Open Access

Open Access

ARTICLE

Enhancement of Mechanical Properties of Natural Rubber Filled Activated Carbon Materials from Agricultural Waste

Department of Advanced Materials Engineering, Faculty of Engineering, Burapha University, Chonburi, 20131, Thailand

* Corresponding Author: Worawut Muangrat. Email:

Journal of Renewable Materials 2025, 13(4), 817-827. https://doi.org/10.32604/jrm.2025.02024-0017

Received 15 October 2024; Accepted 20 December 2024; Issue published 21 April 2025

Abstract

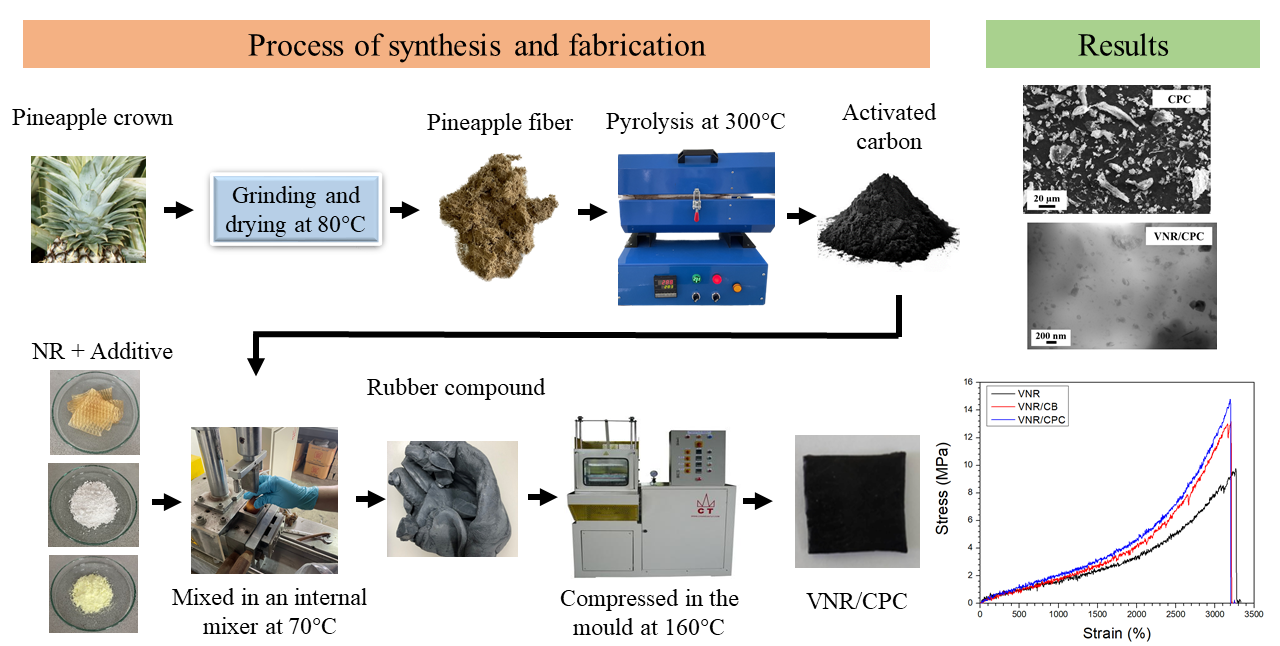

Herein, cure characteristics, morphology, and mechanical properties of natural rubber filled with activated carbon-based materials were investigated. Carbon-based materials were prepared from bagasse, coffee grounds and pineapple crowns by the pyrolysis method at temperatures in the range of 300°C. As-synthesized carbon materials were characterized by optical microscopy (OM), scanning electron microscopy (SEM), and Fourier-transform infrared spectroscopy (FTIR) to analyze size distribution, morphology, and functional groups, respectively. OM and SEM analysis revealed that particles, flakes, and a small quantity of fiber-like carbon were obtained using bagasse and pineapple crown as raw materials, while honeycomb-like carbon materials can be derived from coffee grounds. To investigate the mechanical properties, natural rubber was filled with carbon black and as-synthesized carbon materials by the internal mixing and compression molding process. Transmission electron microscopy (TEM) was utilized to characterize the dispersion of carbon materials in the rubber matrix. The results of tensile testing showed that the natural rubber mixed with as-synthesized carbon materials from pineapple crowns exhibited 54% and 74% improvement in the ultimate tensile strength and Young’s modulus, respectively, compared with natural rubber without filled carbon materials. The enhancement in mechanical properties by activated carbon materials derived from pineapple crowns can be attributed to the flake- and fiber-like structures and good dispersion of carbon materials in the rubber matrix. In addition, it is higher than that of rubber mixed with carbon black. The results demonstrated that as-synthesized carbon materials from pineapple crowns have the potential materials to substitute carbon black in the rubber compound industry.Graphic Abstract

Keywords

Natural rubber is the elastomeric material that is widely used in rubber industries such as tire and automotive assemblies, thermal insulation, gaskets, etc. [1–5]. It has a higher elastic character than synthetic rubber because of its broad molecular distribution, which does not occur in synthetic rubber. However, the rubber does not have high mechanical properties, although it is vulcanized or crosslinked in a three-dimensional network with sulfur (sulfur vulcanization reaction). Thus, most rubber industries use reinforcing filler to increase mechanical strength as rubber composites [6–9]. The reinforcing filler that is commonly used in rubber industries is divided into two types, which are black and white filler. The white reinforcing filler means the silica with different allotropes, such as precipitate silica and fume silica. Silica is selected in rubber compounds if the rubber would like to add some color with improving some mechanical properties, including tensile modulus and rolling resistance [10–13]. The disadvantage of using silica as a reinforcing filler is the high cost of materials, which is the major reason, and it might not improve mechanical properties well as compared with some carbon materials. Thus, if the rubber product is not concerned with the color of the product, carbon materials are frequently selected for use as the reinforcing filler in rubber compounds. The common carbon material that is used in rubber industries is carbon black (CB), which is a small spherical carbon particle that agglomerates and forms a cluster in the size of a micrometer. It is synthesized from petrochemicals as raw materials. There were many researchers studying rubber/CB composite in the past [14–17], which enhanced mechanical properties after an additional amount of CB into the rubber matrix. Although the filling of CB into rubber improves the mechanical properties, the raw materials for synthesizing CB are petroleum and a fossil fuel that generate greenhouse gases. In addition, CB needs high-cost specialized processing methods and contains impurities such as sulfur and volatile organic compounds [18,19].

The Sustainable Development Goals (SDGs) call upon countries to take action to eradicate poverty and protect the planet. Sustainability requires reducing waste, such as reusing, recycling, and upcycling. Agriculture is one of the most important industrial sectors in Thailand. Each year, enormous quantities of agricultural waste are produced and released into the environment. The amount of agricultural waste produced between February and May 2024 was approximately 45 million tons, according to the report from the Department of Agricultural Extension, Ministry of Agriculture and Cooperatives, Thailand. Due to their abundance, high carbon content, and low-cost resource, agricultural wastes are considered potential resources for converting as activated carbon materials [20–24]. Our previous work [25,26] considered using agricultural waste, which was durian bark or peel, as a carbon source from the pyrolysis process to substitute CB for a reinforcing material in natural rubber foam and compared it with other carbon materials such as CB, multi-walled carbon nanotubes, graphite, and graphene derivatives. The results of mechanical properties in a natural rubber foam matrix filled with carbon synthesized from durian bark were compared with those of carbon materials in a natural rubber foam matrix.

In this work, the activated carbon-obtained agricultural wastes, such as bagasse, pineapple crown, and coffee ground, were synthesized by the pyrolysis method. Natural rubber was compounded with as-synthesized carbon materials by an internal mixing and compression molding process. The mechanical properties of natural rubber and natural rubber-filled activated carbon materials were investigated. To understand the mechanical behavior, optical microscopy (OM), electron microscopy, and Fourier-transform infrared spectroscopy (FTIR) were utilized for characterization.

2.1 Preparation of Carbon-Based Materials

Activated carbon-based materials were prepared by the pyrolysis method. Agricultural waste consists of waste bagasse, coffee grounds and pineapple crowns. As-prepared biomass waste was separately placed into a tube furnace. The temperature was raised from room temperature to 300°C for 60 min using a heating rate of 10°C/min under nitrogen gas with a flow rate of 500 standard cubic centimeters per minute (sccm). The reaction temperature was maintained for 30 min and then cooled down to room temperature under nitrogen atmosphere. All samples were kept at room temperature. As-synthesized carbon materials from bagasse, pineapple crown, and coffee ground were denoted as activated carbon materials-derived bagasse (CBG), activated carbon materials-derived pineapple crown (CPC), and activated carbon materials-derived coffee ground (CCG), respectively.

2.2 Preparation of Rubber-Carbon Composites

Air-dried natural rubber sheet was masticated in an internal mixer (Chareontut, MX75, Samutprakarn, Thailand) at 70°C and 60 rounds per minute (rpm) of rotational speed for 2 min to soften rubber before mixing with other ingredients. CB (C300, supported by Chemical Village Co., Ltd., Samutprakarn, Thailand) and as-prepared carbon materials from agricultural waste such as bagasse, coffee grounds and pineapple crowns and CB were first mixed with rubber at 5 parts per hundred rubber (phr) because the shear rate of rubber was high due to the short period of molecular scissoring during mastication. Then, 5 phr of zinc oxide, 2 phr of stearic acid, 2.5 phr of N-tert-butyl-2-benzothiazolesulfenamide (TBBS) accelerator and 0.5 phr of sulfur were mixed for 8 min, which was shorter than scorching time [25,26]. All rubber chemicals that were used in this work were the commercial grade that was used in rubber industries. Rubber compounding with carbon materials was left at room temperature overnight to release the stress after compounding before the testing and fabricating process. Then, as-prepared samples were compressed at 160°C for 30 min to shape the composite materials.

2.3 Characterization: Morphology, Structure Analysis, Chemical Functional Group and Cure Characteristics

The size distribution and morphology were characterized by OM (ZEISS, Axiolab 5, Oberkochen, Germany) and scanning electron microscopy (SEM, LEO 1450 VP, ZEISS, Cambridge, England). CB and as-synthesized carbon materials were separately dispersed in deionized (DI) water by using a sonicate bath for 5 min and separately dropped into a glass slide with a cover to observe and count the particles for particle size distribution by OM. The particle size was measured by the ferreted diameter by the program at least 150 particles per type of CB and as-synthesized carbon materials to collect the precision data. The chemical functional groups of as-synthesized carbon materials from agricultural waste and CB were characterized by FTIR (is50 FT-IR, Thermo Fisher Scientific, Madison, WI, USA) with attenuated total reflectance (ATR) mode. The wavenumber ranged from 400 to 4000 cm−1 and resolution was set at 64 cm−1. All samples were dehumidified in a hot air oven at 110°C overnight before testing. The structure of vulcanized natural rubber (VNR) composites with CB and as-synthesized carbon materials after compressed in the mold was observed by transmission electron microscope (TEM, Philips, Tecnai 20, Eindhoven, Netherlands). As-prepared composite materials were separately embedded in the epoxy resin and cut with an ultramicrotome (Leica, Leica Ultracut R) before placing it into the copper grid and observing the dispersion of carbon materials in the rubber matrix by TEM. Rubber compound was measured cure characteristics by moving die rheometer (Gotech, M-3000AU, Taiwan) at 160°C for 30 min, which was the processing temperature of our work. After testing, the scorching time (ts1) and cure time (tc90) of all compounds were used as an information to prepare the sample specimen.

The ultimate tensile strength (UTS), Young’s modulus, and elongation at break were tested by a universal testing machine (Narin Instrument Co., Ltd., NRI-TS500-50B, Samutprakarn, Thailand). The VNR composites with CB and as-synthesized carbon materials were prepared as dumbbell shape according to the standard ASTM D638 Type V. The loading speed was 500 mm/min.

3.1 Morphology and Size Distribution of Carbon Black and As-Synthesized Carbon Materials

Fig. 1 shows the low- and high-magnification SEM images of CB, CBG, CPC, and CCG. SEM reveals that the structure of CB is agglomerated as large clusters (Fig. 1a,b). As-synthesized carbon materials from bagasse and pineapple crown present particles with irregular shapes (Fig. 1c–f). In addition, a few fiber-like structures were observed. CCG exhibits porous honeycomb structures with pore sizes in the range of 20–30 µm (Fig. 1g,h). The size distribution of CBG, CPC, and CCG was compared with CB after observation by OM. The size distribution after calculation using the statistic method shown in Fig. 2 displays the smallest size of CB (Fig. 2a) followed by CPC (Fig. 2c), CCG (Fig. 2d), and CBG (Fig. 2b) in terms of mode (high frequency), which were correlated with the arithmetic mean diameter (

Figure 1: SEM images of (a, b) CB, (c, d) CBG, (e, f) CPC and (g, h) CCG

Figure 2: Particle size distribution of (a) CB, (b) CBG, (c) CPC and (d) CCG

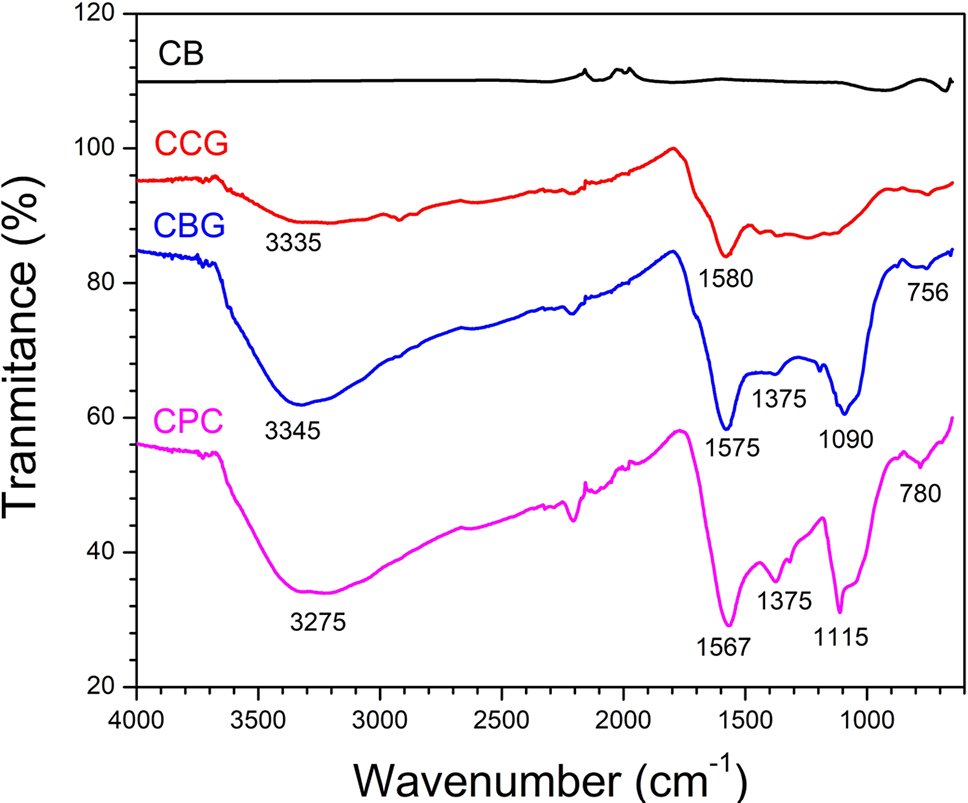

3.2 Chemical Functional Group Analysis

CB, CBG, CPC, and CCG were analyzed chemical functional groups by FTIR with ATR mode. The results in Fig. 3 shows that the CB particle does not have any chemical functional group after testing, meaning that this grade might not be treated on the surface by any chemicals for better dispersion obtained by the supplier. Inversely, as-synthesized carbon materials from agricultural waste observe chemical functional groups with different characters. CBG and CPC were observed the chemical peaks at around 3300, 1500, 1300, 1100, and 700 cm−1 which referred to O-H stretching, C=C stretching, C-N/C-NH3 stretching, C-O stretching, and N-H wagging of primary or secondary amines while CCG did not appear the peaks at around 1300 and 750 cm−1 which meant it did not have an amine functional group or slightly a small amount of this functional group on the surface. This might affect the different cure characteristics of natural rubber/carbon composites [26].

Figure 3: Chemical functional group of all samples analyzed by FTIR

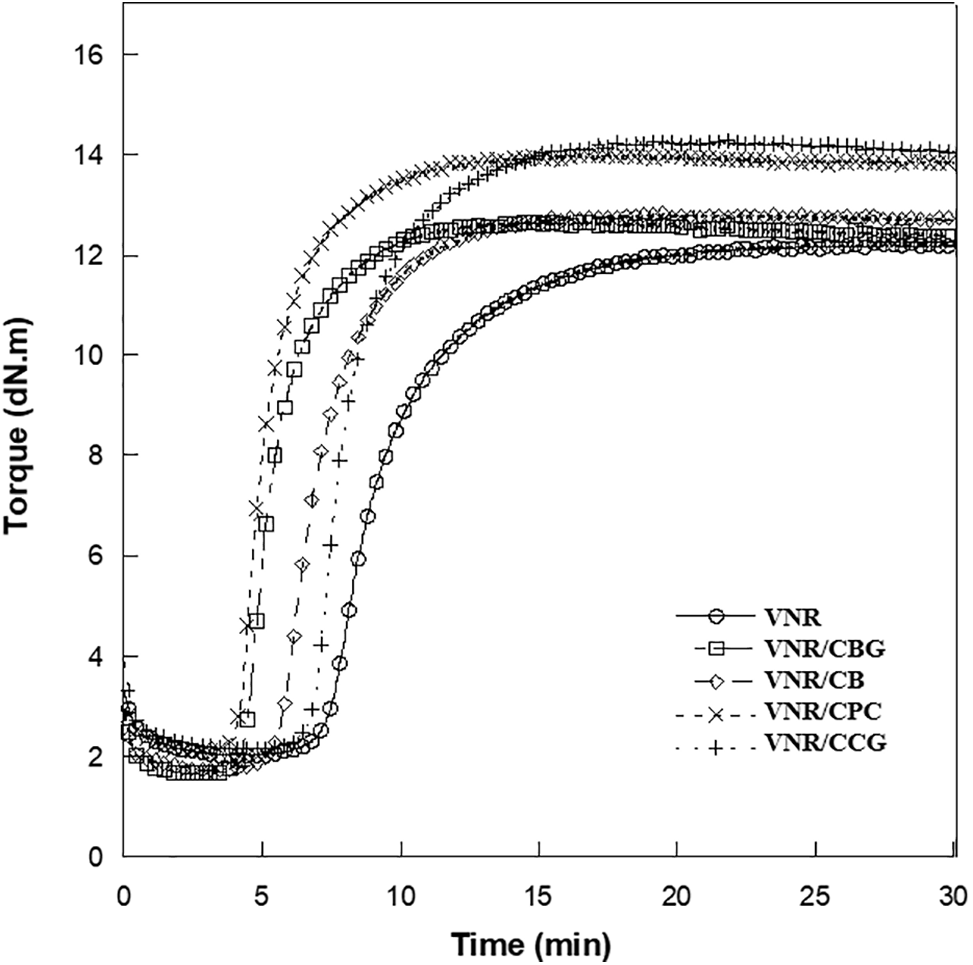

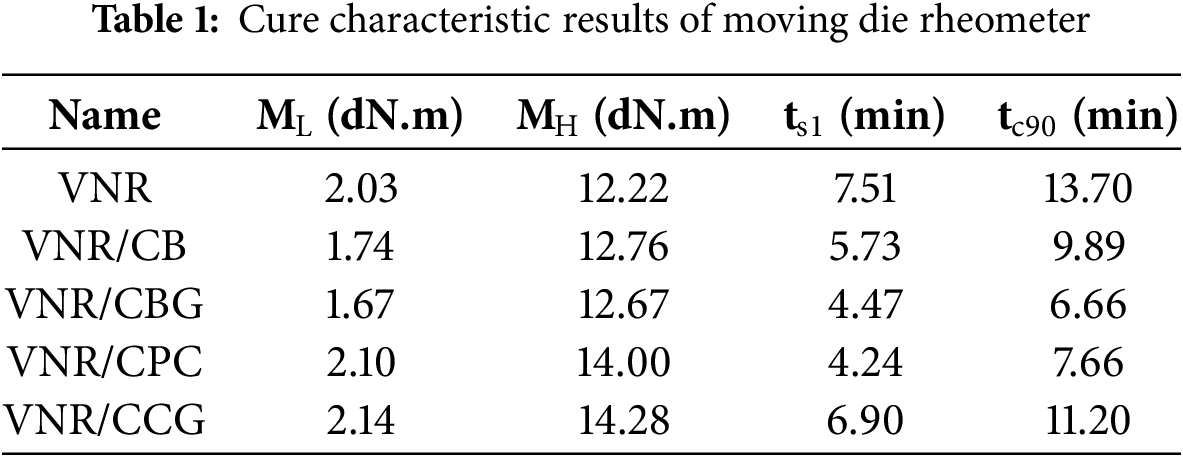

3.3 Cure Behavior of Vulcanized Natural Rubber/Carbon Composites

Rubber compounding after mixing with as-synthesized carbon materials was measured cure behavior by moving die rheometer to obtain the cure kinetic parameters and observe the characteristics of its compound after vulcanization. The cure characteristic is shown in Fig. 4, which found the higher torque of VNR/carbon composites compared to VNR because the higher solid content from additional carbon into the compound might increase the viscosity and conduct heat transfer through the rubber compound due to the high thermal conductivity of carbon [26]. Moreover, VNR/CCG and VNR/CPC showed the highest torque after vulcanizing, while VNR/CBG and VNR/CB exhibited slightly higher torque after vulcanizing than VNR. This might be the effect of different sizes, shapes and the strength of carbon that reinforced vulcanized natural rubber/carbon composites differently. The summary of cure kinetic parameters is shown in Table 1. The fastest ts1 was observed when compound rubber with VNR/CPC and VNR/CBG, meaning that the short period of a rubber compound can flow in the mold. The tc90 also displayed in the same trend as scorching time. It can be seen that VNR/CB has a slower cure rate than other VNR/carbon composites because it does not have any chemical functional group on its surface that can accelerate the vulcanization reaction (oxygen and amine functional groups). In our previous works [26–28] and other work [29], the amine functional group on the surface of filler can accelerate sulfur vulcanization, but in this work, the faster cure rate of VNR/carbon composites than VNR due to the better heat transfer of carbon composites [26]. In addition, VNR/CPC and VNR/CBG exhibit higher cure rate than VNR/CCG. This might be the effect of the amine functional group on the surface of them as discussed in chemical functional group analysis, which was measured by FTIR. It can be concluded that compound rubber with CPC and CBG can accelerate the vulcanization reaction faster than other carbon types in this work.

Figure 4: Cure characteristics of VNR and its composite with different as-synthesized carbon materials

3.4 Morphology of Vulcanized Natural Rubber/Carbon Composites

Fig. 5 shows TEM images of the dispersion of CB and as-synthesized carbon materials from agricultural waste in a rubber matrix. The TEM images showed that CB and CBG were agglomerated in the rubber matrix (Fig. 5a,b) while CPC and CCG exhibited well dispersed in the rubber matrix (Fig. 5c,d). The dispensability of carbon materials in a rubber matrix related to the mechanical properties of the VNR/carbon composite. The better dispersion of carbon materials resulted in the high tensile strength and Young’s modulus. Other factors might influence the mechanical properties, such as the size and shape of carbon and the microstructure of carbon, which will be further discussed.

Figure 5: TEM images of (a) VNR/CB, (b) VNR/CBG, (c) VNR/CPC, and (d) VNR/CCG

3.5 Mechanical Properties of Vulcanized Natural Rubber/Carbon Composites

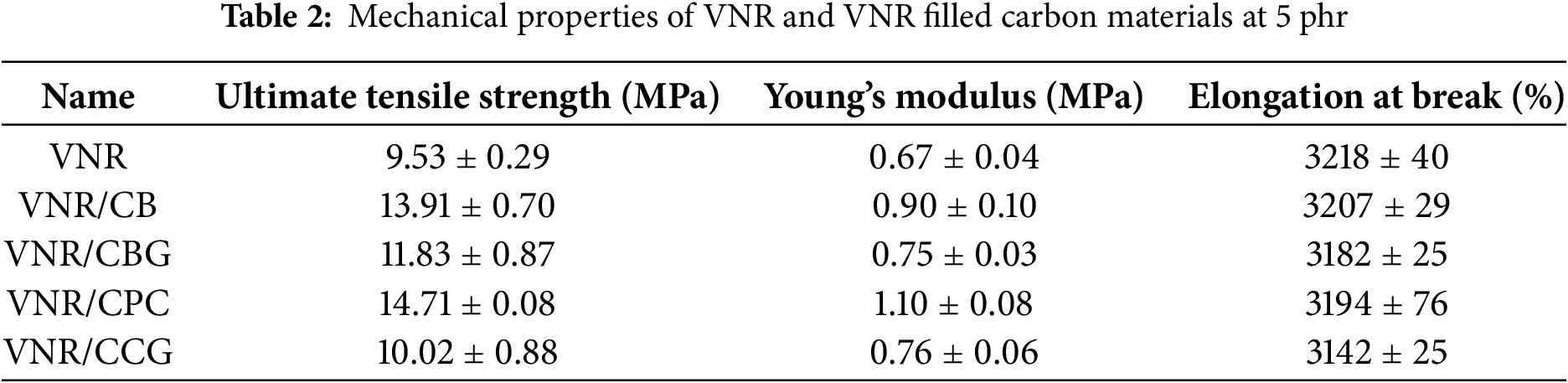

The mechanical properties of VNR and VNR-filled activated carbon materials are shown in Fig. 6 and summarized in Table 2. The addition of activated carbon materials from agricultural waste in natural rubber improves the UTS and Young’s modulus, but elongation at break slightly decreases. Results show that the incorporation of carbon materials into VNR improves the UTS and Young’s modulus. Remarkably, UTS and Young’s modulus of VNR/CPC exhibit 54.36% and 73.55%, respectively, an improvement compared with VNR. Furthermore, the UTS and Young’s modulus of VNR/CPC are better than that of VNR/CB. These results indicated that activated carbon materials from pineapple crown waste have great potential to replace commercial CB for enhanced mechanical properties of composite materials.

Figure 6: Stress-strain curves of VNR and VNR composite with carbon materials at 5 phr

However, VNR/CBG and VNR/CCG have lower mechanical properties than VNR/CB, which means that as-synthesized carbon materials from bagasse and coffee grounds do not have enough potential as reinforcing filler. The improvement in the UTS and Young’s modulus is attributed to the dispersion of carbon materials in the VNR matrix [30–33] and the structure of carbon materials [34–36]. For VNR/CPC, good dispersion and adhesion of activated carbon materials in the VNR matrix increased the tensile strength and Young’s modulus. In the case of VNR/CB and VNR/CBG, the agglomeration of activated carbon materials in the VNR matrix decreased the reinforcement, resulting in a low tensile strength and Young’s modulus of composites. Although activated carbon materials-derived coffee grounds show good dispersion in the VNR matrix, their porous structure is weak and unstable, resulting in low tensile strength and Young’s modulus. On the other hand, the elongation at break slightly decreases after filling carbon materials into VNR because the interfacial interaction between the VNR matrix and carbon materials initiates the cracking defect of materials after stretching, resulting in decreased elongation at the break of VNR-filled carbon materials [35,36].

Agricultural wastes such as bagasse, coffee grounds, and pineapple crowns, were successfully converted as activated carbon materials by the pyrolysis method. As-synthesized carbon materials from bagasse and pineapple crown show particles with irregular shapes and a few fiber-like structures, while coffee grounds exhibit a porous honeycomb structure. As-synthesized activated carbon materials were filled into rubber by an internal mixing and compression molding process to investigate mechanical properties. VNR-filled pineapple crown-derived activated carbon materials exhibited a significant enhancement in the UTS and Young’s modulus. In addition, the UTS and Young’s modulus of VNR/CPG is higher than that of VNR/CB. The improvement of mechanical properties by as-synthesized activated carbon from pineapple crowns-derived particles and fiber-like structures, as well as better dispersion in the VNR matrix. This work proposed the potential of activated carbon materials derived from pineapple crowns to replace CB for improvement of the mechanical properties in the VNR matrix.

Acknowledgement: This work was supported by the Faculty of Engineering, Burapha University.

Funding Statement: This research was funded by Faculty of Engineering, Burapha University, grant number 003/2567.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: Pollawat Charoeythornkhajhornchai, Worawut Muangrat; data collection: Pollawat Charoeythornkhajhornchai, Piyamas Saehia, Thidaporn Butchan, Nawapol Lertumpai, Worawut Muangrat; analysis and interpretation of results: Pollawat Charoeythornkhajhornchai, Worawut Muangrat; draft manuscript preparation: Pollawat Charoeythornkhajhornchai, Worawut Muangrat. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The authors confirm that the data supporting the findings of this study are available within the article.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Sattayanurak S, Sahakaro K, Kaewsakul W, Dierkes WK, Reuvekamp LAEM, Blume A, et al. Synergistic effect by high specific surface area carbon black as secondary filler in silica reinforced natural rubber tire tread compounds. Polym Test. 2020;81:106173. doi:10.1016/j.polymertesting.2019.106173. [Google Scholar] [CrossRef]

2. Aiza Jaafar CN, Zainol I, Ishak NS, Ilyas RA, Sapuan SM. Adjusting silica/rubber interfacial interactions and properties via the click reactions between liquid polybutadiene and silane. Compos Sci Technol. 2021;213:108903. doi:10.1016/j.compscitech.2021.108903. [Google Scholar] [CrossRef]

3. Miao X, Duan X, Cheng H, Duan H, Zhang Z, Liu Y, et al. Green and energy-saving tread rubber by constructing chemical cross-linking interface between graphene oxide and natural rubber. Compos Commun. 2024;51:102067. doi:10.1016/j.coco.2024.102067. [Google Scholar] [CrossRef]

4. Utrera-Barrios S, Verdejo R, López-Manchado MA, Santana MH. Self-healing elastomers: a sustainable solution for automotive applications. Eur Polym J. 2023;190:112023. doi:10.1016/j.eurpolymj.2023.112023. [Google Scholar] [CrossRef]

5. Xiao Y, Li B, Huang Y, Gong Z, Diao P, Wang C, et al. High-value application of kaolin by wet mixing method in low heat generation and high wear-resistant natural rubber composites. Appl Clay Sci. 2024;261:107574. doi:10.1016/j.clay.2024.107574. [Google Scholar] [CrossRef]

6. Joly S, Garnaud G, Ollitrault R, Bokobza L, Mark JE. Organically modified layered silicates as reinforcing fillers for natural rubber. Chem Mat. 2002;14(12):4202–08. [Google Scholar]

7. Rattanasom N, Saowapark T, Deeprasertkul C. Reinforcement of natural rubber with silica/carbon black hybrid filler. Polym Test. 2007;26(4):369–77. [Google Scholar]

8. Wang JC, Chen YH, Wang JH. Novel reinforcing filler: application to natural rubber (NR) system. J Elastom Plast. 2005;37(3):169–80. [Google Scholar]

9. Rattanasom N, Prasertsri S, Ruangritnumchai T. Comparison of the mechanical properties at similar hardness level of natural rubber filled with various reinforcing-fillers. Polym Test. 2009;28(1):8–12. doi:10.1016/j.polymertesting.2008.08.004. [Google Scholar] [CrossRef]

10. Prasertsri S, Rattanasom N. Mechanical and damping properties of silica/natural rubber composites prepared from latex system. Polym Test. 2011;30(5):515–26. doi:10.1016/j.polymertesting.2011.04.001. [Google Scholar] [CrossRef]

11. Theppradit T, Prasassarakich P, Poompradub S. Surface modification of silica particles and its effects on cure and mechanical properties of the natural rubber composites. Mater Chem Phys. 2014;148(3):940–48. doi:10.1016/j.matchemphys.2014.09.003. [Google Scholar] [CrossRef]

12. Choophun N, Chaiammart N, Sukthavon K, eranitisagul C, Laobuthee A, Watthanaphanit A, et al. Natural rubber composites reinforced with green silica from rice husk: effect of filler loading on mechanical properties. J Compos Sci. 2022;6(12):369. doi:10.3390/jcs6120369. [Google Scholar] [CrossRef]

13. Wang Z, Luo Z, Xu Y, Zhong J, Zhang H, Liang J. Preparation and performance of natural rubber latex treatment for silica filled natural rubber composites. J Appl Polym Sci. 2023;140(25):e53966. doi:10.1002/app.v140.25. [Google Scholar] [CrossRef]

14. Salaeh S, Nakason C. Influence of modified natural rubber and structure of carbon black on properties of natural rubber compounds. Polym Compos. 2012;33(4):489–500. doi:10.1002/pc.v33.4. [Google Scholar] [CrossRef]

15. Sae-Oui P, Thepsuwan U, Thaptong P, Sirisinha C. Comparison of reinforcing efficiency of carbon black, conductive carbon black, and carbon nanotube in natural rubber. Adv Polym Technol. 2014;33(4):21422. doi:10.1002/adv.2014.33.issue-4. [Google Scholar] [CrossRef]

16. Kaliyathan AV, Rane AV, Huskic M, Kanny K, Kunaver M, Kalarikkal N, et al. The effect of adding carbon black to natural rubber/butadiene rubber blends on curing, morphological, and mechanical characteristics. J Appl Polym Sci. 2022;139:e51967. doi:10.1002/app.v139.16. [Google Scholar] [CrossRef]

17. Fan Y, Fowler GD, Zhao M. The past, present and future of carbon black as a rubber reinforcing filler—a review. J Clean Prod. 2020;247:119115. doi:10.1016/j.jclepro.2019.119115. [Google Scholar] [CrossRef]

18. Watson AY, Valberg PA. Carbon black and soot: two different substances. Am Ind Hyg Assoc J. 2001;62(2):218–28. [Google Scholar]

19. Coccato A, Jehlicka J, Moens L, Vandenabeele P. Raman spectroscopy for the investigation of carbon-based black pigments. J Raman Spectrosc. 2015;46(10):1003–15. doi:10.1002/jrs.v46.10. [Google Scholar] [CrossRef]

20. Yahya MA, Al-Qodah Z, Zanariah Ngah CW. Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: a review. Renew Sustain Energy Rev. 2015;46:218–35. doi:10.1016/j.rser.2015.02.051. [Google Scholar] [CrossRef]

21. Ukanwa KS, Patchigolla K, Sakrabani R, Anthony E, Mandavgane S. A review of chemicals to produce activated carbon from agricultural waste Biomass. Sustainability. 2019;11(22):6204. doi:10.3390/su11226204. [Google Scholar] [CrossRef]

22. Chouikhi N, Cecilia JA, Vilarrasa-García E, Serrano-Cantador L, Besghaier S, Chlendi M, et al. Valorization of agricultural waste as a carbon materials for selective separation and storage of CO2, H2 and N2. Biomass Bioenergy. 2021;155:106297. doi:10.1016/j.biombioe.2021.106297. [Google Scholar] [CrossRef]

23. Bade MM, Dubale AA, Bebizuh DF, Atlabachew M. Highly efficient multisubstrate agricultural waste-derived activated carbon for enhanced CO2 capture. ACS Omega. 2022;7(22):18770–79. doi:10.1021/acsomega.2c01528. [Google Scholar] [PubMed] [CrossRef]

24. Zhang J, Duan C, Huang X, Meng M, Li Y, Huang H, et al. A review on research progress and prospects of agricultural waste-based activated carbon: preparation, application, and source of raw materials. J Mater Sci. 2024;59:5271–92. doi:10.1007/s10853-024-09526-3. [Google Scholar] [CrossRef]

25. Charoeythornkhajhornchai P, Owakusumsirisakul J, Khamloet W, Nungjumnong P. Effect of carbon synthesized from durian bark on properties of natural rubber composite foam. Key Eng Mater. 2021;876:13–8. doi:10.4028/www.scientific.net/KEM.876. [Google Scholar] [CrossRef]

26. Charoeythornkhajhornchai P, Khamloet W, Nungjumnong P. Effect of carbon allotropes on foam formation, cure characteristics, mechanical and thermal properties of NRF/carbon composites. J Cell Plast. 2022;58(1):41–57. doi:10.1177/0021955X20979548. [Google Scholar] [CrossRef]

27. Nakaramontri Y, Kummerlöwe C, Nakason C, Vennemann N. The effect of surface functionalization of carbon nanotubes on properties of natural rubber/carbon nanotube composites. Polym Compos. 2014;36(11):2113–22. doi:10.1002/pc.23122. [Google Scholar] [CrossRef]

28. Charoeythornkhajhornchai P, Samthong C, Somwangthanaroj A. Effect of graphene treated with cyclohexyl diamine by diazonium reaction on cure kinetics, mechanical, thermal, and physical properties of natural rubber/graphene nanocomposite foam. Polym Compos. 2019;40(52):E1766–76. doi:10.1002/pc.25160. [Google Scholar] [CrossRef]

29. Usha Devi KS, Ponnamma D, Causin V, Maria HJ, Thomas S. Enhanced morphology and mechanical characteristics of clay/styrene butadiene rubber nanocomposites. Appl Clay Sci. 2015;114(5):568–76. doi:10.1016/j.clay.2015.07.009. [Google Scholar] [CrossRef]

30. Fakhru’l-Razi A, Atieh MA, Girun N, Chuah TG, El-Sadig M, Biak DRA. Effect of multi-wall carbon nanotubes on the mechanical properties of natural rubber. Compos Struct. 2006;75:496–500. doi:10.1016/j.compstruct.2006.04.035. [Google Scholar] [CrossRef]

31. Arrigo R, Bartoli M, Malucelli G. Poly(lactic acid)–biochar biocomposites: effect of processing and filler content on rheological, thermal, and mechanical properties. Polymers. 2020;12(4):892. doi:10.3390/polym12040892. [Google Scholar] [PubMed] [CrossRef]

32. Nuryanta MI, Aryaswara LG, Korsmik R, Klimova-Korsmik O, Nugraha AD, Darmanto S, et al. The interconnection of carbon active addition on mechanical properties of hybrid agel/glass fiber-reinforced green composite. Polymers. 2023;15(11):2411. doi:10.3390/polym15112411. [Google Scholar] [PubMed] [CrossRef]

33. Guo X, Guo S, Liu G, Bai L, Liu H, Xu Y, et al. Improving dispersion of carbon nanotubes in natural rubber by using waterjet-produced rubber powder as a carrier. Polymers. 2023;15(3):477. doi:10.3390/polym15030477. [Google Scholar] [PubMed] [CrossRef]

34. Ji X, Zhang X, Yue J, Lu Y, Zhang L. Comparative study on the effect of carbon nanotubes and carbon black on fatigue properties of natural rubber composites. Int J Fatigue. 2022;163:107094. doi:10.1016/j.ijfatigue.2022.107094. [Google Scholar] [CrossRef]

35. Nah C, Lim JY, Cho BH, Hong CK, Gent AN. Reinforcing rubber with carbon nanotubes. J Appl Polym Sci. 2010;118(3):1571–81. [Google Scholar]

36. Zhao Q, Niu F, Liu J, Yin H. Research progress of natural rubber wet mixing technology. Polymers. 2024;16(13):1899. doi:10.3390/polym16131899. [Google Scholar] [PubMed] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools