Open Access

Open Access

ARTICLE

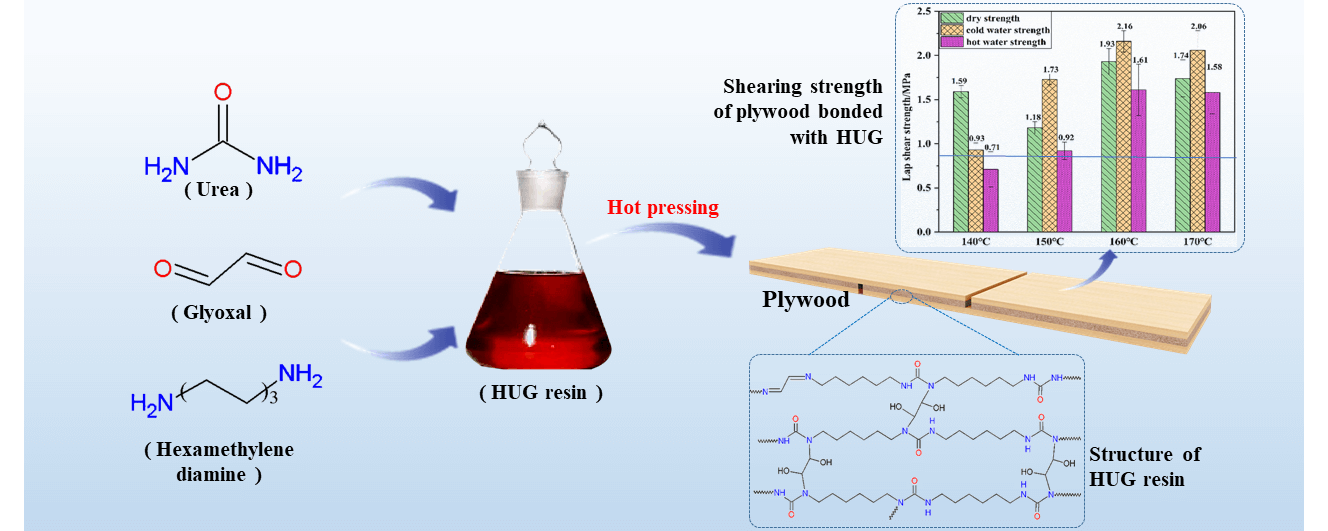

Preparation of Environmentally Friendly Urea-Hexanediamine-Glyoxal (HUG) Resin Wood Adhesive

1 Yunnan Key Laboratory of Wood Adhesives and Glue Products, College of Material Science and Engineering, Southwest Forestry University, Kunming, 650224, China

2 International Joint Research Center for Biomass Materials, Southwest Forestry University, Kunming, 650224, China

3 College of Chemical and Materials Engineering, Zhejiang A&F University, Hangzhou, 311300, China

4 LERMAB, University of Lorraine, Epinal, 88000, France

* Corresponding Author: Xuedong Xi. Email:

# These two authors have contributed equally to this work

Journal of Renewable Materials 2024, 12(2), 235-244. https://doi.org/10.32604/jrm.2023.029537

Received 24 February 2023; Accepted 08 May 2023; Issue published 11 March 2024

Abstract

Using non-toxic, low-volatile glyoxal to completely replace formaldehyde for preparing urea-glyoxal (UG) resin adhesive is a hot research topic that could be of great interest for the wood industry. However, urea-glyoxal (UG) resins prepared by just using glyoxal instead of formaldehyde usually yields a lower degree of polymerization. This results in a poorer bonding performance and water resistance of UG resins. A good solution is to pre-react urea to preform polyurea molecules presenting already a certain degree of polymerization, and then to condense these with glyoxal to obtain a novel UG resin. Therefore, in this present work, the urea was reacted with hexamethylene diamine to form a polyurea named HU, and then this was used to react it with different amounts of glyoxal to synthesize hexamethylenediamine-urea-glyoxal (HUG) polycondensation resins, and to use this for bonding plywood. The results show that the glyoxal can well react with HU polyuria via addition and schiff base reaction, and also the HUG resin exhibits excellent bonding strength and water resistance. The shear strength of the plywood bonded with this HUG at 160°C hot press temperature as high as 1.93 MPa, 2.16 MPa and 1.61 MPa, respectively, which meets the requirement of the China national standard GB/T 9846-2015 (≥0.7 MPa), and can be a good choice as a wood adhesive for industrial application.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools