Open Access

Open Access

REVIEW

Nanocellulose-Based Adhesives for Sustainable Wood-Polymer Composites: Recent Advancement and Future Perspective

1 Department of Agro-Industrial Technology, Universitas Padjadjaran, Bandung, 45363, Indonesia

2 Reseach Collaboration Center for Biomass and Biorefinery, BRIN and Universitas Padjadjaran, Bandung, 45363, Indonesia

3 Department of Forest Product Technology, Faculty of Forestry, Universitas Sumatera Utara, Medan, 20355, Indonesia

4 School of Life Sciences and Technology, Institut Teknologi Bandung, Bandung, 40132, Indonesia

5 Department of Forest Products, Faculty of Forestry and Environment, IPB University, Bogor, 16680, Indonesia

6 Institute of Wood Technology and Renewable Materials, Department of Material Sciences and Process Engineering, University of Natural Resources and Life Sciences, Vienna, 3430, Austria

7 Research Center for Biomass and Bioproducts, National Research and Innovation Agency, Cibinong, 16911, Indonesia

* Corresponding Authors: Efri Mardawati. Email: ; Lukmanul Hakim Zaini. Email:

Journal of Renewable Materials 2025, 13(4), 773-798. https://doi.org/10.32604/jrm.2025.058359

Received 10 September 2024; Accepted 31 December 2024; Issue published 21 April 2025

Abstract

Nanocellulose-based adhesives are gaining attention as a viable alternative to conventional adhesives, offering benefits such as cost-effectiveness and scalability, which make them suitable for various sectors, including cosmetics, pharmaceuticals, biodegradable products, and as reinforcing agents in natural adhesives. This review delves into the current advancements in nanocellulose-based adhesive solutions for sustainable and eco-friendly wood composites, using systematic review methods and bibliometric analysis. Data were collected from the Scopus database, spanning from 2007 to 2024, and visualized using VOSviewer to highlight emerging trends in the field. The analysis revealed that nanocellulose shows great potential as a reinforcing component for traditional adhesives used in wood products such as phenol-formaldehyde (PF), urea-formaldehyde (UF), polymeric diphenylmethane diisocyanate (pMDI), and melamine-urea adhesives. Nanocellulose, derived from the most abundant biopolymer, cellulose, has been utilized in its nanoscale form for adhesive applications. This review emphasizes the advancements in using cellulose nanocrystals (CNC) and cellulose nanofibrils (CNF) to develop sustainable adhesives. It explores both the challenges and future prospects for large-scale production and application of nanocellulose-based adhesives.Keywords

Europe is presently undergoing a transition towards a more sustainable and substantial utilization of natural resources through the expansion of primary production and the sustainable conversion of waste materials [1]. There is a substantial market demand for wood-based panels used across various industrial sectors, including construction and furniture manufacturing [2]. Adhesives play a pivotal role in optimizing the use of wood, with traditional wood composite production relying heavily on adhesives derived from fossil-based polymers such as phenol-formaldehyde (PF), urea-formaldehyde (UF), polymeric diphenylmethane diisocyanate (pMDI), and melamine urea-formaldehyde (MUF) [3,4]. While these adhesives provide excellent durability, their toxicity poses environmental and health concerns and complicates the recycling process of wood composites.

In response, recent decades have witnessed a surge in research focused on developing bio-based adhesives that are abundant, sustainable, renewable, and exhibit enhanced performance characteristics. Bio-based adhesives derived from sources such as starch [5,6], sago [7], soy protein [8], lignin [9], and various cellulose materials [10–12] have garnered significant interest. Among these, cellulose—a naturally occurring, linear glucose polymer linked by β-1,4 glycosidic bonds—is the most abundant organic compound and offers substantial potential as a raw material for wood adhesives due to its biodegradability, non-toxicity, and renewability [13–15]. Notably, the modification of cellulose into nanocellulose enhances its physical properties, including tensile and compressive strengths, thereby expanding its application potential [16]. There are several techniques for modifying cellulose, such as chemical and physical techniques [17]. One of the most popular techniques for chemical modification uses solvents. Alkaline solvents are frequently utilized in the chemical modification of cellulose [18]. These solvents will disintegrate or swell cellulose fibres, making the hydroxyl groups on cellulose more accessible to other chemical reactions because of their strong alkaline properties [19]. The physical method with microwave treatment has started to be developed for cellulose modification because it has the efficiency of high heating speed, ease of use, and ability to alter cellulose’s ultrastructure and break the polymer structure of lignocellulose (hemicellulose and lignin) [20].

Nanocellulose is classified into cellulose nanocrystals (CNC) and cellulose nanofibrils (CNF) [21]. The incorporation of nanocellulose into adhesive formulations provides numerous advantages, such as adjusting adhesive viscosity, improving mechanical, physical, and thermal properties, and reducing formaldehyde emissions [22]. The development of cellulose-based adhesives is still limited, as nanocellulose is known to establish strong cohesive bonds to produce very strong coatings (>100 MPa) after drying, so cellulose often does not exhibit sufficient adhesive strength to link diverse substrates together [23]. Applications of nanocellulose in wood adhesives include CNC for enhancing adhesive properties [24], CNF in particleboard production [25], and coatings for paper [26]. For instance, Cataldi et al. [27] demonstrated the use of CNC as a reinforcing agent in poly(2-ethyl-2-oxazoline), a water-soluble thermoplastic adhesive used in the restoration of oil paintings, resulting in improved adhesive creep compliance and modulus of elasticity. Additionally, the enhancement of mechanical properties in particleboards and oriented strand boards has been explored using CNF-reinforced UF and MUF adhesives [28].

Despite significant progress, research on nanocellulose-based adhesives continues to evolve, necessitating ongoing evaluation of the current state of publications in this field. Bibliometric analysis serves as a valuable tool for mapping the research landscape, enabling the identification of key developments and interconnections within the domain [29]. By providing a graphical representation of a scientific discipline, bibliometric mapping facilitates an understanding of publication and citation patterns [30]. This review aims to draw attention to the continuous advancements in the application of nanocellulose as a sustainable adhesive solution. Initially, a literature review with Vosviewer covered some topics, including the year of publication, productivity, authors and affiliation country, document type, keywords, most documents published in journals, and the most referenced documents. An analysis of recent advancements in cellulose and other adhesive kinds was then conducted. We conclude by discussing the present difficulties and potential future developments in creating adhesives based on nanocellulose for environmentally friendly wood-polymer composites.

The literature data for this study was collected from the Scopus database [31]. An initial search was performed on 19 January 2024, using the query “TITLE-ABS-KEY (nanocellulose AND adhesives),” which yielded 237 documents. To refine the results, filters were applied to include only documents at the final publication stage (“Pubstage = Final”) and in English, resulting in a total of 225 documents. The search covered the period from January 2007 to January 2024. Documents meeting the inclusion criteria for analysis were exported in comma-separated value (*.csv) and research information system (.ris) formats. The metadata of each document was meticulously verified through manual inspection using Mendeley Reference Manager to ensure completeness, focusing specifically on titles, abstracts, and keywords.

2.2 Bibliometric Analysis and Mapping Publications

Bibliometric analysis was conducted using VOSviewer version 1.6.18 for Windows, following established procedures as described in the literature [32]. The metadata utilized for the analysis included fields such as authors, co-authors, titles, abstracts, and keywords. A minimum threshold of five occurrences per term was applied, and duplicate or irrelevant keywords were removed to ensure the accuracy and relevance of the data. The refined data was then mapped using VOSviewer, which facilitated the visualization and assessment of emerging trends through bibliometric mapping. Three types of visualizations were generated: network visualization, density visualization, and overlay visualization, each illustrating co-citation networks and relationships among the items analyzed.

3 Characteristics of the Related Literature

Bibliometric analysis using VOSviewer has been reported [33,34]. The progression of publications about nanocellulose and adhesives from 2007 to 2024 is shown in (Fig. 1).

Figure 1: Total number of documents obtained related to nanocellulose and adhesives in period 2007–2024. Created with Origin2018

A preliminary investigation was published on 22 November 2007 under the title “Modification of Nanocellulose With A Xyloglucan-RGD Conjugate Enhances Adhesion and Proliferation of Endothelial Cells: Implications for Tissue Engineering” [35]. As illustrated in Fig. 1, initial interest in nanocellulose-based adhesives was limited, with no research publications on the topic from 2008 to 2010. The field saw renewed activity in 2011 with just one publication. From 2019 to 2024, the number of related documents has fluctuated significantly. A noticeable increase in research interest began in 2017, marked by the publication of a book chapter titled “The Use of Wheat Straw as an Agricultural Waste in Composites for Semi-Structural Applications” [36], along with one article from the International Journal of Adhesion and Adhesives and a conference paper from the ICCM (International Conferences on Composite Materials) [37,38]. Interest in research on nanocellulose and adhesives is expected to continue growing throughout 2024, with further publications anticipated by the end of December 2024.

3.2 Productivity of Authors and Affiliate Countries

A VOSviewer can analyze author productivity and affiliation. Dubé, M.A., from the University of Ottawa in Ottawa, Canada, has the strongest bond strength with a total link strength of 43, 18 documents, and 149 citations. Dubé, M.A. collaborated with several authors, which are presented in (Fig. 2). Several countries that have published the most research on nanocellulose and adhesives can be seen in (Fig. 3). In terms of the number of publications, China holds the top position with 67 published documents, followed by the United States with 35 published documents.

Figure 2: Author and co-author collaborative network visualization. Created with VOSviewers 1.6.18

Figure 3: Affiliation country of publications regarding nanocellulose and adhesives. Created by Datawrapper

After conducting a manual search in Mendeley Reference Manager and using the specified criteria, we obtained 207 papers. Fig. 4 displays the distribution of document types at the top and identifies the raw materials utilized in adhesive formulations at the bottom for the time spanning from 2007 to 2024. The data reveals that the predominant kind of publication consisted of articles, accounting for 87.4% of the total with 181 documents, closely followed by conference papers. A total of 10 papers, accounting for 4.8% of the total, consist of article reviews and book chapters. Each document includes up to 8 articles, representing 3.9% of the total. Multiple laboratory research endeavours focus on the development of diverse bio-based adhesives possessing superior quality, plentiful availability, sustainable characteristics, and renewable features. Researchers are explicitly exploring cellulose, nanocellulose, and modified nanocellulose as potential raw materials for wood binding purposes.

Figure 4: Number of publications based on document types and identification of nanocellulose-based wood adhesives. Created by Datawrapper

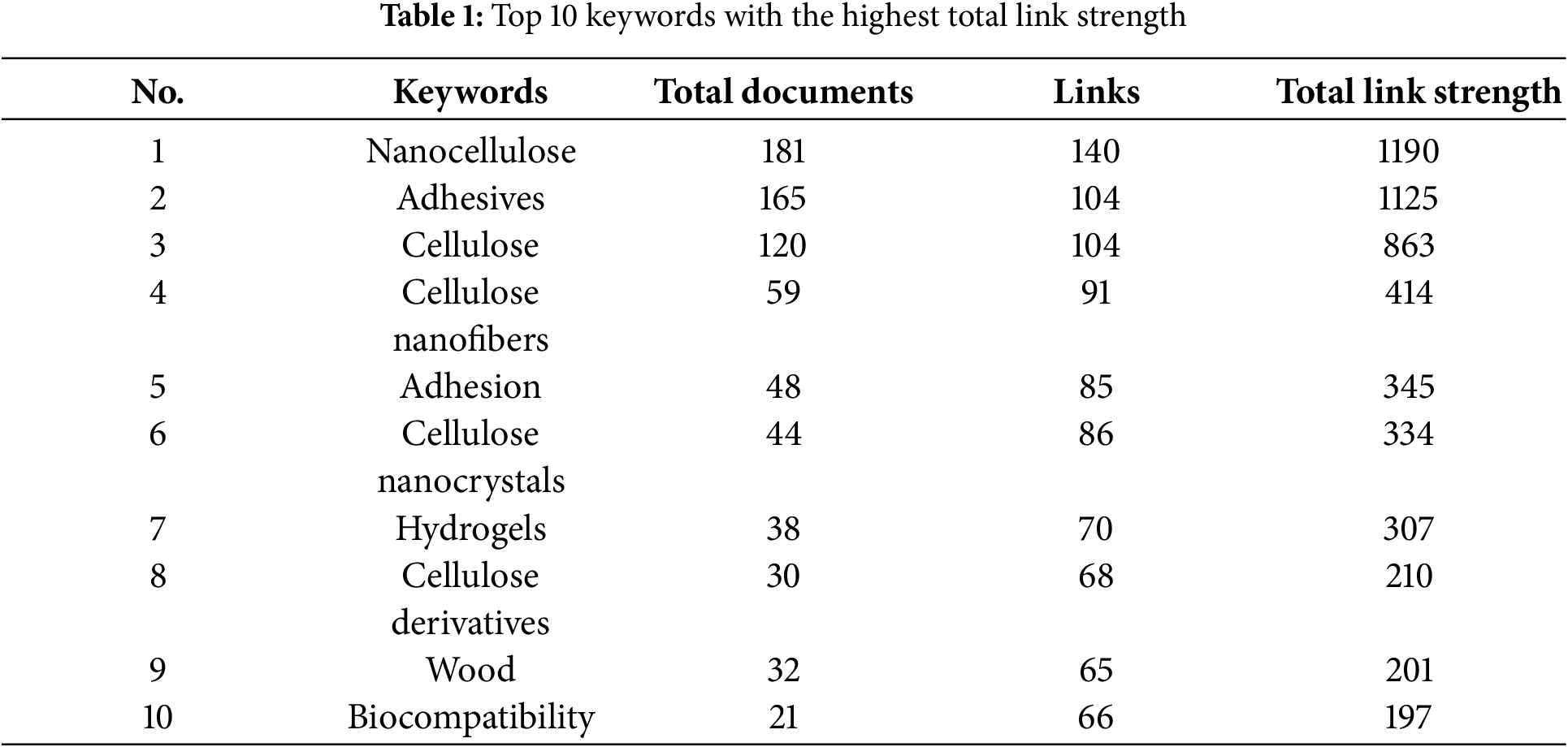

The results of a bibliometric analysis of keywords were used to generate the visual map, which is tabulated on the top 10 keywords with the highest links and total link strength. A link is a connection between two nodes that contain identical information about a paper, such as the names of two authors or keywords that describe the document’s contents [39]. The data in Table 1 shows that experiment journals almost always mention the terms “nanocellulose” and “adhesives”.

Keywords are nouns or phrases that can succinctly encapsulate the entirety of the significance or fundamental substance of a research study, hence facilitating the analysis of research patterns within a scientific field [39,40]. Co-occurrence keyword analysis is conducted to find terms that are often used together in one or more publications [41]. Fig. 5 shows three visualizations generated by VOSviewer using the terms [42]. Fig. 5a presents clusters representing each researched topic area in the form of network visualization. The terms “nanocellulose and adhesives” are included as keywords in this research. Fig. 5b illustrates an overlay visualization format that displays the year in which research on the most searched terms was conducted. Fig. 5c displays the density visualization of the frequency of phrase usage in research using density visualization. The hue of a phrase can be employed to evaluate its frequency of usage. The frequency of a word is directly proportional to the lightness of its color [43].

Figure 5: Network visualization should be listed as (a) network visualization, (b) overlay visualization, and (c) density visualization of nanocellulose adhesives. Created with VOSviewers 1.6.18

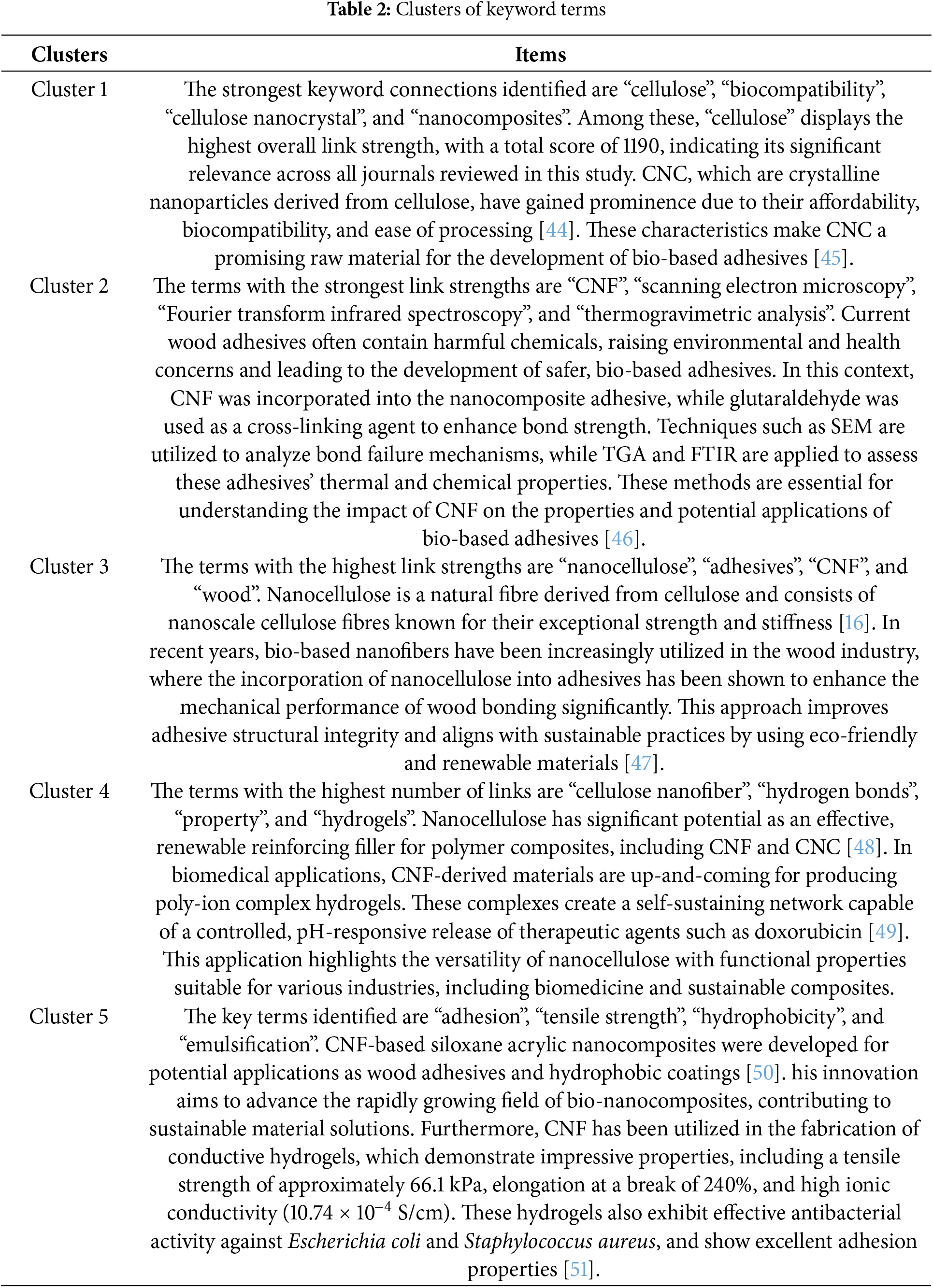

The analysis is conducted using Vosviewer, with a restriction of no more than five relationships between terms [42]. A comprehensive examination of 2770 frequently used terms in the field of nanocellulose-based adhesives revealed that only 105 keywords possess robust associations. These keywords are categorized into the subsequent 5 clusters. Table 2 shows the cluster details of the network visualization keywords.

3.4.1 Relevant Cellulose Types Based on the Number of Co-Occurrences

A comprehensive analysis was conducted on the experimental studies (181 documents) regarding the types of cellulose utilised in each investigation. Bio-based adhesives consist of the following: cellulose (5 documents), nanocellulose (18 documents), then modified nanocellulose such as cellulose nanofibrils as the most widely used adhesive bio-base with 62 documents, followed by cellulose nanocrystals with 29 documents, and bacterial cellulose with 3 documents. The utilization of nanocellulose as a precursor substance for wood adhesive is depicted in (Fig. 6). Furthermore, an additional substance, formaldehyde, was discovered to have been incorporated into the nanocellulose-based adhesive formulation to enhance its performance.

Figure 6: Diagram types of cellulose used for nanocellulose-based adhesives

3.4.2 Wood Product Applications of Nanocellulose-Based Adhesives

Adhesives based on nanocellulose have the potential to serve as reinforcing components for conventional adhesives used in a variety of wood products. The bibliometric analysis conducted using VOSviewer identifies the following keywords: particle board (7 occurrences), plywood (11 occurrences), wood adhesives (6 occurrences), and biomedical (3 occurrences). The ongoing progress in utilizing nanocellulose as a foundational material for wood binders has led to the emergence of nanocellulose-based biomaterials intended for biomedical purposes [52].

3.4.3 Chemical Modification of Nanocellulose as Adhesive

The purpose of chemical modification of nanoparticles is to enhance the thermal, mechanical, and chemical characteristics of different polymer matrices [53]. Nanocellulose is among the materials that exhibit the most significant potential in terms of its capacity to generate composites that are both biocompatible and environmentally sustainable [54]. To enhance the mechanical properties of the composite material, the cellulose material is subjected to modification in order to improve its compatibility with the hydrophobic polymer matrix. With only a few percent of nanocellulose in the polymer matrix, it is possible to substantially enhance the composite material’s mechanical properties [55], and distribute the filler material more uniformly. The bibliometric analysis describes the most common modification techniques for nanocellulose, such as cross-linking (6 co-occurrences), oxidation (6 co-occurrences), and hydrolysis (3 co-occurrences), which frequently occur as keywords in recent research.

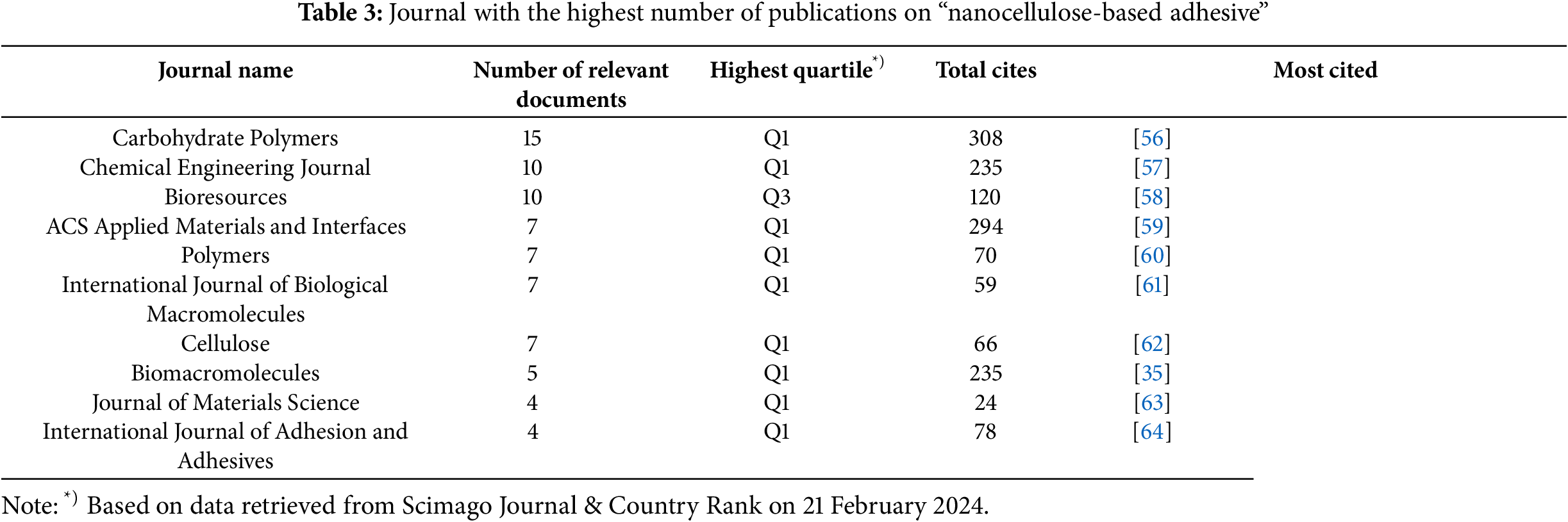

3.5 Most Documents Published in Journal and Most Cited Document

The list of journals with the highest number of published documents can be seen in Table 3. Ten publishers were found to have released more than five documents during the period from 2007 to 2024. The journal with the most contributions was Carbohydrate Polymers, with 15 manuscripts and 308 citations, followed by Chemical Engineering Journal, with 10 manuscripts and 235 citations. The manuscripts listed in Table 3 generally have a rank in the first quartile (Q1) and third quartile (Q3), which shows that these journals have had a significant impact on the development of scientific disciplines, especially nanocellulose-based adhesives.

Highly cited manuscripts were subsequently subjected to an analysis. Evidently, the research influenced the respective authors, as the amount of citations is substantial. Based on citation results, the article with the title “Modification of nanocellulose with a xyloglucan-RGD conjugate enhances adhesion and proliferation of endothelial cells: Implications for tissue engineering,” published by Biomacromolecules in 2007, has the highest number of citations during the 2007–2024 period [35]. This suggests that the first study on cellulose-based adhesives inspired subsequent research and was built upon it.

3.6 Recent Developments in Various Types of Adhesives

Nanocellulose is a cellulose-based material with dimensions of 10–100 nm in length and 1–100 nm in diameter. Nanocellulose exhibits several benefits in comparison to pure cellulose, including its robustness, water-binding capability, and exceptional tensile strength of up to 2 GPa [65]. Nanocellulose is used as a dispersive thickener, a polymer reinforcing agent in filters, and an additive in biodegradable products.

Cellulose nanofibrils and cellulose nanocrystals are two types of nanocellulose distinguished by their shape. Nanocellulose classification is based on dimensions, characteristics, and isolation methods. Fig. 7 shows schematics for CNF and CNC. The cellulose source and isolation procedure determines the properties of nanocellulose; CNF and CNC have chemically similar but physically distinct properties. This is because CNF are typically formed from cellulose fibres using a mechanical method, whereas CNC is obtained through acid hydrolysis to dissolve the amorphous phase [66]. Several modified cellulose derivatives, including fibrillated cellulose, microcrystalline cellulose (MCC), carboxymethyl cellulose (CMC), and dialdehyde cellulose (DAC), have been produced for widespread usage as adhesives.

Figure 7: Schematic of (a) CNF and (b) CNC [67]. Open access CC BY-NC-ND 4.0

CNF is a nanocellulose material produced through a homogenization or grinding process with a diameter of between 5 and 30 nm and amorphous and crystalline zones that make up its structure [68]. Reinforcing materials, film and paper membranes, and adsorbents are all possible applications for CNF [69]. Previous research has examined the application of CNF as a natural binder in particleboard [70,71]. CNF is added together with wood particles during fabrication with variations in CNF addition of 0, 3, 5, 10, and 20 wt.%. The SEM image shows the Particleboard with CNF added (Fig. 8). An increase in interparticle bonding will occur with the addition of CNF. This is because CNF sticks to the wood particles; it entangles itself on the particle surface and fills in the spaces between the particles as aggregates. The aggregates are attributed to the physical entanglement and hydrogen bonds of CNF.

Figure 8: SEM images of the CNF-covered particleboard (a) aggregates of CNF covered the wood particles, (b) CNF entangled the surface of wood particles, (c) aggregated CNF formed a ‘‘nonporous membrane-like’’ structure [71]. Open Access CC BY-NC-ND 4.0

The mechanical characteristics of particleboard bonded with PF and UF resins were compared with those of CNF. Evolution of the MOR (Fig. 9a), MOE (Fig. 9b), and IB (Fig. 9c) of the board as a function of the percentage of CNF or the percentage of two types of resin (UF and PF). The mechanical strength of the board increases as the amount of CNF or resin increases. Furthermore, boards containing 20% CNF exhibit superior mechanical properties compared to boards containing 1% UF or 1% PF. Boards containing 20 wt.% CNF exhibit superior water resistance properties compared to boards containing 1 weight percent UF or PF, in addition to their superior mechanical properties.

Figure 9: Adhesion properties of particleboards containing CNF (a) Modulus of Rupture (MOR), (b) Modulus of Elasticity (MOE), and (c) Internal Bond (IB) [71]. Open Access CC BY-NC-ND 4.0

CNC is crystalline nanoparticles made of cellulose consisting of acicular particles with high crystallinity, elongated rod-shaped with a length in the range of 100–500 nm and a diameter between 2.0–15.0 nm [72]. CNC can be used as a raw material for bioethanol, biofuel, pulp mills [73], composite film [74], bioplastics [75], and wood adhesives. Research has focused on the stability and rheological characteristics of UF resin compositions modified with nanocellulose. Fig. 10 illustrates the curve of speed-viscosity for UF resin and nanocellulose.

Figure 10: Curve of speed-viscosity for UF resins and nanocellulose [76]. Open access CC BY-NC-ND 4.0

Adhesives modified with CNC produced a lower viscosity than unmodified resin, as demonstrated by Hochmanska et al. [76]. Fig. 11 shows that after four weeks of storage, the UF resin modified with CNC retained its appropriate rheological properties and viscosity. Compared to industrial resin, the viscosity percentage decreased by approximately 1.5 times after four weeks of storage. The material’s potential in terms of viscosity and rheological properties is demonstrated to be that of CNC-modified UF adhesive through these results. This suggests that using CNC as a stabilizer could extend UF resin’s longevity.

Figure 11: Viscosity of (a) UF1-CNC and (b) UF2-CNC compounds after 4 weeks of storage [76]. Open access CC BY-NC-ND 4.0

Cellulose is a component of plant cell walls, algae, and bacteria. Cellulose produced by several bacteria, such as Acetobacter xylinum, produces cellulose with the following properties: a high yield value [77], crystallinity, fibre length, and strength that are much higher than plant cellulose [78], and the ability to be shaped into films of specific thicknesses and shapes [79]. The use of bacterial cellulose in particle board technology has been studied by Wacikowski et al. [80]. The bacterial strain of Kombucha employed in this investigation was efficient in multiplying cellulose in combination with a particle content of 5%. To multiply cellulose, bacteria of the Kombucha strain were grown for 14 days on industrial pine particles. After cultivation for 7 days, the expanded cellulose was weighed, dried, and used to make particle board using an adhesive based on urea-formaldehyde resin.

Particleboard with a single layer is manufactured in two distinct varieties. The first variant is a control board that does not contain bacterial cellulose, and the second variant is a board that grows bacterial cellulose. An analysis of the mechanical properties of particleboard grown with BC is depicted in Fig. 12. As a result, single-layer particleboard containing BC had lower MOR (13%) and MOE (11%) values compared to control particleboard (MOR = 17%, MOE = 15%). We assume this is due to the medium’s low pH influencing the wood particles. Internal bonding strength (IB) resulted in test characteristic values 5% higher than the control particle board. Particleboard bonded with BC-based adhesives satisfies the MOR, MOE, and IB value criteria for LP1 panels as specified in EN 16368:2011. Meanwhile, an analysis of the physical properties of particle board grown with BC is depicted in Fig. 13. Single-layer particleboard containing BC experienced 35% lower swelling compared to control particleboard. Following a two-hour soaking in water, particleboard containing BC exhibited a 22% increase in absorption capacity value compared to the control particleboard. In contrast, the absorption capacity of the particle board containing BC was observed to be 5% lower in comparison to the control particle board after a 24-h immersion in water.

Figure 12: Adhesion properties of particleboards bonded with BC-based adhesives [80]. Open access CC BY-NC-ND 4.0

Figure 13: Physical properties values of particle boards [80]. Open access CC BY-NC-ND 4.0

3.6.2 MCC (Microcrystalline Cellulose)

MCC is pure cellulose, which is derived from the α-cellulose found in high-quality wood pulp [81]. MCC has the characteristics of easy flow, compatibility, and good binding ability [82,83]. Powdered MCC finds application as a filler and binder in various products, including medical tablets and foods. Its most notable function is as a reinforcing agent in the formulation of polymer composites. Conversely, colloidal MCC finds utility as a stabilizer for suspensions, a retainer of water, a viscosity regulator, and an emulsifier in diverse pastes and creams [84]. Cataldi et al. [27] investigate the physical and thermo-mechanical properties of thin adhesive films made from CNC and MCC as reinforcing fillers of poly(2-ethyl-2-oxazoline) used in oil painting restoration. The stability of adhesive transparency in CNC is demonstrated by UV-vis spectroscopy (Fig. 14), while MCC experiences a gradual degradation of openness. Thermal analysis proved a progressive increase in the glass transition temperature of the polymer matrix induced by CNC, while no effect was observed for MCC. CNC and MCC can enhance the stabilization effect on the neat matrix by increasing the storage modulus and decreasing the coefficient of thermal expansion and creep compliance with increasing filler content. The adhesive strength of AQ500 is diminished in proportion to the filler content when CNC and MCC are utilized. However, this decrease in τB for CMC-filled adhesive connections is significantly pronounced at 30 wt.% CMC. The decrease in the adhesive properties of the filled samples due to cellulose aggregates that triggers such premature failure is likely combined with an insufficient level of adhesion between the adhesive and the filler. The application of CNC on the adhesive during a single lap shear test on a substrate glued with ancient oil painting demonstrated enhanced dimensional stability of the joints under quasistatic and creep conditions, in contrast to MCC, which failed the test attributable to a shear stress (τ0 = 50% of the value AQ500 τB) that exceeded their actual power.

Figure 14: Results of UV-vis spectroscopy: (a) transparency (T) of neat AQ500 and corresponding microcomposites; (b) transparency (T) of neat AQ500 and corresponding nanocomposites; (c) relative transparency (T/T0) values in the visible wavelengths range as a function of the filler content of micro- (AQ500-CMC) and nanocomposites (AQ500-CNC) [27]. Open Access CC BY-NC-ND 4.0

Cellulose is the most abundant biopolymer in the world and is derived from renewable sources [85]. Cellulose production reaches 180 billion tons/year [86]. The widespread availability, low cost, and ease of processing cellulose have garnered the interest of researchers for their potential applications [87]. As adhesives, numerous modified cellulose derivatives have been developed and implemented, including ethyl cellulose [88], microcrystalline cellulose (MCC) [89], carboxymethyl cellulose (CMC) [62,90], dialdehyde cellulose (DAC) [91,92], and nanocellulose [76,93,94]. Nanocellulose, which is a cellulose derivative, exhibits extraordinary characteristics in comparison to other substances [95,96]. The increasing number of publications each year demonstrates the researchers’ deep interest in developing adhesives based on nanocellulose.

Nanocellulose, a cellulose-derived material at the nanoscale, primarily exists in two forms: cellulose nanofibrils (CNF) and cellulose nanocrystals (CNC) [97]. CNF is widely used as a thickening agent in coatings and adhesives, as well as a reinforcing component in composite materials [98]. Conversely, CNC is employed in high-performance materials and composites, offering superior mechanical properties [99]. Future advancements in nanocellulose-based adhesives should align with the growing market trends towards a green economy, emphasizing sustainable and eco-friendly products. A key challenge in this area is the effective utilization of biomass as the primary resource for nanocellulose production, adhering to the biorefinery concept. This concept involves the comprehensive use of biomass to produce a diverse array of derivative products, including food, biomaterials, and bioenergy [100].

To increase cellulose’s physical characteristics and chemical resistance, cellulose modification is required [101,102]. The results of bibliometric analysis show numerous modification methods commonly used by researchers, such as cross-linking, oxidation, and hydrolysis. To develop nanocellulose-based adhesives, environmentally friendly cross-linkers and chemicals must be applied. GTA (glutaraldehyde) is an effective cross-linking agent for gluten, and the adhesive presents significant strength and water resistance [46]. In addition, in the research by Pang et al. [62], bio-based carboxymethylated wood fibers (CMWFs) were used to develop high-performance soybean meal-based adhesives. A carboxymethylation pretreatment was applied to wood fibre (WF) to provide a substantial number of carboxyl groups and facilitate its dispersion in the soy protein matrix. By forming a double “cross-linking core” with soy protein side chains, CMWF, composed of numerous carboxyl groups, enables a stable adhesive system. TEMPO ((2,2,6,6-tetramethylpiperidin-1-yl)oxyl)-catalyzed cellulose oxidation is a trending technique that facilitates the generation of CNF in quantity while maintaining energy efficiency and cost-effectiveness [103]. The acid hydrolysis technique was used to modify the nanocellulose because of its high mechanical strength and crystallinity [104].

CNF and CNC are potent bio-based compounds with great potential for reinforcing polymer matrices. To boost bonding performance, Kamboj et al. [105], a polyurethane adhesive (PUR) was created and reinforced with CNC and cellulose acetate nanofibers. Reinforced adhesive is used to prepare lap joints using spruce and beech wood. As a result, PUR combined with nanocellulose significantly increased elastic modulus by 33% in spruce wood but only by 12% in beech wood. Cyclic moisture exposure reduced the elasticity of both types of CNC-reinforced PUR. However, for the 0.5% CNF-reinforced PUR joint, the value increased by 5%. PUR reinforcement with nanocellulose significantly increased the shear strength of spruce wood by 45% more than that of beech wood by 35%. Meanwhile, CNF and CNC were strengthened on polyvinyl acetate (PVAc) adhesive. Adding nanocellulose to PVAc adhesive significantly increases the joint’s elastic stiffness and shear strength. Maximum elastic stiffness and shear strength values were achieved by adding 1% nanocellulose.

Researchers have become concerned about the future development of nanocellulose in biomedical applications. Nanocellulose has the potential to significantly advance biomedical materials of the next generation. It has been widely applied in medical implants, tissue engineering, drug delivery, wound healing, diagnostics, and other medical applications, with concrete examples in these fields. A study investigated the capability of CNC as drug delivery excipients to bind water-soluble antibiotics (tetracycline and doxorubicin) and the potential of cationic CNC to bind nonionizing hydrophobic anticancer agents (docetaxel, paclitaxel, and etoposide) [106]. An alternative method for spray-drying CNF tablets to produce tablets with a lower granular porosity than commercial MCC was demonstrated in another study examining the effects of spray-drying treatment on CNF tablets [107]. Implementing nanocellulose-based adhesives offers cost-effectiveness and scalability benefits, thereby facilitating their extensive application in the medical field.

To enhance industrial application, the development of nanocellulose in polymer composites faces several challenges. The most significant barrier is the high production cost. According to Kaur et al. (2021), factors such as the cost of raw materials, pre-treatment methods, and acids used for hydrolysis influence overall production expenses [108]. For instance, using organic acids like citric acid for cellulose nanocrystal (CNC) production reduces capital costs by approximately 40% compared to strong acids like sulfuric acid, offering a more economically and environmentally friendly alternative. Researchers are also exploring enzymatic nanocellulose synthesis as a cost-effective substitute for expensive chemicals.

Squinca et al. highlight that the cost of producing nanocellulose depends on product type, production scale, raw material source, and the technology employed [109]. Specialized equipment, such as high-pressure homogenizers, can increase production expenses, while the costs of chemicals like hydrogen peroxide and sulfuric acid also contribute. Additionally, drying, storage, and transportation processes further influence production costs. As the demand for nanocellulose continues to grow, there is a push to develop more efficient and sustainable production methods. Nevertheless, economic challenges persist, including the limited commercial availability of nanocellulose and the absence of standardized production methods and regulations. Costs are anticipated to decline as new, sustainable production technologies are developed.

Furthermore, Shen et al. investigated the barriers to commercializing polymer composites enhanced with nanocellulose, identifying issues related to functionalization and large-scale production [110]. One key challenge is ensuring compatibility between nanocellulose and polymer matrices. Functionalizing nanocellulose to improve interfacial bonding and overall composite performance is essential, yet diverse techniques are required to achieve the complex synergistic effects needed when combining nanocellulose with other nanofillers. These challenges underscore the need for further research to increase production capacity and optimise costs. The commercialization of nanocellulose-reinforced composites hinges on reducing their high costs and addressing the need for pre-treatment before integration into polymer matrices.

According to bibliometric analysis, the number of publications on nanocellulose-based adhesives increased significantly in 2019 and fluctuated until 2024. Researchers generally conducted experimental studies, with China having the most publications and Dubé, M.A., from the University of Ottawa in Ottawa, Canada, having the strongest bond strength among other authors. Publications of experimental studies of nanocellulose-based adhesives are often in the first quartile (Q1) and third quartile (Q3).

As interest in developing nanocellulose-based adhesives continues to grow, there has been a corresponding increase in the publication of experimental studies and reviews in this field. Various forms of nanocellulose, including cellulose nanofibrils (CNF) and cellulose nanocrystals (CNC), must be rigorously evaluated for their effectiveness as adhesive materials. Nanocellulose offers several advantages as a raw adhesive material, including its high tensile strength, excellent water-binding capacity, and robust bonding capabilities. Common modifications of cellulose, such as cross-linking, oxidation, and hydrolysis, have expanded its use across a range of applications, including particleboard, plywood, wood adhesives, and biomedical materials. Future research should focus on optimizing the environmentally friendly, cost-effective, and user-friendly utilization of these biobased materials.

The large-scale application of nanocellulose-based adhesives, particularly in efforts to reduce carbon emissions and fuel consumption, faces several challenges. By focusing on developing technologies and materials modified with higher value-added materials, we can overcome these challenges and increase the sustainable production of nanocellulose. Utilizing economies of scale in this manner allows for attaining cost-competitive production.

There are ongoing discussions about the potential of nanocellulose in biomedical applications, highlighting the need for continued innovation and refinement in this area. Nonetheless, the research and development of nanocellulose and its composites are expected to grow significantly over the coming decades. With its natural adhesive properties and environmental benefits, nanocellulose holds substantial promise for various technological and biomedical applications.

Acknowledgement: This study was supported by the Department of Agro-Industrial Technology, Universitas Padjadjaran, and the Research Organization of Nanotechnology and Materials, National Research and Innovation Agency, Indonesia.

Funding Statement: This study was funded by the Research Collaboration Center for Biomass and Biorefinery, Universitas Padjadjaran and BRIN, Indonesia, Grant Number 2534/II.7/HK.01.00/5/2023 and B-723/II.7/HK.01.00/4/2024.

Author Contributions: The authors confirm their contribution to the paper as follows: study conception and design: Amelia Hariry, Efri Mardawati, Lukmanul Hakim Zaini, and Muhammad Adly Rahandi Lubis; data collection: Amelia Hariry, Efri Mardawati, and Muhammad Adly Rahandi Lubis; analysis and interpretation of results: Amelia Hariry, Efri Mardawati, Tati Karliati, Apri Heri Iswanto, and Muhammad Adly Rahandi Lubis; validation: Amelia Hariry, Apri Heri Iswanto, and Muhammad Adly Rahandi Lubis; draft manuscript preparation: Amelia Hariry, Efri Mardawati, Lukmanul Hakim Zaini, and Muhammad Adly Rahandi Lubis; review and editing of the manuscript: Amelia Hariry, Tati Karliati, Apri Heri Iswanto, Lukmanul Hakim Zaini, and Muhammad Adly Rahandi Lubis. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Not applicable.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Frihart CR. Wood adhesion and adhesives 9. In: Handbook of wood chemistry and wood composites. 2nd ed. Boca Raton: Rowell; 2013. p. 256–319. doi:10.1201/b12487-13. [Google Scholar] [CrossRef]

2. Vamza I, Krigers G, Valters K. A review of bio-based adhesives from primary and secondary biomass for wood composite applications. Environ Clim Technol. 2022;26:1350–60. doi:10.2478/rtuect-2022-0102. [Google Scholar] [CrossRef]

3. Islam MN, Rahman F, Das AK, Hiziroglu S. An overview of different types and potential of bio-based adhesives used for wood products. Int J Adhes Adhes. 2022;112:102992. doi:10.1016/j.ijadhadh.2021.102992. [Google Scholar] [CrossRef]

4. Aristri MA, Adly M, Lubis R, Yadav SM, Antov P, Papadopoulos AN, et al. Recent developments in lignin- and tannin-based non-isocyanate polyurethane resins for wood adhesives—a review. Appl Sci. 2021;11(9):4242. doi:10.3390/app11094242. [Google Scholar] [CrossRef]

5. Watcharakitti J, Win EE, Nimnuan J, Smith SM. Modified starch-based adhesives: a review. Polymers. 2023;14(10):2023. doi:10.3390/polym14102023. [Google Scholar] [PubMed] [CrossRef]

6. Boussetta A, Benhamou AA, Hassan C, Ablouh E-H, Mennani M, Kasbaji M, et al. Formulation and characterization of chitin-starch bio-based wood adhesive for the manufacturing of formaldehyde-free composite particleboards. Waste Biomass Valorization. 2023;14:3671–87. doi:10.1007/s12649-023-02091-x. [Google Scholar] [CrossRef]

7. Baini R, Demong M, Hui JLC, Kamal MM, Samat NASA, Rahman MR, et al. Characterization of bio-adhesive derived from sarawak native sago starch. IOP Conf Ser Mater Sci Eng. 2021;1101:012041. doi:10.1088/1757-899X/1101/1/012041. [Google Scholar] [CrossRef]

8. Li H, Wang Y, Xie W, Tang Y, Yang F, Gong C, et al. Preparation and characterization of soybean protein adhesives modified with an environmental-friendly tannin-based resin. Polymers. 2023;15(10):2289. doi:10.3390/polym15102289. [Google Scholar] [PubMed] [CrossRef]

9. Siahkamari M, Emmanuel S, Hodge DB, Nejad M. Lignin-glyoxal: a fully biobased formaldehyde-free wood adhesive for interior engineered wood products. ACS Sustain Chem Eng. 2022;10:3430–41. doi:10.1021/acssuschemeng.1c06843. [Google Scholar] [CrossRef]

10. Karagiannidis E, Markessini C, Athanassiadou E. Micro-fibrillated cellulose in adhesive systems for the production of wood-based panels. Molecules. 2020;25(20):4846. doi:10.3390/molecules25204846. [Google Scholar] [PubMed] [CrossRef]

11. Li Z, Du G, Yang H, Liu T, Yuan J, Liu C, et al. Construction of a cellulose-based high-performance adhesive with a crosslinking structure bridged by Schiff base and ureido groups. Int J Biol Macromol. 2022;223:971–9. doi:10.1016/j.ijbiomac.2022.11.069. [Google Scholar] [PubMed] [CrossRef]

12. Melendez-Rodriguez B, Torres-Giner S, Angulo I, Pardo-Figuerez M, Hilliou L, Escuin JM, et al. High-oxygen-barrier multilayer films based on polyhydroxyalkanoates and cellulose nanocrystals. Nanomaterials. 2021;11(6):1443. doi:10.3390/nano11061443. [Google Scholar] [PubMed] [CrossRef]

13. Klemm D, Heublein B, Fink H, Bohn A. Cellulose: fascinating biopolymer and sustainable raw material angewandte. Polym Sci. 2005;44:3358–93. doi:10.1002/anie.200460587. [Google Scholar] [PubMed] [CrossRef]

14. Lismeri L, Zari PM, Novarani T, Darni Y. Cellulose acetate synthesis from cassava stem waste. J Chem Environ Eng. 2016;11:82–91. doi:10.23955/rkl.v11i2.5407. [Google Scholar] [CrossRef]

15. Mulyadi I. Isolation and characterization of cellulose: a review. J Saintika Unpam. 2019;1:177–82. doi:10.32493/jsmu.v1i2.2381. [Google Scholar] [CrossRef]

16. Zhuo X, Liu C, Pan R, Dong X, Li Y. Nanocellulose mechanically isolated from Amorpha fruticosa linn. ACS Sustain Chem Eng. 2017;5:4414–20. doi:10.1021/acssuschemeng.7b00478. [Google Scholar] [CrossRef]

17. Zhu H, Han Z, Cheng J, Sun D. Modification of cellulose from sugarcane (Saccharum officinarum) bagasse pulp by cold plasma: dissolution, structure and surface chemistry analysis. Food Chem. 2022;374:131675. doi:10.1016/j.foodchem.2021.131675. [Google Scholar] [PubMed] [CrossRef]

18. Magalh S, Fernandes C, Pedrosa JFS, Medronho B, Ferreira PJT, Rasteiro G. Eco-friendly methods for extraction and modification of cellulose: an overview. Polymers. 2023;15(14):3138. doi:10.3390/polym15143138. [Google Scholar] [PubMed] [CrossRef]

19. Permatasari H, Gulo F, Lesmini B. The effect of H2SO4 and NaOH concentration on bamboo powder delignification (Gigantochloa apus). J Chem Educ Res. 2014;1:131–40. doi:10.36706/jppk.v1i2.1891. [Google Scholar] [CrossRef]

20. Han Z, Li Y, Luo D, Zhao Q, Cheng J, Wang J. Structural variations of rice starch affected by constant power microwave treatment. Food Chem. 2021;359:129887. doi:10.1016/j.foodchem.2021.129887. [Google Scholar] [PubMed] [CrossRef]

21. Zhu M, Zhang J, Xu W, Xiong R, Huang C. Cellulose-based fibrous materials for self-powered wearable pressure sensor: a mini review. Cellulose. 2023;30:1981–98. doi:10.1007/s10570-022-05023-5. [Google Scholar] [CrossRef]

22. Eyholzer C, Lo F, Bordeanu N, Richter K. DMA analysis and wood bonding of PVAc latex reinforced with cellulose nanofibrils. Cellulose. 2010;17:387–98. doi:10.1007/s10570-010-9396-8. [Google Scholar] [CrossRef]

23. Sun X, Pang Z, Zhu Y, Yu Z, Yang P, Liu L, et al. All-cellulose hydrogel-based adhesive. Innov Mater. 2023;1(3):100040. doi:10.59717/j.xinn-mater.2023.100040. [Google Scholar] [CrossRef]

24. Kaboorani A, Riedl B, Blanchet P, Fellin M, Hosseinaei O, Wang S. Nanocrystalline cellulose (NCCa renewable nano-material for polyvinyl acetate (PVA) adhesive. Eur Polym J. 2012;48:1829–37. doi:10.1016/j.eurpolymj.2012.08.008. [Google Scholar] [CrossRef]

25. Cheng HN, Kilgore K, Ford C, Fortier C, Dowd MK, Kilgore K, et al. Cottonseed protein-based wood adhesive reinforced with nanocellulose. J Adhes Sci Technol. 2019;33(12):1357–68. doi:10.1080/01694243.2019.1596650. [Google Scholar] [CrossRef]

26. Spagnuolo L, Orsi RD, Operamolla A. Nanocellulose for paper and textile coating: the importance of surface chemistry. ChemPlusChem Rev. 2022;87(8):e202200204. doi:10.1002/cplu.202200204. [Google Scholar] [PubMed] [CrossRef]

27. Cataldi A, Berglund L, Deflorian F, Pegoretti A. A comparison between micro- and nanocellulose-filled composite adhesives for oil paintings restoration. Nanocomposites. 2015;1:195–203. doi:10.1080/20550324.2015.1117239. [Google Scholar] [CrossRef]

28. Veigel S, Rathke J, Weigl M, Gindl-Altmutter W. Particle board and oriented strand board prepared with nanocellulose-reinforced adhesive. J Nanomater. 2012;2012:245. doi:10.1155/2012/158503. [Google Scholar] [CrossRef]

29. Hariry A, Mardawati E, Masruchin N. Nanocellulose research trends from pineapple plant waste in indonesia: bibliometric analysis using vosviewer. Asian J Appl Res Community Dev Empower. 2023;7(2):1–7. doi:10.29165/ajarcde.v7i2.247. [Google Scholar] [CrossRef]

30. Herawati P, Utami SB, Karlina N. Bibliometric analysis: development of research and publications regarding program coordination using vosviewer. J Pustaka Budaya. 2022;9:1–8. doi:10.31849/pb.v9i1.8599. [Google Scholar] [CrossRef]

31. Bayu A, Nandiyanto D, Biddinika MK, Triawan F. How bibliographic dataset portrays decreasing number of scientific publication from indonesia. Indones J Sci Technol. 2020;5:154–75. doi:10.17509/ijost.v5i1.22265. [Google Scholar] [CrossRef]

32. Arias A, Gonz S, Vetroni M, Salvador R, Carlos A, Francisco D, et al. Recent developments in bio-based adhesives from renewable natural resources. J Clean Prod J. 2021;314:127892. doi:10.1016/j.jclepro.2021.127892. [Google Scholar] [CrossRef]

33. Donthu N, Kumar S, Mukherjee D, Pandey N, Marc W. How to conduct a bibliometric analysis: an overview and guidelines. J Bus Res. 2021;133:285–96. doi:10.1016/j.jbusres.2021.04.070. [Google Scholar] [CrossRef]

34. Passas I. Bibliometric analysis: the main steps. Encyclopedia. 2024;4:1014–25. doi:10.3390/encyclopedia4020065. [Google Scholar] [CrossRef]

35. Bodin A, Ahrenstedt L, Fink H, Brumer H, Risberg B, Gatenholm P. Modification of nanocellulose with a xyloglucan-RGD conjugate enhances adhesion and proliferation of endothelial cells: implications for tissue engineering. Biomacromolecules. 2007;8:3697–704. doi:10.1021/bm070343q. [Google Scholar] [PubMed] [CrossRef]

36. Santulli C. The use of wheat straw as an agricultural waste in composites for semi-structural applications. In: Handbook-composites-renewable-materials. Ascoli Piceno, Italy: Università Degli Studi Di Camerino, School of Architecture and Design (SADWiley; 2017. p. 515–31. doi:10.1002/9781119441632.ch38. [Google Scholar] [CrossRef]

37. Kajtna J, Šebenik U. Novel acrylic/nanocellulose microsphere with improved adhesive properties. Int J Adhes Adhes. 2017;74:100–6. doi:10.1016/j.ijadhadh.2016.11.013. [Google Scholar] [CrossRef]

38. Frisk N, Sain M, Oksman K. Nanocellulose reinforced bio-polyurethane foams as core in sandwich composite panels. In: International Conference on Composite Materials; 2017; Sweden: International Committee on Composite Materials. [Google Scholar]

39. Rodr G, Mar C, Cort P, Montero C, Rosales V, Galarce C. Bibliometric analysis of the green gluing technique (2000–2020trends and perspectives. Forest. 2022;13:1–16. doi:10.3390/f13101714. [Google Scholar] [CrossRef]

40. Xiang C, Wang Y, Liu H. A scientometrics review on nonpoint source pollution research. Ecol Eng. 2017;99:400–8. doi:10.1016/j.ecoleng.2016.11.028. [Google Scholar] [CrossRef]

41. Zhang L, Geng Y. A bibliometric analysis on waste electrical and electronic equipment research. Environ Sci Pollut Res. 2019;26:21098–108. doi:10.1007/s11356-019-05409-2. [Google Scholar] [PubMed] [CrossRef]

42. Al Husaeni DF, Nandiyanto ABD. Bibliometric using vosviewer with publish or perish (using Google Scholar datafrom step-by-step processing for users to the practical examples in the analysis of digital learning articles in pre and post COVID-19 pandemic. ASEAN J Sci Eng. 2022;2:19–46. [Google Scholar]

43. Al Husaeni DN, Nandiyanto ABD, Maryanti R. Bibliometric analysis of special needs education keyword using vosviewer indexed by google scholar. Indones J Commun Spec Needs Educ. 2023;3(1):1–10. [Google Scholar]

44. Li K, Jin S, Zhang F, Zhou Y, Zeng G, Li J, et al. Bioinspired phenol-amine chemistry for developing bioadhesives based on biomineralized cellulose nanocrystals. Carbohydr Polym. 2022;296:119892. doi:10.1016/j.carbpol.2022.119892. [Google Scholar] [PubMed] [CrossRef]

45. Gomri C, Cretin M, Semsarilar M. Recent progress on chemical modification of cellulose nanocrystal (CNC) and its application in nanocomposite films and membranes—a comprehensive review. Carbohydr Polym. 2022;294:119790. doi:10.1016/j.carbpol.2022.119790. [Google Scholar] [PubMed] [CrossRef]

46. Oh M, Ma Q, Simsek S, Bajwa D, Jiang L. Comparative study of zein- and gluten-based wood adhesives containing cellulose nanofibers and crosslinking agent for improved bond strength. Int J Adhes Adhes. 2019;92:44–57. doi:10.1016/j.ijadhadh.2019.04.004. [Google Scholar] [CrossRef]

47. Veigel S, Pinkl S, Gindl-Altmutter W. Nanocellulose-modified wood adhesives. In: Biobased adhes. Sources, character applications. Vienna, Tulln, Austria: BOKU-University of Natural Resources and Life Sciences, Department of Material Sciences and Process Engineering, Institute of Wood Technology and Renewable Materials, Wiley; 2023. p. 415–26. doi:10.1002/9781394175406.ch14. [Google Scholar] [CrossRef]

48. Barkane A, Kampe E, Platnieks O, Gaidukovs S. Cellulose nanocrystals vs. Cellulose nanofibers: a comparative study of reinforcing effects in uv-cured vegetable oil nanocomposites. Nanomater. 2021;11(7):1791. doi:10.3390/nano11071791. [Google Scholar] [PubMed] [CrossRef]

49. Hujaya SD, Lorite GS, Vainio SJ, Liimatainen H. Polyion complex hydrogels from chemically modified cellulose nanofibrils: structure-function relationship and potential for controlled and pH-responsive release of doxorubicin. Acta Biomater. 2018;75:346–57. doi:10.1016/j.actbio.2018.06.013. [Google Scholar] [PubMed] [CrossRef]

50. Neelambaram P, Thounchiyath T, Narayan R, Chakrabarty A. Cellulose nanofiber-incorporated high-solid siloxane acrylic latex by mini-emulsion polymerization for hydrophobic coating and wood adhesive. Polym Adv Technol. 2023;34:3859–69. doi:10.1002/pat.6187. [Google Scholar] [CrossRef]

51. Wei J, Zhang X, Wang F, Shao Y, Zhang W-B, Wu H. One-step preparation of highly viscoelastic, stretchable, antibacterial, biocompatible, wearable, conductive composite hydrogel with extensive adhesion. Compos Sci Technol. 2023;231:109793. doi:10.1016/j.compscitech.2022.109793. [Google Scholar] [CrossRef]

52. Tamimi ZA, Tiari S, Ji X, Piovesan D, Madura AR, Chen L. Preparation of nanocellulose-based biomaterials for biomedical applications. In: Proceedings of the International Conference Theorem Applications Nanoscience Nanotechnology; 2023; Erie, PA, USA: Department of Biomedical, Industrial & Systems Engineering, Gannon University 109 University Square, Avestia Publishing. Vol. 7. doi:10.11159/tann23.121. [Google Scholar] [CrossRef]

53. Gadhave RV, Dhawale PV, Sorate CS. Surface modification of cellulose with silanes for adhesive application: review. J Polym Chem. 2021;11:11–30. doi:10.4236/ojpchem.2021.112002. [Google Scholar] [CrossRef]

54. Teramoto Y. Recent advances in multi-scale experimental analysis to assess the role of compatibilizers in cellulosic filler-reinforced plastic composites. J Compos Sci. 2021;5(5):138. doi:10.3390/jcs5050138. [Google Scholar] [CrossRef]

55. Zhang Y, Zhang Y, Xu W, Wu H, Shao Y, Han X, et al. Preparation methods of cellulose nanocrystal and its application in treatment of environmental pollution: a mini-review. Colloid Interface Sci Commun. 2023;53:100707. doi:10.1016/j.colcom.2023.100707. [Google Scholar] [CrossRef]

56. Chen Y, Zhang Y, Mensaha A, Li D, Wang Q, Wei Q. A plant-inspired long-lasting adhesive bilayer nanocomposite hydrogel based on redox-active Ag/Tannic acid-Cellulose nanofibers. Carbohydr Polym. 2021;255:117508. doi:10.1016/j.carbpol.2020.117508. [Google Scholar] [PubMed] [CrossRef]

57. Wang Z, Zhang S, Zhao S, Kang H, Wang Z, Xia C, et al. Facile biomimetic self-coacervation of tannic acid and polycation: tough and wide pH range of underwater adhesives. Chem Eng J. 2021;404:127069. doi:10.1016/j.cej.2020.127069. [Google Scholar] [CrossRef]

58. Liu C, Zhang Y, Wang S, Meng Y, Hosseinaei O. Micromechanical properties of the interphase in cellulose nanofiber-reinforced phenol formaldehyde bondlines. BioRes. 2014;9:5529–41. doi:10.15376/biores.9.3.5529-5541. [Google Scholar] [CrossRef]

59. Wang D-C, Yu H-Y, Qi D, Ramasamy M, Yao J, Tang F, et al. Supramolecular self-assembly of 3D conductive cellulose nanofiber aerogels for flexible supercapacitors and ultrasensitive sensors. ACS Appl Mater Interfaces. 2019;11:24435–46. doi:10.1021/acsami.9b06527. [Google Scholar] [PubMed] [CrossRef]

60. Zheng Y, Pierce AF, Wagner WL, Khalil HA, Chen Z, Servais AB, et al. Functional adhesion of pectin biopolymers to the lung visceral pleura. Polymers. 2021;13(17):2976. doi:10.3390/polym13172976. [Google Scholar] [PubMed] [CrossRef]

61. Samyn P. A platform for functionalization of cellulose, chitin/chitosan, alginate with polydopamine: a review on fundamentals and technical applications. Int J Biol Macromol. 2021;178:71–93. doi:10.1016/j.ijbiomac.2021.02.091. [Google Scholar] [PubMed] [CrossRef]

62. Pang H, Wang Y, Chang Z, Xia C, Han C, Liu H, et al. Soy meal adhesive with high strength and water resistance via carboxymethylated wood fiber-induced crosslinking. Cellulose. 2021;28:3569–84. doi:10.1007/s10570-021-03732-x. [Google Scholar] [CrossRef]

63. Ren C, Li M, Huang W, Zhang Y, Huang J. Superhydrophobic coating with excellent robustness and UV resistance fabricated using hydrothermal treated lignin nanoparticles by one-step spray. J Mater Sci. 2022;57:18356–69. doi:10.1007/s10853-022-07787-4. [Google Scholar] [CrossRef]

64. Moslemi A, Zolfagharlou koohi M, Behzad T, Pizzi A. Addition of cellulose nanofibers extracted from rice straw to urea formaldehyde resin; effect on the adhesive characteristics and medium density fiberboard properties. Int J Adhes Adhes. 2020;99:102582. doi:10.1016/j.ijadhadh.2020.102582. [Google Scholar] [CrossRef]

65. Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, et al. Nanocelluloses: a new family of nature-based materials. Angew Chemie-Int Ed. 2011;50:5438–66. doi:10.1002/anie.201001273. [Google Scholar] [PubMed] [CrossRef]

66. Nagarajan KJ, Ramanujam NR, Sanjay MR, Siengchin S, Surya Rajan B, Sathick Basha K, et al. A comprehensive review on cellulose nanocrystals and cellulose nanofibers: pretreatment, preparation, and characterization. Polym Compos. 2021;42:1588–630. doi:10.1002/pc.25929. [Google Scholar] [CrossRef]

67. Phanthong P, Reubroycharoen P, Hao X, Xu G, Abudula A, Guan G. Nanocellulose: extraction and application. Carbon Resour Convers. 2018;1(1):32–43. doi:10.1016/j.crcon.2018.05.004. [Google Scholar] [CrossRef]

68. Rojas J, Bedoya M, Ciro Y. Current trends in the production of cellulose nanoparticles and nanocomposites for biomedical applications. Cellul-Fundam Asp Curr Trends. 2015. doi:10.5772/61334. [Google Scholar] [CrossRef]

69. Samyn P, Dufresne A. Review: nanoparticles and nanostructured materials in papermaking. J Mater Sci. 2018;53:146–84. doi:10.1007/s10853-017-1525-4. [Google Scholar] [CrossRef]

70. Yalçın ÖÜ. Improved properties of particleboards produced with urea formaldehyde adhesive containing nanofibrillated cellulose and titanium dioxide. BioResources. 2023;18:3267–78. doi:10.15376/biores.18.2.3267-3278. [Google Scholar] [CrossRef]

71. Kojima Y, Kato N, Ota K, Kobori H, Suzuki S, Aoki K, et al. Cellulose nanofiber as complete natural binder for particleboard. For Prod J. 2019;68:203–10. doi:10.13073/FPJ-D-18-00034. [Google Scholar] [CrossRef]

72. García A, Gandini A, Labidi J, Belgacem N, Bras J. Industrial and crop wastes: a new source for nanocellulose biorefinery. Ind Crops Prod. 2016;93:26–38. doi:10.1016/j.indcrop.2016.06.004. [Google Scholar] [CrossRef]

73. Mardawati E, Werner A, Kresnowati P, Setiadi T. The enzymatic hydrolysis of oil palm empty fruit bunches to xylose. J Japan Inst Energy. 2014;93:973–8. doi:10.3775/jie.93.973. [Google Scholar] [CrossRef]

74. Nguyen YTH, Ly TB, Bui BAT, Le PK. Biodegradable polyvinyl alcohol composite film reinforced by crystalline nanocellulose from rice straw. Chem Eng Trans. 2023;106:493–8. doi:10.3303/CET23106083. [Google Scholar] [CrossRef]

75. Laya S, Shamina S, Moossa PP. Production of bioplastic from rice straw cellulose. Pharma Innov J. 2022;11:1742–4. [Google Scholar]

76. Hochmańska P, Janiszewska D. Stability and rheological behavior of nanocellulose-modified UF resin compositions. BioResources. 2019;14:1850–66. doi:10.15376/biores.14.1.1850-1866. [Google Scholar] [CrossRef]

77. Liany SA, Syafira W, Putri A, Khasanah AU. Effect of bacterial cellulose formation on various substrate variations and combinations. Berk Ilm Biol. 2022;13:13–20. doi:10.22146/bib.v13i2.4396. [Google Scholar] [CrossRef]

78. Petersen N, Gatenholm P. Bacterial cellulose-based materials and medical devices: current state and perspectives. Appl Microbiol Biotechnol. 2011;91:1277–86. doi:10.1007/s00253-011-3432-y. [Google Scholar] [PubMed] [CrossRef]

79. Isogai A, Saito T, Fukuzumi H. TEMPO-oxidized cellulose nanofibers. Nanoscale. 2011;2:71–85. doi:10.1039/C0NR00583E. [Google Scholar] [PubMed] [CrossRef]

80. Wacikowski B, Michałowski M. The possibility of using bacterial cellulose in particleboard technology. For Wood Technol. 2020;23:16–23. doi:10.5604/01.3001.0014.3046. [Google Scholar] [CrossRef]

81. Randis R, Darmadi DB, Gapsari F, Sonief A. Isolation and characterization of microcrystalline cellulose from oil palm fronds biomass using consecutive chemical treatments. Case Stud Chem Environ Eng. 2024;9:100616. doi:10.1016/j.cscee.2024.100616. [Google Scholar] [CrossRef]

82. Raja PM, Rangkuti IUP, Ginting MH. Preparation and characterization of cellulose microcrystalline made from palm oil midrib. Earth Environ Sci. 2021;819:012002. doi:10.1088/1755-1315/819/1/012002. [Google Scholar] [CrossRef]

83. Effendi F, Elvia R, Amir H. Preparation and characterization of microcrystalline cellulose (MCC) from empty oil palm fruit bunches. J Educ Chem. 2018;2:52–7. doi:10.33369/atp.v2i1.4672. [Google Scholar] [CrossRef]

84. Trache D, Hussin MH, Tan C, Chuin H, Sabar S, Fazita MRN, et al. Microcrystalline cellulose: isolation, characterization and bio-composites application—a review. Int J Biol Macromol. 2016;93:789–804. doi:10.1016/j.ijbiomac.2016.09.056. [Google Scholar] [PubMed] [CrossRef]

85. Gupta PK, Raghunath SS, Prasanna DV, Venkat P, Shree V, Chandrananthi C, et al. An update on overview of cellulose, its structure and applications. In: Cellulose. UK: IntechOpen; 2019. p. 1–21. doi:10.5772/intechopen.84727. [Google Scholar] [CrossRef]

86. Sundarraj AA, Vasudevan RT. A review on cellulose and its utilization from agroindustrial waste. Drug Invent Today. 2018;10:89–94. [Google Scholar]

87. Motaung TE, Linganiso LZ. Critical review on agrowaste cellulose applications for biopolymers. Int J Plast Technol. 2018;22:185–216. doi:10.1007/s12588-018-9219-6. [Google Scholar] [CrossRef]

88. Kholisoh I, Darojah Z, Firmania E, Natijah H, Hartati I. The effect of cooking time and acetic acid ratio used by microwaves on the organosolv pulping process of cane bases (Saccharum officinarum L.). Pros SNST. 2016;1:28–32. [Google Scholar]

89. Cataldi A, Dorigato A, Deflorian F, Berglund L, Pegoretti A. Polymer composite with micro- and nanocellulose for artwork protection and restoration. In: 16th European Conference Composition Materials, ECCM 2014; 2014; Trento, Italy. [Google Scholar]

90. Luotonen OIV, Greca LG, Nyström G, Guo J, Richardson JJ, Rojas OJ, et al. Benchmarking supramolecular adhesive behavior of nanocelluloses, cellulose derivatives and proteins. Carbohydr Polym. 2022;292:119681. doi:10.1016/j.carbpol.2022.119681. [Google Scholar] [PubMed] [CrossRef]

91. Xu J, Li X, Liu R, Shang Z, Long L, Qiu H, et al. Dialdehyde modified cellulose nanofibers enhanced the physical properties of decorative paper impregnated by aldehyde-free adhesive. Carbohydr Polym. 2020;250:116941. doi:10.1016/j.carbpol.2020.116941. [Google Scholar] [PubMed] [CrossRef]

92. Ni K, Du G, Liu C, Wu Y, Yang H, Yin C, et al. Cross-linked entanglement of aldehyde and amine-functionalized nanocellulose reinforced with biomineralization to produce an all-bio-based adhesive. Chem Eng J. 2023;465:142888. doi:10.1016/j.cej.2023.142888. [Google Scholar] [CrossRef]

93. Jordan JH, Cheng HN, Easson MW, Yao W, Condon BD, Gibb BC. Effect of nanocellulose on the properties of cottonseed protein isolate as a paper strength agent. Materials. 2021;14(15):4128. doi:10.3390/ma14154128. [Google Scholar] [PubMed] [CrossRef]

94. Wibowo ES, Park B-D. Direct measurement of surface adhesion between thin films of nanocellulose and urea-formaldehyde resin adhesives. Cellulose. 2021;28:8459–81. doi:10.1007/s10570-021-04088-y. [Google Scholar] [CrossRef]

95. Grishkewich N, Mohammed N, Tang J, Tam KC. Recent advances in the application of cellulose nanocrystals. Curr Opin Colloid Interface Sci. 2017;29:32–45. doi:10.1016/j.cocis.2017.01.005. [Google Scholar] [CrossRef]

96. Mishra RK, Sabu A, Tiwari SK. Materials chemistry and the futurist eco-friendly applications of nanocellulose: status and prospect. J Saudi Chem Soc. 2018;22:949–78. doi:10.1016/j.jscs.2018.02.005. [Google Scholar] [CrossRef]

97. Hendrawati TY, Umar E, Ramadhan AI, Sari AM, Salsabila M, Suryani R, et al. Synthesis and characterization of powdered nanocellulose from empty palm bunches using ultrasonification. Technology. 2023;15:159–66. [Google Scholar]

98. Silva FAGS, Dourado F, Gama M, Poças F. Nanocellulose bio-based composites for food packaging. Nanomaterials. 2020;10(10):2041. doi:10.3390/nano10102041. [Google Scholar] [PubMed] [CrossRef]

99. Thipchai P, Punyodom W, Jantanasakulwong K, Thanakkasaranee S. Preparation and characterization of cellulose nanocrystals from bamboos and their application in cassava. Polymers. 2023;15(12):2622. doi:10.3390/polym15122622. [Google Scholar] [PubMed] [CrossRef]

100. Schieb P, Lescieux-Katir H, The’not M, Cle’ment-Larosie`re B. Biorefinery 2030, future prospects for the bioeconomy. London: Springer Science; 2015. doi:10.1007/978-3-662-47374-0. [Google Scholar] [CrossRef]

101. Lee KY, Aitomäki Y, Berglund LA, Oksman K, Bismarck A. On the use of nanocellulose as reinforcement in polymer matrix composites. Compos Sci Technol. 2014;105:15–27. doi:10.1016/j.compscitech.2014.08.032. [Google Scholar] [CrossRef]

102. Li F, Xie Z, Wen J, Tang T, Jiang L, Hu G, et al. Synthesis of cellulose-Poly(acrylic acid) using sugarcane bagasse extracted cellulose fibres for the removal of heavy metal ions. Int J Mol Sci. 2023;24(10):8922. doi:10.3390/ijms24108922. [Google Scholar] [PubMed] [CrossRef]

103. Camargos CHM, Poggi G, Chelazzi D, Baglioni P, Rezende CA. Strategies to mitigate the synergistic effects of moist-heat aging on TEMPO-oxidized nanocellulose. Polym Degrad Stab. 2022;200:109943. doi:10.1016/j.polymdegradstab.2022.109943. [Google Scholar] [CrossRef]

104. Pawcenis D, Leśniak M, Szumera M, Sitarz M, Profic-Paczkowska J. Effect of hydrolysis time, pH and surfactant type on stability of hydrochloric acid hydrolyzed nanocellulose. Int J Biol Macromol. 2022;222:1996–2005. doi:10.1016/j.ijbiomac.2022.09.289. [Google Scholar] [CrossRef]

105. Kamboj G, Gaff M, Smardzewski J, Haviarová E, Hui D, Rousek R, et al. Comparative study on the properties of cellulose nanofiber (CNF) and cellulose nanocrystals (CNC) reinforced 1C-PUR adhesive bonded wooden joints. Constr Build Mater. 2022;344:128262. doi:10.1016/j.conbuildmat.2022.128262. [Google Scholar] [CrossRef]

106. Lin N, Dufresne A. Nanocellulose in biomedicine: current status and future prospect. Eur Polym J. 2014;59:302–25. doi:10.1016/j.eurpolymj.2014.07.025. [Google Scholar] [CrossRef]

107. Kolakovic R, Peltonen L, Laaksonen T, Putkisto K, Laukkanen A, Hirvonen J. Spray-dried cellulose nanofibers as novel tablet excipient. AAPS PharmSciTech. 2011;12:1366–73. [Google Scholar] [PubMed]

108. Kaur P, Sharma N, Munagala M, Rajkhowa R. Nanocellulose: resources, physio-chemical properties, current uses and future applications. Front Nanotechnol. 2021;3:747329. doi:10.3389/fnano.2021.747329. [Google Scholar] [CrossRef]

109. Squinca P, Bilatto S, Badino AC, Farinas CS. Nanocellulose production in future biorefineries: an integrated approach using tailor-made enzymes. ACS Sustain Chem Eng. 2020;8:2277–86. doi:10.1021/acssuschemeng.9b06790. [Google Scholar] [CrossRef]

110. Shen R, Xue S, Xu Y, Liu Q, Feng Z, Ren H, et al. Research progress and development demand of nanocellulose reinforced polymer composites. Polymers. 2020;12(9):2113. doi:10.3390/polym12092113. [Google Scholar] [PubMed] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools