Open Access

Open Access

ARTICLE

CFD Analysis of Corrugated Plate Designs to Improve Heat Transfer Efficiency in Plate Heat Exchangers

1 Faculty of Engineering Science & Technology, Hamdard University, Madinat al-Hikmah Hakim Mohammed Said Road, Karachi, 74600, Sindh, Pakistan

2 National University of Science & Technology, PNEC Library, PNS JAUHAR, Habib Ibrahim Rahmatullah Road, Karachi, 44000, Sindh, Pakistan

3 Mechanical Engineering Department, Quaid-e-Awam University of Engineering, Science & Technology, Nawabshah, 67480, Sindh, Pakistan

4 Faculty of Mechanical & Automotive Engineering Technology, Universiti Malaysia Pahang Al-Sultan Abdullah, Pekan, 26600, Pahang, Malaysia

5 Centre for Automotive Engineering, Universiti Malaysia Pahang AI Sultan Abdullah, Pekan, 26600, Pahang, Malaysia

6 Centre for Research in Advanced Fluid & Processes, Universiti Malaysia Pahang Al-Sultan Abdullah, Gambang, 26300, Pahang, Malaysia

* Corresponding Author: Kashif Ahmed Soomro. Email:

Energy Engineering 2025, 122(12), 4857-4872. https://doi.org/10.32604/ee.2025.069847

Received 01 July 2025; Accepted 29 September 2025; Issue published 27 November 2025

Abstract

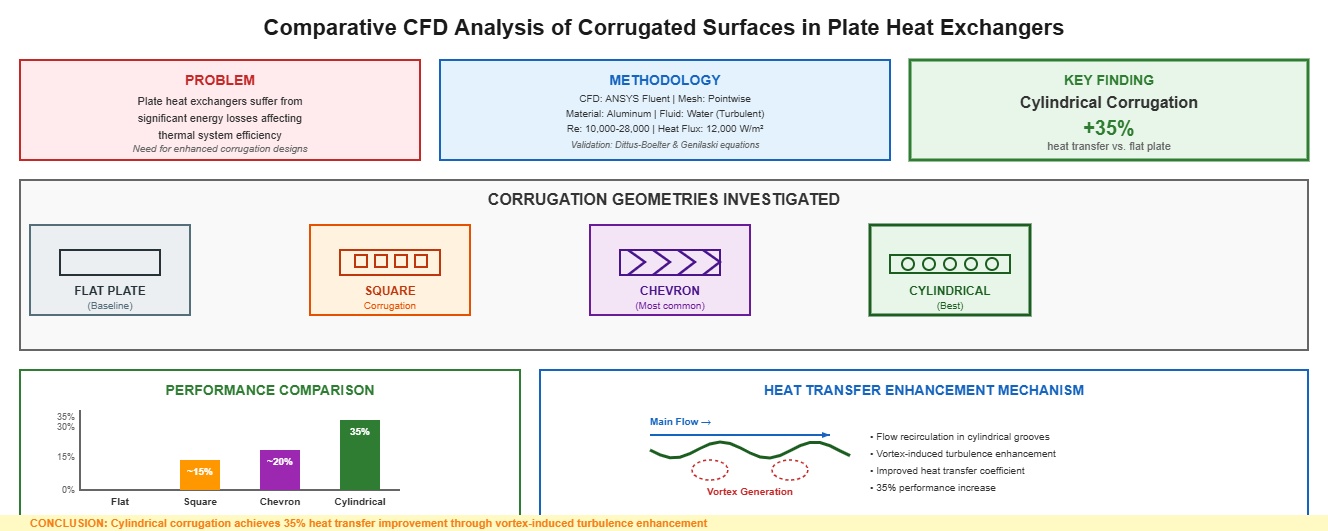

Plate heat exchangers suffer from significant energy losses, which adversely affect the overall efficiency of thermal systems. To address this challenge, various heat transfer enhancement techniques have been investigated. Notably, the incorporation of surface corrugations is widely recognized as both effective and practical. Chevron corrugation is the most employed design. However, there remains a need to investigate alternative geometries that may offer superior performance. This study aims to find a novel corrugation design by conducting a comparative CFD analysis of flat, square, chevron, and cylindrical corrugated surfaces, assessing their impact on heat transfer enhancement within a plate heat exchanger. ANSYS Fluent software was used for simulation at four distinct Reynolds numbers (10,000, 18,000, 26,000, and 28,000), with a heat flux of 12,000 W/m2. A structured mesh was generated using Pointwise software. The material of the solid plates was modelled as aluminum, the fluid was modelled as water, and the flow was turbulent. To obtain a fully developed turbulent flow, a separate inlet duct was modelled, and the output velocity profile of the inlet duct was input into the plate heat exchanger. The Nusselt number (Nu) and heat-transfer coefficient (h) were calculated to evaluate the performance of all surfaces. The results indicate that cylindrical corrugated surfaces exhibit higher Nusselt numbers than chevron, square, and flat plates. This higher performance is because of the generation of vortices in the middle of the cylindrical texture. Consequently, flow recirculation occurs, leading to reattachment to the mainstream flow. This phenomenon induces increased turbulence, thereby enhancing the heat transfer efficiency. To validate the results, a grid-convergence independence test was performed for three different mesh sizes. In addition, empirical calculations were performed using the Dittus-Boelter and the Genilaski equations to validate the results of the flat-plate heat exchanger. It was concluded that the cylinder was the best corrugated surface and had a maximum heat transfer 35% higher than that of a flat plate.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools