Open Access

Open Access

ARTICLE

Heat Transfer and Flow Dynamics of Ternary Hybrid Nanofluid over a Permeable Disk under Magnetic Field and Joule Heating Effects

1 Fakulti Teknologi dan Kejuruteraan Mekanikal, Universiti Teknikal Malaysia Melaka, Hang Tuah Jaya, Durian Tunggal, Melaka, 76100, Malaysia

2 Department of Mathematics and Statistics, Faculty of Science, Universiti Putra Malaysia, Serdang, 43400, Malaysia

3 Department of Mathematics, Babeş-Bolyai University, Cluj-Napoca, 400084, Romania

* Corresponding Author: Najiyah Safwa Khashi’ie. Email:

Frontiers in Heat and Mass Transfer 2025, 23(2), 383-395. https://doi.org/10.32604/fhmt.2025.063023

Received 02 January 2025; Accepted 27 February 2025; Issue published 25 April 2025

Abstract

This study investigates the heat transfer and flow dynamics of a ternary hybrid nanofluid comprising alumina, copper, and silica/titania nanoparticles dispersed in water. The analysis considers the effects of suction, magnetic field, and Joule heating over a permeable shrinking disk. A mathematical model is developed and converted to a system of differential equations using similarity transformation which then, solved numerically using the bvp4c solver in Matlab software. The study introduces a novel comparative analysis of alumina-copper-silica and alumina-copper-titania nanofluids, revealing distinct thermal conductivity behaviors and identifying critical suction values necessary for flow stabilization. Dual solutions are found within a specific range of parameters such that the minimum required suction values for flow stability, with for alumina-copper-silica/water and for alumina-copper-titania/water. The results indicate that increasing suction by 1% enhances the skin friction coefficient by up to 4.17% and improves heat transfer efficiency by approximately 1%, highlighting its crucial role in stabilizing the opposing flow induced by the shrinking disk. Additionally, the inclusion of 1% silica nanoparticles reduces both skin friction and heat transfer rate by approximately 0.28% and 0.85%, respectively, while 1% titania concentration increases skin friction by 3.02% but results in a slight heat transfer loss of up to 0.61%. These findings confirm the superior thermal performance of alumina-copper-titania/water, making it a promising candidate for enhanced cooling systems, energy-efficient heat exchangers, and industrial thermal management applications.Keywords

Nanofluids, with their ability to significantly enhance heat transfer efficiency and optimize energy consumption, have emerged as a transformative innovation in engineerinssg processes, revolutionizing applications in energy systems, thermal management, and advanced manufacturing technologies [1–3]. Among them, hybrid nanofluid, formed by blending two or more types of nanoparticles in a base fluid, represents a groundbreaking advancement. By carefully selecting nanoparticle combinations, these fluids exhibit superior thermophysical properties as compared to traditional single-nanoparticle nanofluids, making them ideal for energy efficiency. Their exceptional thermal and physical characteristics have spurred extensive research into their applications, benefits, and limitations in diverse fields (see Nabil et al. [4], Adun et al. [5], Oladapo et al. [6], and Yu et al. [7]). Extensive research has been conducted on the boundary layer flow (BLF) of hybrid nanofluids, with early numerical investigations led by Takabi and Salehi [8] and Devi and Devi [9], who examined the impact of hybrid nanoparticle suspensions on heat transfer enhancement over stretching surfaces. In addition, Devi et al. [10,11] also demonstrated the increased thermal conductivity and flow stability of hybrid nanofluids over traditional nanofluids. Since then, many researchers opted the thermophysical properties of the hybrid nanofluid as highlighted by Takabi et al. [8] and Devi et al. [9] in the studies of boundary layer flow subjected to various surfaces. As research progressed, Waqas et al. [12], Khan et al. [13], Bilal et al. [14], Khashi’ie et al. [15,16], Li et al. [17], Ali et al. [18] and Tassaddiq et al. [19] explored hybrid nanofluid dynamics over permeable and radially shrinking/stretching surfaces, revealing the influence of magnetohydrodynamics (MHD), velocity slip, and thermal radiation on heat and mass transfer. Meanwhile, Rahman et al. [20] focused on MHD-driven hybrid nanofluid flow over a rotating disk, highlighting the occurrence of dual solutions, boundary layer separation, and the role of heat generation in modifying energy transfer mechanisms. However, despite these advances, several critical gaps remain in the understanding of hybrid nanofluid behaviour, particularly in ternary hybrid nanofluids, which incorporate three distinct nanoparticles to achieve even greater control over thermophysical properties.

Expanding on this concept, ternary hybrid nanofluid (THNF), which integrates three distinct nanoparticles, provides further advancements by offering greater control over properties such as thermal conductivity, viscosity, and stability. Recent numerical studies have investigated the behaviour of these fluids under complex physical conditions, including magnetic fields, velocity and thermal slip, radiation, heat generation or absorption, and suction effects. For example, Jamrus et al. [21] demonstrated enhanced heat transfer performance with the increase of titania concentration in a copper-alumina-titania/water nanofluid model. Furthermore, dual solutions for ternary hybrid nanofluid Hiemenz flow over a shrinking surface have been analyzed by Jamrus et al. [22], who found that ternary hybrid, such as Cu-Al2O3-TiO2, achieved higher skin friction and heat transfer coefficients as compared to hybrid nanofluid like Cu-Al2O3. Hussein et al. [23,24] numerically studied the ternary nanofluid flow induced by a shrinking cylinder with velocity slip and Joule heating effects, respectively. Mahmood et al. [25,26] analyzed THNF flow over a curved surface with suction and Lorentz force, focusing on momentum and thermal boundary layer modifications. However, they did not evaluate minimum suction requirements for flow stability, which is a significant component of this study. Mumtaz et al. [27,28] and Shinwari et al. [29] conducted a series of studies on radiative THNF flow in porous media and curved geometries, incorporating multiple slip constraints and cross-diffusion effects. While their models advanced the understanding of THNF behaviour in complex environments, they did not address the stability implications of dual solutions in suction-induced shrinking flows. Alharbi [30] investigated slip flow of THNF with suction, showing that heat transport is strongly influenced by suction variations. However, the study did not focus on comparative thermal performance between different ternary nanoparticle compositions, a key contribution of the present work.

The study of MHD (magnetohydrodynamic) flows in nanofluids has been extensively conducted, particularly in the context of fractional order derivatives and modified heat transfer models. For example, Khan et al. [31] applied advanced numerical simulations using distributed fractional-order derivatives and the Cattaneo heat flux model to analyze MHD fluid flow, demonstrating the importance of non-Fourier heat conduction in energy transport. However, these approaches have yet to be systematically applied to ternary hybrid nanofluids subjected to suction and Joule heating, which is a key focus of this study. Furthermore, artificial intelligence-driven models, such as artificial neural networks (ANNs), have been employed to predict heat and mass transfer behaviour in chemically reactive fluids over complex surfaces. While Khan et al. [32] used ANN-based techniques to analyze heat transfer dynamics across variable-thickness surfaces, this study focuses on solving nonlinear coupled differential equations using the bvp4c solver. These data-driven methodologies offer potential future extensions for optimizing THNF-based cooling systems in energy-efficient industrial processes.

Despite significant progress in the study of nanofluids, there remains a limited understanding of ternary hybrid nanofluids under the combined influences of suction, Joule heating, and disk surface. To address this limitation, the current study delves into the flow and thermal characteristics of a ternary hybrid nanofluid, specifically copper-alumina-titania/water, over a shrinking disk. The investigation incorporates crucial parameters, including suction, Joule heating, and magnetic field effects, to emulate realistic conditions encountered in engineering systems. Suction is particularly emphasized due to its role in stabilizing reverse flow originating from shrinking surfaces. Many researchers have highlighted the importance of suction in maintaining the reverse flow due to shrinking surface (see Jamrus et al. [33], Memon et al. [34]). By analyzing dual solutions, identifying critical separation points, and assessing the influence of physical parameters, this study seeks to advance the understanding of ternary hybrid nanofluids. A single-phase nanofluid model forms the basis of this numerical study, where governing partial differential equations (PDEs) are transformed into a system of ordinary differential equations (ODEs) via similarity transformation. The resulting equations are solved using the bvp4c solver. To validate the model’s accuracy, numerical findings are compared with previously reported results under specific conditions. The insights gained from this research contribute to the enhancement of thermal management strategies and provide a foundation for future advancements in energy-efficient technologies.

This study extends existing research by analyzing the behaviour of ternary hybrid nanofluids (alumina-copper-silica and alumina-copper-titania) under these external influences over a permeable shrinking disk. The novelty of this work lies in the following:

• Comparative analysis of two ternary hybrid nanofluids to evaluate differences in heat transfer efficiency and flow stability.

• Identification of critical suction values necessary to maintain flow stability, which is essential for optimizing fluid-based thermal management systems.

• Dual solution analysis, reveals non-unique flow behaviour, which is important for practical applications where multiple stable/unstable flow regimes can occur.

By addressing these aspects, this study advances the state of knowledge in nanofluid-based thermal management, providing valuable insights for optimizing energy systems, high-performance cooling devices, and industrial heat exchangers. The findings also establish a foundation for future research on complex nanofluid behaviour under dynamic operating conditions.

This study examines the symmetrical flow behavior of a THNF, composed of aluminum oxide (Al2O3), copper (Cu), and titanium dioxide (TiO2) nanoparticles suspended in a water medium, interacting with a disk undergoing stretching or shrinking motion. The influence of both magnetic force and velocity slip is considered to evaluate their impact on the heat transfer characteristic. Using a cylindrical coordinate system

• Nanoparticles are homogeneously dispersed in the base fluid, ensuring a uniform thermophysical response.

• No nanoparticle aggregation occurs, meaning that Brownian motion and thermophoresis are neglected.

• Thermal equilibrium is assumed between the nanoparticles and the base fluid, meaning that all nanoparticles and the surrounding fluid share the same temperature field. Several studies have validated the single-phase nanofluid model for moderate nanoparticle volume fractions

This model is widely used in boundary layer nanofluid studies and has been validated in previous research, including Khashi’ie et al. [15] and Jamrus et al. [33]. The enhanced physical properties of the ternary nanofluid are embedded into the governing equations that describe flow and thermal transport. These mathematical formulations are constructed from conservation laws for momentum and energy and are customized for this specific nanofluid system, utilizing established methodologies from previous literature (see Khashi’ie et al. [15], Jamrus et al. [33]).

while the boundary conditions are:

The velocity components in the radial

In boundary layer flow analysis, similarity transformations are crucial in reducing the complexity of partial differential equations (PDEs) into ordinary differential equations (ODEs). The transformations chosen in this study are derived based on physical considerations of the problem and prior research on shrinking/stretching flows in nanofluids. Similarity transformations which fulfill Eq. (1) are based on previous literature on disk flow (see Khashi’ie et al. [15], Jamrus et al. [33]).

The system of ODEs can be obtained by substituting Eq. (5) into Eqs. (2)–(4), so that (see Khashi’ie et al. [15], Jamrus et al. [33]):

In addition to the suction parameter, the study incorporates several key parameters, including

The key physical quantities examined in this study include the skin friction coefficient

Utilizing the similarity transformations from Eq. (5) in Eq. (10), the simplified formulations for the skin friction coefficient and the local Nusselt number are:

The transformed equations are solved numerically using the bvp4c solver in MATLAB, which is a collocation-based finite difference method capable of accurately resolving boundary layer equations with dual solutions. It was chosen for this study due to its high accuracy in solving similarity equations particularly in nanofluid flows and efficiency in handling multiple solutions, making it ideal for studying dual solutions in shrinking flows. The results are generated by numerically solving Eqs. (6)–(8) using the bvp4c solver in the Matlab software. These results are presented in Figs. 1–5, Tables 3 and 4 within a specific range of the parameters as discussed in the previous section. The choice of governing parameters are based on the main references (for comparison between hybrid nanofluid and ternary nanofluid) and also depends on the availability of dual solutions. It is important to discover all the possible solutions since previous literatures have shown that the opposing flow may lead to the occurrence of multiple solutions (see Refs. [36–40]), In this numerical study, the magnitude of physical parameters are

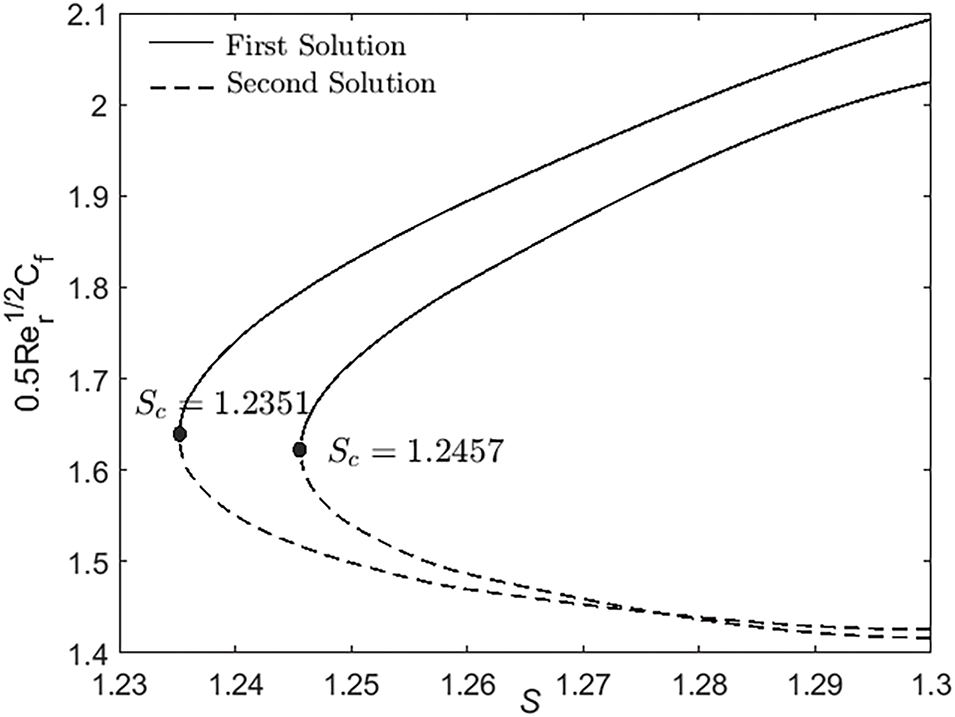

Figure 1:

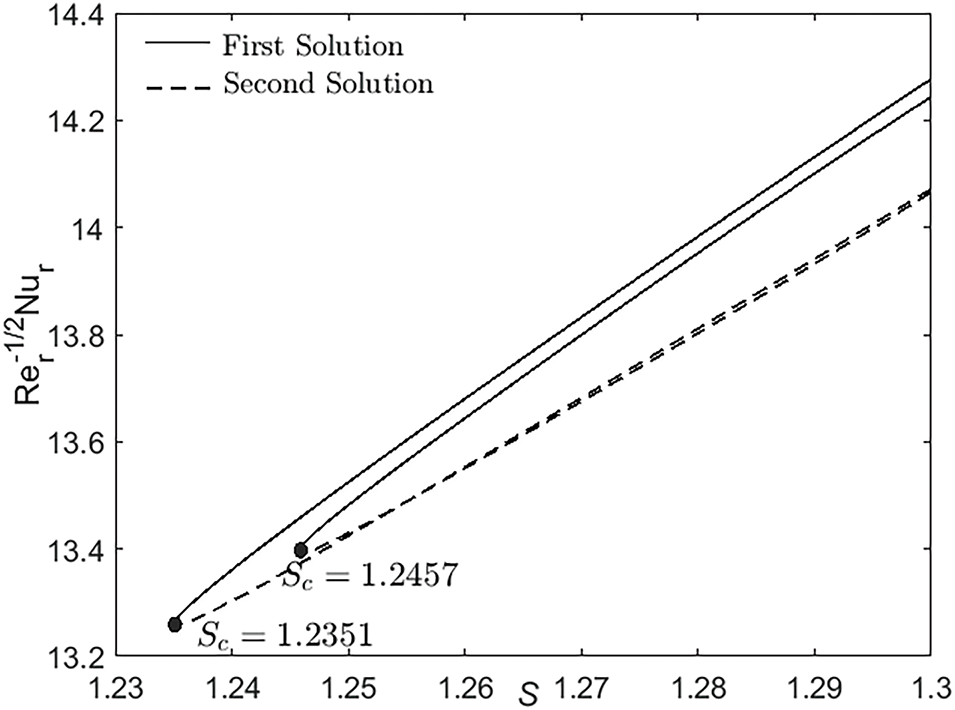

Figure 2:

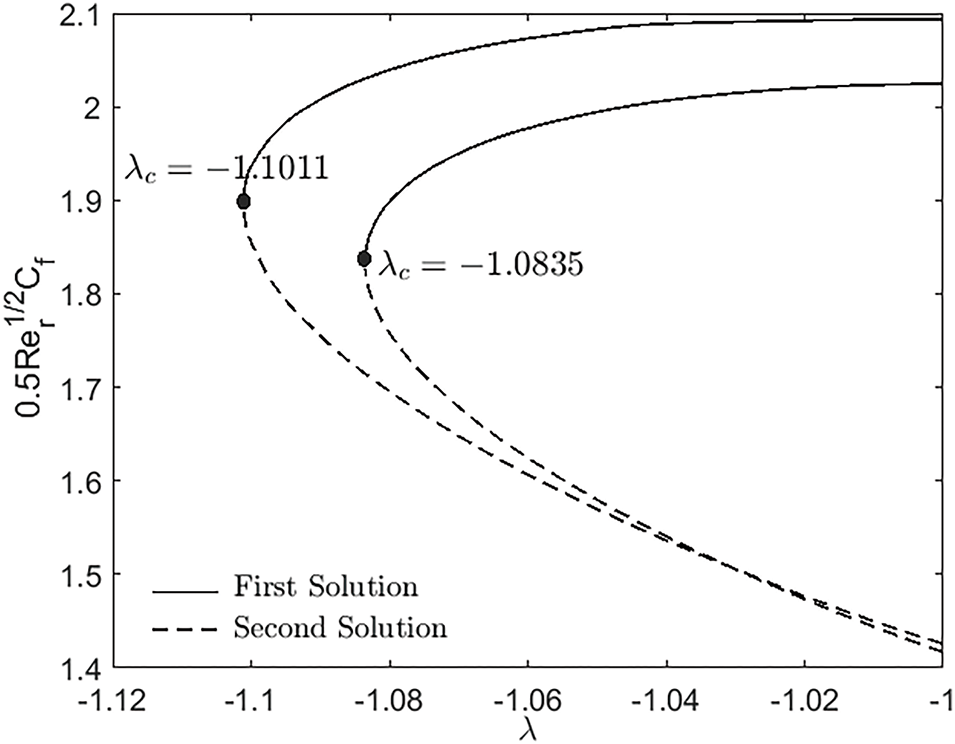

Figure 3:

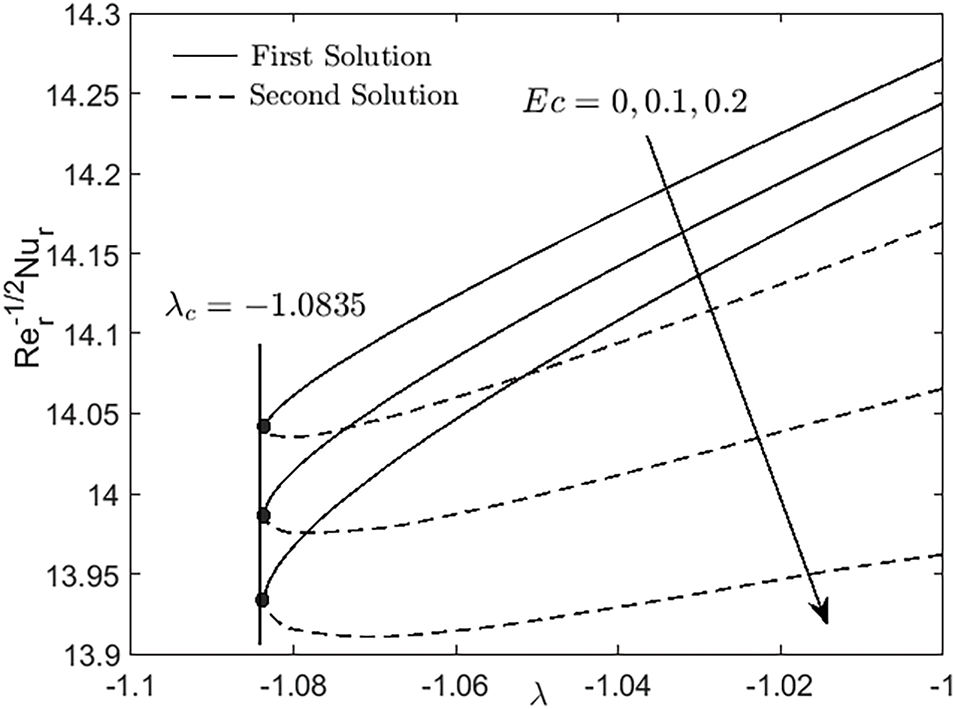

Figure 4:

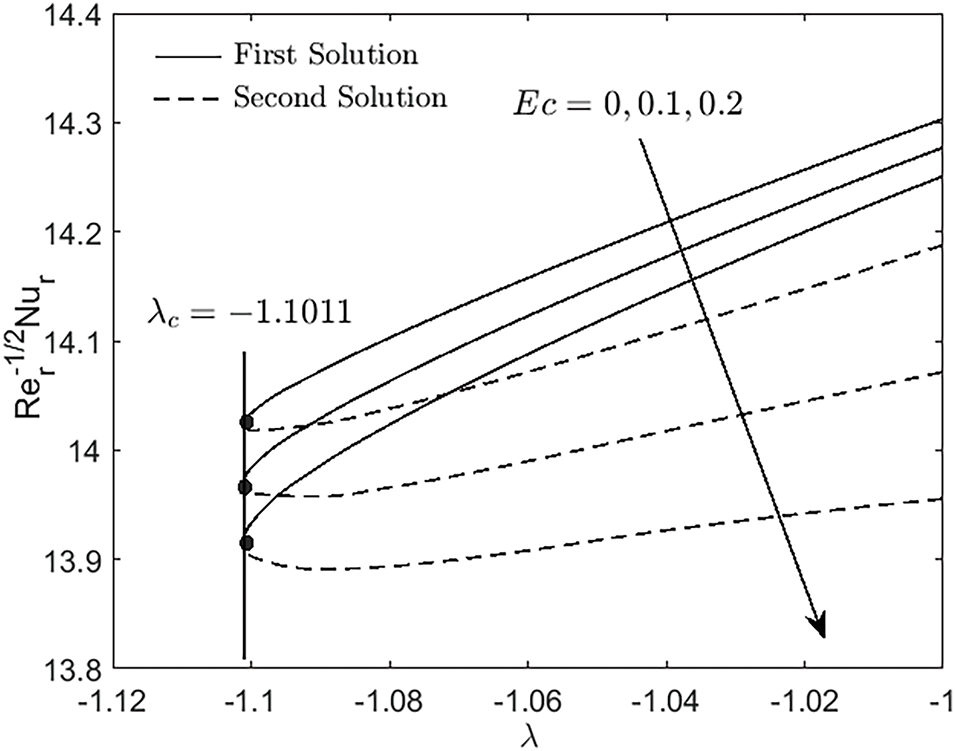

Figure 5:

Figs. 1 and 2 illustrate the variations in the skin friction coefficient and heat transfer coefficient as a function of the suction parameter. It is evident that the suction parameter plays a critical role in both nanofluid systems and must be incorporated into the physical model to stabilize the opposing flow induced by the shrinking disk. The critical minimum suction values are identified to maintain and stabilize the opposing flow such that

Fig. 3 compares the skin friction coefficient for two ternary nanofluid combinations which are alumina-copper-silica/water (Al2O3-Cu-SiO2/water) and alumina-copper-titania/water (Al2O3-Cu-TiO2/water) under magnetic field effect with magnitude

Figs. 4 and 5 highlight the critical role of nanoparticle composition in determining the thermal performance of nanofluids under the influence of Eckert number. Both nanofluids exhibit a decrease in

This study explored the heat transfer and flow dynamics of a ternary hybrid nanofluid (THNF) consisting of alumina, copper, and silica/titania nanoparticles over a permeable shrinking disk, incorporating the effects of suction, magnetic field, and Joule heating. The findings highlight the critical role of suction in stabilizing opposing flow, with an increase of 1% suction enhancing the skin friction coefficient by 4.17% and heat transfer efficiency by approximately 1%. The comparative analysis between alumina-copper-silica and alumina-copper-titania nanofluids revealed that:

- Al2O3-Cu-TiO2/water exhibits superior thermal performance, attributed to its higher thermal conductivity.

- Al2O3-Cu-SiO2 water shows a slight reduction in both skin friction and heat transfer, confirming the influence of nanoparticle composition on thermal efficiency.

- The study identified critical suction values necessary for flow stabilization, providing insights into controlling boundary layer separation in shrinking flows.

These findings establish Al2O3-Cu-TiO2/water as a promising solution for high-performance cooling systems, energy-efficient heat exchangers, and industrial thermal management applications. Future research should explore unsteady flow behavior, non-Newtonian ternary nanofluids, and machine-learning-based optimization techniques to further refine THNF thermal performance.

Acknowledgement: The authors would like to thank Universiti Teknikal Malaysia Melaka, Universiti Putra Malaysia and Babeş-Bolyai University for the research support.

Funding Statement: This research was funded by Universiti Teknikal Malaysia Melaka, through Fakulti Teknologi dan Kejuruteraan Mekanikal (FTKM)’s publication fund-K23003.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and mathematical formulation: Umi Nadrah Hussein, Najiyah Safwa Khashi’ie, Norihan Md Arifin, Ioan Pop; data collection: Umi Nadrah Hussein, Najiyah Safwa Khashi’ie; analysis and interpretation of results: Umi Nadrah Hussein, Najiyah Safwa Khashi’ie; draft manuscript preparation: Umi Nadrah Hussein, Najiyah Safwa Khashi’ie, Norihan Md Arifin. All authors reviewed the results and approved the final version of sthe manuscript.

Availability of Data and Materials: Not applicable.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Habibishandiz M, Saghir MZ. A critical review of heat transfer enhancement methods in the presence of porous media, nanofluids, and microorganisms. Therm Sci Eng Prog. 2022;30(10):101267. doi:10.1016/j.tsep.2022.101267. [Google Scholar] [CrossRef]

2. Younes H, Mao M, Murshed SS, Lou D, Hong H, Peterson GP. Nanofluids: key parameters to enhance thermal conductivity and its applications. Appl Therm Eng. 2022;207:118202. doi:10.1016/j.applthermaleng.2022.118202. [Google Scholar] [CrossRef]

3. Okonkwo EC, Wole-Osho I, Almanassra IW, Abdullatif YM, Al-Ansari T. An updated review of nanofluids in various heat transfer devices. J Therm Anal Calorim. 2021;145(6):2817–72. doi:10.1007/s10973-020-09760-2. [Google Scholar] [CrossRef]

4. Nabil MF, Azmi WH, Hamid KA, Zawawi NN, Priyandoko G, Mamat R. Thermo-physical properties of hybrid nanofluids and hybrid nanolubricants: a comprehensive review on performance. Int Comm Heat Mass Transf. 2017;83(6):30–9. doi:10.1016/j.icheatmasstransfer.2017.03.008. [Google Scholar] [CrossRef]

5. Adun H, Kavaz D, Dagbasi M. Review of ternary hybrid nanofluid: synthesis, stability, thermophysical properties, heat transfer applications, and environmental effects. J Cleaner Prod. 2021;328:129525. doi:10.1016/j.jclepro.2021.129525. [Google Scholar] [CrossRef]

6. Oladapo OA, Ajala OA, Akindele AO, Aselebe LO, Obalalu AM, Ohaegbue AD, et al. Analysis of variable properties on ternary and tetra hybrid nanofluids using Blasius Rayleigh-Stokes time dependent variable: a model for solar aeronautical engineering. Int J Thermofluids. 2024;23:100775. [Google Scholar]

7. Yu Y, Du J, Hou J, Jin X, Wang R. Investigation into the underlying mechanisms of the improvement of thermal conductivity of the hybrid nanofluids. Int J Heat Mass Transf. 2024;226:125468. [Google Scholar]

8. Takabi B, Salehi S. Augmentation of the heat transfer performance of a sinusoidal corrugated enclosure by employing hybrid nanofluid. Adv Mech Eng. 2014;6:147059. [Google Scholar]

9. Devi SA, Devi SS. Numerical investigation of hydromagnetic hybrid Cu-Al2O3/water nanofluid flow over a permeable stretching sheet with suction. Int J Nonlin Sci Numer Simul. 2016;17(5):249–57. [Google Scholar]

10. Devi SS, Devi SA. Numerical investigation of three-dimensional hybrid Cu-Al2O3/water nanofluid flow over a stretching sheet with effecting Lorentz force subject to Newtonian heating. Canadian J Phys. 2016;94(5):490–6. [Google Scholar]

11. Devi SS, Devi SA. Heat transfer enhancement of Cu-Al2O3/water hybrid nanofluid flow over a stretching sheet. J Niger Math Soc. 2017;36(2):419–33. [Google Scholar]

12. Waqas H, Farooq U, Naseem R, Hussain S, Alghamdi M. Impact of MHD radiative flow of hybrid nanofluid over a rotating disk. Case Stud Therm Eng. 2021;26:101015. [Google Scholar]

13. Khan U, Zaib A, Abu Bakar S, Ishak A. Unsteady stagnation-point flow of a hybrid nanofluid over a spinning disk: analysis of dual solutions. Neural Comp Appl. 2022;34(10):8193–210. [Google Scholar]

14. Bilal M, Saeed A. Numerical computation for the dual solution of Sisko hybrid nanofluid flow through a heated shrinking/stretching porous disk. Int J Ambient Energy. 2022;43(1):8802–11. [Google Scholar]

15. Khashi’ie NS, Arifin NM, Nazar R, Hafidzuddin EH, Wahi N, Pop I. Magnetohydrodynamics (MHD) axisymmetric flow and heat transfer of a hybrid nanofluid past a radially permeable stretching/shrinking sheet with Joule heating. Chin J Phys. 2020;64:251–63. [Google Scholar]

16. Khashi’ie NS, Arifin NM, Pop I. Unsteady axisymmetric flow and heat transfer of a hybrid nanofluid over a permeable stretching/shrinking disc. Int J Numer Methods Heat Fluid Flow. 2021;31(6):2005–21. doi:10.1108/HFF-07-2020-0421. [Google Scholar] [CrossRef]

17. Li YX, Muhammad T, Bilal M, Khan MA, Ahmadian A, Pansera BA. Fractional simulation for Darcy-Forchheimer hybrid nanoliquid flow with partial slip over a spinning disk. Alex Eng J. 2021;60(5):4787–96. doi:10.1016/j.aej.2021.03.062. [Google Scholar] [CrossRef]

18. Ali B, Mishra NK, Rafique K, Jubair S, Mahmood Z, Eldin SM. Mixed convective flow of hybrid nanofluid over a heated stretching disk with zero-mass flux using the modified Buongiorno model. Alex Eng J. 2023;72(12):83–96. doi:10.1016/j.aej.2023.03.078. [Google Scholar] [CrossRef]

19. Tassaddiq A, Khan S, Bilal M, Gul T, Mukhtar S, Shah Z, et al. Heat and mass transfer together with hybrid nanofluid flow over a rotating disk. AIP Adv. 2020;10(5):055317. doi:10.1063/5.0010181. [Google Scholar] [CrossRef]

20. Rahman NA, Khashi’ie NS, Hamzah KB, Zainal NA, Waini I, Pop I. Axisymmetric hybrid nanofluid flow over a radially shrinking disk with heat generation and magnetic field effects. JP J Heat Mass Transf. 2024;37(3):365–75. doi:10.17654/0973576324025. [Google Scholar] [CrossRef]

21. Jamrus FN, Waini I, Khan U, Ishak A. Effects of magnetohydrodynamics and velocity slip on mixed convective flow of thermally stratified ternary hybrid nanofluid over a stretching/shrinking sheet. Case Stud Therm Eng. 2024;55(66):104161. doi:10.1016/j.csite.2024.104161. [Google Scholar] [CrossRef]

22. Jamrus FN, Ishak A, Waini I, Khan U, Siddiqui MI, Madhukesh JK. Aspects of non-unique solutions for hiemenz flow filled with ternary hybrid nanofluid over a stretching/shrinking sheet. Adv Math Phys. 2024;2024(1):7253630. doi:10.1155/2024/7253630. [Google Scholar] [CrossRef]

23. Hussein UN, Khashi’ie NS, Arifin NM, Pop I. Magnetohydrodynamics (MHD) flow of ternary nanofluid and heat transfer past a permeable cylinder with velocity slip. Chin J Phys. 2025;93(15):328–39. doi:10.1016/j.cjph.2024.12.002. [Google Scholar] [CrossRef]

24. Hussein UN, Khashi’ie NS, Hamzah KB, Arifin NM, Pop I. Joule heating effect on ternary nanofluid flow and heat transfer over a permeable cylinder. JP J Heat Mass Transf. 2024;37(6):831–41. doi:10.17654/0973576324051. [Google Scholar] [CrossRef]

25. Mahmood Z, Khan U, Saleem S, Rafique K, Eldin SM. Numerical analysis of ternary hybrid nanofluid flow over a stagnation region of stretching/shrinking curved surface with suction and Lorentz force. J Magn Mag Mater. 2023;573(3):170654. doi:10.1016/j.jmmm.2023.170654. [Google Scholar] [CrossRef]

26. Mahmood Z, Ahammad NA, Alhazmi SE, Khan U, Bani-Fwaz MZ. Ternary hybrid nanofluid near a stretching/shrinking sheet with heat generation/absorption and velocity slip on unsteady stagnation point flow. Int J Mod Phys B. 2022;36(29):2250209. doi:10.1142/S0217979222502095. [Google Scholar] [CrossRef]

27. Mumtaz M, Islam S, Ullah H, Dawar A, Shah Z. A numerical approach to radiative ternary nanofluid flow on curved geometry with porous media and multiple slip constraints. ZAMM-J Appl Math Mech/Z Für Angew Math Und Mech. 2024;104(10):e202300914. doi:10.1002/zamm.202300914. [Google Scholar] [CrossRef]

28. Mumtaz M, Islam S, Ullah H, Dawar A, Shah Z. A numerical approach to radiative ternary nanofluid flow on curved geometry with cross-diffusion and second order velocity slip constraints. Int J Heat Fluid Flow. 2024;105:109255. doi:10.1016/j.ijheatfluidflow.2023.109255. [Google Scholar] [CrossRef]

29. Shinwari W, Hayat T, Abbas Z, Momani S. A numerical study on the flow of water-based ternary hybrid nanomaterials on a stretchable curved sheet. Nanoscale Adv. 2023;5(22):6249–61. doi:10.1039/D3NA00572K. [Google Scholar] [PubMed] [CrossRef]

30. Alharbi AA. Thermal analysis of heat transport in a slip flow of ternary hybrid nanofluid with suction upon a stretching/shrinking sheet. Case Stud Therm Eng. 2024;54(25–26):103965. doi:10.1016/j.csite.2023.103965. [Google Scholar] [CrossRef]

31. Khan M, Alhowaity A, Imran M, Hussien M, Alroobaea R, Anwar MS. Advanced numerical simulation techniques in MHD fluid flow analysis using distributed fractional order derivatives and Cattaneo heat flux model. ZAMM-J Appl Math Mech/Z Für Angew Math Und Mech. 2024;104(5):e202300622. doi:10.1002/zamm.202300622. [Google Scholar] [CrossRef]

32. Khan M, Imran M. ANN-driven insights into heat and mass transfer dynamics in chemical reactive fluids across variable-thickness surfaces. Heat Transf. 2024;53(8):4551–71. doi:10.1002/htj.23144. [Google Scholar] [CrossRef]

33. Jamrus FN, Ishak A, Waini I, Khan U. Radiative influence on axisymmetric ternary hybrid nanofluid flow with convective boundary conditions over a nonlinearly permeable stretching/shrinking disk. Int J Numer Methods Heat Fluid Flow. 2024;34(12):4333–61. doi:10.1108/HFF-04-2024-0324. [Google Scholar] [CrossRef]

34. Memon MA, Jacob K, Lanjwani HB, Mahmoud EE. Darcy-Forchheimer MHD micropolar water based hybrid nanofluid flow, heat and mass transfer features past on stretching/shrinking surface with slip and radiation effects. Results Eng. 2024;23(1):102534. doi:10.1016/j.rineng.2024.102534. [Google Scholar] [CrossRef]

35. Buongiorno J. Convective transport in nanofluids. J Heat Transf. 2006;128(3):240–50. doi:10.1115/1.2150834. [Google Scholar] [CrossRef]

36. Sarfraz M, Yasir M, Khan M. Multiple solutions for non-linear radiative mixed convective hybrid nanofluid flow over an exponentially shrinking surface. Sci Rep. 2023;13(1):3443. doi:10.1038/s41598-023-29892-3. [Google Scholar] [PubMed] [CrossRef]

37. Lund LA, Omar Z, Khan I, Seikh AH, Sherif ES, Nisar KS. Stability analysis and multiple solution of Cu-Al2O3/H2O nanofluid contains hybrid nanomaterials over a shrinking surface in the presence of viscous dissipation. J Mater Res Tech. 2020;9(1):421–32. doi:10.1016/j.jmrt.2019.10.071. [Google Scholar] [CrossRef]

38. Ahmed S, Chen ZM, Ishaq M. Multiple solutions in magnetohydrodynamic stagnation flow of hybrid nanofluid past a sheet with mathematical chemical reactions model and stability analysis. Phys Fluids. 2023;35(7):072002. doi:10.1063/5.0157429. [Google Scholar] [CrossRef]

39. Yan L, Dero S, Khan I, Mari IA, Baleanu D, Nisar KS, et al. Dual solutions and stability analysis of magnetized hybrid nanofluid with Joule heating and multiple slip conditions. Processes. 2020;8(3):332. doi:10.3390/pr8030332. [Google Scholar] [CrossRef]

40. Khan M, Qamar M, Alqahtani AS, Malik MY. On multiple solutions of cubic catalysis chemically reactive flow of hybrid nanofluids. Results Eng. 2024;24(6):103404. doi:10.1016/j.rineng.2024.103404. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools