Open Access

Open Access

REVIEW

Transforming the Leather Industry: A Comprehensive Review on Leather Alternatives

Leather Engineering Department, Ethiopian Institution of Textile and Fashion Technology, Bahir Dar University, Bahir Dar, P.O. Box 1037, Ethiopia

* Corresponding Author: Alehegn Atalay Birlie. Email:

Journal of Renewable Materials 2025, 13(9), 1783-1802. https://doi.org/10.32604/jrm.2025.02025-0039

Received 17 February 2025; Accepted 07 May 2025; Issue published 22 September 2025

Abstract

This study explores vegan leather, an eco-friendly substitute for conventional animal-derived leather. Using materials like polyurethane, pineapple leaves, cork, and recycled plastics, vegan leather aims to transform the fashion industry and consumer products while addressing environmental concerns. Despite its advantages, challenges related to availability and durability persist. The booming market for vegan leather is expected to reach billions of dollars, reflecting a broader societal shift towards sustainable and cruelty-free alternatives. The review traces the historical development of vegan leather from its origins in Germany to modern innovations like Mylo and Piñatex. By comparing these materials to conventional leather, the study assesses their potential to replace animal-derived leather. Looking at different types of sustainable leather, like synthetic, plant-based, mycelium, and collagen-based leather, shows how they connect with being environmentally friendly and made from natural materials. The ultimate aim is to contribute to ongoing discussions about transitioning to a circular economy, where durable bio-based and biodegradable materials offer a promising future for sustainable leather alternatives.Keywords

The meat industry supplies the raw animal hides needed to produce traditional leather. This suggests that leather is a byproduct that may last a lifetime, depending on its intended use. However, the meat industry produced 14.5% of global greenhouse gas emissions in 2013. Furthermore, it is impossible to ignore the impact of leather because it is a byproduct given these emissions and the fact that the leather market is worth approximately $400 billion year [1].

There has been work done on developing leather substitutes due to the significant environmental impact of animal leather. Plastic-based leather, which is typically made of polyvinyl chloride (PVC) or polyurethane (PU), is one category of substitutes that have surfaced [2].

In the meantime, new leather alternatives are being invented that are biodegradable and not based on fossil fuels. The history of animal-free leather dates back to the late 19th century in Germany. During this time, the first known alternative leather, called Presstoff, was developed from layered and treated paper pulp due to the rationing of animal leather caused by impending wars [3]. This marked the early stages of the development of synthetic and plant-based leather alternatives. Over the years, various materials have been developed, such as Mylo, made from mycelium, and Piñatex, made from pineapple leaves, offering sustainable alternatives to conventional leather due to their biodegradable nature [2]. The history of animal-free leather showcases a continuous evolution of materials and technologies, driven by the growing demand for sustainable and ethical fashion choices. This research focuses on the identification of this new group of leather alternatives and their characteristics compared to traditional leather. The main goal of this review is to identify how likely these innovative materials are to replace animal leather.

Customers and innovators are becoming more aware of and interested in sustainable leather alternatives like synthetic leather, plant-based leather, mycelium leather, Laboratory cultured Collagen leather as a result of the demand for products that support society’s shift towards a circular economy [4]. The intricate relationship among sustainability, biodegradability, and biobased materials is crucial to this change. “Bio-based” refers to a substance that is produced by living things, including fungi, plants, and animals [5]. One example of a bio-based product is animal leather. Something’s ability to break down by microorganisms is referred to as its biodegradability. From a cyclical perspective, products should break down into substances that don’t harm the natural. Leather is bio-based, but not always biodegradable due to the cross-linking compounds added during the tanning processes [6]. The goal for sustainable leather alternative producers is to create a bio-based product from replenishable resources that is bio-degradable and durable at the same time.

Toxic chemicals are used in the manufacture of PVC, and hazardous byproducts including dioxins are produced. Furthermore, the primary source of energy for these materials is fossil fuels, which raises the issue of greenhouse gas emissions related to the extraction and refinement of fossil fuels. Numerous other issues exist as well, like plastic pollution. It is projected that there are about 250,000 t of plastic in maritime habitats [7]. Second, the chlorine found in PVC can create a variety of chlorinated compounds that are hazardous to the landfills and marine ecosystems where the PVC has accumulated. A third issue is that the manufacturing of PU leathers requires hazardous substances like N and N-dimethylformamide [8].

2.1.1 Properties of Synthetic Leather

Synthetic leather is a versatile material with several advantages, including its durability, resilience, waterproofness, breathable properties, heat resistance, and color variety. It is suitable for various applications such as outerwear, athletic gear, and upholstery. Some types are designed for comfort, while others offer heat resistance, making them suitable for upholstery and automotive interiors. Most of these properties make synthetic leather a popular choice for a variety of products, offering a balance of performance, durability, and ethical considerations [9].

2.1.2 Production Process of Synthetic Leather

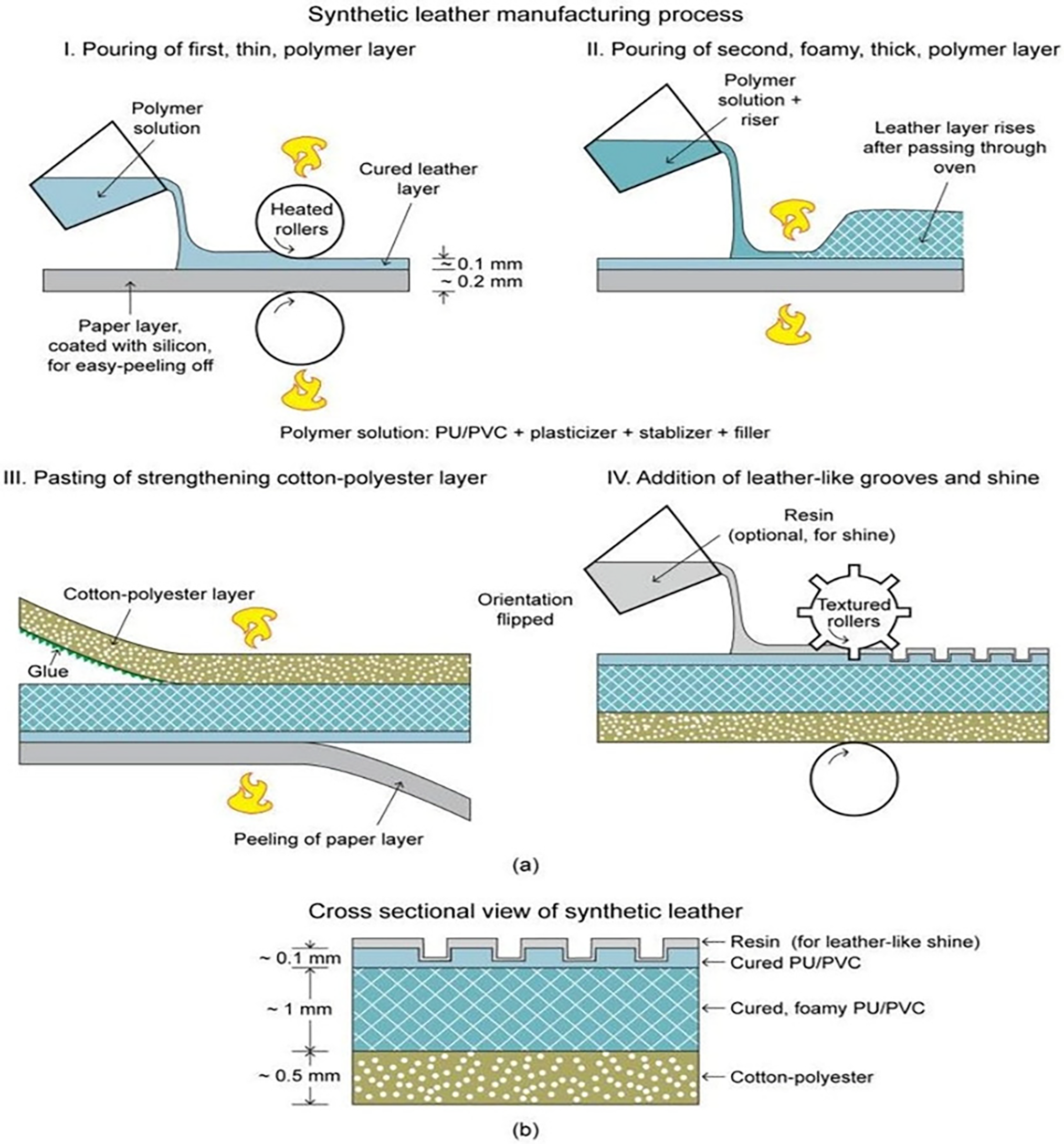

Synthetic leather production involves several steps, including obtaining the base material, formulating the plastic, coating the fabric, adding a color coat, and adding a textured finish [10]. The base material is typically cotton or polyester, which are porous and require special manufacturing. The plastic substances used are polyurethane (PU) and polyvinyl chloride (PVC), which are made by combining salt and petroleum. The base fabric is then coated with the plastic substance using methods like calendaring, which involves a mixture of PVC and pigments. A color coat is then added using dyes or pigments to create different colors. A textured finish is often added using stamping or embossing. The production process of synthetic leather has evolved to become more efficient and cost-effective, with the specific process varying depending on the material used as shown in Fig. 1 below [11].

Figure 1: Synthetic leather manufacturing process (a,b) [12]. Adopted from Journal of Applied Science, Willey © 2009

2.1.3 Benefits and Uses of Synthetic Leather

Synthetic leather, also known as faux or artificial leather, is a man-made material that mimics the look and feel of real leather. It offers several benefits, including affordability, animal welfare, consistency, durability, versatility, and lower environmental impact [13]. Synthetic leather is more affordable than genuine leather, making it an attractive option for those on a budget. It is also animal-friendly, as it doesn’t involve the use of animal products. It can be manufactured to have a consistent texture and appearance, making it easier to clean and maintain.

Synthetic leather is often used in the fashion industry for clothing items like jackets, pants, skirts, and shoes. It is also used in furniture upholstery, automotive interiors, accessories, sports equipment, and electronic devices. It is preferred for its durability and resistance to wear and tear, making it a popular choice for both manufacturers and consumers but it is incomparable with conventional leather [14].

In addition to its use in clothing, synthetic leather is also used in furniture upholstery, automotive interiors, accessories, sports equipment, and electronic devices. Overall, synthetic leather offers a wide range of benefits and applications across various industries, making it a popular choice for both manufacturers and consumers [15].

2.1.4 Comparison: Synthetic Leather vs. Conventional Leather

Both bovine leather and synthetic leather production have significant environmental impacts, including greenhouse gas emissions, deforestation, high water consumption, and pollution from tanning chemicals. Synthetic leather production also relies on fossil fuels and chemicals, with manufacturing processes affecting water usage, energy consumption, and chemical use. The leather industry has been working towards implementing a zero-discharge policy to address the significant environmental impacts of leather production, particularly the high-water consumption and wastewater generation. The Zero Discharge of Hazardous Chemicals (ZDHC) Programmed was formed in 2011 with the recognition that a holistic system change was needed in the leather industry. The ZDHC has developed a Manufacturing Restricted Substances List (MRSL) to eliminate the use of hazardous chemicals in leather production [16].

The Zero Liquid Discharge (ZLD) system is being implemented in the tannery industry to ensure zero water emission and treat wastewater by recycling, recovery, and reuse using advanced cleanup technology [17]. The ZLD system consists of pre-treatment, tertiary treatment, softening, reverse osmosis (RO) desalination, and thermal evaporation to separate salts. By adopting this system, water consumption is reduced, and the tannery industry can mitigate environmental disasters in areas where it is a strong economic actor [17]. However, the leather industry is facing significant water usage issues, with estimates of 17,128 L of water used for one leather tote bag and 12,370 L for a pair of leather boots. Cowhides can use up to 14 times more water than alternatives like polyurethane vinyl (PU leather). However, the industry has reduced its water footprint by over 35% in the past 25 years through new processes and technologies. Some tanners can recycle 40% of their wastewater back into production. ECCO Leather has developed a “water-free” tanning process called DriTan, saving 20 L of water per hide and eliminating 600 t of sludge annually [18].

Synthetic leather production is significantly lower in water consumption compared to traditional bovine leather production. Cowhides use up to 14 times more water than alternatives like polyurethane vinyl (PU leather) [19]. PET, a common material used in synthetic leathers, has a blue water footprint of 10 L per kg, but when including the grey water footprint to account for pollution mitigation, the total water footprint rises to 235 L per kg. In contrast, the water required to make synthetic leather alternatives is two to three times less than the water needed for genuine automotive leather. The difference is estimated to be 2–3 times less water usage for synthetic leather alternatives [20].

Genuine leather is a natural leather made from animal hides, obtained through chemical treatments and finishing. It has a natural ‘grain’ surface and distinctive leather smell, while synthetic leather is fake leather made from a fabric base coated with plastic [21]. Genuine leather is softer, flexible, and has a distinctive leather smell. Synthetic leather, on the other hand, has a rubbery or shiny surface feel, is colder to the touch, and often has a ‘plastic’ smell. It burns more easily and has a more artificial smell when burned. In summary, genuine leather is known for its durability and unique characteristics, while synthetic leather offers affordability, versatility, and ease of maintenance [22].

Water Consumption Summery for: Synthetic vs. Traditional Leather

Traditional leather production is highly water-intensive, requiring 14,000–17,000 L of water per square meter, with livestock farming accounting for approximately 93% of this footprint. In contrast, synthetic leather (PU/PVC) uses significantly less water (500–1000 L per square meter) during manufacturing, primarily for polymer processing [23]. However, synthetic alternatives come with a trade-off, as they depend on fossil fuels and generate higher carbon emissions (up to 5.7 kg CO2e/m2) compared to bovine leather (3.5 kg CO2e/m2) [24]. While synthetic leather reduces water consumption by 90%–95%, emerging alternatives like mycelium and plant-based materials show potential but need further development in scalability, cost efficiency, and consumer awareness. To promote sustainable adoption, comprehensive life cycle assessments (LCAs) and policy support, such as subsidies for biomaterials, are essential.

2.1.5 Environmental Impact of Synthetic Leather

Synthetic leathers are made from various materials, including a fabric base coated with a layer of plastic, typically polyurethane (PU) or polyvinyl chloride (PVC). The fabric base provides structure and strength, while the plastic coating gives it the appearance and texture of real leather. However, not all synthetic leathers are made using the same composition or manufacturing process. Recycling synthetic leather presents challenges due to its complexity, as the recycling process must consider all components involved, including the fabric base, polymer coating, and any other materials like metal studs or embellishments.

To recycle synthetic leather effectively, the different components need to be separated, such as removing the polymer coating from the fabric base and separating any additional materials like metal studs. Material compatibility may also play a role in recycling requirements, with the fabric base being recyclable through textile recycling processes, while the polymer coating may require specialized recycling methods for plastics. Advancements in recycling technologies may offer solutions for handling complex materials more efficiently, such as chemical recycling or mechanical separation techniques [23].

Design considerations for synthetic leather products can improve their environmental sustainability by choosing materials that are easier to recycle or reducing the use of non-recyclable components [24]. While synthetic leather presents challenges for recycling due to its composite nature, efforts to develop recycling infrastructure and technologies tailored to these materials are ongoing.

Recycled PET polyester, derived from plastic bottles and manufacturing waste, is a more environmentally friendly option. PVC and phthalates, a common material, are energy-intensive and rely on fossil fuels, while phthalates are carcinogenic byproducts. Polyurethane (PU) leather, made from petroleum-based polyurethane, is more environmentally friendly but still contributes to plastic waste. Microfiber leather, made from a fabric base coated with PVA, is a biodegradable material that can be broken down by microorganisms, making it a more environmentally friendly option. However, it is crucial to consider the overall production process, waste generation, and end-of-life considerations when evaluating the environmental impact of synthetic leather. Overall, the environmental impact of synthetic leather depends on the materials used in its production [25].

2.1.6 Market Potential for Synthetic Leather

The market potential for synthetic leather is significant due to its versatility, cost-effectiveness, and low maintenance. Synthetic leather, also known as faux leather, is made from plastics and polymers, making it a more affordable and easier to care for alternative to genuine leather [26].

It is commonly used in various applications such as clothing, footwear, upholstery, and accessories. Synthetic leather is abrasion-resistant, water-resistant, and available in a wide variety of textures, colors, and finishes, making it a popular choice in today’s marketplace. While it may be less durable than genuine leather, its low cost and ease of maintenance make it a useful material for a wide range of products. As the demand for sustainable continues to rise, synthetic leather is expected to play a significant role in fashion, furniture, and automotive industries.

Therefore, the market potential for synthetic leather remains strong, driven by its affordability, versatility, and increasing consumer demand for ethical and sustainable products [27].

Draw Backs of Synthetic Leather

Synthetic leather, also known as faux or vegan leather, is a popular alternative to traditional leather due to its affordability and versatility. However, it has significant environmental and health drawbacks. Made from polyurethane (PU) or polyvinyl chloride (PVC), synthetic leather relies on fossil fuels, contributing to plastic pollution and greenhouse gas emissions [28]). It is non-biodegradable, sheds microplastics that harm marine life [29], and releases toxic chemicals like phthalates and dioxins, posing health risks to both consumers and factory workers. Additionally, synthetic leather is less durable than genuine leather, prone to cracking and peeling, lacks breathability [28], and is difficult to repair. Its composite structure makes recycling nearly impossible, leading to landfill accumulation [27] and poor integration into a circular economy [25]. While synthetic leather avoids animal use, its environmental and durability issues highlight the need for more sustainable alternatives, such as bio-based or mycelium leather, supported by advancements in material science and recycling technologies.

A substitute material for conventional and synthetic leather is mycelium, which is the fungal root structure. The network of tube-like roots, or hyphae, that make up a mycelium. These are the biggest organisms on Earth, with hyphae measuring between 1 and 30 µm in diameter. They can fuse and branch to form networks that cover kilometers. These networks’ characteristics are mostly determined by their surroundings. Beta-glucans predominate on the hyphae’s outside, while chitin crosslinked with polysaccharides makes up the hyphae’s core [4]. Mycelium structures are strengthened and given rigidity by the chitin microfibrils. Since the manufacture of mycelium-based leathers is a highly inventive and competitive industry, the specifics of the procedure vary depending on the research group or company. On the other hand, a broad procedure outline is available. The common mixture for fungal spores includes sawdust and other organic components. Using sawdust and organic material that comes from another business as a waste stream can help make the production process more sustainable [30].

Sawdust is a waste stream from the wood industry that is recovered by a business named Mycotech. To eliminate any microbial competition for the fungus, the recovered sawdust is first steam-treated [31]. After that, sawdust and other organic materials are combined with the fungus mixture, and the mycelium-growing process begins in a high-CO2 atmosphere. Solid state fermentation is the term for this process.

Since temperature and humidity have the greatest effects on mycelium growth, they are carefully regulated throughout this process. The hyphae rapidly expand during this step in an attempt to get oxygen, which stops the fungus from developing fruitbodies.

The mycelium has developed into a structure resembling foam after about a week, and can then be processed into mycelium leather. It was found that the resulting mycelium structure became stiffer when the provided substrate was tougher to consume [32].

Thirdly, a moisturizer is applied, and the material is compressed to less than half its original thickness in order to maintain its flexibility. Lastly, the material might be embossed or colored to suit the final product’s tastes. Instead of growing mycelium on a solid substrate as in the solid-state fermentation process, conventional papermaking techniques can be applied to the processing of mycelium produced by liquid fermentation [33].

2.2.1 Process of Making Mycelium Leather

Mycelium leather is a leather-like material made by sterilizing a mixture of agricultural waste and mycelium spores. The mycelium grows and spreads, creating a mat-like structure. Once harvested, it is shaped and molded into the desired form using techniques similar to traditional leather production. The leather is then dried and finished in a drying chamber, subjected to heat and pressure to remove moisture, strengthen the material, and give it a leather-like texture. This process involves several steps to create a durable and durable leather product [31].

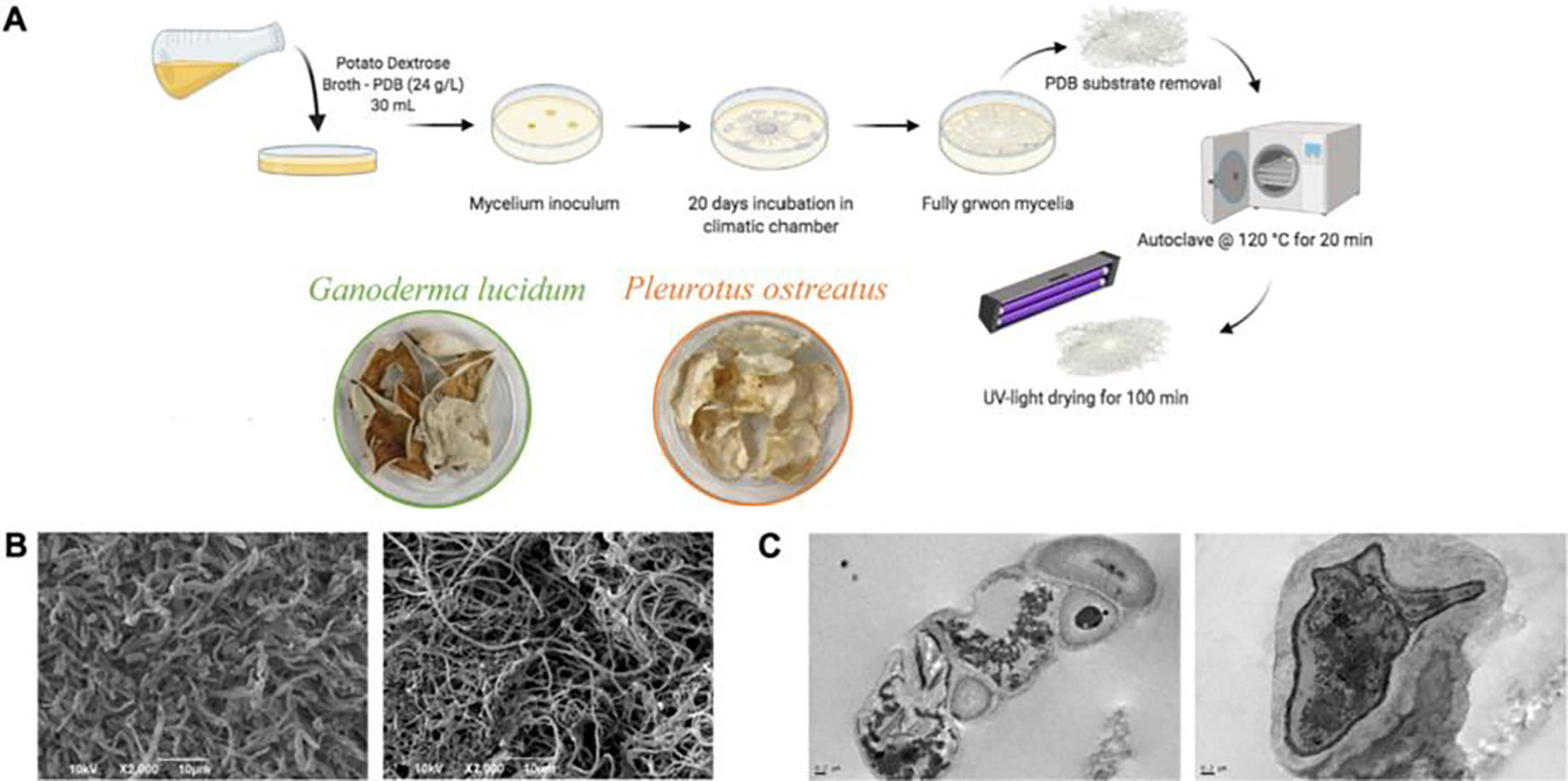

Some companies, like Microworks, have developed techniques to engineer mycelium during growth to create proprietary, interlocking cellular structures, allowing for the customization of the biomaterial for traits such as softness, durability, and strength. This is achieved by adding mycelium to an agricultural byproduct like sawdust, which the mycelium then breaks down and absorbs as energy. Mycelium leather has been used in various applications, including clothing, bags, furniture, and even building bricks. The material is lightweight, flexible, non-toxic, waterproof, and fire-resistant, making it an attractive option for environmentally conscious consumers and industries and preparation of it is shown in Fig. 2 below [34].

Figure 2: Preparation of Mycelium based leather (A–C) [33]. Adopted from this paper © 2024 Sag Journal

Mechanical Property of Mycelium Leather

Pure mycelium leather, derived from the root-like structure of fungi, is an emerging biomaterial with unique mechanical properties that make it a promising alternative to traditional leather. However, research on its mechanical properties is still in the early stages, and data can vary depending on the species of fungi, growth conditions, and post-processing methods. Below is a summary of the known mechanical properties of pure mycelium leather, supported by available research and data.

Mechanical Properties of Pure Mycelium Leather

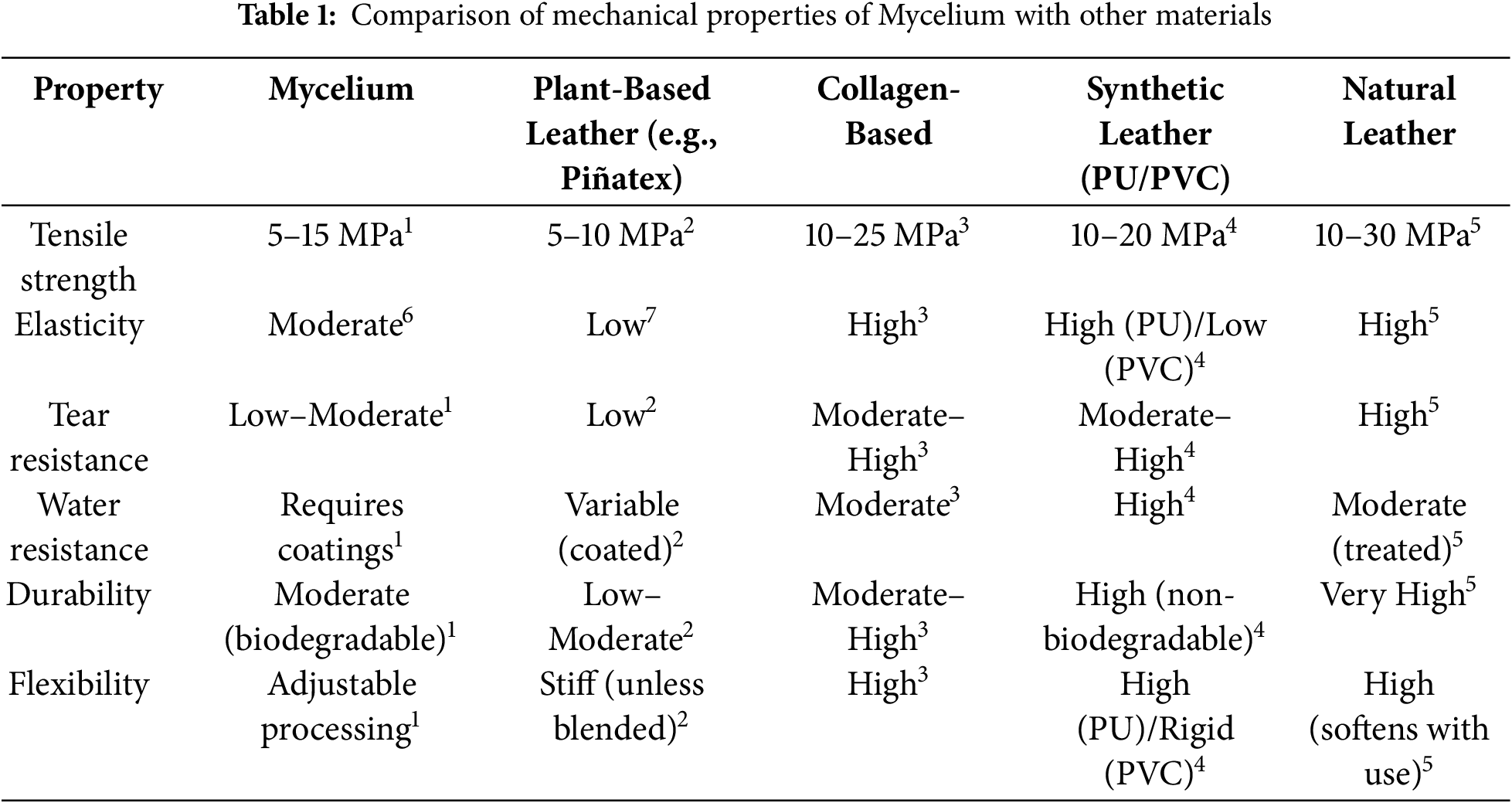

Mycelium leather demonstrates promising but variable mechanical properties compared to traditional and synthetic leathers. Its tensile strength (5–15 MPa) falls within the lower range of animal leather (10–30 MPa) and overlaps with synthetic leather (5–20 MPa) [35]. It offers good flexibility, with elongation at break values of 10%–50%, making it suitable for apparel and accessories [36]. However, its stiffness (Young’s modulus: 50–500 MPa) is generally lower than animal leather (100–1000 MPa) but comparable to some synthetic alternatives [37]. Tear resistance (10–20 N/mm) is moderate but typically inferior to animal leather [36], and its overall durability is lower, though post-processing treatments like compression or natural binders can enhance performance [38]. Additionally, mycelium leather’s density (0.5–1.2 g/cm3) and thickness (0.5–2 mm) can be adjusted during cultivation [36], offering customization potential for different applications. While not yet as robust as conventional leathers, ongoing research into processing techniques may improve its mechanical properties (Table 1).

Pure mycelium leather exhibits moderate mechanical properties, making it suitable for applications like fashion accessories, apparel, and upholstery. While it may not yet match the durability and strength of traditional animal leather, ongoing research and advancements in cultivation and post-processing techniques are expected to improve its performance. As technology matures, mycelium leather has the potential to become a viable, sustainable alternative to conventional leather.

2.2.2 Benefits of Using Mycelium Leather

Mycelium leather is a sustainable and eco-friendly alternative to traditional animal-based and synthetic leather. It requires few direct energy inputs and can utilize agricultural/industrial waste as feedstock, making it a cost-effective and environmentally friendly option. Mycelium leather has a lower environmental impact in terms of greenhouse gas emissions, water usage, and chemical pollution compared to animal-based and synthetic leathers. It is also biodegradable, unlike petroleum-based synthetic leathers which have long degradation spans. The fungal mycelium used to produce the leather is a renewable, natural material that can be broken down at the end of its lifecycle. One study found that treating mycelium leather with a polylactic acid coating improved its tear and flex strength, making it more durable and biodegradable than animal-based leather. Overall, mycelium leather offers a promising alternative to traditional leather and synthetic options with a lower environmental impact [34].

Mycelium leather, a biodegradable material, is often impregnated with synthetic polymers like resin to protect and reinforce it, potentially hindering its biodegradability in a natural environment. A study found that treating mycelium leather with a polylactic acid coating improved its tear and flex strength, but it’s unclear if this impacts biodegradability. The selection of additional materials used with mycelium leather, such as fabric backings or reinforcing meshes, can influence the overall sustainability and biodegradability of the final product. Prioritizing eco-friendly practices and minimizing non-biodegradable elements is crucial. In summary, while pure mycelium leather is highly biodegradable and eco-friendly, impregnating it with synthetic resins or coatings may reduce its beneficial properties. The specific materials used in combination with mycelium are key factors in determining the environmental impact and biodegradability of the final leather alternative product [34].

Genuine leather is a natural, biodegradable material derived from animal hides, which decomposes naturally in landfills within 25 to 50 years, compared to synthetic leathers made from materials like polyurethane or polyvinyl chloride, which can take hundreds of years to break down, contributing to plastic pollution. It is also highly regulated worldwide, promoting a circular economy and requiring fewer chemical treatments compared to synthetic vegan leathers. Genuine leather is also extremely durable, with accessories lasting for years, reducing overall consumption and waste compared to less durable synthetic alternatives. While leather production has some environmental impacts, the durability and biodegradability of genuine leather make it a more sustainable choice. Overall, genuine leather is a more eco-friendly and biodegradable option compared to synthetic leather alternatives made from petroleum-based plastics [31].

2.2.3 Comparison: Mycelium Leather and Genuine Leather

The comparison between mycelium-based materials and traditional leather, particularly in terms of strength characteristics and the influence of coatings like polylactic acid (PLA), is a complex and multifaceted issue. Factors such as coating thickness and penetration depth, as well as the testing conditions and dimensions of the materials being compared, play a crucial role in evaluating the effectiveness of these materials. Thicker coatings may provide more reinforcement but may also affect the material’s flexibility and other properties [35].

Comparing the performance of pure, uncoated mycelium-based materials against uncoated leather under similar conditions can provide valuable insights into their inherent strengths and weaknesses. This comparison can help assess the effectiveness of coatings in improving performance and identify areas for further improvement [36]. In addition to the aforementioned factors, industry expertise and consultancy insights highlight the complexity of enhancing the performance of mycelium-based materials. Understanding the limitations and potential of these materials is essential for developing effective solutions and advancing the industry [37].

In conclusion, while claims about the enhanced strength of mycelium-based materials with coatings like PLA may be made, a comprehensive evaluation is crucial. Industry experience underscores the importance of rigorous scrutiny and ongoing research to advance the understanding and application of mycelium-based materials.

Mycelium leather and animal leather have some similarities and differences. According to a study, mycelium leather and synthetic leather have similar levels of durability, and both were found to be less durable than genuine leather. However, when mycelium leather was treated with a special coating (polylactic acid), it improved its tear and flex strength [35]. It can be customized for specific traits, such as softness, durability, and strength, by engineering the mycelium during growth. On the other hand, animal leather is a natural material that has been used for centuries and has a unique texture, feel, and smell. However, animal leather production requires raising animals, which has a significant environmental impact, including greenhouse gas emissions and water usage. Additionally, animal leather is not biodegradable and can take years to decompose [36]. Mycelium leather, on the other hand, is 100% biodegradable, making it an eco-friendlier option compared to traditional leather. Mycelium leather production requires relatively little space, energy, chemicals, or water, and it generates far less waste compared to traditional leather production. However, the cost of mycelium leather is currently higher than that of traditional leather [34].

Draw Backs of Mycelium Leather

Mycelium leather faces challenges in scaling up production, reducing costs, and achieving consistent quality. Limited consumer awareness and acceptance are crucial for its successful adoption. Further research and development are needed to improve properties and expand applications. Limited availability in fashion products is another issue [39]. Despite its potential, mycelium leather has a lower environmental impact compared to traditional leather. Careful management of agricultural waste and water is necessary in the production process. Despite these challenges, mycelium leather has the potential to revolutionize the fashion industry. Therefore, further research and development are needed to fully realize its potential [40].

Cellulose, which is found in plant components, gives plant-based leathers their final stiffness. The linear polysaccharide cellulose plays a significant role in the cell walls of green plants. The cellulose in these cell walls is arranged into microfibrils, which give the plant stiffness and strength [38].

Production methods vary according on the cellulose source utilized, and they are difficult to describe due to the companies that produce these kinds of leathers operating in secret. The usage of a woven substrate made of polyester or cotton is a common feature shared by the majority of plant-based leathers discovered for this study. Made from the fibers of pineapple leaves, a by-product of the pineapple industry, Piñatex is one of the top plant-based leathers. To make a non-woven mesh, the fibers from the leaves are removed, dried, cleaned, and combined with corn polylactic acid (PLA) [2].

Partially inspired by cactus leaves, Desserto is composed of a woven base composed of polyester, cotton, or a combination of both, a compact layer, and a foam layer (Black). Mexico grows this cactus, which are harvested twice a year. They only collect fully developed cactus leaves, allowing the cacti on their plantations to thrive for around eight years. Here, neither herbicide nor irrigation are required. After being washed and crushed, the cactus leaves are sun-dried for three days. After that, the leaves’ proteins and fibers are removed to make a combination that is later made into Desserto leather [41].

Bio-Based Content of Plant-Based Leather

Plant-based leather is an innovative and sustainable alternative to traditional animal leather and synthetic leather. It is made from renewable plant resources, such as agricultural byproducts (e.g., pineapple leaves, apple peels, cactus) or natural polymers (e.g., cellulose, starch). The bio-based content of plant-based leather refers to the proportion of the material derived from biological sources, as opposed to synthetic or petroleum-based components. Below is a detailed analysis of the bio-based content of plant-based leather, including examples, challenges, and references.

Bio-Based Content of Plant-Based Leather

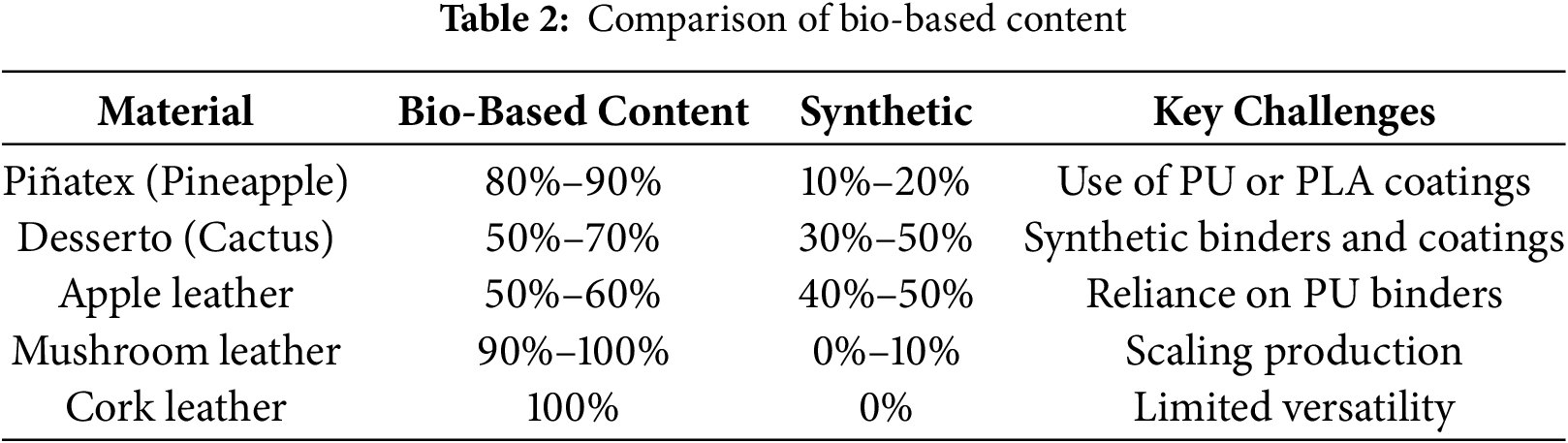

Plant-based leathers vary significantly in their bio-based content depending on the raw materials and manufacturing processes used. Piñatex, made from pineapple leaf fibers, has a high bio-based content (80%–90%) but incorporates PLA or PU binders, reducing its biodegradability [41]. Similarly, Desserto (cactus leather) contains 50%–70% bio-based materials, though synthetic coatings lower its sustainability profile [42]. Apple leather, derived from apple waste, achieves 50%–60% bio-based content but relies on PU binders, limiting its eco-friendliness. In contrast, mycelium (mushroom) leather is nearly 100% bio-based and biodegradable, though production scalability remains a challenge [43]. Cork leather stands out as fully natural (100% bio-based) but lacks versatility in applications [42]. The bio-based content of these materials is influenced by factors such as raw material selection, synthetic binders, and processing methods—highlighting the trade-offs between sustainability, durability, and functionality in plant-based leather alternatives (Table 2).

The bio-based content of plant-based leather varies widely, ranging from 50% to 100%, depending on the raw materials and processing methods used. While many plant-based leathers rely on synthetic binders or coatings to achieve desired properties, ongoing innovations aim to increase bio-based content and reduce environmental impact. As technology advances, plant-based leather is expected to become a more sustainable and viable alternative to traditional leather.

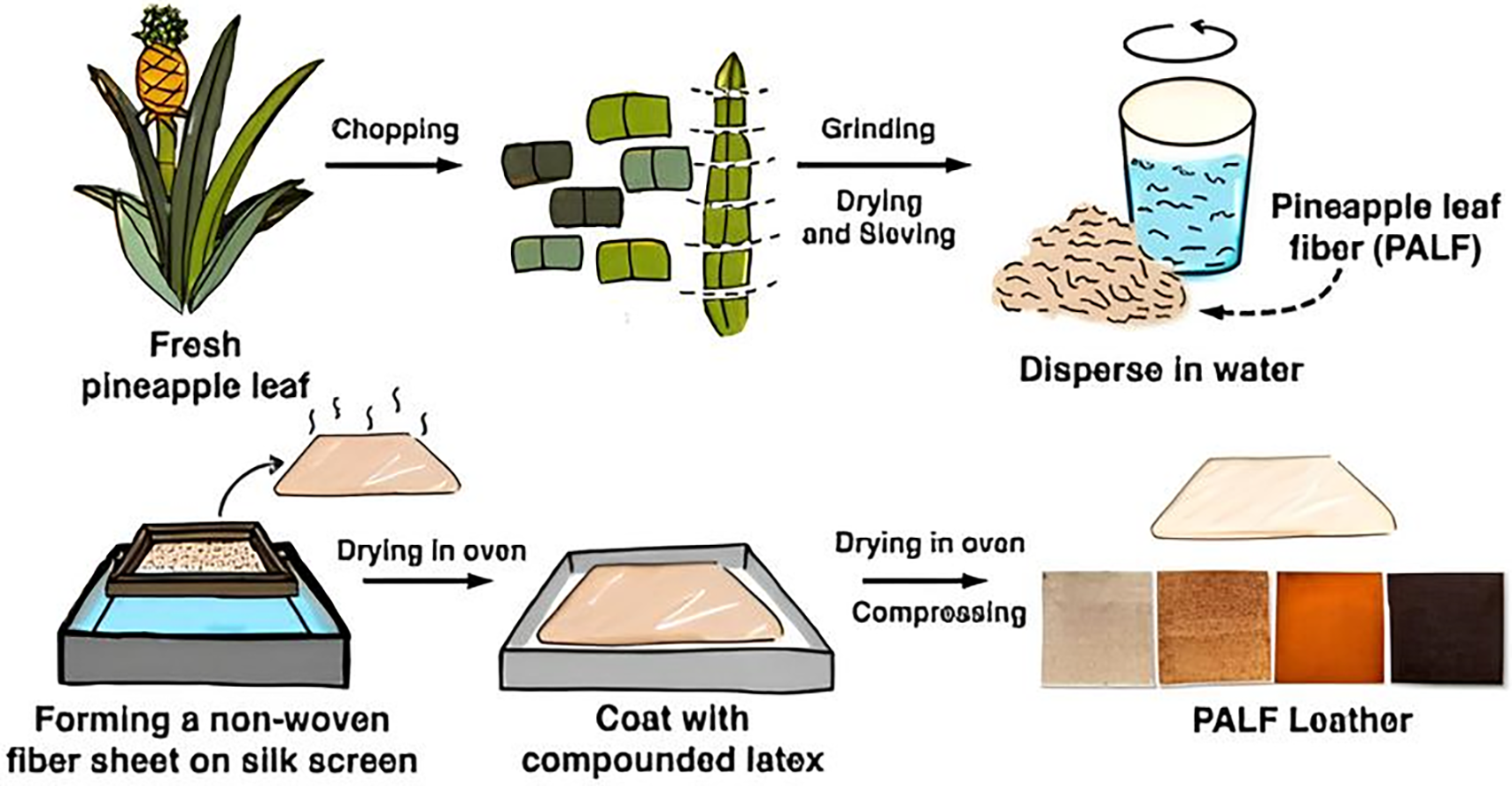

2.3.1 Production Process of Plant-Based Leather

The process begins with disassembling plant fibers to form a pulp, which can be done through methods like soaking in water and drying for mushroom leather or extracting fibers from leaves for pineapple leather. The pulp is then combined with a binding agent like polymer or natural latex to create a durable material. The mixture is then spread into leather sheets, which can be cut into smaller pieces for the final product. The sheets are then dyed and finished using natural or synthetic dyes to achieve the desired color and texture. Finally, the sheets are dried and pressed to ensure durability [39].

For specific plant-based leather types, the production process may vary. For example, cork leather is made by harvesting cork from trees, which is then ground and compressed into a mat, and finally coated with a polymer to improve durability. The production process of plant-based leather has several advantages over traditional leather, including its environmental friendliness, lower use of toxic chemicals, and biodegradability (Fig. 3).

Figure 3: Production Process of Plant-Based Leather [2]. Adopted from Willey Journal © 2021

2.3.2 Comparison: Plant-Based Leather vs. Animal Leather

Plant-based leather is generally more environmentally friendly than traditional leather due to its fewer toxic chemicals and waste production. Traditional leather production is highly polluting, using toxic chemicals like chromium and formaldehyde in the tanning process [44]. Plant-based leather typically involves breaking down plant fibers and combining them with a binding agent like polymer or natural latex. Traditional leather is made from animal hides, which are tanned using toxic chemicals and take longer to produce. Plant-based leather can be durable and water-resistant, while traditional leather may involve toxic chemicals and waste.

Its versatility is also significant, as it can be made from various plant materials, offering a range of textures and colors. In contrast, traditional leather is limited to animal hides, which can vary in quality and texture [40].

The leather industry’s environmental impact is a complex and sensitive topic, with concerns raised about the accuracy of statements regarding its impact on the environment. Key points to consider include chemical usage, regulations and practices, life cycle assessment, transparency, and accountability.

Chemical usage, such as chromium (III) sulfate, has lower toxicity than chromium (VI), but it still has environmental implications. Regulations and practices can vary depending on geographical location, regulatory standards, and industry practices. Regions with stricter regulations may operate with greater environmental responsibility. A comprehensive life cycle assessment (LCA) is necessary to evaluate the environmental footprint of materials, considering factors like resource extraction, manufacturing processes, transportation, product use, and end-of-life disposal [41].

Transparency and accountability are essential when making claims about the environmental benefits of alternative materials. Industry expertise in mycelium-based materials and experience in addressing strength-related challenges highlight the complexity of enhancing their performance. Understanding the limitations and potential of these materials is crucial for developing effective solutions and advancing the industry [42].

2.3.3 Environmental Impact of Plant-Based Leather

Plant-based leather has a lower environmental impact compared to traditional leather. The production of traditional leather is a highly polluting industry, with toxic chemicals such as chromium and formaldehyde commonly used in the tanning process. In contrast, the production of plant-based leather uses fewer toxic chemicals and produces less waste. Furthermore, some plant-based materials used to make plant-based leather, such as cork and pineapple leaves, are considered waste products from other industries and would otherwise be discarded. Plant-based leather is often used as an environmentally friendly alternative to traditional leather [43]. However, some plant-based leather may contain banned chemicals and plastics, which can have negative environmental impacts. The environmental impact of plant-based leather production varies depending on the specific material and production process used. Overall, plant-based leather offers a more sustainable and ethical alternative to traditional leather, with a lower environmental impact and fewer toxic chemicals used in production [42].

The drawbacks of plant-based leather include:

Plant-based leather faces several challenges, including complex manufacturing processes, higher production costs, and limited availability of innovative sources. These include the high cost of sourcing and processing plant-based materials like fruits, mushrooms, or plant fibers, which can limit consumer affordability and hinder market growth.

Additionally, the production of plant-based leather is more expensive than traditional leather, which can also limit its affordability. Despite these challenges, plant-based leather continues to gain traction as a sustainable and ethical alternative to traditional leather, and future advancements in technology and production processes are expected to address these challenges.

2.4 Laboratory Cultured Collagen Based Leather

The term “animal-free leather” typically refers to materials that mimic the look and feel of traditional leather but are produced without using animal-derived ingredients. Collagen-based leather, however, does involve the use of animal-derived collagen [43].

Collagen is a protein found in the connective tissues of animals, including skin, bones, and tendons. In the context of collagen-based leather, collagen is usually sourced from animal byproducts such as hides, skins, or bones. This collagen can then be processed and used to create a material that resembles traditional leather in appearance and texture [44].

While collagen-based leather may not involve directly using animal hides or skins, it still relies on animal-derived collagen as a key ingredient. Therefore, it may not meet the criteria for being considered completely animal-free. While collagen-based leather may offer certain advantages compared to traditional leather, such as potentially reduced environmental impact or ethical considerations, it may not be suitable for those seeking entirely animal-free alternatives [41].

As explained in the conventional leather section, the material that forms the main support for leather is collagen. The collagenous matrix of animal skins provides the perfect basis for leather, as it can be modified to fit various functions, and it is very durable. Efforts have gone into producing this collagen matrix without killing the animal. Modern Meadow, a company situated in New Jersey, started research into lab-cultured leather. This lab-cultured leather is created by taking cells from a cow without seriously harming it. These cells are multiplied in the lab and put on the right medium to promote collagen production (Jakab, Marga et al., 2019). Collagen in animal skins consists of various layers with different coordination of collagen fibrils. The resulting matrix is able to withstand a high level of wear. For example, collagen in the corium layer of the skin is coordinated in a weave-like structure, which was not successfully reproduced with the lab-cultured collagen. Modern Meadow decided to move away from tissue engineering to work with a mixture of enzymes and yeast cells that were DNA edited to produce collagen [44].

2.4.1 Methods of Producing Laboratory Collagen Based Leather

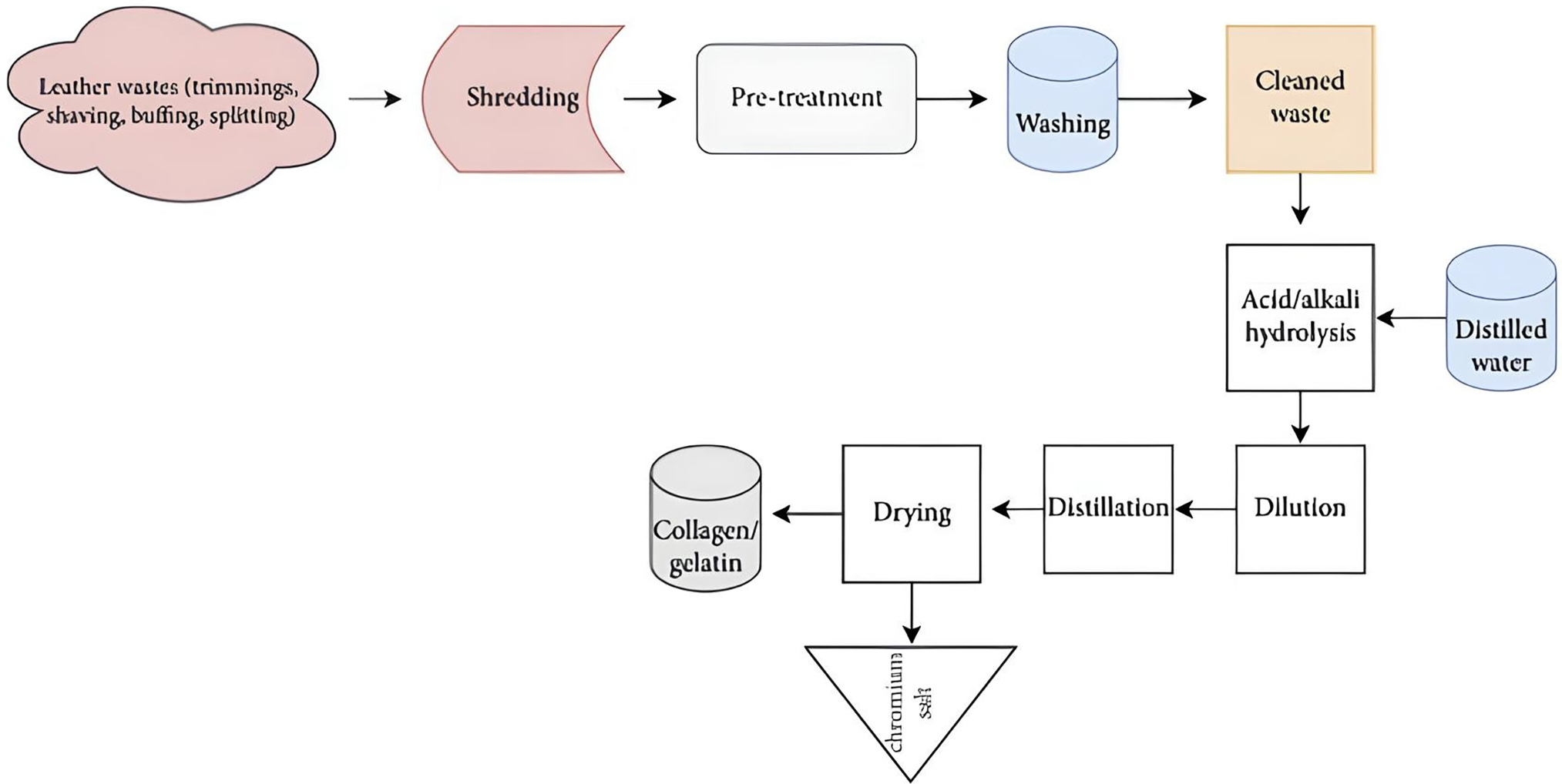

Laboratory-cultured collagen-based leather is a type of leather-like material produced using collagen derived from laboratory-cultured cells rather than traditional animal sources as shown in Fig. 4 below. This biotechnological process involves cell culture, collagen production, extracellular matrix formation, processing, and finishing [44]. The process involves cultured cells from animal or sustainable sources, providing growth factors, nutrients, and environmental conditions conducive to collagen synthesis.

Figure 4: Collagen-based leather manufacturing [24]. Adopted from © Eli Siver publisher, 2023

The extracellular matrix, formed by the cultured cells, mimics the structure found in natural tissues and provides the foundation for the leather-like material. The extracellular matrix is harvested and processed to create a flexible and durable material with properties similar to traditional leather. Additional treatments may be applied to achieve desired aesthetics and performance characteristics [45].

Laboratory-cultured collagen-based leather offers several advantages over traditional leather, including reduced environmental impact, ethical considerations, customization, and consistency and quality control. It can reduce the need for large-scale animal farming, deforestation, water consumption, and greenhouse gas emissions. It also allows for greater control over the properties of the material, enabling customization of factors such as texture, thickness, and color. However, challenges remain in scaling up production, optimizing the production process for efficiency and cost-effectiveness, and addressing regulatory and consumer acceptance issues. Despite these challenges, laboratory-cultured collagen-based leather holds promise as a sustainable and ethical alternative to traditional leather in the future [32].

Laboratory-cultured collagen-based leather, also known as cultured or bio-fabricated leather, is a promising alternative to traditional leather production methods. In this approach, collagen, the primary protein found in animal skin and connective tissues, is produced through biotechnological processes in a laboratory setting.

The methods of producing collagen-based leather involve the extraction of collagen from leather production waste and its subsequent application in various processes. Research has focused on obtaining collagen from non-tanned waste of leather production, such as limed pelt, delimed pelt, and flashings, through acid hydrolysis and subsequent precipitation. This extracted collagen has been utilized for leather finishing, aiming to enhance the final appearance, durability, and quality of leather products. Additionally, collagen recovered from leather-tanned solid wastes has been employed to improve the quality of low-grade leather, contributing to a cleaner and circular production flow. The application of extracted collagen in leather processing has been investigated for its potential to create biobased finished leather, offering an eco-friendly alternative to traditional synthetic chemical-based finishing techniques. Furthermore, the development of collagen-based products for leather finishing has been explored, with a focus on the feasibility and effectiveness of these products in enhancing the properties of leather. Overall, the methods of producing collagen-based leather involve the utilization of collagen extracted from leather production waste to create sustainable and high-quality leather products [46].

2.4.2 The Challenges in Producing Collagen-Based Leather Include

The feasibility and effectiveness of collagen-based products for leather finishing are crucial for their practical application and benefits. Traditional leather finishing techniques often involve synthetic chemicals, which can lead to environmental and health concerns. Collagen-based products should address these issues. The use of collagen extracted from leather production waste promotes sustainability and a circular production flow, but implementing these practices and scalability may pose challenges. Proper waste management and resource utilization strategies are necessary for the efficient utilization of non-tanned waste for collagen extraction. Economic viability is also crucial for the widespread adoption of collagen-based leather production [47].

Addressing these challenges will be crucial for the successful production and adoption of collagen-based leather, contributing to the sustainability and environmental friendliness of the leather industry.

2.4.3 Comparison of Collagen Leather and Conventional Leather

Collagen-based leather, derived from animal proteins, represents an innovative approach to reducing the environmental impact of traditional leather production. However, it is important to note that collagen, even when lab-grown, is still an animal-derived material. This distinguishes it from truly animal-free alternatives such as plant-based (e.g., pineapple, cactus), fungi-based (e.g., mycelium), and synthetic leathers, which are entirely free of animal inputs. While lab-grown collagen eliminates the need for animal farming and reduces associated environmental harms, it does not fully align with the definition of “animal-free leather”.

Lab-grown collagen is produced using cellular agriculture techniques, where animal cells are cultured in a controlled environment to produce collagen fibers. This method significantly reduces land use, water consumption, and greenhouse gas emissions compared to traditional leather production (Kumar et al., 2020). However, the process still relies on animal-derived starter cells, which may not satisfy the ethical or environmental concerns of consumers seeking completely animal-free products. In contrast, plant-based, fungi-based, and synthetic leathers are derived from renewable or non-animal resources and do not involve animals at any stage of production, making them more aligned with the principles of a circular and cruelty-free economy [42].

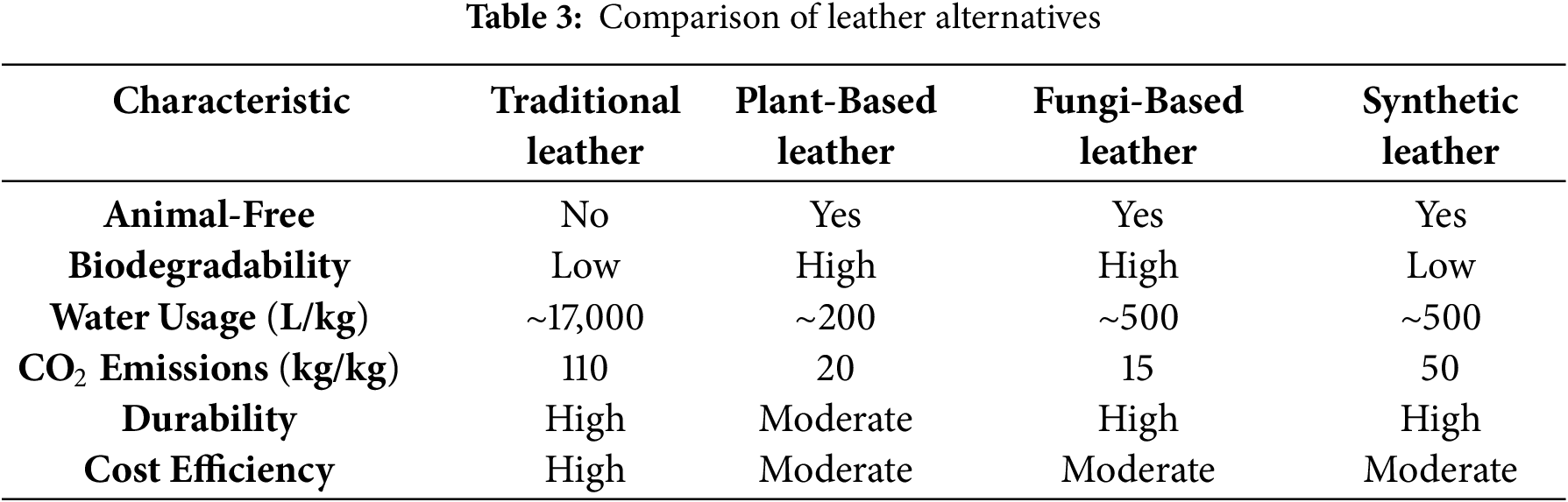

Quantitative Analysis of Leather Alternatives

A comparative analysis of leather alternatives reveals key differences in lifecycle impact, durability, and cost efficiency. Traditional leather has the highest environmental footprint, consuming ~17,000 L of water per kg and generating significant CO2 emissions from livestock and tanning. In contrast, collagen-based leather reduces water use by 50% and emissions by 30–40% but remains energy-intensive [24]. Plant-based leathers (e.g., Piñatex, cactus leather) show substantial improvements, using as little as 200 L of water per kg and offering lower carbon footprints due to renewable sourcing [4]. Fungi-based (mycelium) leather performs best environmentally, cutting CO2 emissions by up to 80% with minimal water use. However, synthetic leathers (PU/PVC) contribute to plastic pollution and greenhouse gases despite avoiding animal inputs [6].

In terms of durability, traditional leather remains the benchmark, lasting decades with care. Collagen-based leather matches mid-grade traditional leather in strength [24], while plant-based options vary—Piñatex requires synthetic reinforcements, and mycelium leather shows promise in tensile strength. Synthetic leathers are highly wear-resistant but degrade into microplastics.

Cost efficiency varies widely: traditional leather is expensive due to livestock and tanning; collagen-based leather is currently costly but may decrease with scaling; plant and fungi-based options are moderately priced; and synthetic leather remains the most affordable, though dependent on petrochemical markets. Overall, bio-based alternatives offer more sustainable options, but trade-offs in durability, cost, and scalability must be addressed for wider adoption (Table 3).

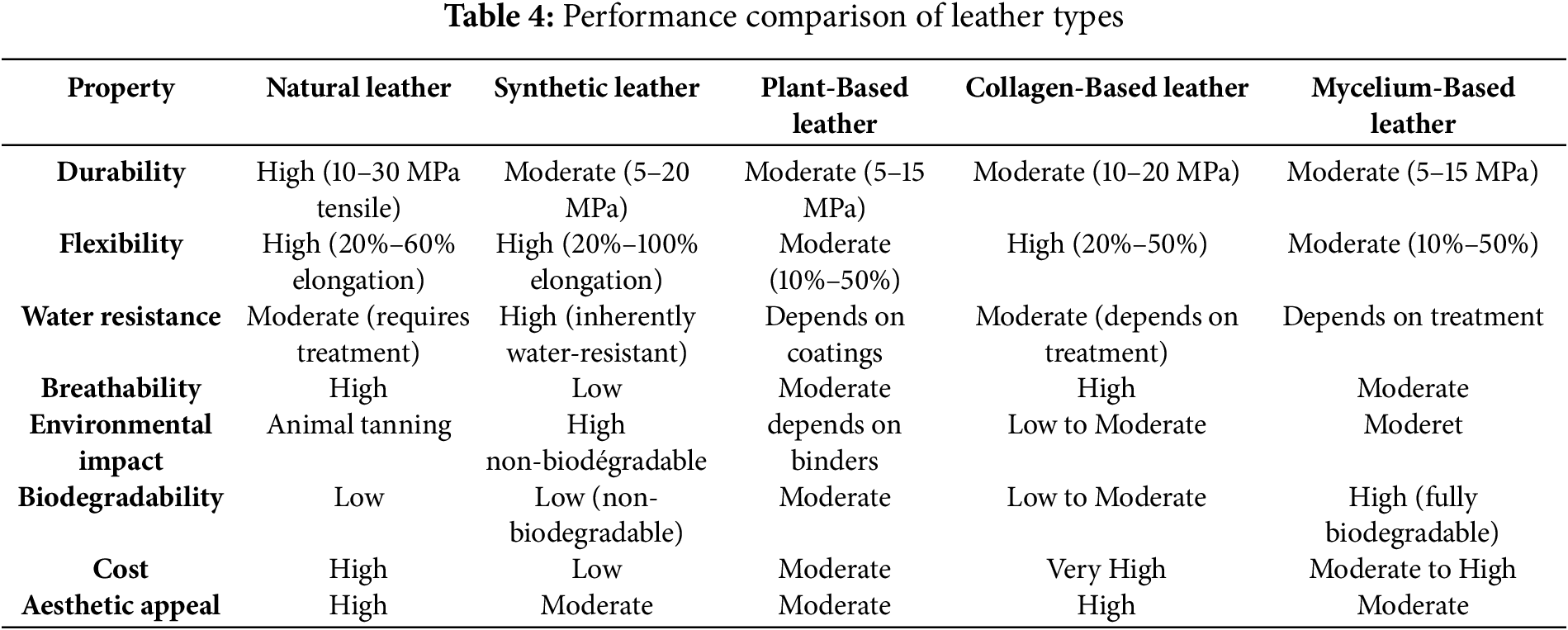

Performance Comparison of Leather Types

Below is a performance comparison table of different types of leather, including natural leather, synthetic leather, plant-based leather, collagen-based leather, and mycelium-based leather. The table evaluates key performance metrics such as durability, flexibility, water (Table 4).

The performance of bio-based and synthetic leathers varies significantly across different metrics. While natural leather remains the gold standard for durability and aesthetics, its environmental impact is a major drawback. Synthetic leather is cost-effective and versatile but suffers from environmental and biodegradability issues. Plant-based leather offers a moderate balance but often relies on synthetic binders. Collagen-based leather mimics natural leather well but is expensive, while mycelium-based leather is highly sustainable but still developing in terms of durability and scalability. The choice of material depends on the specific application and the balance between performance, cost, and sustainability.

3 Challenges of Sustainable Leather

Sustainable leather alternatives including mycelium, collagen-based, plant-based, and synthetic leather offer ethical and environmental advantages but face adoption challenges. Mycelium leather struggles with scalability due to energy-intensive production, higher costs, and variable durability compared to traditional leather [32]. Collagen-based leather, while eliminating animal slaughter, remains costly and faces ethical concerns over animal-derived growth factors, along with regulatory hurdles. Plant-based leathers (e.g., Piñatex, cactus leather) suffer from material inconsistency, reliance on synthetic binders that reduce biodegradability [23,25], and limited durability for high-performance uses. Synthetic leather (PU/PVC), though affordable, contributes to plastic pollution, contains toxic chemicals like phthalates [12], and is perceived as lower quality. Common barriers across all alternatives include higher production costs, consumer skepticism about performance and luxury appeal, and underdeveloped supply chains. Overcoming these challenges demands further innovation, investment, and cross-industry collaboration to improve scalability, performance, and market acceptance.

4 The Future of Fashion: Animal-Free Leather

The fashion industry is increasingly adopting sustainable leather alternatives, with mycelium leather emerging as a leading solution due to its biodegradability and low environmental impact. Companies like Bolt Threads (Mylo) and Myko Works are collaborating with luxury brands to commercialize this fungal-based material, while technological advancements aim to improve scalability and reduce costs [32]. Plant-based options like Piñatex (pineapple leaf fiber) and Desserto (cactus leather) are gaining mainstream acceptance through partnerships with major brands such as Hugo Boss and H&M. Meanwhile, collagen-based leather offers high-end potential through lab-grown technology that replicates traditional leather’s qualities while addressing ethical concerns through animal-free growth media.

Key trends driving this shift include: (1) growing consumer demand for sustainable materials, (2) cross-industry collaborations accelerating innovation, (3) biotechnological advancements enabling high-performance alternatives, (4) supportive regulatory policies promoting eco-friendly options, and (5) increasing awareness of animal welfare and environmental issues. While challenges like production costs, regulatory hurdles, and consumer acceptance persist, the convergence of these factors suggests a promising future for animal-free leather alternatives in creating a more ethical and sustainable fashion industry.

Sustainable leather, also known as vegan leather, has emerged as a popular choice for environmentally conscious consumers seeking sustainable and ethical fashion alternatives. Vegan leather is generally considered more ethical and environmentally friendly than traditional animal leather, as it is cruelty-free and often made from sustainable materials like pineapple leaves, cork, or recycled plastic. However, vegan leather still faces challenges such as availability and durability compared to traditional leather. The quality and durability of vegan leather have improved significantly in recent years, but it is still considered less durable than traditional leather in some aspects. Despite these challenges, the global plant-based leather market is projected to grow significantly, reflecting the increasing adoption of vegan leather by designers, artisans, and fashion brands. As innovations continue to scale up and improve, some industry experts believe that an animal-free future in fashion is on the horizon, where vegan materials are the norm.

Acknowledgement: The author is highly grateful for the technical support received from the Ethiopian Institute of Textile and Fashion Technology, Bahir Dar University, Bahir Dar, Ethiopia.

Funding Statement: The author received no specific funding for this study.

Availability of Data and Materials: The data used to support the findings of this study are available from the corresponding author upon request.

Ethics Approval: Not applicable.

Conflicts of Interest: The author declares no conflicts of interest to report regarding the present study.

References

1. Dixit S, Yadav A, Dwivedi PD, Das M. Toxic hazards of leather industry and technologies to combat threat: a review. J Clean Prod. 2015;87:39–49. doi:10.1016/j.jclepro.2014.10.017. [Google Scholar] [CrossRef]

2. Duangsuwan S, Junkong P, Phinyocheep P, Thanawan S, Amornsakchai T. Development of green leather alternative from natural rubber and pineapple leaf fiber. Sustainability. 2023;15(21):15400. doi:10.3390/su152115400. [Google Scholar] [CrossRef]

3. Pandya A, Rodriguez CQ. A framework to investigate the potential of brewery wastes’ utilization in eco-friendly leather production: a consumer study. Int J Sustain Fash Text. 2023;2(2):227–50. doi:10.1386/sft_00031_1. [Google Scholar] [CrossRef]

4. Amobonye A, Lalung J, Awasthi MK, Pillai S. Fungal mycelium as leather alternative: a sustainable biogenic material for the fashion industry. Sustain Mater Technol. 2023;38(164):e00724. doi:10.1016/j.susmat.2023.e00724. [Google Scholar] [CrossRef]

5. Manan S, Atta OM, Shahzad A, Ul-Islam M, Ullah MW, Yang G. Applications of fungal mycelium-based functional biomaterials. In: Deshmukh SK, Deshpande MV, Sridhar KR, editors. Fungal biopolymers and biocomposites. Singapore: Springer; 2022. p. 147–68. doi:10.1007/978-981-19-1000-5_9. [Google Scholar] [CrossRef]

6. Spinnewijn O. Innovative leather alternatives: a short-lived trend or the future of fashion [dissertation]?. Utrecht, The Netherlands: Utrecht University; 2022. [Google Scholar]

7. Sharma S, Sharma V, Chatterjee S. Contribution of plastic and microplastic to global climate change and their conjoining impacts on the environment—a review. Sci Total Environ. 2023;875(10):162627. doi:10.1016/j.scitotenv.2023.162627. [Google Scholar] [PubMed] [CrossRef]

8. Shi Y, Huang H, Zheng L, Tian Y, Gong Z, Wang J, et al. Releases of microplastics and chemicals from nonwoven polyester fabric-based polyurethane synthetic leather by photoaging. Sci Total Environ. 2023;902(17–18):166584. doi:10.1016/j.scitotenv.2023.166584. [Google Scholar] [PubMed] [CrossRef]

9. Xing W, Xi J, Cai W, Zhang W, Wang B, Chen L, et al. Preparation and properties of multifunctional polyurethane synthetic leather nanocomposites. Appl Sci Manuf. 2023;169:107534. [Google Scholar]

10. Gilon N, Soyer M, Redon M, Fauvet P. Separation of leather, synthetic leather and polymers using handheld laser-induced breakdown spectroscopy. Sensors. 2023;23(5):2648. doi:10.3390/s23052648. [Google Scholar] [PubMed] [CrossRef]

11. Cai W, Xin W, Zhang H, Luo Y. Synthesis and application of a low dye absorption waterborne polyurethane for microfiber synthetic leather. Coatings. 2022;12(6):728. doi:10.3390/coatings12060728. [Google Scholar] [CrossRef]

12. Sudha TB, Thanikaivelan P, Aaron KP, Krishnaraj K, Chandrasekaran B. Comfort, chemical, mechanical, and structural properties of natural and synthetic leathers used for apparel. J Appl Polym Sci. 2009;114(3):1761–7. doi:10.1002/app.30589. [Google Scholar] [CrossRef]

13. Yan L, Zhou J, Li H, Zhong R, Zhuang J, Xu X, et al. Wearable synthetic leather-based high-performance X-ray shielding materials enabled by the plant polyphenol-and hierarchical structure-facilitated dispersion. Col Leather. 2023;5(1):12. doi:10.1186/s42825-023-00119-5. [Google Scholar] [CrossRef]

14. Ferreira da Silva PP. Environmental performance of leather and leather-like materials applied to footwear [master’s thesis]. Trondheim, Norway: Norwegian University of Science and Technology; 2023. [Google Scholar]

15. Hassan MM, Harris J, Busfield JJ, Bilotti E. A review of the green chemistry approaches to leather tanning in imparting sustainable leather manufacturing. Green Chem. 2023;25(19):7441–69. doi:10.1039/d3gc02948d. [Google Scholar] [CrossRef]

16. Pilo Pais A. Analysis of REACH environmental legislation and related costs affecting companies: the case of eco-toxicological standards in the textile, clothing, leather, and footwear sectors [master’s thesis]. Turin, Italy: Politecnico di Torino; 2022. [Google Scholar]

17. Amutha K. Sustainable chemical management and zero discharges. In: Muthu SS, editor. Sustainable fibres and textiles. Amsterdam, The Netherlands: Elsevier; 2017. p. 347–66. doi:10.1016/b978-0-08-102041-8.00012-3. [Google Scholar] [CrossRef]

18. Prasannamedha G, Sentihilkumar P. Chemical compliance and regulations in textiles and fashion. Chem Manag Text Fash. 2021;135–54. doi:10.1016/b978-0-12-820494-8.00007-1. [Google Scholar] [CrossRef]

19. Bacardit A, Baquero G, Sorolla S, Ollé L. Evaluation of a new sustainable continuous system for processing bovine leather. J Clean Prod. 2015;101(5):197–204. doi:10.1016/j.jclepro.2015.04.012. [Google Scholar] [CrossRef]

20. Hildebrandt J, Thrän D, Bezama A. The circularity of potential bio-textile production routes: comparing life cycle impacts of bio-based materials used within the manufacturing of selected leather substitutes. J Clean Prod. 2021;287(1):125470. doi:10.1016/j.jclepro.2020.125470. [Google Scholar] [CrossRef]

21. Carcione F, Defeo GA, Galli I, Bartalini S, Mazzotti D. Material circularity: a novel method for biobased carbon quantification of leather, artificial leather, and trendy alternatives. Coatings. 2023;13(5):892. doi:10.3390/coatings13050892. [Google Scholar] [CrossRef]

22. Bielak E, Marcinkowska E. Heavy metals in leathers, artificial leathers, and textiles in the context of quality and safety of use. Sci Rep. 2022;12(1):5061. doi:10.1038/s41598-022-08911-9. [Google Scholar] [PubMed] [CrossRef]

23. Prado V, Daystar J, Wallace M, Pires S, Laurin L. Evaluating alternative environmental decision support matrices for future Higg MSI scenarios. Int J Life Cycle Assess. 2021;26(7):1357–73. doi:10.1007/s11367-021-01928-8. [Google Scholar] [CrossRef]

24. Gargano M, Florio C, Sannia G, Lettera V. From leather wastes to leather: enhancement of low quality leather using collagen recovered from leather tanned wastes. Clean Technol Environ Policy. 2023;25(9):3065–74. doi:10.21203/rs.3.rs-2487216/v1. [Google Scholar] [CrossRef]

25. Ballús O, Guix M, Baquero G, Bacardit A. Life cycle environmental impacts of a biobased acrylic polymer for leather production. Polymers. 2023;15(5):1318. doi:10.3390/polym15051318. [Google Scholar] [PubMed] [CrossRef]

26. Tewari S, Reshamwala SM, Bhatt L, Kale RD. Vegan leather: a sustainable reality or a marketing gimmick? Environ Sci Pollut Res. 2024;31(3):3361–75. doi:10.1007/s11356-023-31491-8. [Google Scholar] [PubMed] [CrossRef]

27. Tekletsadik S. Selection of best leather item using an FAHP method to launch new leather industry in Ethiopia: a case study. J Future Sustain. 2023;3(2):85–96. [Google Scholar]

28. Niinimäki K, Peters G, Dahlbo H, Perry P, Rissanen T, Gwilt A. The environmental price of fast fashion. Nat Rev Earth Environ. 2020;1(4):189–200. doi:10.1038/s43017-020-0039-9. [Google Scholar] [CrossRef]

29. Forbes G. About greenpeace international. 2023 [cited 2025 May 6]. Available from: https://apps1.unep.org/resolutions/uploads/230113_greenpeace_international.pdf. [Google Scholar]

30. Wijayarathna EKB, Mohammadkhani G, Soufiani AM, Adolfsson KH, Ferreira JA, Hakkarainen M, et al. Fungal textile alternatives from bread waste with leather-like properties. Resour Conserv Recycl. 2022;179:106041. doi:10.1016/j.resconrec.2021.106041. [Google Scholar] [CrossRef]

31. Elsacker E, Vandelook S, Peeters E. Recent technological innovations in mycelium materials as leather substitutes: a patent review. Front Bioeng Biotechnol. 2023;11:1204861. doi:10.3389/fbioe.2023.1204861. [Google Scholar] [PubMed] [CrossRef]

32. Ariyani N, Wijayanti S, Putra N, Kusumawati M, Setiawan A, Isharyadi F, et al. Mycelium-based leather potential for sustainability: a review. In: Proceedings of the International Conference on Environmental, Mining, and Sustainable Development; 2024 May 25; Padang, Indonesia. [Google Scholar]

33. Peeters E, Salueña Martin J, Vandelook S. Growing sustainable materials from filamentous fungi. Biochem. 2023;45(3):8–13. doi:10.1042/bio_2023_120. [Google Scholar] [CrossRef]

34. Crawford A, Branco S, Sheldon L, Ebert L. Experimental fabrication methods for mycelium leather production. In: Proceedings of the CEES, 2023 2nd International Conference on Construction, Energy, Environment & Sustainability; 2023 Jun 27–30; Funchal, Portugal. [Google Scholar]

35. Sardroudi NP, Sorolla S, Casas C, Bacardit A. A study of the composting capacity of different kinds of leathers, leatherette and alternative materials. Sustainability. 2024;16(6):2324. doi:10.3390/su16062324. [Google Scholar] [CrossRef]

36. Karaca C, Karaca G. Comparison of fungi with sclerotia as sustainable materials for product design. In: Proceedings of the 4th International Conference on Environmental Design (ICED2023); 2023 Oct 20–22; Athens, Greece. [Google Scholar]

37. Whabi V, Yu B, Xu J. From nature to design: tailoring pure Mycelial materials for the needs of tomorrow. J Fungi. 2024;10(3):183. doi:10.3390/jof10030183. [Google Scholar] [PubMed] [CrossRef]

38. Pedersen GB, Blaschek L, Frandsen KE, Noack LC, Persson S. Cellulose synthesis in land plants. Mol Plant. 2023;16(1):206–31. doi:10.1016/j.molp.2022.12.015. [Google Scholar] [PubMed] [CrossRef]

39. Kefale GY, Kebede ZT, Birlie AA. A systematic review on potential bio leather substitute for natural leather. J Eng. 2023;2023(1):1629174. doi:10.1155/2023/1629174. [Google Scholar] [CrossRef]

40. Meyer M, Dietrich S, Schulz H, Mondschein A. Comparison of the technical performance of leather, artificial leather, and trendy alternatives. Coatings. 2021;11(2):226. doi:10.3390/coatings11020226. [Google Scholar] [CrossRef]

41. Quaratesi I, Badea E, Călinescu I, Sardroudi NP, Zengin G, Casas C, et al. Eco-friendly alternatives in leather production: performance of biodegradable alginate-based retanned leather compared to conventional leathers and plant-based materials. Appl Sci. 2024;14(22):10263. doi:10.3390/app142210263. [Google Scholar] [CrossRef]

42. Pavani C, Rao PA, Vishnu P, Raja H, Sriram, Sirisha N. Vegan leather from agricultural waste: exploring sustainable and cruelty-free alternatives. In: Arya RK, Verros GD, Verma OP, Hussain CM, editors. From waste to wealth. Singapore: Springer; 2024. p. 951–64. doi:10.1007/978-981-99-7552-5_42. [Google Scholar] [CrossRef]

43. Wilson D, Tsigkou O, Bosworth L, Jones C. Leather-like materials by cellular agriculture. Text Prog. 2023;55(1):1–45. doi:10.1080/00405167.2023.2188835. [Google Scholar] [CrossRef]

44. Feng B, Yang H, Zhu M, Li J, Chang H-M, Leung PC, et al. Collagen-based biomaterials in organoid technology for reproductive medicine: composition, characteristics, and applications. Col Leather. 2023;5(1):35. doi:10.1186/s42825-023-00142-6. [Google Scholar] [CrossRef]

45. Chriki S, Ellies-Oury M-P, Hocquette J-F. What do we know today about cultured muscle to produce meat and its acceptability in the world?. In: Purslow P, editor. New aspects of meat quality. 2nd ed. Amsterdam, The Netherlands: Elsevier; 2022. p. 507–32 doi:10.1016/b978-0-323-85879-3.00002-7. [Google Scholar] [CrossRef]

46. Maistrenko L, Iungin O, Savchuk O, Okhmat O. Collagen matrices from leather industry wastes for biomedical application. In: Proceedings of the 8th International Conference on Advanced Materials and Systems (ICAMS 2020); 2020 Oct 1–3; Bucharest, Romania. [Google Scholar]

47. Zheng M, Wang X, Chen Y, Yue O, Bai Z, Cui B, et al. A review of recent progress on collagen-based biomaterials. Adv Healthc Mater. 2023;12(16):2202042. doi:10.1002/adhm.202370080. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools