Open Access

Open Access

ARTICLE

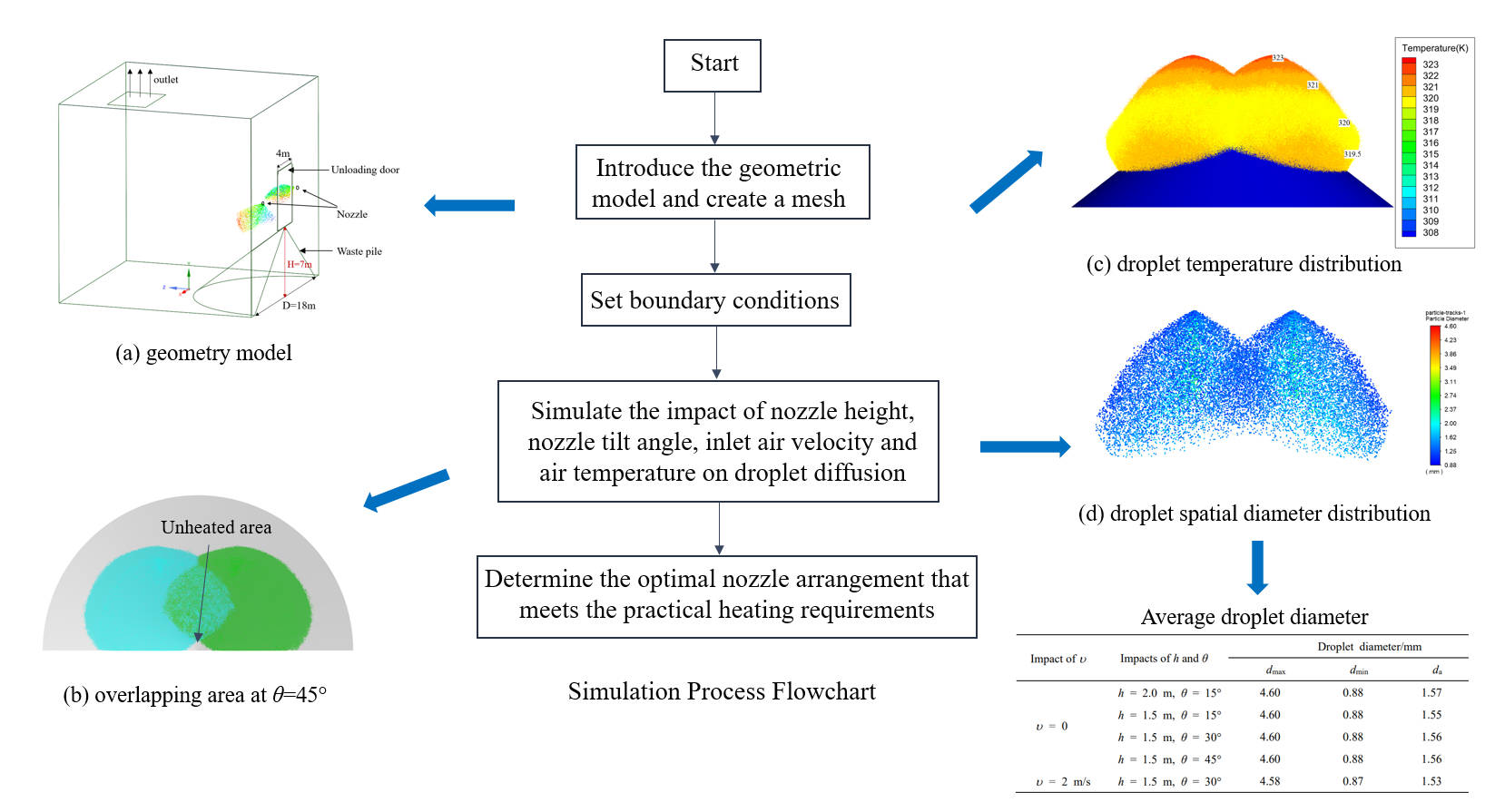

Numerical Analysis of Dual Atomizing Nozzle Jets in a Waste Warehouse

1 Waste Incineration Division, CUCDE Environmental Technology Co., Ltd., Beijing, 100120, China

2 Renqiu Shenneng Environment Co., Ltd., Renqiu, 061000, China

3 Department of Power Engineering, North China Electric Power University, Baoding, 071003, China

* Corresponding Author: Xuemin Ye. Email:

Fluid Dynamics & Materials Processing 2025, 21(5), 1063-1077. https://doi.org/10.32604/fdmp.2025.063769

Received 23 January 2025; Accepted 24 March 2025; Issue published 30 May 2025

Abstract

Enhancing the fermentation efficiency of waste in waste warehouses is pivotal for accelerating the pyrolysis process and minimizing harmful gas emissions. This study proposes an integrated approach, combining hot air injection with dual atomizing nozzles, for the thermal treatment of waste piles. Numerical simulations are employed to investigate the influence of various parameters, namely, nozzle height, nozzle tilt angle, inlet air velocity and air temperature, on the droplet diffusion process, spread area, droplet temperature, and droplet size distribution. The results show that reducing the nozzle height increases the temperature of droplets upon their deposition on the waste pile. Specifically, when the nozzle height is lowered to 1.5 m, the temperature of the droplets reaching the waste pile is 1°C higher than when the nozzle height is set at 2 m. Furthermore, an increase in the nozzle tilt angle expands the overlapping heating area. For instance, when the nozzle angle is increased from 15° to 30°, the overlapping spread area expands by 3.21 m2. Additionally, increasing the inlet air velocity enhances the droplet diffusion range. At an air velocity of 2 m/s, the droplet diffusion range grows to 14.4 m, representing a 6.7% increase compared to the no-wind condition. While the average droplet diameter decreases to 1.53 mm, the droplet temperature decreases by 1°C. Moreover, the droplet temperature is found to become smaller as the ambient temperature inside the waste warehouse declines. Specifically, a 5°C reduction in the ambient temperature results in a 1°C decrease in the average temperature of the atomized droplets. The study concludes that a nozzle height of 1.5 m and a nozzle tilt angle of 30° effectively meet practical heating requirements.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools