Open Access

Open Access

ARTICLE

Behavior of Sandwich Glued Laminated Bamboo Structures with a Core Formed by Bioplastic Fiber Using 3D Printing Technology

Department of Civil Engineering, Faculty of Engineering, King Mongkut’s University of Technology Thonburi (KMUTT), Thung Khru, Bang Mod, Bangkok, 10140, Thailand

* Corresponding Author: Tawich Pulngern. Email:

(This article belongs to the Special Issue: Advances in Eco-friendly Wood-Based Composites: Design, Manufacturing, Properties and Applications)

Journal of Renewable Materials 2025, 13(12), 2453-2478. https://doi.org/10.32604/jrm.2025.02025-0137

Received 04 July 2025; Accepted 20 October 2025; Issue published 23 December 2025

Abstract

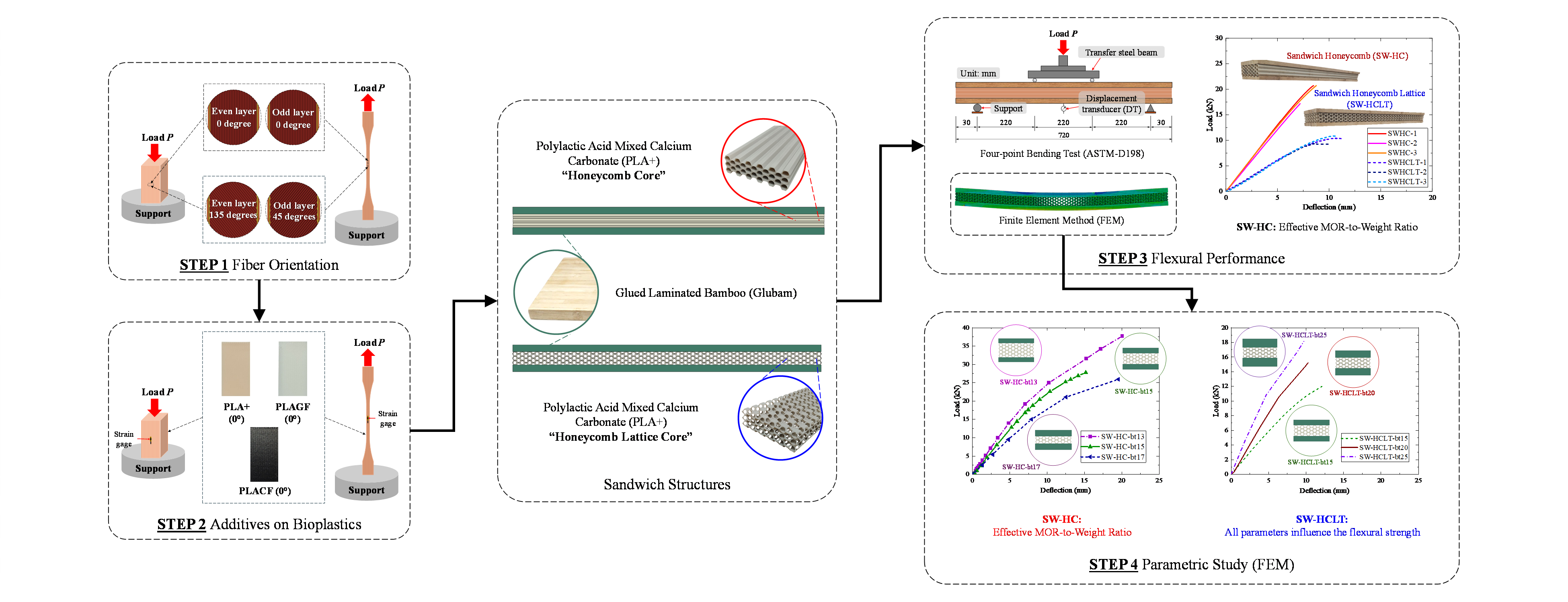

This research investigates the behavior of sandwich glued laminated bamboo (Glubam) structures with a core formed by biodegradable plastic fibers, specifically polylactic acid (PLA), fabricated using 3D printing technology. The influence of various fiber printing orientations (0° and 45/135°) on tensile and compressive properties was investigated. The experimental results indicated that polylactic acid with calcium carbonate (PLA+) printed unidirectionally and aligned with the loading direction (0°) exhibits superior tensile and compressive strengths compared to specimens printed bidirectionally at 45/135°. Furthermore, the effect of additives on bioplastics of carbon fiber (PLA-CF) and glass fiber (PLA-GF) additives in PLA-based composites was evaluated in comparison with PLA+ specimens. The finding indicated that PLA+ has a higher strength-to-cost ratio compared to PLA-CF and PLA-GF. Therefore, unidirectionally printed PLA+ was selected as the core material in two geometries: honeycomb and honeycomb lattice. These cores were sandwiched between Glubam panels on the top and bottom surfaces of the structures. Flexural performance was evaluated through four-point bending tests, which revealed that sandwich structures with a honeycomb core achieved a flexural strength-to-weight ratio 56.51% higher than those with a honeycomb lattice core. A parametric study using the finite element model was conducted to evaluate the effect of core scale, cross-sectional depth, Glubam thickness, core depth, and the number of honeycomb elements. The results showed that reducing the Glubam thickness while increasing the 3D-printed core depth significantly improved the flexural performance of honeycomb sandwich structures. Notably, reduced Glubam panel thickness coupled with increased core depth enhanced their flexural performance.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools