Open Access

Open Access

ARTICLE

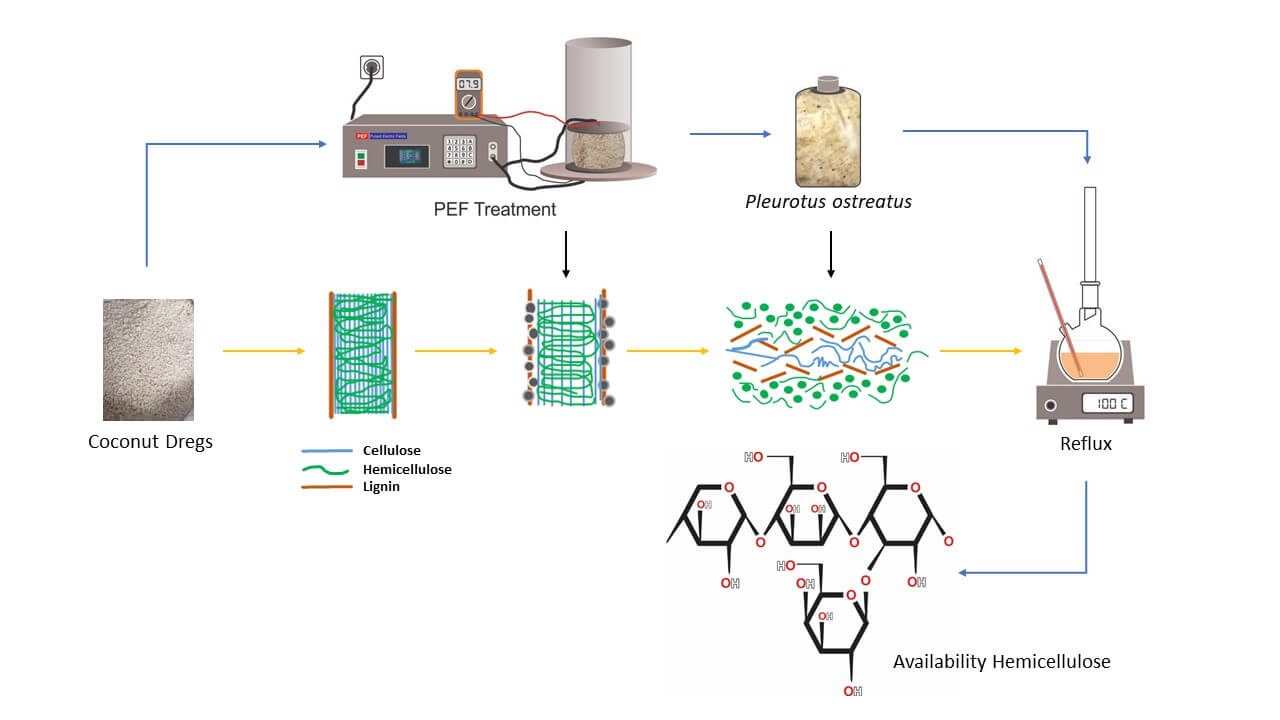

Stepwise Pretreatment of Pulsed Electric Fields and Solid Substrate Fermentation Using Pleurotus ostreatus on Coconut Dregs

1 Agro-Industrial Technology, Faculty of Agricultural Technology, University of Brawijaya, Malang, 65145, Indonesia

2 Agro-Industrial Technology, Faculty of Agricultural Technology, University of Andalas, Padang, 25163, Indonesia

3 Agricultural and Biosystem Engineering, Faculty of Agricultural Technology, University of Brawijaya, Malang, 65145, Indonesia

* Corresponding Authors: Wenny Surya Murtius. Email: ; Bambang Dwi Argo. Email:

(This article belongs to the Special Issue: Special issue from 1st International Conference of Natural Fiber and Biocomposite (1st ICONFIB) 2024 )

Journal of Renewable Materials 2025, 13(5), 997-1020. https://doi.org/10.32604/jrm.2025.02024-0004

Received 01 October 2024; Accepted 18 December 2024; Issue published 20 May 2025

Abstract

A stepwise pretreatment process for coconut dregs (CD) has been investigated to enhance availability of hemicellulose. Recently, lignocellulose-rich agricultural waste such as CD has garnered substantial attention as a sustainable raw material for producing value-added bio-products. To optimize the process variables within the stepwise pretreatment using Pulsed Electric Field (PEF) and Solid-State Fermentation (SSF), Response Surface Methodology (RSM) based on Central Composite Design (CCD) was employed. PEF, a non-thermal physical treatment, offers advantages such as low energy consumption and reduced processing times, while SSF utilizes Pleurotus ostreatus to promote biodegradation. A statistical model was constructed using a three-factor CCD that included five center points and axial points, with variables including PEF treatment duration (30, 60, and 90 s), substrate particle size (20, 40, and 60 mesh), and incubation time (10, 20, and 30 days). Changes in lignocellulose composition were analyzed to evaluate their effects on the process. The optimal parameters identified were a particle size of 40 mesh, a PEF treatment duration of 61 s, and an incubation period of 12.5 days. Under these conditions, the process yielded an impressive increase in hemicellulose availability by 106.53%, a minimization of cellulose loss to 6.28%, and a successful delignification resulting in a 21.78% removal of lignin.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools