Open Access

Open Access

ARTICLE

Infrared and Microwave Radiation Assisted Self-Healing Property of Exfoliated-Graphene Incorporated Styrene-Isoprene-Styrene Nanocomposites

1 Defence Materials and Stores Research and Development Establishment (DMSRDE), Kanpur, 208013, India

* Corresponding Authors: Shilpi Tiwari. Email: ; Dibyendu S. Bag. Email:

Journal of Polymer Materials 2025, 42(1), 187-204. https://doi.org/10.32604/jpm.2025.057322

Received 14 August 2024; Accepted 20 November 2024; Issue published 27 March 2025

Abstract

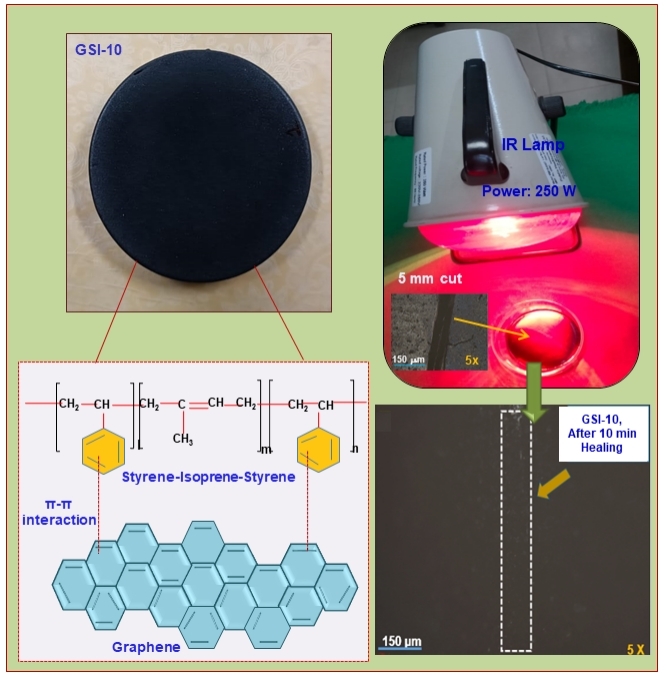

Smart materials with self-healing properties are highly desired. This study investigates graphene-incorporated styrene-isoprene-styrene (SIS) nanocomposites for their self-healing property assisted by Infrared (IR) and microwave radiation. The good thermal conductivity and energy-absorbing capacity of graphene offer self-healing capability to SIS/GnP nanocomposites due to their exposure to IR and microwave radiation. The absorbed energy in graphene is transferred to the SIS matrix, facilitating the diffusion, re-entanglement, and restoration of the SIS polymer chains, resulting in multiple times self-healing capabilities using various external stimuli. All SIS/GnP nanocomposite samples exhibit self-healing behavior, and the healing efficiency rises with increasing GnP content in the nanocomposites and healing time. The cut mark on the SIS/GnP nanocomposite sample (having 10 wt.% of GnP) entirely disappears when the sample is placed in contact with IR radiation (at 250 W) for 10 min. In addition, the sample is completely healed when exposed to microwave radiation (at 900 W) for less than 30 s. The good dispersion of the graphene nanoplates in the SIS matrix was observed in SEM micrographs. Strong interfacial interactions between the SIS copolymer chains and exfoliated graphene (GnP) due to π-π stacking stabilize graphene dispersion against agglomeration. The effect of graphene nanoplates on the SIS thermoplastic elastomer’s thermal stability and phase transition is also studied by Thermo-gravimetric analysis (TGA) and Differential Scanning Calorimetry (DSC) analysis.Graphic Abstract

Keywords

Unique damage detection and self-healing capabilities are observed in biological materials and systems. In these systems, damage incidence initiates internal mechanisms that lead to a healing process and thus prolong the lifespan and safety of the materials. Therefore, numerous researchers have been inspired to develop this particular characteristic of self-healing capability in polymeric materials [1–4]. Polymeric materials have extensive applications, such as structural, aerospace, electronics, and transport, but these materials are inclined to failure after damage. Therefore, various prevalent self-healing approaches have been explored for developing self-healing polymeric materials. These approaches include extrinsic or intrinsic self-healing mechanisms [5,6].

An earlier approach to extrinsic self-healing was reported by White et al. [7] in 2001. The healing strategy was based on releasing healing agents from the pre-embedded healing agents containing microcapsules broken during crack propagation and subsequently curing the healing agent by a dispersed catalyst in the polymer composites.

However, the practical application problem always arises: (i) microcapsules must be broken during crack propagation, and the healing agent should flow out from microcapsules, and also (ii) once healed, no more healing agent is present to heal the crack. Therefore, these healing mechanisms are applicable only for a single time, whereas multiple-time self-healing can be achieved through an intrinsic self-healing mechanism. According to this mechanism, the materials can heal the cracks by forming reversible covalent bonds (such as disulfide, alkoxyamine, and Diels-Alder reaction) [8] or dynamic non-covalent interactions (such as host-guest interactions [9], hydrogen bonds [10], π–π stacking interactions [11], and metal-ligand interactions) [12]. However, in such cases, healing is facilitated by applying light, heat, chemical binders, and others. The heat distribution in the polymeric material can be increased by reinforcing the nanofillers with high thermal conductivity. This leads to an improvement in the heat resistance of the material. Current research focuses on developing innovative self-healing nanocomposite materials with good mechanical properties and healing efficiencies [13,14]. In the past, numerous carbon-based fillers such as graphene [15], CNT [16], and carbon black [17] have also been reinforced into the matrix to develop self-healable elastomeric nanocomposites. The structural and geometrical characteristics of each filler type significantly affect the nanocomposites’ final properties. However, they all work to improve the thermal and mechanical properties of the elastomers. Apart from the continuous developments in self-healing nanocomposite materials, significant progress has been made in using graphene to facilitate the self-healing process.

Among all carbon-based nanofillers, only graphene has many π-electrons, which can be utilized to develop a self-healing material based on π–π stacking interactions (dynamic non-covalent interactions). Graphene is composed of a planar monolayer of sp2 hybridized carbon atoms. These carbon atoms are hexagonally positioned in a two-dimensional honeycomb lattice. The remarkable electronic, optical, thermal, and mechanical properties of graphene have drawn much attention recently. A higher surface area to volume ratio is also one of its significant features. Graphene can be utilized in an extensive range of products, including energy-storage materials, electronic devices, shielding, and anti-static coatings, such as in ballistic uses, automotive, fuel cells, batteries, water purification, waterproof electronics, military protective equipment, tissue engineering and cell culture, sensors, food packaging, aerospace, and others due to its fascinating qualities. Its intriguing properties include optical transmittance (≈98%), high electron mobility, high thermal conductivity (up to 5000 W/mK), and a modulus of elasticity of about 1 TPa [18–20].

Various studies have reported an enhancement in the thermal conductivity due to the incorporation of graphene into the polymer matrix [21–23]. As a result of their planar structure and good thermal contraction, graphene-based polymer nanocomposites have also found fascinating applications as high-performance thermal interface materials. In addition, the graphene’s flawless sp2 carbon network structure results in superior electrical and thermal conductivities. Graphene also exhibits good microwave and IR radiation-absorbing capability. Therefore, inclusion of graphene in the polymer matrix can improve the heat transfer capacity of the composite and its capability to self-heal the micro-damage in response to external stimuli such as heat, IR, and microwave radiation. From this perspective, graphene can be utilized as a potential nanofiller that can absorb energy from external stimuli and transfer this energy to the damaged sites in the polymer materials, thus healing the damage. Hence, appropriate and repeatable self-healing in graphene-based polymer nanocomposites can be achieved by applying electrical energy, IR, and microwave radiation as stimuli. Taking advantage of this property, numerous research groups have previously developed graphene-incorporated elastomeric nanocomposites, which showed good self-healing ability under electromagnetic waves, infrared light, electricity, and others [24].

Han et al. [25] fabricated a graphene-oxide-based supramolecular hydrogel that exhibited self-healing properties at room temperature. The hydrogel was able to repair itself via re-construction of the network when it was damaged by a knife and further stacked together for 1 min. A thermoplastic polyurethane and graphene composite exhibited good mechanical and self-healing properties. These composites tended to heal themselves via electromagnetic waves, IR light, and electricity. The healing efficiency was higher than 98%, and these composites also showed repeatable healing behavior without any decrease in healing efficiency [26]. Xiao et al. analyzed the self-healing properties of a composite of epoxy and nano-layered graphene [27]. Dong et al. developed a self-healing hybrid material made up of graphene, poly (acrylic acid), and poly (acrylamide) [28]. The damaged samples were repaired in 20 min by providing conventional heating at 37°C. It was suggested that enhanced π-interactions due to the large number of π-electrons in graphene led to good healing behavior.

This study aims to develop a self-healing elastomeric composite material that can be repeatedly healed by external stimuli such as microwave and IR radiation. It follows the self-healing mechanism based on π-π stacking interactions. Graphene consists of many π-electrons and exhibits good microwave and IR radiation absorbing capability. Styrene-isoprene block copolymer (SIS) was taken due to the presence of π-electrons, which led to π-π stacking interaction of π-conjugated GnP nanosheets with π-conjugated segments of SIS copolymer.

Therefore, this study incorporates exfoliated graphene (GnP) into thermoplastic elastomers and styrene-isoprene block copolymers (SIS) to develop a self-healing nanocomposite material. SIS copolymers are low-priced, large-volume, high-performance thermoplastic elastomers with low hardness, high strength, and low viscosity for easy thermoplastic processing. These copolymers are produced by ionic copolymerization via sequentially adding styrene, isoprene (2-methyl-1,3-butadiene), and styrene to a reactor. Generally, the percentage of styrene ranges in SIS from 15 to 40 wt.%. The isoprene domain segments offer toughness and flexibility, whereas the styrene segments serve as physical crosslinks, which improve abrasion resistance and mechanical strength when cooled below the melting point [29–31]. These characteristics of graphene and SIS copolymer lead to combining graphene and SIS materials, resulting in self-healing nanocomposite materials with improved mechanical properties and multiple times healing capabilities using various external stimuli.

Exfoliated graphene (Grade M, average diameter 25 µm, Density 2.2 g/cm3, average thickness 6–8 nm, and surface area 120–150 m2g−1) was purchased from XG Sciences, USA and used as received. The styrene-isoprene-styrene block copolymer (SIS, GLOBALPRENE 5517, LCY GRIT CORP, Carlsbad, CA, USA) used in this study comprised of styrene (15–20 wt. %) and isoprene (80–85 wt. %) units. The specific gravity of SIS is 0.93 g/cc, while its melt flow rate is 20 g/10 min at 190°C/2.16 kg load. Tetrahydrofuran (LR) was purchased from Ranbaxy Laboratories Ltd. (Gurugram, India).

2.2 Preparation of SIS/GnP Nanocomposite Films

Nanofillers tend to agglomerate, forming micron-sized clusters. Therefore, uniform nanofiller dispersion is necessary to achieve the desired thermal and mechanical properties. This study employed the ultrasonic method for better graphene dispersion in SIS solution to prepare SIS/GnP nanocomposites.

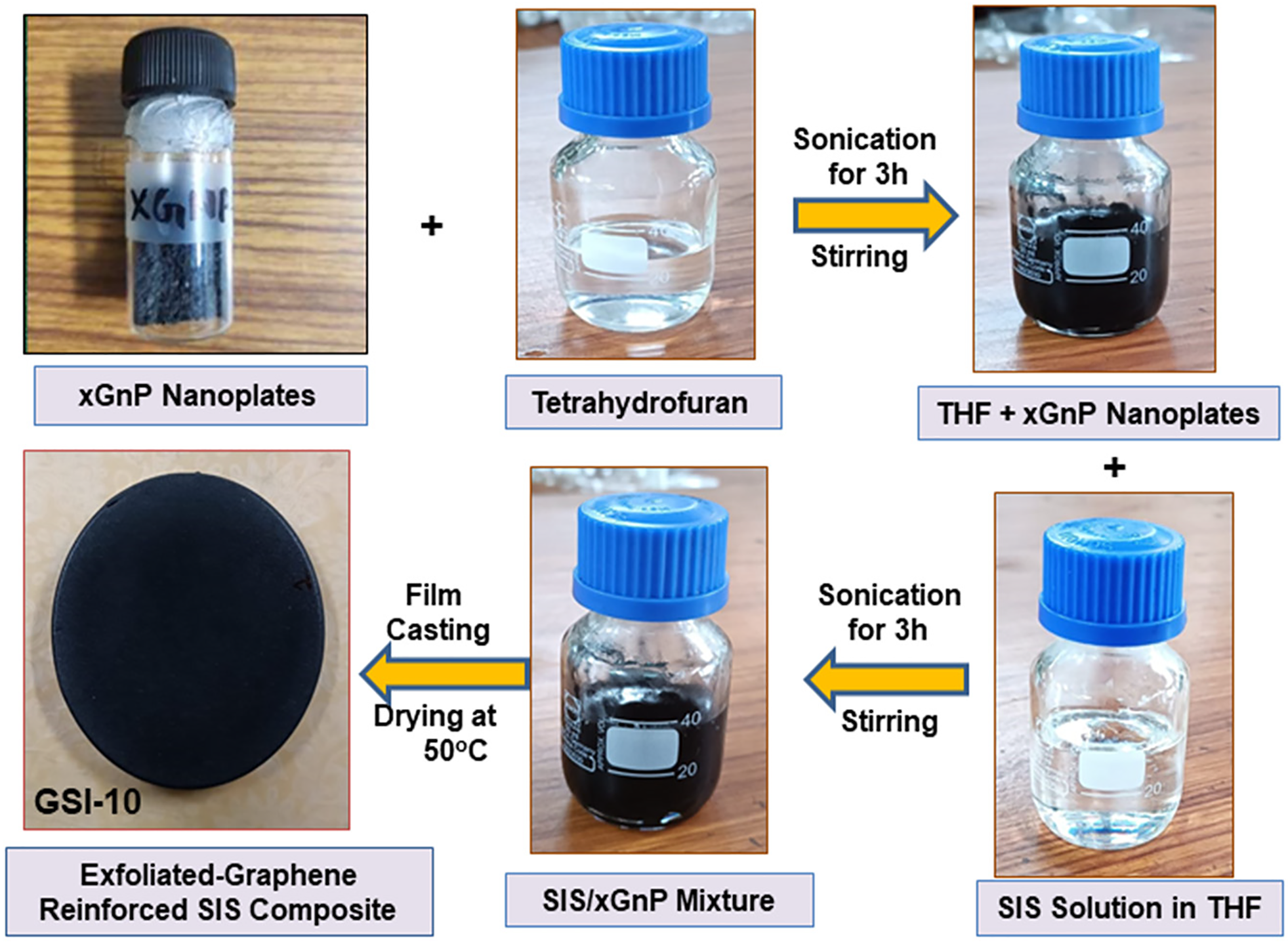

Nanocomposite films of SIS with varying concentrations of graphene (GnP) fillers were fabricated, as depicted in Fig. 1. Firstly, SIS was dissolved in THF for 2 h at 40°C under vigorous stirring to obtain a homogeneous solution. In the second step, different concentrations (1, 3, 5, 7, and 10 wt.%) of GnP powders were dispersed in THF by ultra-sonication (Model No. YJ5120-1, CERoHS, Jiangmen, China) with Ultrasonic Power: 120 W and Heat Power: 75 W for 3 h at room temperature to get stable dispersion of GnP in THF. The samples were designated as GSI-1, GSI-3, GSI-5, GSI-7, and GSI-10. Then, GnP-THF suspension was mixed with SIS solution by another ultra-sonication for 3 h at room temperature. This black viscous solution was transferred to a petri dish to cast the film, which was dried at 50°C for 24 h. The film thickness was 1 mm.

Figure 1: Schematic representation of methodology followed for preparation of SIS/GnP nanocomposites

3.1 Thermo-Gravimetric Analysis

The thermograms and DTG curves were obtained by a thermal gravimetric analyzer (TGA-4000, TA instruments, New Castle, DE, USA). A small quantity of 10 to 20 mg was taken into a platinum crucible and heated in nitrogen gas under a constant flow of 20 mL min−1. The heating temperature ranged from 25 to 700°C with a heating rate of 10°C min−1.

3.2 Differential Scanning Colourimeter

The glass transition temperature of the prepared samples was obtained by DSC analysis. Standard DSC heating, cooling, and heating were performed on a differential scanning calorimeter (DSC2-00918, TA instruments, New Castle, PA, USA), and dry N2 was used as an inert atmosphere. About 20 mg of sample weight was kept in aluminum pans heated at 10°C min−1 from −65 to 400°C, then cooled down to −65°C at 10°C min−1. The sample was again heated to 400°C at 10°C min−1.

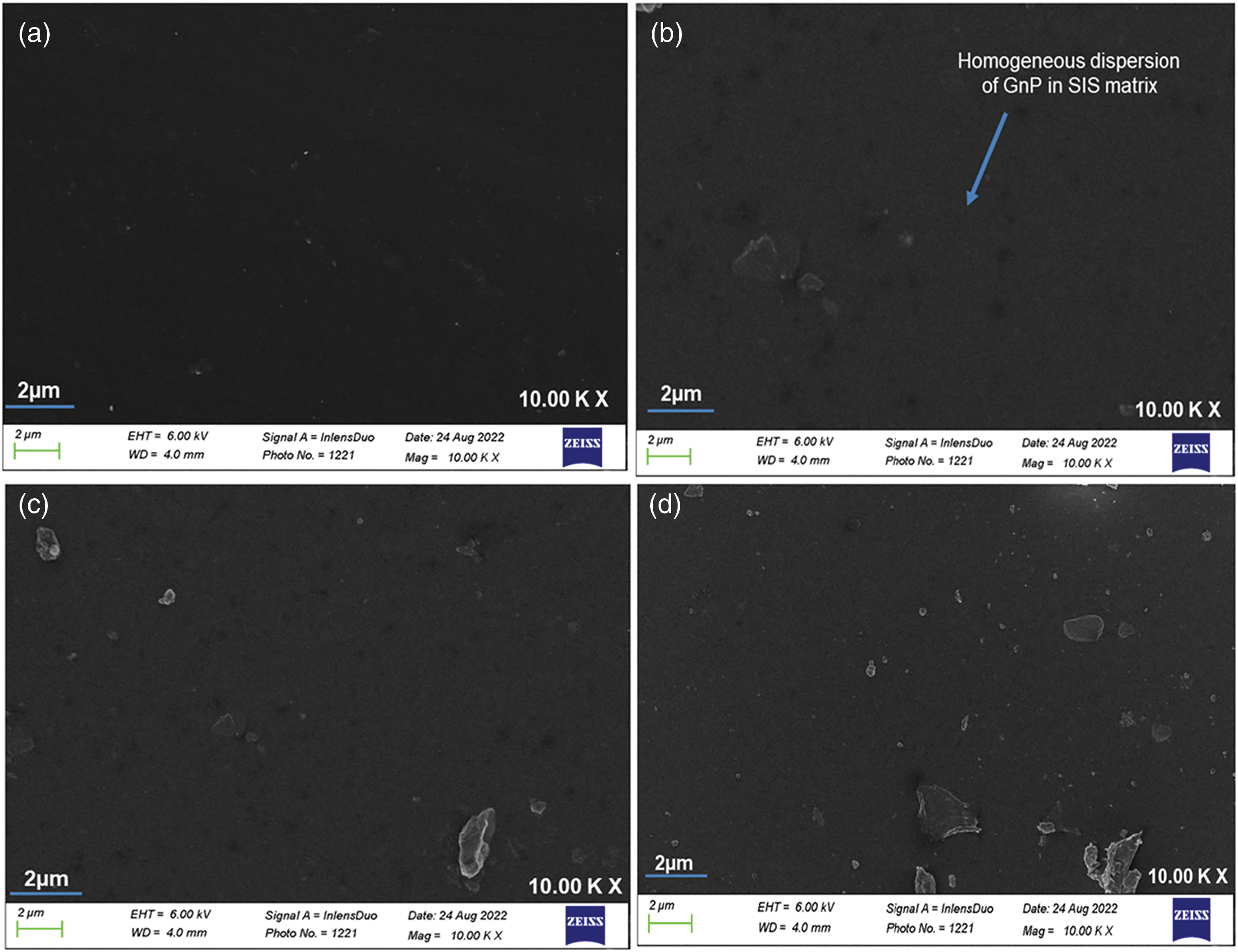

3.3 Scanning Electron Microscope

A scanning electron microscope was utilized to gain a better qualitative understanding of the dispersion of graphene into the SIS matrix. Before analysis, the samples were kept in the sputter, and a thin layer of gold was coated on the surface of the samples. Then, the coated samples were kept in a scanning electron microscope (TESCAN, MIRA-3 LMH, Scientific Instruments, Brno, Czech) operating at an accelerating voltage of 20 kV.

FTIR spectra of neat SIS and SIS/GnP nanocomposite samples were recorded using an FTIR spectrophotometer (Bruker FTIR alpha (ALPHA II), Karlsruhe, Germany). The samples were subjected to FTIR analysis using infrared radiation across 667 to 4000 cm−1 at a scanning rate of 4 cm−1.

A Shore A durometer was used to perform a hardness test as per ASTM D-2240. A hardened steel rod indenter was pressed in this device against the material to ensure it was parallel to the sample’s surface. The hardness of the samples was determined by applying stiff contact pressure for 10 s. The value of hardness was noted by reading the Shore A scale. The test was performed at five points in the sample, and the average value is reported.

Tensile testing of the specimen was performed as per ASTM D 638 (type iv). The dimensions of the dumbbell-shaped tensile specimen were 33 mm in gauge length, 6 mm in width, and 3.2 mm in thickness. The test was conducted using an extension rate of 50 mm/min and a preload of 0.3 Newton (Universal Testing Machine, Model No. 5566, Instron, Norwood, MA, USA) tensile machine. Five samples were tested for each composition of the nanocomposite.

The cut-and-heal approach was followed to study the self-healing properties of the prepared samples. Microwave and IR radiation were employed to facilitate self-healing in the samples. An infrared lamp (FM018-6007, Voltage: 220–250 V, Power: 250 W, and Frequency: 50 Hz, Fidelis Healthcare Pvt., Ltd., New Delhi, India) was utilized as the light source to facilitate the self-healing process in SIS/GnP nanocomposite samples. In the middle of the film samples, a 5 mm cut was made by a razor blade. Then the damaged samples were allowed to heal under near-infrared (IR) light for a certain period (10 and 15 min).

As graphene tends to absorb electromagnetic radiation, a domestic microwave oven (Power: 900 W, and Frequency: 2.45 GHz) was utilized to explore the electromagnetic healing behavior of the nanocomposites (SIS/GnP) samples. The damaged samples were irradiated for 30 s and 2 min.

An optical microscope was employed to observe the healing ability of damaged samples at room temperature, and the samples were assisted in healing under IR light and microwave radiation. After healing for a specified time, the healed samples were examined qualitatively under a 3D optical profilometer (ZETA TM-300, KLA Instruments, Milpitas, CA, USA). The healing was investigated in terms of closure/repair of the cut mark of the film samples.

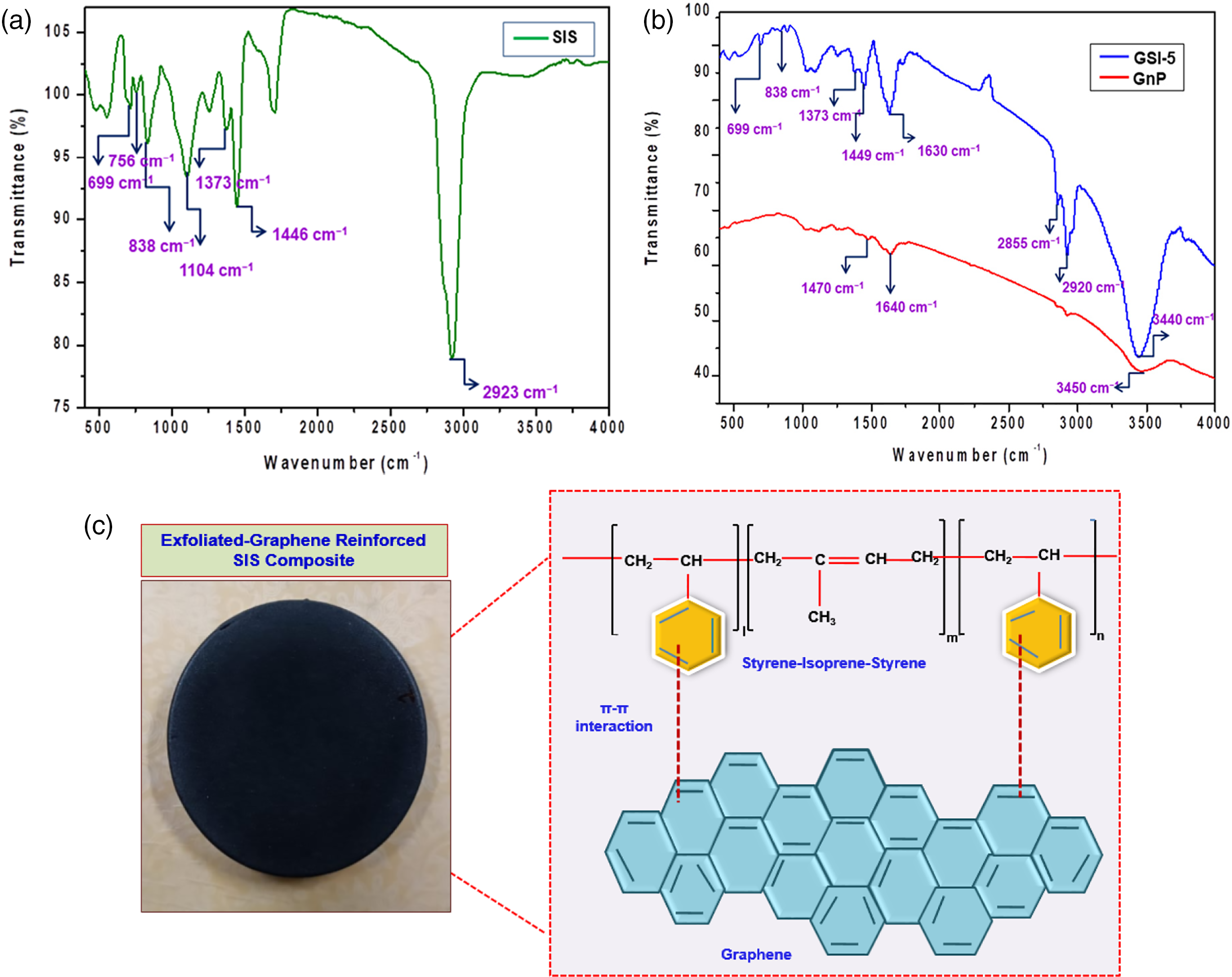

The FTIR spectra of SIS and SIS/GnP nanocomposites are shown in Fig. 2a,b. The peaks at 2923 and 2920 cm−1 represent the asymmetric stretching of CH2 of polymeric alkyl chains, and the peaks at 1446 and 1449 cm−1 correspond to CH2–CH3 bending. The appearance of a peak near 1373 cm−1 shows CH3 bending, while the peak at 838 cm−1 indicates C–H bending of phenyl ring substitution. The peak at 752 cm−1 is related to the C–H bending in alkene, whereas the peak near 699 cm−1 results from mono-substituted benzene, i.e., styrene unit in SIS polymer. Therefore, 838 cm−1 was selected for the isoprene unit, which appears from two severely overlapped peaks, 835 cm−1 from cis-1,4-units and 840 cm−1 from trans-1,4-units [32].

Figure 2: FTIR spectra of (a) SIS, (b) SIS/GnP nanocomposites (GnP and GSI-5), and (c) Schematic representation of π-π interaction between styrene-isoprene-styrene and graphene

FTIR spectrum of GnP is shown in Fig. 2b. An intense peak near 1640 cm−1 of aromatic C=C stretching in graphene is shifted towards a lower frequency, i.e., from 1630–1628 cm−1 [33]. This indicates the π-π stacking interaction of π-conjugated GnP nanosheets with π-conjugated segments of SIS copolymer (Fig. 2c). The peak at 1470 cm−1 is related to the C-H bending vibrations of CH2 groups. In addition, a small peak is located near 3450 cm−1, possibly due to some extent of hydroxyl groups in GnP.

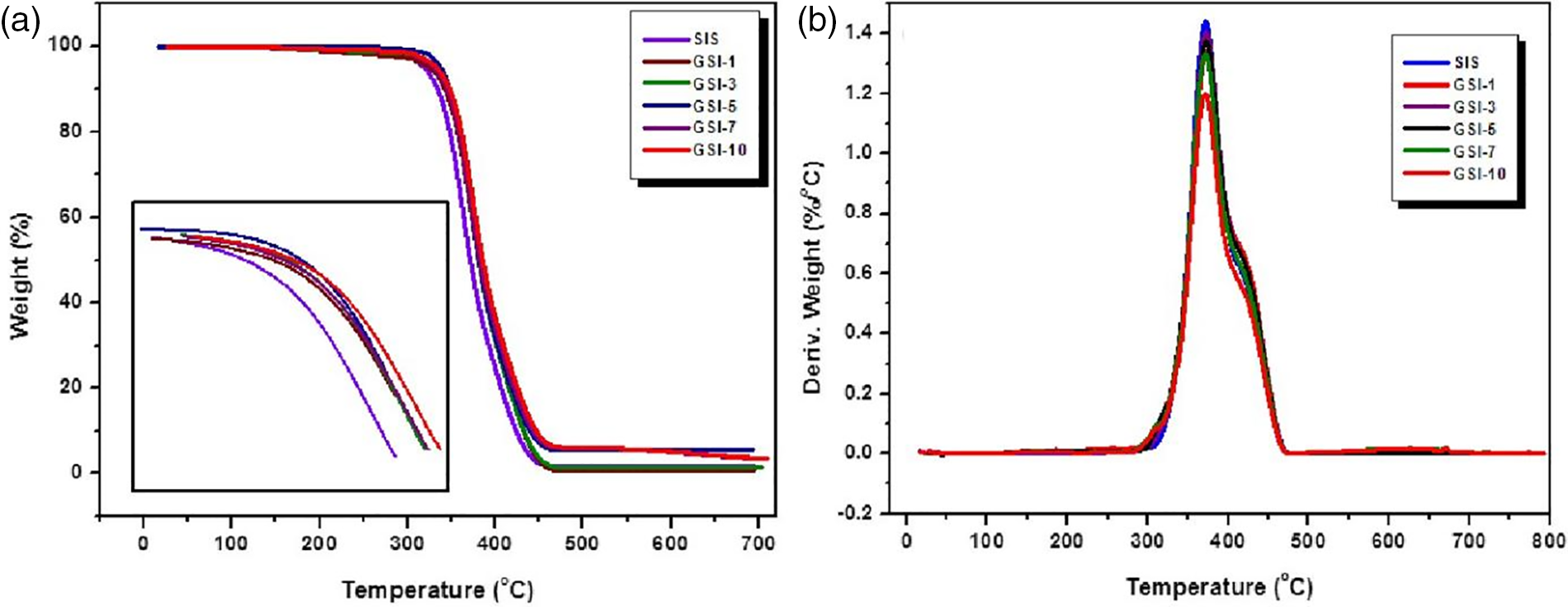

4.2 Thermo-Gravimetric Analysis ( TGA)

Fig. 3a,b depict thermograms of weight loss (TG) and its derivative of weight loss (DTG). The intersection of tangents at the first inflection point and the mid-point of the degradation process are employed to calculate the initial degradation temperature. Thermal degradation curves of nanocomposites indicate that the nanocomposites’ thermal stability and char yield are improved with the incorporation of graphene, and higher thermal stability is observed for the sample with 10 wt.% of graphene. The aromatic groups of SIS copolymer exhibit π-π interactions with π-electrons of graphene, which confines the polymer chains’ flexibility and mobility. Graphene also is a rigid filler that fills the free volume between polymer chains. These phenomena result in an improvement in the thermal stability of the nanocomposites. In SIS copolymer, styrene is a dispersed phase within a continuous isoprene phase. The thermograms showed that the initial degradation temperature for all the SIS/GnP nanocomposites is ~344°C whereas the final degradation temperature is ~418°C (Fig. 3a). The appearance of a single peak in DTG curves indicates the occurrence of a single-step degradation process (Fig. 3b). The decomposition temperature of neat SIS is lower as compared to SIS/GnP nanocomposites. An enhancement in the thermal stability of the SIS/GnP nanocomposites can be credited to the good dispersion of nanofiller, which reduces the free volume between polymer chains and thus lowers the degradation of the nanocomposites. A strong interfacial interaction between π-conjugated GnP nanofiller and π-conjugated segments of SIS copolymer might also represent the cause of the good thermal stability. The dispersion of nanoplates limited the mobility of the polymer chains. In addition, some other factors, such as the rigidity of the nanofillers, the high aspect ratio, and strong interfacial interaction between the nanofiller and the matrix, also contribute to the good thermal stability of the nanocomposite.

Figure 3: (a) Weight loss vs. temperature and (b) derivative weight loss vs. temperature for SIS and SIS/GnP nanocomposites at a heating rate of 10°C min−1

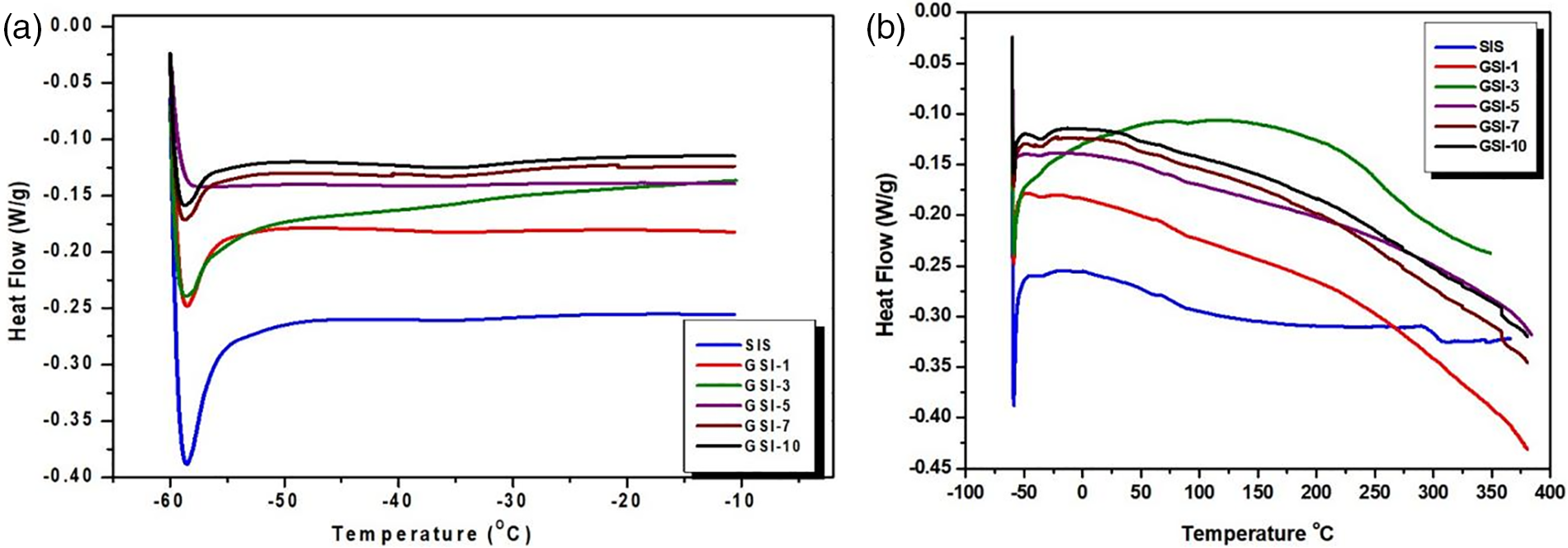

4.3 Differential Scanning Calorimetry (DSC)

The glass transition temperature (Tg) and total enthalpy (ΔH) were obtained by DSC analysis. Fig. 4a,b displays DSC scans of the nanocomposite samples. The area of an exothermic peak attained from DSC analysis was employed to determine the value of ΔH. The value of ΔH was calculated 3.31 J/g for the sample GSI-1, whereas it was found to be 81.02 J/g for the sample reinforced with 5 wt.% of graphene. The ΔH values were calculated to be 107.13 and 163.82 J/g for the samples incorporated with 7 and 10 wt.% graphene, respectively. The improved ΔH values can be attributed to the created constraint in the mobility of the polymer chains due to the inclusion of nanoplates into the SIS matrix. This improvement is particularly impressive when homogeneous dispersion and interfacial interaction are improved. An endothermic peak was observed near Tg, possibly due to an enthalpy recovery process (Fig. 4a).

Figure 4: DSC curve of neat SIS and SIS/GnP nanocomposites at a heating rate of 10°C/min (a) In the temperature range of (−60°C to −10°C) and (b) In the temperature range of (−60°C to −400°C)

The glass transition temperature of the SIS copolymer was obtained to be ~−47°C, and the value of Tg was slightly improved with the incorporation of graphene (Fig. 4b). This improvement in glass transition temperature can be due to the strengthening of the nanocomposite’s rigidity caused by the interaction between the components, which reduces the molecular mobility of polymer chains. The improvement in the enthalpy upon the addition of graphene is due to the strong interaction between SIS copolymer chains and graphene, which restricts the polymer chains’ molecular mobility and flexibility.

The mechanical characteristics of the polymer nanocomposite are controlled by the aspect ratio of the nanofillers and are affected by other factors such as dispersion of filler into the matrix, unintegrated structure of fillers, interfacial bonding, and agglomeration of fillers. The interfacial bonding can affect the ability to transfer load from the polymer matrix to the nanofillers.

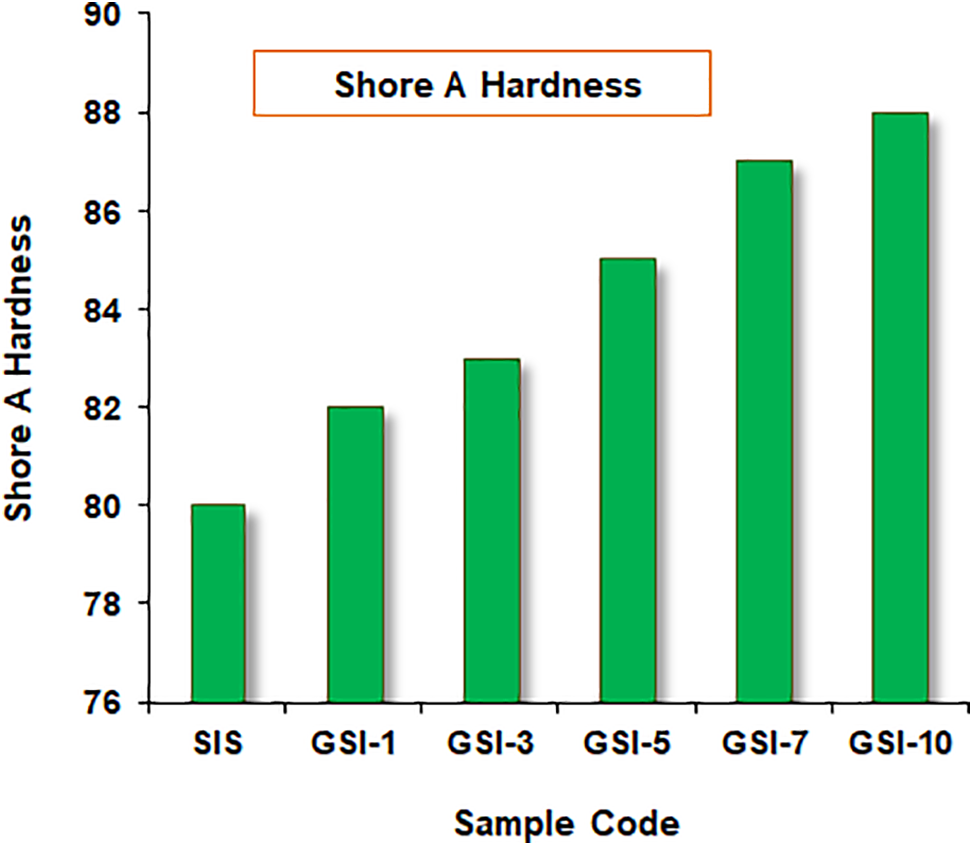

The prepared SIS/GnP nanocomposite samples were characterized for their Shore-A Hardness properties. The results of the hardness test are shown in Fig. 5. The hardness value of all SIS/GnP nanocomposite samples is more than that of virgin SIS copolymers. In addition, the hardness increases with the increasing graphene concentration in the nanocomposite. The improved interfacial bonding between graphene and SIS is responsible for the increase in the Shore A hardness by allowing stresses to be transferred appreciably through the intermolecular structures. The maximum value of Shore A hardness is 88 for GSI-10. This improvement in Shore A hardness is consistent with the high amount of GnP in sample GSI-10. An ascending trend in Shore A hardness is credited to enhanced interaction with styrene phase physical crosslinks. Strong interfacial interactions between the polymer and exfoliated graphene lead to stabilized dispersion against agglomeration.

Figure 5: Graph for variation of Shore A Hardness of neat SIS and SIS/GnP nanocomposites

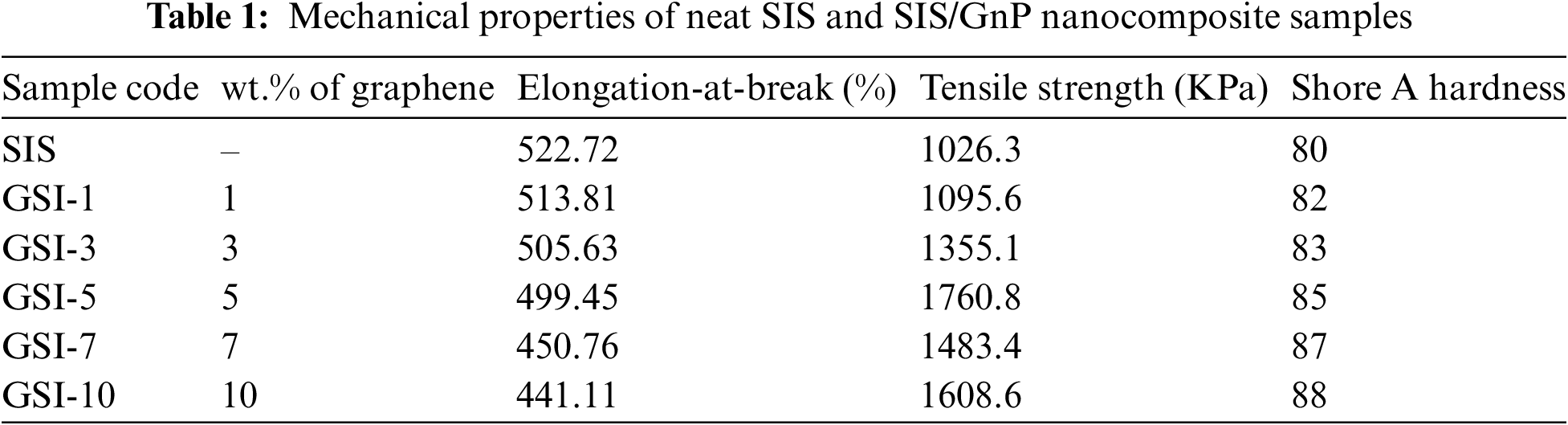

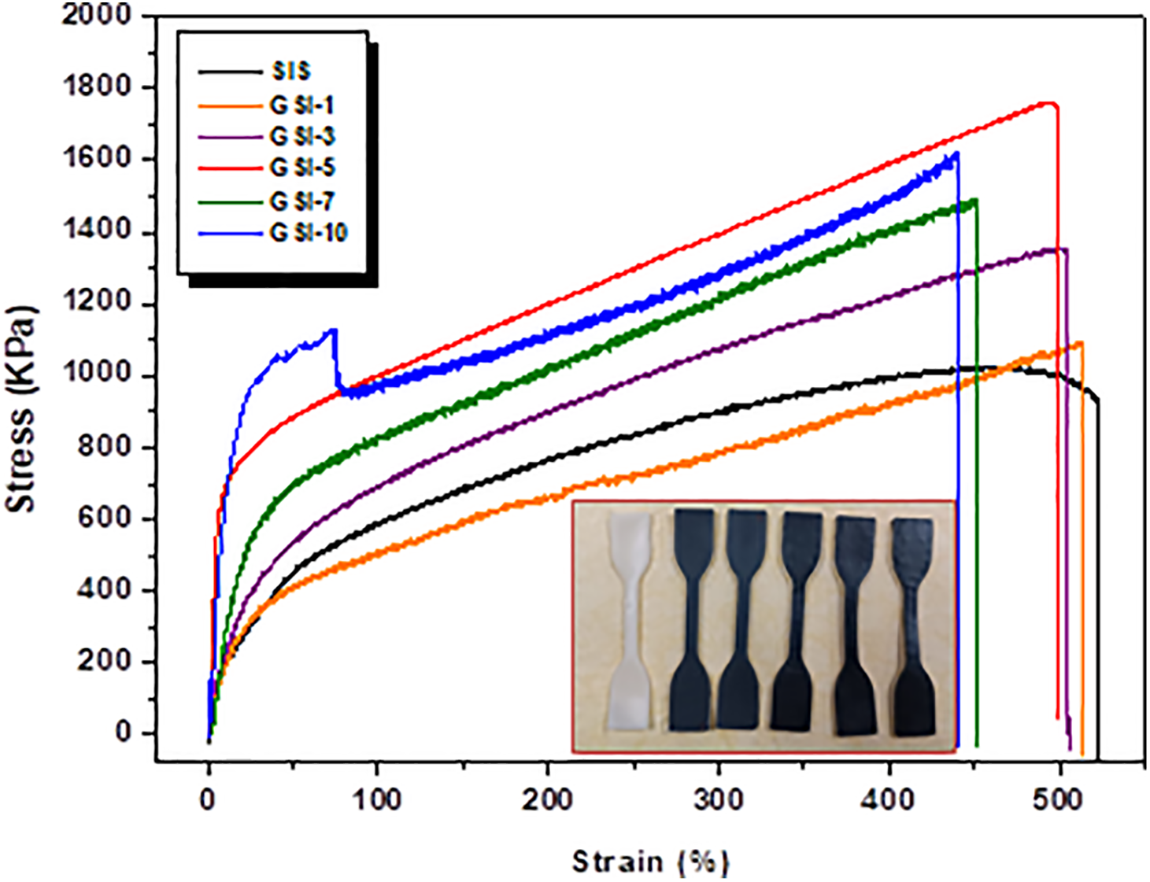

Table 1 represents the effect of adding GnP on Young’s modulus, tensile strength, and elongation-at-break of the nanocomposites. The stress vs. strain curves of neat SIS and SIS/GnP nanocomposites samples are shown in Fig. 6. The value of elongation-at-break and tensile strength of the neat SIS sample was obtained at 522.7% and 1026.3 KPa, respectively. Young’s modulus and tensile strength were found to be increased by adding a nanofiller into the SIS polymer matrix. On adding 1 and 3 wt.% of GnP into the SIS copolymer matrix, the tensile strength improved to 6.75% and 32.03%, respectively, whereas a diminution in the elongation-at-break was observed.

Figure 6: Stress vs. strain graph of neat SIS and SIS/GnP nanocomposite samples

The relative stiffness is associated with the Young’s modulus. The stiffness of composites is increased by the addition of nanofillers, which lowers the elongation-at-break. With 5 wt.% loading of GnP, the elongation-at-break for the sample (GSI-5) is 4.45% lower than neat SIS. The elongation-at-break for sample GSI-10 was 15.63% lower than that of neat SIS. This can be credited to a high GnP content, which increases stiffness. It indicates that GnP provides good stiffness to SIS/GnP nanocomposites. The maximum tensile strength value, i.e., 1760.8 KPa, was obtained for the sample with 5 wt.% of GnP. This was about 71.56% higher than that of neat SIS. This enhancement in the tensile strength can be attributed to the higher surface area compared to the volume ratio of graphene, which improves the interfacial interaction between filler and matrix. The GnP was uniformly dispersed between the interface of styrene and isoprene units, which improved the strength of the material. The reinforcing material, GnP, also acts as a cross-linker due to π-π interactions between filler and matrix in SIS/GnP nanocomposites. As a rule, a high interaction area between nanofiller and polymer may contribute to a substantial stress transfer from polymer matrix to nanofillers.

Hence, GnP is expected to be a good reinforcing material due to its large surface area and high aspect ratio, which allow the fillers to integrate their high strength and stiffness into the bulk polymeric material [34]. Fillers tend to constrain the crack propagation, which can eventually interrupt the failure of the material. With the further increase of the content of GnP from 7 to 10 wt.%, the tensile strength of the nanocomposite was dramatically reduced. The tensile strength values for the GSI-7 and GSI-10 samples were 1483.4 and 1608.6 KPa, respectively. Higher loading of nanofiller results in the formation of some micron-sized clusters, which prevent the uniform dispersion of the filler into the matrix and, thus, create some voids or gaps. These voids can act as stress concentration points, which decrease the strength of the material. In most cases, damage is initiated by these aggregated regions, and then, due to external forces, the nanofillers are pulled out, leaving the smooth polymer matrix. These phenomena lead to weak interfacial bonding and thus reduce the mechanical properties.

4.5 Scanning Electron Microscopy (SEM)

In particular, the interfacial interaction between matrix and reinforcement is significant for exploring phase morphology because reinforcement plays a significant role in forming a finer morphology. The overall morphology of neat SIS and SIS/GnP nanocomposites reinforced with different wt.% of GnP was investigated using scanning electron microscopy (SEM). A flat and smooth surface was observed in a neat SIS sample (Fig. 7a), whereas Fig. 7b shows that the surface of the sample, GSI-1, is rougher as compared to neat SIS. The homogeneous dispersion and well-wrapping of GnP in SIS were observed in the micrograph of samples of GSI-3 and GSI-5 when seen under 10 K x magnifications (Fig. 7c,d). SEM micrographs indicated that well-performed interfacial interaction is generated due to the addition of exfoliated graphene, which reduces the voids at the interface and promotes a decrease in the system’s free volume. Thus, it improves the thermal and mechanical properties of nanocomposites. When the concentration of the GnP is moderate, the nanosheets can be uniformly dispersed in the SIS, and this efficiently stimulates the thermal movement of the SIS and makes the surface of the sample rough and complex. Sample GSI-5 demonstrated higher reinforcement efficiency as the micrographs of this sample showed no gaps or voids. The SIS matrix and GnP were well-compatible due to the uniform dispersion of GnP into the SIS matrix. Good interfacial interaction between the filler and matrix promotes good mechanical and thermal properties. Good interfacial adhesion was achieved due to π-π stacking interaction between GnP and SIS copolymer chains. This can be observed in the SEM micrograph figures where GnP was wrapped well with an SIS matrix layer. The entire distribution of GnP nanosheets is facilitated by this π-π stacking interaction, which can also enhance the thermal and mechanical properties of the nanocomposites. Fig. 7e,f indicates that agglomeration is also seen when more GnP is incorporated into SIS, which reduces the material’s mechanical strength.

Figure 7: SEM micrographs of samples (a) neat SIS, (b) GSI-1, (c) GSI-3, (d) GSI-5, (e) GSI-7, and (f) GSI-10

4.6 Study of Self-Healing Property of SIS/GnP Nanocomposites

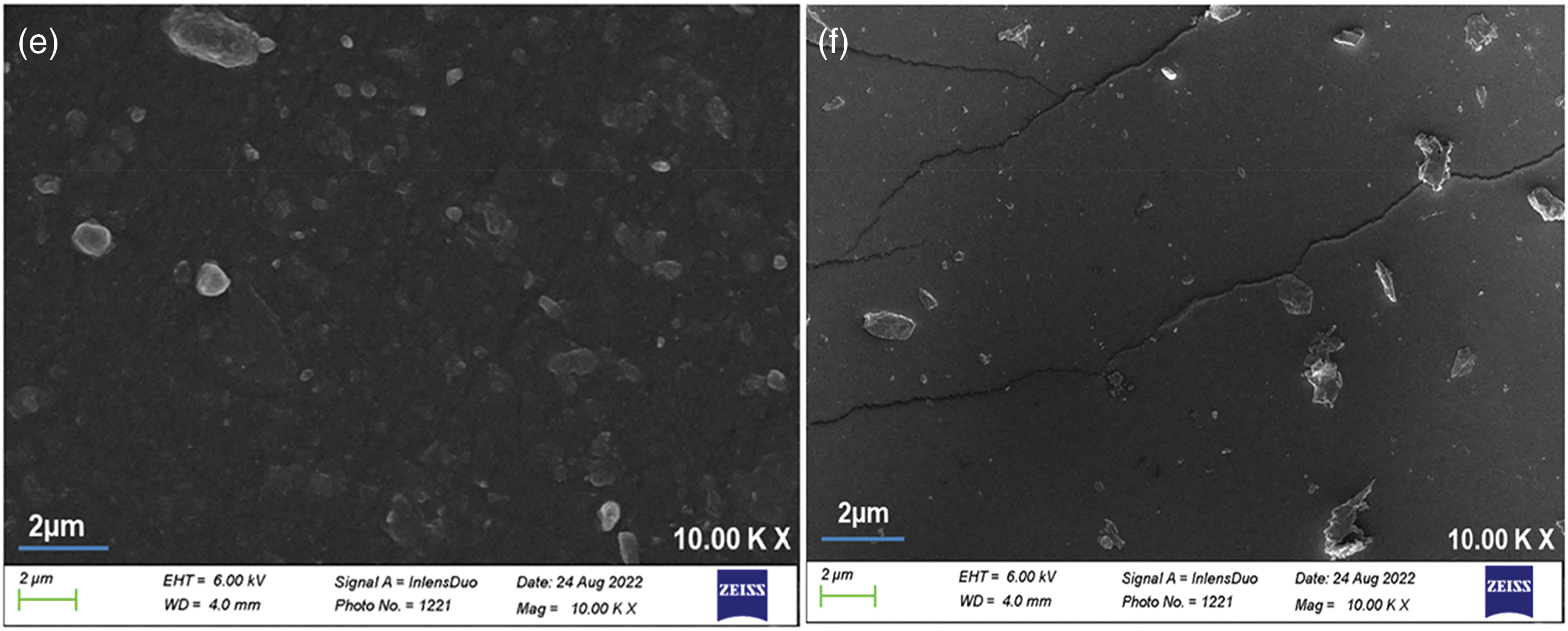

Both IR and microwave radiation were employed to facilitate self-healing in the samples. The self-healing performance of healed SIS/GnP nanocomposite film samples was studied using optical microscope images.

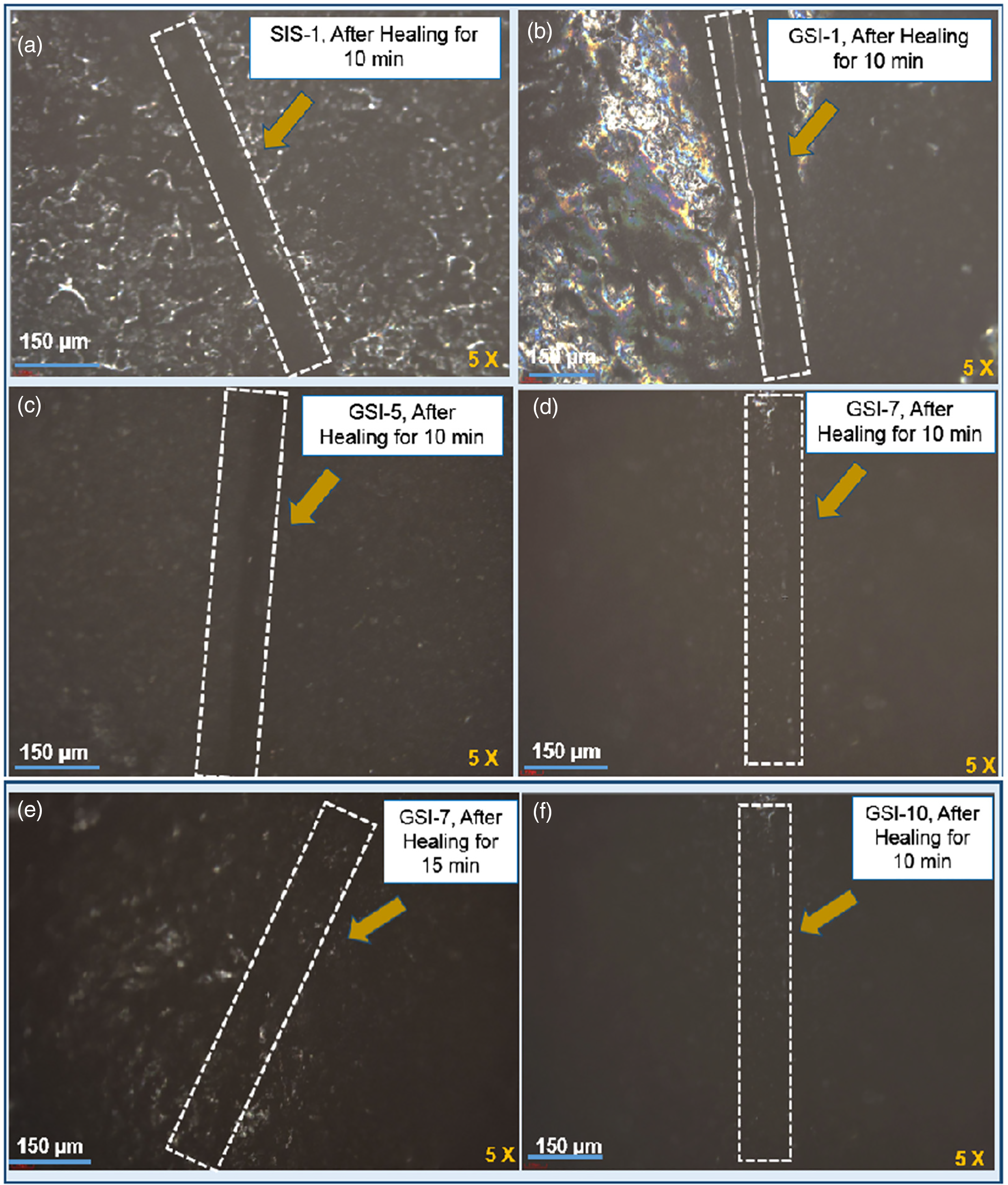

4.6.1 Infrared Assisted Self-Healing

Fig. 8 shows the optical images of samples SIS, GSI-1, GSI-5, GSI-7, and GSI-10 before and after healing assisted by infrared light. Before applying the infrared light, a visible cut is vividly shown in the optical image of the samples SIS, GSI-1, GSI-7, and GSI-10. Neat SIS and all SIS/GnP nanocomposite samples did not show healing at room temperature. This may be due to the limited mobility of the polymer chains at room temperature and the lack of external stimuli like electricity, IR, and microwave radiation. Fig. 8a depicts that the cut mark in the neat SIS sample was not repaired under IR irradiation. Zero healing efficiency was obtained for this sample even after it was exposed to 10 min of IR radiation. The optical micrographs showed that the healing behavior of graphene-reinforced composites was different from the neat SIS matrix. All the samples of SIS/GnP nanocomposites showed healing behavior because graphene exhibits good IR absorbing capacity, thus facilitating the healing process. In addition, an effective transfer of the thermal energy (arises due to the Joule effect) from the IR absorption to the SIS matrix is possible due to the superior thermal conductivity of graphene. The reinforcement (GnP) is an efficient nanoscale heater, and during the healing process, it efficiently transfers appropriate energy to the matrix [26].

Figure 8: Optical microscope images of (a) neat SIS, (b) GSI-1, (c) GSI-5, (d) GSI-7 samples after 10 min infrared assisted self-healing, (e) GSI-7 sample after 15 min infrared assisted self-healing, and (f) GSI-10 sample after 10 min infrared assisted self-healing

All nanocomposite samples showed good self-healing behavior as compared to neat SIS. However, GSI-1 and GSI-3 samples did not show appreciable healing (Fig. 8b), and it can be attributed to the low weight percentage of GnP nanofillers, which cannot provide sufficient energy for interchain diffusion. The healing in the sample GSI-5 is better than in samples GSI-1 and GSI-3 (Fig. 8c). When the GnP concentration is high (7 wt.%), the GnP sheets accelerate the thermal movement of the SIS polymer chains and make the surface of the sample rough. The optical microscopes of the healed SIS/GnP nanocomposite film samples after 10 and 15 min exposure under infrared lamp irradiation are shown in Fig. 8d,e. This can be possible due to inter-diffusion and further solidification of the polymer melt. Maximum self-healing efficiency is obtained for the sample GSI-10. The visible fracture of the cut-off sample, as illustrated in Fig. 8e, completely disappears during the healing process. The damaged site is steadily repaired as the infrared irradiation time increases. In addition, the healing was enhanced by increasing the infrared radiation for 15 min. In all nanocomposite samples, the diameter of the cut mark was less than that after healing by applying infrared radiation for 10 min. In addition, the surface of nanocomposite films becomes bright gradually as the irradiation time increases. These micrographs showed that these samples can fully repair the cut mark. The cut mark on the sample GSI-10 disappeared entirely when the sample was placed in contact with IR radiation for 10 min (Fig. 8f). Nevertheless, some blisters also appeared near the damage zones in the nanocomposite film samples. After healing, the sample’s surface seemed irregular, possibly due to interdiffusion of the polymer melts during the healing process. The GnP significantly enhanced the IR and microwave absorbance, leading to a self-healing SIS/GnP nanocomposite, where the effect was most pronounced with increasing graphene content and irradiation time (Fig. 9).

Figure 9: (a) Comparative qualitative evaluation of effect of graphene concentration on the self-healing property of SIS/GnP nanocomposite assisted by IR radiation (based the results observed in Optical Microscope (Fig. 8)); (b) Images showing IR radiation assisted healing process

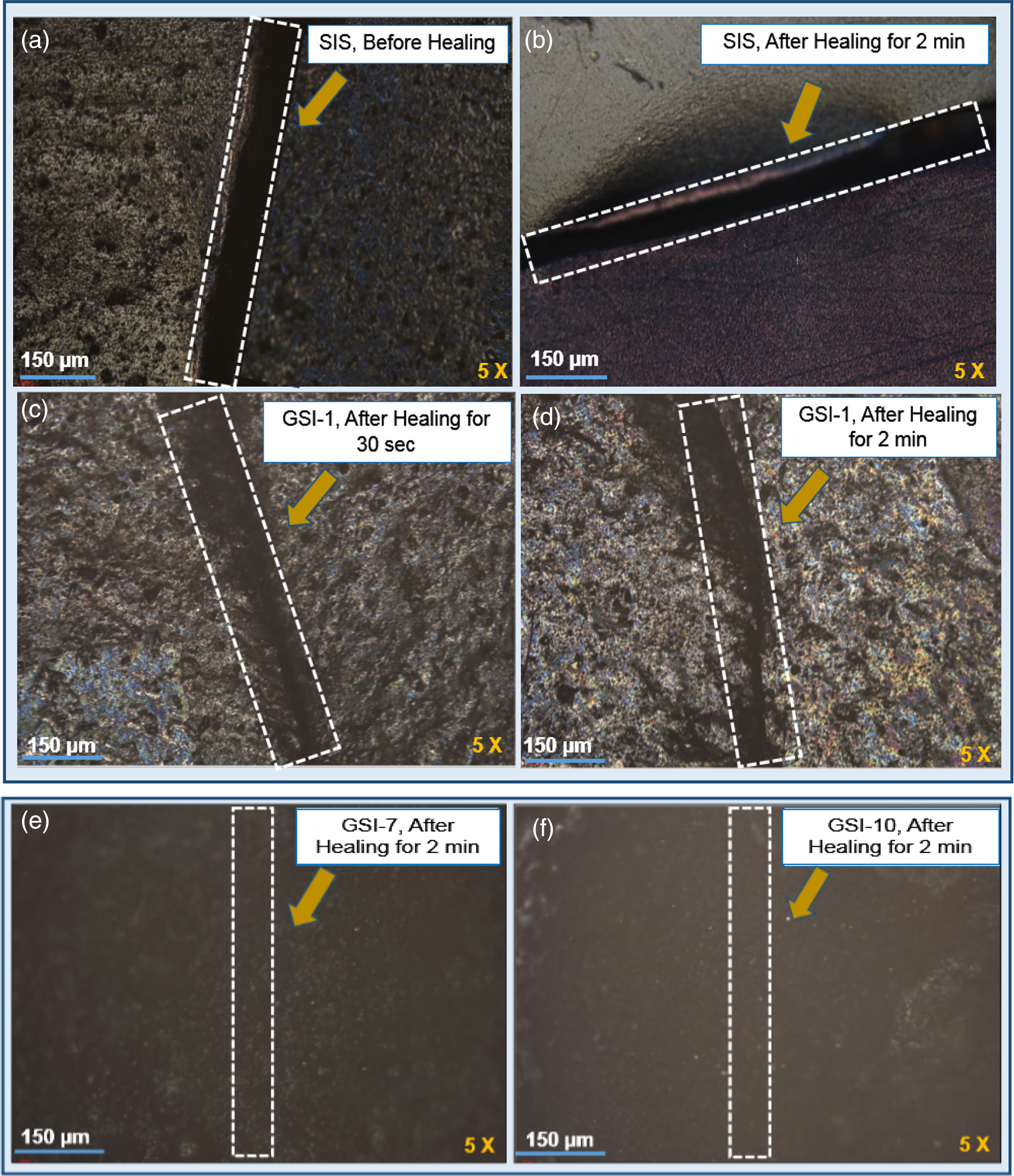

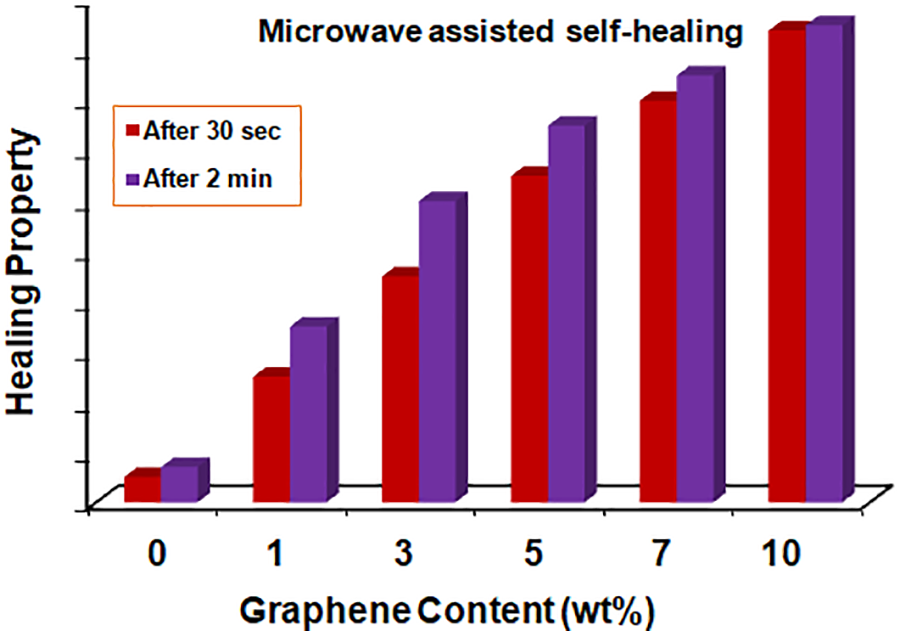

4.6.2 Microwave Assisted Healing

The optical micrographs showed the healing behavior of the samples (before and after exposing them to microwave radiation) for 30 s and 2 min. Fig. 10a,b depicts that the cut mark in the neat SIS sample is not repaired under microwave irradiation. When SIS/GnP nanocomposites were exposed to microwave radiation, the samples were quickly and homogeneously heated. Then, the SIS chains get diffused at the damage site and re-entangled to heal the damage. A sample reinforced with 1 wt.% GnP possessed poor healing efficiency as it cannot be completely healed the crack in 2 min. This can be due to the insufficient availability of GnP; thus, it cannot transfer the heat required for complete healing.

Figure 10: Optical microscope images of (a) and (b) neat SIS samples (before and after microwave radiation healing at 900 W for 30 s and 2 min, respectively), (c) and (d) GSI-1 sample (after microwave radiation healing at 900 W for 30 s and 2 min, respectively), (e) and (f) GSI-7 and GSI-10 samples (after microwave radiation healing at 900 W for 2 min, respectively)

The SIS/GnP nanocomposites reinforced with 5 and 7 wt.% GnP showed efficient healing behavior. It requires a shorter time to achieve healing in the sample GSI-10. Fig. 10c,d indicates that healing is improved with increasing exposure time. The nanocomposite films, which consist of GnP loading of 7 and 10 wt.%, are almost fully healed, demonstrating a superior self-healing ability. The temperature of these film samples rises quickly due to the high photo-thermal conversion efficiency of GnP [35]. The SIS/GnP nanocomposite film samples healed the cut mark when the temperature exceeded the SIS’s glass transition temperature (Tg). This is attributed to the free movement of SIS soft chains, which resulted in wetting, diffusion, and surface rearrangement between the styrene-isoprene-styrene molecular chains. The cut mark completely disappeared for the sample GSI-10, indicating that the time required to attain such high healing behavior was too short. For example, a composite reinforced with 5 wt.% GnP needs 2 min at 900 W to completely heal, whereas a composite reinforced with 10 wt.% GnP needs only 30 s to achieve the same healing efficiency (Fig. 10e,f). The results showed that GnP content and applied exposure time both have a significant effect on the healing efficiency (Fig. 11). This trend is reliable with the results reported by Huang et al. [26] while working on graphene-reinforced thermoplastic polyurethane composites.

Figure 11: Comparative qualitative evaluation of the effect of graphene concentration on the self-healing property of SIS/GnP nanocomposite assisted by microwave radiation (based on the results observed in Optical Microscope (Fig. 10))

The exfoliated graphene (GnP) is incorporated into the styrene-isoprene-styrene (SIS) polymer matrix to improve the thermoplastic elastomer’s properties and facilitate self-healing behavior in the nanocomposites. SEM micrographs revealed good dispersion of the graphene nanoplates in the SIS matrix, indicating that ultrasonication is a highly efficient method for preparing homogeneous nanocomposites. The stress-strain results revealed that SIS/GnP nanocomposite with 5 wt.% graphene has good tensile strength compared to the others. Shore A Hardness was improved by adding nanofillers into SIS, and the maximum value was 87 for GSI-10 (10 wt.% graphene-reinforced SIS nanocomposites). In addition, the sample, GSI-10, was more thermal stable than the other composition, having an initial degradation temperature of 344°C, whereas the final degradation temperature was observed as 418°C.

Graphene-incorporated nanocomposites (SIS/GnP) exhibited good self-healing properties facilitated by IR and microwave radiation. Graphene’s effect on improving self-healing ability was pronounced when the graphene content was increased in the nanocomposite and with the nanocomposites’ exposure/irradiation time. The reinforcing nanofillers GnP is an efficient nanoscale heater. During radiation (IR and microwave) exposure, it efficiently absorbs and transfers the appropriate energy to the SIS matrix, facilitating the healing process due to the interdiffusion, re-entanglement, and restoration of the SIS polymer chains. This type of nanocomposites have multiple times self-healing capabilities with various external stimuli.

Acknowledgement: The authors sincerely acknowledge the contribution of Sudhanshu Mishra, Technical Officer of this establishment, for optical microscope analysis. The authors also acknowledge the Director, DMSRDE, for providing the necessary support to conduct the laboratory research.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm their contribution to the paper as follows: Experimental work, characterization, and drafting of paper: Shilpi Tiwari; Experimental work and characterization: Manjari Srivastava; Review, corrections, and final revision: Dibyendu S. Bag. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data presented in this study are available on request from the corresponding author.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Zhai L, Narkar A, Ahn K. Self-healing polymers with nanomaterials and nanostructures. Nano Today. 2020;30:100826. doi:10.1016/j.nantod.2019.100826. [Google Scholar] [CrossRef]

2. Wu H, Fei J, Huang K, Chen Z, Wei Y, Zhong Q, et al. The role of graphene oxide in dramatically enhancing the mechanical and photo responsive self-healing properties of poly (N, N-dimethylacrylamide) hybrid hydrogels. Mater Res Express. 2021;8:105302. doi:10.1088/2053-1591/ac2bd2. [Google Scholar] [CrossRef]

3. Islam S, Bhat G. Progress and challenges in self-healing composite materials. Mater Adv. 2021;2:1896–926. doi:10.1039/D0MA00873G. [Google Scholar] [CrossRef]

4. Sabet M. Unveiling advanced self-healing mechanisms in graphene polymer composites for next-generation applications in aerospace, automotive, and electronics. Polym Plast Technol And Mater. 2024;63:2032–59. [Google Scholar]

5. Zhu X, Zhang W, Lu G, Zhao H, Wang L. Ultrahigh mechanical strength and robust room-temperature self-healing properties of a polyurethane-graphene oxide network resulting from multiple dynamic bonds. ACS Nano. 2022;16(10):16724–35. doi:10.1021/acsnano.2c06264. [Google Scholar] [PubMed] [CrossRef]

6. Luo X, Wu Y, Guo M, Yang X, Xie L, Lai J, et al. Multi-functional polyurethane composites with self-healing and shape memory properties enhanced by graphene oxide. J Appl Polym Sci. 2021;138:50827. doi:10.1002/app.50827. [Google Scholar] [CrossRef]

7. White SR, Sottos NR, Geubelle PH, Moore JS, Kessler MR, Sriram SR, et al. Autonomic healing of polymer composites. Nature. 2001;409:794–7. doi:10.1038/35057232. [Google Scholar] [PubMed] [CrossRef]

8. Liu Y-L, Chuo T-W. Self-healing polymers based on thermally reversible diels-alder chemistry. Polym Chem. 2013;4(7):2194–205. doi:10.1039/c2py20957h. [Google Scholar] [CrossRef]

9. Zhang L, Wang D, Xu L, Zhang A. A supramolecular polymer with ultra-stretchable, notch-insensitive, rapid self-healing and adhesive properties. Polym Chem. 2021;12(5):660–9. doi:10.1039/D0PY01536A. [Google Scholar] [CrossRef]

10. Yang Y, Urban MW. Self-healing of polymers via supramolecular chemistry. Adv Mater Interfaces. 2018;5(17):1800384. doi:10.1002/admi.201800384. [Google Scholar] [CrossRef]

11. Deflorian F, Rossi S, Scrinzi E. Self-healing supramolecular polyurethane coatings: preliminary study of the corrosion protective properties. Corros Eng Sci Technol. 2013;48(2):147–54. [Google Scholar]

12. Kalista SJ, Ward TC, Oyetunji Z. Self-healing of poly (ethylene-co-methacrylic acid) copolymers following projectile puncture. Mech Adv Mater Struct. 2007;14:391–7. [Google Scholar]

13. Du Y, Li D, Liu L, Gai G. Recent achievements of self-healing graphene/polymer composites. Polymers. 2018;10(2):114. [Google Scholar] [PubMed]

14. Zarepour A, Ahmadi S, Rabiee N, Zarrabi A, Iravani S. Self-healing MXene- and graphene-based composites: properties and applications. Nano-Micro Lett. 2023;15:100. [Google Scholar]

15. Niu P, Bao N, Zhao H, Yan S, Liu B, Wu Y, et al. Room-temperature self-healing elastomer-graphene composite conducting wires with superior strength for stretchable electronics. Compos Sci Technol. 2022;219:109261. [Google Scholar]

16. Bonab VS, Karimkhani V, Manas-Zloczower I. Ultra-fast microwave assisted self-healing of covalent adaptive polyurethane networks with carbon nanotubes. Macromol Mater Eng. 2018;304(1):1800405. [Google Scholar]

17. Zhang L, Zhang J, Liu H, Wu Q, Xiong H, Huang G, et al. Reinforcing self-healing and re-processableIonomers with carbon black: an investigation on the network structure and molecular mobility. Compos Sci Technol. 2021;216:109035. [Google Scholar]

18. Huang X, Qi X, Boey F, Zhang H. Graphene-based composites. Chem Soc Rev. 2012;41(2):666. [Google Scholar] [PubMed]

19. Fu X, Lin J, Liang Z, Yao R, Wu W, Fang Z, et al. Graphene oxide as a promising nanofiller for polymer composite. Surf Inter. 2023;37:10274. [Google Scholar]

20. Tiwari SK, Sahoo S, Wang N, Huczko A. Graphene research and their outputs: status and prospect. J Sci-Adv Mater Dev. 2020;5(1):10. [Google Scholar]

21. Yu H, Chen C, Sun J, Zhang H, Feng Y, Qin M, et al. Highly thermally conductive polymer/graphene composites with rapid room-temperature self-healing capacity. Nano-Micro Lett. 2022;14:135. doi:10.1007/s40820-022-00882-w. [Google Scholar] [PubMed] [CrossRef]

22. Al-Hartomy OA, Al-Ghamdi AA, Al-Salamy F, Dishovsky N, Shtarkova R, Iliev V, et al. Dielectric and microwave properties of graphene nanoplatelets/carbon black filled natural rubber composites. Int J Mater Chem. 2012;2(3):116–22. doi:10.5923/j.ijmc.20120203.06. [Google Scholar] [CrossRef]

23. Araby S, Zhang L, Kuan H-C, Dai J-B, Majewski P, Ma J. A novel approach to electrically and thermally conductive elastomers using graphene. Polymer. 2013;54(14):3663–70. doi:10.1016/j.polymer.2013.05.014. [Google Scholar] [CrossRef]

24. Jilani A, Hussain SZ, Khan AAP, Khan A, Othman MHD, Ansari MO. Graphene-based material for self-healing: mechanism, synthesis, characteristics, and applications, self-healing composite materials from design to applications. In: Woodhead publishing series in composites science and engineering. Cambridge: Woodhead Publishing; 2020. p. 163–75. [Google Scholar]

25. Han D, Yan L. Supramolecular hydrogel of chitosan in the presence of graphene oxide nanosheets as 2D cross-linkers. ACS Sustain Chem Eng. 2014;2(2):296–300. doi:10.1021/sc400352a. [Google Scholar] [CrossRef]

26. Huang L, Yi N, Wu Y, Zhang Y, Zhang Q, Huang Y, et al. Multichannel and repeatable self-healing of mechanical enhanced graphene-thermoplastic polyurethane composites. Adv Mater. 2013;25(15):2224–8. doi:10.1002/adma.201204768. [Google Scholar] [PubMed] [CrossRef]

27. Xiao X, Xie T, Cheng Y. Self-healable graphene polymer composites. J Mater Chem. 2010;20:3508–14. [Google Scholar]

28. Dong J, Ding J, Weng J, Dai L. Graphene enhances the shape memory of poly (acrylamide-co-acrylic acid) grafted on graphene. Macromol Rapid Commun. 2013;34:659–64. [Google Scholar] [PubMed]

29. Drobny J. Properties of styrene-isoprene-styrene block copolymers. In: Drobny J, editor. Specialty thermoplastics. SpringerMaterials; 2015. p. 143–5. [Google Scholar]

30. Špitalský Z, Kratochvíla J, Csomorová K, Krupa I, Graça MPF, Costa LC. Mechanical and electrical properties of styrene-isoprene-styrene copolymer doped with expanded graphite nanoplatelets. J Nanomater. 2015;7:168485. [Google Scholar]

31. Ansari S, Neelanchery MM, Ushus D. Graphene/poly(styrene-b-isoprene-b-styrene) nanocomposite optical actuators. J Appl Polym Sci. 2013;130:3902–8. [Google Scholar]

32. Zhang P, He J, Zhou X. An FTIR standard addition method for quantification of bound styrene in its copolymers. Polym Test. 2008;27(2):153–7. [Google Scholar]

33. Song Y, Yu J, Yu L, Alam FE, Dai W, Li C. Enhancing the thermal, electrical, and mechanical properties of silicone rubber by addition of graphene nanoplatelets. Mater Des. 2015;88:950–7. doi:10.1016/j.matdes.2015.09.064. [Google Scholar] [CrossRef]

34. Papageorgiou DG, Kinloch IA, Young RJ. Graphene/elastomer nanocomposites. Carbon. 2015;95:460–84. doi:10.1016/j.carbon.2015.08.055. [Google Scholar] [CrossRef]

35. Jia P, Shi Y, Song F, Bei Y, Huang C, Zhang M, et al. Bio-based and degradable vitrimer-graphene/graphene oxide composites with self-healing ability stimulated by heat, electricity and microwave as temperature and fire warning sensors. Compos Sci Technol. 2022;227(23):109573. doi:10.1016/j.compscitech.2022.109573. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools