Open Access

Open Access

ARTICLE

Preparation and Properties of Acrylonitrile Butadiene Styrene/Polycarbonate Composite Filament for Fused Deposition Modeling

Naval Architecture and Port Engineering College, Shandong Jiaotong University, Weihai, 264200, China

* Corresponding Author: Jin Ding. Email:

Journal of Polymer Materials 2025, 42(1), 221-236. https://doi.org/10.32604/jpm.2025.058587

Received 15 September 2024; Accepted 16 December 2024; Issue published 27 March 2025

Abstract

Acrylonitrile–butadiene–styrene (ABS) is the main material used in fused deposition modeling (FDM), which has good toughness and strength, but the single ABS material has poor heat resistance, which tends to cause warping and deformation during the printing process. Polycarbonate (PC) exhibits good performance in heat resistance, allowing it to maintain stable performance at higher temperatures. In this work, PC was used as a blending modifier to prepare five kinds of ABS/PC composite filaments, and the mechanical and thermal properties of the ABS/PC (Acrylonitrile–butadiene–styrene/Polycarbonate) composite filaments were studied and analyzed. Results showed that the glass transition temperature (Tg) of the blend increased continuously as the PC content increased. When the mass fraction of ABS/PC was 50/50, the glass transition temperature of the blend increased by 21.21%, and the tensile strength of the composites reached 40.23 MPa, which was an increase of 36.47% compared with that of pure ABS. However, the impact strength of the composites decreased with the addition of PC. Moreover, with the increase in the mass fraction of PC, the printing accuracy error increased from 0.02 to 0.18 mm. The results of this paper will promote the improvement of ABS printing performance and enrich the available materials for FDM.Keywords

3D printing technology fabricates tangible objects from digital models, addressing the issue of precise material distribution control that traditional processing methods struggle to achieve, thus enabling the controlled, quantitative, and on-demand printing of diverse materials. It has broad application prospects in various fields [1–3]. 3D printing technology is mainly divided into Stereo Lithography Apparatus (SLA), Selective Laser Sintering (SLS), Laminated Object Manufacturing (LOM) and Fused Deposition Modeling (FDM), etc. [4]. FDM technology is widely used because of its simple operation and low cost [5,6]. Acrylonitrile–butadiene–styrene (ABS) material is composed of Acrylonitrile (AN), Butadiene (BD) and styrene is a kind of resin with high toughness, high strength and easy processing. However, problems such as warping cracking and poor heat resistance in the printing process of ABS greatly limit its further development [7–9], and stability at high temperatures has become an urgent problem for ABS materials [10].

At present, the performance improvement of ABS is mainly through two aspects: one is to improve the mechanical and thermal properties of ABS materials through material modification, and the second is to improve the overall performance of the material by optimizing the process parameters of the printing process. Since the 20th century, scholars have devoted themselves to studying polymer blending systems to enhance physical properties. Polycarbonate (PC), with its high impact strength, dimensional stability, and toughness, is a widely used polymer for high-strength applications [11,12]. The combination of ABS and PC forms ABS/PC composite materials that combine the mechanical strength of PC with the good workability of ABS [13], which can be used in many different fields, such as electronic housings [14], the automotive industry [15], and building parts [16,17].

Krache et al. analyzed the mechanical and thermal properties of PC/ABS with different mass fractions through impact test, bending test, thermal deflection temperature, and Vicat softening test, as well as examined the morphologies by SEM observation [18]. The test results showed that the composites with 60 wt% PC and 40 wt% ABS exhibited the best mechanical and thermal properties. Yuan et al. found that the addition of PC greatly improved the heat resistance of ABS, as well as the flexural strength and flow rate of the composites [19]. Li et al. conducted a pyrolysis analysis of PC and ABS materials, as well as the pyrolysis behavior of PC/ABS materials from a kinetic point of view, the analysis shows that the PC material will take the lead in pyrolysis to ensure that the ABS material is not affected in the pyrolysis process, which improves the heat-resistant properties of the composite materials [20]. Bi et al. prepared PC/ABS composites with MBS as a compatibilizer by blending and extrusion. Their results showed that the content of PC is proportional to the tensile strength and heat resistance of the composite, and the impact toughness of the composite is optimal when the content of PC reaches 60% [21]. After the addition of MBS, the impact properties of the composite are improved, but the heat resistance and rigidity are reduced. Tambrallimath et al. added graphene flakes to PC and ABS composites and printed them using the FDM technique. The glass transition temperature increased with the addition of graphene flakes [22].

Besides changing the properties of the material itself, the influence of printing parameters on the properties is also important. Mohamed et al. studied the effect of FDM processing parameters on the properties of PC/ABS composites and summarized the optimal processing parameters such as printing direction, slice height and number of filled layers for PC/ABS composites [23]. Nabavi-Kivi et al. investigated the effect of fracture resistance of specimens with different printing speeds using FDM technique and found that 30 and 70 mm/s exhibited the highest and lowest tensile strengths, respectively, which was supported by the combination of SEM cross-section analysis with different fracture angles [24]. Syrlybayev et al. studied the influence of printing parameters such as printing temperature, speed, direction, and heating platform temperature on the tensile and bending properties of ABS materials [25]. Their results showed that proper printing temperature had a good effect on the interlayer porosity and warpage, and high printing speed could enhance the orientation of the molecular chains of ABS materials. The mechanical properties of longitudinal printing samples were generally better than those of transverse printing. Tuan et al. discussed the treatment of various problems during FDM-based printing of ABS materials in terms of pore formation, anisotropic behavior, computer design limitations, and layer-by-layer appearance [26]. They found that direct conversion of computer-aided design (CAD) files to 3D printable slice file format usually led to inaccuracies and defects in the printing of ABS materials, especially in curved surface printing. Shirmohammadi et al. used a mixed artificial neural network model and particle swarm optimization algorithm to test the specimen roughness through five independent parameters [27]. Their results show that the layer thickness is directly related to the surface roughness, and the greater the layer thickness, the greater the surface roughness. With the increase in printing speed, roughness decreases first and then increases. Tran et al. turned off the cooling fan during FDM printing to increase the printing temperature [28]. They found that although high-temperature printing reduced the impact strength, it increased the tensile strength and maximum load-carrying capacity.

To the best of our knowledge, there is no study addressing the impact of PC content and FDM printing parameters on the thermal and mechanical properties of ABS/PC filaments. For this purpose, five ABS/PC composite filaments with different mass ratios were prepared, an orthogonal experimental method was adopted to optimize printing parameters. Compared to pure ABS resin, the heat resistance, melt flowability, tensile and impact mechanical properties were systematically analyzed to investigate the relationship between the PC content and properties of the ABS/PC filaments.

The ABS (757K) and PC (945A) resins were obtained from Zhenjiang Qimei Chemical Co., Ltd., China and Saudi Basic Industry Corporation respectively (SABIC, Riyadh, Saudi Arabia). The original characteristics of ABS and PC are shown in Table 1.

2.1.1 ABS/PC Filaments Preparation

ABS and PC particles in accordance with different ratios were placed in a blender to mix evenly, and all materials were dried at 80°C for 6 h in an air-circulating oven before application. The dried mixed pellets were placed into a single screw extruder (L/D ratio: 14; diameter: 15 mm; SJ15, China). The extrusion temperature of the single screw extruder was set between 220°C and 230°C, the cylinder temperature was set to 90°C–100°C and the rotational speed was set to 600 rpm. In this state, the mixed pellets were prepared into 1.75 ± 0.05 mm wires. The influence of the PC content on the ABS/PC composite filaments preparation is shown in Table 2.

As shown in Table 2, when the mass fractions of ABS/PC were 100/0, 90/10, 80/20, 70/30, and 50/50, good filaments making conditions were observed, and the diameters of the filaments met the requirements. Therefore, the filament was prepared in ratios of 100/0, 90/10, 80/20, 70/30, and 50/50, corresponding to samples P1, P2, P3, P4, and P5, respectively.

According to ISO 527-2:2012 and ISO 180:2019 test standards, the tensile and impact test specimens are drawn using Solidworks 2019 software (Dassault Systemes, Wichita, KS, USA), exported as .stl format files, and sliced by setting printing parameters through ideaMaker slicing software (Flash Print 5, Hangzhou, China). The slicing file was inputted into the FDM printer (Creatpor Pro2, Zhejiang Flash Casting 3D Technology Corporation, Jinhua, China) to print, and the preparation of the tensile and impact test specimens was completed, and the initial parameters of printing were set, as shown in Table 3.

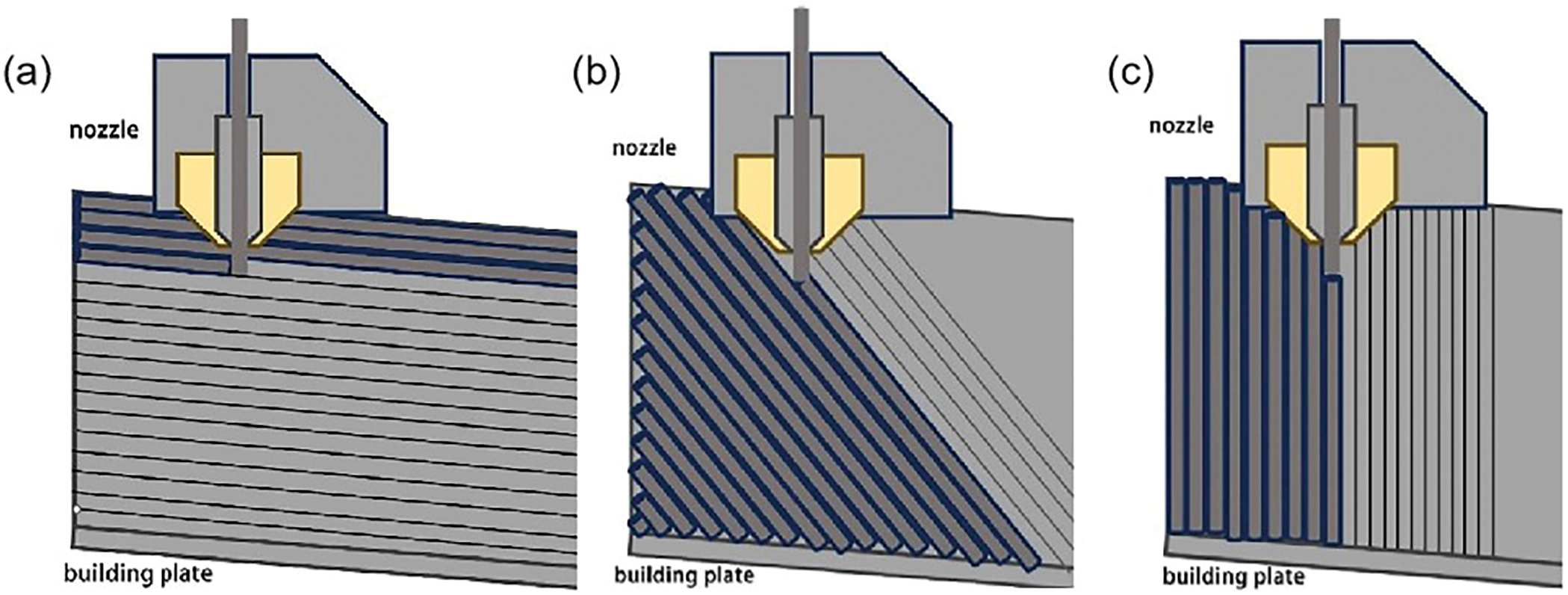

For the printing direction, we evaluated 0°, 45°, and 90°, as illustrated in Fig. 1. During the printing process, we observed that the printing effects of the 0° and 90° directions were unsatisfactory, resulting in cracks and other defects in the printed specimens. Therefore, we selected the 45° printing direction and achieved rapid forming through alternating printing. To ensure the accuracy and reliability of our experimental data, we printed five specimens for each composition, which allowed us to increase the sample size and make the experimental results more robust.

Figure 1: Schematic of FDM print direction. (a) Print direction 0° (b) Print direction 45° (c) Print direction 90°

2.2 Method of Performance Test

The tensile test sample was prepared according to the ISO 527-2:2012 standard. The test was carried out at room temperature, the test speed was 5 mm/min, and five samples were prepared in each group. After the test was completed, the stability parameters of each group of samples were calculated. The average value was obtained, which was regarded as the performance test value.

The impact performance test sample was prepared in accordance with the ISO 180:2019 standard. Before the test, a V-shaped notch was made in the middle position of the sample with an impact notch prototype. The notch depth was 2 mm, and the bottom radius was 0.25 mm. The test was carried out at room temperature, and an energy hammer of 2.75 J was selected for the test. Prepare five samples for each group of tests, after the completion of the test, calculate the average value of each group of experiments as the performance test value to ensure the accuracy of the data.

The impact section morphology was observed by scanning electron microscopy (SEM; EM6900, Beijing Zhongke Technology Co., Ltd., Beijing, China). Before the observation, the surface was sprayed with gold twice.

Digital calipers were used to measure the dimensions of the impact performance test specimens, and the error between the actual specimen thickness dimension and the drawn specimen thickness dimension was measured.

Experiments were carried out on specimens of different ratios using a Melt Flow Rate Meter, where the weight of the shear specimen was weighed using a balance and entered into the instrument to calculate the melt flow rate.

According to ISO 11357-1:2016, the glass transition temperature of different proportions of blends was measured by DSC technology to evaluate the degree of heat resistance improvement. The DSC test was conducted under the protection of nitrogen, heated to 200°C at the rate of 20°C/min, cooled to room temperature after holding for 5 min, and heated to 200°C at the same rate again. The DSC curve was tested and analyzed in the process.

3.1 Influence of Printing Parameters on the Comprehensive Properties of ABS/PC Composites

For this experiment, taking ABS/PC (50/50) as an example, four main FDM printing parameters, namely, platform temperature (A), nozzle temperature (B), filling type (C), and fill density (D), were selected for the L9 (34) orthogonal test. The factors were randomly arranged, the horizontal interaction between the factors was ignored, the results were sorted by range analysis, and the optimal parameter combination was selected. The parameter settings of the FDM printing orthogonal test are shown in Table 4. The influence of FDM printing parameters on the mechanical properties of the ABS/PC composites was analyzed by an orthogonal test, as shown in Table 5.

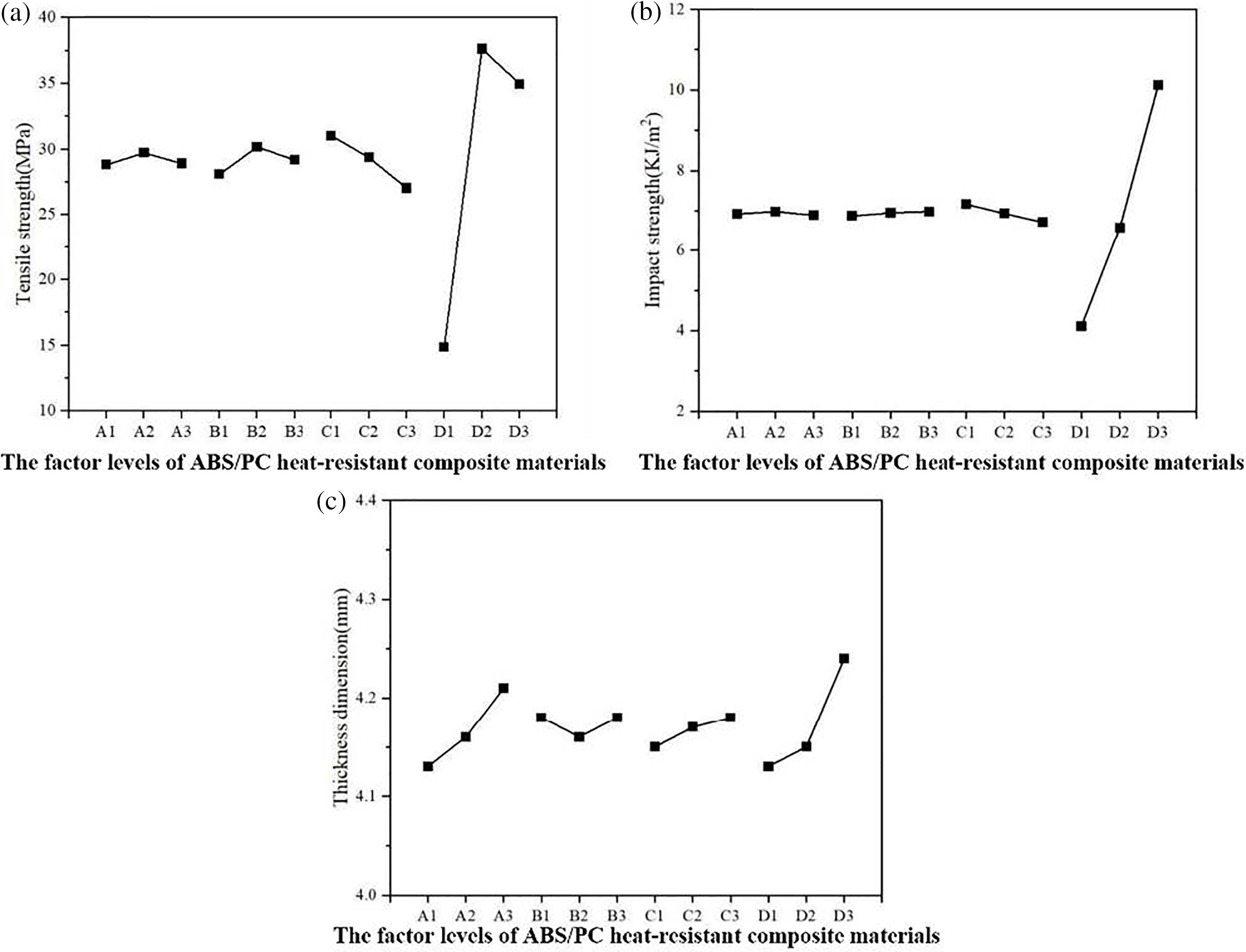

The trends of the influencing factors’ levels were determined through orthogonal experiments, as depicted in Fig. 2. It is evident that adjustments in both the platform and nozzle temperatures can significantly affect the durability of the printed product. Specifically, an excessively high platform temperature can lead to the formation of numerous air bubbles during the printing process, resulting in an uneven surface and potentially inaccurate printed products. Conversely, a platform temperature that is too low can impair the material’s adhesion to the platform, increasing the risk of the printed product detaching from the platform. Similarly, an overly high nozzle temperature may cause the material to melt excessively, thereby weakening the printed product’s strength and increasing the likelihood of distortion or breakage. When the nozzle temperature is too low, the material fails to melt adequately, leading to an unsmooth surface or even imperfections on the printed product, which negatively impacts print accuracy.

Figure 2: Trend of the impact of factor levels of ABS/PC composite materials on the performance of specimens. (a) The influence trend of factor level on tensile strength (b) The influence trend of factor level on impact strength (c) Influence trend of factor level on actual thickness size

On the other hand, the type of filling has a substantial impact on both the tensile strength and the overall quality and accuracy of the printed material. In terms of strength and stability, samples with linear infill exhibited superior overall performance and the highest tensile strength, along with ease of use. An increase in filling density boosts strength and stiffness. However, as the infill density rises, the nozzle requires greater force to pull the wire through the heater, causing noticeable fluctuations in the printing process. Furthermore, an excessive wire volume can complicate the printer’s ability to accurately control the thickness of each layer, potentially affecting the surface quality of the printed product and reducing printing accuracy.

To ensure optimal overall performance of the composite material, we will group the same impact parameters for ABS/PC material into three sets of data. For each set, we will calculate the average values of tensile strength, impact strength, and actual thickness. Subsequently, we will compute the polar deviation using these averages. This polar deviation will be utilized to assess the degree of influence that impact factors have on the product’s performance (Eqs. (1)–(3)).

where

The larger the value of R, the greater the influence of the influencing factors on the performance is indicated. Singh et al. In their study of the influence of different factors on decision-making, the parameters are weighted to determine the degree of influence of different parameters and the magnitude of the extreme deviation is one of the ways of determining the importance [29]. It also aids in illustrating the accuracy of the polar deviation in determining the impact of influencing factors on performance.

It can be seen that printing parameters play an important role in the mechanical properties of parts [30]. In order to investigate the effect of printing parameters on the properties, Shanmugam et al. found that higher extrusion temperature improved the interlayer joining effect, but too high temperature led to polymer degradation and pore creation, while higher packing density improved both thermal and mechanical properties of the material [31]. In consideration of the aforementioned factors, the optimal printing parameters for ABS/PC composite filaments are as follows, platform temperature 105°C, nozzle temperature 210°C, linear filling, and 45% fill density. This configuration is represented by the factor level parameter A2B2C1D2.

3.2 Effect of PC Content on the Heat Resistance of ABS/PC Composites

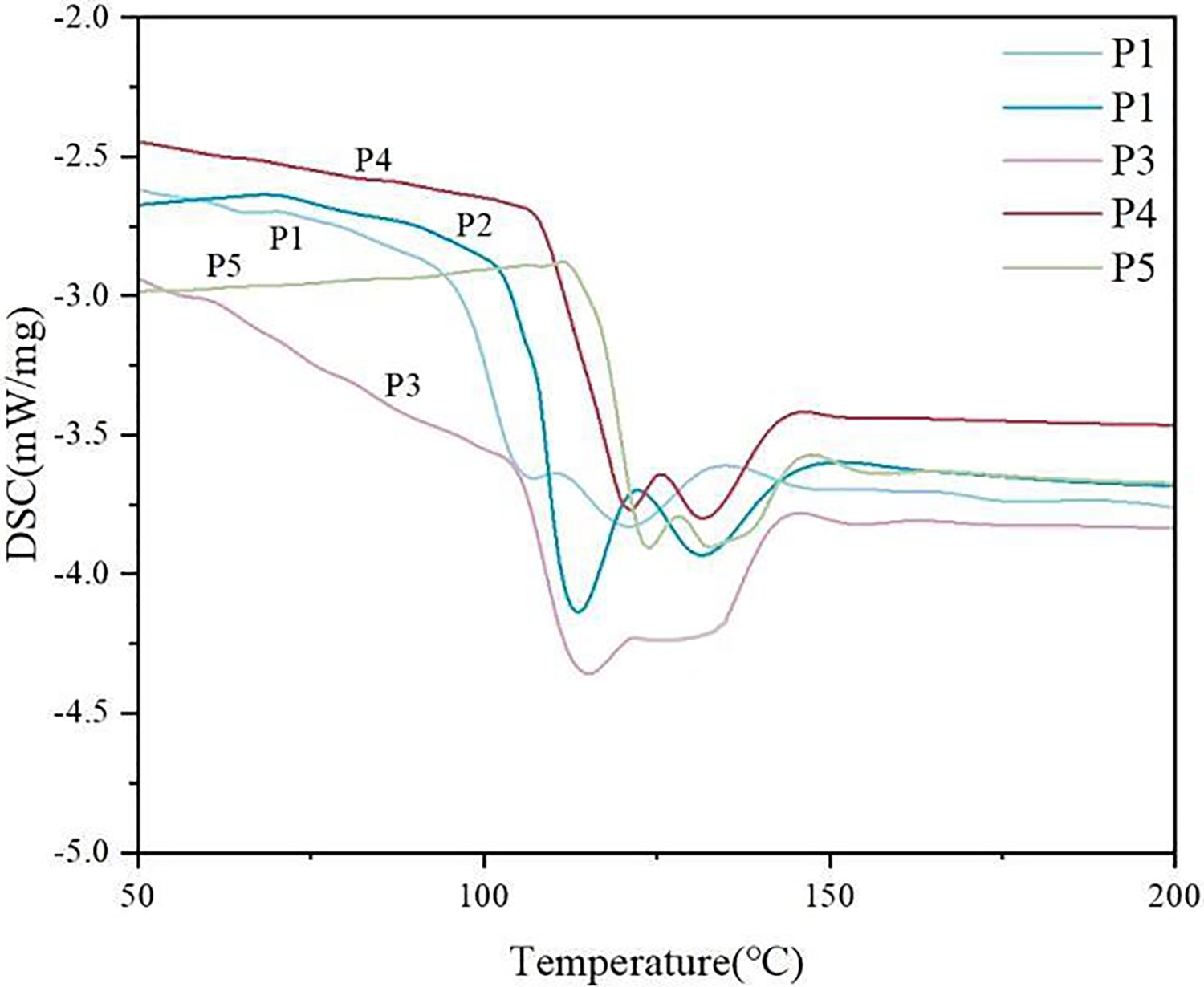

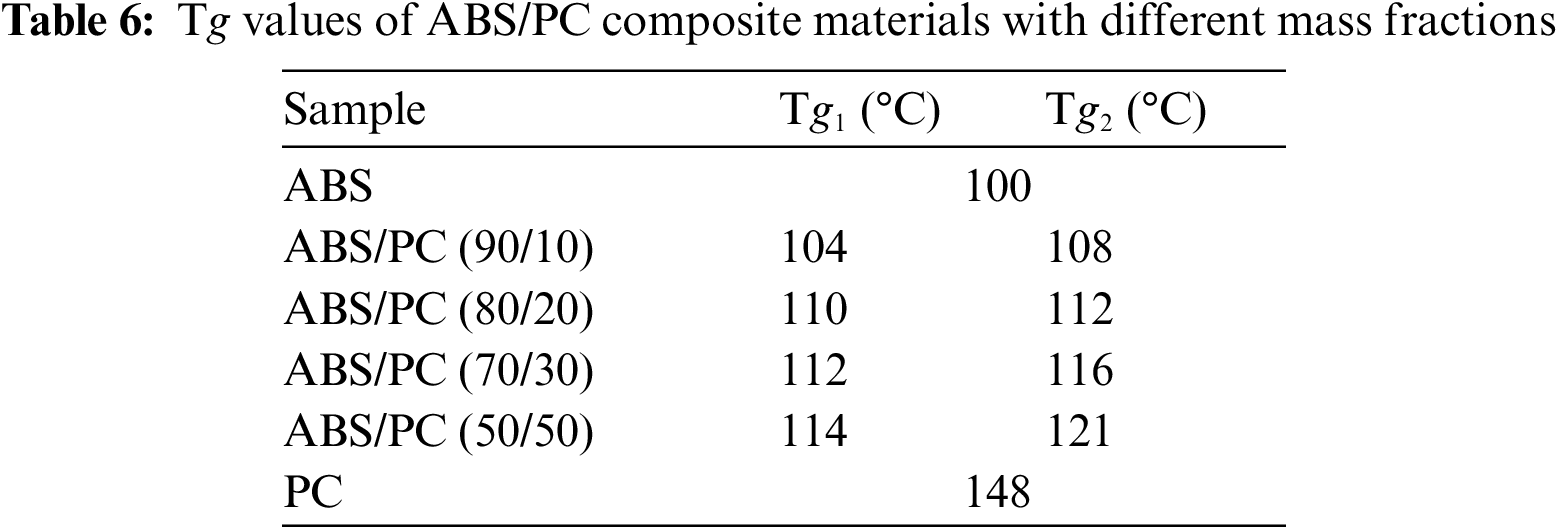

The Tg curves of ABS/PC composites with different mass fractions are shown in Fig. 3. Due to the partial miscibility of ABS and PC, the blend forms a heterogeneous system, exhibiting two glass transition temperatures. As the mass fraction of PC increased, the Tg range of the composites gradually ascended. Specifically, when the mass fraction of ABS and PC reached a 50/50 ratio, as indicated in Table 6, the Tg of the composite materials surged by 21.21% in comparison to that of pure ABS material and the Tg of PC materials are provided by the manufacturer. This outcome stems from the abundant aromatic ring structure within the PC molecular chain. When PC is mixed with ABS, the PC molecular chains are interwoven in the ABS molecular network, and the terminal hydroxyl groups in the PC molecules as well as certain functional groups in ABS react chemically to form covalent bonds, resulting in tight and strong structure, which improves the overall heat resistance of the composite [18]. The Tg level is intimately tied to the heat resistance of polymer materials. For materials destined for use in high-temperature environments, a higher Tg signifies that they maintain stability across a broader temperature spectrum and exhibit reduced susceptibility to thermal deformation. Khamidullin et al. also proved that the higher the Tg, the better the stability when they studied the effect of heat capacity of resin polymers by using the DSC to determine Tg [32]. The addition of PC greatly improves the Tg of the composites and makes them stable at high temperatures.

Figure 3: DSC curves of ABS/PC composite materials with different mass fractions

3.3 Influence of PC Content on Mechanical Properties of ABS/PC Composites

3.3.1 Effect of PC Content on Tensile Properties of ABS/PC Composites

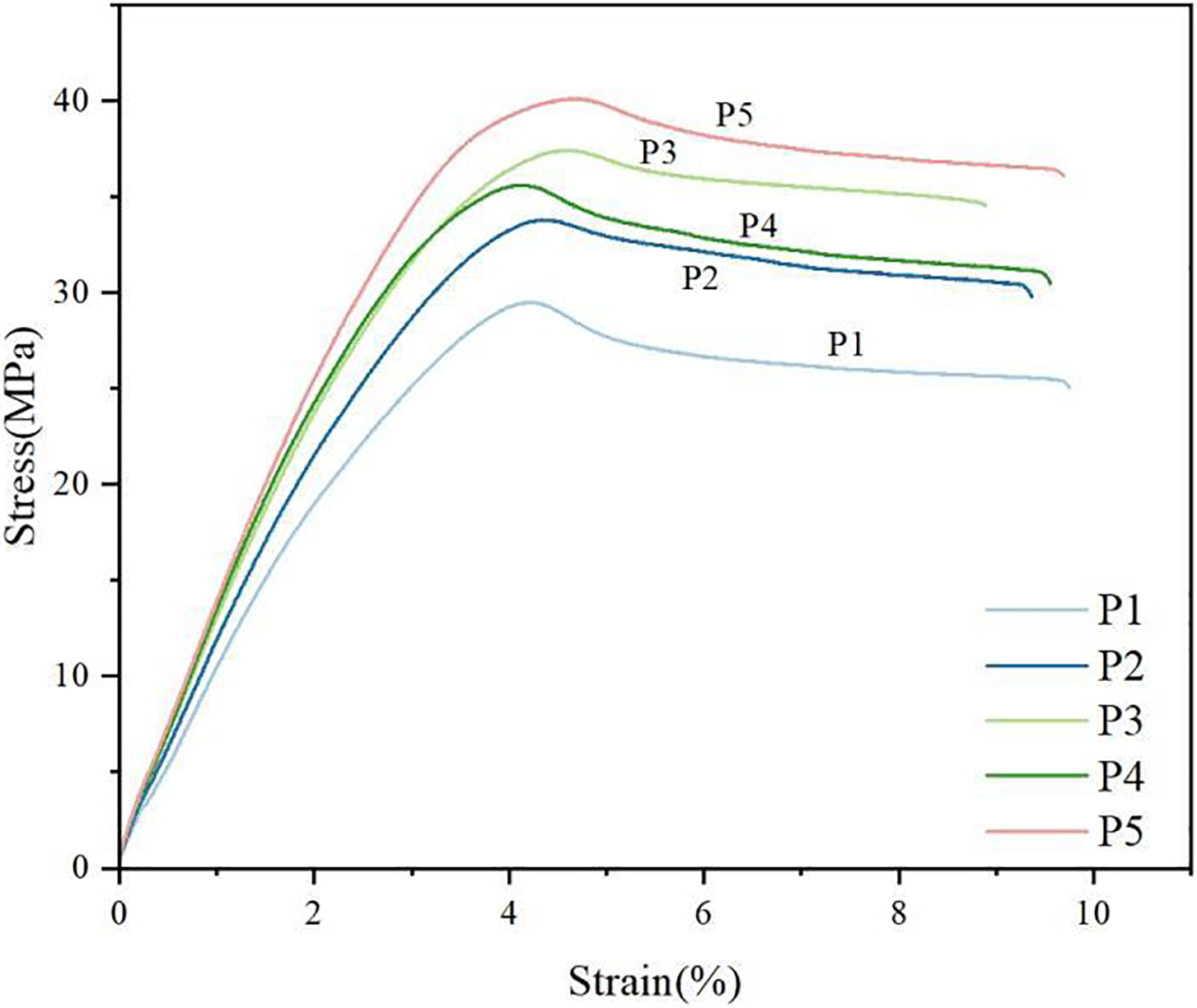

The analysis of mechanical properties takes the setting of the A2B2C1D2 factor-level parameter as an example. The stress-strain curves of ABS/PC composites with different mass fractions are shown in Fig. 4. The stress-strain curves of ABS/PC composites with different mass fractions exhibited obvious yield stages. The tensile strength of pure ABS was 29.48 MPa. When the mass fraction of the ABS/PC composites was 50/50, the tensile strength of the ABS/PC composites reached the highest point, which was 40.23 MPa. At this time, the average maximum tensile strength of the sample increased by 36.47% compared with that of pure ABS. Thus, the addition of PC improved the tensile strength of the composites. This is because PC has high rigidity and cohesion, which can form an effective reinforcing phase in the ABS matrix and improve the tensile properties of the material, so the addition of PC to ABS can improve the tensile strength of the composite materials.

Figure 4: Stress-strain curves of ABS/PC composite materials with different mass fractions

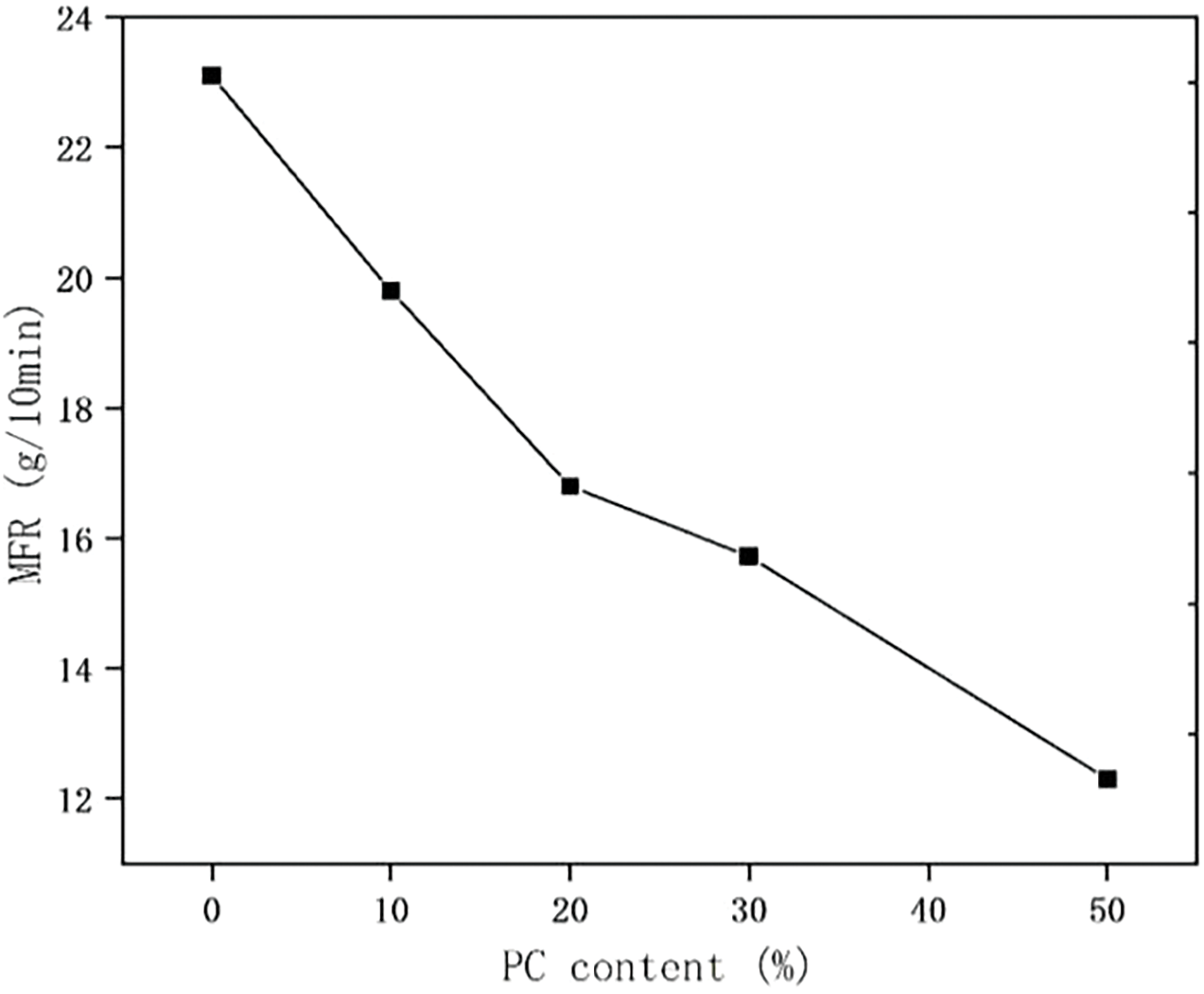

3.4 Effect of PC Content on Melt Flow Rate of ABS/PC Composites

As shown in Fig. 5, the melt flow rate of ABS/PC composites undergoes a notable decrease with the increasing mass fraction of PC. When the mass fraction of ABS and PC reaches a 50/50 ratio, the melt flow rate of the composites drops to 12.3 g/10 min, marking a significant reduction of 10.8 g/10 min compared to the 23.1 g/10 min melt flow rate of pure ABS. This indicates that the incorporation of PC has a considerable impact on the melt flow rate of the composites. The reason for this is that PC, as a high-viscosity polymer, typically has a relatively high molecular weight. Additionally, PC molecular chains are rich in aromatic ring structures, which may form strong intermolecular forces such as π-π stacking. These intermolecular forces increase the cohesive force between molecular chains. Morales-Zamudio et al. observed that the Van der Waals force generated by the phenolic ring in PC increases the elongation, which further proves that the intermolecular forces formed by PC increase the degree of bonding between the substances and also decrease the fluidity [33]. When PC is blended with ABS, the high molecular weight characteristic of PC significantly affects the fluidity of the entire composite material, resulting in a decrease in the melt flow rate of the composite.

Figure 5: Effect of PC content on melt flow rate

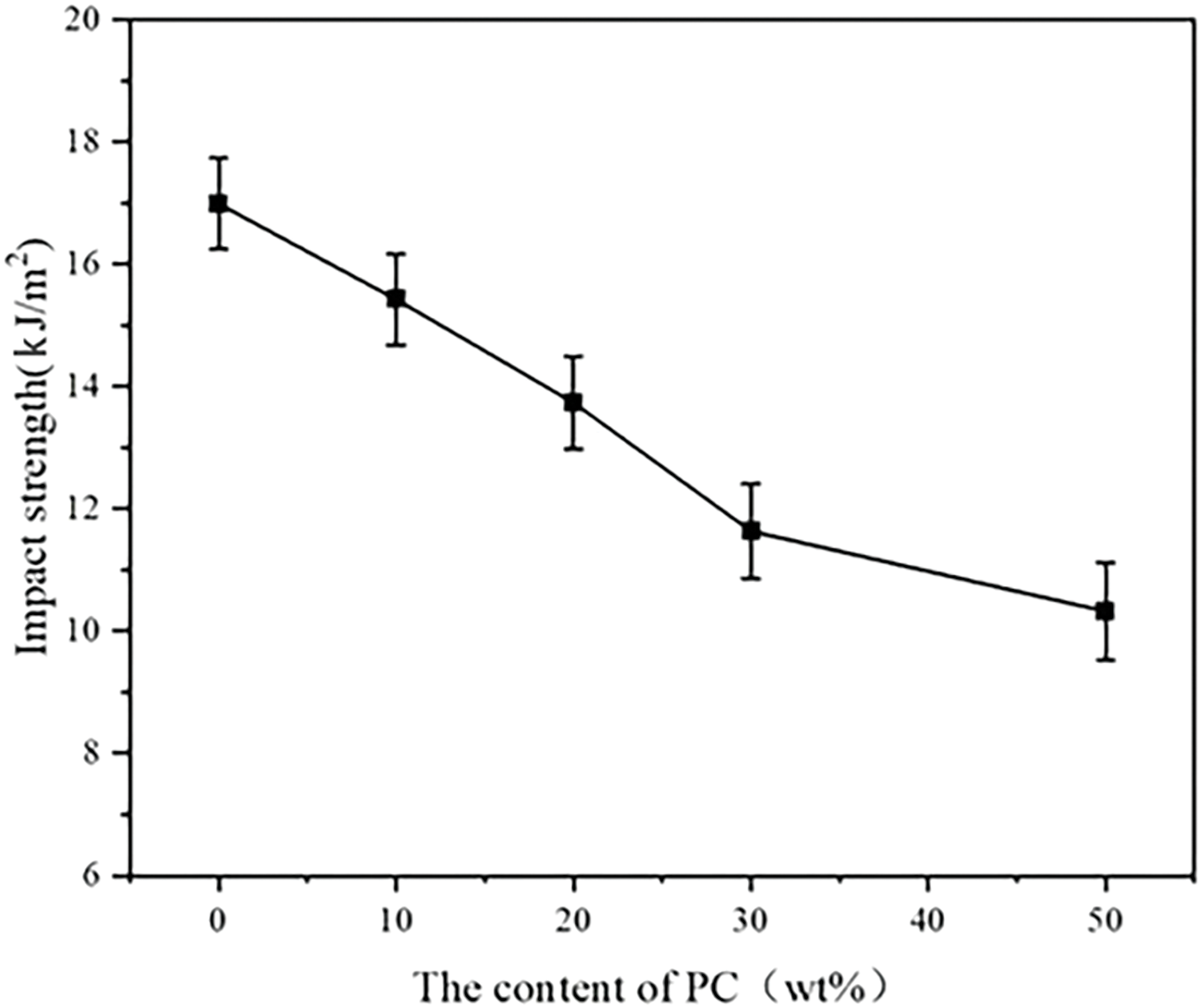

3.4.1 Effect of PC Content on Impact Properties of ABS/PC Composite Materials

As shown in Fig. 6, with the increase in PC mass fraction, the notched impact strength of the ABS/PC composites showed an obvious decreasing trend. When the mass fraction of ABS and PC was 90/10, the notched impact strength of the ABS/PC composites was 15.42 kJ/m2, showing good impact resistance. However, when the mass fraction of ABS and PC reached 50/50, the notched impact strength of the composite decreased significantly to 10.42 kJ/m2, which was about 38.67% lower than that of pure ABS. This indicates that the composites with higher PC mass fraction are more likely to fracture at the notches or vulnerable points when subjected to impact, and the toughness of the composites is also affected. This is due to the fact that PC, as a high-performance polymer, has high strength but its toughness is relatively poor, especially when notched. Wang et al. found that the notched impact strength of PC composites in general decreases with the increase of PC content, which confirms the reliability of the conclusion that the notched impact strength of ABS/PC composites tends to be significantly reduced with the increase of PC mass fraction [34].

Figure 6: Notch impact strength of ABS/PC composite materials with different mass fractions

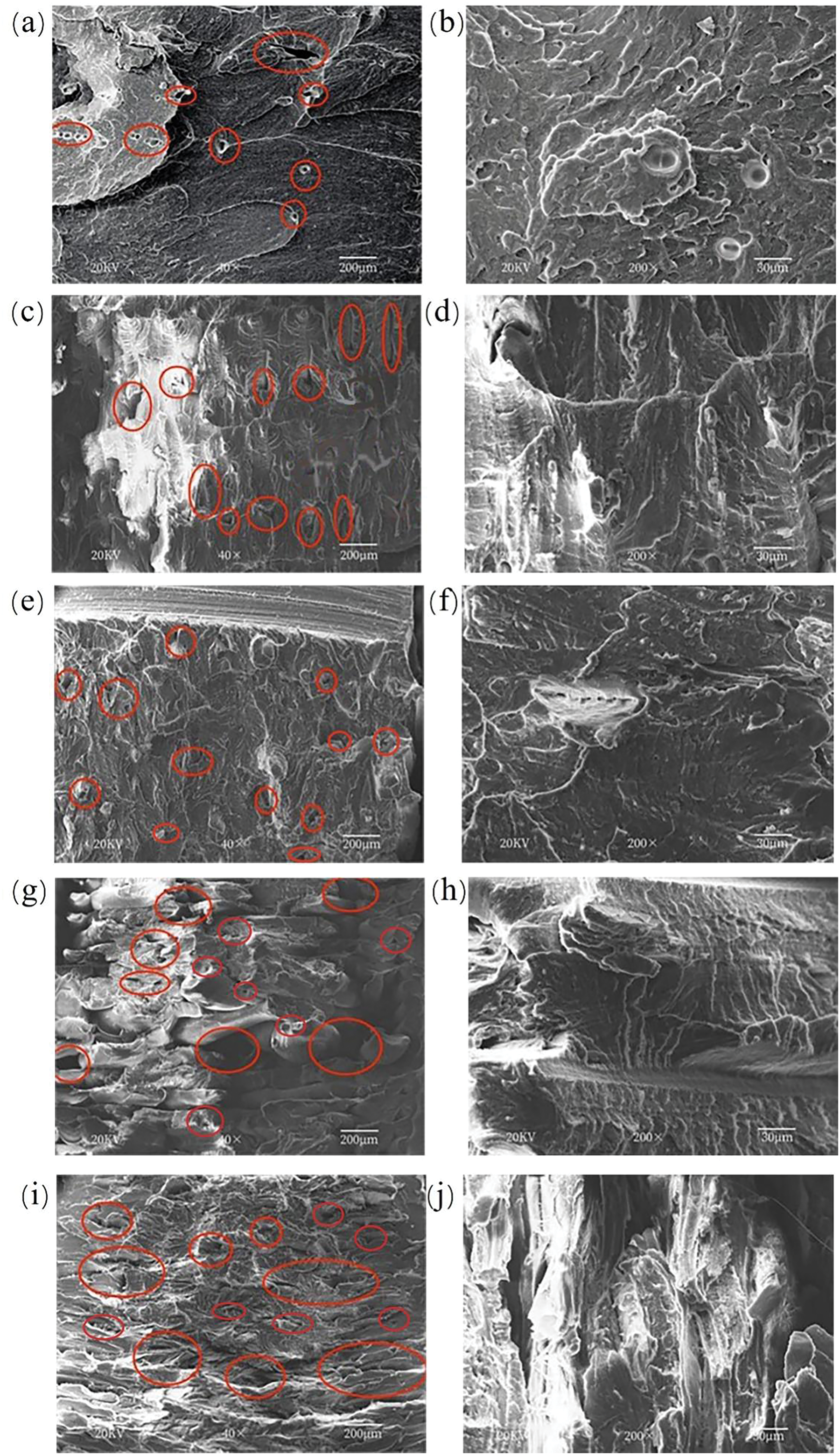

3.4.2 SEM Analysis of Impact Strength of ABS/PC Composites

The impact cross-section morphologies of ABS/PC composites with different mass fractions are shown in Fig. 7. In Fig. 7a, the impact cross-section morphology of pure ABS material was relatively flat, and the interlayer fusion was good. A small number of interlayer pores and voids shown in the circle mark indicated that in pure ABS material, the interlayer porosity was low, the bond between layers was relatively tight. This tight bond provided the material with good toughness, allowing it to disperse and absorb energy efficiently when impacted. On the microscopic morphology, Fig. 7b shows that the pure ABS material exhibited a typical silvering phenomenon. The production and development process of silver striation is a process of energy consumption, which helps the material disperse and absorb the impact energy when it is impacted. The polybutadiene (PB) rubber particles in ABS resin are a key factor in inducing the production of these silver lines. At the same time, the presence of rubber particles inhibits the transformation of silver stripes into cracks to a certain extent, thereby enhancing the toughness of the material.

Figure 7: SEM images of impact cross-sectional morphology of ABS/PC composite materials with different mass fractions. (a) ABS/PC (100/0) × 40; (b) ABS/PC (100/0) × 200; (c) ABS/PC (90/10) × 40; (d) ABS/PC (90/10) × 200; (e) ABS/PC (80/20) × 40; (f) ABS/PC (80/20) × 200; (g) ABS/PC (70/30) × 40; (h) ABS/PC (70/30) × 200; (i) ABS/PC (50/50) × 40; (j) ABS/PC (50/50) × 200

With the increase in the mass fraction of PC, Fig. 7c–j showed that cracks in ABS/PC blends vary under different PC contents. When the PC content is low, cracks are more likely to propagate along the rubber phase in ABS. The fracture interface may be relatively smooth, exhibiting certain ductile fracture characteristics. However, when the PC content is high, due to the worsening compatibility between PC and ABS, the degree of phase separation intensifies, and the interfacial bonding strength decreases, causing cracks to propagate more along the interface between PC and ABS. The fracture interface may become rougher, displaying more brittle fracture characteristics.

3.5 Influence of PC Content on the Printing Accuracy of ABS/PC Composite Filaments

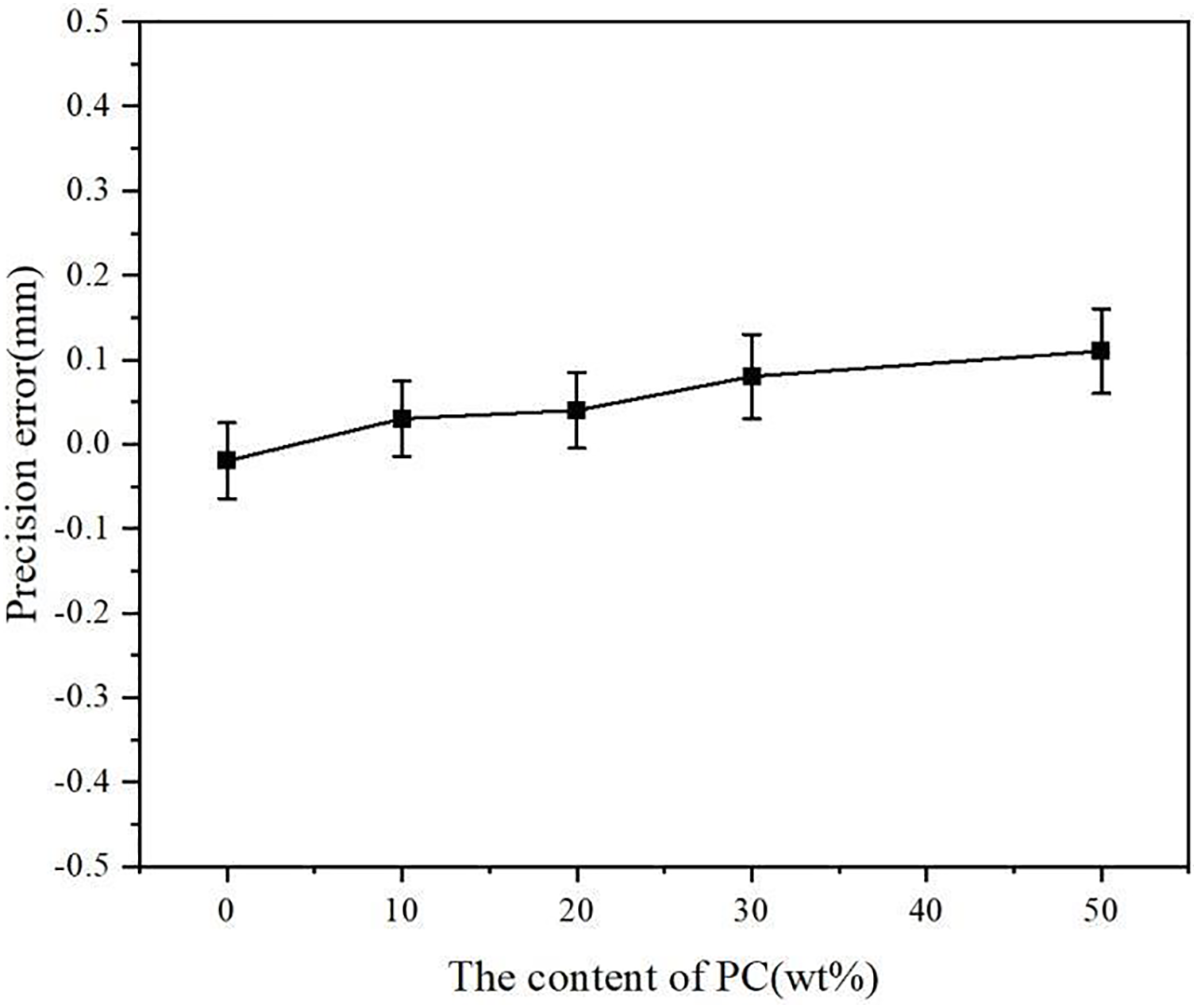

The printing accuracy is critical for evaluating the forming quality of ABS/PC composites printed products. Taking the A2B2C1D2 factor level parameter setting as an example, by observing Fig. 8, we found that the actual thickness size changed with the increase in PC mass fraction. It is particularly noteworthy that the error printing accuracy of pure ABS is minimized, with only 0.02 mm. This indicates that the ABS material can realize the design dimensions more accurately and the molding accuracy of the printed products is higher than that of ABS/PC composite filaments.

Figure 8: Thickness of impact test specimens for ABS/PC composite materials with different mass fractions

With the increase in the PC mass fraction, the printing accuracy error showed a clear upward trend. When the ABS/PC mass fraction was 50/50, the error rose to about 0.18 mm. This result was mainly due to the particularity of the PC molecular structure. The PC material has a high shrinkage rate. In the FDM printing process, large volume contraction occurs when the material cools from the molten state to the solid state. If the shrinkage rate of the material is too large, the size of the printed product presents a large deviation from the design size, which affects the forming accuracy. In addition, the high viscosity of PC material is an important factor leading to the increase in printing accuracy error. The high viscosity makes the fluidity of PC in the printing process poor, which not only affects the uniform distribution of the material but also may cause the bond between the printing layers to be loose. Therefore, as the mass fraction of the PC increases, the fluidity of the entire blend materials may gradually worsen, which in turn negatively affects the accuracy of the final product. In addition, with the addition of PC, the uneven distribution of the material results in different cooling temperatures, which can easily lead to defects such as uneven printed surfaces and internal air holes in the product.

In this work, five kinds of ABS/PC composite filaments with different proportions were prepared, and the influence of the PC content on the heat resistance, mechanical properties, and molding accuracy of ABS/PC filaments was studied. The main conclusions are as follows:

1. Taking ABS/PC (50/50) as an example, the optimal printing parameters were determined, that is, the platform temperature was 105°C, the nozzle temperature was 210°C, the filling type was linear, and the fill density was 45%.

2. When the mass fraction of ABS/PC was 50/50, Tg of the composites reached the highest value, and Tg of the composites increased by 21.21% compared with that of the pure ABS materials. It can be seen that the special structure formed by PC material and ABS matrix enhanced the overall heat resistance of the composite materials.

3. PC resin can form an effective strengthening phase in the ABS matrix to enhance the tensile strength of the composites. When the mass fraction of ABS/PC was 50/50, the tensile strength was 40.23 MPa and increased by 36.47% than that of ABS resin. The impact strength of the composites was 10.42 kJ/m2, which decreased by 38.67% compared with the pure ABS. The melt flow rate of ABS/PC also decreased from 23.1 g/10 to 12.3 g/10 min with increasing PC content.

4. With the increase in the mass fraction of PC, the printing accuracy error of the composite materials showed an upward trend, and the error increased from 0.02 to 0.18 mm.

Overall, the incorporation of PC notably enhances the tensile strength and heat resistance of ABS/PC composite filaments. However, it also results in a minor diminution in notched impact strength and molding precision. This decline is primarily attributed to the brittle fracture caused by PC’s high stiffness and cohesive properties, coupled with a decrease in the melt flow rate stemming from its high viscosity. Despite these drawbacks, the pivotal role of PC in augmenting the material’s heat resistance cannot be understated.

Acknowledgement: We are very grateful to Shandong University for providing us with instrumentation support.

Funding Statement: The research was funded by the Natural Science Foundation of Shandong Province (grant no. ZR2020KF024), Yantai City Science and Technology Plan Project (grant no. 2022ZDCX016), the University Research Project of Shandong Province (grant no. J17KB007), and Natural Science Foundation of Shandong Jiaotong University (grant no. Z201937).

Author Contributions: Study conception and design: Shanlong Che and Jin Ding; data collection: Shanlong Che, Dianchen Li, Guangliang Qu, Guochen Wang and Yunyan Hao; analysis and interpretation of results: Shanlong Che, Jin Ding and Dianchen Li; draft manuscript preparation: Shanlong Che. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The authors confirm that the data supporting the findings of this study are available within the article.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Tang T-M, Lu Y, Li Z-Y, Ni H-J, Nie F-Q. Preparation and properties of a new 3D printing material ABS. Mod Chem Ind. 2015;35(7):50–2. doi:10.16606/j.cnki.issn0253-4320.2015.07.031. [Google Scholar] [CrossRef]

2. Han J, Wang Y, Tian X, Jiang B, Xia L. Research on process parameter optimization design of fused deposition (FDM) 3D printing. Manuf Technol Mach Tool. 2016;66(6):139–142+146. doi:10.19287/j.cnki.1005-2402.2016.06.027. [Google Scholar] [CrossRef]

3. Yu D, Li X, Wang D. Process analysis and application of melt deposition rapid prototyping. Mach Design Manuf. 2011;49(8):65–7. doi:10.19356/j.cnki.1001-3997.2011.08.025. [Google Scholar] [CrossRef]

4. Wang X, Zhang Y, Li P, Li D, Dong Q, Zhou Y, et al. Preparation and properties of low warping glass fiber modified ABS granules based on FDM. Plast Sci Technol. 2023;51(1):47–51. doi:10.15925/j.cnki.issn1005-3360.2023.01.009. [Google Scholar] [CrossRef]

5. Lee CH, Padzil FNBM, Lee SH, Ainun ZMA, Abdullah LC. Potential for natural fiber reinforcement in PLA polymer filaments for fused deposition modeling (FDM) additive manufacturing: a review. Polym. 2021;13(9):1407. doi:10.3390/polym13091407. [Google Scholar] [PubMed] [CrossRef]

6. Khosravani MR, Schüürmann J, Berto F, Reinicke T. On the post-processing of 3D-printed ABS parts. Polym. 2021;13(10):1559. doi:10.3390/polym13101559. [Google Scholar] [PubMed] [CrossRef]

7. Shao J, Guo Z. Effect of TPP and MBS on properties of PC/ABS alloy. China Plast. 2015;29(12):14–7. doi:10.19491/j.issn.1001-9278.2015.12.003. [Google Scholar] [CrossRef]

8. Kucherov FA, Gordeev EG, Kashin AS, Ananikov VP. Three-dimensional printing with biomass-derived PEF for carbon-neutral manufacturing. Angew Chem Int Ed. 2017;56(50):15931–35. doi:10.1002/anie.201708528. [Google Scholar] [PubMed] [CrossRef]

9. Goo B, Kim J-B, Ahn D-G, Park K. Irreversible and repeatable shape transformation of additively manufactured annular composite structures. Materials. 2021;14(6):1383. doi:10.3390/ma14061383. [Google Scholar] [PubMed] [CrossRef]

10. Hu K-H, Kao C-S, Duh Y-S. Studies on the runaway reaction of ABS polymerization process. J Hazard Mater. 2008;159(1):25–34. doi:10.1016/j.jhazmat.2007.09.124. [Google Scholar] [PubMed] [CrossRef]

11. Wildes G, Keskkula H, Paul DR. Fracture characterization of PC/ABS blends: effect of reactive compatibilization, ABS type and rubber concentration. Polymers. 1999;40(25):7089–107. doi:10.1016/S0032-3861(98)00865-9. [Google Scholar] [CrossRef]

12. Bärwinkel S, Seidel A, Hobeika S, Hufen R, Mörl M, Altstädt V. Morphology formation in PC/ABS blends during thermal processing and the effect of the viscosity ratio of blend partners. Materials. 2016;9(8):659. doi:10.3390/ma9080659. [Google Scholar] [PubMed] [CrossRef]

13. Andrzejewski J, Mohanty AK, Misra M. Development of hybrid composites reinforced with biocarbon/carbon fiber system. The comparative study for PC, ABS and PC/ABS based materials. Composit Part B. 2020;200:108319. doi:10.1016/j.compositesb.2020.108319. [Google Scholar] [CrossRef]

14. dos Anjos EGR, Marini J, Gomes NAS, Rezende MC, Passador FR. Synergistic effect of adding graphene nanoplates and carbon nanotubes in polycarbonate/acrylonitrile-styrene-butadiene copolymer blend. J Appl Polym Sci. 2022;139(37):0021–8995. doi:10.1002/app.52873. [Google Scholar] [CrossRef]

15. Wu N, Lang S. Flame retardancy and toughness modification of flame retardant polycarbonate/acrylonitrile-butadiene-styrene/AHP composites. Polym Degrad Stab. 2016;123(3):26–35. doi:10.1016/j.polymdegradstab.2015.11.007. [Google Scholar] [CrossRef]

16. Wu J, Wang W, Chen X, Li N. Double percolation and segregated structures formed in polymer alloy with excellent electrical conductivity. Polym Compos. 2020;42(2):693–700. doi:10.1002/pc.25858. [Google Scholar] [CrossRef]

17. Li C, Zhang H, Zhang X, Zhang Z, Li N, Liu Y, et al. Construction of bi-continuous structure in fPC/ABS-hBN(GB) composites with simultaneous enhanced thermal conductivity and mechanical properties. Compos Sci Technol. 2022;223(10):109437. doi:10.1016/j.compscitech.2022.109437. [Google Scholar] [CrossRef]

18. Krache R, Debah I. Some mechanical and thermal properties of PC/ABS blends. Mater Sci App. 2011;2(5):404–10. doi:10.4236/msa.2011.25052. [Google Scholar] [CrossRef]

19. Yuan Y, Yan W. Properties of 3D printing PC/ABS alloy. Eng Plast Appl. 2018;46(8):34–9. doi:10.3969/j.issn.1001-3539.2018.08.007. [Google Scholar] [CrossRef]

20. Li M, Wang W, Yu J. Comparison of the pyrolysis behavior of PC, ABS and PC/ABS. J Anal Appl Pyrolysis. 2024;183:106774. doi:10.1016/j.jaap.2024.106774. [Google Scholar] [CrossRef]

21. Bi J, Zhang C, Zhang Y, Zhang W. Research on heat resistance and impact resistance of PC/ABS alloy. Shandong Chem Ind. 2018;47(16):12–14+18. doi:10.19319/j.cnki.issn.1008-021x.2018.16.006. [Google Scholar] [CrossRef]

22. Tambrallimath V, Keshavamurthy R, Saravanabavan D, Koppad PG, Kumar GSP. Thermal behavior of PC-ABS based graphene filled polymer nanocomposite synthesized by FDM process. Compos Commun. 2019;15(2):129–34. doi:10.1016/j.coco.2019.07.009. [Google Scholar] [CrossRef]

23. Mohamed OA, Masood SH, Bhowmik JL. Experimental investigation of time-dependent mechanical properties of PC-ABS prototypes processed by FDM additive manufacturing process. Mater Lett. 2017;193(15):58–62. doi:10.1016/j.matlet.2017.01.104. [Google Scholar] [CrossRef]

24. Nabavi-Kivi A, Ayatollahi MR, Rezaeian P, Razavi N. Investigating the effect of printing speed and mode mixity on the fracture behavior of FDM-ABS specimens. Theor Appl Fract Mech. 2022;118:103223. doi:10.1016/j.tafmec.2021.103223. [Google Scholar] [CrossRef]

25. Syrlybayev D, Zharylkassyn B, Seisekulova A, Akhmetov M, Perveen A, Talamona D. Optimisation of strength properties of FDM printed parts—a critical review. Polymers. 2021;13(10):1587. doi:10.3390/polym13101587. [Google Scholar] [PubMed] [CrossRef]

26. Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D. Additive manufacturing (3D printinga review of materials, methods, applications and challenges. Composit Part B. 2018;143(15):172–96. doi:10.1016/j.compositesb.2018.02.012. [Google Scholar] [CrossRef]

27. Shirmohammadi M, Goushchi SJ, Keshtiban PM. Optimization of 3D printing process parameters to minimize surface roughness with hybrid artificial neural network model and particle swarm algorithm. Prog Addit Manuf. 2021;6(2):199–215. doi:10.1007/s40964-021-00166-6. [Google Scholar] [CrossRef]

28. Tran TQ, Canturri C, Deng X, Tham CL, Ng FL. Enhanced tensile strength of acrylonitrile butadiene styrene composite specimens fabricated by overheat fused filament fabrication printing. Composit Part B. 2022;235(15):109783. doi:10.1016/j.compositesb.2022.109783. [Google Scholar] [CrossRef]

29. Singh T, Singh V, Ranakoti L, Kumar S. Optimization on tribological properties of natural fiber reinforced brake friction composite materials: effect of objective and subjective weighting methods. Polym Test. 2023;117(6):107873. doi:10.1016/j.polymertesting.2022.107873. [Google Scholar] [CrossRef]

30. Alzyod H, Ficzere P. The influence of the layer orientation on ultimate tensile strength of 3D printed poly-lactic acid. Jordan J Mech Ind Eng. 2022;16:361–7. doi:10.59038/jjmie/16. [Google Scholar] [CrossRef]

31. Shanmugam V, Babu K, Kannan G, Mensah RA, Samantaray SK, Das O. The thermal properties of FDM printed polymeric materials: a review. Polym Degrad Stab. 2024;228:110902. doi:10.1016/j.polymdegradstab.2024.110902. [Google Scholar] [CrossRef]

32. Khamidullin OL, Madiyarova GM, Amirova LM. Structural effects on heat capacity, moisture absorption and thermal expansion of epoxy-novolac polymers. Chem Phys. 2024;587:112422. doi:10.1016/j.chemphys.2024.112422. [Google Scholar] [CrossRef]

33. Morales-Zamudio L, Lozano T, Caballero-Briones F, Zamudio MAM, Angeles-San Martin ME, de Lira-Gomez P, et al. Structure and mechanical properties of graphene oxide-reinforced polycarbonate. Mater Chem Phys. 2021;261:124180. doi:10.1016/j.matchemphys.2020.124180. [Google Scholar] [CrossRef]

34. Wang J, Li C, Zhang X, Xia L, Zhang X, Wu H, Guo S. Polycarbonate toughening with reduced graphene oxide: toward high toughness, strength and notch resistance. Chem Eng J. 2017;325:474–84. doi:10.1016/j.cej.2017.05.090. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools