Open Access

Open Access

ARTICLE

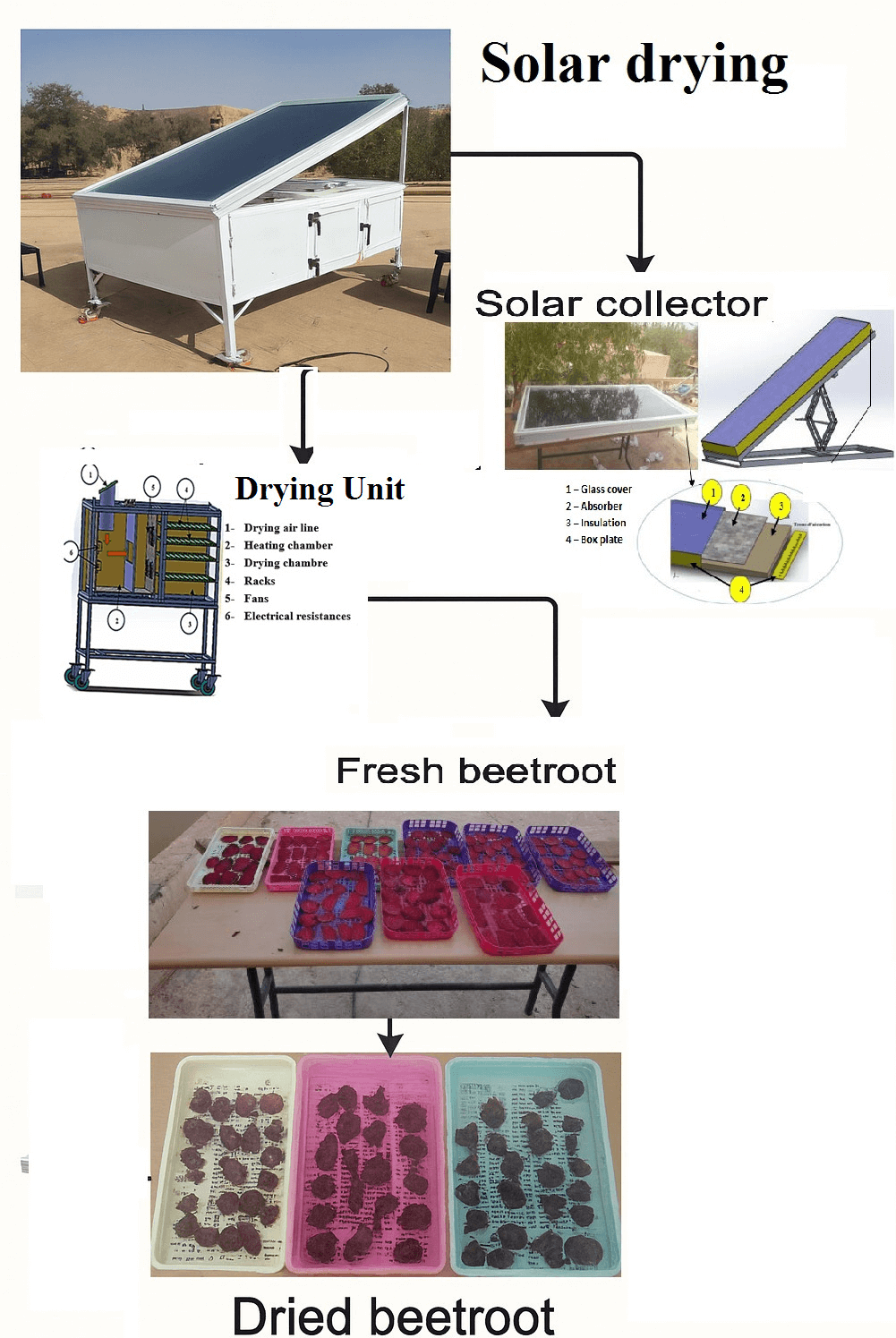

Design and Development of a Forced-Convection Solar Dryer: Application to Beetroot Cultivated in Béchar, Algeria

1 Laboratory for the Development of Renewable Energies and Their Applications in Saharan Areas (LDREAS), Faculty of Exact Science, University of Tahri Mohamed Béchar, P.O. Box 417, Béchar, 08000, Algeria

2 Laboratory of Arid Zones Energetic-(ENERGARID), Faculty of Technology, University of Tahri Mohamed Béchar, P.O. Box 417, Béchar, 08000, Algeria

3 Department of Mechanical Engineering, University of New Brunswick, Fredericton, NB E3B 5A3, Canada

* Corresponding Author: Lyes Bennamoun. Email:

(This article belongs to the Special Issue: Recent Advance and Development in Solar Energy)

Energy Engineering 2026, 123(2), 17 https://doi.org/10.32604/ee.2025.073329

Received 16 September 2025; Accepted 27 November 2025; Issue published 27 January 2026

Abstract

The aim of this study is to design, build, and evaluate an indirect forced convection solar dryer adapted to semi-arid climate, such as that of Béchar situated in the west south region of Algeria. The tested drying system consists of a flat-plate solar collector, an insulated two-chamber drying unit, and an Arduino-controlled device that ensures uniform temperature distribution and real-time monitoring using DHT22 sensors. Drying tests were conducted on locally grown beet slices at air temperatures of 45°C, 60°C, and 80°C, with a constant air velocity of 1.2 m/s and a mass flow rate of 0.0027 kg/s. The collector reached a maximum temperature of 65°C, with thermal efficiencies ranging from 20% to 35%. In these conditions, the drying times were cut down to 200–300 min, and the beet’s moisture content dropped to 0.47, 0.27, and 0.24 g/g dry matter, respectively. The experimental data were fitted to several empirical models, including the logarithmic model. The modelled results showed strong agreement with the experimental ones (correlation coefficients r = 0.9919–0.9989; standard errors SE = 0.017–0.043; root-mean-square errors RMSE = 0.016–0.027). The results demonstrate that the system operates efficiently and consistently, making it suitable for the sustainable drying of agricultural and medicinal products in arid climates.Graphic Abstract

Keywords

Cite This Article

Copyright © 2026 The Author(s). Published by Tech Science Press.

Copyright © 2026 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools