Open Access

Open Access

ARTICLE

Evaluating Dying Efficiency and Energy Performance of a Hybrid Solar Dryer with Natural, Forced, and Hybrid Convection Modes for Tomatoes

1 Department of Electrical Engineering, Mehran University of Engineering & Technology, Jamshoro, 76062, Pakistan

2 Department of Mechanical & Industrial Engineering, College of Engineering, Qatar University, Doha, 22976, Qatar

* Corresponding Author: Shoaib Ahmed Khatri. Email:

(This article belongs to the Special Issue: Heat and Mass Transfer in Renewable Energy Systems: Challenges and Innovations)

Frontiers in Heat and Mass Transfer 2025, 23(2), 479-505. https://doi.org/10.32604/fhmt.2025.063937

Received 29 January 2025; Accepted 11 March 2025; Issue published 25 April 2025

Abstract

This research focuses on developing innovative hybrid solar dryers that combine solar Photovoltaic (PV) and solar thermal systems for sustainable food preservation in Pakistan, addressing the country’s pressing issues of high post-harvest losses and unreliable energy sources. The proposed active hybrid solar dryer features a drying cabinet, two Direct Current (DC) fans for forced convection, and a resistive heating element powered by a 180 W solar PV panel. An energy-storing battery ensures continuous supply to the auxiliaries during periods of low solar irradiance, poor weather conditions, or nighttime. Tomatoes, a delicate and in-demand crop, were selected for experimentation due to their high perishability. Three experiments were conducted on the same prototype: natural convection direct solar dryer (NCDSD), forced convection direct solar dryer (FCDSD), and forced convection hybrid solar dryer (FCHSD). Each experiment began with 0.2 kg of tomatoes at 94% moisture content, achieving significant reductions: 28.57% with NCDSD, 16.667% with FCDSD, and 16.667% with FCHSD. The observed drying rates varied: 1.161 kg/h for NCDSD, 2.062 kg/h for FCDSD, and 2.8642 kg/h for FCHSD. This study presents a comparative analysis of efficiency, drying rate, and cost-effectiveness, alongside the system’s economic and environmental feasibility.Keywords

Nomenclature

| Collector Area (m2) | |

| Solar Intensity (W/m2) | |

| Moisture content wet basis | |

| Thermal efficiency | |

| Moisture content dried basis | |

| Initial weight (kg) | |

| Final weight (kg) | |

| Dried product weight | |

| Mass of water (kg) | |

| Specific heat capacity = 1.005 kJ/kg°C | |

| Difference of temp. | |

| Enthalpy of liquid water (kJ/kg) | |

| Enthalpy of water vapor (kJ/kg) | |

| Moisture content in the product (kg) | |

| Radiation heat absorbed | |

| Absorptivity of the material | |

| Heat lost by convection | |

| Thermal resistance of sample | |

| Thickness of the sample (m) | |

| Sample’s Thermal conductivity (W/Km) | |

| Incident energy | |

| Useful energy | |

| Mass flow rate (kg/s) | |

| Temp. inside dryer | |

| Ambient temp. | |

| Air velocity inside the dryer ( | |

| Area of element wire | |

| Energy to evaporate moisture | |

| Energy to raise temp. of moisture (kJ) | |

| Drying efficiency | |

| Latent heat of vaporization of water (kJ/kg) | |

| Heat of electric heater (W) | |

| Drying time | |

| Stefan-Boltzmann constant = | |

| Air density in ( | |

| Emissivity of element | |

| Temperature of element | |

| Power consumption of element (W) | |

| Heat Transfer Coefficient = | |

| Drying rate (kg/h) | |

| Initial moisture content | |

| Final moisture content | |

| Total time taken for drying | |

| Moisture rate | |

| Equilibrium moisture | |

| Moisture | |

| NC | Natural convection |

| FC | Forced convection |

| DSD | Direct solar dryer |

| ISD | Indirect solar dryer |

| MSD | Mixed-mode solar dryer |

| HSD | Hybrid solar dryer |

| GSD | Greenhouse solar dryer |

| HExSD | Heat Exchanger solar dryer |

Pakistan’s agricultural land makes it self-sufficient, but sustainable food supplies face challenges due to climate variability, energy scarcity, and post-harvest losses. Improper handling and storage lead to food decay, mainly caused by poor water quality that fosters microorganisms [1]. However, creating dehydrated agricultural goods can help distribute them globally, driving sustainable development benefits [2]. Global food demand is expected to surge by 60% by 2050, underscoring the urgent need for enhanced food preservation techniques to manage the increased supply [3]. Traditional food drying methods, such as fossil fuel and open sun drying, have limitations and drawbacks, including resource limitations, higher costs, environmental concerns, and contaminations [4]. Dryers, especially indirect solar dryers, offer a contamination-free solution by isolating the foodstuff from the environment [5]. Solar dryers are evaluated based on air circulation, heat transfer, and drying chamber design [6]. The passive mode of air circulation relies on natural convection, whereas the active mode utilizes forced convection, which can be integrated with any heat transfer method or drying chamber design [7]. Mugi and Chandramohan [8] developed a forced convection indirect solar dryer (FCISD) system, which outperforms natural convection indirect solar dryer (NCISD) systems in drying guava slices, with a 26.19% increase in drying efficiency (6.84%) and 20.54% reduction in energy consumption. Heat transfer methods can be classified as direct, indirect, or mixed-mode, where direct methods involve solar radiation incident on the crop, indirect methods use a separate solar collector, and mixed-mode methods combine features of both [9]. Mixed-mode solar dryers offer a cost-effective and efficient alternative, providing a time-effective solution for food drying [10]. Hybrid solar dryers offer enhanced drying efficiency throughout the day, with systems like PV-hybridized solar dryers enabling continuous operation of fans for forced convection, independent of external power sources [11]. Integrating techniques like Phase Change Materials (PCM) or heat exchangers or solar air heaters can further enhance dryers’ efficiency to a greater extent [12]. Modifying the solar collector plate of the passive-mode ISD dryer with multiple metallic solar concentrators and enclosing its drying cabinet with a greenhouse plastic material boosts its drying performance considerably beyond that of the OSD method [13]. The temperature inside a dryer is much higher than the open sunlight drying temperature [14].

A significant body of research has been dedicated to the design, development, and evaluation of solar dryers. Rabha et al. [15] designed a solar tunnel dryer, demonstrating 22.1%–40.2% thermal efficiency and 21%–98% exergetic efficiency for drying ghost chilli and ginger, with energy consumption of 18.72 and 8.82 kWh/kg. Abi Mathew et al. [16] developed a novel thermal energy storage integrated evacuated tube heat pipe solar dryer, achieving 10%–30% thermal efficiency and 2.6-year payback period, suitable for drying agricultural products like tomatoes and carrots. César et al. [17] evaluated a mixed-mode solar dryer for drying pear slices, finding that the mixed mode forced convection achieved the shortest drying time, while the Indirect mode natural convection had the highest drying efficiency, and the mixed mode natural convection exhibited the highest exergy efficiency. Essalhi et al. [18] demonstrated that an indirect solar dryer with a water storage tank significantly reduces grape drying time (by 40%) compared to open sun drying. Mugi et al. [19] developed an active-mode indirect solar dryer (AMISD) that outperforms its passive counterpart (PMISD) in efficiency, economic viability, and environmental sustainability for drying guava slices. Maridurai et al. [20] demonstrated that incorporating V-corrugated fins in a solar dryer significantly enhances thermal efficiency and drying performance compared to wavy fins, achieving an efficiency improvement of up to 64.61%. Hussain et al. [21] found that a modified sun drying technique, involving removal and covering of dates during nighttime (SDT4), significantly improved fruit quality characters of ‘Hillawi’ dates, reducing weight loss and moisture content while enhancing total soluble solids, sugars, phytonutrients, and antioxidants. Mohammed et al. [22] demonstrated that advanced solar drying technology (ISD) significantly enhanced the sensory and nutritional properties of dried mangoes and pineapples, surpassing traditional solar drying methods. This breakthrough has far-reaching implications for reducing post-harvest losses and increasing access to high-quality dried fruit products in East Africa. This study addressed the knowledge and adoption gap by designing and testing a low-cost solar dryer for rural Pakistan. The results showed substantial improvements in drying efficiency, energy savings, and product quality compared to open sun drying. Notably, the hybrid mode forced convection operation yielded optimal results, showcasing its potential for widespread adoption and transformative impact on the drying industry. This research aims to promote sustainable solar drying technologies, reducing post-harvest losses and increasing food availability in Pakistan. Future studies can focus on scaling up, exploring other crops, and disseminating this technology to rural communities.

2.1 Design and Construction of the Hybrid Direct Solar Dryer

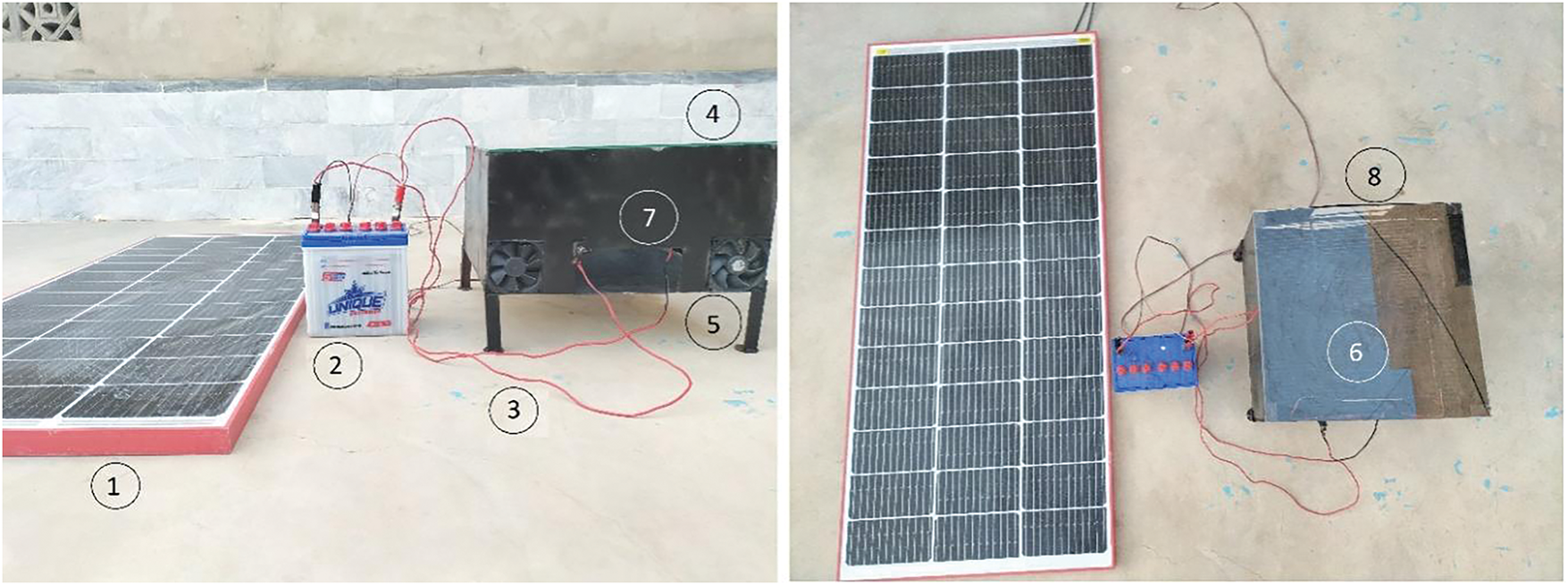

A hybrid direct solar dryer was designed using durable iron material for longevity. The cabinet measures 18 × 18 inches, elevated on 8-inch iron stands for improved airflow and thermal performance. The black-painted iron enhances absorptivity, maximizing internal temperatures by capturing solar radiation. A removable lattice-shaped drying tray inside allows better air circulation and uniform drying. Two DC fans, installed below the tray, ensure continuous airflow, while an outlet window releases hot, moist air. Unlike traditional solar dryers that either rely solely on natural convection or require external power sources for heating, our system integrates a single PV panel to simultaneously power both forced convection (DC fans) and a resistive heating element. It continuously maintains the drying process, even when the solar radiation decreases. For this study, the used resistive heating element is a Nickel-Chromium (NiCr) wire with 30 Ohm resistance and 180 W power rating connected to the PV panel. This feature is particularly beneficial for rural Pakistan, where grid electricity is unreliable, making conventional dryers ineffective. A 180 W solar PV panel powers the fans and heater, with a 20 AH battery for energy storage, ensuring uninterrupted operation even in low sunlight or at night. The prototype is shown in Fig. 1.

Figure 1: Hardware prototype of dryer.1-PV Panel, 2-Battery, 3-Connecting Wires, 4-Dryer Cabinet, 5-DC fans, 6-Resistive heating element, 7-Air inlet Window, 8-Air outlet window

2.2 Experimental Setup and Procedure

The experiment took place in Village Umar Abad near Shahpur Chakar, Sindh, Pakistan, located at latitude 26°859 N and longitude 68°3747 E. The drying process was carried out from July 12th to July 17th, 2024. To evaluate the performance of the hybrid solar dryer under different conditions, the experiments were performed using three distinct configurations.

In the first experiment, the dryer was operated in natural convection mode, meaning that neither the fans nor the heating element was utilized. This setup relied solely on ambient air circulation and solar heat to facilitate the drying process. Tomato slices were evenly spread across the lattice tray, and the drying process was monitored over several hours, measuring the temperature and humidity levels within the dryer at regular intervals.

2.2.2 Forced Convection with Fans

In the second experimental setup, the dryer was modified to incorporate two DC fans, while the heating element remained inactive. The fans were activated to augment airflow inside the cabinet, facilitating accelerated moisture evacuation from the tomato slices. This configuration’s operation time was intentionally consistent with the natural convection mode, enabling a direct comparison of drying efficiency between the two setups. The parameters that were meticulously recorded throughout the drying process included dryer temperature, ambient temperature, airflow velocity, and humidity levels. This comprehensive data collection allowed for a thorough analysis of the drying dynamics and the impact of enhanced airflow on moisture removal. By maintaining the same operation time as the natural convection mode, the researchers aimed to isolate the effects of forced convection and evaluate its efficacy in improving drying efficiency.

2.2.3 Hybrid Operation with Heating Element

The third experimental configuration utilized a hybrid approach, activating both the fans and heating element to create a comprehensive drying system. By combining forced airflow with additional heat, this mode targeted optimal drying performance and accelerated moisture removal. The resistive heating element also heated the airflow passing through the dryer, causing the internal temperature to rise above what was possible with forced convection alone. This additional heating maintained drying operations during peaks or lacks of solar intensity and during non-irradiated hours, optimizing temperature and thus improving moisture extraction efficiency. This is because hot airflow increases the rate of moisture evaporation from the product and retains less moisture, while cold airflow retains more moisture and slows down drying. Similar to the previous setups, temperature, airflow and humidity readings were taken at regular intervals to assess the effectiveness of this configuration.

2.3 Preparation of Drying Product

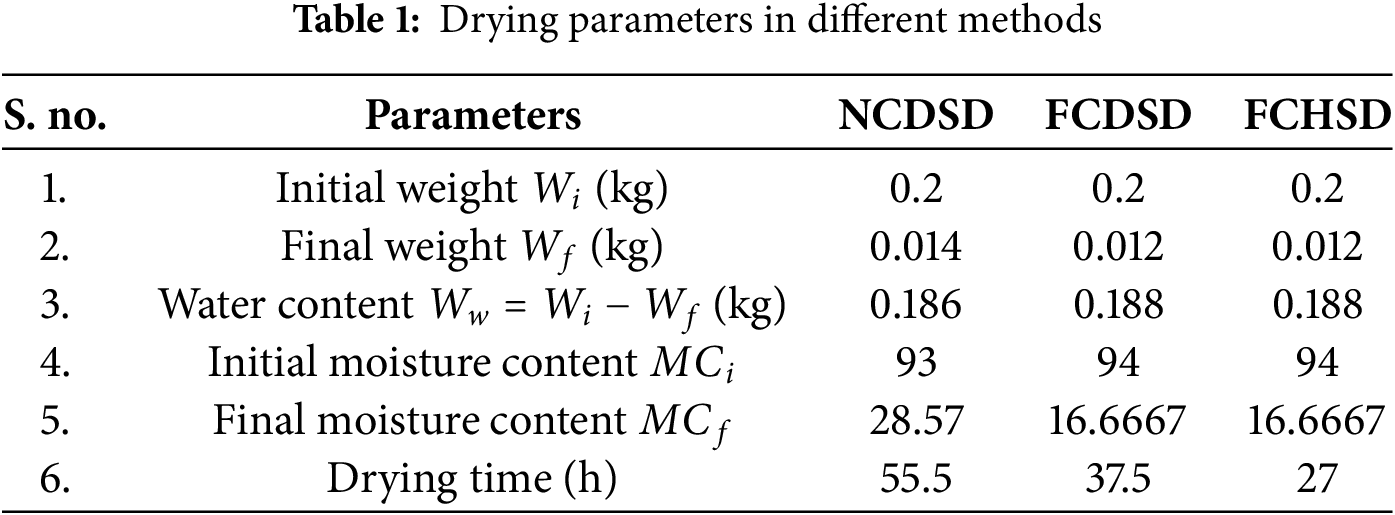

Tomatoes were selected for the drying experiment, sourced from Shahpur Chakar City. A total of 600 g of ripe, uniform-sized tomatoes (200 g in each setup) were sliced into 7 mm pieces. The drying process was carefully monitored for all three setups, with key parameters such as initial and final weights, water content, moisture content, and drying time recorded. A battery backup-maintained consistency during low solar intensity. The table of drying parameters in both of three experiments is given below, Table 1.

The results demonstrate that the hybrid configuration (FCHSD) achieved the shortest drying time of 27 h while maintaining consistent performance, thanks to the battery backup during periods of low solar intensity. The forced convection setup (FCDSD) also performed efficiently with a drying time of 38 h, while the natural convection setup (NCDSD) required the longest time of 55.5 h. All methods effectively reduced the final moisture content to approximately 10% (d.b.), highlighting the potential of solar dryers for sustainable food preservation.

2.4 Data Collection and Analysis

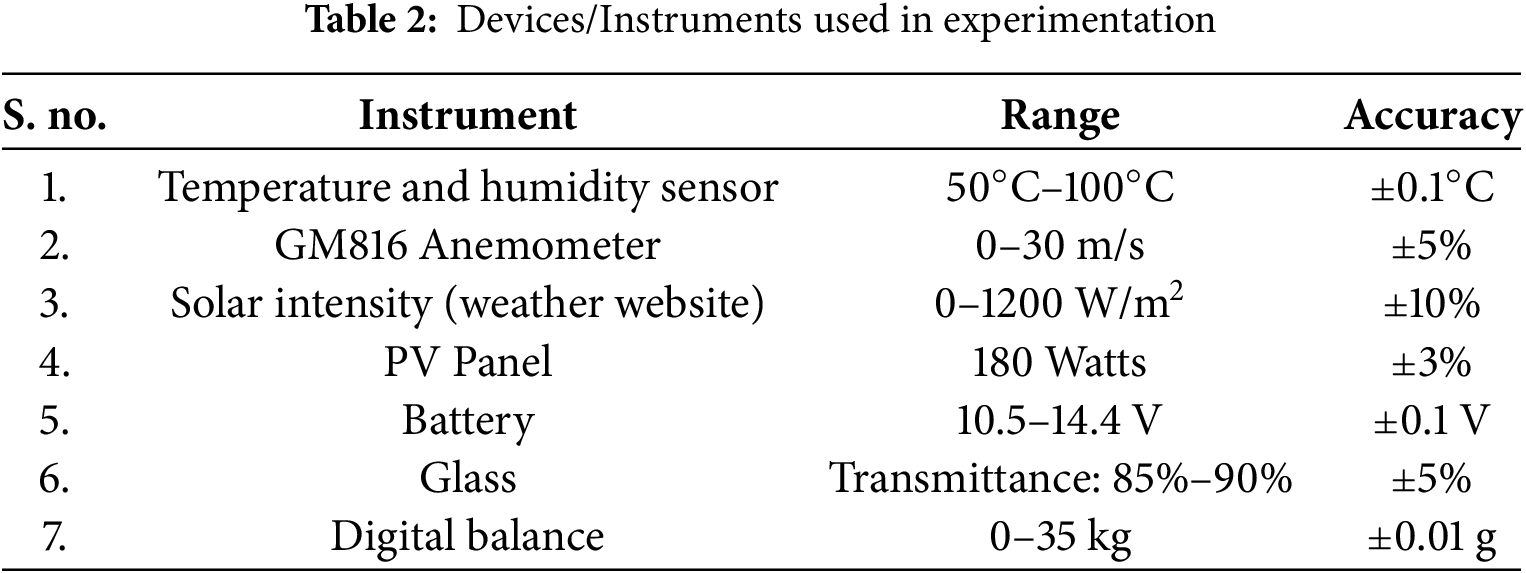

During each experimental run, various key parameters were carefully monitored and recorded to assess the dryer’s performance under different conditions, using different devices given in Table 2:

• Solar Intensity: The solar energy available for drying was tracked in real time using an internet-based source. These findings enabled an assessment of solar energy utilization efficiency across various configurations.

• Temperature: Internal dryer temperature and ambient temperature were simultaneously recorded using temperature sensors. This allowed for a comparative analysis of the internal climate and the impact of each experimental setup.

• Humidity: Humidity levels were recorded both inside the dryer and in the surrounding environment (ambient humidity) using hygrometers. This helped determine the moisture conditions inside the dryer and assess the influence of ambient humidity on the drying process.

• Airflow: Airflow was measured both inside the dryer and in the ambient environment using anemometers. These measurements were crucial for evaluating how airflow influenced the drying process and the overall performance of the dryer under different setups.

The drying performance was evaluated through several key metrics, including moisture content, heat energy, thermal efficiency, drying efficiency, and drying rate. These metrics were calculated based on the initial and final weights of the tomato slices. This comprehensive data collection allowed for a thorough comparison of the effectiveness of each drying mode, providing valuable insights into their performance under varying conditions. The collected data facilitated a detailed analysis of the drying process, enabling researchers to identify optimal configurations and refine the design for improved efficiency.

2.5 Calculations of Performance Parameters

To track the drying process, the moisture content (MC) on a wet basis was calculated. Throughout the experiments, the weight of tomato slices was recorded at regular intervals using a high-precision digital balance. The initial moisture content (

here

The final moisture content then was calculated by following Eq. (2):

here

The energy calculations, including both the sensible, latent heat, heat absorbed and heat loss are determined by Afzal et al. [24] as outlined below:

Sensible Heat Energy: The energy required to raise the temperature of the moisture in the agricultural products is calculated using the Eq. (3):

where

Latent Heat Energy: The energy necessary to evaporate the moisture from the product is given by the Eq. (4):

where

Heat Absorbed: The heat absorbed by the collector from radiation was determined using Eq. (5):

Heat Loss: The heat loss through convection from the collector was calculated using Eq. (6):

where,

The thermal efficiency of the solar dryer, as described by Ferreira et al. [25], was calculated using the incident solar energy on the dryer, given by the Eq. (8):

The energy used to raise the airflow temperature was determined using the mass flow rate of air (

here the mass flow rate (

Now, the thermal efficiency

The thermal efficiency here is the ratio of the energy used to raise the airflow temperature to the total incident solar energy.

The drying efficiency of the hybrid solar dryer

where

and the

where

Heat Transfer Coefficient h (for free convection, typically ranges from

Surface Area

here

Therefore

In cases where the electric heater is not used (first and second setups), the drying efficiency

here

The drying rate represents the speed at which moisture is extracted from a specific fruit sample and can be determined using Eq. (17). For the designed experiment, the drying rate was calculated by measuring the difference in moisture content over a given time period [28].

The moisture ratio (MR) represents the relative amount of moisture remaining in a food sample during the drying process, compared to its initial moisture content. It is defined by Eq. (19), as provided by César et al. [29].

here

3.1 Solar Dryer Performance in Various Operational Modes

This study evaluated the drying behavior, temperature profiles, humidity control, and energy efficiencies in three distinct operational modes of a hybrid solar dryer—natural convection, forced convection with fans, and hybrid convection with fans and a heating element. The following sections analyze the performance of each mode, focusing on moisture reduction kinetics, drying rates, energy consumption, and overall effectiveness in maintaining favorable drying conditions for tomato slices. One main benefit of our hybrid solar dryer is that the dual-use photovoltaic (PV) panel system, powers not only the airflow (DC fans) but also the supplementary heating (resistive element). This means that it doesn’t need any extra energy, lowering operational costs than traditional driers requiring additional electrical or fuel heating sources. This makes this system extremely cost effective, especially for small scale farmers as solar energy costs nothing and they really are a person that saves long term, despite having to invest upfront. Plus, add on the battery backup if we need to keep it running when it is cloudy or at night, without using any other currents.

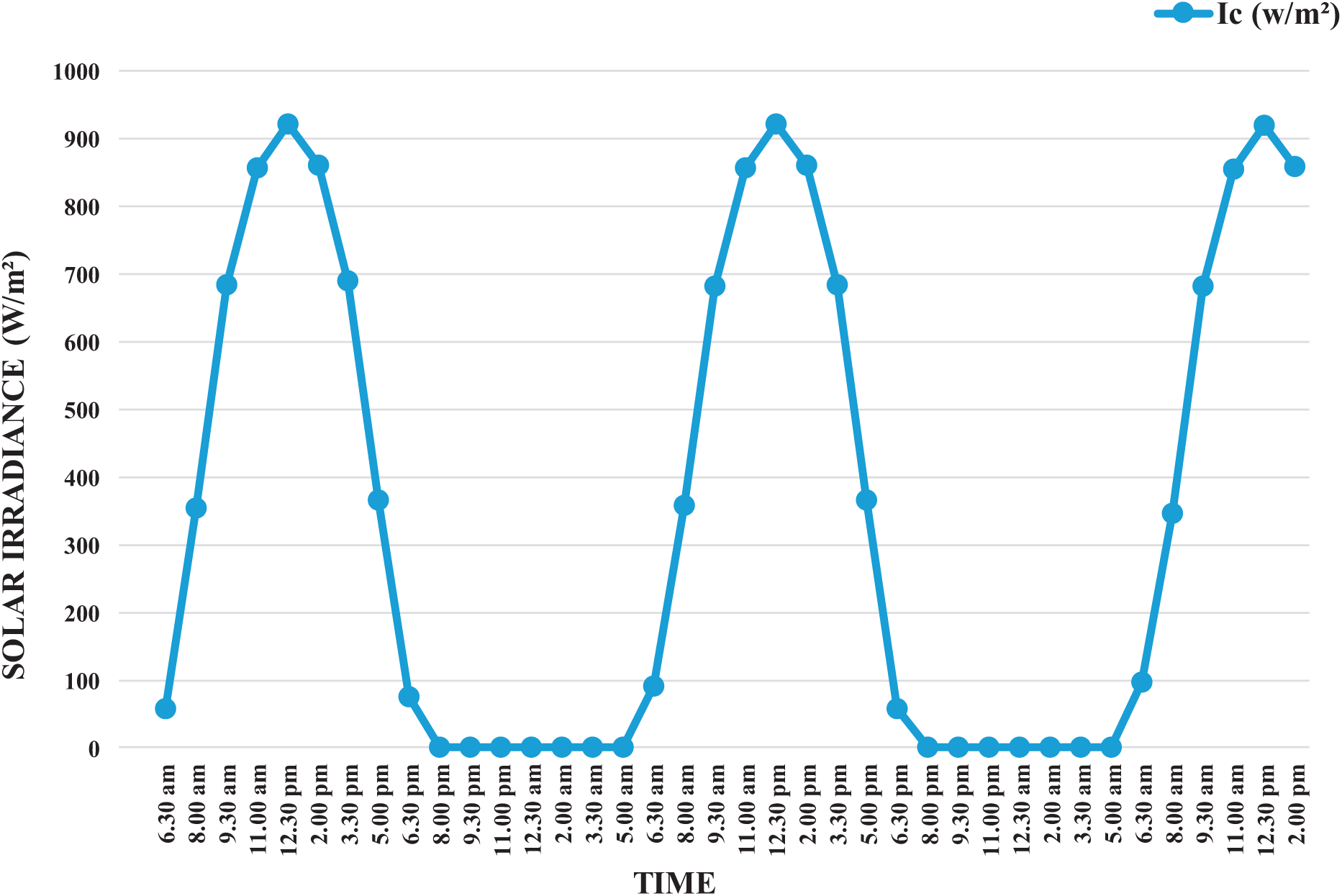

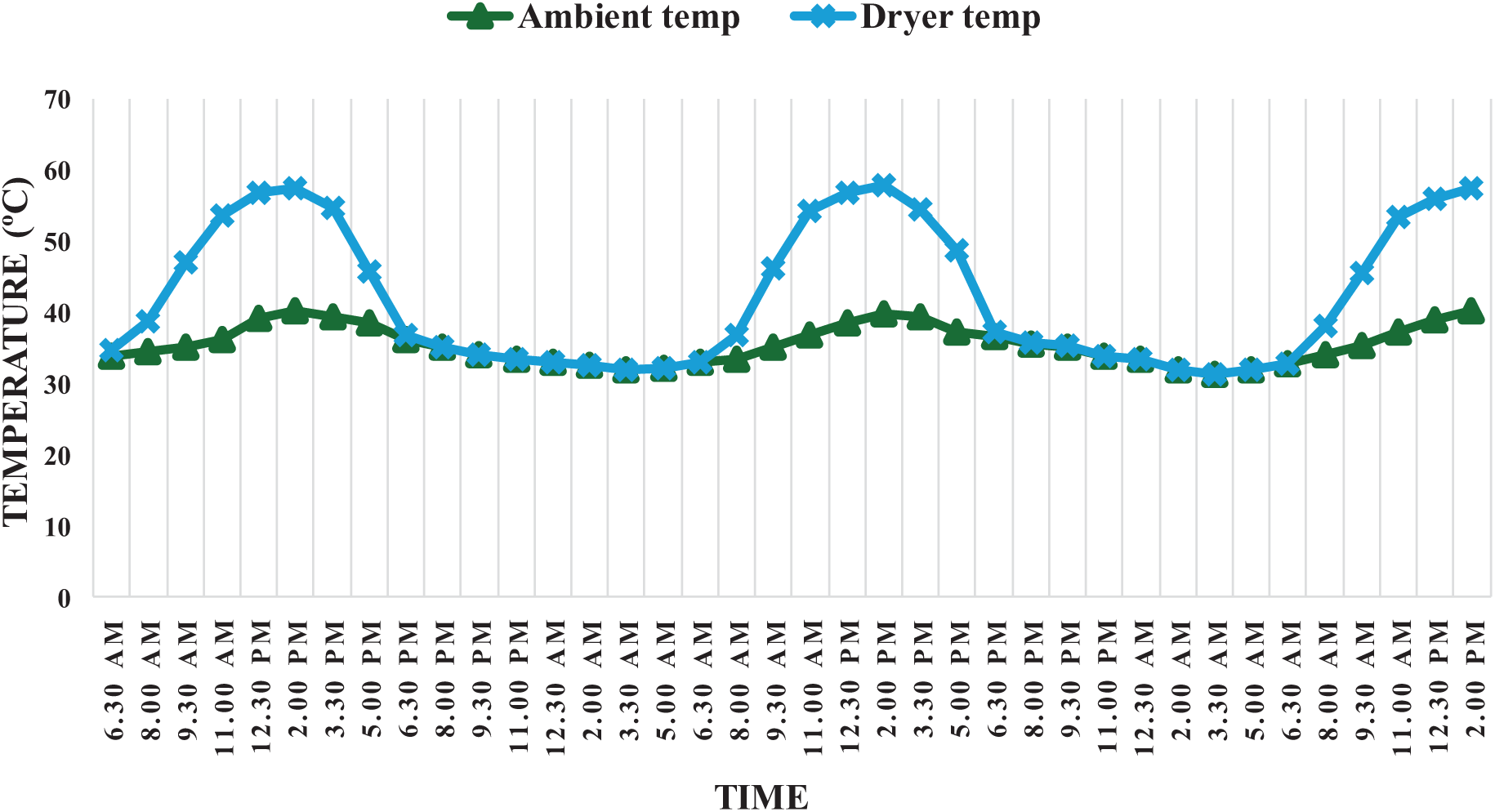

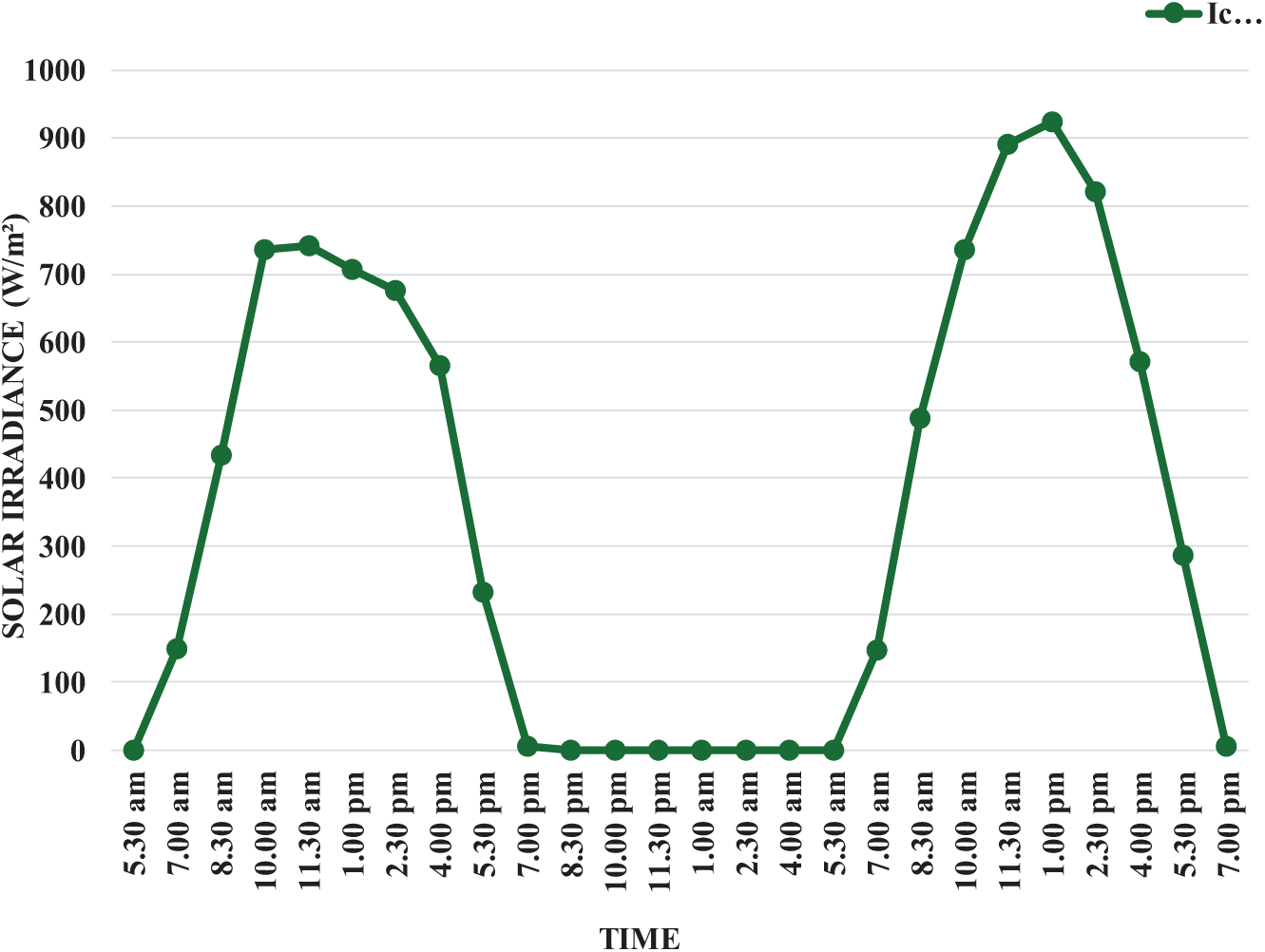

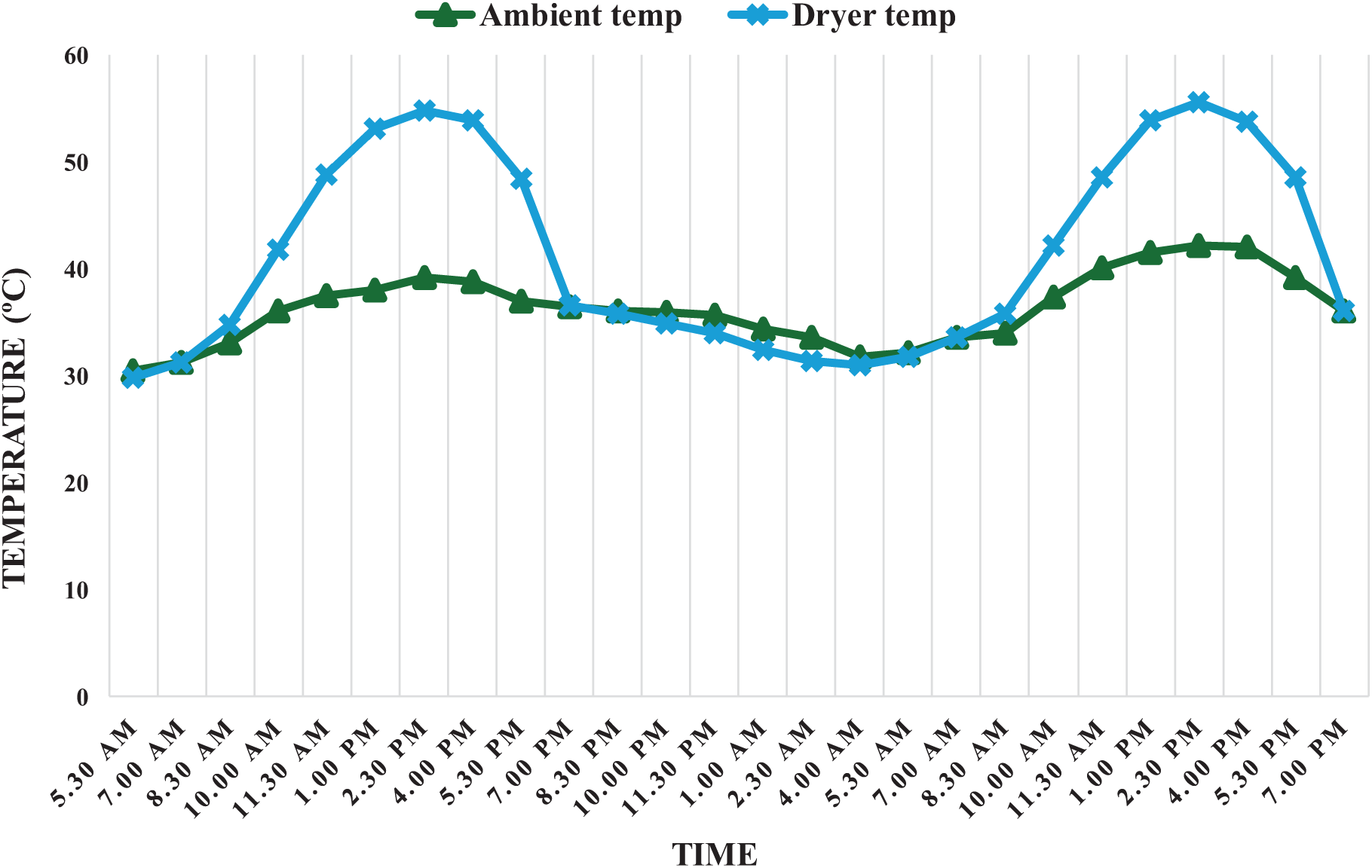

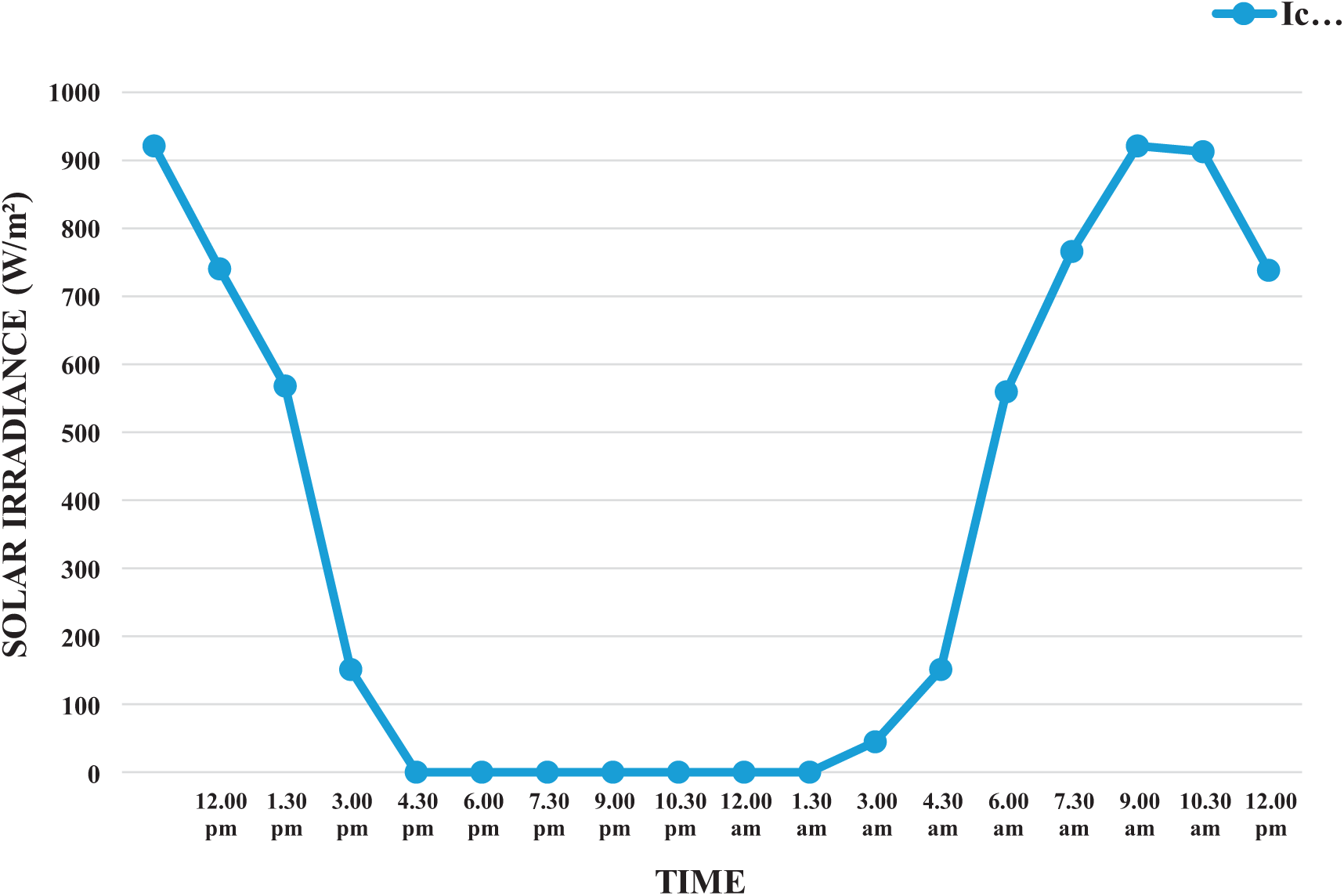

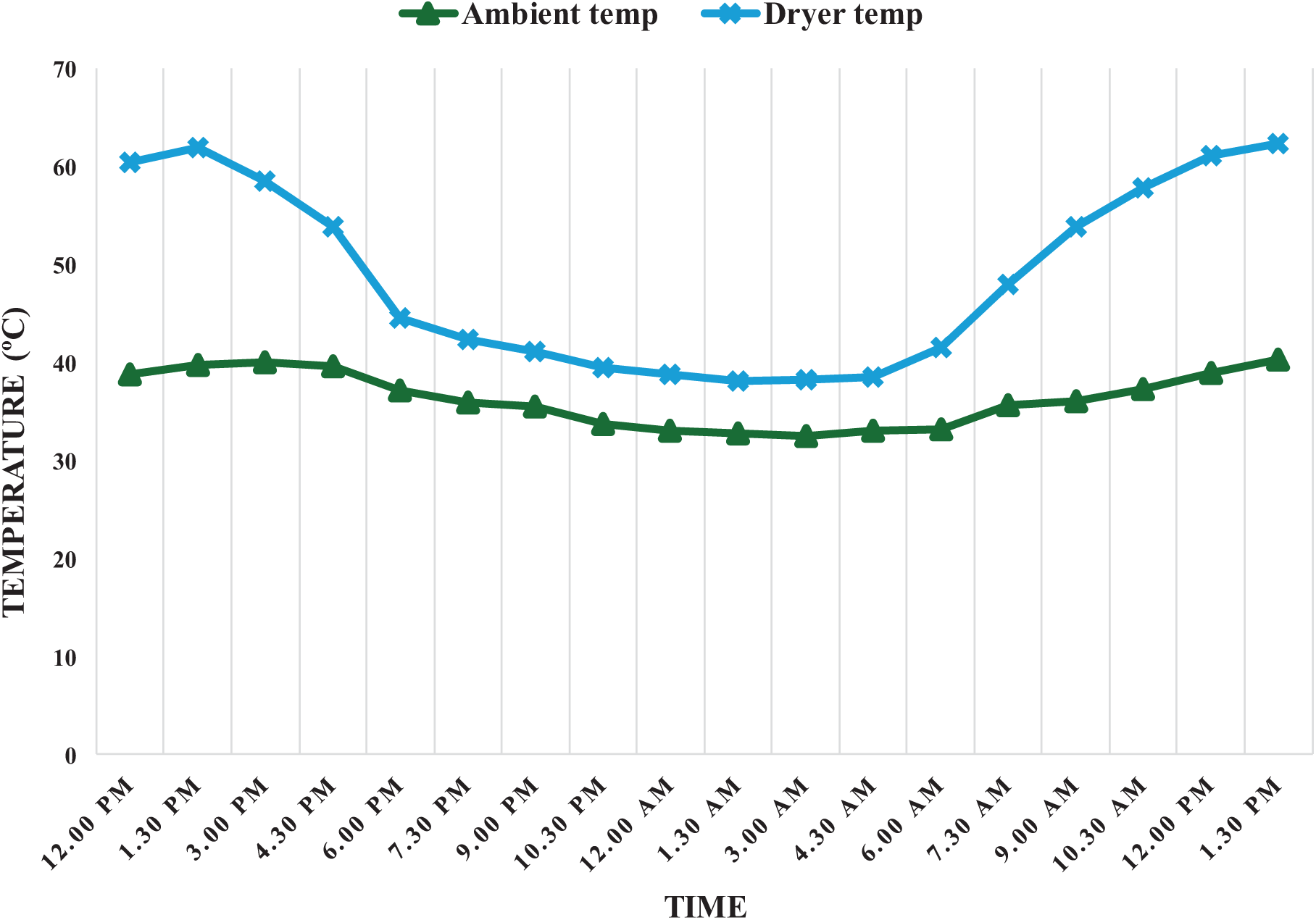

The natural convection solar dryer relied entirely on solar radiation and ambient airflow to drive the drying process of tomatoes. This mode of drying took over 55.5 h to complete, with the experiment conducted on July 12th, 13th, and 14th. The solar irradiance during these days is plotted in Fig. 2, showing fluctuations in solar radiation. The internal temperature within the drying chamber varied correspondingly, peaking around midday at 12:30 p.m. with a maximum solar irradiance of 923 W/m2. This resulted in average high temperatures of approximately 40.1°C ambient and 57.8°C inside the dryer. In contrast, temperatures dropped to ambient levels overnight, recording a minimum of 31.2°C ambient and equivalent temperature inside the dryer at 3:30 a.m. as shown in Fig. 3, where solar irradiance was zero.

Figure 2: Solar irradiance plotted for NCDSD

Figure 3: Ambient temp. and dryer temp. in NCDSD

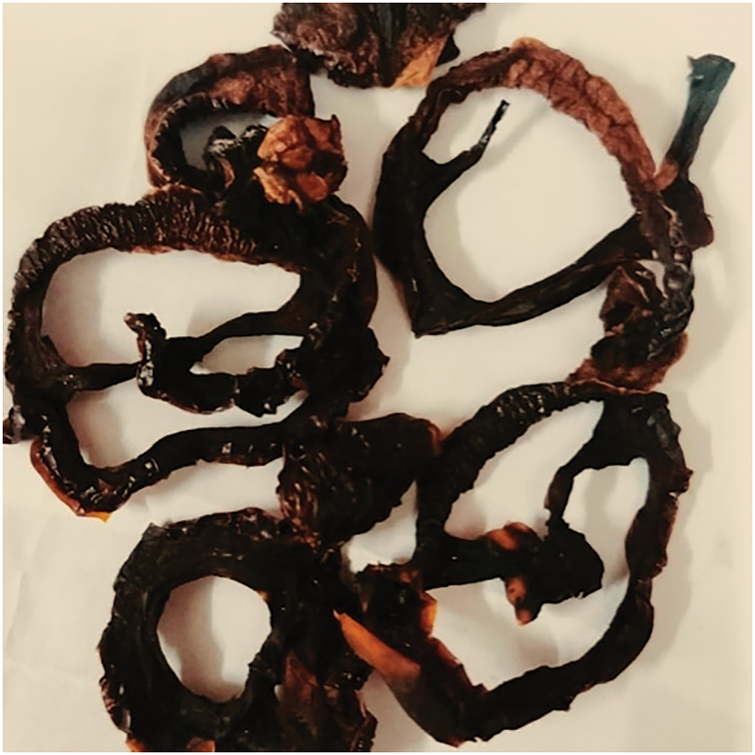

However, a major drawback of this setup was noticeable color degradation in the dried tomatoes. The prolonged exposure to direct sunlight and extended drying time contributed to oxidation and loss of natural color.

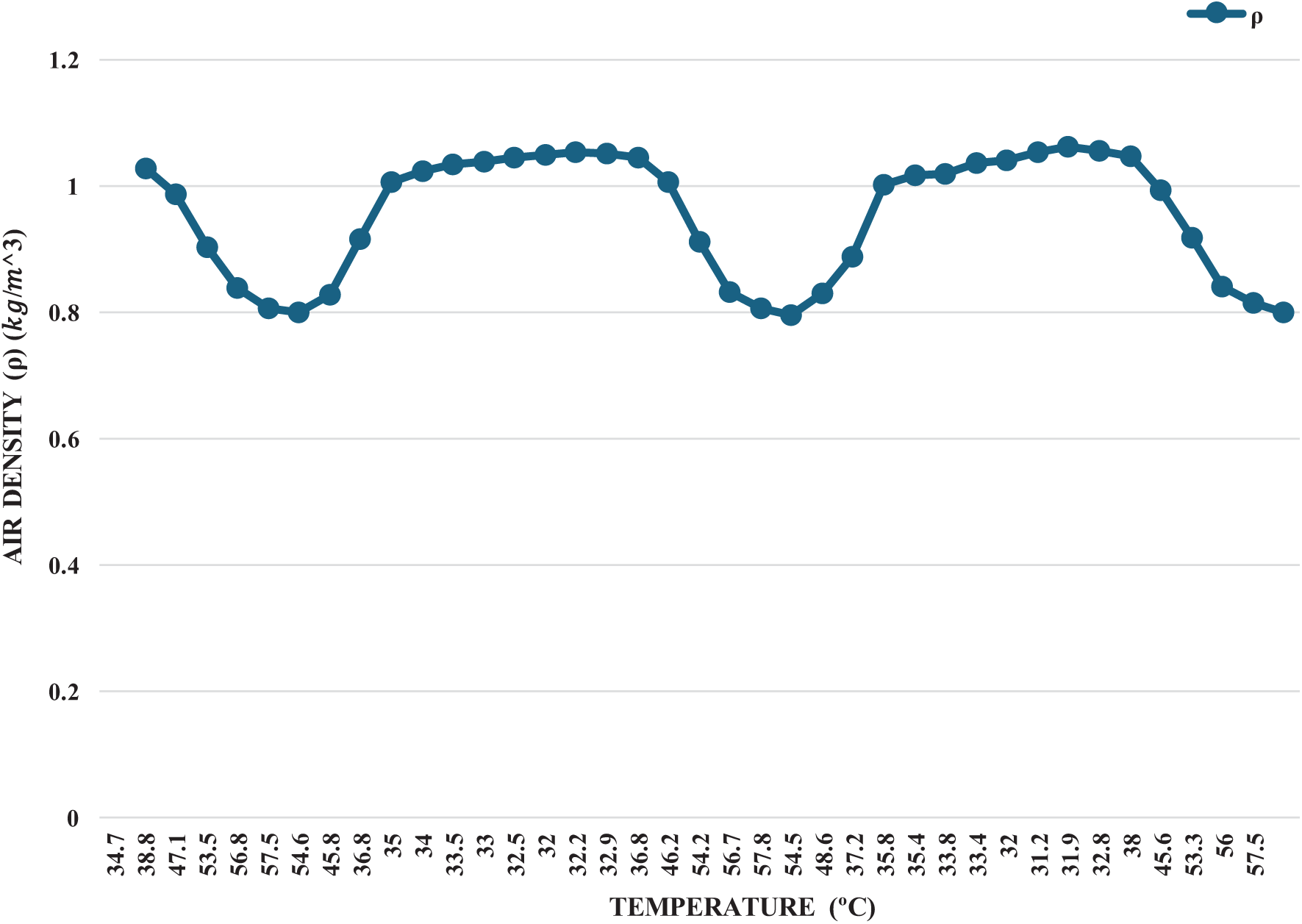

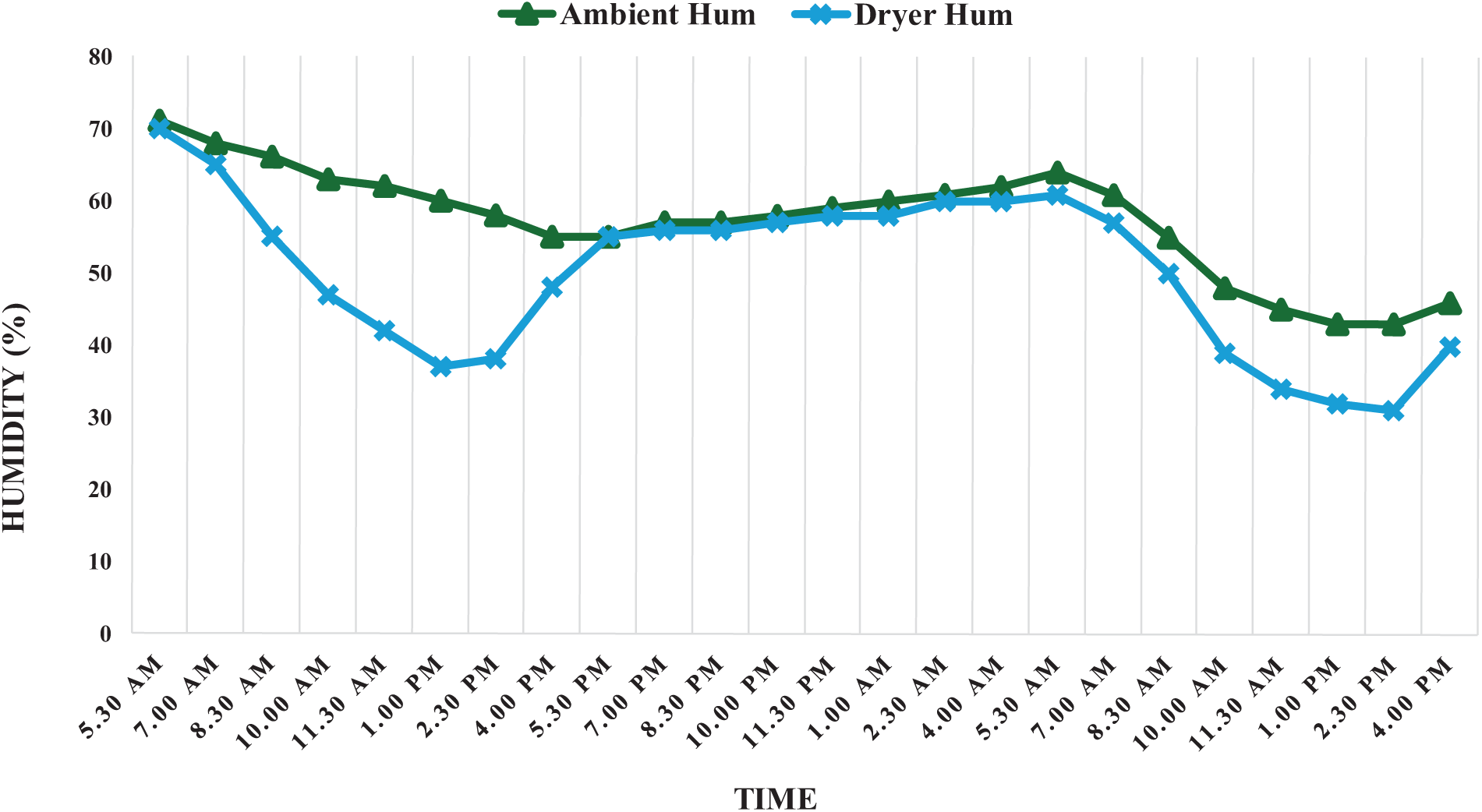

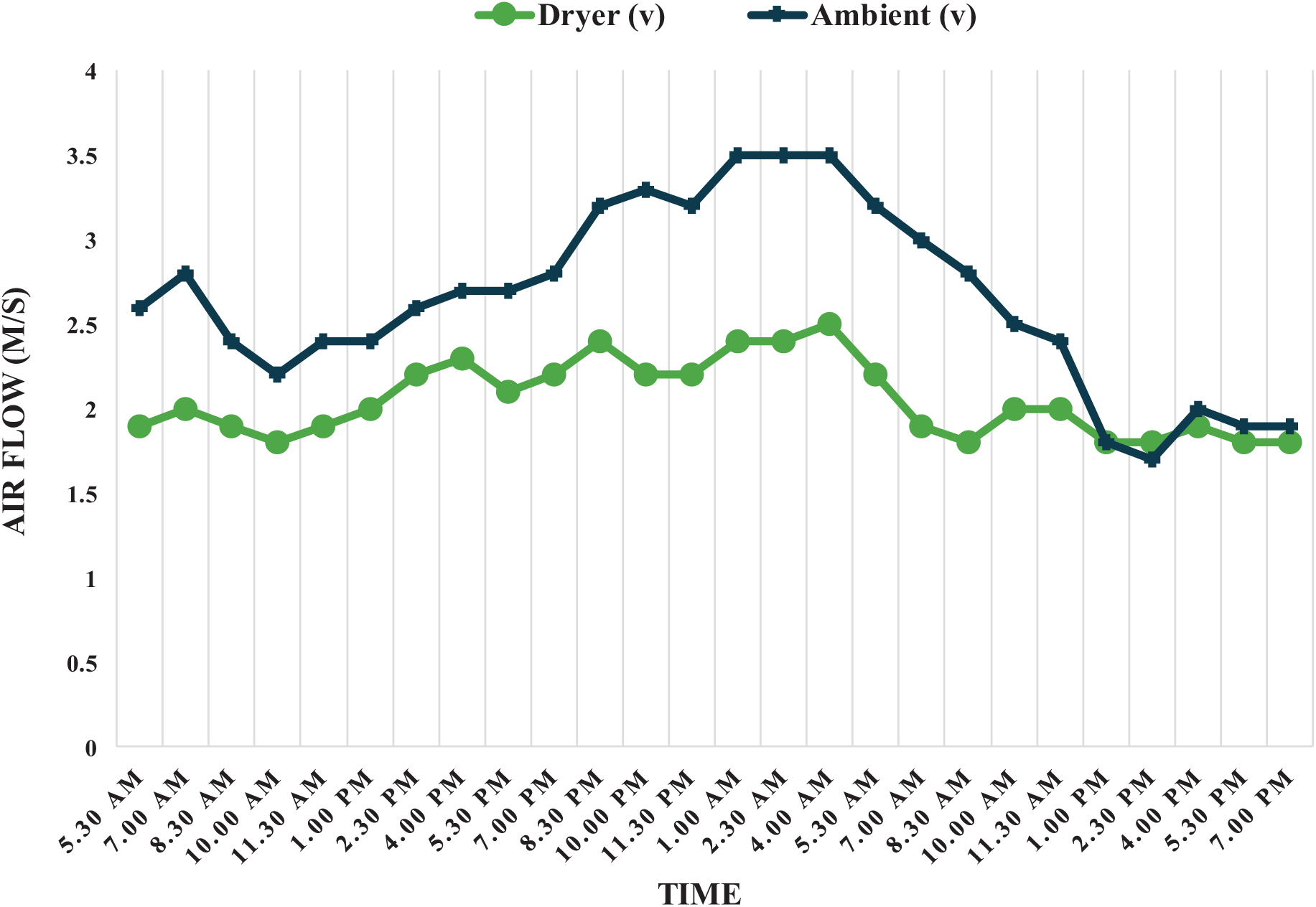

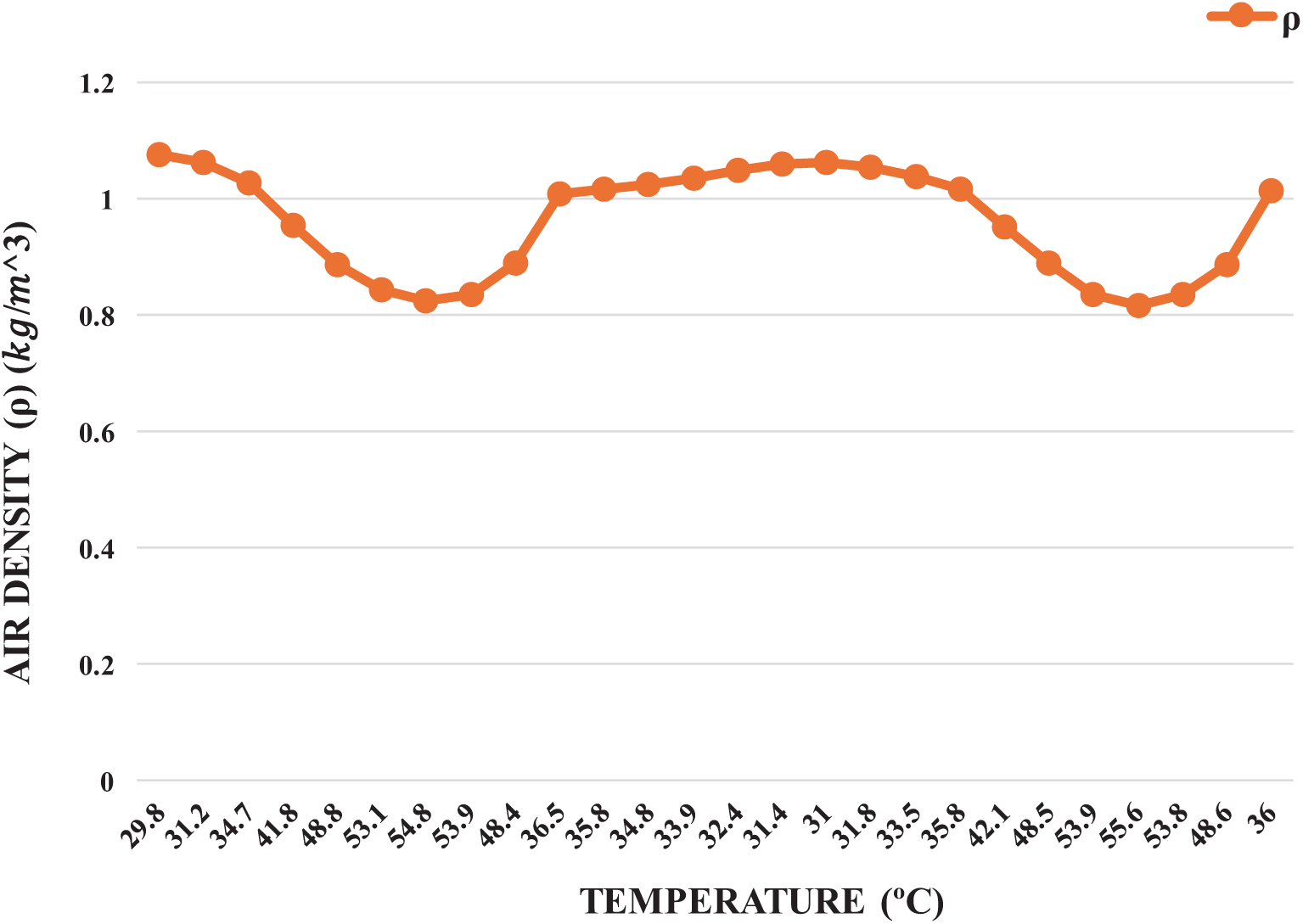

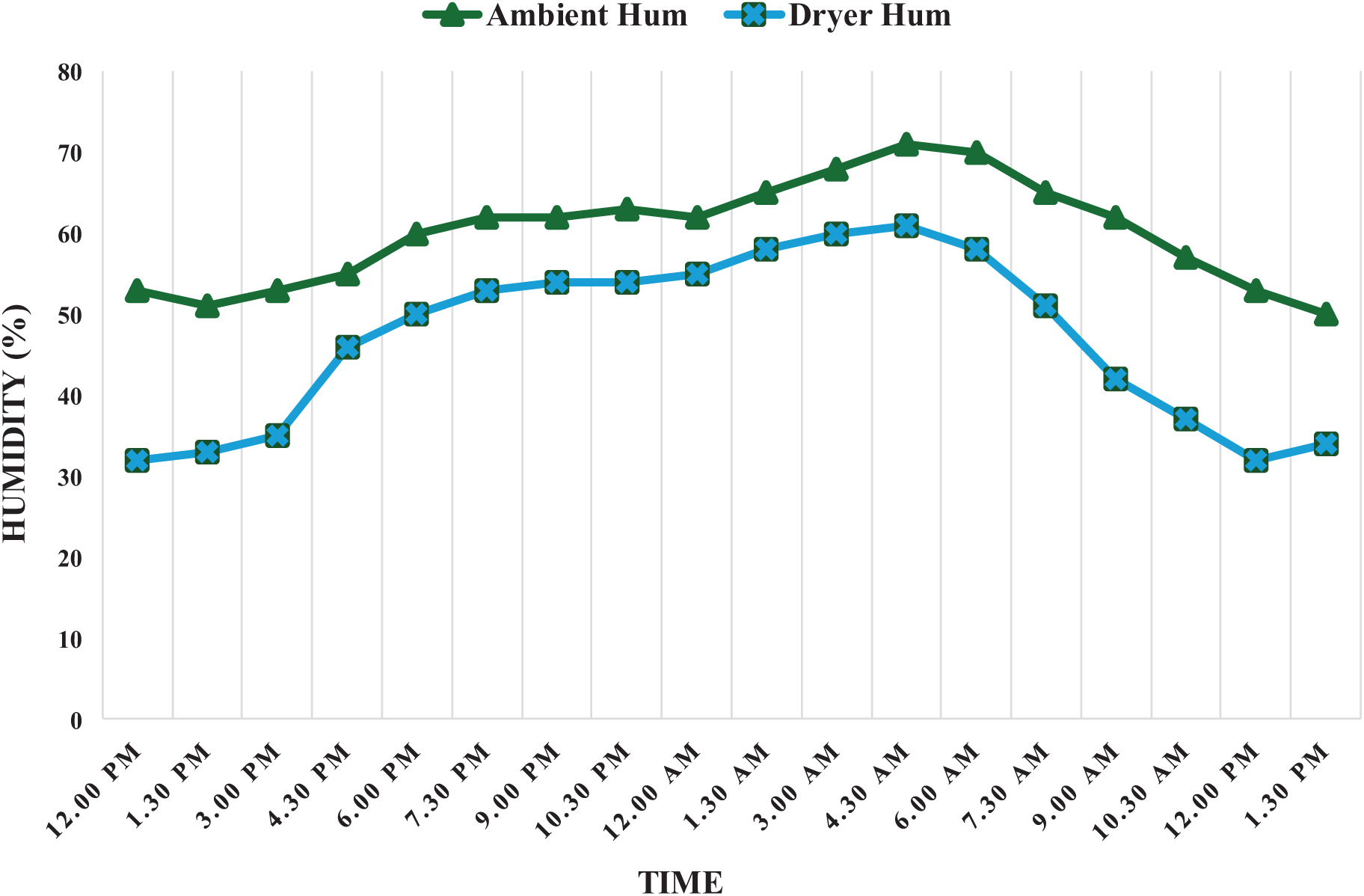

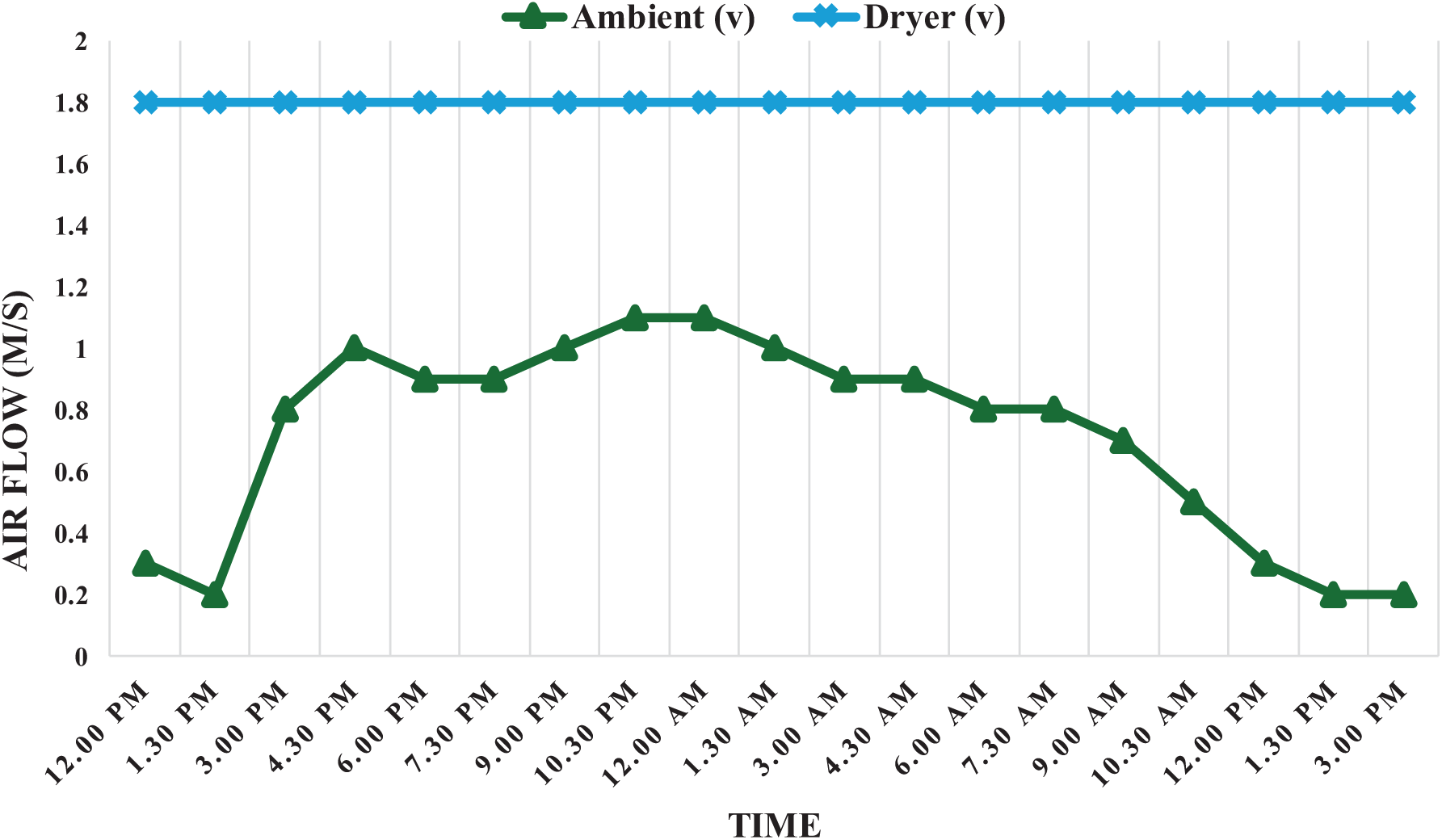

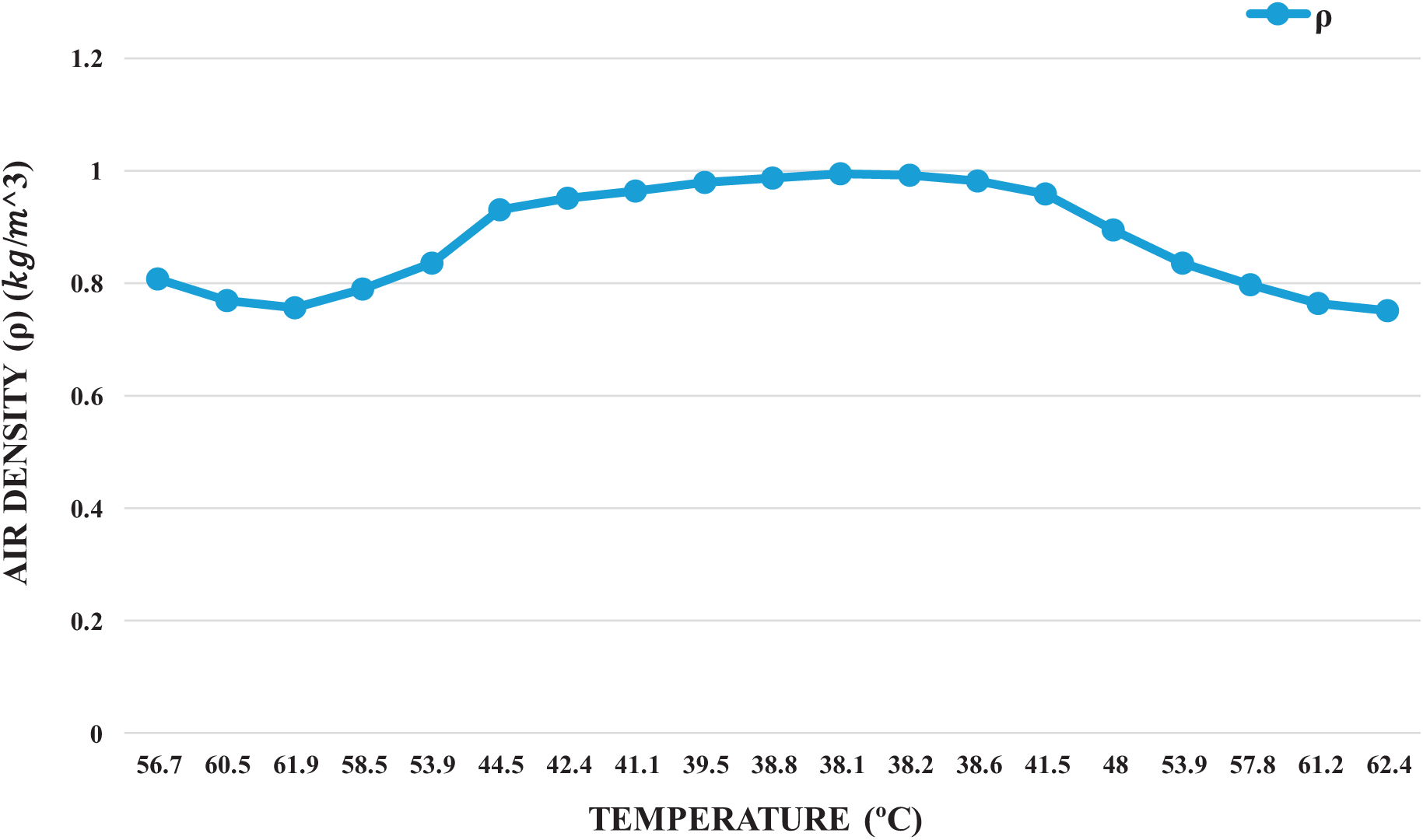

Without forced airflow or additional heating, this drying mode exhibited significant variability in internal humidity, particularly during evening hours when cooler conditions led to increased condensation within the dryer. The ambient humidity fluctuated between 57% and 77% during peak sunlight and non-peak hours, respectively. Similarly, the internal humidity of the dryer ranged from 36% to 77% during peak sunlight and non-peak hours, as shown in Fig. 4. Limited ventilation in the natural convection mode resulted in moisture accumulation within the dryer, slowing the evaporation process. Airflow speeds were significantly lower inside the dryer, ranging from 0.1 to 0.2 m/s, compared to ambient air speeds, which varied from 1.9 to 3.3 m/s, as plotted in Fig. 5. The air density at different temperatures is illustrated in Fig. 6.

Figure 4: Ambient humidity and dryer humidity in NCDSD

Figure 5: Ambient air flow and air flow inside dryer in NCDSD

Figure 6: Air density inside the dryer in NCDSD

Moisture Content Reduction and Drying Rate: The initial moisture content of the tomato slices, approximately 94%, decreased gradually over the 55-h drying period, achieving a final moisture content of 28.57% on a dry basis. The drying rate in this mode was relatively low, with an average value of 1.1 61 kg/h. The slow kinetics observed were primarily due to limited air exchange, hindering efficient heat and mass flow rates and resulting in an extended drying period. The mass flow rate observed during experimentation and calculations ranged from a minimum of 0.016702 kg/s to a maximum of 0.044398 kg/s, with an average of 0.032679 kg/s.

3.1.2 Forced Convection Mode with Fans

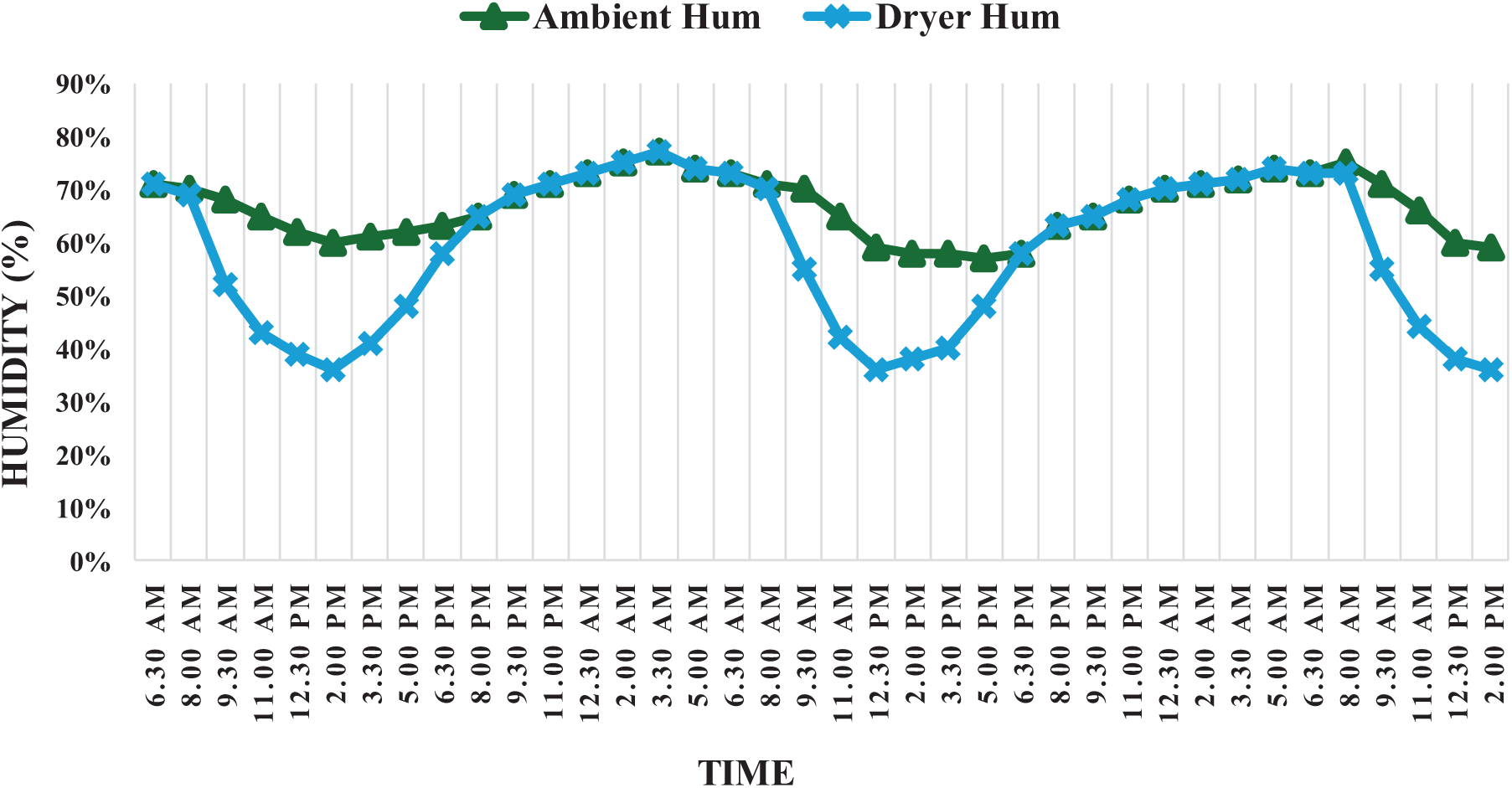

The forced convection setup employed two DC fans to maintain continuous airflow, significantly enhancing the efficiency of the solar drying process for tomatoes. This experiment, conducted on July 15th and 16th, achieved a drying time of over 37.5 h. The solar irradiance data for these days is presented in Fig. 7. With the introduction of forced airflow, the drying chamber demonstrated enhanced temperature stability, with internal temperatures fluctuating between 31°C and 55.6°C, while the ambient temperature at the same time ranged from 31.2°C to 42.1°C, as plotted in Fig. 8. Notably, the maximum solar irradiance recorded was 924 W/m2 at 1:00 p.m. on July 16th.

Figure 7: Solar irradiance plotted for FCDSD

Figure 8: Air temperature inside the dryer in FCDSD

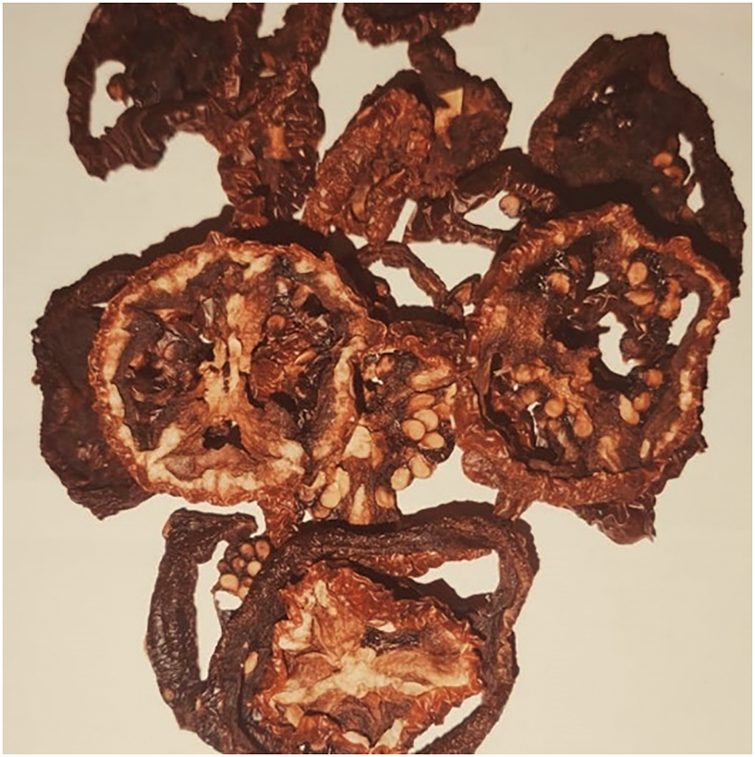

The continuous ventilation provided by the fans reduced thermal stratification, creating a more uniform temperature profile compared to natural convection. This resulted in improved drying conditions and increased efficiency. Furthermore, the airflow generated by the fans also maintained internal humidity levels consistently lower than those in the natural convection mode, with readings ranging from 31% to 71%, compared to ambient humidity levels of 43% to 73%, as plotted in Fig. 9. The operation of the fans ensured optimal airflow inside the dryer, ranging from 1.8 to 2.5 m/s. Thele ambient airflow measured between 1.7 and 3.5 m/s, as shown in Fig. 10. This indicates enhanced control over moisture accumulation within the chamber. The air density throughout the experiment for this setup is plotted in Fig. 11. Compared to the natural convection mode, forced convection resulted in better color retention. The reduced drying time limited oxidative damage, preserving the natural appearance of the dried tomatoes.

Figure 9: Ambient humidity and dryer humidity in FCDSD

Figure 10: Ambient air flow and air flow inside dryer in FCDSD

Figure 11: Air density inside the dryer in FCDSD

Moisture Content Reduction and Drying Rate: The drying time in the forced convection mode was reduced to 37 h, achieving a final moisture content of 16.667% on a dry basis, which indicates a marked improvement over natural convection. The average drying rate increased to 2.062 kg/h, demonstrating the critical role of airflow in accelerating moisture removal from tomato slices. The mass flow rate observed during experimentation and calculations ranged from a minimum of 0.307778 kg/s to a maximum of 0.556025 kg/s, with an average of 0.414289 kg/s.

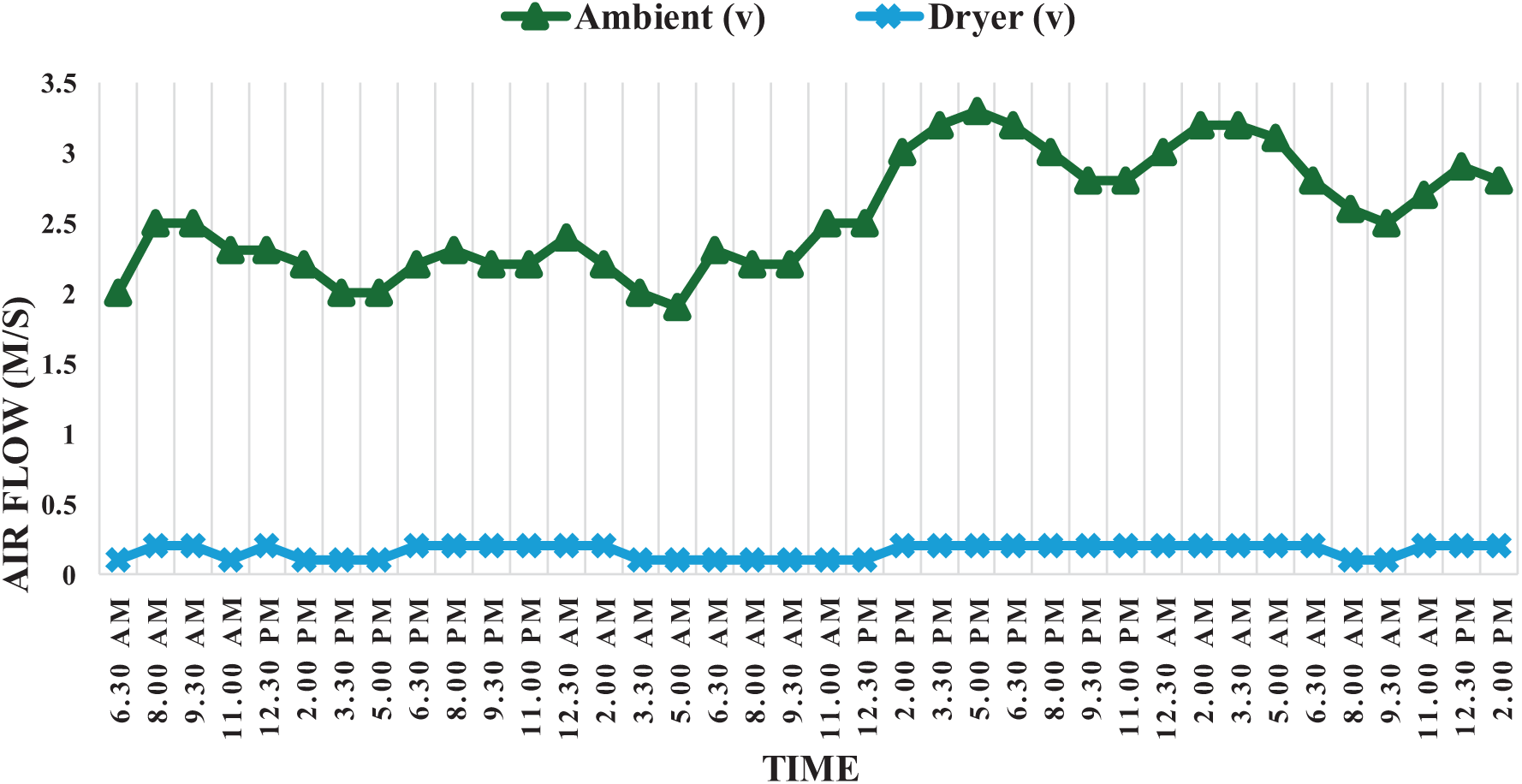

3.1.3 Hybrid Convection Mode with Fans and Heating Element

The hybrid convection setup integrated both fans for continuous airflow and a heating element to provide supplementary heat, ensuring optimal drying performance under various solar conditions. This configuration reduced the drying time to 27 h, with the experiment conducted on July 17th. The maximum solar irradiance observed was 920 W/m2 at 12:00 p.m. The solar irradiance profile for this day is presented in Fig. 12. In this setup, the internal temperature within the drying chamber was consistently high and well-maintained, reaching peak values between 38.2°C and 60.4°C.

Figure 12: Solar irradiance plotted for FCHSD

This was achieved despite ambient temperatures ranging from 31.1°C to 40.3°C, as illustrated in Fig. 13. Unlike forced convection alone, which relies on ambient conditions, the hybrid mode provided additional heat input, maintaining elevated temperatures and ensuring faster moisture evaporation. The heating element worked in conjunction with forced airflow to accelerate moisture removal by preventing temperature fluctuations within the chamber and minimizing reliance solely on solar irradiance.

Figure 13: Air temperature inside the dryer in FCHSD

Since hot air has a higher capacity to hold and remove moisture compared to cold air, the heated airflow in hybrid convection mode dried the tomatoes faster than forced convection alone. Therefore, the internal humidity levels were maintained between 32% and 61%, while ambient humidity ranged from 51% to 71%, as presented in Fig. 14. However, the operation of the fans ensured constant airflow within the dryer at 1.8 m/s, unaffected by fluctuating external airflow. In contrast, ambient airflow varied significantly, ranging from 0.2 to 1.2 m/s, as shown in Fig. 15. This consistent hot airflow contributed to better control over humidity levels within the dryer. This setup provided a warm, low-humidity environment conducive to rapid moisture removal, with minimal condensation within the chamber. The density variations of air at different temperatures are illustrated in Fig. 16. Among all methods, hybrid convection preserved the best product color. The combination of forced airflow and controlled heating significantly minimized prolonged sun exposure, reducing oxidation and retaining the natural red color of tomatoes.

Figure 14: Ambient humidity and dryer humidity in FCHSD

Figure 15: Ambient air flow and air flow inside dryer in FCHSD

Figure 16: Air density inside the dryer in FCHSD

Moisture Content Reduction and Drying Rate: The initial moisture content of the tomato slices, approximately 94%, decreased steadily throughout the 27-h drying period, reaching a final moisture content of 16.67% on a dry basis. This reduction was achieved with an average drying rate of 2.8642 kg/h, showcasing the accelerated drying kinetics enabled by the combined effect of elevated temperature and consistent airflow. The mass flow rate observed during experimentation ranged from a minimum of 0.282193 kg/s to a maximum of 0.3736235 kg/s, with an average of 0.3312054 kg/s. Overall, the hybrid convection mode demonstrated the highest drying efficiency among the setups, with the additional heating element enabling rapid moisture reduction and stable drying conditions. This configuration effectively addressed the limitations of solar drying, providing a reliable and efficient method for drying tomatoes.

Analysis of heat energy absorption revealed substantial variations in the efficiency of each drying method. Owing to reduced airflow that trapped the heat within the dryer leading to maximum accumulation, the Natural Convection Direct Solar Dryer (NCDSD) recorded the highest sensible heat absorption of 53,369.87 J. However, Forced Convection Direct Solar Dryer (FCDSD) absorbed 42,422.39 J due to continuous flow of air, which kept the heat from accumulating indefinitely. The Forced Convection Hybrid Solar Dryer (FCHSD) recorded the least sensible heat absorption (31,989.22 J) because the heating element promoted moisture evaporation at the expense of heat accumulation, thereby favoring the use of latent heat. The FCHSD exhibited significantly higher latent heat absorption of 24.52 J, surpassing the 18.48 J for NCDSD and 11.04 J for FCDSD. The heating element in hybrid mode raised air temperature, improving moisture removal efficiency. This elevated latent heat absorption in the hybrid system indicates its effectiveness in vaporizing moisture during drying. NCDSD absorbed moderate latent heat due to slow drying, while FCDSD had the lowest absorption as airflow increased evaporation but lacked additional heat input. The final dried products obtained after each experimentation are shown in Figs. 17–19 for NCDSD, FCDSD and FCHSD, respectively.

Figure 17: Dried tomatoes sample in NCDSD

Figure 18: Dried tomatoes sample in FCDSD

Figure 19: Dried tomatoes sample in FCHSD

Heat absorption rates also illustrate the efficiency of each method. The NCDSD achieved the highest absorption rate of 141.27 W, followed by the FCDSD at 95.30 W, and the FCHSD at 77.31 W. Although forced convection setups exhibit lower absorption rates, they demonstrate improved heat transfer efficiency due to continuous airflow provided by fans. However, heat loss varied across methods. The NCDSD experienced the highest loss at 4156.90 W, due to passive heating inefficiencies while the FCDSD showed a reduced heat loss of 2419.245 W due to better heat transfer. Conversely, the FCHSD recorded a loss of 4037.00 W, but its enhanced latent heat utilization ensured faster and more efficient drying. These findings confirm that NCDSD retains more sensible heat due to slow air movement, while FCHSD optimizes latent heat absorption through additional heating, enabling faster drying.

From our analysis, it can be said that-Natural convection systems can absorb maximum heat, but the heat is dissipated in these systems due to lack of airflow control. On the other hand, forced convection solely enhances transfer, and there are losses which happen due to states throughout temperature. The hybrid convection mode sustains slightly more ideal conditions on the inside, but with better thermal insulation, such heat loss should be reduced. To enhance the efficiency of future designs, we suggest incorporating improved insulation materials, phase change materials (PCM) for thermal storage, and optimized airflow regulation mechanisms. By addressing heat loss patterns and energy utilization, future solar dryers can achieve even greater efficiency, reducing drying times and energy consumption.

The comparative analysis highlights the distinct advantages and limitations of each drying method, emphasizing the importance of optimizing system design for efficient heat energy utilization and minimizing heat loss.

The thermal efficiency of the various drying methods showed significant disparities. Notably, the Natural Convection Dryer with Solar Drying (NCDSD) had a thermal efficiency of merely 0.24%, underscoring its inefficiencies stemming from limited airflow and inadequate humidity control. In stark contrast, the Forced Convection Dryer with Solar Drying (FCDSD) demonstrated remarkable enhancements, achieving a thermal efficiency of 2.37%. This substantial gain is directly attributable to the boosted airflow generated by the fans, which augments heat transfer and mitigates moisture buildup within the dryer. The Forced Convection Hybrid Solar Dryer (FCHSD) showcased the most impressive thermal efficiency at 5.00%, leveraging the synergistic benefits of forced airflow and supplemental heating. This notable achievement highlights the potential of hybrid systems to optimize thermal management, streamline energy utilization, and elevate overall drying efficiency.

Further evidence supporting these findings is provided by the drying efficiencies of the systems. The Natural Convection Dryer with Solar Drying (NCDSD) displayed a remarkably low drying efficiency of 0.043%. This outcome is attributed to inherent limitations in airflow and temperature control. In contrast, the Forced Convection Dryer with Solar Drying (FCDSD) demonstrated a substantial increase in drying efficiency, reaching 0.160%. This enhancement underscores the significant impact of improved airflow on moisture removal rates. The Forced Convection Hybrid Solar Dryer (FCHSD) surpassed both preceding methods with an impressive drying efficiency of 0.675%. This notable improvement is primarily attributed to the hybrid system’s capacity to maintain optimal temperatures and effectively control humidity levels. Consequently, moisture evaporation from the tomato slices occurred more rapidly.

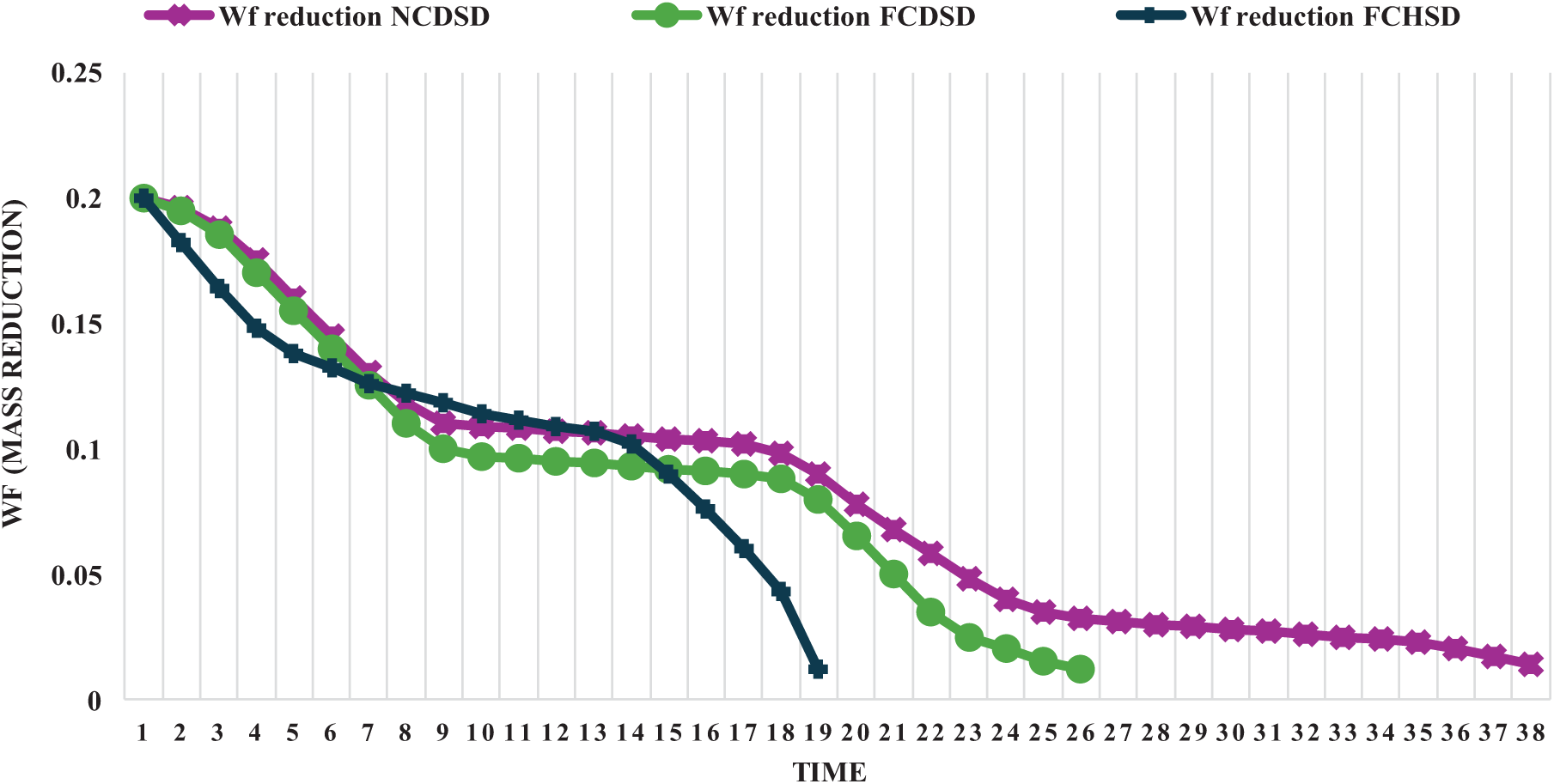

The moisture ratio, a metric indicating the residual moisture content in tomato slices during drying, revealed notable disparities. The Natural Convection Dryer with Solar Drying (NCDSD) exhibited a higher moisture ratio of 0.242, underscoring its slower moisture removal rate. Conversely, both the Forced Convection Dryer with Solar Drying (FCDSD) and the Forced Convection Hybrid Solar Dryer (FCHSD) displayed a significantly lower moisture ratio of 0.101. This highlights their enhanced capability to efficiently reduce moisture content and maintain optimal levels throughout the drying process. These findings emphasize the pivotal role of forced airflow and supplemental heating in accelerating moisture removal and achieving consistent drying outcomes. Although natural convection effectively harnesses solar energy under ideal conditions, its limitations become apparent in prolonged drying times and diminished efficiencies due to inadequate airflow and moisture control.

In stark contrast, the forced convection method substantially enhances these parameters through augmented airflow, thereby optimizing drying performance. However, the hybrid convection setup, which combines forced airflow with supplemental heating, provides the most effective drying conditions overall. This system not only yields the highest thermal and drying efficiencies but also demonstrates rapid moisture reduction, showcasing its potential as a superior solution for solar drying applications, particularly for agricultural products like tomatoes in lesser time. The moisture content was reduced to same percentage in all three experiments, however the time required to achieve this moisture level is varied for each setup as shown in Fig. 20.

Figure 20: Comparison of moisture reduction in all three experiments

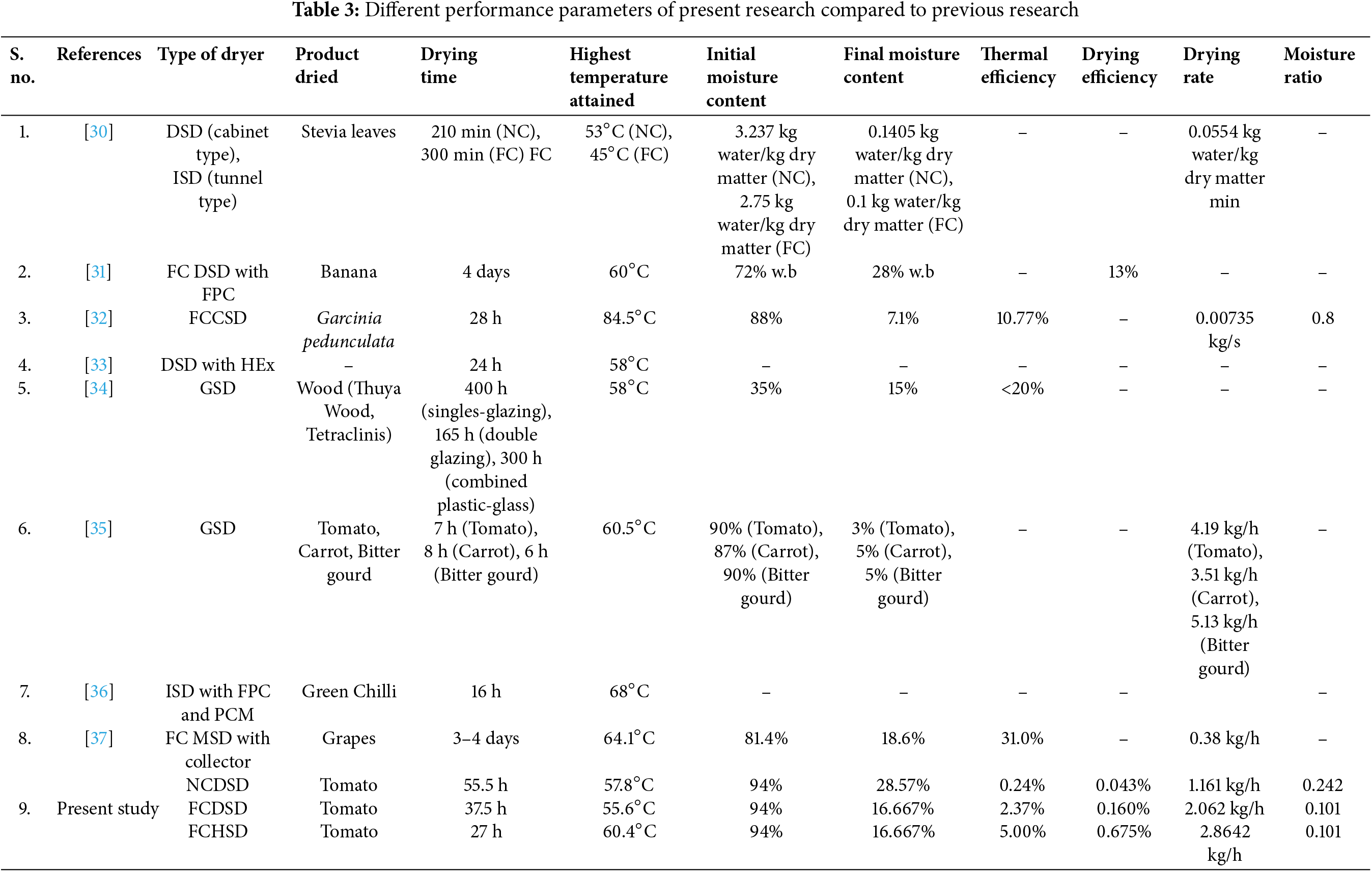

These findings highlight the need for further exploration and optimization of hybrid solar drying technologies to enhance food preservation and reduce post-harvest losses Table 3 presents various research studies on different solar dryer models and provides a comparison with the parameters of the present study’s dryer. It has been found in this study that the rate of precipitation of Forced Convection Hybrid Solar Dryer (FCHSD) is 0.675% which is very high and the researchers who conducted the study found out that it was a lot better than the efficiency of the ones that were built previously in the whole world. There are many factors that could be the direct reason for the high quality in this case but one of the prominent reasons is the creation of forced convection and addition resistance Nickel-chromium (NiCr) element powered entirely by a self-sufficient PV system, which in turn ensures more stable drying conditions and faster moisture removal. In contrast to the earlier dryers that were employing grid electricity or biomass the system that we are using operates independently and hence it allows solar energy to dry continuously even when there is little solar radiation. To the best of our knowledge, the concept of PV-powered resistive heating has never been implemented in the past solar dryers thus our system is more efficient, sustainable and practical for off-grid applications.

4 Conclusion and Recommendations

This study investigated the performance of a hybrid solar dryer in three operational modes—natural convection, forced convection, and hybrid convection—for drying tomatoes. The results demonstrate the effectiveness of the hybrid convection mode in achieving rapid moisture reduction, stable drying conditions, and improved energy efficiency.

• The hybrid convection mode significantly reduced the drying time to 27 h, outperforming natural convection (55 h) and forced convection (37 h) by 51% and 27%, respectively.

• The hybrid convection mode achieved the lowest final moisture content (16.67%), closely followed by forced convection (16.667%), and significantly outperforming natural convection (28.57%).

• The hybrid convection mode exhibited the highest average drying rate (2.8642 kg/h), surpassing forced convection (2.062 kg/h) and natural convection (1.161 kg/h).

• The hybrid convection mode achieved the highest thermal efficiency (5.00%), followed by forced convection (2.37%) and natural convection (0.24%), highlighting its ability to optimize energy utilization.

• The hybrid convection mode demonstrated the highest drying efficiency (0.675%), outperforming forced convection (0.160%) and natural convection (0.043%).

• Hybrid and forced convection modes achieved a 0.101 moisture ratio, ensuring effective moisture removal and humidity control.

Pakistan loses a huge amount of post-harvest products due to inefficiency of drying infrastructure. Traditional methods such as open sun drying are not effective because they waste a lot of time and are weather dependent. Our hybrid solar dryer addresses these challenges by ensuring continuous drying through PV-powered heating, reducing spoilage and improving food preservation. This technology can be scaled for rural use, promoting sustainable food production and reducing reliance on unreliable drying techniques.

In conclusion, this study demonstrates the superiority of the hybrid convection mode in solar drying applications, particularly for agricultural products like tomatoes. The combined effect of forced airflow and supplemental heating enables rapid moisture reduction, stable drying conditions, and improved energy efficiency. However, color degradation was observed in the natural convection mode due to prolonged exposure to sunlight. The forced and hybrid convection methods showed improved color retention, with the hybrid mode yielding the best results. To further optimize product quality, future enhancements could include:

• Using a controlled intermittent drying process to reduce prolonged exposure to heat.

• Integrating UV-protective layers in the dryer design to minimize oxidative effects.

• These findings have significant implications for the development of efficient and sustainable solar drying technologies, which can contribute to reducing post-harvest losses and promoting food security in Pakistan.

This prototype is designed for small-scale applications, particularly for rural and household use. Scaling up for industrial applications would require modifications such as increasing the drying cabinet size, adding more trays, using higher-capacity PV panels and heating elements, and optimizing airflow distribution for uniform drying. Integrating the dryer with renewable energy sources and developing smart solar dryers with advanced sensors and automation systems can also enhance its sustainability and efficiency. A comprehensive economic and environmental impact assessment is also recommended.

Acknowledgement: The authors would like to acknowledge Mehran University of Engineering and Technology Jamshoro and Ignite National Technology Fund.

Funding Statement: This study is supported by the Ignite National Technology fund, under National Grassroots Initiatives Program of ICT R&D (NIGRI), Project ID. NGIRI-2024-23901 of 2024.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: Sadaf Gul Unar and Shoaib Ahmed Khatri; data collection: Sadaf Gul Unar, Muhammad Faraz Arain, and Syed Rafay Ahmed Zaidi; analysis and interpretation of results: Sadaf Gul Unar, Shoaib Ahmed Khatri, Nayyar Hussain Mirjat, Muhammad Faraz Arain, and Laveet Kumar; draft manuscript preparation: Sadaf Gul Unar, Shoaib Ahmed Khatri, and Nayyar Hussain Mirjat. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Data available within the article.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Devan P, Bibin C, Shabrin IA, Gokulnath R, Karthick D. Solar drying of fruits—a comprehensive review. Mater Today Proc. 2020;33:253–60. doi:10.1016/j.matpr.2020.04.041. [Google Scholar] [CrossRef]

2. Messina S, González F, Saldaña C, Peña-Sandoval GR, Tadeo H, Juárez-Rosete CR, et al. Solar powered dryers in agricultural produce processing for sustainable rural development worldwide: a case study from Nayarit-Mexico. Clean Circ Bioeconomy. 2022;3:100027. doi:10.1016/j.clcb.2022.100027. [Google Scholar] [CrossRef]

3. Ahmadi A, Das B, Ehyaei M, Esmaeilion F, Assad MEH, Jamali D, et al. Energy, exergy, and techno-economic performance analyses of solar dryers for agro products: a comprehensive review. Sol Energy. 2021;228:349–73. doi:10.1016/j.solener.2021.09.060. [Google Scholar] [CrossRef]

4. Gupta A, Das B, Biswas A, Mondol J. An environmental and economic evaluation of solar photovoltaic thermal dryer. Int J Environ Sci Technol. 2022;19:10773–92. doi:10.1007/s13762-021-03739-8. [Google Scholar] [CrossRef]

5. Singh S, Gill R, Hans V, Singh M. A novel active-mode indirect solar dryer for agricultural products: experimental evaluation and economic feasibility. Energy. 2021;222:119956. doi:10.1016/j.energy.2021.119956. [Google Scholar] [CrossRef]

6. El Hage H, Herez A, Ramadan M, Bazzi H, Khaled M. An investigation on solar drying: a review with economic and environmental assessment. Energy. 2018;157:815–29. doi:10.1016/j.energy.2018.05.197. [Google Scholar] [CrossRef]

7. Saini RK, Saini DK, Gupta R, Verma P, Thakur R, Kumar S. Technological development in solar dryers from 2016 to 2021—a review. Renew Sustain Energy Rev. 2023;188:113855. doi:10.1016/j.rser.2023.113855. [Google Scholar] [CrossRef]

8. Mugi VR, Chandramohan V. Comparison of drying kinetics, thermal and performance parameters during drying guava slices in natural and forced convection indirect solar dryers. Sol Energy. 2022;234:319–29. doi:10.1016/j.solener.2022.02.012. [Google Scholar] [CrossRef]

9. Tomar V, Tiwari G, Norton B. Solar dryers for tropical food preservation: thermophysics of crops, systems and components. Sol Energy. 2017;154:2–13. doi:10.1016/j.solener.2017.05.066. [Google Scholar] [CrossRef]

10. Kumar P, Singh D. Advanced technologies and performance investigations of solar dryers: a review. Renew Energy Focus. 2020;35:148–58. doi:10.1016/j.ref.2020.10.003. [Google Scholar] [CrossRef]

11. Goud M, Reddy MVV, Chandramohan V, Suresh S. A novel indirect solar dryer with inlet fans powered by solar PV panels: drying kinetics of Capsicum Annum and Abelmoschus esculentus with dryer performance. Sol Energy. 2019;194:871–85. doi:10.1016/j.solener.2019.11.031. [Google Scholar] [CrossRef]

12. Lakshmi D, Muthukumar P, Layek A, Nayak PK. Performance analyses of mixed mode forced convection solar dryer for drying of stevia leaves. Sol Energy. 2019;188:507–18. doi:10.1016/j.solener.2019.06.009. [Google Scholar] [CrossRef]

13. Mohammed S, Fatumah N, Shadia N. Drying performance and economic analysis of novel hybrid passive-mode and active-mode solar dryers for drying fruits in East Africa. J Stored Prod Res. 2020;88:101634. doi:10.1016/j.jspr.2020.101634. [Google Scholar] [CrossRef]

14. Bhatti Z, Ilyas SZ, Korai MB, Shar AI. The designing and optimization of solar dryers for improving the quality of dates in Khairpur. Pakistan Pol J Environ Stud. 2022;31(5):4043–50. doi:10.15244/pjoes/148057. [Google Scholar] [CrossRef]

15. Rabha D, Muthukumar P, Somayaji C. Energy and exergy analyses of the solar drying processes of ghost chilli pepper and ginger. Renew Energy. 2017;105:764–73. doi:10.1016/j.renene.2017.01.007. [Google Scholar] [CrossRef]

16. Abi Mathew A, Thangavel V. A novel thermal energy storage integrated evacuated tube heat pipe solar dryer for agricultural products: performance and economic evaluation. Renew Energy. 2021;179:1674–93. [Google Scholar]

17. César L-VE, Lilia C-MA, Octavio G-V, Orlando SS, Alfredo DN. Energy and exergy analyses of a mixed-mode solar dryer of pear slices (Pyrus communis L.). Energy. 2021;220:119740. [Google Scholar]

18. Essalhi H, Benchrifa M, Tadili R, Bargach M. Experimental and theoretical analysis of drying grapes under an indirect solar dryer and in open sun. Innov Food Sci Emerg Technol. 2018;49:58–64. [Google Scholar]

19. Mugi VR, Chandramohan V. Energy, exergy, economic and environmental (4E) analysis of passive and active-modes indirect type solar dryers while drying guava slices. Sustain Energy Technol Assess. 2022;52:102250. [Google Scholar]

20. Maridurai T, Ramesh G, Manivelmuralidaran V, Backiyaraj A, Sathish T, Balakrishnan E. Investigation of fin geometries impact on thermal efficiency of solar dryer. Mater Today Proc. 2021;46:4236–9. [Google Scholar]

21. Hussain I, Ahmad S, Amjad M, Ahmed R. Effect of modified sun drying techniques on fruit quality characters of dates harvested at rutab stage. J Agric Res. 2014;52(3):415. [Google Scholar]

22. Mohammed S, Edna M, Siraj K. The effect of traditional and improved solar drying methods on the sensory quality and nutritional composition of fruits: a case of mangoes and pineapples. Heliyon. 2020;6(6):e04163. doi:10.1016/j.heliyon.2020.e04163. [Google Scholar] [PubMed] [CrossRef]

23. Gbaha P, Andoh HY, Saraka JK, Koua BK, Toure S. Experimental investigation of a solar dryer with natural convective heat flow. Renew Energy. 2007;32(11):1817–29. doi:10.1016/j.renene.2006.10.011. [Google Scholar] [CrossRef]

24. Afzal A, Iqbal T, Ikram K, Anjum MN, Umair M, Azam M, et al. Development of a hybrid mixed-mode solar dryer for product drying. Heliyon. 2023;9(3):e14144. doi:10.1016/j.heliyon.2023.e14144. [Google Scholar] [PubMed] [CrossRef]

25. Ferreira A, Charbel A, Silva J. Experimental analysis of a hybrid dryer. Therm Eng. 2007;6(2):3–7. doi:10.5380/reterm.v6i2.61680. [Google Scholar] [CrossRef]

26. Chaudhari RH, Gora A, Modi V, Chaudhari H. Economic analysis of hybrid solar dryer for ginger drying. Int J Curr Microbiol Appl Sci. 2018;7(11):2725–31. doi:10.20546/ijcmas.2018.711.312. [Google Scholar] [CrossRef]

27. Brouche M, Lahoud C, Lahoud MF, Lahoud C. Solar drying simulation of different products: lebanese case. Energy Rep. 2020;6:548–64. doi:10.1016/j.egyr.2020.09.032. [Google Scholar] [CrossRef]

28. Aymen E, Hamdi I, Kooli S, Guizani A. Drying of red pepper slices in a solar greenhouse dryer and under open sun: experimental and mathematical investigations. Innov Food Sci Emerg Technol. 2019;52:262–70. doi:10.1016/j.ifset.2019.01.001. [Google Scholar] [CrossRef]

29. César L-VE, Lilia C-MA, Octavio G-V, Isaac PF, Rogelio BO. Thermal performance of a passive, mixed-type solar dryer for tomato slices (Solanum lycopersicum). Renew Energy. 2020;147:845–55. doi:10.1016/j.renene.2019.09.018. [Google Scholar] [CrossRef]

30. Téllez MC, Figueroa IP, Téllez BC, Vidaña ECL, Ortiz AL. Solar drying of Stevia (Rebaudiana Bertoni) leaves using direct and indirect technologies. Sol Energy. 2018;159:898–907. doi:10.1016/j.solener.2017.11.031. [Google Scholar] [CrossRef]

31. Nabnean S, Nimnuan P. Experimental performance of direct forced convection household solar dryer for drying banana. Case Stud Therm Eng. 2020;22:100787. doi:10.1016/j.csite.2020.100787. [Google Scholar] [CrossRef]

32. Dutta P, Dutta PP, Kalita P. Thermal performance studies for drying of Garcinia pedunculata in a free convection corrugated type of solar dryer. Renew Energy. 2021;163:599–612. doi:10.1016/j.renene.2020.08.118. [Google Scholar] [CrossRef]

33. Sandali M, Boubekri A, Mennouche D, Gherraf N. Improvement of a direct solar dryer performance using a geothermal water heat exchanger as supplementary energetic supply. An experimental investigation and simulation study. Renew Energy. 2019;135:186–96. [Google Scholar]

34. Bekkioui N. Performance comparison and economic analysis of three solar dryer designs for wood using a numerical simulation. Renew Energy. 2021;164:815–23. doi:10.1016/j.renene.2020.09.126. [Google Scholar] [CrossRef]

35. Philip N, Duraipandi S, Sreekumar A. Techno-economic analysis of greenhouse solar dryer for drying agricultural produce. Renew Energy. 2022;199:613–27. doi:10.1016/j.renene.2022.08.148. [Google Scholar] [CrossRef]

36. Salve S, Fulambarkar A. A solar dryer for drying green chili in a forced convection for increasing the moisture removing rate. Mater Today Proc. 2021;45:3170–6. doi:10.1016/j.matpr.2020.12.360. [Google Scholar] [CrossRef]

37. Pardhi CB, Bhagoria JL. Development and performance evaluation of mixed-mode solar dryer with forced convection. Int J Energy Environ Eng. 2013;4:1–8. doi:10.1186/2251-6832-4-23. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools