Open Access

Open Access

ARTICLE

Bio-Composite Films from Carrageenan/Starch Reinforced with Nanocellulose for Active Edible Food Packaging: Development and Optimization

1 St. Petersburg State University, 7/9 Universitetskaya nab, St. Petersburg, 199034, Russia

2 Instituto de Química, Universidade Federal de Uberlândia, Campus Santa Mônica, Av. João Naves de Ávila, 2121, Uberlândia, 38400-902, Minas Gerais, Brazil

3 Mendeleev University of Chemical Technology of Russia, Miusskaya sq., 9, Moscow, 125047, Russia

4 International and Inter University Centre for Nanoscience and Nanotechnology, Mahatma Gandhi University, Kottayam, 686560, Kerala, India

5 Centre for Nanostructures and Advanced Materials, Chemicals Cluster, Council for Scientific and Industrial Research, Pretoria, 0001, South Africa

* Corresponding Authors: Daniel Pasquini. Email: ; Anastasia Penkova. Email:

Journal of Renewable Materials 2025, 13(6), 1139-1168. https://doi.org/10.32604/jrm.2025.02024-0023

Received 24 October 2024; Accepted 07 February 2025; Issue published 23 June 2025

Abstract

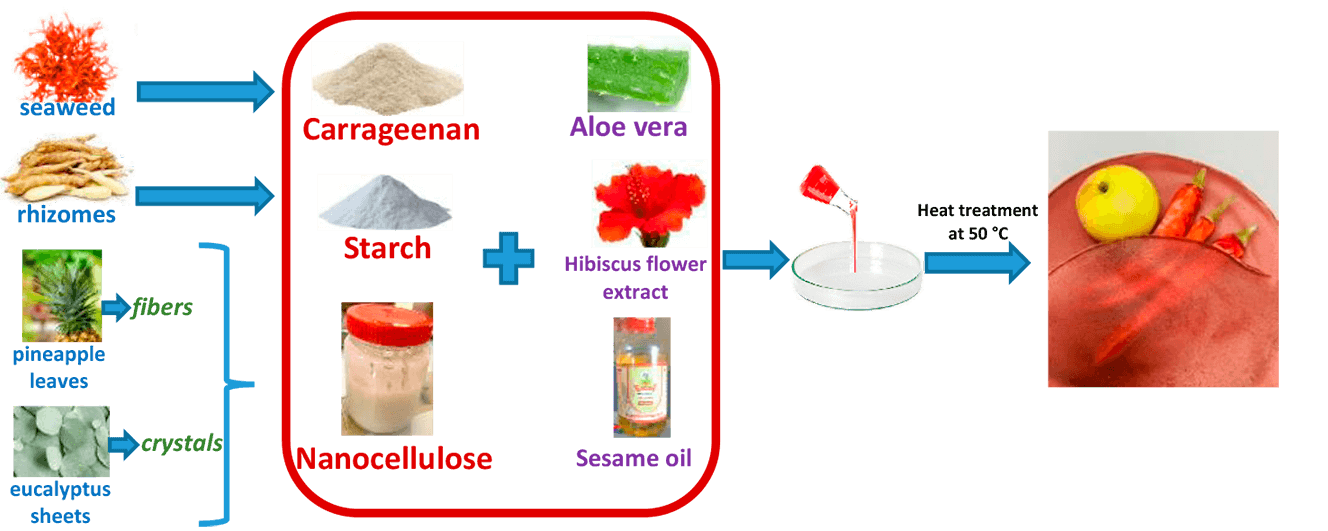

Petrochemical plastics are widely used for food protection and preservation; however, they exhibit poor biodegradability, resisting natural degradation through physical, chemical, or enzymatic processes. As a sustainable alternative to conventional plastic packaging, edible films offer effective barriers against moisture, gases, and microbial contamination while being biodegradable, biocompatible, and environmentally friendly. In this study, novel active food packaging materials (in film form) were developed by incorporating starch, carrageenan, nanocellulose (NC), Aloe vera, and hibiscus flower extract. The effects of varying the matrix composition (26.5–73.5 wt.% starch/carrageenan), NC concentration (2.77–17.07 wt.%), and particle type (fibers or crystals) on the film structure and characteristics were analyzed using various methods. Scanning electron microscopy demonstrated good homogeneity and effective dispersion of NC within the blend matrix. An increased carrageenan content in the film improved wettability, moisture absorption, solubility, and water vapor permeability. The mechanical properties of the films were enhanced by NC incorporation and higher carrageenan content. The developed films also exhibited effective UV radiation barriers and biodegradability. Films with low carrageenan content (less than 33.3%) and high NC content (7%, 10% crystals or 10%, 15% fibers) exhibited optimal properties, including enhanced water resistance, hydrophobicity, and mechanical strength, along with reduced water vapor permeability. However, the high water solubility and moisture absorption (above 55% and 14%, respectively) indicated their unsuitability as packaging materials for food products with wet surfaces and high humidity. The results suggest that these films are well suited for use as edible food packaging for fruits and vegetables.Graphic Abstract

Keywords

Supplementary Material

Supplementary Material FileCite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools