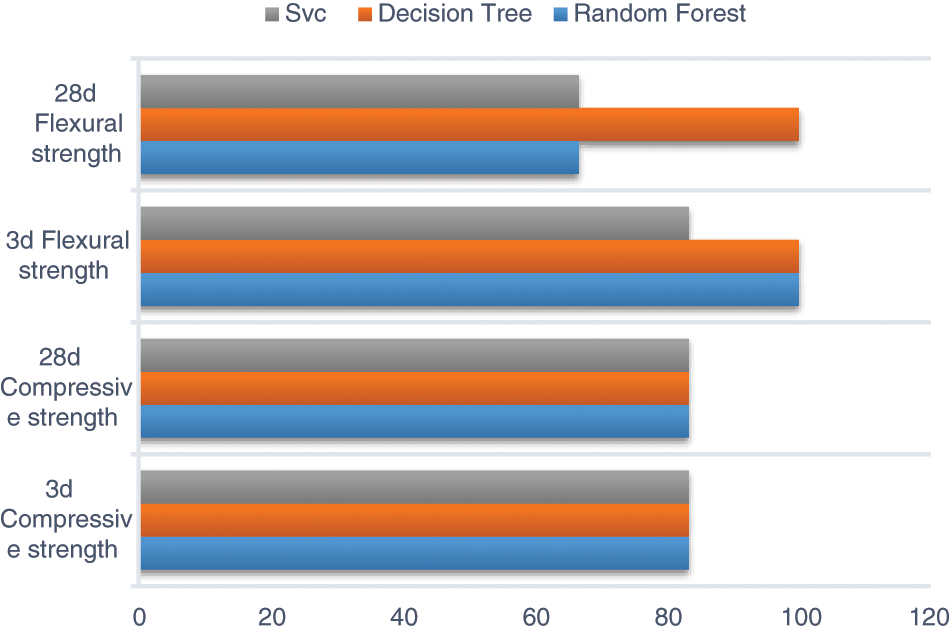

The input layer of the ANN used in this paper includes six factors, namely cement, water-cement ratio, fly ash, sand ration, CaO admixture, Na2SO4 admixture, and four other factors, namely compressive strength at 3- and 28-day, and flexural strength at 3- and 28-day, as the output layer. The software score for the three models is shown in Fig. 10. It is clear from the figure below that the decision tree ANN model predicts more accurate results than the random forest ANN model and the support vector machine ANN model.

Figure 10: Software scoring of each algorithm model

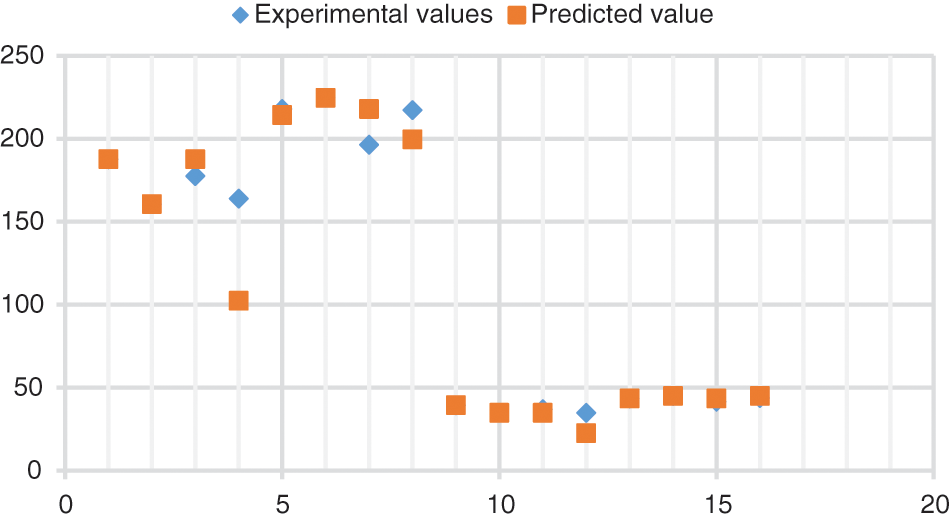

When the mechanical strength of composite inspired fly ash concrete was predicted based on the decision tree ANN model, the software scores for compressive and flexural strengths at 3- and 28-day were relatively high, and the predicted values were in good agreement with the experimental values, which indicates that the decision tree artificial neural net model has good application. Fig. 11 shows the error analysis of some of the predicted and experimental values of the decision tree model.

Figure 11: Error analysis graph for some predicted and experimental values

The addition of the compound activator can effectively stimulate fly ash activity and improve the mechanical properties of concrete, thus effectively promoting the comprehensive use of fly ash, which has significant environmental and economic benefits. In this paper, the effect of different dosing amounts of the compound activator and the ratio of CaO to Na2SO4 in the compound activator on the strength of fly ash concrete was analyzed through indoor tests, and the best compound activator solution was proposed on this basis. The mechanical strength of composite excited fly ash concrete was also analyzed and predicted using random forest ANNs, decision tree ANNs and support vector machines, with the following conclusions:

1. The mechanical strength of fly ash concrete at 3- and 28-day was greatest when CaO and Na2SO4 were blended at 8% alone.

2. Na2SO4 has a relatively large impact on the early stage of fly ash concrete, which can greatly improve the mechanical strength of fly ash concrete in the early stage, while with the increase in age Na2SO4 dosing will lead to a reduction in strength.

3. The best 3-day mechanical strength of fly ash concrete is achieved at 8% of compound activator while, the best 28-day mechanical strength of fly ash concrete is achieved at 4% of the compound activator.

4. The 3-day mechanical strength of fly ash concrete is better when the dosing ratio of CaO to Na2SO4 in the compound activator is 1:1, and the 28-day strength of fly ash concrete is greatest when the dosing ratio of CaO to Na2SO4 in the compound activator is 1:1 at 4%. The mechanical strength of fly ash concrete at 28-day is favored when the ratio of CaO to Na2SO4 is 4:1 in the 8% and 12% compound excitants.

5. The decision tree ANN model effectively predicts the mechanical strength of composite excited fly ash concrete with more accurate results, which provides a reference for subsequent studies such as simplified indoor tests.

This paper analyses the mechanical strength of fly ash concrete mixed with compound excitant from a macroscopic point of view, and recommends that it is necessary to study the microscopic performance mechanism of compound excitant on the mechanical properties of fly ash concrete.

Funding Statement: This work was supported by the Scientific Research Fund Project of Yunnan Education Department (Grant Numbers 2023J1974 and 2023J1976) and the Yunnan University Professional Degree Graduate Student Practical Innovation Fund Project (Grant Number ZC-22222374), also supported by the Yunnan Provincial Education Department Fund (Grant No. 2022Y286).

Author Contributions: This article was written by the following authors, who have contributed to this article. Shanqing Shao (writing—original draft preparation, methodology); Aimin Gong (validation, conceptualization); Xiaoshuang Chen (formal analysis, investigation); Ran Wang (data curation, resources); Jing Xu (data curation, project administration); Fulai Wang (writing—review and editing, supervision); Feipeng Liu (writing—review and editing, supervision).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Xu, T., Lan, H. P., Yang, C., Li, N., Ji, Z. B. et al. (2018). Comparative analysis of physical and chemical properties of fly ash. Inorganic Salt Industry, 50(7), 65–68. [Google Scholar]

2. Alharbi, Y. R., Abadel, A. A., Salah, A. A., Mayhoub, O. A., Kohail, M. (2021). Engineering properties of alkali activated materials reactive powder concrete. Construction and Building Materials, 271(9), 121550. [Google Scholar]

3. Buema, G., Trifas, L. M., Harja, M. (2021). Removal of toxic copper ion from aqueous media by adsorption on fly ash-derived zeolites: Kinetic and equilibrium studies. Polymers, 13(20), 3468 [Google Scholar] [PubMed]

4. Gencel, O., Koksal, F., Ozel, C., Brostow, W. (2012). Combined effects of fly ash and waste ferrochromium on properties of concrete. Construction and Building Materials, 29(7), 633–640. [Google Scholar]

5. Kotova, O. B., Ignatiev, G. V., Shushkov, D. A., Harja, M., Broekmans, M. A. (2020). Preparation and properties of ceramic materials from coal fly ash. Minerals: Structure, Properties, Methods of Investigation: 9th Geoscience Conference for Young Scientists, pp. 101–107. Berlin, Germany: Springer International Publishing. [Google Scholar]

6. Chen, X., Wang, J., Zhu, G. R., Chen, Q. (2017). A review of the main modulating factors of the mechanical properties of geopolymers. Silicate Bulletin, 36(9), 2994–3002. [Google Scholar]

7. de Vargas, A. S., Dal Molin, D. C., Vilela, A. C., Da Silva, F. J., Pavao, B. et al. (2011). The effects of Na2O/SiO2 molar ratio, curing temperature and age on compressive strength, morphology and microstructure of alkali-activated fly ash-based geopolymers. Cement and Concrete Composites, 33(6), 653–660. [Google Scholar]

8. Li, X., Lu, D. Y., Li, M. H., Chen, X. R., Sun, Y. F. et al. (2015). Advances in porous geopolymer insulation materials. Materials Guide, 29(23), 58–62+78. [Google Scholar]

9. Hager, I., Sitarz, M., Mróz, K. (2021). Fly ash based geopolymer mortar for high-temperature application—Effect of slag addition. Journal of Cleaner Production, 316, 128168. [Google Scholar]

10. Ranjbar, N., Mehrali, M., Mehrali, M., Alengaram, U. J., Jumaat, M. Z. (2016). High tensile strength fly ash based geopolymer composite using copper coated micro steel fiber. Construction and Building Materials, 112, 629–638. [Google Scholar]

11. Monticelli, C., Natali, M. E., Balbo, A., Chiavari, C., Zanotto, F. et al. (2016). Corrosion behavior of steel in alkali-activated fly ash mortars in the light of their microstructural, mechanical and chemical characterization. Cement and Concrete Research, 80(300), 60–68. [Google Scholar]

12. Pather, B., Ekolu, S. O., Quainoo, H. (2021). Effects of aggregate types on acid corrosion attack upon fly-ash geopolymer and Portland cement concretes—Comparative study. Construction and Building Materials, 313(1), 125468. [Google Scholar]

13. Ma, P. C., Li, X., Wen, Z. Y., Meng, F. H., Li, Z. (2021). Progress in the study of active excitation and mechanism of fly ash. Inorganic Salt Industry, 53(10), 28–35. [Google Scholar]

14. Yi, C. X., Tan, W. J., Zhu, W. C. (2018). Effect of composite excitants on the strength of large dose fly ash cements. Mineral Conservation and Utilization, 1, 117–122. [Google Scholar]

15. Wu, C. C., Yang, H. L., Kong, X. M., Song, C. Y., Hu, Y. T. (2010). Effect of composite excitant on the early mechanical properties of large dose fly ash cement mortar. Concrete, 8(2010), 110–112. [Google Scholar]

16. Naderpour, H., Rafiean, A. H., Fakharian, P. (2018). Compressive strength prediction of environmentally friendly concrete using artificial neural networks. Journal of Building Engineering, 16, 213–219. [Google Scholar]

17. Shahmansouri, A. A., Yazdani, M., Ghanbari, S., Bengar, H. A., Jafari, A. et al. (2021). Artificial neural network model to predict the compressive strength of eco-friendly geopolymer concrete incorporating silica fume and natural zeolite. Journal of Cleaner Production, 279(2), 123697. [Google Scholar]

18. Pacheco-Torgal, F., Moura, D., Ding, Y., Jalali, S. (2011). Composition, strength and workability of alkali-activated metakaolin based mortars. Construction and Building Materials, 25(9), 3732–3745. [Google Scholar]

19. He, J., Zhang, J., Yu, Y., Zhang, G. (2012). The strength and microstructure of two geopolymers derived from metakaolin and red mud-fly ash admixture: A comparative study. Construction and Building Materials, 30(11), 80–91. [Google Scholar]

20. Poulesquen, A., Frizon, F., Lambertin, D. (2013). Rheological behavior of alkali-activated metakaolin during geopolymerization. Cement-Based Materials for Nuclear Waste Storage, 225–238. [Google Scholar]

21. Kandiri, A., Sartipi, F., Kioumarsi, M. (2021). Predicting compressive strength of concrete containing recycled aggregate using modified ANN with different optimization algorithms. Applied Sciences, 11(2), 485. [Google Scholar]

22. Ahmad, A., Chaiyasarn, K., Farooq, F., Ahmad, W., Suparp, S. et al. (2021). Compressive strength prediction via gene expression programming (GEP) and artificial neural network (ANN) for concrete containing RCA. Buildings, 11(8), 324. [Google Scholar]

23. Dantas, A. T. A., Leite, M. B., de Jesus Nagahama, K. (2013). Prediction of compressive strength of concrete containing construction and demolition waste using artificial neural networks. Construction and Building Materials, 38, 717–722. [Google Scholar]

24. Shao, S., Wang, R., Gong, A., Li, R., Xu, J. et al.(2023). Study and neural network analysis on durability of basalt fibre concrete. Water, 15(6), 1016. [Google Scholar]

25. Liu, F., Xu, J., Tan, S., Gong, A., Li, H. (2022). Orthogonal experiments and neural networks analysis of concrete performance. Water, 14(16), 2520. [Google Scholar]

26. Sun, G., Sun, W. (2012). Multi-scale modeling of the effective chloride ion diffusion coefficient in cement-based composite materials. Journal of Wuhan University of Technology (Materials Science Edition), 27(2), 364–373. [Google Scholar]

27. Pan, S., Zheng, Z., Guo, Z., Luo, H. (2022). An optimized XGBoost method for predicting reservoir porosity using petrophysical logs. Journal of Petroleum Science and Engineering, 208(2), 109520. [Google Scholar]

28. Taffese, W. Z., Sistonen, E., Puttonen, J. (2015). Prediction of concrete carbonation depth using decision trees. Proceedings of 23rd European Symposium on Artificial Neural Networks, Computer Intelligence Machine LearningBruges, Belgium. [Google Scholar]

29. Dong, W., Huang, Y., Lehane, B., Ma, G. (2020). XGBoost algorithm-based prediction of concrete electrical resistivity for structural health monitoring. Automation in Construction, 114(8), 103155. [Google Scholar]

30. Taffese, W. Z., Sistonen, E., Puttonen, J. (2015). CaPrM: Carbonation prediction model for reinforced concrete using machine learning methods. Construction and Building Materials, 100, 70–82. [Google Scholar]

31. Lavercombe, A., Huang, X., Kaewunruen, S. (2021). Machine learning application to eco-friendly concrete design for decarbonisation. Sustainability, 13(24), 13663. [Google Scholar]

32. Duan, Z. H., Kou, S. C., Poon, C. S. (2013). Using artificial neural networks for predicting the elastic modulus of recycled aggregate concrete. Construction and Building Materials, 44(7), 524–532. [Google Scholar]

33. Liu, K., Alam, M. S., Zhu, J., Zheng, J., Chi, L. (2021). Prediction of carbonation depth for recycled aggregate concrete using ANN hybridized with swarm intelligence algorithms. Construction and Building Materials, 301(1), 124382. [Google Scholar]

34. Oliveira, V., Sousa, V., Dias-Ferreira, C. (2019). Artificial neural network modelling of the amount of separately-collected household packaging waste. Journal of cleaner production, 210, 401–409. [Google Scholar]

35. Mata, J. (2010). Interpretation of concrete dam behaviour with artificial neural network and multiple linear regression models. Engineering Structures, 33(3), 903–910. [Google Scholar]

36. Xiong, L., Zhang, D., Zhang, Y. (2020). Water leakage image recognition of shield tunnel via learning deep feature representation. Journal of Visual Communication and Image Representation, 71(6), 102708. [Google Scholar]

37. Liu, F., Wang, S., Zhang, Y. (2018). An overview of support vector machine models and applications. Computer System Applications, 27(4), 1–9. [Google Scholar]

38. Ma, P., Li, X., Wen, Z., Meng, F., Li, Z. (2021). Progress in the study of active excitation and mechanism of fly ash. Inorganic Salt Industry, 53(10), 28–35. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools