Open Access

Open Access

REVIEW

A Review on Coir Fibre, Coir Fibre Reinforced Polymer Composites and Their Current Applications

1 Department of Materials and Metallurgical Engineering, Faculty of Engineering, Federal University Oye-Ekiti, Ekiti, 371104, Nigeria

2 School of Engineering, Robert Gordon University, Aberdeen, AB 10 7AQ, UK

3 Metallurgical and Materials Engineering Department, University of São Paulo, Sao Paulo, SP 05508-220, Brazil

* Corresponding Author: Chioma Ifeyinwa Madueke. Email:

Journal of Renewable Materials 2024, 12(12), 2017-2047. https://doi.org/10.32604/jrm.2024.055207

Received 20 June 2024; Accepted 08 October 2024; Issue published 20 December 2024

Abstract

Coir fibre has generated much interest as an eco-friendly, sustainable fibre with low density. This review findings show that coir fibres are abundant, with an average global annual production of 1019.7 × 103 tonnes, with about 63% of this volume produced from India. Extraction of coir has been carried out through water retting. However, the retting period has been limited to 4–10 months. The lignin content of coir is more than 60% higher than that of other natural fibres; hence, coir could double as a source of lignin for other applications. The diameter of coir fibres varies from 0.006 mm (Vietnam) to 0.577 mm (Thailand), and their tensile strength ranges from 68.4 MPa (Tanzania) to 343 MPa (Vietnam). Coir fibres from Vietnam and India exhibit the highest elongation at break (63.8%) and the highest Young’s modulus (6 GPa), respectively. More than 50% of the researchers within the scope of the reviewed studies employed the hand layup (HLU) manufacturing method with an epoxy resin matrix. Fibre volume fractions used range between 10%–65%. An outstanding tensile strength of 62.92 MPa at 49% fibre volume fraction was recorded for coir composites where the fibres were unidirectionally oriented and stacked in three layers, manufactured using epoxy resin and the HLU technique. Only a few works have been done using Vacuum-assisted resin transfer moulding (VARTM). The curing of composites was mostly carried out at an unspecified temperature and duration. A defined fibre volume fraction with a defined mixing and mixing time of the matrix is imperative. The degree of uniform dispersity of the fibres in the matrix is lacking. The creep behaviour of coir composites, coating and wider treatment parameters need to be explored for advanced applications. Recent findings on the applications of coir composites are equally highlighted.Keywords

Notations and Abbreviations

| TGA | Thermo-gravimetric analysis |

| RTM | Resin transfer moulding |

| HLU | Hand lay up |

| VARTM | Vacuum-assisted resin transfer moulding |

| SEM | Scanning electron microscopy |

| PLA | Polylactic acid |

| NaOH | Sodium hydroxide |

| PU | Polyurethane |

| IFSS | Interfacial shear strength |

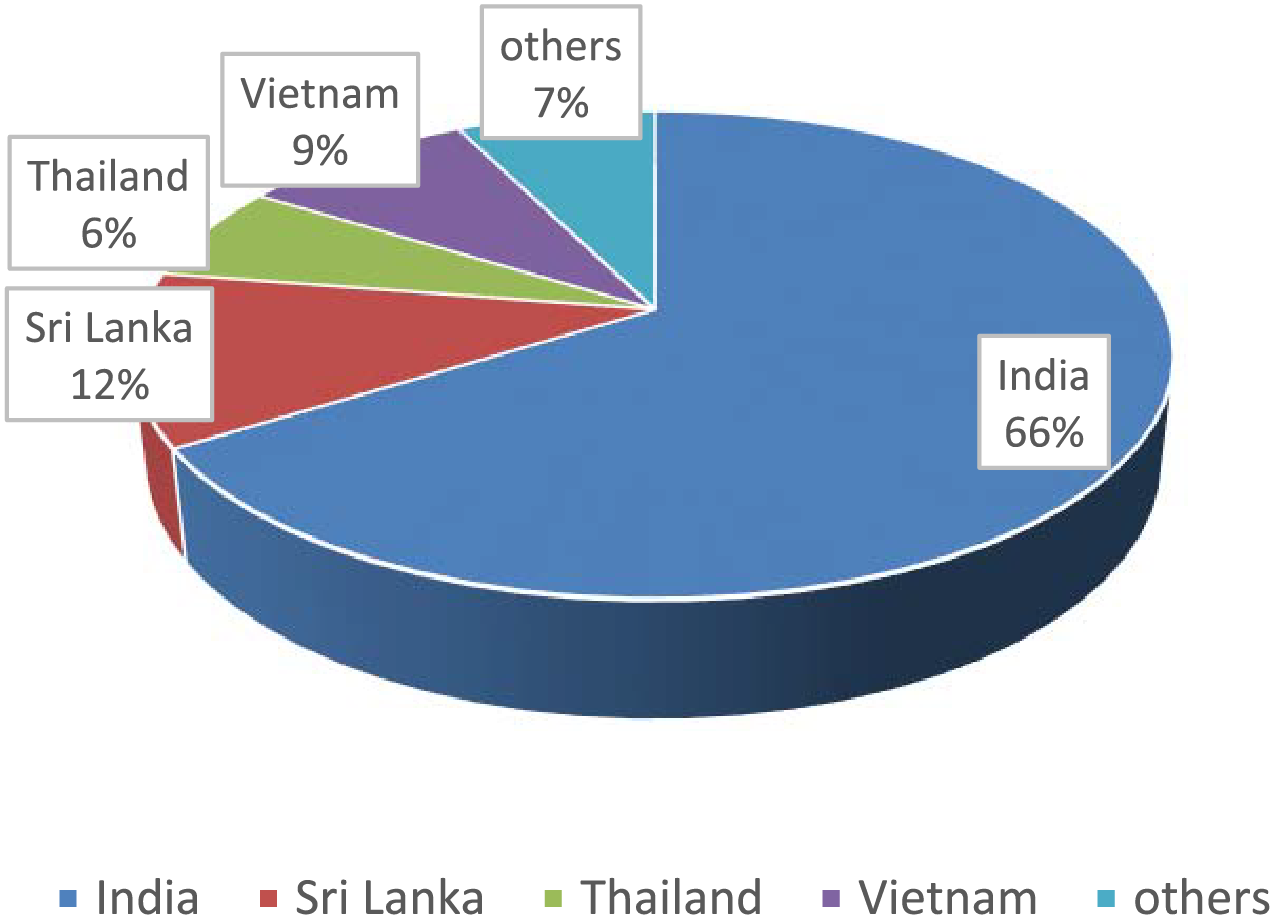

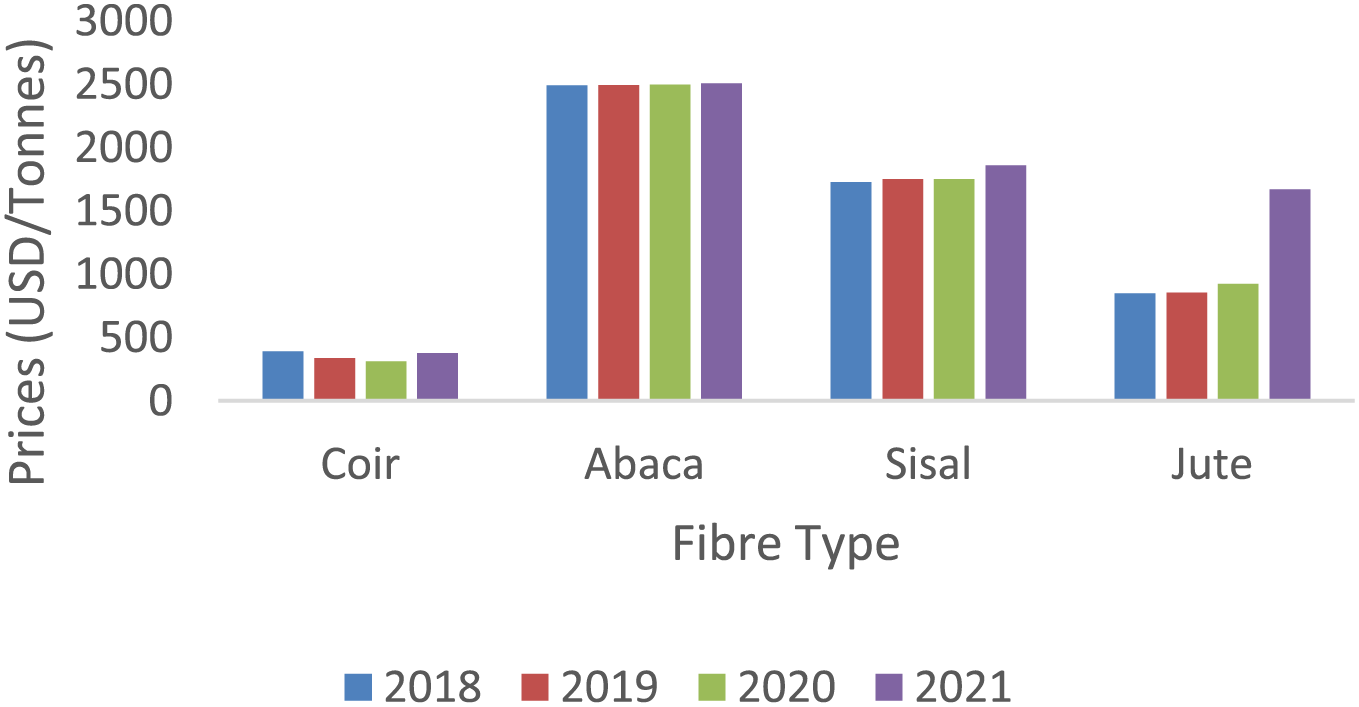

Environmental safety, depletion of crude oil and non-renewability of synthetic fibres such as glass and carbon have led to massive explorations of natural fibres such as coir for use as reinforcements in composites. Coir fibres are obtained from the mesocarp of mature (brown) or premature (white) coconut husks. These coconuts thrive well in tropical countries such as India, Brazil, China, Indonesia, Colombia, Malaysia and some parts of Africa [1–4]. Fig. 1 shows the top global producers of coconut fibres. Coir fibres are in abundance, with an average global annual production of 1019.7 103 tonnes, for five consecutive years (2015–2020), with about 63% of this volume produced from India [5,6] Annual export (from producing countries such as China, Sri Lanka and others) and import (North America, Europe and others) of coir fibre have been on a steady increase as shown in Fig. 2, with an average import and export of more than 1000 × 103 tonnes within these years. Coir fibre remains the cheapest (see Fig. 3) of the natural fibres that have been considered for technical application. The price of coir fibre has been between 302 and 390 USD per tonne for four consecutive years.

Figure 1: Global production of coir fibre from different countries adapted from FAO [5,6]

Figure 2: World import/export of coir fibres adapted from FAO [6]

Figure 3: Price of coir in comparison with other natural fibres fibre adapted from FAO [6]

Coir fibre is used outdoors because of its high weather resistance as a result of its high lignin content [7]. Lignin in plants is much less hydrophilic than hemicellulose and cellulose and thus reduces water absorption; moreover, lignin serves as a protective barrier against insect and fungal attacks. Lignin surrounds and protects cellulose, contributing to the increased stiffness and toughness of the fibre. It also enhances durability against decay in damp environments. Therefore, coir fibre, with its high lignin content, is particularly suitable for outdoor applications where it may be exposed to harsh weather conditions [8]. These applications include structural uses such as thatched roofing, mattings and incorporation into concrete. Coir fibre, due to its helical arrangement of microfibrils, can be stretched beyond its elastic limit without breaking, and it exhibits exceptional acoustic properties [9]. When compared to petroleum-based fibres, coir offers numerous benefits. These include being low-cost, readily available, having a relatively low density, non-toxicity, sustainability, renewability, environmental friendliness, reduced tool wear, and a lower energy requirement in composite applications. However, coir has several drawbacks, including poor resistance to moisture absorption, inconsistency in fibre length, diameter, and mechanical properties, relatively high porosity, and significantly lower mechanical properties compared to synthetic fibres. Additionally, its low degradation temperature limits the choices for matrix selection. Coir fibre is widely utilized as reinforcement in composites. Composites are essentially composed of reinforcement and a matrix. The matrix, or binder, maintains the reinforcement’s orientation, secures the fibre, and shields it from adjacent fibres and environmental factors. Meanwhile, the reinforcement distributes stress to the matrix, enhancing the composite’s strength and stiffness. The extent of load transfer depends on the critical fibre length, fibre orientation, and the level of fibre-matrix interfacial bond strength, as indicated in Eqs. (1)–(3):

where

Nevertheless, coir fibres with random orientation and coir fibres that are exceptionally short possess complexities of load distribution along the interfaces.

The mechanical properties of coir fibre, such as tensile strength, flexural strength, thermal and impact properties, and sound and water absorption properties, have been extensively researched. This study offers insights into the production and availability of coir fibre; it compares the properties of coir fibre based on their origins. Coir fibre composites were studied, particularly the factors that contribute to their performance. It notes an exceptional tensile strength of 62.92 MPa at 49% fibre volume fraction achieved through HLU in coir composites, which was thoroughly examined. The study also analyses fibre treatments and their impact on the composites. The review encompasses coir composites used as green composites (biocomposites), such as coir/PLA and coir/bio-epoxy, as well as their incorporation in synthetic polymer composites and cement-based composites. Their properties, effects, and applications are discussed in further sections. Finally, it underscores the applications of coir composites and suggests areas for future research in advanced applications. The extraction methods for coir, along with its chemical composition and microstructure, have been examined in the following sections.

2 Extraction, Chemical Composition and Properties of Coir Fibre

2.1 Extraction of Coir Fibres from Coconut Husk

Coconut fruit is made up of the coconut husk that bears the fibre (coir). Coconut husk contains about 20%–30% of coconut fibre [10], while the rest is the pith. Extraction of coir fibre can be carried out manually or by water retting [11]. Retting of coconut is a means of separating the leather-like exocarp from the fibrous mesocarp; this involves immersion of coconut husks in water for about 5 months [12] or 6–10 months [13].

In some research instances, coir fibres have been specified as water-retted, yet the retting details are often omitted. The Coir Board of India and The Coir Institute of Sri Lanka have established standardized retting procedures. Retting can be performed in various mediums, including deionized (DI) water, salt water (SW), or a chemical medium. Retted coir fibres exhibit differences in their crystalline index based on the medium used, and also in their tensile properties, with salt water-retted fibres demonstrating superior properties compared to those retted in deionized water [8]. During retting, coir fibre undergoes several stages, such as de-fiberizing and combing, where fibres from different sources may become intermixed. Combing is repeated as often as necessary without an automated gauge to indicate when the desired standard is achieved. The combing process can be quite severe and may cause significant surface damage to the fibres. This is expected to significantly affect the fibre diameter and, as a result, its mechanical properties. The de-fiberising process and combing should be better automated to achieve better yield and efficiency, which are likely to lead to improved properties [4]. Other natural fibres have been extracted either manually or through retting, as noted by [14–16]. Coir fibres typically range from 8 to 300 mm in length [17], with an average fineness of 27.94 Tex and an average diameter between 0.09 and 0.39 mm [18–20]. Coir obtained via retting or manual extraction can be utilized in various forms, including chopped fibres, unidirectional long lengths, or crushed particulates of different micron sizes for composite production.

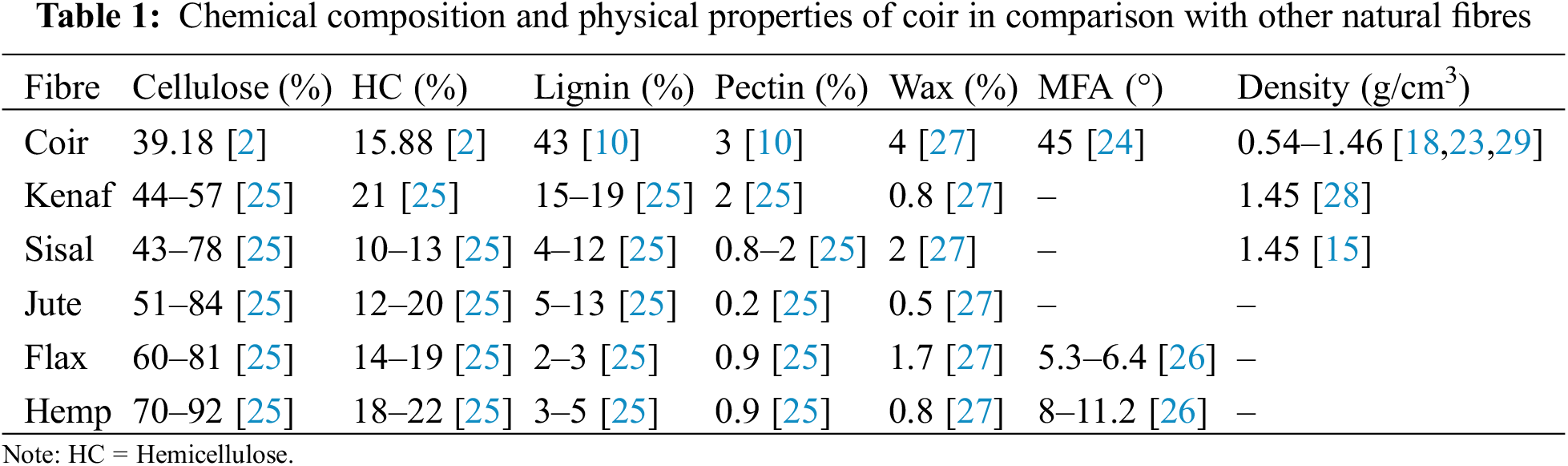

Table 1 shows the chemical composition of coir fibre with other natural fibres. The overall characteristics of coir fibre are greatly affected by the concentration of its chemical constituents. The strength of natural fibres is notably determined by the amount of cellulose and lignin they contain [18]. Coir has one of the lowest densities among natural fibres considered for technical uses (refer to Table 1), which translates to considerable weight reduction and enhances specific properties. Lignin, an amorphous material [21], enhances the fibres’ elasticity and provides resistance to biodegradation. The lignin content in coir is over 60% higher than in other natural fibres, making it exceptionally suitable for outdoor applications due to its superior resistance to weathering and greater toughness. Lignin serves both as a binder for cellulose fibres and as an energy storage mechanism. Coir’s microfibrillar angle (MFA) is over 50% greater than that of other natural fibres, resulting in the lowest cellulose content. A higher microfibrillar angle correlates with reduced cellulose content and reduced strength [22]. With the lowest density (see Table 1 [2,10,15,18,23–29]), coir is ideal for lightweight applications.

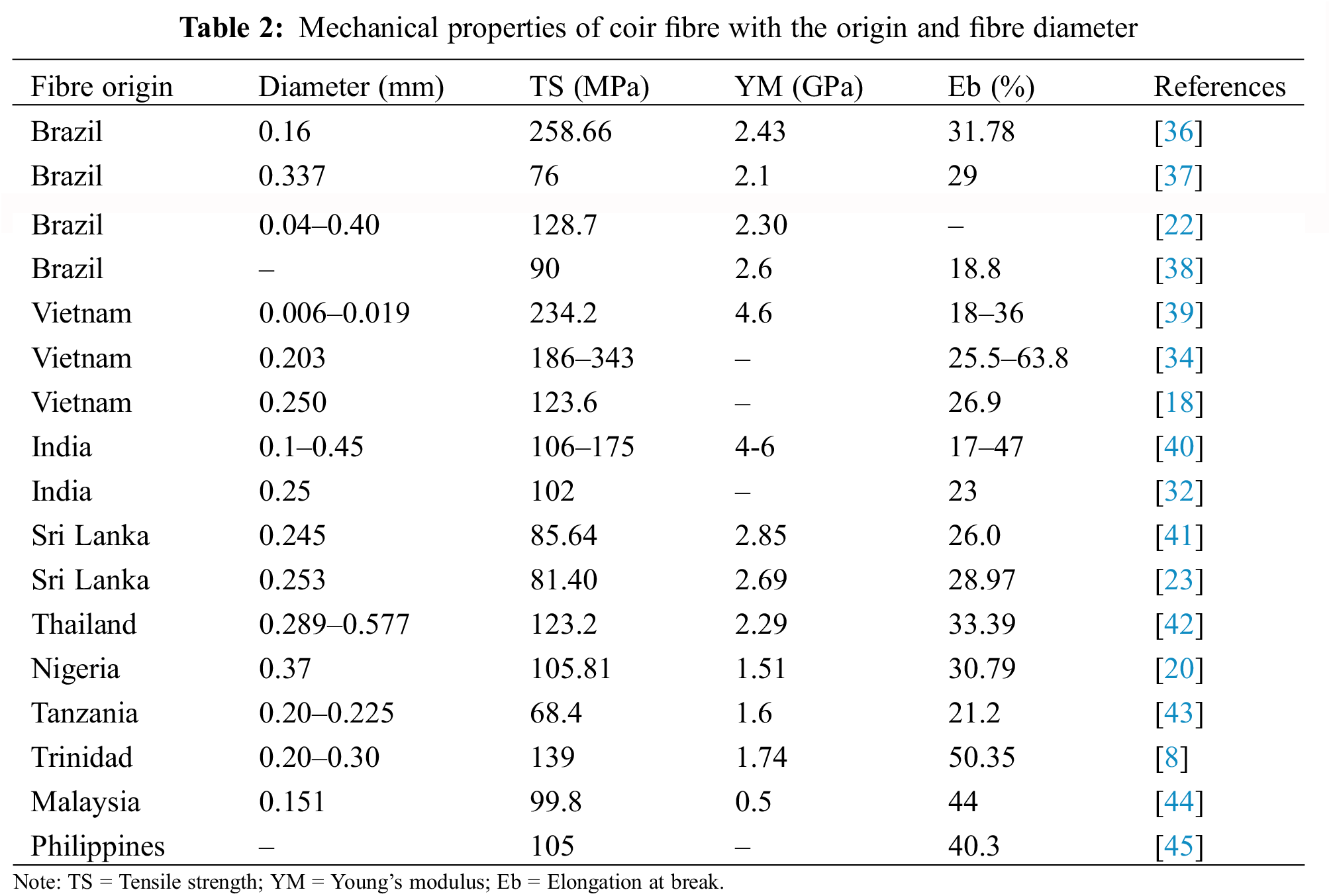

2.3 Mechanical Properties of Coir with Emphasis on Fibre Origin and Diameter

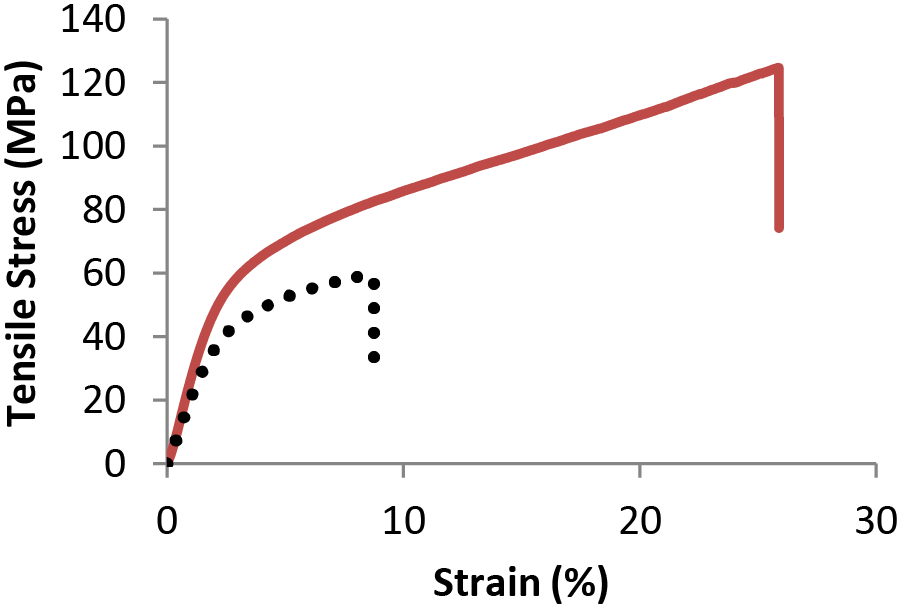

Composites consist of reinforcements (fibre) and matrix; thus, the properties of the reinforcing fibres and the interfacial bond strength between the fibre and the matrix significantly determine the composites’ overall properties. Table 2 presents findings on the mechanical properties of coir fibres, highlighting the influence of origin and diameter. It indicates that fibres from Sri Lanka, Vietnam, and Brazil show increased tensile strength and stiffness with reduced diameter. However, this varies compared to fibres from other origins, underscoring the significance of fibre origin and diameter in mechanical properties [30–33]. As depicted in Fig. 4, tensile properties such as strength and elongation are affected by fibre diameter. Thicker fibres have more pores, leading to a larger [34] diameter [35], which correlates with a higher likelihood of failure due to the increased pore presence. The tensile strength of coir fibre is significantly influenced by the gauge length. Tensile properties are also influenced by the fibre extraction method [30], maturity [22], and processing conditions [10]. From Table 2, coir fibre diameter ranges from 0.006 mm (Vietnam) to 0.577 mm (Thailand), and tensile strength spans from 68.4 MPa (Tanzania) to 343 MPa (Vietnam). Notably, Vietnamese and Indian coir fibres exhibit the highest elongation at break, 63.8%, and Young’s modulus, 6 GPa, respectively. Vietnamese coir fibre, possessing a tensile strength of 343 MPa, can effectively compete with jute fibre and may be utilized in comparable applications with jute fibre. It is also suitable for applications where high elongation is crucial, for instance, in components that require energy absorption before plastic deformation, like foam padding. Conversely, coir fibres from Tanzania, Malaysia, and the Philippines, which exhibit lower tensile strength, can be appropriately used for products like brushes and foot mats.

Figure 4: Stress/strain graph of coir fibre at diameters; = 0.281 mm (−) and 0.342 mm (...)

Previous researches that have been carried out on coir as regards their tensile strength shows that the tensile strength of coir fibre linearly increases as the gauge length increases and vice-versa [46,47]. However, there exists a critical fibre length for optimal performance as discussed in Section 4.3.2.

2.4 Thermal Responses of Coir Fibre

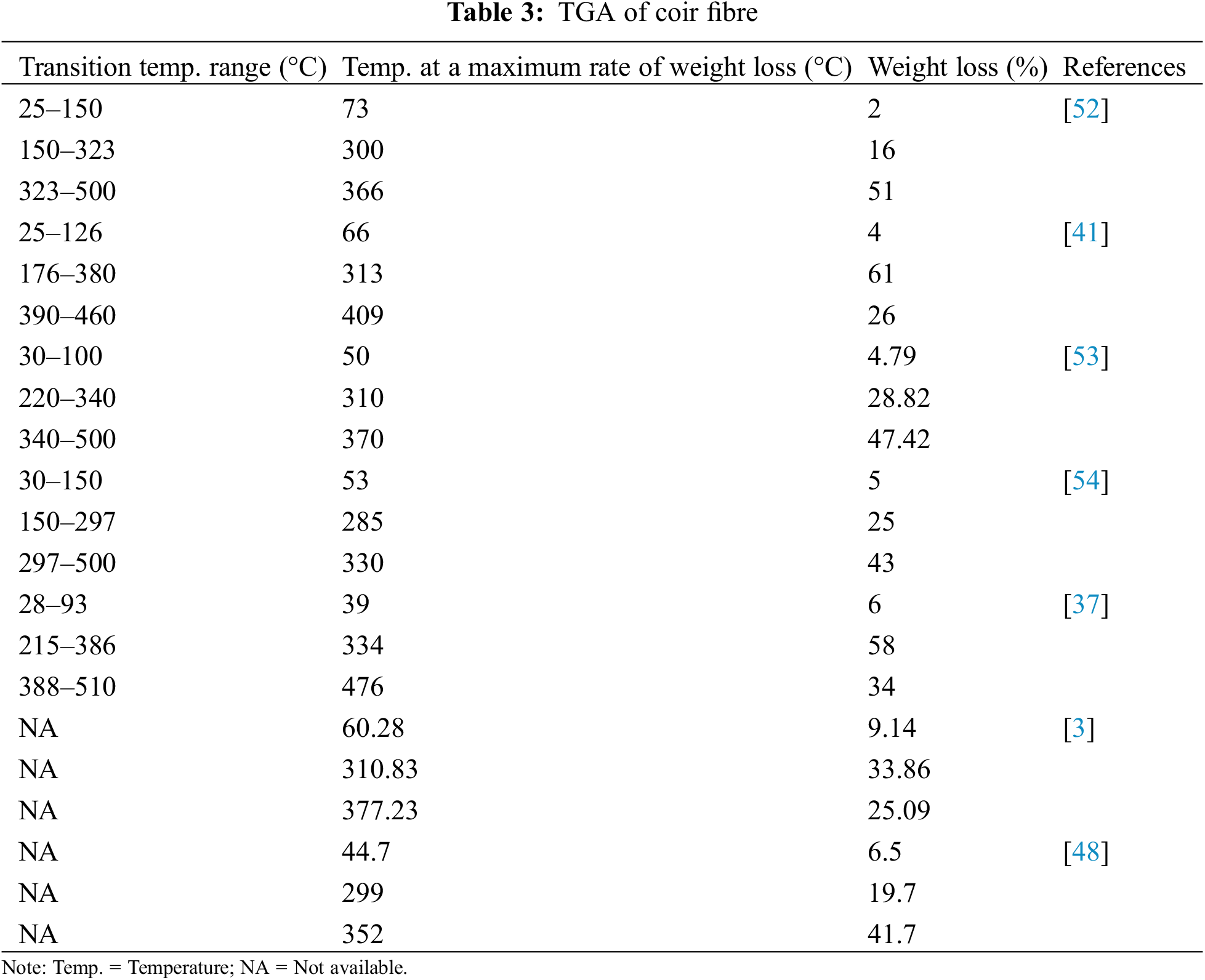

Natural fibres are generally prone to thermal degradation due to temperature gradient. A fibre is thermally stable to the point it can withstand thermal degradation. Therefore, thermogravimetric analysis (TGA) of natural fibres is important. Thermal degradation of coir fibres mostly occurs in three stages [3,48]. The first stage is usually a result of loss in moisture or evaporation [3,18]; the second and third stages have been attributed to degradation of hemicellulose and degradation of cellulose, respectively. These stages with their corresponding loss in the weight of the fibres are displayed in Table 3; the loss in the weight of the fibre in the first stage (evaporation) is not more than 10%. In some cases, the weight loss of the fibre increases as the temperature increases. Some variations in the thermal stability of coir fibre have been attributed to the extraction processes. Thermal stresses have been noted to be induced by the high speed of the test, leading to the softening of the matrix, giving rise to mass loss or increased wear, and finally resulting in the formation of microcracks and debonding [49]. From Table 3, the least weight loss of about 2%–9% occurred as a result of thermal degradation, mostly in the first stage at temperatures between 25°C–150°C. Hence coir fibres can conveniently be used in composite applications where service temperature does not exceed 150°C, such as automobile dashboard/instrument panels, wind turbine blades and geotextiles. Moreover, specific treatments have been recognized for enhancing the thermal stability of natural fibres, such as noted by [50,51]. These treatments are discussed in further sections.

2.5 Microstructural Characterisations of Coir

Coir fibres are typically multicellular, comprising xylem, parenchyma, phloem and xylem-parenchyma. The arrangement of these cells, their number and their shape, distinguish coir from other natural fibres by giving it its unique properties. The elementary fibres within the coir fibre bundle have a large number of microfibrils, and these elementary fibres are bonded together with the help of the middle lamella [39]. Scanning Electron Microscopy (SEM) is employed to examine the morphology of coir fibre. This morphology showcases numerous lumens and a central core, the lacuna, which contributes to the low density of coir. The surface of the fibre is rough with globular protrusions known as tyloses that aid in interlocking with the matrix. However, during resin impregnation, these pores might not be filled, resulting in less-than-optimal mechanical properties in the composites. The tyloses are longitudinally aligned, with occasional pits where protrusions are missing. The considerable inherent porosity of coir fibre is likely a factor in its reduced tensile strength. Tyloses enhance the interlocking of fibres and matrices within composites. The longitudinal cross-section shows a helical structure of the elementary fibres. Coir fibres are increasingly prone to intrinsic flaws as the stress application rate increases. Also, viscoelastic polymers exhibit increased apparent stiffness with rising stress application rates. The failure mechanisms in natural fibres, such as coir relate to the behaviour of the microfibrillar angle under tensile loading. The microfibril angle in the secondary wall layer significantly influences Young’s modulus, with this impact varying according to the radius of the fibre [39]. The multi-cellular microstructure of coir, composed of helically arranged elementary fibrils [22], leads to the uncoiling of these helices under tensile load at relatively low-stress levels. Additionally, the presence of lacunae, intrinsic porosity, and tyloses suggests that the tensile stress coir fibres can withstand can be significantly lower than that of a solid fibre with a comparable cross-section. The microfibril angle has been related to the Young’s modulus [22,40] using Eq. (4):

where

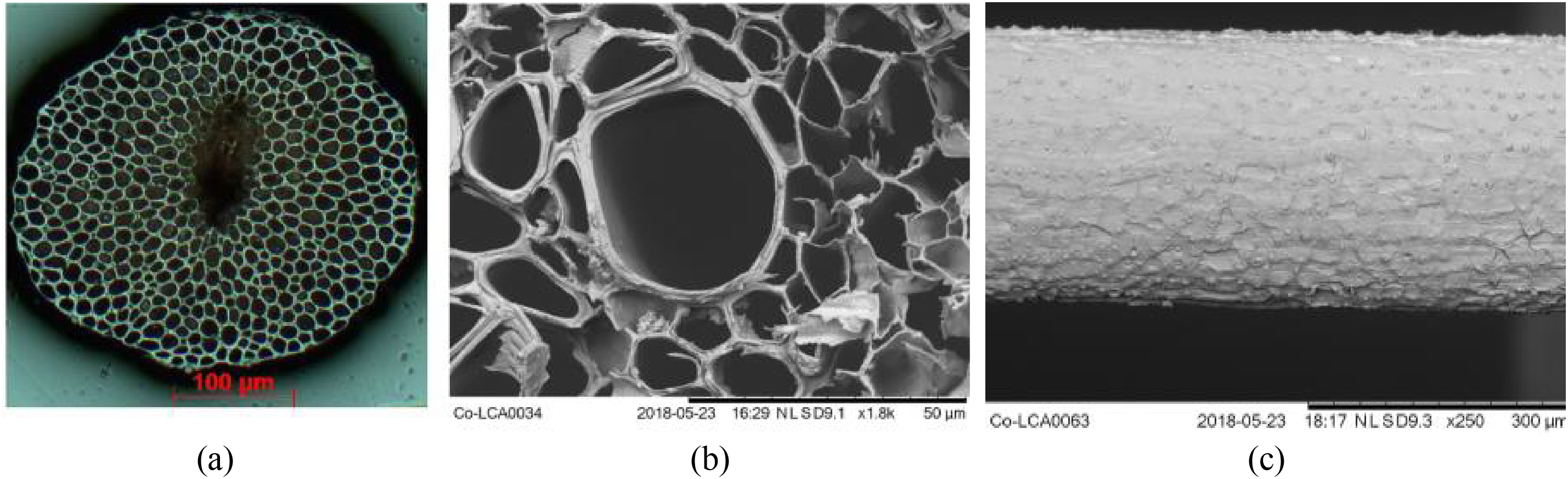

The properties of coir fibre are largely dependent on its microstructure. Fig. 5a,b shows the optical and scanning electron microscopy of the cross-section of the coir, while the coir surface is shown in Fig. 5c, where a rough surface can be observed. The rough surface has been reported to aid adhesion to the polymer matrix, thus providing mechanical interlocking of the fibre/polymer (see Section 4, for SEM of coir fibre in the polymer matrix). Fig. 5b shows elementary fibres. Fig. 5a shows the presence of smaller lumens and a larger one called lacuna [35]. These lumens have been noted to aid resin flow. The lacuna may not always be centrally located; the position of the lacuna depends on the sectioned part of the fibre (that is head, middle or tail) [4]. Lumen influences the mechanical properties of the fibre. The fibre porosity is in the range of 21.1% to 46.3 % [35,39]. The fibre surface displays a series of protrusions rather known as tyloses. Plants with many tyloses have been noted to be less prone to pathogen attack; hence, coir has a higher resistance to attack and much slower degradation than other natural fibers.

Figure 5: Cross-section of coir using (a) Optical microscopy, (b) SEM and (c) Surface of coir

3 Drawbacks and Chemical Treatments of Coir Fibre

Coir possesses a good number of drawbacks which may limit its use as reinforcement in composites. The key drawbacks include:

• Variability in the length of coir fibre, diameter and thus mechanical properties

• Poor resistance to moisture absorption

• Relatively high porosity

• Significantly lower mechanical properties when compared to synthetic fibres

• Low degradation temperatures limit the options for selecting the matrix

Natural fibres are hydrophilic due to the presence of the hydroxyl (OH) group. Therefore, they are prone to moisture ingress. The degree of water absorption or moisture penetration in coir fibre is influenced by various factors, such as the temperature of the water and environmental conditions. Higher weight gain in the fibre has been observed at elevated temperatures compared to room temperature [50]. The rate of absorption increases with temperature, which is attributable to molecular processes (see Section 4.3). This brings about reduced interfacial bond strength between the fibre and the polymer matrix, hence, a significant reduction in their mechanical properties when compared with synthetic fibres such as glass and carbon. Other drawbacks include: limited length of the fibres, non-uniformity of the fibres, especially along their length because they possess complex multi-layered cell wall and lumen structures [15,19], reduced thermal stability, high porosity, harsh extraction processes, swelling of the fibres due to the plant constitution leading to debonding and seasonal planting conditions. Coir fibres possess much lower diameters (less than 0.5 mm); as a result, it is practically difficult to measure the fibre strain via an extensometer. They are prone to insect and microbial attacks. Some of these downsides of coir fibres are attributed to their chemical composition (see Table 1) as well as their structure (see Fig. 6) and inherent defects as a natural fibre. The chemical components of these fibres, such as cellulose (OH group), allow for high moisture ingress of the fibres. Besides, polymeric matrixes such as epoxy, which are often used with fibre reinforcement, have an entirely different structure, hence incompatible with the fibre and, as a result, poor stress transfer at the interface (poor interfacial bonding). Therefore, chemical treatment of coir before use in the composite is necessary to mitigate these drawbacks.

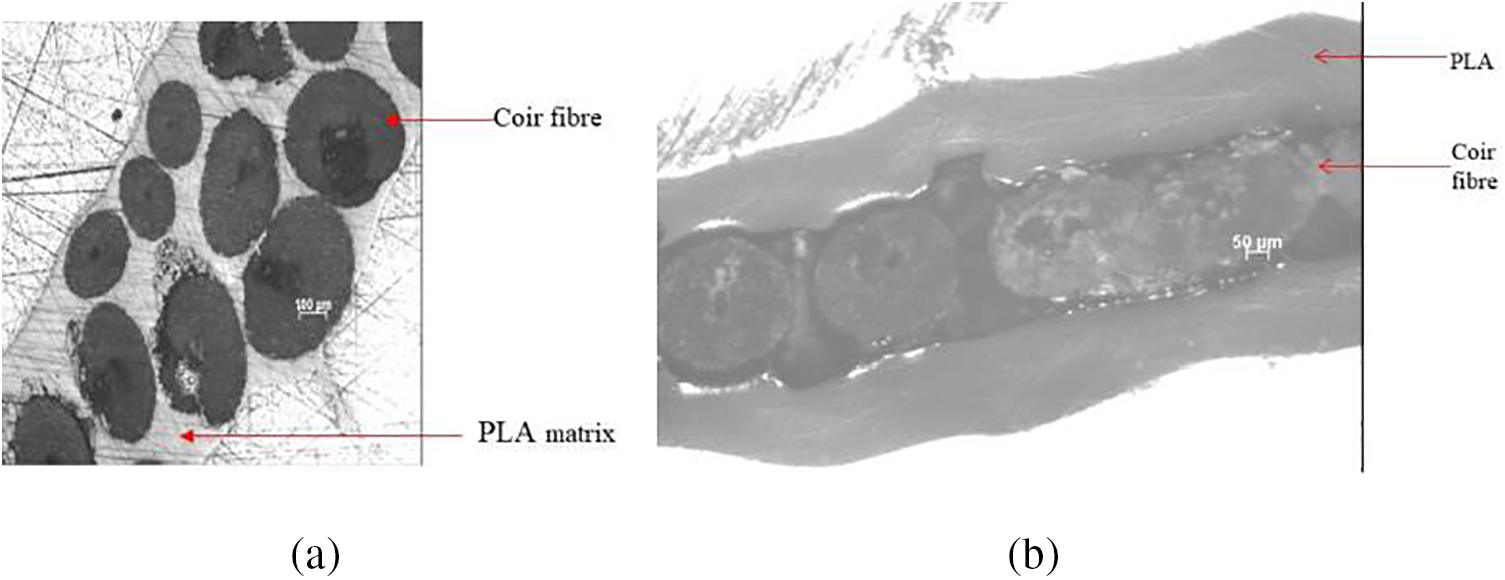

Figure 6: Microstructure of coir fibre reinforced PLA composite showing: (a) poor compatibility of the fibre in the matrix (b) fibre pull-out

3.2 Treatments of Coir Fibre and Mechanical Performance of Treated Coir Fibres

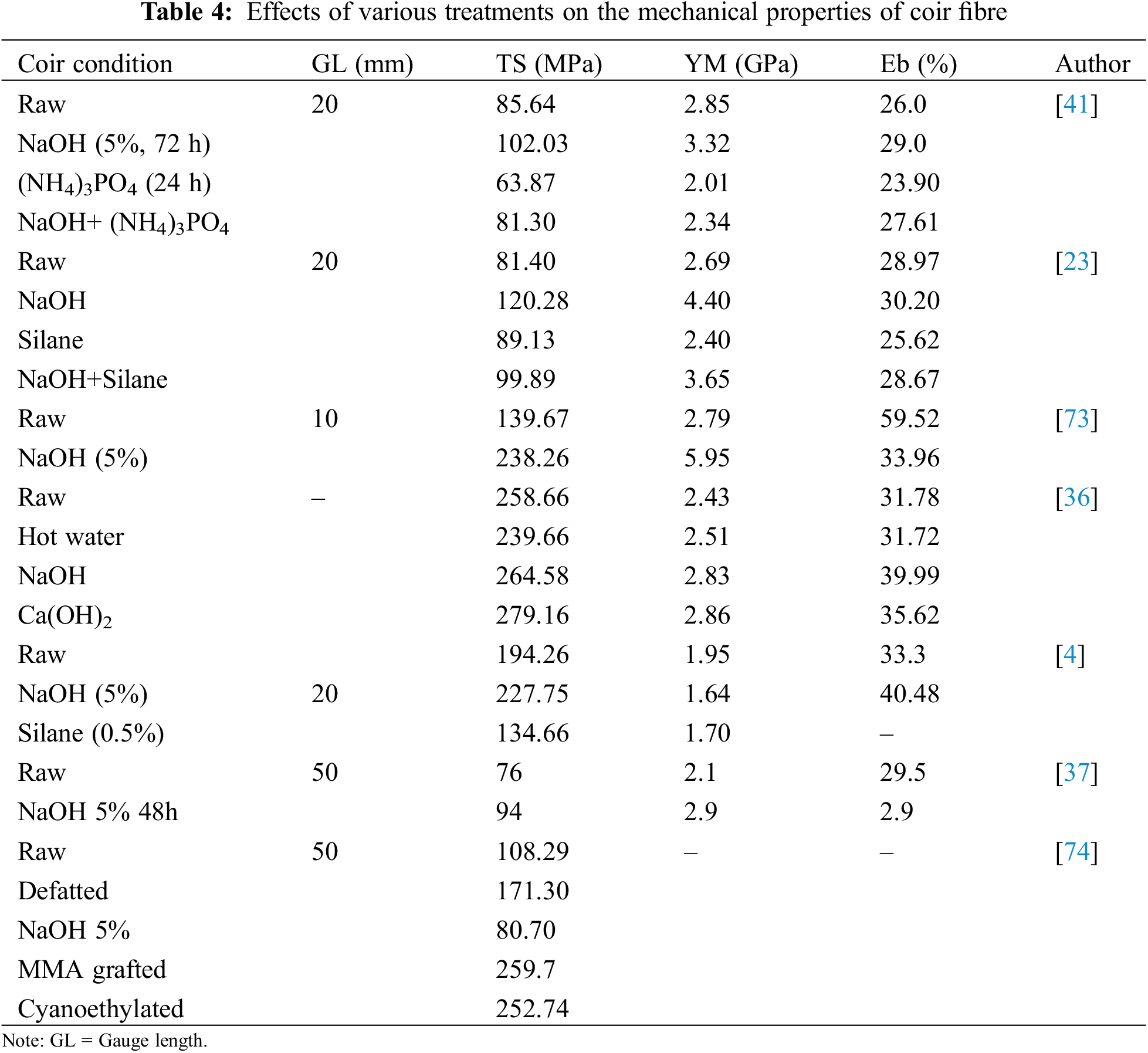

Coir fibres are washed and dried to remove surface debris before chemical treatments. Treatments that have been carried out on coir include alkali treatment [55–57], acetylation, use of silane and other coupling agents, oxidation, UV aging and grafting with acrylate monomer (EMA) using UV radiation. The main reason for surface treatments of natural fibres is to improve the interfacial bond strength between the fibre and the matrix. Others are to improve their resistance to thermal degradation [24,58–60], reduce water absorption [14,61,62], increase storage modulus [55], improve flame retardance [50], enhance damping factor [63], prevent microbial attack [64], and to resist the deterioration of their composites [65]. NaOH treatment has been the most widely reported and the most effective so far. Silane treatment has been reported as the most effective coupling agent for natural fibres. Therefore, these two treatments are subsequently reviewed in detail.

3.2.1 Alkali Treatment of Coir Fibre

Alkali treatment, particularly mercerization, is widely recognized as the predominant method for processing natural fibres. Numerous studies have documented the use of alkalis, such as sodium hydroxide (NaOH), to enhance the properties of fibres like coir. The treatment typically involves immersing coir fibre in various concentrations of NaOH for set periods and at specific temperatures. Alkali treatment improves the adhesion between fibre and resin by removing substances like wax and reducing or eliminating chemical components such as lignin and hemicellulose from the fibre. NaOH reacts with the OH group of the fibre, as shown in Eq. (5). These processes result in alterations to the organization of units within the cellulose macromolecule. Removing these substances disrupts hydrogen bonding, which increases surface roughness. This treatment reportedly enhances adhesion to the matrix.

NaOH treatment has been reported to have a good number of effects on the fibres. Such effects include improved tensile strength [56,66,67] through a decrease in lignin content [68,69], thickening of the cell wall, changes in the structure of tyloses, and reduction in fibre diameter, thereby increasing the aspect ratio. Other effects include the removal of globular protrusions on the fibre surface, resulting in rougher surfaces [70], for improved mechanical interlocking between the fibre and the resin hence improved interfacial bond strength, closure of lacuna and reduction of pore size, better fibre wetting and less water absorption than untreated, weight reduction as well as the increase in the crystallinity index [48] and increase in thermal stability have been reported. Some of the researchers subsequently manufactured coir composites with the treated fibres using a polymer matrix (see Table 4). However, most treatments were carried out only at room temperature and with 5% NaOH concentration. Besides, most of the experiments were not designed and the factors responsible for the changes (concentration, duration or temperature) were not ascertained.

Silane is a coupling agent used in natural fibres. The fibres are usually soaked in the silane solution with a known concentration for a defined duration and temperature. Some of the common silanes that have been used to treat coir fibre include organo-silane, methacryloxypropyltrimethoxy silane, trimethoxysilyl propylamine silane and 3-(Aminopropyl) trimethoxysilane. However, results showed that silane and NaOH-treated fibres displayed better mechanical properties than silane-treated fibres alone [23]. Silane treatment carried out on coir before the manufacture of composites revealed an 8.33% increase in Young’s modulus and a decrease in strength by 13.79% [71]. When coir fibres were pre-treated with 5% NaOH at room temperature for 4 h followed by 0.1% ethoxy silane in water at room temperature for 120 min, a significant increase in strength of the composites by 57.52% was observed. However, a reduction in weight by 4.3% and 3.9% for untreated and NaOH pre-treated coir fibres, respectively were observed [72]. A weight reduction of 4.3% and 3.9% for non-NaOH pre-treated and NaOH-pre-treated coir fibres, respectively were reported. Treatment temperatures were not effectively observed. However, silane concentration, temperature and duration have not yet been optimised for effective results in the treatment of natural fibres for composite manufacture. Other coupling agents that have been used on natural fibres include; Maleated polypropylene (MAPP) and Maleic Anhydride grafted copolymer used to improve the interfacial bond strength between the polymer and the matrix. The effects of various treatments on the mechanical properties of coir fibre are summarised in Table 4.

4 Coir Fibre Reinforced Polymer Composites: Manufacture and Properties

Owing to the unique properties of natural fibres, their manufacturing techniques are carefully selected. Natural fibres have a temperature limit (as previously discussed) above which fibre degradation and loss of properties set in. For improved mechanical properties, the interface, processing conditions, type of matrix (thermoset or thermoplastic) and manufacturing techniques are duly considered. Natural fibre composites have been manufactured using hand layup (HLU) [75–78], resin infusion [70], hot press [79], injection moulding [11], extrusion, compression moulding [80,81], vacuum-assisted resin transfer moulding (VARTM) and Vacuum bagging [82]. Coir fibre composites have been manufactured using thermoplastic and thermosetting matrices such as epoxy resin, polyester, polyurethane, polyvinyl chloride and polypropylene. Composites made from entirely bio-based materials (otherwise termed ‘green composites’) utilizing biodegradable matrices combined with natural fibres such as coir have been reported. Biopolymers such as bio epoxy, PLA and other thermoplastic starch have been utilized as matrices for coir fibres [83–85]. Fig. 6 shows the microstructure of the coir/PLA composite, indicating the poor compatibility of the fibre and the matrix. Regardless of reported poor compatibility between the fibre and matrix, improvement in some of the properties such as crystallinity index and thermal stability of treated coir fibre-reinforced PLA composites, have been recorded [86]. Besides, improved processing techniques and fibre orientation could lead to improvement in their performance and, subsequently higher commercialization [87].

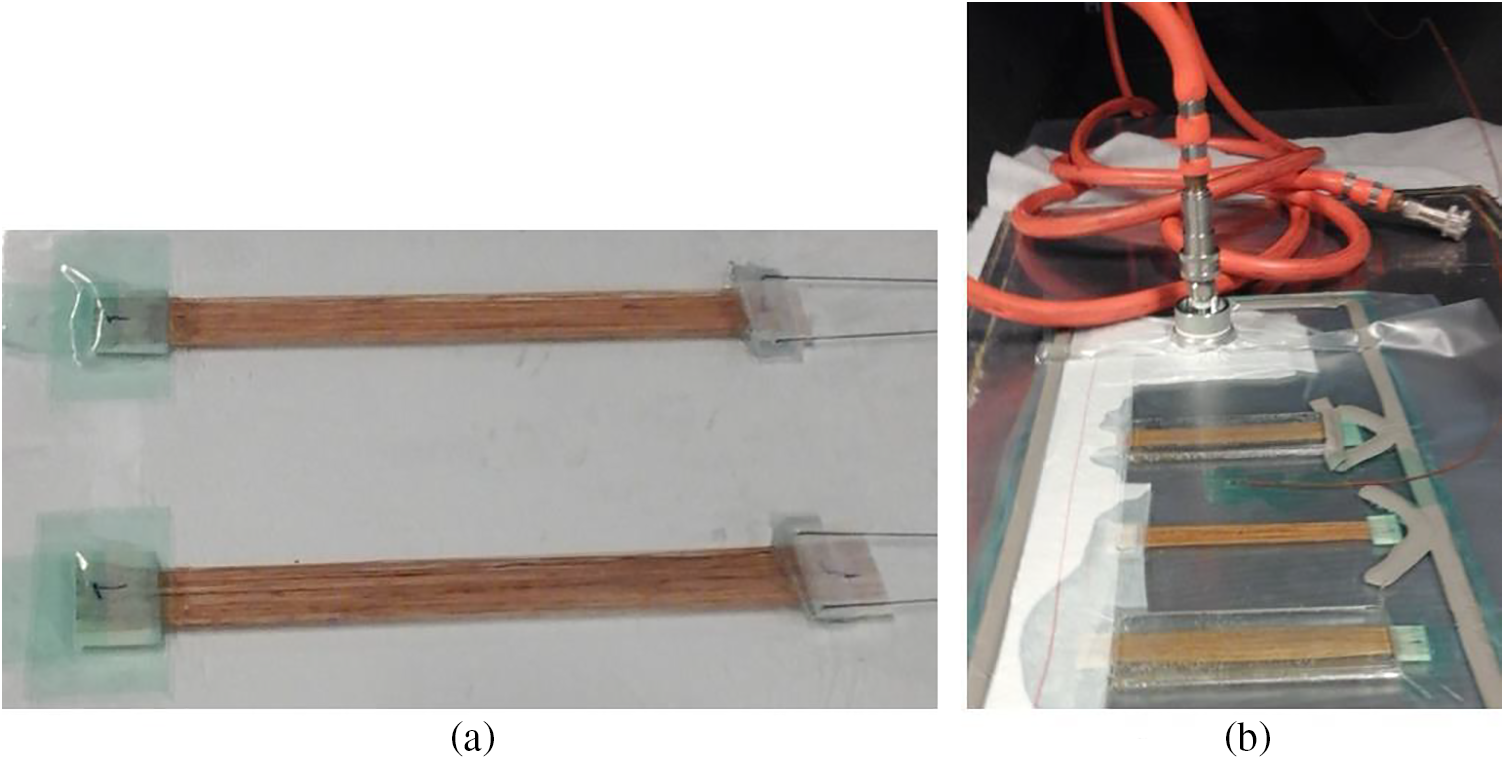

Green composites of other natural fibres that have been investigated include flax/PLA [88,89], pineapple leaf/PLA [90], datepalm/bio-epoxy [91] and sisal/PLA [81], where a significant increase in the fracture toughness has been achieved as a result of natural fibre reinforcement. Coir, as well as other natural fibres, have been used in reinforcing concrete. The high elongation at break (above 35%) of coir fibre has been recommended as a property that may lead to the bridging effect of the force-carrying ability in the cement-based matrix and subsequently improve the ductility of cement [27,92]. An increment in both the tensile and compressive strength of concrete observed when natural fibre was included raised the toughness potential of the concrete [93]. Other natural fibres that have been used to reinforce concrete include hemp [93], where hemp-rope confined lightweight aggregate concrete displayed enhanced ultimate compressive strength and strain. Natural fibre has led to an improvement in the modulus of elasticity, flexural, compressive and tensile strength of concrete as well as a drop in the workability of the concrete [92]. Fibres have been prepared with different orientations (see Fig. 7a) and fibre volume fractions. The cure of the composites has been achieved at room temperature or by using an air oven, vacuum oven, autoclave (see Fig. 7b) or electron beam for a perfect finish. Common manufacturing techniques that have been used for coir composites include HLU, resin infusion, hot press, injection moulding and compression moulding; these will be reviewed in a subsequent section.

Figure 7: Coir fibre composites (a) Unidirectionally-aligned and (b) to be cured in an autoclave

4.1 Manufacture of Coir Composites: Hand Layup (HLU), Resin Transfer Moulding (RTM), Hot Press, Injection Moulding and Compression Moulding

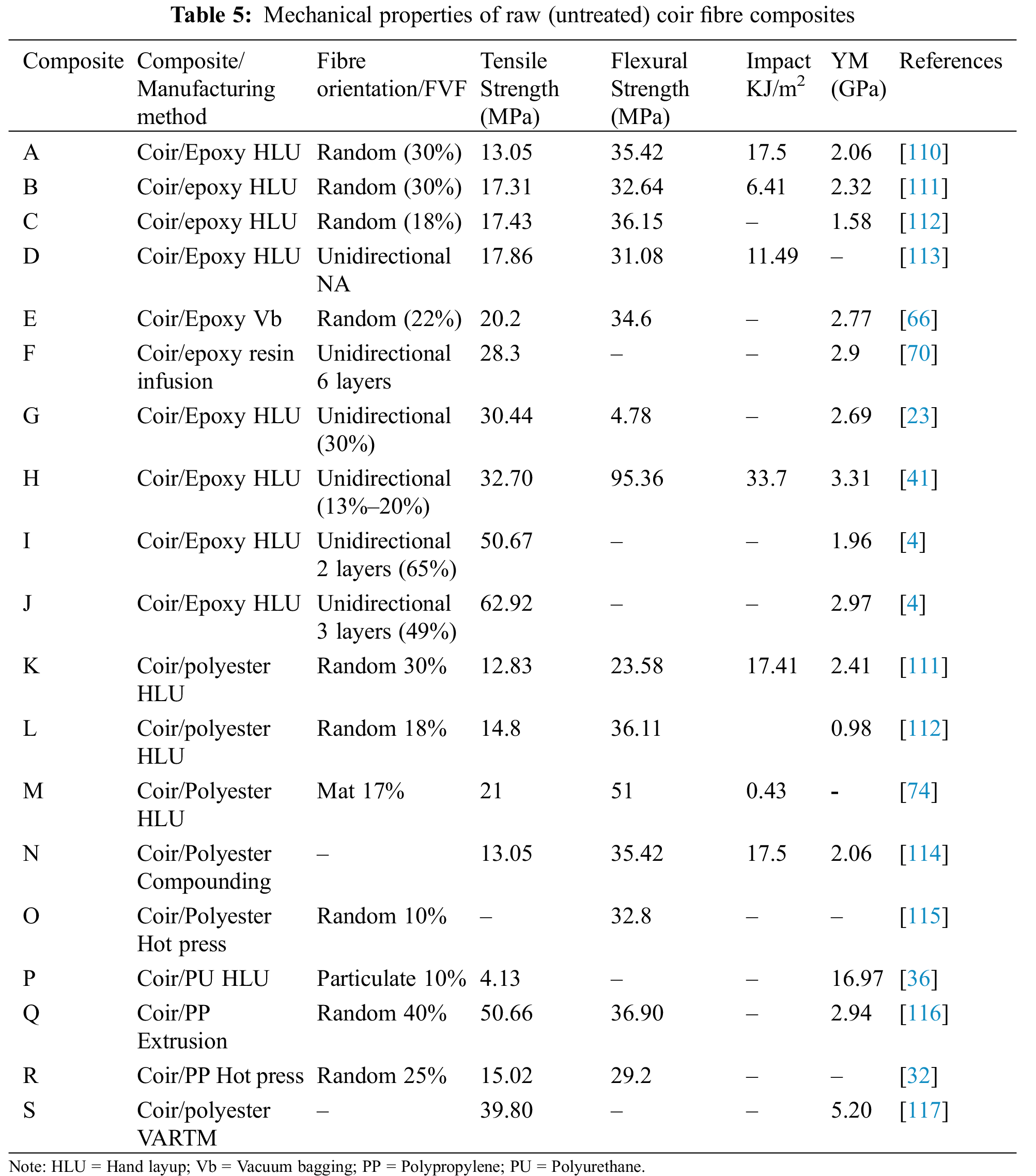

Table 5 shows that coir fibre composites have been manufactured with epoxy, polyester, polypropylene and polyurethane matrix. Epoxy and unsaturated polyester resins are thermoset resins that do not give off volatiles during cross-linking. Epoxy resin is a thermoset polymer that has been predominantly used for coir fibre matrices and even for high-performance composites. Epoxy possesses inherent advantages such as excellent wettability, and high thermal and dimensional stability; it is also less volatile and can successfully be used at room temperature. Unsaturated polyester cures at room temperature with methyl ethyl ketone peroxide used as an accelerator. Epoxy is predominantly used as a matrix to manufacture composites via HLU. In HLU, the reinforcing fibres are in most cases, manually impregnated by the resin, where the skill and expertise of the operator play an important role in the result of the composite [94]. In RTM, a mould or steel panel is used to form the panel surfaces. The reinforcing fibres are placed into the mould cavity; the mould is then closed before the introduction of the resin. RTM comes in different forms concerning how the resin is introduced into the mould. RTM includes resin infusion and vacuum-assisted resin transfer moulding (VARTM). Fibres are impregnated and preforms laminated using resin infusion. The vacuum pressure, resin inlet, resin trap and clamps are carefully monitored. Coir fibre composites with epoxy matrix have been manufactured using resin infusion as shown in Table 5.

Coir composites such as coir/PBS [73] have been manufactured using a hot press at a pressure of 10 MPa, temperature of 150°C and a duration of 10 min. Cooling was carried out by quenching in ice water. The parameters to watch are processing temperature, pressure, dwell time, sample dimensions, and the viscosity of the resin. Other important parameters include means of cooling such as quenching or air cooling. Coir/polybutylene succinate and coir/PLA have been manufactured using a hot press. A composite manufactured using HLU can be consolidated in a hot press platen.

The manufacturing of coir composites through injection moulding is not widely practised. However, Reference [1] successfully utilized injection moulding to produce coir fibre-reinforced polyvinyl chloride (PVC). Initially, the fibres were ground to various sieve sizes at different fibre volume fractions and then combined with the matrix material before being fed into the hopper. The rotating screw and the heater band within the barrel facilitated the formation of the composite. Key parameters in the manufacture of composites by injection moulding include injection temperature, pressure, rate, and holding pressure [1] manufactured a PVC/Coir composite using an injection pressure of 130 MPa, a temperature of 190°C, and a holding pressure of 190 MPa. In injection moulding, the mould clamping force is verified to ensure it is adequate to keep the mould closed. The required mould clamping force is calculated as follows:

Eqs. (7) and (8) are for circular and rectangular plates, respectively. where F = mould clamping force,

This expression is used to estimate the clamping force depending on the shape of the material.

Other natural fibres have been manufactured using injection moulding including ramie/PLA [95]. Compression moulding can be used to manufacture composites of thermosetting or thermoplastics matrix. The granular plastic can first be converted into sheets by placing the granules on a steel mould of the compression moulding machine and compressed at a certain pressure, temperature and duration. Afterward, the fibres are stacked onto the produced sheets according to the experimental design or stacking sequence adopted to form laminates [80,81,96,97]. For compression moulding, the compaction force ‘F’ is given by:

Other methods that have been used to manufacture natural fibre composites include vacuum infusion, filament winding and pultrusion [98].

4.2 Properties of Coir Fibre Composites

Table 5 gives a summary of the mechanical properties, manufacturing techniques, fibre volume fractions and fibre orientation that have been used in coir fibre-reinforced composites. Table 5 shows that over 50% of the researchers used the HLU manufacturing method and epoxy matrix. The volume fraction used ranges between 10–65% with both random and unidirectional fibre orientations. Over 35% of the researchers manufactured coir composites with fibres unidirectionally oriented.

From the Table, fibre volume fractions of about 10% yielded poorer results than those of over 20% concerning mechanical properties. Randomly oriented fibres produce less desirable properties in composites than unidirectionally oriented fibres in terms of tensile and flexural strengths.

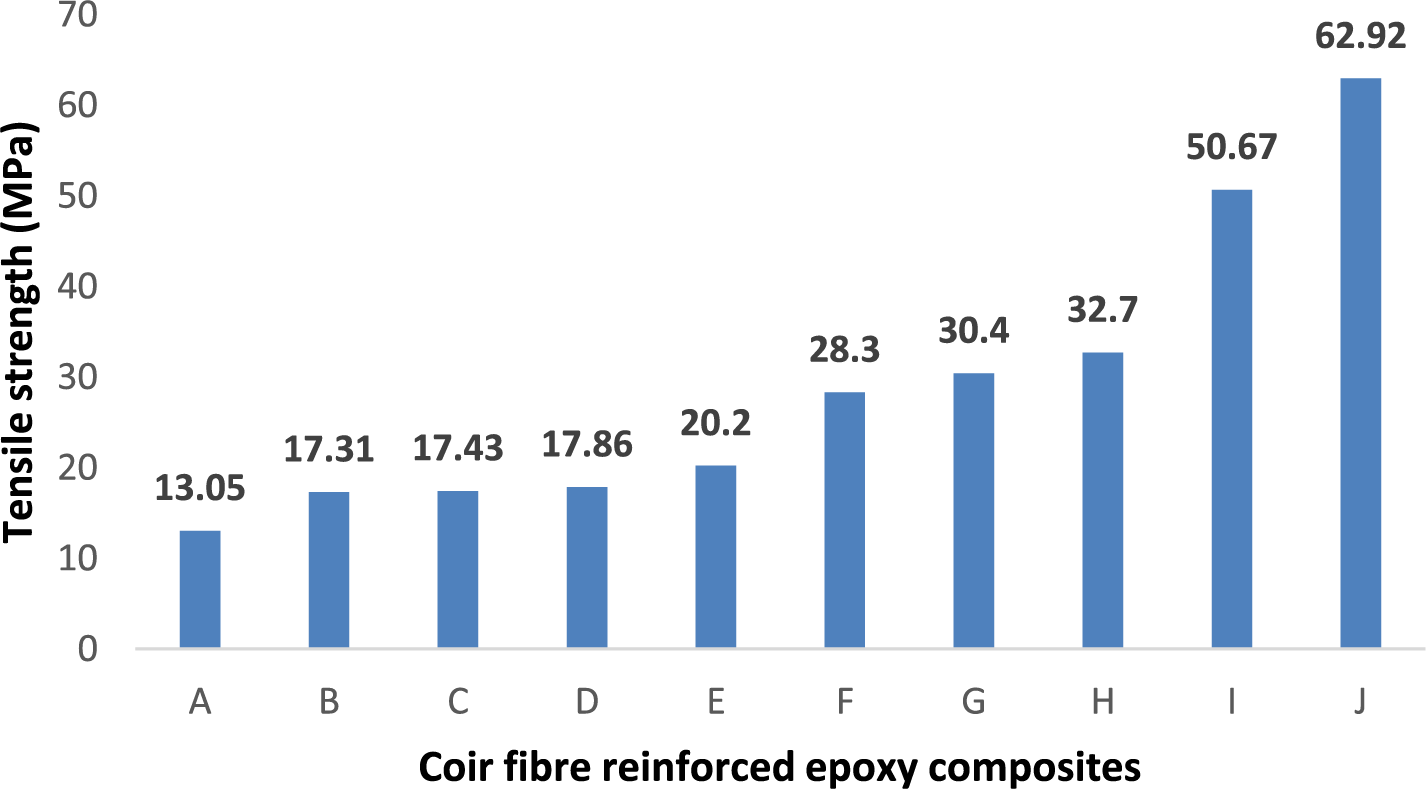

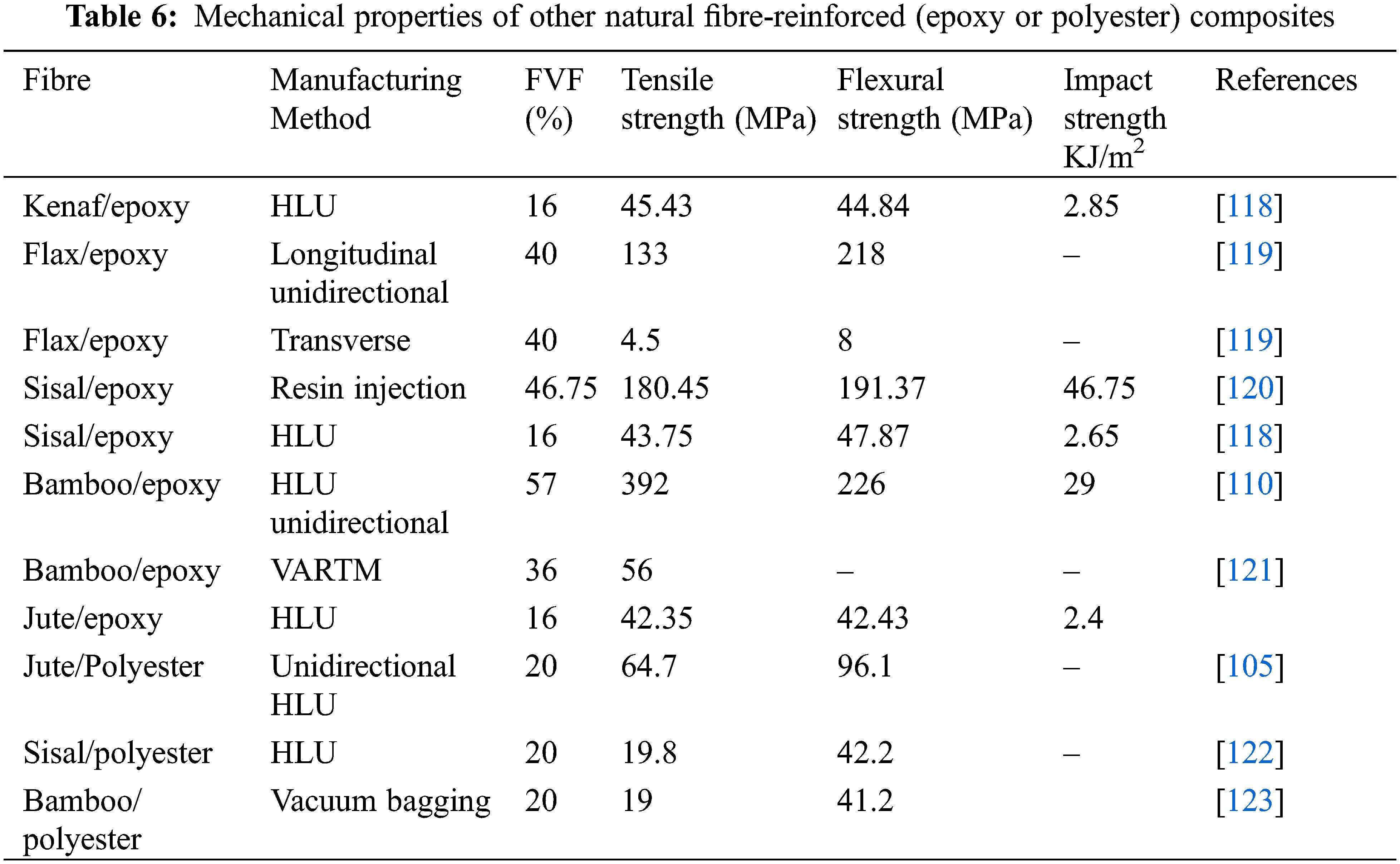

Fig. 8, deducted from Table 5, shows the tensile strength of the coir epoxy composite to range between 13.05 to 62.92 MPa (A–J). The highest tensile strength achieved was 62.92 MPa (J) with 49% fibre volume fraction unidirectionally oriented and stacked in three layers, manufactured using HLU. 50% of HLU-manufactured coir/epoxy composites with unidirectionally oriented coir fibres possess an average tensile strength of 41%. This is comparable to the tensile strengths of sisal, jute and Kenaf fibre-reinforced epoxy composites manufactured using HLU, as shown in Table 6. The impact strength of coir is over 90% higher than those of sisal, jute and Kenaf epoxy composites manufactured via HLU. However, the flexural properties of coir/epoxy composites were 15% lower than those of sisal, jute and Kenaf epoxy composites manufactured using HLU. Not much has been done on the creep behaviour of coir composites as has been recorded in jute-reinforced composites [99].

Figure 8: Tensile strengths of coir fibre-reinforced epoxy composite

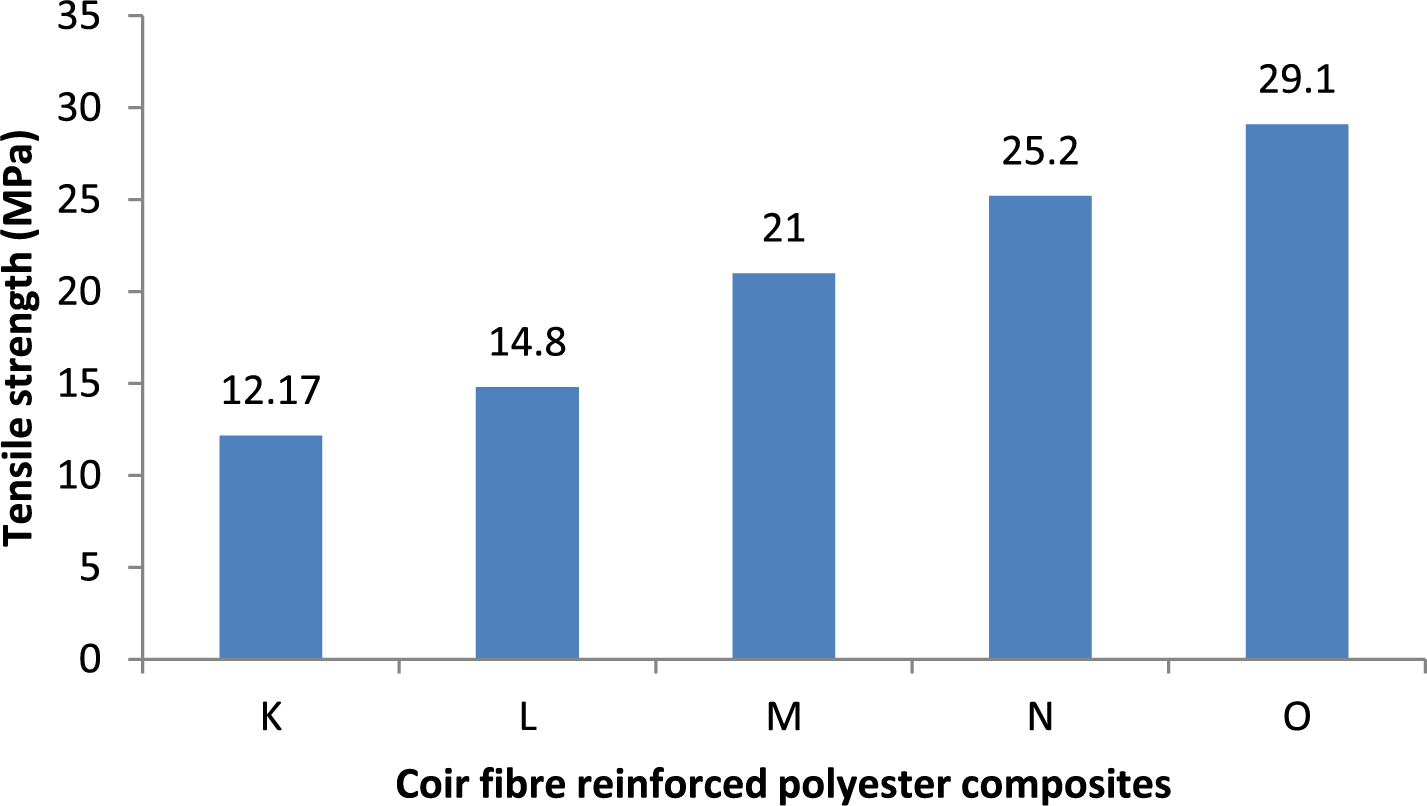

Fig. 9, deducted from Table 5, gives a clearer picture of the coir/polyester composite where the highest and the lowest tensile strengths were 29.1 and 4.13 MPa respectively with an average of 18.32 MPa. However, this cannot be compared with the tensile strength of other natural fibres using a polyester matrix, as shown in Table 6. The mechanical properties, as seen, have invariably been influenced by several factors such as the type of matrix, type of fibre [25,100], size of fibre [98], manufacturing method [101], fibre treatment [69,102–104], fibre orientation [105], stacking sequence [106] and fibre volume fraction [107–109]. Some of these factors will be reviewed in the subsequent section.

Figure 9: Tensile strengths of coir fibre-reinforced polyester composites

4.3 Influence of Composite Parameters

Fibre volume fraction, fibre treatment, fibre length and fibre orientation on the properties of the composites.

4.3.1 Fibre Volume Fraction and Void Content

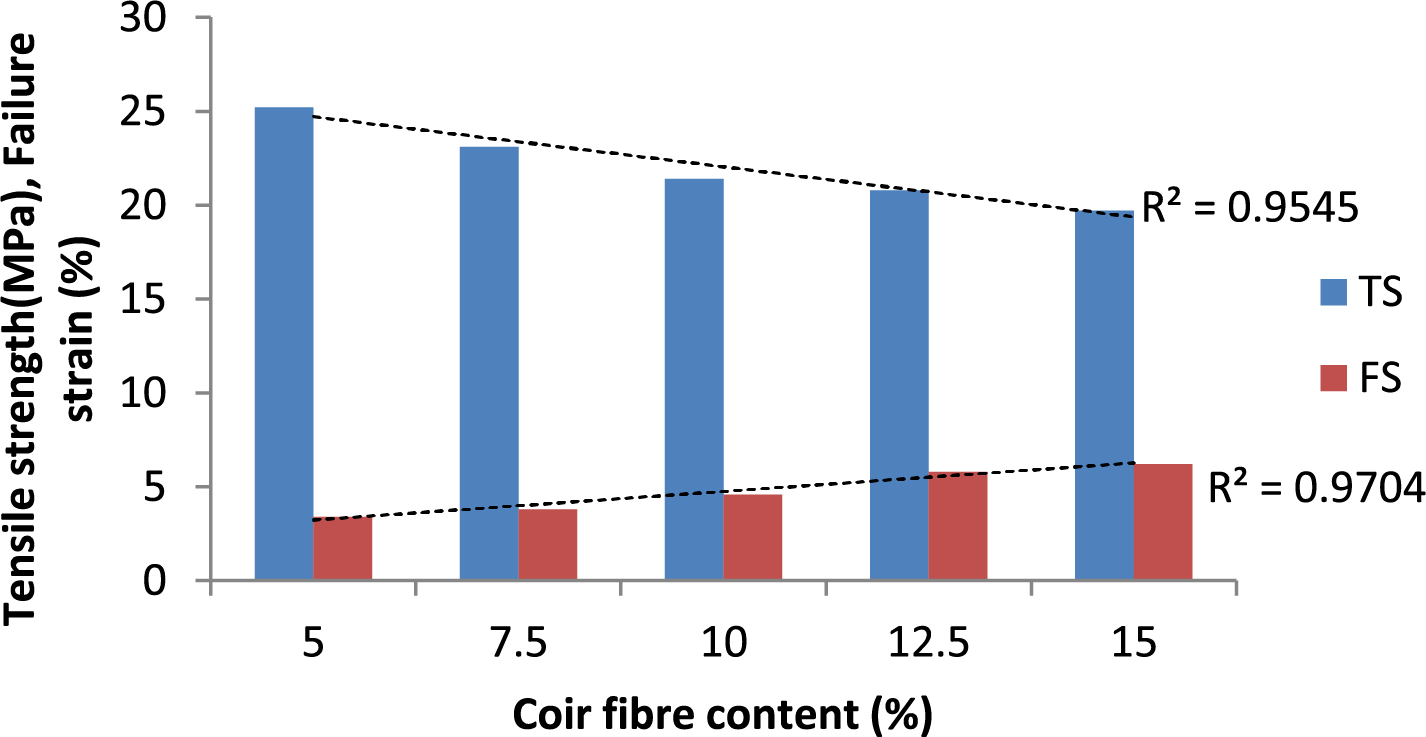

The fibre volume fraction has a significant impact on the mechanical properties of composites, as shown in Table 5 and discussed in Section 5. An increase in fibre volume fraction enhances the strength of coir fibre, as shown in Fig. 10. Observations indicate reduced swelling and water absorption with increased fibre content [84]. There is also a noted increase in compressive strength with a higher fibre content [124]. Furthermore, the inclusion of coir powder has been shown to augment the thermal insulation properties of the composites, suggesting their potential in applications requiring robust thermal resistance and insulation [125].

Figure 10: Influence of fibre content on the tensile strength and failure strain of coir castor oil-based PU composite adapted from Naveen et al. [114]

However, a definite increase in fibre loading does not necessarily lead to an improvement in the tensile properties of the composite. This is because there is a critical volume threshold beyond which any additional fibres contribute to a reduction in tensile strength. Research indicates that at lower fibre contents, approximately 2.7% for sisal and 10% for pineapple leaf fibres, the fibres merely act as defects within the composites. They are insufficient to effectively reinforce the matrix, resulting in lower stress tolerance and ultimately leading to the debonding of the fibres [46].

However, in Table 5, despite both composites A and B having an identical fibre volume fraction of 30% and being manufactured using HLU with randomly oriented fibres, their tensile strength and impact energy differ markedly. This discrepancy may be due to the factors previously outlined. Flexural strength has been reported to increase with fibre loading. However, this might not always be the case (see Table 5) as a result of weak interfacial bond strength between the fibre and the matrix, inherent properties of fibre and matrix and processing conditions such as fibre removal or extraction method are contributors. Flexural strength is dependent on the strength and elongation of the fibres [118]. Low flexural strength has been attributed to the presence of void in the fibre [112]. Impact strength increases with fibre loading and an increase in the lumen-filled ratio [120]. Coir is notorious for a high number of lumen with lacuna as the largest lumen; hence, a bigger lumen, easier penetration of resin [126], and increased impact strength. High impact strength is as a result of high shear modulus and high interfacial bond strength [118]. An increase in fibre volume fraction leads to an increase in elongation at break [36]. Fig. 10 shows the effect of fibre loading on the mechanical properties of coir fibre/epoxy composites where the tensile strength decreases with an increase in fibre loading; this has been attributed to insufficient adhesion, increase in void formation, reduction in the workability of the composites and an increase in the crack formation as the volume of fibre increases [95,127,128] as well as an increase in the level of impurities [118]. However, References [17,128] observed that tensile strength and stiffness increase with the increase in fibre loading, up to a certain point (about 30%) as a result of the fibre, matrix or type of orientation, Reference [129] noted that at a higher weight content of the fibre (60%), an increase in tensile strength was observed, this was attributed to a decrease in the number of voids as the fibres are being sufficiently impregnated with more lumens being filled with resin. Void content (VCon) can be obtained from Eq. (10):

where

The tensile, flexural and impact strength of coir/epoxy composites increase with the increase in fibre length [110]. However, some researchers have observed no significant variation in the tensile strength with a change in length. According to [130], there exists a critical fibre length for optimally improved composites, and for [131], fibre dispersion and fibre length are affected by the rate of mixing and mixing time. The hardness decreases with an increase in the length of the fibre [110].

Different treatments have been adopted for coir fibre before composite manufacture (see Section 3.2).

4.3.3 Treatments and Interfacial Bond Strength

Treatments are carried out on coir fibres before composite manufacture for various reasons. One of these reasons is to reduce water absorption. Several treatments have been used on coir fibre to reduce its affinity for water. Such treatments include alkali (NaOH) treatment, use of silane coupling agents, coating of fibre, and treatment with gamma-ray irradiation. For coir composites, the degree of water absorption depends on the volume of fibre used, fibre orientation, type of matrix and environmental condition. Reference [50] reported an increase in water absorption as a result of an increase in fibre loading for HDPE/Coir and LDPE/Coir. However, LDPE/Coir has higher weight gain than HDPE; this has been attributed to the branching of the polymer chain in the LDPE microstructure with voids. The degree of water absorption is a function of the degree of fibre loading. Appreciably higher water absorption has been recorded for only 5 wt% fibre loading than at 10–15 wt% [50]. Moisture absorption promotes the swelling of the fibre and influences the dimensional stability of the composite. For coir fibre/wheat gluten biocomposites [42], the addition of 10% fibres reduced the water absorption of the materials from 75% to 66.5%. At a reduced time, less water is absorbed. As the silane coupling agent reacts with the hydroxyl group, there is a decrease in the diffusion rate, leading to reduced moisture absorption. Applying a latex coating functions similarly by partially shielding the pores in the fibre, thus reducing the moisture ingress of the fibre. Treatment with gamma-ray irradiation results in a decrease in capillary action, leading to reduced moisture absorption [4]. Given the structure of coir, which is characterized by numerous pores and a high degree of porosity in its natural state, it might be anticipated that coir fibres would absorb more moisture than sisal and jute, which are denser and less porous. However, this is not so. As the fibre content increases, moisture ingress tends to rise due to the higher cellulose content. It is anticipated that coir fibres with certain diameters will be significantly less susceptible to moisture penetration compared to other natural fibres when treated with chemicals and coupling agents with improved interfacial bond strength.

Interfacial bond strength can be investigated through the interfacial shear strength (IFSS) values calculated from fibre pull-out test for composites (see Eq. (12)).

where

The tensile properties (tensile strength and Young’s modulus) of coir of coir/epoxy composites increase on surface treatment [36]. Alkali treatment leads to an improvement in the interfacial bonding between the fibre and the matrix by providing additional sites for mechanical interlocking and hence boosts adhesion and improves interfacial bond strength. Silane on alkalized fibres yields higher tensile properties [23], and flexural properties also increase on alkali treatment [74], an appropriate treatment is always imperative [134]. However, the concentration of treatment chemicals is a critical factor that needs to be considered to minimize deterioration of the cell wall and, hence, reduction in properties.

The tensile strength of composites with longitudinally oriented fibres has been confirmed to be higher than that of composites with transverse and randomly oriented fibres. Maximum strength and stiffness are achieved when the fibres are aligned longitudinally to the applied force [105]. The tensile properties of composites depend on the orientation of the reinforcing fibres [87]. Composites with transversely oriented fibres exhibit reduced tensile properties due to the uneven distribution and high localization of stresses, which leads to a significant reduction in strength, as indicated in Table 5. Conversely, fibres that are aligned parallel or at 0° to the direction of the applied force are more effective in transferring stress, as reported by [94]. Fibers oriented perpendicularly to the applied load are the only ones that can effectively reinforce a composite [135]. In composites with long reinforcing fibres, these long coir fibres are aligned perpendicular to the applied load. An enhancement in tensile strength and Young’s modulus was noted for composites with longitudinally aligned fibres. This is attributed to the fibres being oriented perpendicularly to the direction of crack propagation, which leads to an increase in both the tensile strength and Young’s modulus of the composites. The failure mode of composites depends on the orientation of the fibre reinforcements [136]. For composites of reliable quality, both perfect impregnation of the reinforcements and strong interfacial bond formation have to be adequately addressed.

4.3.5 Specific Factors that Might Have Contributed to the Tensile Strength of 62.92 MPa at a 49% Fibre Volume Fraction in Coir/Epoxy Composite J of Fig. 8

The likely contributors to the observed high tensile strength of coir composites J of Fig. 8 can be attributed to a host of factors such as:

(i) Type of matrix (epoxy): The mechanical properties of the matrix are a contributory factor to the mechanical properties of the composite. Epoxy resin, a polymer with low molecular weight, exhibits properties that are considerably superior to those of many other resins traditionally utilized as matrices in natural fibre composites; epoxy possesses low volatility, excellent wettability, and high thermal stability [25].

(ii) Factors related to resin impregnation: Factors that could affect the impregnation of fibres by the resin may include the pore size of the fibre and resin conditions, such as the concentration of the binding resin. It has been reported that the degree of wetting and permeability by resin and the uniformity of the resin within the fibre, as well as the application pressure of the resin, affects to a large extent the outcome and the properties of the composites. This can be described using the Navier-Stokes equation for the motion of a fluid (Eq. (13)).

Stokes equation for motion of fluid:

f = forces exerted on the fluid

(iii) Fibre arrays: Dense/closely-packed arrays of aligned fibres (preforms), fibres arranged (in parallel) very close to one another without gaps. unidirectional arrays of continuous fibres will yield superior mechanical properties when compared to their short-fibre counterparts [70].

(iv) Fibre/matrix interface: The interface facilitates load transfer and is instrumental in determining the failure mode of composites. The synergy between the fibres and the matrix contributes to the overall behaviour of the composite. This interface is defined by its interfacial energy (J/m2) and interfacial frictional shear stress (MPa). The effectiveness of stress transfer from the resin to the fibre within the interface region is a function of the degree of adhesion, as previously discussed.

(v) Additional factors may include enhanced fibre orientation and alignment [137], improved wetting [105], close packing of fibres [126], adequate interlocking of fibre with matrix, fibre orientation, and fibre stacking [100,105,118]. Furthermore, the species and origin of the fibre also play a role.

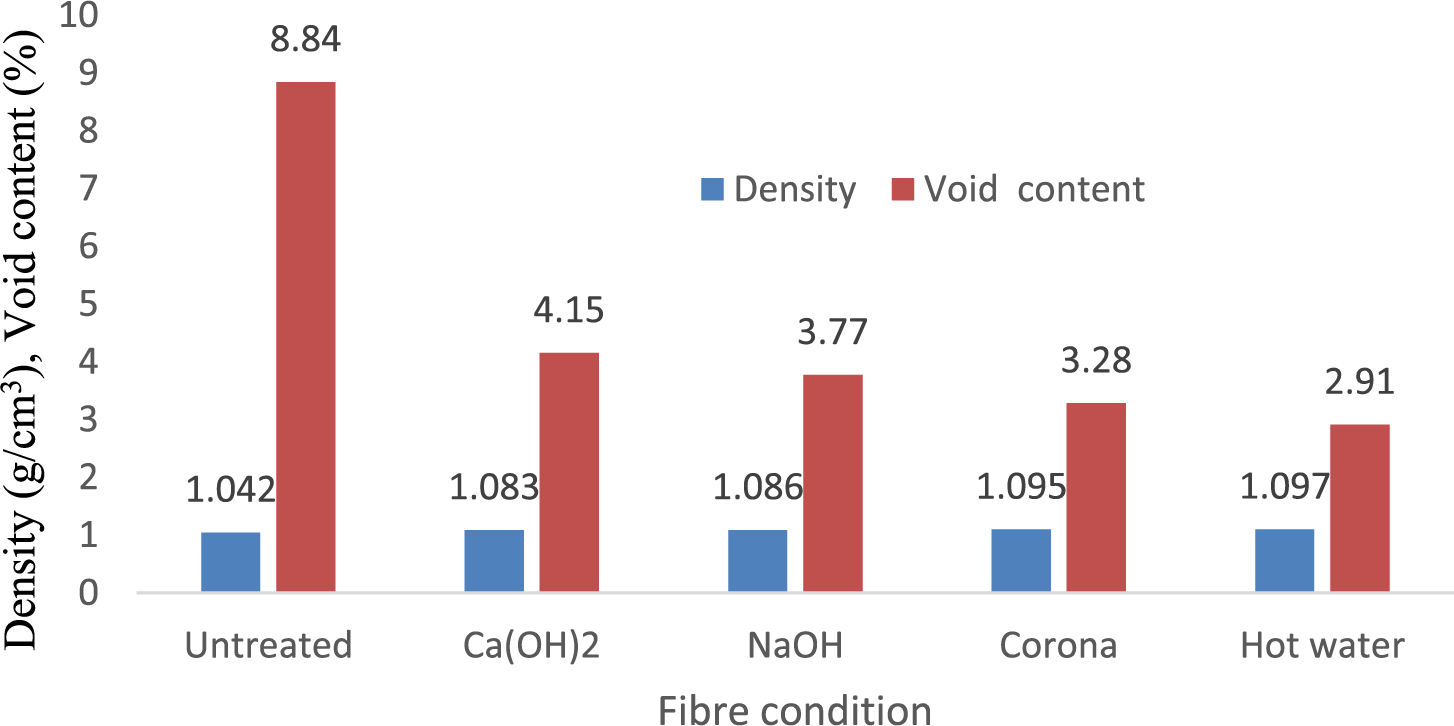

4.4 Thermal Properties, Density and Void Content of Coir Composites

The thermal stability of composites is a subset of the thermal stability of both the resin and the fibre; treated fibres show better thermal stability in composites than untreated [36]. However, not all treatments lead to an improvement in thermal resistance. Enzymatic treatment improves thermal stability [138] as well as glycidyl methacrylate [58]. A reduction in void content and density of coir composites is observed with treated fibres, as shown in Fig. 11. Void is observed in the composite as a result of the inability of the matrix to displace all the air entrapped within the fibre as the fibre is being impregnated. The presence of void (see Eq. (10)), especially at a significant level, significantly reduces both the mechanical and physical properties of composites [139]. Voids can be attributed to partial wetting out of the fibres by the matrix and processing conditions [10]. The addition of a wetting agent brings about an improvement in interfacial compatibility and, hence, improved mechanical properties. Therefore, perfect impregnation and interfacial bond strength are imperative for improved composite structures.

Figure 11: Density and void content of untreated and treated coir fibre/polyurethane composite adapted from Faria et al. [36]

4.5 Water Absorption of Coir Fibre-ReInforced Composites

High moisture ingress gives rise to poor wettability and weak interfacial bond strength between fibres and matrices, leading to the deterioration of composites. Water absorption of coir fibre can be determined using the following equation:

where

Recent researches show that water absorption is higher in untreated coir fibre composites than in treated [36]. Water absorption significantly decreases on fibre treatment; this can be attributed to the reduction of the free hydroxyl (OH) group [10] and hence improved interfacial bonding between the fibres and the resin. The coating has been carried out on other natural fibres such as jute, sisal and bamboo to reduce the susceptibility of the composites to moisture ingress [140].

5 Traditional and Modern Applications of Coir Fibre and Coir Fibre Reinforced Composites

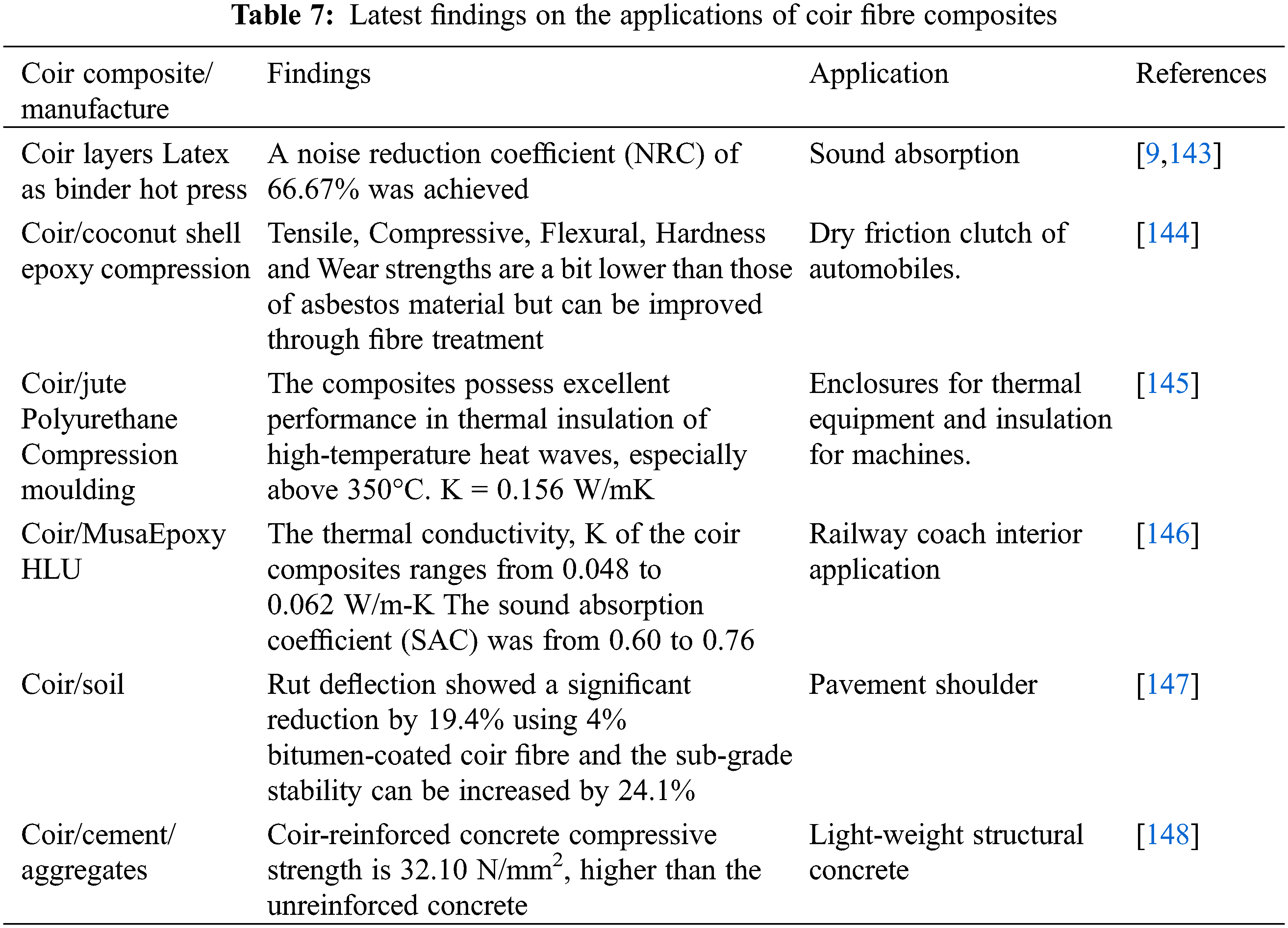

Some of the traditional applications of coir are in coir mats, blankets, brushes [62,141], safety helmets, roofing components [142], packaging materials [100], concrete [124], ropes, twine, rug, geotextiles [127] and for sand reinforcement and electrical insulation [1]. Table 7 shows the latest findings on the applications of coir fibre composites. Given the unique properties of coir fibre, including its exceptionally low density, porosity, stretchability (notably high elongation at break), and significant resistance to microbial degradation, it is most advantageous to direct its application towards areas such as geotextiles, sound absorption materials and thermal insulation enclosures. Thermal insulators resist heat gain and loss. Their effectiveness depends on the service temperature, material density, and thermal conductivity. Coir is known for its low thermal conductivity, which helps maintain consistent indoor temperatures by reducing heat transfer. Such thermal insulators are essential in applications like building materials. Additionally, coir fibre possesses superior acoustic properties, effectively reducing noise in automotive vehicles and other mechanical devices. The intricacies of this will be fully addressed in a subsequent review.

6 Knowledge Gap/Future Research Directions

Improved techniques for sorting and close-packing alignment of coir fibres remain an issue, as this will boost the mechanical properties of the composites. Extraction of coir fibre is rather harsh and leads to a significant loss in properties, especially during de-fiberising and combing, a better approach needs to be sought for improved properties. Treatment of coir fibre, especially in the area of coating and wider treatment parameters, needs to be investigated. Measurement of the degree of uniformity of fibre dispersion within the matrix has not been provided. Within the reviewed research papers; only a few works have been done using other manufacturing techniques, such a vacuum-assisted resin transfer moulding (VARTM) and injection moulding. The cure of the composites was mostly carried out at an unspecified temperature and duration. Curing in autoclave and vacuum ovens has rarely been reported. Mechanical properties of the composites depend on a host of factors, including fibre volume fraction. An absolute or a range of coir fibre volume fractions for improved properties with defined mixing and mixing time of the matrix is lacking. Not much has been done on the creep behaviour of coir fibre composites as has been recorded for other natural fibres. Research on coir for use in limb prostheses as in other natural fibres has rarely been recorded. Hybridization of coir fibre with a higher strength natural fibre such as flax, as well as hybridization of coir fibre with synthetic fibre such as glass or carbon, needs to be investigated. Employing nano-sized particles of coir fibre alongside those of a stronger natural fibre can improve interaction. Similarly, the use of coir fibre nano-particles with synthetic fibre nano-particles needs to be explored. Additionally, the additive manufacturing of coir fibre composites can achieve the precise shape and structural integrity.

The work summarizes the global availability of coir fibre and the tensile properties of coir fibre concerning the fibre origin. The diameter of coir fibres varies from 0.006 mm (Vietnam) to 0.577 mm (Thailand), and their tensile strength ranges from 68.4 MPa (Tanzania) to 343 MPa (Vietnam). Coir fibres from Vietnam and India exhibit the highest elongation at break, at 63.8%, and the highest Young’s modulus, at 6 GPa, respectively. More than 50% of the researchers within the scope of the reviewed studies employed the hand layup (HLU) manufacturing method with an epoxy resin matrix. NaOH (at 5%) concentration and silane were predominantly used in the treatment of coir fibres. NaOH improved the single fibre properties and the properties of their composites, especially when it is followed by silane treatment. In coir composite manufacturing, many researchers have used the hand layup technique using epoxy and polyester matrix. Only a few works have been done using other manufacturing techniques, such as VARTM and injection moulding. The cure of the composites was mostly carried out in the air oven. Curing in autoclave and vacuum ovens has been scarcely reported. Mechanical properties of the composites depend on several factors, namely, processing technique/manufacturing method, fibre volume fraction, type of treatment on the fibre and the fibre length. From the findings, more investigations on the treatment of coir fibre especially in the area of coating and wider treatment parameters are needed.

Acknowledgement: The authors gratefully acknowledge the supervisors at the School of Engineering, University of Birmingham, UK and the Tertiary Education Trust Fund, Nigeria.

Funding Statement: The authors received no specific funding.

Author Contributions: Data collection: Chioma Ifeyinwa Madueke; Analysis and interpretation of results: Chioma Ifeyinwa Madueke; Draft manuscript preparation: Chioma Ifeyinwa Madueke, Okwunna Maryjane Ekechukwu, Funsho Olaitan Kolawole. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Data availability does not apply to this article as no new data were used in this present study.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Aravindh S, Venkatachalam G. Investigations on dielectric constant of coir powder-reinforced PVC composites investigations on dielectric constant of coir powder-reinforced. J Nat Fibers. 2023;20(2):431. doi:10.1080/15440478.2023.2239501. [Google Scholar] [CrossRef]

2. Schiavon Z, Borges PM, Jose J. Physical-mechanical properties and microstructure changes in mortars with chemically treated coir fibres. J Mater Res Technol. 2024;30:4030–43. doi:10.1016/j.jmrt.2024.04.109. [Google Scholar] [CrossRef]

3. Ru S, Yang R, Yang S, Zhao C. Effects of physical and mechanical properties of coir fiber and reinforced epoxy composites treated with acetic anhydride and alkali. J Nat Fibers. 2023;20(2). doi:10.1080/15440478.2023.2285819. [Google Scholar] [CrossRef]

4. Madueke CI. Tensile properties of as-received and surface-treated coir fibres and composites (Thesis). University of Birmingham: UK; 2021. [Google Scholar]

5. Food and Agriculture Organization (FAO) of the United Nations FAO. Jute, kenaf, sisal, abaca, coir and allied fibres statistics bulletin 2018. Rome, 2019. [Google Scholar]

6. Food and Agriculture Organization (FAO) of the United Nations FAO. Jute, kenaf, sisal, abaca, coir and allied fibres statistical bulletin 2021. Rome, 2022. [Google Scholar]

7. Geethamma VG, Kalaprasad G, Groeninckx G, Thomas S. Dynamic mechanical behaviour of short coir fibre reinforced natural rubber composites. Compos Part A Appl Sci Manuf. 2005;36(11):1499–506. doi:10.1016/j.compositesa.2005.03.004. [Google Scholar] [CrossRef]

8. Mathura N, Cree D. Characterization and mechanical property of Trinidad coir fibres. J Appl Poly Sci. 2016;43692:1–9. [Google Scholar]

9. Bhuvaneswari V, Devarajan B, Arulmurugan B, Mahendran R, Rajkumar S. A critical review on hygrothermal and sound absorption behavior of natural-fiber-reinforced polymer composites. Polymers. 2022;14(21):4727. doi:10.3390/polym14214727. [Google Scholar] [PubMed] [CrossRef]

10. Mir SS, Hasan SMN, Hossain J, Hasan M. Chemical modification effect on the mechanical properties of coir fiber. Eng J. Feb. 2012;16(2):73–84. doi:10.4186/ej.2012.16.2.732012. [Google Scholar] [CrossRef]

11. Adeniyi AG, Onifade DV, Ighalo JO, Adeoye AS. A review of coir fibre reinforced polymer composites. Compos Part B Eng. 2019;176(37):107305. doi:10.1016/j.compositesb.2019.107305. [Google Scholar] [CrossRef]

12. Karthikeyan A, Balamurugan K, Kalpana A. The effect of sodium hydroxide treatment and fibre length on the tensile property of coir fibre-reinforced epoxy composites. Sci Eng Compos Mater. 2014;21(3):315–21. [Google Scholar]

13. Rajan A, Abraham TE, Abraham TE. Coir fiber–process and opportunities coir fiber–process and opportunities: part 1. J Nat Fibers. 2008;3(4):29–41. doi:10.1300/J395v03n04_03. [Google Scholar] [CrossRef]

14. Gashawtena E, Kidane A, Sirahbizu B. Fabrication and characterization of natural fiber-polymer composites for prosthesis socket application. J Nat Fibers. 2024;21(1):2354399. doi:10.1080/15440478.2024.2354399. [Google Scholar] [CrossRef]

15. Kassegn E, Sirhabizu B, Berhanu T, Buffel B, Buffel B. Experimental study on single fiber tensile properties of sisal fibers using a digital image correlation method as a strain measurement. J Nat Fibers. 2024;21(1):2325557. doi:10.1080/15440478.2024.2325557. [Google Scholar] [CrossRef]

16. Kovačević Z, Strgačić S, Bischof S. Barley straw fiber extraction in the context of a circular economy. Fibers. 2023;11(12):108. [Google Scholar]

17. Jumaidin R, Gazari AS, Kamaruddin ZH. Mechanical properties of thermoplastic cassava starch/coconut fibre composites: effect of fibre size. Sci Technol. 2024;32:91–113. [Google Scholar]

18. Bui H, Sebaibi N, Boutouil M, Levacher D. Determination and review of physical and mechanical properties of raw and treated coconut fibers for their recycling in construction materials. Fibers. 2020;8(6):37. doi:10.3390/fib8060037. [Google Scholar] [CrossRef]

19. Wasti S, Hubbard AM, Clarkson CM, Johnston E, Tekinalp H, Ozcan S, et al. Long coir and glass fibre reinforced polypropylene hybrid composites prepared via wet-laid technique. Compos Part C Open Access. 2024;14:100445. [Google Scholar]

20. Madueke CI, Umunakwe R, Mbah OM. Comparing the properties of Nigeria’s coir fibre and those of some other countries for composite applications. MRS Adv. 2022;7(28):625–628. doi:10.1557/s43580-021-00202-1. [Google Scholar] [CrossRef]

21. Musthaq MA, Dhakal HN, Zhang Z, Barouni A. The effect of various environmental conditions on the impact damage behaviour of natural-fibre-reinforced composites (NFRCs)–a critical review. Polymers. 2023;15(5):1229. [Google Scholar] [PubMed]

22. Fa´bio T, Thais Helena D, Satyanarayana KG. A studies on lignocellulosic fibres of Brazil. Part II: morphology and properties of Brazilian coconut fibres. Compos Part A Appl Sci Manuf. 2007;38:1710–21. [Google Scholar]

23. Rait GK. Effect of surface treatments on the mechanical properties of coir fibres and coir fibre reinforced composites (MS Dissertation). University of Birmingham: UK; 2014. [Google Scholar]

24. Jeevan RH, Singh S, Ramulu PJ, Santos TF, Santos M, Sanjay MR, et al. Effect of chemical treatment on physio-mechanical properties of lignocellulose natural fibre extracted from the bark of careya arborea tree. Helion. 2024;10(5):e26706. [Google Scholar]

25. Ismail S. Review on natural plant fibres and their hybrid composites for structural applications : recent trends and future perspectives. Compos Part C. 2022;9:100322. [Google Scholar]

26. Richely E, Nuez L, Biopolym UR. Influence of defects on the tensile behaviour of flax fibres : cellulose microfibrils evolution by synchrotron X-ray diffraction and finite element modelling. Compos Part C. 2022;9:100300. [Google Scholar]

27. Khan M. A comprehensive review on epoxy biocomposites based on natural fibers and bio-fillers : challenges, recent developments and applications. Adv Fiber Mater. 2022;4(4):683–704. [Google Scholar]

28. Reddy I, Manikanth V, Madhava R, Santosh P. Experimental investigation on mechanical and viscoelastic properties of kenaf, basalt and carbon fiber reinforced hybrid epoxy polymer composites. In: International Conference on Materials Engineering, Materials Chemistry and Materials Physics, 2024; Bhimavaram, India. doi:10.1088/1742-6596/2765/1/012006. [Google Scholar] [CrossRef]

29. Satyanarayana KG, Sukumaran K, Pillaim PSGK. Materials science of some lignocellulosic fibers. Metallogr. 1986;19(4):389–400. [Google Scholar]

30. Gao X, Zhu D, Fan S, Rahman Z, Guo S, Chen F. Structural and mechanical properties of bamboo fiber bundle and fiber/bundle reinforced composites: a review. J Mater Res Technol. 2022;19:1162–90. [Google Scholar]

31. Mann GS, Azum N, Khan A, Rub MA, Hassan I, Fatima K, et al. Green composites based on animal fiber and their applications for a sustainable future. Polymers. 2023;15(3):601. doi:10.3390/polym15030601. [Google Scholar] [PubMed] [CrossRef]

32. Ichim M, Stelea L, Filip I, Lisa G. Thermal and mechanical characterization of coir fibre–reinforced polypropylene biocomposites. Crystals. 2022;12:1249. doi:10.3390/cryst12091249. [Google Scholar] [CrossRef]

33. Shadhin MD, Jayaraman R, Rahman M, Mann M. Effect of fibre surface treatment on mechanical, interfacial, and moisture absorption properties of cattail fibre-reinforced composites. Appl Polymer. 2024;141(1):e54765. [Google Scholar]

34. Defoirdt N, Biswas S, Vriese LD, Quan L, Tran N, Acker JV. Assessment of the tensile properties of coir, bamboo and jute fibre. Compos Part A. 2010;41(5):588–95. doi:10.1016/j.compositesa.2010.01.005. [Google Scholar] [CrossRef]

35. Luz FS, Paciornik S, Monteiro SN, Silva LC, Tommasini VIOJ. Porosity assessment for different diameters of coir lignocellulosic fibers. JOM. 2017;69(10):2045–51. doi:10.1007/s11837-017-2528-y. [Google Scholar] [CrossRef]

36. Faria DL, Mendes LM, Benedito J, Junior G. Effect of surface treatment on the technological properties of coconut fiber–reinforced plant polyurethane composites. Environ Sci Pollut Res. 2023;30(18):52124–40. doi:10.1007/s11356-023-25946-1. [Google Scholar] [PubMed] [CrossRef]

37. Silva GG, Souza DADE, Machado JC, Hourston DJ. Mechanical and thermal characterization of native Brazilian coir-fibre. J Appl Polym Sci. 2000;76(7):1197–206. doi:10.1002/(ISSN)1097-4628. [Google Scholar] [CrossRef]

38. Ernestina M, Fidelis A, Vitorino T, Pereira C, Dias R, Filho T. The effect of fiber morphology on the tensile strength of natural fibers. Integr Med Res. 2013;2(2):149–57. doi:10.1016/j.jmrt.2013.02.003. [Google Scholar] [CrossRef]

39. Tran LQN, Minh TN, Fuentes CA, Chi TT, Van Vuure AW, Verpoest I. Investigation of microstructure and tensile properties of porous natural coir fibre for use in composite materials. Ind Crop Prod. 2015;65:437–45. doi:10.1016/j.indcrop.2014.10.064. [Google Scholar] [CrossRef]

40. Mukherjee PS, Satyanarayana KG. Structure and properties of some vegetable fibres. J Mater Sci. 1986;21(1):51–6. doi:10.1007/BF01144698. [Google Scholar] [CrossRef]

41. Brintz D. Manufacturing and evaluating fire retardant coir fibre composites (Dessertation). University of Birmingham: UK; 2014. [Google Scholar]

42. Muensri P, Kunanopparat T, Menut P, Siriwattanayotin S. Effect of lignin removal on the properties of coconut coir fiber/wheat gluten biocomposite. Compos Part A Appl Sci Manuf. 2011;42(2):173–9. doi:10.1016/j.compositesa.2010.11.002. [Google Scholar] [CrossRef]

43. Ezekiel N, Ndazi B, Nyahumwa C, Karlsson S. Effect of temperature and durations of heating on coir fibers. Ind Crop Prod. 2011;33(3):638–43. doi:10.1016/j.indcrop.2010.12.030. [Google Scholar] [CrossRef]

44. Alhelmy MS, Buana S, Pasbaskhsh P, Goh KL, Bateni F. Elasticity, microstructure and thermal stability of foliage and fruit fibres from four tropical crops. Fibers Polym. 2013;14(4):623–9. doi:10.1007/s12221-013-0623-4. [Google Scholar] [CrossRef]

45. Van Dam JEG, Van Den Oever MJA, Keijsers ERP, Van Der Putten JC, Anayron C, Josol F, et al. Process for production of high density/high-performance binderless boards from whole coconut husk: part 2: coconut husk morphology, composition and properties. Ind Crops Prod. 2006;24:96–104. [Google Scholar]

46. Mir SS, Hasan M, Hasan SMN, Hossain J, Nafsin N. Effect of chemical treatment on the properties of coir fiber reinforced polypropylene and polyethylene composites. Polym Compos. 2017;38(7):1259–65. [Google Scholar]

47. Kulkarni G, Satyanarayana KG, Rohatgi PK. Weibull analysis of strengths of coir fibres. Fibre Sci Technol. 1983;19:59–76. [Google Scholar]

48. Barrera-Fajardo I. Investigation of the effect of chemical treatment on the properties of colombian banana and coir fibers and their adhesion behavior on polylactic acid and unsaturated. Fibers. 2024;12(1):6. [Google Scholar]

49. Patil PH, Rahul K, Shetty P, Dias VJ, Resham IV, Shetty M, et al. Influence of process parameters on tribological behaviour of Hemp powder reinforced epoxy composites. Cogent Eng. 2024;11(1):2322075. doi:10.1080/23311916.2024.2322075. [Google Scholar] [CrossRef]

50. Chen X, Ma Y, Liu S, Zhang A, Liu W, Huang S. A tannic acid-based intumescent flame retardant for improving flame retardancy of epoxy composites. Adv Ind Eng Polym Res. 2024. doi:10.1016/j.aiepr.2024.04.003. [Google Scholar] [CrossRef]

51. Camillo MDO, Mateus M, Candido VS, Da L, Dias C, Monteiro SN, et al. Assessment of hydrothermal treatment effects on coir fibers for incorporation into polyurethane matrix biocomposites derived from castor oil. Polymers. 2023;15(23):4614. doi:10.3390/polym15234614. [Google Scholar] [PubMed] [CrossRef]

52. Zhang L, Sun Z, Liang D, Jing Lyn WX. Preparation and performance evaluation of PLA/coir fibre biocomposites. BioResources. 2017;12(4):7349–62. doi:10.15376/biores.12.4.7349-7362. [Google Scholar] [CrossRef]

53. Brígida AIS, Calado VMA, Gonçalves LRB, Coelho MAZ. Effect of chemical treatments on properties of green coconut fiber. Carbohydr Polym. 2010;79(4):832–8. doi:10.1016/j.carbpol.2009.10.005. [Google Scholar] [CrossRef]

54. Rosa MF, Sen CB, Medeiros ES, Wood DF, Williams TG, Mattoso LHC, et al. Bioresource technology effect of fiber treatments on tensile and thermal properties of starch/ethylene vinyl alcohol copolymers/coir biocomposites. Bioresour Technol. 2009;100(21):5196–202. doi:10.1016/j.biortech.2009.03.085. [Google Scholar] [CrossRef]

55. Mokhen TC, Mtibe A, Mokhothu TH, Mochan MJ, John MJ. A review on bast-fibre-reinforced hybrid composites and their applications. Polymers. 2023;15(16):3414. doi:10.3390/polym15163414. [Google Scholar] [PubMed] [CrossRef]

56. Shahapurkar K, Yassin M, Chenrayan V, Althoey F, Ozkilic YO, Tirth V, et al. Impact and compression behavior of habesha moringa/bamboo fiber reinforced epoxy composites. J Nat Fibers. 2024;21(1):2311301. doi:10.1080/15440478.2024.2311301. [Google Scholar] [CrossRef]

57. Ismadi, Juwono A, Munawar S. Investigation of fiber content on physical-mechanical. AIP Conf Proc. 2024;2973:060007, Indonesia. doi:10.1063/5.0184729. [Google Scholar] [CrossRef]

58. Hiremath VS, Reddy DM, Reddy R, Sanjeev A, Dhilipkumar T, Naveen J. Thermal degradation and fire retardant behaviour of natural fibre reinforced polymeric composites–a comprehensive review. J Mater Res Technol. 2024;30:4053–63. doi:10.1016/j.jmrt.2024.04.085. [Google Scholar] [CrossRef]

59. Sathish S, Prabhu L, Gokulkumar S, Karthi N, Balaji D, Vigneshkumar N. Extraction, treatment and applications of natural fibers for bio-composites–a critical review. Int Poly Process. 2021;36(2):114–30. doi:10.1515/ipp-2020-4004. [Google Scholar] [CrossRef]

60. Ramaiah G, Tilahun A, Negawo TA, Yacob S, Legese R, Asfaw D, et al. Development of green composite utilizing sisal strands and sustainable 3-D printed PLA layers. Text Leather Rev. 2024;7:938–70. doi:10.31881/TLR.2024.076. [Google Scholar] [CrossRef]

61. Islam T, Rafi AS. Advancements and challenges in natural fiber-reinforced hybrid composites : a comprehensive review. SPE Polymers. 2024;5(4):481–506. [Google Scholar]

62. Khan F, Hossain N, Hasan F, Rahman SMM, Khan S. Applications in engineering science advances of natural fiber composites in diverse engineering applications–a review. Appl Eng Sci. 2024;18:100184. doi:10.1016/j.apples.2024.100184. [Google Scholar] [CrossRef]

63. Kowalczyk M, Piorkowska EKPPM. Mechanical and thermal properties of PLA composites with cellulose nanofibers and standard size fibers. Composit Part A: Appl Sci Manuf. 2011;42:1509–14. doi:10.1016/j.compositesa.2011.07.00. [Google Scholar] [CrossRef]

64. Elfaleh I, Abbassi F, Habibi M, Ahmad F, Guedri M, Nasri M, et al. A comprehensive review of natural fibers and their composites: an eco-friendly alternative to conventional materials. Results Eng. 2011 Oct;42(10):1509–1514. doi:10.1016/j.rineng.2023.101271. [Google Scholar] [CrossRef]

65. Anil A, E TJ, George G. Dynamic mechanical properties and ageing studies of coir-sisal yarn reinforced polypropylene commingled composites. Polym Polym Composit. 2023;31:09673911221150145. doi:10.1177/09673911221150145. [Google Scholar] [CrossRef]

66. Yan L, Chouw N, Huang L, Kasal B. Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr Build Mater. 2016;112(4):168–82. doi:10.1016/j.conbuildmat.2016.02.182. [Google Scholar] [CrossRef]

67. Seisa K, Chinnasamy V, Ude AU. Surface treatments of natural fibres in fibre reinforced composites: a review. Fibres Text East Eur. 2022;30(2):82–9. [Google Scholar]

68. Aulia MP, Mulana F, Amin A, Zuhra Z. Effect of filler ratio on mechanical and thermal properties of coconut fiber/fly ash-reinforced hybrid polymer composites. AIP Conf Proc. 2024;3082(1):040023. doi:10.1177/09673911221150145. [Google Scholar] [CrossRef]

69. Hosseini B, Li H, Hui D. Effect of fiber treatment on physical and mechanical properties of natural fibre-reinforced composites: a review. Rev Adv Mater Sci. 2023;62(1):20230131. [Google Scholar]

70. Kim H. Hybrid composites with natural fibres (Dessertation). University of Birmingham: UK; 2014. [Google Scholar]

71. Arrakhiz FZ, El Achaby M, Kakou AC, Vaudreuil S, Benmoussa K, Bouhfid R, et al. Mechanical properties of high density polyethylene reinforced with chemically modified coir fibers: impact of chemical treatments. J Mater. 2012;37:379–83. doi:10.1016/j.matdes.2012.01.020. [Google Scholar] [CrossRef]

72. Hemsri S, Grieco K, Asandei AD, Parnas RS. Wheat gluten composites reinforced with coconut fibre. Compos Part A Appl Sci Manuf. 2012;43(7):1160–8. doi:10.1016/j.compositesa.2012.02.011. [Google Scholar] [CrossRef]

73. Nam TH, Ogihara S, Tung NH, Kobayashi S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly(butylene succinate) biodegradable composites. Compos Part B Eng. 2011;42(6):1648–56. doi:10.1016/j.compositesb.2011.04.001. [Google Scholar] [CrossRef]

74. Rout J, Misra M, Tripathy SS, Nayak SK, Mohanty AK. The influence of fibre treatment on the performance of coir-polyester composites. Compos Sci Technol. 2001;61(9):1303–10. [Google Scholar]

75. Alipour A, Jayaraman K. Performance of flax/epoxy composites made from fabrics of different structures. Fibers. 2024;12(4):34. [Google Scholar]

76. Uyanik MC, Erturk TA. Recent developments of natural fibres: natural fibre biocomposites, treatments, and characterizations. J Phy: Conf Ser. 2023;2549(1):012001. [Google Scholar]

77. Shamsuri AA. The impact of organic salts on the tensile properties of polymer biocomposites. Int J Adv Eng Mang Res. 2024;6(6):2021. [Google Scholar]

78. Srivastava S, Sarang S. Fabrication and testing of nano bio-silica, hemp, and bamboo fibre-reinforced chitosan bio-composite material. Jordan J Mech Ind Eng. 2024;1(2):401–10. [Google Scholar]

79. Ravishankar P, Arya M, Dhakal H, Gouda F, Skrifvars M, Khalili P. Assessing the mechanical performance of natural fiber thermoplastic composite sandwiches for advanced applications. Results Mater. 2024;23(18):100600. doi:10.1016/j.rinma.2024.100600. [Google Scholar] [CrossRef]

80. Castro-franco AD, Siqueiros-hern M, Garc V, Mendoza-muñoz I, Vargas-osuna LE, Magaña-almaguer HD. A review of natural fiber-reinforced composites for lower-limb prosthetic designs. Polymers. 2024;16(9):1293. doi:10.3390/polym16091293. [Google Scholar] [PubMed] [CrossRef]

81. Ramirez C.Agaliotis E, Pettarin V. Fracture toughness and overall characterisation of PLA based biocomposites with natural fibers: a comparative study. Polymer. 2024;307:127309. doi:10.1016/j.polymer.2024.127309. [Google Scholar] [CrossRef]

82. Oliveira M, Neves V, Banea MD. Mechanical and thermal characterization of bamboo and interlaminar hybrid bamboo/synthetic fibre-reinforced epoxy composites. Materials. 2024;17(8):1777. doi:10.3390/ma17081777. [Google Scholar] [PubMed] [CrossRef]

83. Madueke CI, Agunsoye OJ, Umunakwe R, Bolasodun B, Kolawole F, Borisade SG, et al. Investigations into the tensile properties and microstructural features of coconut fibre (coir) reinforced Polylactic acid (PLA) biodegradable composites. UNIZIK J Eng Appl Sci. 2023;2(2):301–10. [Google Scholar]

84. Prasad MDS, Jayavel S, Gnanamoorthy R. Effect of coir fiber reinforcement in PLA on the heat transfer characteristics-numerical simulations. Mater Today: Proc. 2023 Apr 28. doi:10.1016/j.matpr.2023.04.132. [Google Scholar] [CrossRef]

85. Zainudin MZ, Mansor MR, Ali MB, Jameel Y, Sapuan SM. Effect of varying fibre loadings on the impact performance of kenaf and coir reinforced bioepoxy composites. J Nat Fib Polym Composit. 2023;2(1):1–8. [Google Scholar]

86. Mogan K, Jumaidin R, Ilyas RA. Environmental properties of coconut fiber/reinforced thermoplastic starch/beeswax hybrid composites. Pertanika J Sci Technol. 2023;31(S1):21–38. doi:10.47836/pjst.31.S1.02. [Google Scholar] [CrossRef]

87. Agwu N, Ozoegwu CG. Critical investigation on the effect of fiber geometry and orientation on the effective mechanical properties of fibre-reinforced polymer composites. Mech Adv Mater Struct. 2023;30(15):3051–60. doi:10.1080/15376494.2022.2068206. [Google Scholar] [CrossRef]

88. Jiao-wang L, Martínez MA, Santiuste C. Moisture effect on tensile and low-velocity impact tests of flax fabric-reinforced PLA biocomposite. Polym Compos. 2024;45(13):11816–28. doi:10.1002/pc.28601. [Google Scholar] [CrossRef]

89. Vern YR, Mansor MR, Shaharuzaman MA. Natural fibre composite selection for two-stroke marine engine under-piston door using hybrid AHP and TOPSIS methods. Int J Light Mater Manuf. 2024;3(1):40. doi:10.1016/j.ijlmm.2024.07.006. [Google Scholar] [CrossRef]

90. Mustafa Z, Razali AS, Fadzullah SH, Malingsm SD, Osman AF, Ratanawilai T. Mechanical and biodegradation properties of biodegradable unidirectional pineapple leaf fibre/polylactic acid composites. AIP Conf Proc. 2022;2496(1):020007, Malaysia. doi:10.1063/5.0091422. [Google Scholar] [CrossRef]

91. Shariff M, B. NAM, Arpitha GR, Waleed A, Musabah S. Feasibility study on mechanical properties of date palm fiber and epoxy bio-composite for automotive applications. Tuijin Jishu/J Propul Technol. 2023;44(3):1426–35. [Google Scholar]

92. Katman HYB, Khai WJ, Bheel N, Kumar A, Benjeddou O. Fabrication and characterization of cement-based hybrid concrete containing coir fiber for advancing concrete construction. Buildings. 2022;12(9):1450. doi:10.3390/buildings12091450. [Google Scholar] [CrossRef]

93. Suparp S, Ali N, Zand AW, Chaiyasarn K, Rashid MU, Yooprasertchai E, et al. Axial load enhancement of lightweight aggregate concrete (LAC) using environmentally sustainable composites. Buildings. 2022;12(6):851. [Google Scholar]

94. Madueke CI, Umunakwe R, Mbah OM. A review on the factors affecting the properties of natural fibre polymer composites. Niger J Technol. 2022;41(1):55–64. [Google Scholar]

95. Jakab S, Singh S. Agricultural by-product filled poly(lactic acid) biocomposites with enhanced biodegradability : the effect of flax seed meal and rapeseed straw. Compos Part C. 2024;14:100464. [Google Scholar]

96. Mwaikambo LY, Tucker N, Clark AJ. Mechanical properties of hemp fibre reinforced euphorbia composites. Macromol Mater Eng. 2007;292(9):993–1000. [Google Scholar]

97. Duangsuwan S, Amornsakchai T, Phinyocheep P, Thanawan S. Achieving high-performance green composites from pineapple leaf fiber−poly(butylene succinate) through both fiber alignment and matrix orientation across the thickness. ACS Omega. 2023;8:35693–705. [Google Scholar] [PubMed]

98. Demir M. Investigation of low-velocity impact behaviours of polymer composites reinforced with different natural fiber fabrics. Polym Compos. 2024;45(6):4928–46. doi:10.1002/pc.28099. [Google Scholar] [CrossRef]