Open Access

Open Access

REVIEW

Lignocellulosic Biocomposite Membranes for Air Filtration and Environmental Protection: A Review

1 Center of Hydrogen Energy (CHE), Institute of Future Energy (IFE), Faculty of Chemical and Energy Engineering, Universiti Teknologi Malaysia (UTM), Skudai, 81310, Malaysia

2 Department of Physics, Faculty of Science, Universiti Putra Malaysia, UPM Serdang, Serdang, 43400, Malaysia

3 Department of Agricultural and Biological Engineering, Faculty of Engineering and Technology, Kwara State University, Malete, 23431, Nigeria

4 Department of Physics, Faculty of Natural and Applied Sciences, Sule Lamido Universiti Kafin Hausa, Kafin Hausa, 048, Nigeria

5 Institute of Nanoscience and Nanotechnology (INO2), Universiti Putra Malaysia, Serdang, 43400, Malaysia

6 Institute of Energy Infrastructure (IEI), Universiti Tenaga Nasional (UNITEN), Putrajaya Campus, Jalan Ikram-Uniten, Kajang, 43000, Malaysia

7 High-Speed Reacting Flow Laboratory (HiREF), Faculty of Mechanical Engineering, Department of Thermo-Fluids of Mechanical Engineering, Universiti Teknologi Malaysia, Skudai, 81310, Malaysia

8 Department of Mechanical Precision Engineering (MPE), Malaysia-Japan International Institute of Technology (MJIIT), Universiti Teknologi Malaysia, Kuala Lumpur, 54100, Malaysia

* Corresponding Author: Abiodun Abdulhameed Amusa. Email:

(This article belongs to the Special Issue: Biodegradable Polymer and Biomass Composites)

Journal of Renewable Materials 2025, 13(2), 251-272. https://doi.org/10.32604/jrm.2025.057487

Received 19 August 2024; Accepted 17 December 2024; Issue published 20 February 2025

Abstract

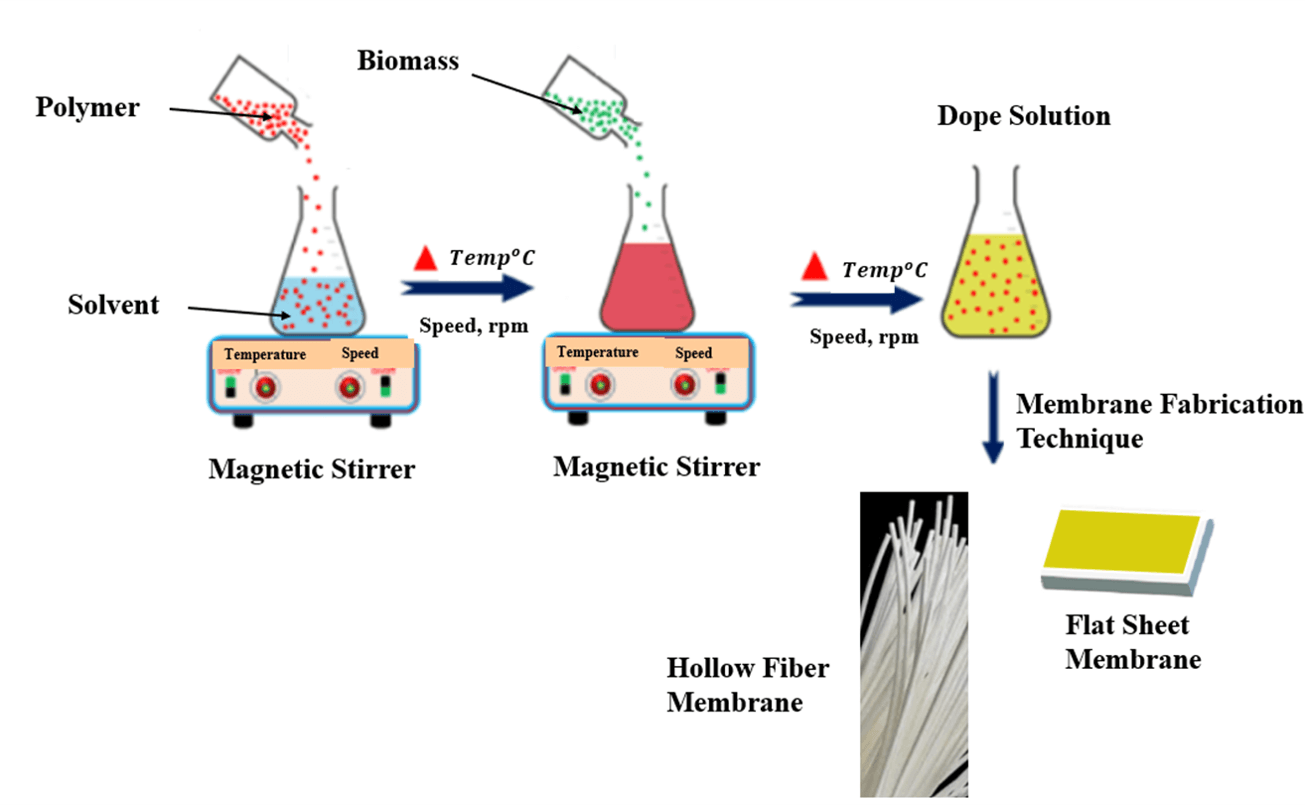

The increasing severity of air pollution necessitates more effective and sustained air filtration technology. Concurrently, the desire for more environmentally friendly, sustainable materials with better filtering performance and less environmental impact drives the move away from conventional synthetic membranes. This review presents lignocellulosic biocomposite (LigBioComp) membranes as an alternative to traditional synthetic membranes. It focuses on their materials, fabrication, and functionalization techniques while exploring challenges and proposing methods for resourceful utilization. Renowned for their abundance and renewable nature, lignocellulosic materials consist of cellulose, hemicellulose, and lignin. Various applications can benefit from their antibacterial properties, large surface area, and remarkable mechanical strength. LigBioComp membranes are fabricated through casting, electrospinning, and freeze-drying, with advancements in fabrication techniques enhancing their performance and applicability. It is suggested to use solvent-free or low-solvent techniques such as Layer-by-Layer assembly to minimize environmental impact. Freeze-drying and electrospinning with green solvents can be used for achieving specific membrane properties, though energy consumption should be considered. Apply dry-wet spinning and solvent casting processes selectively. Functional groups, including carboxyl, hydroxyl, or amino groups, can significantly improve the membrane’s capacity to capture particulate matter. Chemical etching or the precise deposition of nanoparticles can further optimize pore size and distribution. The choice of chemicals and methods is critical in functionalization, with silane coupling agents, polyethyleneimine, and polydopamine. Future research should prioritize refining fabrication methods, advancing functionalization strategies, and conducting performance and recyclability assessments on hybrid and composite materials. This will enhance integrated systems and contribute to the development of smart filters.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools