Open Access

Open Access

REVIEW

Lignocellulosic Biocomposite Membranes for Air Filtration and Environmental Protection: A Review

1 Center of Hydrogen Energy (CHE), Institute of Future Energy (IFE), Faculty of Chemical and Energy Engineering, Universiti Teknologi Malaysia (UTM), Skudai, 81310, Malaysia

2 Department of Physics, Faculty of Science, Universiti Putra Malaysia, UPM Serdang, Serdang, 43400, Malaysia

3 Department of Agricultural and Biological Engineering, Faculty of Engineering and Technology, Kwara State University, Malete, 23431, Nigeria

4 Department of Physics, Faculty of Natural and Applied Sciences, Sule Lamido Universiti Kafin Hausa, Kafin Hausa, 048, Nigeria

5 Institute of Nanoscience and Nanotechnology (INO2), Universiti Putra Malaysia, Serdang, 43400, Malaysia

6 Institute of Energy Infrastructure (IEI), Universiti Tenaga Nasional (UNITEN), Putrajaya Campus, Jalan Ikram-Uniten, Kajang, 43000, Malaysia

7 High-Speed Reacting Flow Laboratory (HiREF), Faculty of Mechanical Engineering, Department of Thermo-Fluids of Mechanical Engineering, Universiti Teknologi Malaysia, Skudai, 81310, Malaysia

8 Department of Mechanical Precision Engineering (MPE), Malaysia-Japan International Institute of Technology (MJIIT), Universiti Teknologi Malaysia, Kuala Lumpur, 54100, Malaysia

* Corresponding Author: Abiodun Abdulhameed Amusa. Email:

(This article belongs to the Special Issue: Biodegradable Polymer and Biomass Composites)

Journal of Renewable Materials 2025, 13(2), 251-272. https://doi.org/10.32604/jrm.2025.057487

Received 19 August 2024; Accepted 17 December 2024; Issue published 20 February 2025

Abstract

The increasing severity of air pollution necessitates more effective and sustained air filtration technology. Concurrently, the desire for more environmentally friendly, sustainable materials with better filtering performance and less environmental impact drives the move away from conventional synthetic membranes. This review presents lignocellulosic biocomposite (LigBioComp) membranes as an alternative to traditional synthetic membranes. It focuses on their materials, fabrication, and functionalization techniques while exploring challenges and proposing methods for resourceful utilization. Renowned for their abundance and renewable nature, lignocellulosic materials consist of cellulose, hemicellulose, and lignin. Various applications can benefit from their antibacterial properties, large surface area, and remarkable mechanical strength. LigBioComp membranes are fabricated through casting, electrospinning, and freeze-drying, with advancements in fabrication techniques enhancing their performance and applicability. It is suggested to use solvent-free or low-solvent techniques such as Layer-by-Layer assembly to minimize environmental impact. Freeze-drying and electrospinning with green solvents can be used for achieving specific membrane properties, though energy consumption should be considered. Apply dry-wet spinning and solvent casting processes selectively. Functional groups, including carboxyl, hydroxyl, or amino groups, can significantly improve the membrane’s capacity to capture particulate matter. Chemical etching or the precise deposition of nanoparticles can further optimize pore size and distribution. The choice of chemicals and methods is critical in functionalization, with silane coupling agents, polyethyleneimine, and polydopamine. Future research should prioritize refining fabrication methods, advancing functionalization strategies, and conducting performance and recyclability assessments on hybrid and composite materials. This will enhance integrated systems and contribute to the development of smart filters.Graphic Abstract

Keywords

Nomenclature

| LigBioComp | Lignocellulosic biocomposite |

| WHO | World Health Organization |

| PM | Particulate matter |

| O3 | Ground-level ozone |

| SO2 | Sulfur dioxide |

| NOx | Nitrogen oxides |

| VOCs | Volatile organic compounds |

| AFM | Atomic force microscopy |

| SEM | Scanning electron microscopy |

| PVA | Polyvinyl alcohol |

Human health and ecology are seriously endangered by air pollution. Various sources release pollutants into the atmosphere. Natural events that cause air pollution include wildfires and volcanic eruptions. Also, agricultural activities, vehicle emissions, and industrial operations can facilitate air pollutants. The World Health Organization (WHO) estimates that air pollution results in millions of premature deaths annually [1]. The main contributors include particulate matter (PM), ground-level ozone (O3), sulfur dioxide (SO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs) [2]. PM can enter the bloodstream and penetrate deep into the lungs, causing respiratory and cardiovascular disorders, as well as worsening pre-existing medical conditions. Most concerning are tiny particles known as PM2.5 with a diameter of 2.5 μm or less. An increased risk of heart attacks and strokes, chronic bronchitis, and declining lung function have all been related to prolonged exposure to PM2.5 [3,4]. VOCs entail chemicals such as toluene, formaldehyde, and benzene. In addition to causing headaches and irritation of the eyes, nose, and throat, prolonged exposure to VOCs can harm the liver, kidneys, and central nervous system [5]. Some VOCs such as benzene are proven carcinogens [6].

Moreover, air pollution affects ecosystems, contributing to issues such as acid rain. Acidity in soils and water bodies is caused by the deposition of sulfur and nitrogen compounds in the atmosphere. As a result, ecosystems are disturbed, and biodiversity is decreased, affecting aquatic and plant life [7,8]. Crops are damaged by air pollution, leading to lower yields and having negative impacts on agricultural output [9]. Reduced photosynthesis and stunted growth are the results of O3, which is created when VOCs and NOx react in the presence of sunlight [10]. The greenhouse effect is intensified by air pollution, leading to global warming and related climate changes due to the increased atmospheric concentration of greenhouse gases [11]. Traditionally, air pollution has been reduced using conventional air filtration systems, often based on synthetic materials like polymers and activated carbon. However, these technologies have limitations. The high cost of production and potential lack of biodegradability of synthetic materials result in environmental pollution when inappropriately discarded. The benefits of environmental air filtration are countered by the greenhouse gas emissions related to the production and disposal of synthetic filters. Over time, conventional filters can become inefficient due to particle clogging, making them less effective in capturing a variety of pollutants at lower concentrations.

Innovative and environmentally friendly air filtration technologies are desperately needed to mitigate negative environmental effects and reduce air pollution. Biodegradable and renewable materials such as lignocellulosic biomass provide alternatives to synthetic filters. Lignocellulosic materials are sourced from plant biomass and consist of cellulose, hemicellulose, and lignin. These components are abundant, renewable, and biodegradable [12–15]. The distinct chemical and structural characteristics of lignocellulosic biomass make them suitable for air filtration systems. The fabrication of lignocellulosic biocomposite (LigBioComp) membranes is a significant development in the quest for environmentally friendly ways to improve air quality. Efficient, affordable, and environmentally friendly air filtration systems can be developed by capitalizing on the inherent filtration properties of lignocellulosic materials [16]. These systems can overcome the drawbacks of conventional technologies and enhance environmental and public health. LigBioComp membranes offer the potential for functionalization and enhancement to meet specific filtration requirements while utilizing the natural filtration capabilities of plant fibers [17].

Glass and natural fiber biocomposites have distinct advantages in terms of mechanical performance and cost. Glass biocomposites exhibit superior mechanical performance while suffering from significant recyclability issues [18,19]. In contrast, natural fiber biocomposites offer better specific strength and stiffness preferably suitable for use in environments without moisture or harsh conditions [20]. Performance enhancements necessitate innovative approaches. Natural fiber biocomposites are mainly used for low-performance parts, such as automotive panels, made from wood parts, unreinforced plastics, and inexpensive plant fillers in the electronics industry. Nonetheless, challenges should be addressed before natural fiber composites can replace glass fiber composites in more demanding applications [21,22]. LigBioComp membranes and their potential applications in air filtration are reviewed in this study emphasizing solvent-free fabrication methods and applying green solvents. The significance of this review lies in its evaluation of LigBioComp membranes derived from renewable sources, with a focus on green fabrication processes and innovative functionalization approaches. This promotes the commercialization and widespread adoption of sustainable air filtration technologies. A summary of the lignocellulosic materials used in biocomposite membranes is provided. The fabrication of these membranes, functionalization, and modification techniques are also discussed. Environmental sustainability is a key focus. The challenges of using LigBioComp membranes for air filtration have been explored. Viable methods to promote the resourceful utilization of these membranes are proposed to protect the environment by applying effective air filtration technology.

2 Lignocellulosic Materials in Biocomposite

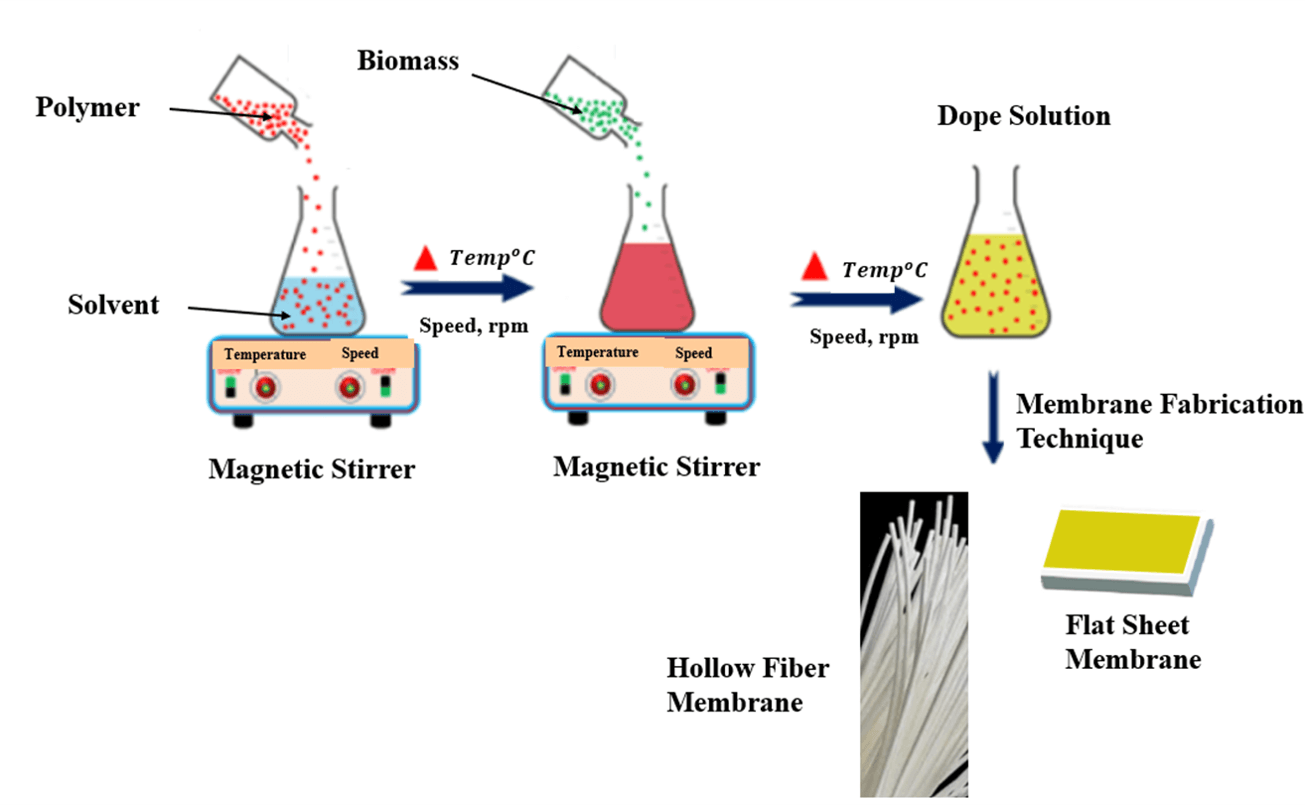

The main constituents of LigBioComp membranes for air filtration combine lignocellulosic biomass, biodegradable polymers, and environmentally friendly solvents (Fig. 1). Lignocellulosic biomass, particularly cellulose, provides a stable and porous structure that supports filtration efficiency. Agricultural byproducts such as corn straw and date pits are commonly utilized sources due to their abundant availability and structural properties, which enhance the filtration capability and mechanical stability of the membranes [23]. Cellulose fibers contribute to the rigidity and microstructure of the membrane, enabling it to capture PM and lignin improves the material’s resistance to degradation in humid or variable environmental conditions. It is a common practice to incorporate polymers into membranes to increase their mechanical strength and flexibility. These polymers act as binders that increase cohesion among cellulose fibers, creating a more resilient composite material capable of withstanding mechanical stress during filtration. These polymer additives provide a balance between durability and environmental friendliness, which is crucial for membranes intended for practical, long-term air filtration applications [24].

Figure 1: Structural components of lignocellulosic biomass-based composite membranes

Eco-friendly solvents, such as ionic liquids, are critical in integrating functional additives within the membrane. These solvents assist in dissolving and dispersing lignocellulosic biomass components, creating a homogeneous blend that enhances the membrane’s structural and functional qualities. Ionic liquids facilitate the incorporation of additional functional additives, such as antimicrobial agents, without compromising the environmental profile of the membrane. This step ensures that the resulting composite exhibits enhanced characteristics, including improved filtration performance, without relying on hazardous or non-biodegradable processing chemicals [25].

Composite membranes incorporated with microcrystalline cellulose (MCC) or nanocellulose fibers, considerably improve the membrane’s mechanical strength, hydrophilicity, and permeability. MCC enhances the hydrophilic nature of membranes, resulting in superior moisture management and reduced fouling during filtration processes. Such composite membranes containing lignocellulosic biomass can be pretreated to achieve specific characteristics, such as improved compatibility with synthetic polymers [26–28]. The naturally hydrophobic lignin can be removed or minimized to enhance the interaction between the biopolymeric and synthetic matrices. This combination of natural and synthetic components improves filtration efficiency and mechanical durability and offers environmental advantages by decreasing reliance on petrochemical-based materials [29,30]. Modifying the lignocellulosic content and structure allows LigBioComp membranes to be tailored for certain filtration requirements, such as removing PM, VOCs, and microorganisms from the air. Moreover, lignocellulosic fibers are renewable, biodegradable, and compatible with various pretreatments that enhance their longevity and stability in air filtration systems [31]. Incorporating nanoparticles, such as titanium dioxide or silver, into the lignocellulosic matrix can enhance the antimicrobial properties of the membranes. This makes the membranes suitable for applications in environments where particle filtration and microbial control are necessary, such as hospitals and cleanrooms [32–34].

Table 1 shows that lignocellulose modified with epoxidized soybean oil resin, derived from agricultural residues like rice husks, offers enhanced mechanical strength and chemical resistance for air filtration applications, though cost and scalability challenges exist [35]. Myco-composites from lignocellulosic waste such as sawdust, noted for their rapid growth and structural robustness, are utilized in structural materials and textiles but face variability in growth conditions [36]. Lignocellulosic agro-residue/polylactic acid biocomposites from rapeseed straw provide biodegradability and high tensile strength for packaging but struggle with thermal stability [37]. Alkaline pretreated nutshells and acetylated lignin biocomposites, sourced from industrial and forestry by-products respectively, are used in composite reinforcement and construction materials but present environmental and cost challenges [38,39]. Maleated technical lignin thermosets and upcycled food waste materials highlight improved polymer compatibility and sustainability, yet face synthesis complexity and feedstock variability. Leveraging sustainable and renewable technologies, such as bio-based catalysts and green processing methods, can mitigate these challenges by enabling more consistent and scalable production processes. Integrating these approaches supports the development of lignocellulosic biocomposites with enhanced performance while aligning with global efforts to reduce environmental impact [40–42]. High-strength, fire-retardant biocomposites and bio-polyol from sunflower oil offer robust properties for construction and coatings but present technical and catalyst recovery issues [43,44]. Comparisons of various lignocellulosic biomasses emphasize the diversity in mechanical and thermal properties for different applications [45,46].

Filtration efficiency and mechanical strength are important for membranes in air filtration, particularly in capturing submicron PM. Cellulose nanofiber (CNF) membranes have shown notable enhancements in filtration efficiency due to targeted chemical modifications. For instance, Khan et al. [47] reported that nitrogen and sulfur-doped carbon dot modifications on CNFs have enabled these membranes to capture particles as small as 0.3 μm, achieving efficiencies between 70% and 81% with increased tensile strength, reaching values up to 9.3 MPa, which supports prolonged usage without degradation, a marked improvement for this challenging particle size. Ashori et al. [48] emphasized that CNF-graphene oxide (GO) composites have shown exceptional results, reaching a filtration efficiency of 99.98% with optimal modifications. Such advancements underscore the effectiveness of strategic modifications, positioning lignocellulosic materials as suitable candidates for high-efficiency air filtration applications. A notable benefit of LigBioComp membranes is their inherent biodegradability, effectively addressing the environmental challenges posed by traditional non-degradable air filters. Lignocellulosic materials break down naturally, significantly reducing the ecological impact associated with disposal. This attribute makes them especially valuable in applications prioritizing sustainability [49]. Advanced processing techniques have been developed to improve the performance and eco-friendliness of these membranes. They will be discussed in the subsequent section.

3 Sustainable Fabrication Techniques for Lignocellulosic Biocomposite Membranes

Sustainable fabrication techniques for LigBioComp membranes are progressing toward creating high-efficiency air filtration systems emphasizing environmental safety and biodegradability. Different fabrication methods for LigBioComp membranes offer unique advantages and limitations for air filtration applications as presented in Table 2. Each approach offers specific benefits that can be leveraged to develop next-generation membranes that are both highly effective and environmentally sustainable. The alignment of various fabrication techniques with renewable bio-sourced polymers is increasingly significant in the context of sustainable development. Biosourced polymers can be used in various processes, including electrospraying, layer-by-layer assembly, freeze-drying, solvent casting, electrospinning (with green solvents), dry-wet spinning, and phase inversion. These methods align with green fabrication principles and can be used with green solvents [50–53]. Electrospraying can use bio-sourced polymers when combined with suitable solvents. This technique has the potential to produce membranes with large surface areas, significantly boosting filtration efficiency, especially for fine particulates. This technique involves using an electric field to spray a polymer solution into micro- or nano-sized particles, which are then collected and formed into membranes [54–56]. The ability to produce very fine fibers or particles enhances filtration performance, but the low production rate and challenges in forming continuous membranes limit its scalability for industrial use. Additionally, the high-voltage requirements and complexity of maintaining uniform particle sizes across large areas pose challenges to widespread adoption in air filtration systems [57,58].

Layer-by-layer (LbL) assembly allows for precise control over membrane thickness and enables the use of different materials, making it effective for membranes tailored to specific filtration requirements [59–61]. This technique involves sequential deposition of alternating positively and negatively charged polymers on a substrate, building the membrane layer by layer with exceptional control over structure and thickness. However, LbL is time-consuming, often limited to thin layers, and may necessitate post-treatment to enhance performance [62,63,81]. Freeze-drying offers an advantage in producing highly porous membranes, which enhance permeability which is beneficial for air filtration. This method freezes a polymer solution and then removes the water through sublimation, creating a porous structure that facilitates airflow. The use of non-toxic solvents like water also adds to its environmental benefits. This approach effectively preserves the structural integrity of biopolymers such as polylactic acid and polyhydroxyalkanoates, producing lightweight, highly porous membranes with interconnected pore networks. The technique enables the customization of pore sizes and distributions, allowing precise adaptation to specific air filtration needs. The lightweight nature of freeze-dried membranes contributes to reduced pressure drops during filtration, enhancing energy efficiency [64]. Integrating nanotechnology into freeze-drying processes significantly improves mechanical strength, thermal stability, and pollutant adsorption capacity due to the increased surface area. However, the energy-intensive process of freezing and sublimating the polymer solution, along with the fragility of the resulting membranes, can reduce their durability in air filtration systems [65].

Solvent casting is a straightforward and inexpensive technique, effective for producing thick membranes, but it lacks control over porosity and can leave behind solvent residues that may affect filtration efficiency [66]. In this process, the polymer is dissolved in a solvent, cast into a mold, and the solvent is evaporated to form a solid membrane. These solvents, derived from renewable sources, are non-toxic and environmentally friendly, adhering to the principles of green chemistry. Common examples include ethanol, isopropanol, and ionic liquids, which effectively dissolve cellulose while preserving its structural properties. A major advantage of green solvents is their ability to facilitate uniform polymer-filler dispersion, which is critical for achieving desired mechanical and functional characteristics in composite membranes. This method is effective for blending cellulose with other biodegradable polymers. Although simple, the method’s limitations in controlling porosity can hinder its use in applications requiring precise particulate filtration [67,68]. Electrospinning with green solvents stands out for producing membranes with a high surface area-to-volume ratio, which is ideal for capturing fine particles in air filtration. Its ability to control nanofiber diameter adds precision to the process [69–71]. However, the slow production rate, high voltage requirements, and challenges with scalability make it less practical for large-scale use. This technique draws a polymer solution into fine nanofibers using a high-voltage electric field, creating a membrane capable of trapping even the smallest airborne particles [72,73,82].

Dry-wet spinning is a flexible method for fabricating membranes with excellent mechanical strength and well-defined pore structures, making it suitable for air filtration. The process involves extruding a polymer solution through a spinneret into a coagulation bath, where phase separation occurs, resulting in membrane solidification. The fabrication process is highly customizable by modifying parameters such as polymer concentration, solvent composition, and spinning speed [74–76]. This technique is valuable because it enables precise control over pore size and distribution, which is crucial for capturing fine airborne particles. Alkali modification, esterification, or graft polymerization are commonly applied to improve filler dispersibility and strengthen interfacial adhesion with the polymer matrix. However, careful management of the solvent and non-solvent exchange during coagulation is essential, as this can be difficult to optimize. Solvent handling introduces safety and environmental concerns, particularly regarding disposal and exposure risks [77]. Phase inversion is another fabrication technique that offers adjustable pore sizes and adaptable membrane structures, making it effective for a variety of filtration applications. This process involves casting a polymer solution into a film and immersing it in a non-solvent bath, where phase separation induces membrane formation. One of its main advantages is the ability to create membranes with diverse porosities and properties, allowing customization for specific filtration needs [78,79]. The reliance on solvents presents environmental challenges, particularly in solvent recovery and disposal, making this method less eco-friendly. The need for specialized equipment to manage and recycle solvents adds complexity and cost [80].

4 Functionalization and Modification of Lignocellulosic Biocomposites Membranes

Functionalization and modification of LigBioComp membranes involve refining the surface chemistry, pore structure, and mechanical properties to enhance filtration efficiency, durability, and resistance to environmental factors. Incorporating functional groups, such as carboxyl, hydroxyl, or amino groups, into lignocellulosic fibers significantly improves the membrane’s ability to capture particulate matter, including fine dust and microorganisms. For instance, grafting hydrophobic or hydrophilic groups can significantly alter moisture resistance and adsorption capacity. Grafting techniques using polyethyleneimine or polydopamine allow the introduction of antimicrobial or catalytic functionalities, enhancing the membrane’s ability to neutralize pollutants. Hydrophobic modifications improve resistance to water and moisture, which is beneficial in humid environments. Conversely, hydrophilic modifications can enhance the capture of water-soluble pollutants. Studies have shown that functionalization with fluorocarbon compounds can significantly increase the hydrophobicity of lignocellulosic fibers, thereby improving their performance in air filtration applications [83]. Incorporating ZIF-8 into cellulose fibers significantly improves their filtration efficiency against particulate matter and toxic gases, achieving up to 98.36% efficiency for 0.3 μm particles [84]. Cellulose nanofibers used in antimicrobial-integrated cellulose filters exhibited high filtration efficiency for non-oily and oily PM, with the additional advantage of rapid biodegradability [85].

Modifying pore size and distribution using chemical etching or nanoparticle deposition can optimize the filtration capabilities of the membranes. Specific chemicals and methods are vital in the modification of LigBioComp membranes. For instance, silane coupling agents like 3-aminopropyltriethoxysilane enhance hydrophobicity and resistance to fouling by facilitating the attachment of functional molecules to the membrane surface. Incorporating nanoparticles such as silver, zinc oxide, or titanium dioxide can improve self-cleaning properties, extending the membrane’s operational life and reducing maintenance needs. Huang et al. [86] explored the development of a three-dimensional (3D) air filter utilizing a zeolitic imidazolate framework-8 on tunicate nanocellulose and glass fiber composite media (ZIF-8@TNC/GF). This filter demonstrated an exceptionally high efficiency of 99.998% against sodium chloride particles at the most penetrating particle size and featured a significant specific surface area of 50.3 m2/g. The ZIF-8@TNC fibers exhibited a hierarchical porous structure that prevented nanocellulose aggregation.

Surface modification techniques, such as coating and plasma treatment, also improve the filtration efficiency of lignocellulosic biocomposites. For instance, plasma treatment can introduce polar groups onto the fiber surface, enhancing their electrostatic interactions with airborne particles. This results in a higher capture efficiency of particulate matter, including fine and ultrafine particles. Physical hydrophobization techniques such as plasma etching and grafting have effectively rendered lignocellulosic materials hydrophobic, achieving contact angles exceeding 120°. This modification significantly enhances their suitability for air filtration applications. Additionally, coatings with nanoparticles or antimicrobial agents can impart new functionalities to the biocomposites, such as antimicrobial properties, which are essential in environments where biological contaminants are a concern. Balagna et al. [87] demonstrated the effectiveness of Sophora flavescens nanoparticles and silver/silica nanocomposites in creating antimicrobial air filters. Additionally, tannin and lignin-derived nanoparticles have shown promising antibacterial and flame-retardant properties when applied to cellulosic substrates [88]. Fan et al. [89] presented a novel multipurpose air filter that combines the antibacterial properties of silver nanoparticles with the superior removal efficiency of a nanofabric based on zein Pickering emulsion.

5 Air Filtration Performance of Lignocellulosic Biocomposite Membranes

The performance of LigBioComp membranes in air filtration is evaluated based on criteria such as pressure drop and reusability in addition to filtration efficiency and durability [90]. Filtration efficiency measures the membrane’s capability to capture pollutants, typically quantified as the percentage of particles or compounds removed from the air [91]. Pressure drops indicate the resistance air encounters as it passes through the membrane. A low-pressure drop is desirable to maintain energy efficiency in ventilation and air conditioning systems. Due to their naturally porous structure, LigBioComp membranes often exhibit lower pressure drops compared to densely packed synthetic filters, allowing for smoother airflow [92]. Durability and reusability are crucial for the practical application of air filtration membranes. LigBioComp membranes modified with nanoparticles or cross-linked polymers show enhanced mechanical strength and resistance to degradation. This makes them suitable for long-term use and multiple cleaning cycles without significant loss in filtration performance. For instance, lignin-based membranes infused with graphene oxide demonstrated excellent durability and can be washed and reused multiple times while maintaining higher filtration efficiency [93].

Composite electrospun membranes of polyacrylonitrile and cellulose nanocrystals demonstrated high filtration efficiency against aerosolized salt nanoparticles, with increased cellulose content enhancing mechanical properties and the quality factor [94]. Similarly, electrospun polyvinyl alcohol-sodium lignosulfonate membranes have shown high PM2.5 removal efficiency and excellent mechanical properties [95]. Chang et al. [96] fabricated lignin-based air filters via electrospinning technology. The addition of polyethylene terephthalate substrates forms composite layers that filter out 95% of small particles. Green electrospinning techniques have been developed to enhance filtration efficiency by incorporating strategies such as the use of biopolymers, non-toxic solvents, and energy reduction. Moreover, the combination of natural polysaccharide biopolymers and hydrophobic polymers in nanofiber membranes has resulted in improved filtration performance, with some membranes achieving a filtration efficiency of 99.9% for particles above PM2.5. The development of air filtration materials that enhance the capture efficiency of PM2.5, while minimizing pressure loss, underscores ongoing efforts to optimize filtration performance [97–99].

The remarkable air filtration capabilities of LigBioComp membranes, demonstrating their versatility and effectiveness in various studies are illustrated in Table 3. Materials such as cellulose fibers, nanocellulose, and cellulose composites exhibit high filtration efficiencies, often exceeding 99% for PM2.5 and PM10. Performance enhancement is achieved through specific treatment methods, including multi-stage pore design, and the introduction of functional groups. These methods optimize pore structures, improve mechanical strength, and add features like biodegradability and moisture resistance. Ma et al. [66] and Lippi et al. [100] emphasized the importance of developing eco-friendly biocomposites for efficient air filters. These materials also provide the benefit of low-pressure drops, which are essential for maintaining airflow and energy efficiency in filtration systems. Additionally, the use of sustainable sources, such as biomass waste, in developing these filters highlights their potential for environmentally sustainable air purification solutions.

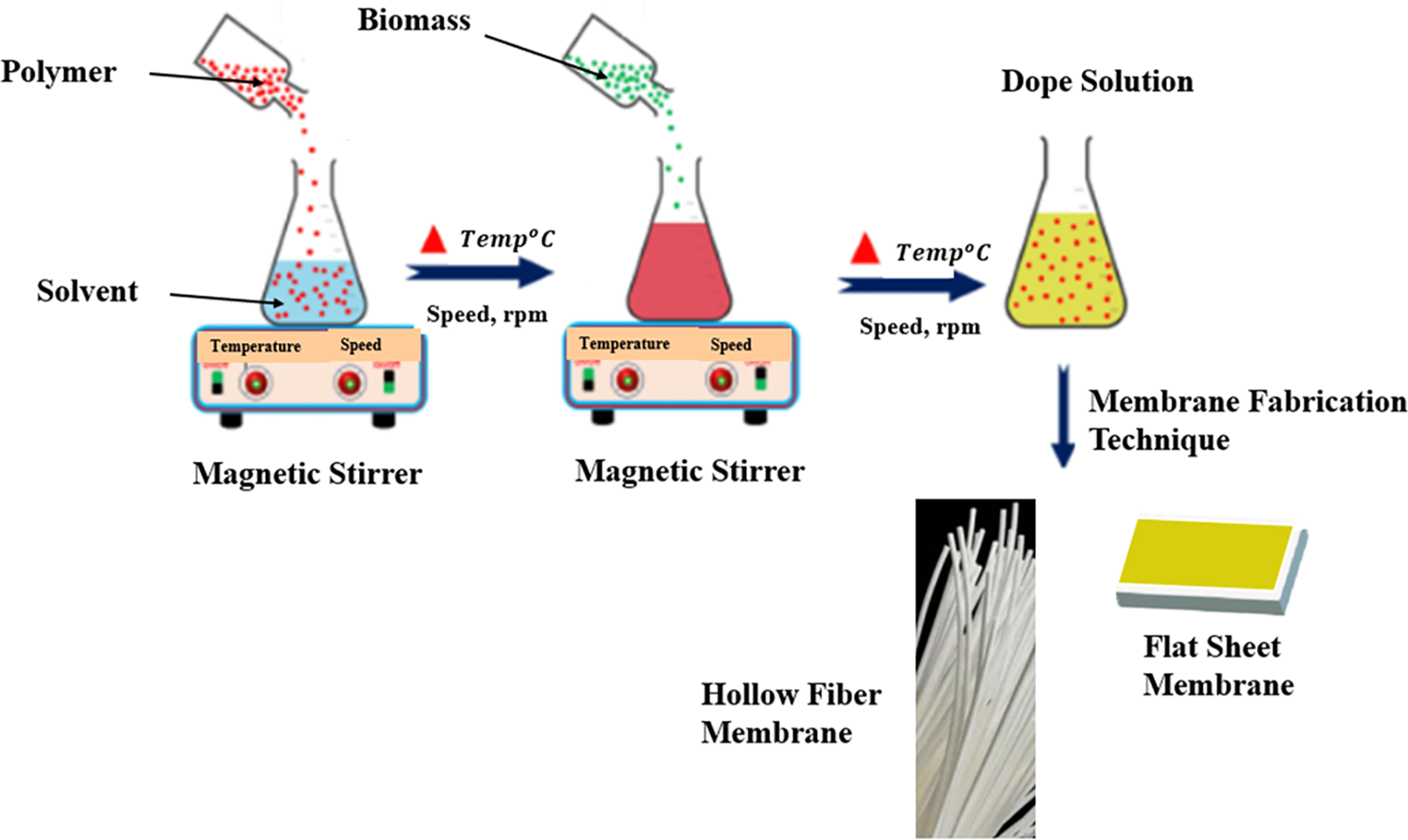

Sawatdee et al. [106] investigated the air filtration efficiency (PFE) of LigBioComp membranes incorporated with empty fruit bunch (EFB) and pulp using an LbL fabrication method. The performance of LigBioComp membranes incorporating acid-hydrolyzed cellulose (EFB-DB3-24hAcid or Pulp-DB-24hAcid) was evaluated against membranes enhanced through additional high-shear homogenization (HS) and ultrasonication (US). These modified variants were designated as EFB-DB3-24hAcid-HS or Pulp-DB3-24hAcid-HS and EFB-DB3-24hAcid-US or Pulp-DB3-24hAcid-US, respectively. The relationship between particle filtration efficiency (%PFE) for 0.3 µm particles and pressure drop (ΔP) is presented in Fig. 2, highlighting key trade-offs in membrane optimization. EFB-DB3-24hAcid-HS exhibited the highest %PFE (97.30%) but also recorded the greatest ΔP (11.56 mm H2O), highlighting the trade-off between filtration efficiency and airflow resistance. Similarly, Pulp-DB-24hAcid-HS achieved a %PFE of 96.90% with a ΔP of 8.51 mm H2O, further emphasizing the relationship between enhanced filtration and increased pressure drop. Balanced performance was demonstrated by EFB-DB3-24hAcid (%PFE = 97.11%, ΔP = 6.09 mm H2O) and Pulp-DB-24hAcid (%PFE = 95.59%, ΔP = 5.75 mm H2O), making these materials suitable for applications that can accommodate moderate pressure resistance. Freeze-dried, ultrasonically treated filters, such as EFB-DB3-24hAcid-US, showed slightly reduced %PFE (96.74%) with a ΔP of 8.85 mm H2O due to increased porosity from structural changes. Optimizing pore structure remains critical for achieving a balance between filtration efficiency and airflow resistance, tailored to specific application needs.

Figure 2: Comparison of particle filtration efficiency and pressure drop across different filters adapted with permission from reference [106]. Copyright©2024, Elsevier

6 New Insights and Limitations

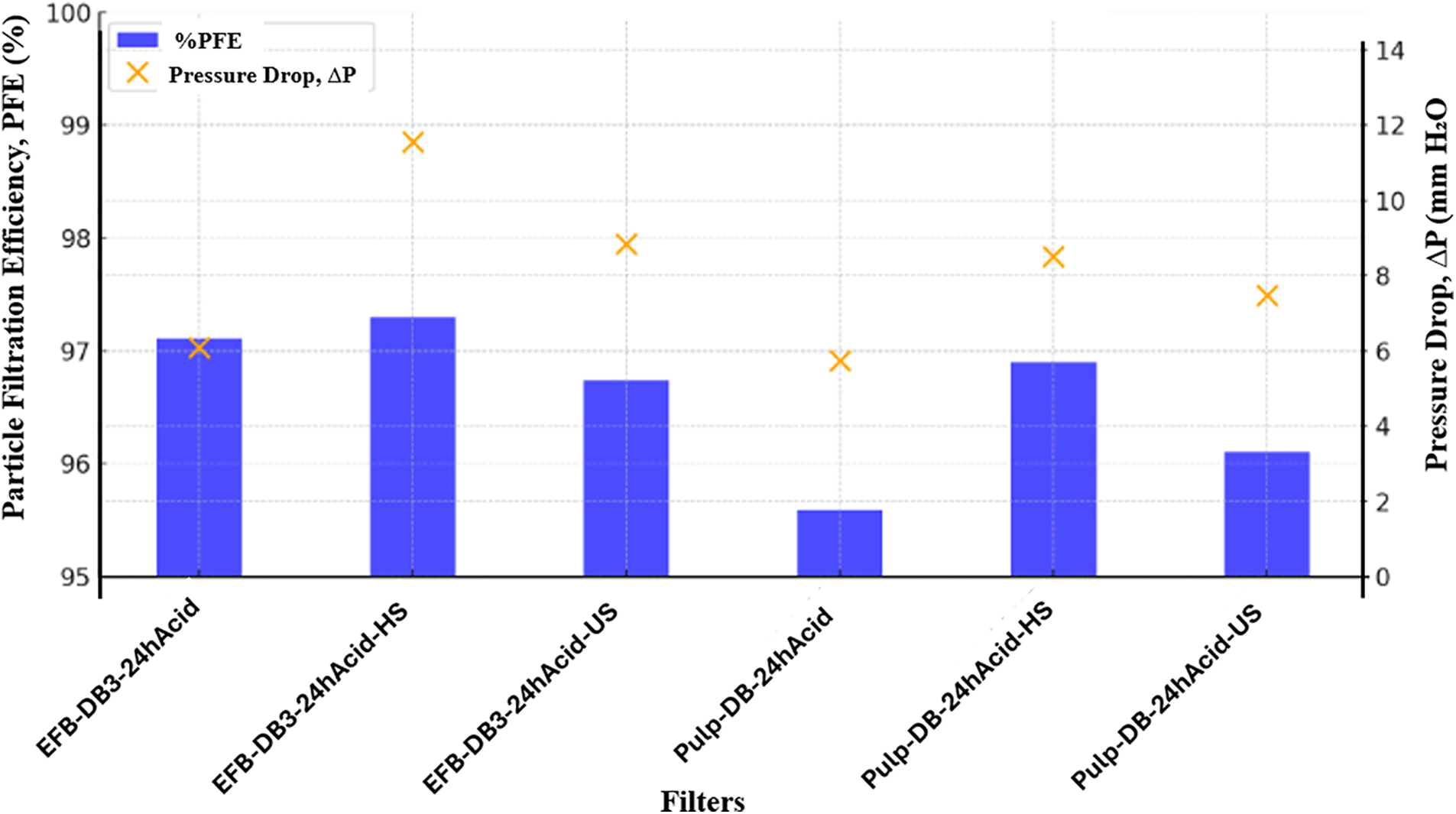

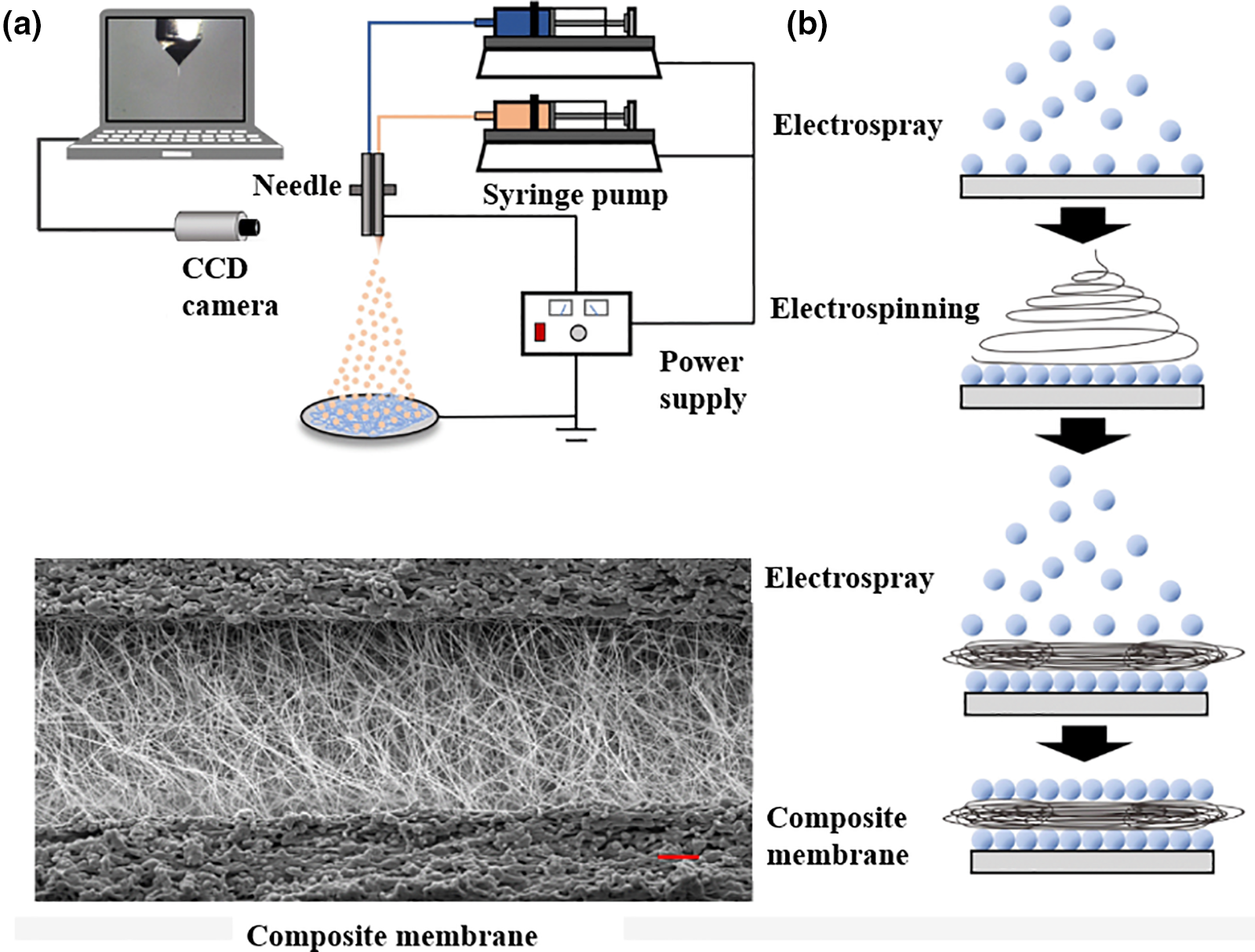

LigBioComp membranes provide effective solutions for high-performance filtration and environmental sustainability, capturing PM and airborne contaminants while offering natural biodegradability. Their end-of-life disposal is also safe for ecosystems, as they can be composted or naturally degraded without environmental harm. Functional upgrades, such as antimicrobial properties and optimized biodegradability, broaden their potential applications beyond conventional air filtration. In situ growth techniques allow for the integration of metal-organic frameworks (MOFs) within cellulose matrices, significantly enhancing gas adsorption capabilities. Electrospinning and electro-spraying create multi-scale fibrous membranes that enhance particle capture and maintain low-pressure drops, achieving filtration efficiencies above 99% for PM0.3 particles [107]. Combining electrospraying with other fabrication techniques can yield hybrid membranes with enhanced properties. Electrospinning and electrospray were used to fabricate LigBioComp membranes via LbL deposition (Fig. 3). The composite membrane was prepared through a LbL assembly process utilizing electrospray and electrospinning techniques. Advances in spinning technologies, computational modeling, and post-processing methods can significantly enhance LigBioComp membrane functionality and durability. The use of green solvents is critical to minimizing environmental impact while maintaining higher membrane performance. Optimizing solvent usage and refining casting parameters can further improve membrane characteristics. Scaling up membrane production is vital for addressing industrial air filtration demands. Innovative strategies should focus on material functionalization, process optimization, and sustainability. In electrospinning, nanofibers can be enhanced with materials such as silver, metal oxides, and graphene oxide, which improves air filtration efficiency. The development of layered composite membranes incorporating advanced materials can increase mechanical strength and multifunctionality.

Figure 3: (a) Electrospray and electrospinning setup. (b) Layer-by-layer deposition process for composite membranes via electrospray and electrospinning adapted with permission from reference [58]. Copyright©2022, Elsevier

Table 4 presents the comparison of cellulose-based composite membranes developed for air filtration applications, detailing their cellulose content, filtration efficiency, key findings, and environmental impact. A notable example is the electrostatically spun mask by Hu et al. [108], which combines high PM capture efficiency with ammonia detection capabilities, providing a self-powered air filtration solution. He et al. [109] developed a composite membrane that combines polyvinyl alcohol, gelatin, and cellulose nanocrystals, achieving high PM2.5 filtration efficiency and thermal stability, making it suitable for industrial environments that experience extreme temperature conditions. Scaffaro et al. [110] introduced polylactic acid (PLA)-based bio-composites that incorporate natural fillers to maintain filtration performance despite fluctuations in humidity and UV exposure. Wang et al. [111] developed a zein-based nanofiber membrane that integrates biodegradable elements with adaptable adsorption capabilities, showcasing the potential for eco-friendly and customizable air purification solutions. Another significant development is the transparent polyvinyl alcohol/sodium lignosulfonate membrane created by Cui et al. [95], which provides both high tensile strength and effective filtration performance. This study exemplifies the adaptability of green electrospinning techniques, opening new avenues for the creation of efficient and sustainable air filtration solutions.

The use of lignocellulosic biocomposite membranes in air filtration introduces several critical limitations and challenges that need to be managed for effective real-world application. These challenges primarily relate to material properties, stability, and adaptation to varying environmental conditions. Lignocellulosic materials, by nature, are highly sensitive to moisture, which can undermine their structural integrity and reduce filtration efficiency, particularly in humid environments [112]. Long-term exposure to harsh environmental factors may accelerate degradation, compromising the longevity and reliability of these membranes. Addressing these sensitivity issues is essential to enhance their viability in diverse operational settings. While membranes such as polylactic acid/copper composites demonstrate strong antimicrobial properties, their long-term stability and effectiveness in varying environmental conditions remain uncertain.

Performance trade-offs and processing complexities complicate the implementation of LigBioComp membranes. Improvements in particle selectivity often come at the expense of airflow permeability, posing a challenge in balancing filtration efficiency with adequate ventilation. While high filtration efficiencies are achievable, the inherent mechanical strength of LigBioComp membranes may be insufficient for demanding applications, thus requiring additional reinforcement strategies to enhance durability [113]. Pretreatment of lignocellulosic biomass, such as pulp refining and chemical modifications, can be resource-intensive, impacting scalability and cost efficiency [114]. Variability in raw lignocellulosic materials introduces quality consistency issues, posing challenges for large-scale production. Despite these hurdles, the potential of LigBioComp membranes to offer sustainable and biodegradable alternatives to synthetic materials continues to drive research aimed at overcoming these limitations and unlocking broader air filtration applications.

This review highlights the benefits of renewable sources, and a variety of fabrication methods of LigBioComp membranes, and examines their potential for environmentally friendly air filtration and sustainable air protection. Solvent-free or low-solvent methods such as electrospinning and LbL assembly should be optimized to reduce environmental impact. Freeze-drying and electrospinning with green solvent techniques can be employed to achieve specific membrane properties, though attention should be given to their energy requirements. Dry-wet spinning and solvent casting processes should be applied selectively, adhering to green chemistry principles. When other methods do not meet performance standards, hybrid-electrospinning with other techniques should be considered alternative. Advances in functionalization and modification yielded improvements in filtration effectiveness and longevity, thereby establishing them as competitive substitutes for traditional synthetic materials. Functional groups such as carboxyl, hydroxyl, or amino groups on lignocellulosic fibers enhance filtration performance by capturing PMs. Techniques such as chemical etching and the incorporation of nanoparticles can further refine the pore size and distribution of the LigBioComp membranes. Hydrophobicity and antimicrobial properties can be enhanced by using silane coupling agents, polyethyleneimine, and polydopamine. Future research efforts should concentrate on refining fabrication techniques to enhance the effectiveness and commercial potential of LigBioComp membranes for air filtration applications. Methods such as electrospinning, LbL assembly, and in-situ growth offer pathways to enhance structural integrity and filtration performance. Developing cost-effective functionalization strategies, including the incorporation of artificial intelligence, smart filters, antimicrobial agents, metal-organic frameworks, and carbon-based nanomaterials, could further improve filtration efficiency and extend membrane lifespan. Enhancements in production scalability are essential, potentially broadening the availability of these eco-friendly filters for industrial and commercial markets. Such investigations will support the development of sustainable, high-performing membranes that can serve as viable, environmentally friendly alternatives in the air filtration industry.

Acknowledgement: The authors are thankful to Universiti Teknologi Malaysia for funding this study.

Funding Statement: This study was funded by the Universiti Teknologi Malaysia (UTM) through research Grant Number: 06E05.

Author Contributions: The authors confirm their contribution to the paper as follows: study conception and design: Abiodun Abdulhameed Amusa; data collection: Abiodun Abdulhameed Amusa; analysis and interpretation of results: Abiodun Abdulhameed Amusa, Anwar Johari, Kamil Kayode Katibi, Ibrahim Garba Shitu, Abdulrahman Oyekanmi Adeleke, Mohd Fairus Mohd Yasin, and Muhammad Thalhah Zainal; draft manuscript preparation: Abiodun Abdulhameed Amusa. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data that support the findings of this study are available from the corresponding author upon reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Abdul-Rahman T, Roy P, Bliss ZSB, Mohammad A, Corriero AC, Patel NT, et al. The impact of air quality on cardiovascular health: a state of the art review. Curr Probl Cardiol. 2024;49(2):102174. doi:10.1016/j.cpcardiol.2023.102174. [Google Scholar] [PubMed] [CrossRef]

2. Vohra K, Vodonos A, Schwartz J, Marais EA, Sulprizio MP, Mickley LJ. Global mortality from outdoor fine particle pollution generated by fossil fuel combustion: results from GEOS-Chem. Environ Res. 2021;195(4):110754. [Google Scholar] [PubMed]

3. Ghorani-Azam A, Riahi-Zanjani B, Balali-Mood M. Effects of air pollution on human health and practical measures for prevention in Iran. J Res Med Sci. 2016;21:65. doi:10.4103/1735-1995.189646. [Google Scholar] [PubMed] [CrossRef]

4. Pili MP, Cagliero L, Panichi V, Bordoni M, Pansarasa O, Cremaschi G, et al. Exposure to pollution during the first thousand days and telomere length regulation: a literature review. Environ Res. 2024;249(5):118323. [Google Scholar] [PubMed]

5. Yuan MH, Kang S, Cho KS. A review of phyto- and microbial-remediation of indoor volatile organic compounds. Chemosphere. 2024;359(7):142120. [Google Scholar] [PubMed]

6. Hussain MS, Gupta G, Mishra R, Patel N, Gupta S, Alzarea SI, et al. Unlocking the secrets: Volatile Organic Compounds (VOCs) and their devastating effects on lung cancer. Pathol-Res Pract. 2024;255(3):155157. [Google Scholar] [PubMed]

7. Leddin D. The impact of climate change, pollution, and biodiversity loss on digestive health and disease. Gastro Hep Adv. 2024;3(4):519–34. doi:10.1016/j.gastha.2024.01.018. [Google Scholar] [PubMed] [CrossRef]

8. Aransiola SA, Zobeashia SSLT, Ikhumetse AA, Musa OI, Abioye OP, Ijah UJJ, et al. Niger delta mangrove ecosystem: biodiversity, past and present pollution, threat and mitigation. Reg Stud Mar Sci. 2024;75(10):103568. [Google Scholar]

9. Ramya A, Dhevagi P, Poornima R, Avudainayagam S, Watanabe M, Agathokleous E. Effect of ozone stress on crop productivity: a threat to food security. Environ Res. 2023;236(11):116816. [Google Scholar] [PubMed]

10. Zhang Y, Han Z, Li X, Zhang H, Yuan X, Feng Z, et al. Plants and related carbon cycling under elevated ground-level ozone: a mini review. Appl Geochem. 2022;144(9):105400. [Google Scholar]

11. Haj-Amor Z, Araya T, Kim DG, Bouri S, Lee J, Ghiloufi W, et al. Soil salinity and its associated effects on soil microorganisms, greenhouse gas emissions, crop yield, biodiversity and desertification: a review. Sci Total Environ. 2022;843(10):156946. [Google Scholar] [PubMed]

12. Dirisu JO, Okokpujie IP, Joseph OO, Oyedepo SO, Falodun O, Tartibu LK, et al. Sustainable biocomposites materials for automotive brake pad application: an overview. J Renew Mater. 2024;12(3):485–511. doi:10.32604/jrm.2024.045188. [Google Scholar] [CrossRef]

13. Amusa AA, Ahmad AL, Adewole JK. Mechanism and compatibility of pretreated lignocellulosic biomass and polymeric mixed matrix membranes: a review. Membranes. 2020;10(12):370. doi:10.3390/membranes10120370. [Google Scholar] [PubMed] [CrossRef]

14. Pizzi A. A review of Soy-Tannin gelling for resins applications. J Renew Mater. 2023;11(1):1–25. doi:10.32604/jrm.2022.023314. [Google Scholar] [CrossRef]

15. Pizzi A, Laborie MP, Candan Z. A review on sources, extractions and analysis methods of a sustainable biomaterial: tannins. J Renew Mater. 2024;12(3):397–425. doi:10.32604/jrm.2023.046074. [Google Scholar] [CrossRef]

16. Farooq A, Islam SR, Al-Amin M, Patoary MK, Hossain MT, Khawar MT, et al. From farm to function: exploring new possibilities with jute nanocellulose applications. Carbohydr Polym. 2024;342(10):122423. [Google Scholar] [PubMed]

17. Amusa AA, Ahmad AL. Enhanced gas separation prowess using functionalized lignin-free lignocellulosic biomass/polysulfone composite membranes. Membranes. 2021;11(3):202. doi:10.3390/membranes11030202. [Google Scholar] [PubMed] [CrossRef]

18. Tamrakar S, Couvreur R, Mielewski D, Gillespie JW, Kiziltas A. Effects of recycling and hygrothermal environment on mechanical properties of thermoplastic composites. Polym Degrad Stab. 2023;207(1):110233. [Google Scholar]

19. Gültürk C, Berber H. Effects of mechanical recycling on the properties of glass fiber-reinforced polyamide 66 composites in automotive components. e-Polymers. 2023;23(1):1–17. doi:10.1515/epoly-2023-0129. [Google Scholar] [CrossRef]

20. Elfaleh I, Abbassi F, Habibi M, Ahmad F, Guedri M, Nasri M, et al. A comprehensive review of natural fibers and their composites: an eco-friendly alternative to conventional materials. Results Eng. 2023;19(9):101271. [Google Scholar]

21. Mohammed W, Osman Z, Elarabi S, Charrier B. A comprehensive analysis of the thermo-chemical properties of sudanese biomass for sustainable applications. J Renew Mater. 2024;12(4):721–36. doi:10.32604/jrm.2024.031050. [Google Scholar] [CrossRef]

22. Skosana SJ, Khoathane C, Malwela T. Driving towards sustainability: a review of natural fiber reinforced polymer composites for eco-friendly automotive light-weighting. J Thermoplast Compos Mater. 2024. doi:10.1177/08927057241254324. [Google Scholar] [CrossRef]

23. Zhang Y, Han Y, Ji X, Zang D, Qiao L, Sheng Z, et al. Continuous air purification by aqueous interface filtration and absorption. Nature. 2022;610(7930):74–80. doi:10.1038/s41586-022-05124-y. [Google Scholar] [PubMed] [CrossRef]

24. Wang J, You C, Xu Y, Xie T, Wang Y. Research advances in electrospun nanofiber membranes for non-invasive medical applications. Micromachines. 2024;15(10):1226. doi:10.3390/mi15101226. [Google Scholar] [PubMed] [CrossRef]

25. Colburn A, Vogler RJ, Patel A, Bezold M, Craven J, Liu C, et al. Composite membranes derived from cellulose and lignin sulfonate for selective separations and antifouling aspects. Nanomater. 2019;9(6):867. doi:10.3390/nano9060867. [Google Scholar] [PubMed] [CrossRef]

26. Jeżo A. Valorization of tree bark-derived suberin in applications for the bio-based composites industry—a recent review. J Renew Mater. 2024;12(6):1029–42. doi:10.32604/jrm.2024.051330. [Google Scholar] [CrossRef]

27. Abolore RS, Jaiswal S, Jaiswal AK. Green and sustainable pretreatment methods for cellulose extraction from lignocellulosic biomass and its applications: a review. Carbohydr Polym Technol Appl. 2024;7(6):100396. [Google Scholar]

28. Amusa AA, Johari A, Yahaya SA. Advancing biomass pyrolysis: a bibliometric analysis of global research trends (2002–2022). In: Environment, development and sustainability. Netherlands: Springer; 2023. p. 1–52. [Google Scholar]

29. Nkuna CN, Mhike W, Ojijo V, Shongwe MB, John MJ. Biocomposites and bionanocomposites from poly(lactide) and cellulosic materials—a review. Cellulose. 2024;31(8):4709–32. doi:10.1007/s10570-024-05913-w. [Google Scholar] [CrossRef]

30. Putra AR, Heri Iswanto A, Nuryawan A, Darmawan S, Windra Madyaratri E, Fatriasari W, et al. Characteristics of biopellets manufactured from various lignocellulosic feedstocks as alternative renewable energy sources. J Renew Mater. 2024;12(6):1103–23. doi:10.32604/jrm.2024.051077. [Google Scholar] [CrossRef]

31. Amusa AA, Ahmad AL, Adewole JK. Study on lignin-free lignocellulosic biomass and PSF-PEG membrane compatibility. BioResources. 2021;16(1):1063–75. [Google Scholar]

32. Rodríguez-Fabià S, Torstensen J, Johansson L, Syverud K. Hydrophobisation of lignocellulosic materials part I: physical modification. Cellulose. 2022;29(10):5375–93. doi:10.1007/s10570-022-04620-8. [Google Scholar] [CrossRef]

33. Rodríguez-Fabià S, Torstensen J, Johansson L, Syverud K, Rodríguez-Fabià S, Johansson L, et al. Hydrophobization of lignocellulosic materials part II: chemical modification. Cellulose. 2022;29(17):8957–95. doi:10.1007/s10570-022-04824-y. [Google Scholar] [CrossRef]

34. Rodríguez-Fabià S, Torstensen J, Johansson L, Syverud K, Rodríguez-Fabià S, Johansson L, et al. Hydrophobization of lignocellulosic materials part III: modification with polymers. Cellulose. 2022;29(11):5943–77. doi:10.1007/s10570-022-04660-0. [Google Scholar] [CrossRef]

35. Gao B, Huang S, Liu Y, Shi X, Jiang R, Shu Z. A novel biocomposite based on lignocellulose modified with epoxidized soybean oil resin. J Appl Polym Sci. 2023;140(43):e54600. doi:10.1002/app.v140.43. [Google Scholar] [CrossRef]

36. Shen SC, Lee NA, Lockett WJ, Acuil AD, Gazdus HB, Spitzer BN, et al. Robust myco-composites as a platform for versatile hybrid-living structural materials. arXiv:2305.12151. 2023. [Google Scholar]

37. Lendvai L. Lignocellulosic agro-residue/polylactic acid (PLA) biocomposites: rapeseed straw as a sustainable filler. Clean Mater. 2023;9(9):100196. [Google Scholar]

38. Tornabene F, Triantafillou T, Brleković F, Mužina K, Kurajica S. The influence of alkaline pretreatment of waste nutshell for use in particulate biocomposites. J Compos Sci. 2024;8(1):26. doi:10.3390/jcs8010026. [Google Scholar] [CrossRef]

39. Johansson M, Skrifvars M, Kadi N, Dhakal HN. Effect of lignin acetylation on the mechanical properties of lignin-poly-lactic acid biocomposites for advanced applications. Ind Crops Prod. 2023;202(10):117049. doi:10.1016/j.indcrop.2023.117049. [Google Scholar] [CrossRef]

40. Subbotina E, Olsén P, Lawoko M, Berglund LA. Maleated technical lignin thermosets and biocomposites designed for degradation. ACS Sustain Chem Eng. 2024;12(9):3632–42. doi:10.1021/acssuschemeng.3c06741. [Google Scholar] [CrossRef]

41. Powell TL, Doughty JJ, Shimabukuro Y, Kirschner CL, Tipton RB. Consumer food waste upcycled into lignocellulosic materials that are utilized in polyethene biocomposites. MRS Adv. 2024;9(8):489–94. doi:10.1557/s43580-024-00897-y. [Google Scholar] [CrossRef]

42. Amusa AA, Johari A, Jalil AA, Abdullah TAT, Adeleke AO, Katibi KK, et al. Sustainable electricity generation and farm-grid utilization from photovoltaic aquaculture: a bibliometric analysis. Int J Environ Sci Technol. 2024;21:7797–818. doi:10.1007/s13762-024-05558-z. [Google Scholar] [CrossRef]

43. Yang Y, Zhang L, Zhang JJ, Ren Y, Huo HF, Zhang X, et al. Fabrication of environmentally, high-strength, fire-retardant biocomposites from small-diameter wood lignin in situ reinforced cellulose matrix. Adv Compos Hybrid Mater. 2023;6(4):1–13. [Google Scholar]

44. Hoang PH, Dat HT. Cascade reaction for bio-polyol synthesis from sunflower oil over a W/ZSM-5 zeolite catalyst for the fabrication of a bio-polyurethane-based porous biocomposite with high oil uptake. RSC Adv. 2024;14(29):20974–81. doi:10.1039/D4RA03671A. [Google Scholar] [PubMed] [CrossRef]

45. Pei P, Sun Y, Zou R, Wang X, Liu J, Liu L, et al. Comparing four kinds of lignocellulosic biomass for the performance of fiber/PHB/PBS bio-composites. BioResources. 2023;18(4):7154–71. doi:10.15376/biores. [Google Scholar] [CrossRef]

46. Liu M, Zhu P, Yan X, Li H, Chen X. The application of solid waste in thermal insulation materials: a review. J Renew Mater. 2024;12(2):329–47. [Google Scholar]

47. Khan MJ, Karim Z, Pongchaikul P, Posoknistakul P, Intra P, Laosiripojana N, et al. Nitrogen and sulfur doped carbon dots coupled cellulose nanofibers: a surface functionalized nanocellulose membranes for air filtration. J Taiwan Inst Chem Eng. 2024;160(7):105324. [Google Scholar]

48. Ashori A, Sepahvand S, Jonoobi M. Development of biodegradable nanofiber filters based on surface-modified cellulose nanofibers with graphene oxide for high removal of airborne particulate matter. Int J Biol Macromol. 2024;261(3):129687. doi:10.1016/j.ijbiomac.2024.129687. [Google Scholar] [PubMed] [CrossRef]

49. Stanislas TT, Bilba K, de Oliveira Santos RP, Onésippe-Potiron C, Savastano Junior H, Arsène MA. Nanocellulose-based membrane as a potential material for high performance biodegradable aerosol respirators for SARS-CoV-2 prevention: a review. Cellulose. 2022;29(15):8001–24. doi:10.1007/s10570-022-04792-3. [Google Scholar] [PubMed] [CrossRef]

50. Posri S, Tangboriboon N. Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol-gel and casting processes for smart membrane applications. Rev Adv Mater Sci. 2023;62(1):20230125. doi:10.1515/rams-2023-0125. [Google Scholar] [CrossRef]

51. Song X, Tang M, Wang C, Li X, Zhu J, Shao J, et al. Stereocomplexation-enhanced electroactivity of poly (lactic acid) nanofibrous membranes for long-term PM capturing and remote respiratory monitoring. ACS Sustain Chem Eng. 2024;12(9):3554–64. doi:10.1021/acssuschemeng.3c06327. [Google Scholar] [CrossRef]

52. Liao M, Tong H, Huang X, Liu F, He J, Mai S. Mechanical properties, biocompatibility and anti-bacterial adhesion property evaluation of silicone-containing resin composite with different formulae. J Renew Mater. 2022;10(12):3201–15. doi:10.32604/jrm.2022.022090. [Google Scholar] [CrossRef]

53. Irfan M, Basri H, Irfan M. An experimental investigation: effect of phase inversion methods on membrane structure and its performance on PEG filtration. J Appl Membr Sci Technol. 2017;17(1):17–23. [Google Scholar]

54. Vatanpour V, Kose-Mutlu B, Koyuncu I. Electrospraying technique in fabrication of separation membranes: a review. Desalination. 2022;533(7):115765. [Google Scholar]

55. Zhang Q, Li Q, Young TM, Harper DP, Wang S. A novel method for fabricating an electrospun poly(vinyl alcohol)/cellulose nanocrystals composite nanofibrous filter with low air resistance for high-efficiency filtration of particulate matter. ACS Sustain Chem Eng. 2019;7(9):8706–14. doi:10.1021/acssuschemeng.9b00605. [Google Scholar] [CrossRef]

56. Zhang Q, Li Q, Zhang L, Wang S, Harper DP, Wu Q, et al. Preparation of electrospun nanofibrous poly(vinyl alcohol)/cellulose nanocrystals air filter for efficient particulate matter removal with repetitive usage capability via facile heat treatment. Chem Eng J. 2020;399(11):125768. [Google Scholar]

57. Liu T, Cai C, Ma R, Deng Y, Tu L, Fan Y, et al. Super-hydrophobic cellulose nanofiber air filter with highly efficient filtration and humidity resistance. ACS Appl Mater Interfaces. 2021;13(20):24032–41. doi:10.1021/acsami.1c04258. [Google Scholar] [PubMed] [CrossRef]

58. Xue Y, Zheng Z, Shen S, Liu G, Xu RX. Combinatory electrospray and electrospinning to produce multi-layered membrane with enhanced mechanical property. Environ Eng Res. 2023;28(2):220023. [Google Scholar]

59. Tian X, Ou Q, Liu J, Liang Y, Pui DYH. Particle loading characteristics of a two-stage filtration system. Sep Purif Technol. 2019;215(5):351–9. [Google Scholar]

60. Sanyal A, Sinha-Ray S. Ultrafine PVDF nanofibers for filtration of air-borne particulate matters: a comprehensive review. Polym. 2021;13(11):1864. doi:10.3390/polym13111864. [Google Scholar] [PubMed] [CrossRef]

61. Ma W, Qi H, Zhang Y, Lin M, Qiu Y, Zhang C. Fabrication of laminated micro/nano filter and its application for inhalable PM removal. Polymers. 2023;15(6):1459. doi:10.3390/polym15061459. [Google Scholar] [PubMed] [CrossRef]

62. Zhao Z, Shi S, Cao H, Li Y, Van der Bruggen B. Layer-by-layer assembly of anion exchange membrane by electrodeposition of polyelectrolytes for improved antifouling performance. J Memb Sci. 2018;558(7):1–8. [Google Scholar]

63. Zhang X, Xu Y, Zhang X, Wu H, Shen J, Chen R, et al. Progress on the layer-by-layer assembly of multilayered polymer composites: strategy, structural control and applications. Prog Polym Sci. 2019;89(2):76–107. [Google Scholar]

64. Poulose A, Parameswaranpillai J, George JJ, Gopi JA, Krishnasamy S, Dominic CDM, et al. Nanocellulose: a fundamental material for science and technology applications. Molecules. 2022;27(22):8032. doi:10.3390/molecules27228032. [Google Scholar] [PubMed] [CrossRef]

65. Nemoto J, Saito T, Isogai A. Simple freeze-drying procedure for producing nanocellulose aerogel-containing, high-performance air filters. ACS Appl Mater Interfaces. 2015;7(35):19809–15. doi:10.1021/acsami.5b05841. [Google Scholar] [PubMed] [CrossRef]

66. Ma S, Zhang M, Yang B, Song S, Nie J, Lu P. Preparation of cellulosic air filters with controllable pore structures via organic solvent-based freeze casting: the key role of fiber dispersion and pore size. BioResources. 2019;13(3):5894–908. [Google Scholar]

67. Ghosal K, Chandra A, Praveen G, Snigdha S, Roy S, Agatemor C, et al. Electrospinning over solvent casting: tuning of mechanical properties of membranes. Sci Rep. 2018;8(1):1–9. [Google Scholar]

68. Piash KPS, Sanyal O. Design strategies for forward osmosis membrane substrates with low structural parameters—a review. Membranes. 2023;13(1):73. doi:10.3390/membranes13010073. [Google Scholar] [PubMed] [CrossRef]

69. Shen R, Shao Z, Xie J, Li H, Zeng Z, Jiang J, et al. Biobased nanofibrous membrane via delayed-volatilizing green electrospinning for high-performance air filtration. ACS Appl Polym Mater. 2023;5(10):8559–69. doi:10.1021/acsapm.3c01666. [Google Scholar] [CrossRef]

70. Yang Y, Zhong M, Wang W, Lu N, Gou Y, Cai W, et al. Engineering biodegradable bacterial cellulose/polylactic acid multi-scale fibrous membrane via co-electrospinning-electrospray strategy for efficient, wet-stable, durable PM0.3 filtration. Sep Purif Technol. 2025;352(1):128143. doi:10.1016/j.seppur.2024.128143. [Google Scholar] [CrossRef]

71. Ma J, Jin X, Lu Y, Yang M, Zhao X, Guo M, et al. Preparation of modified halloysite nanotubes@Ag3PO4/polyacrylonitrile electrospinning membranes for highly efficient air filtration and disinfection. Appl Clay Sci. 2024;253(6):107361. doi:10.1016/j.clay.2024.107361. [Google Scholar] [CrossRef]

72. Wang Q, Shao Z, Sui J, Shen R, Chen R, Gui Z, et al. Preparation of ethyl cellulose bimodal nanofibrous membrane by green electrospinning based on molecular weight regulation for high-performance air filtration. Int J Biol Macromol. 2024;275(8):133411. doi:10.1016/j.ijbiomac.2024.133411. [Google Scholar] [PubMed] [CrossRef]

73. Huang Q, Meng C, Liao M, Kou T, Zhou F, Lu JR, et al. Hierarchically porous, Superhydrophobic PLLA/copper composite fibrous membranes for air filtration. ACS Appl Polym Mater. 2024;6(4):2381–91. doi:10.1021/acsapm.3c03055. [Google Scholar] [CrossRef]

74. Park H, Oh J, Park Y, Kim S, Kim J. Environmentally sustainable particulate filter fabricated via induced phase separation of bioderived fungal chitin and poly (lactic acid). ACS Appl Polym Mater. 2023;5(1):452–62. doi:10.1021/acsapm.2c01589. [Google Scholar] [CrossRef]

75. Yang J, Lu X, Zhang Y, Xu J, Yang Y, Zhou Q. A facile ionic liquid approach to prepare cellulose fiber with good mechanical properties directly from corn stalks. Green Energy Environ. 2020;5(2):223–31. doi:10.1016/j.gee.2019.12.004. [Google Scholar] [CrossRef]

76. Zhang X, Qi Y, Yang J, Dong S, Liu J, Li J, et al. Insight into stabilization behaviors of Lignin/PAN-derived electrospun precursor fibers. Polym Degrad Stab. 2021;191(9):109680. doi:10.1016/j.polymdegradstab.2021.109680. [Google Scholar] [CrossRef]

77. Yan J, Xiao C. Robust preparation and pore structure design of homogeneous braid-reinforced PVDF hollow fiber membrane. Adv Mater Interfaces. 2022;9(12):2102181. doi:10.1002/admi.202102181. [Google Scholar] [CrossRef]

78. Xu X, Liu S, Liu X, Yu J, Ding B. Engineering self-assembled 2D nano-network membranes through hierarchical phase separation for efficient air filtration. J Coll Interface Sci. 2024;657(3):463–71. doi:10.1016/j.jcis.2023.12.014. [Google Scholar] [PubMed] [CrossRef]

79. Arif Z, Sethy NK, Kumari L, Mishra PK, Verma B. Development of antimicrobial and antifouling nanocomposite membranes by a phase inversion technique. J Polym Eng. 2019;39(6):545–55. doi:10.1515/polyeng-2019-0007. [Google Scholar] [CrossRef]

80. Tekin FS, Çulfaz-Emecen PZ. Controlling cellulose membrane performance via solvent choice during precursor membrane formation. ACS Appl Polym Mater. 2023;5(3):2185–94. doi:10.1021/acsapm.2c02185. [Google Scholar] [CrossRef]

81. Hou Q, Wang X, Ragauskas AJ. Preparation and characterization of nanocellulose-polyvinyl alcohol multilayer film by layer-by-layer method. Cellulose. 2019;26(8):4787–98. doi:10.1007/s10570-019-02413-0. [Google Scholar] [CrossRef]

82. Sharma GK, James NR. Progress in electrospun polymer composite fibers for microwave absorption and electromagnetic interference shielding. ACS Appl Electron Mater. 2021;3(11):4657–80. doi:10.1021/acsaelm.1c00827. [Google Scholar] [CrossRef]

83. Liu S, Peng Y, Chen J, Shi W, Yan T, Li B, et al. Engineering surface functional groups on mesoporous silica: towards a humidity-resistant hydrophobic adsorbent. J Mater Chem A. 2018;6(28):13769–77. doi:10.1039/C8TA04082F. [Google Scholar] [CrossRef]

84. Ma S, Zhang M, Nie J, Yang B, Song S, Lu P. Multifunctional cellulose-based air filters with high loadings of metal-organic frameworks prepared by in situ growth method for gas adsorption and antibacterial applications. Cellulose. 2018;25(10):5999–6010. doi:10.1007/s10570-018-1982-1. [Google Scholar] [CrossRef]

85. Liao J, Nie J, Sun B, Jiao T, Zhang M, Song S. A cellulose composite filter with multi-stage pores had high filtration efficiency, low pressure drop, and degradable properties. Chem Eng J. 2024;482(2):148908. [Google Scholar]

86. Huang Z, Dang C, Sun Z, Qi H. High-efficiency air filter media with a three-dimensional network composed of core-shell zeolitic imidazolate framework-8@Tunicate nanocellulose for PM0.3 removal. ACS Appl Mater Interfaces. 2021;13(48):57921–9. doi:10.1021/acsami.1c17052. [Google Scholar] [PubMed] [CrossRef]

87. Balagna C, Perero S, Bosco F, Mollea C, Irfan M, Ferraris M. Antipathogen nanostructured coating for air filters. Appl Surf Sci. 2020;508(4):145283. [Google Scholar]

88. Widsten P, Salo S, Hakkarainen T, Nguyen TL, Borrega M, Fearon O. Antimicrobial and flame-retardant coatings prepared from nano- and microparticles of unmodified and nitrogen-modified polyphenols. Polymers. 2023;15(4):992. doi:10.3390/polym15040992. [Google Scholar] [PubMed] [CrossRef]

89. Fan X, Rong L, Kong L, Li Y, Huang J, Cao Y, et al. Tug-of-war-inspired bio-based air filters with advanced filtration performance. ACS Appl Mater Interfaces. 2021;13(7):8736–44. doi:10.1021/acsami.0c20596. [Google Scholar] [PubMed] [CrossRef]

90. Wang H, Bao Y, Yang X, Lan X, Guo J, Pan Y, et al. Study on filtration performance of PVDF/PUL composite air filtration membrane based on far-field electrospinning. Polymers. 2022;14(16):3294. doi:10.3390/polym14163294. [Google Scholar] [PubMed] [CrossRef]

91. Su Q, Wei Z, Zhu C, Wang X, Zeng W, Wang S, et al. Multilevel structured PASS nanofiber filter with outstanding thermal stability and excellent mechanical property for high-efficiency particulate matter removal. J Hazard Mater. 2022;431(6):128514. doi:10.1016/j.jhazmat.2022.128514. [Google Scholar] [PubMed] [CrossRef]

92. Chang C, Lyu Q, Linghu C, Ji Z, Li G. Prediction of filtration performance of compressed fibrous media. Sep Purif Technol. 2022;287(4):120515. doi:10.1016/j.seppur.2022.120515. [Google Scholar] [CrossRef]

93. Scaffaro R, Citarrella MC, Scaffaro R, Citarrella MC. Nanofibrous polymeric membranes for air filtration application: a review of progress after the COVID-19 pandemic. Macromol Mater Eng. 2023;308(9):2300072. doi:10.1002/mame.v308.9. [Google Scholar] [CrossRef]

94. de Oliveira Santos PR, Hao J, Frollini E, Savastano Junior H, Rutledge GC. Aerosol filtration performance of electrospun membranes comprising polyacrylonitrile and cellulose nanocrystals. J Memb Sci. 2022;650(5):120392. [Google Scholar]

95. Cui J, Lu T, Li F, Wang Y, Lei J, Ma W, et al. Flexible and transparent composite nanofibre membrane that was fabricated via a “green” electrospinning method for efficient particulate matter 2.5 capture. J Colloid Interface Sci. 2021;582(1):506–14. [Google Scholar] [PubMed]

96. Chang CY, Chang FC. Development of electrospun lignin-based fibrous materials for filtration applications. BioResources. 2016;11(1):2202–13. [Google Scholar]

97. Zhang L, Li L, Wang L, Nie J, Ma G. Multilayer electrospun nanofibrous membranes with antibacterial property for air filtration. Appl Surf Sci. 2020;515(5):145962. [Google Scholar]

98. De Riccardis MF. Electrospun nanofibrous membranes for air filtration: a critical review. Compd. 2023;3(3):390–410. [Google Scholar]

99. Cui J, Wang Y, Lu T, Liu K, Huang C. High performance, environmentally friendly and sustainable nanofiber membrane filter for removal of particulate matter 1.0. J Coll Interface Sci. 2021;597(9):48–55. [Google Scholar]

100. Lippi M, Riva L, Caruso M, Punta C. Cellulose for the production of air-filtering systems: a critical review. Materials. 2022;15(3):976. doi:10.3390/ma15030976. [Google Scholar] [PubMed] [CrossRef]

101. Owens LP, Hubbe MA. Performance factors for filtration of air using cellulosic fiber-based media: a review. BioResources. 2023;18(1):2440–519. [Google Scholar]

102. Liu Z, Qin L, Liu S, Zhang J, Wu J, Liang X. Superhydrophobic and highly moisture-resistant PVA@EC composite membrane for air purification. RSC Adv. 2022;12(54):34921–30. doi:10.1039/D2RA05798K. [Google Scholar] [PubMed] [CrossRef]

103. Ángel-Gómez S, Berger S, Niessner J, Álvarez-Láinez ML. Air filtration performance of nanofiber membranes with different morphologies produced by green electrospinning. J Appl Polym Sci. 2024;141(5):e54870. doi:10.1002/app.54870. [Google Scholar] [CrossRef]

104. Martín-Cruz Y, Bordón P, Pulido-Melián E, Saura-Cayuela T, Monzón M. Development of cellulose air filters for capturing fine and ultrafine particles through the valorization of banana cultivation biomass waste. Environments. 2024;11(3):50. doi:10.3390/environments11030050. [Google Scholar] [CrossRef]

105. Hung SH, Bowden JW, Peltier RE, Schiffman JD. Optimizing the packing density and chemistry of cellulose nanofilters for high-efficiency particulate removal. Ind Eng Chem Res. 2021;60(43):15720–9. doi:10.1021/acs.iecr.1c03051. [Google Scholar] [CrossRef]

106. Sawatdee S, Botalo A, Noinonmueng T, Posoknistakul P, Intra P, Pongchaikul P, et al. Fabrication of multilayer cellulose filters isolated from natural biomass for highly efficient air filtration for replacement of synthetic HEPA filters. Process Saf Environ Prot. 2024;12:01562–3. [Google Scholar]

107. Ryu S, Kim D, Lee H, Kim Y, Lee Y, Kim M, et al. Biodegradable nanofiber/metal-organic framework/cotton air filtration membranes enabling simultaneous removal of toxic gases and particulate matter. Polymers. 2023;15(19):3965. doi:10.3390/polym15193965. [Google Scholar] [PubMed] [CrossRef]

108. Hu Z, Wang F, Liu Y, Ma S, Ouyang S, Li M, et al. An electrostatically spun cellulose-based self-powered mask with high efficiency air filtration and ammonia sensing. Int J Biol Macromol. 2024;282(12):137226. [Google Scholar] [PubMed]

109. He Y, Liu H, Ying W. Constructing stable polyvinyl alcohol/gelatin/cellulose nanocrystals composite electrospun membrane with excellent filtration efficiency for PM2.5. Polymers. 2024;16(12):1656. doi:10.3390/polym16121656. [Google Scholar] [PubMed] [CrossRef]

110. Scaffaro R, Citarrella MC. Stable and reusable electrospun bio-composite fibrous membranes based on PLA and natural fillers for air filtration applications. Sustain Mater Technol. 2024;42(12):e01146. [Google Scholar]

111. Wang X, Wang J, Kang J, Zhao Y, Tian H, Jin Y, et al. Natural filter: adjustable hydrophobicity from biodegradable zein nanofiber membrane for high efficiency air purification. Sep Purif Technol. 2025;358(6):130422. [Google Scholar]

112. Cai C, Liu Y, Li L, Dong T, Chen W, Zhou Z, et al. Wet-resistant, dustproof, and germproof self-powered lignocellulosic triboelectric filters for respiratory protection, monitoring, and diagnosis. Chem Eng J. 2023;476(11):146819. [Google Scholar]

113. Wang J, Abbas SC, Li L, Walker CC, Ni Y, Cai Z. Cellulose membranes: synthesis and applications for water and gas separation and purification. Membranes. 2024;14(7):148. doi:10.3390/membranes14070148. [Google Scholar] [PubMed] [CrossRef]

114. Gurupranes SV, Rajendran I, Gokulkumar S, Aravindh M, Sathish S, Elias Uddin M. Preparation, characteristics, and application of biopolymer materials reinforced with lignocellulosic fibres. Int J Polym Sci. 2023;2023(1):1738967. [Google Scholar]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools