Open Access

Open Access

ARTICLE

A Novel Low-Damage Viscoelastic-Surfactant Foam Fracturing Fluid for Tight Reservoirs: Development and Performance Assessment

1 Key Laboratory for Exploration & Development of Unconventional Resources, CNOOC Energy Technology & Services Limited, Tianjin, 300452, China

2 Key Laboratory for Offshore Completion, CNOOC Energy Technology & Services Limited, Tianjin, 300452, China

3 CNOOC EnerTech-Drilling & Production Co., Tianjin, 300452, China

* Corresponding Author: Yu Li. Email:

(This article belongs to the Special Issue: Fluid and Thermal Dynamics in the Development of Unconventional Resources III)

Fluid Dynamics & Materials Processing 2025, 21(10), 2539-2556. https://doi.org/10.32604/fdmp.2025.067685

Received 09 May 2025; Accepted 11 September 2025; Issue published 30 October 2025

Abstract

As oil and gas development increasingly targets unconventional reservoirs, the limitations of conventional hydraulic fracturing, namely high water consumption and significant reservoir damage, have become more pronounced. This has driven growing interest in the development of clean fracturing fluids that minimize both water usage and formation impairment. In this study, a low-liquid-content viscoelastic surfactant (VES) foam fracturing fluid system was formulated and evaluated through laboratory experiments. The optimized formulation comprises 0.2% foaming agent CTAB (cetyltrimethylammonium bromide) and 2% foam stabilizer EAPB (erucamidopropyl betaine). Laboratory tests demonstrated that the VES foam system achieved a composite foam value of 56,700 mL·s, reflecting excellent foaming performance. Proppant transport experiments revealed minimal variation in suspended sand volume over 120 min across different sand ratios, indicating robust sand-carrying capacity even at high proppant concentrations. Rheological measurements showed that the fluid maintained a viscosity above 120 mPa·s after 120 min of shearing at 70°C and a shear rate of 170 s−1, with the elastic modulus exceeding the viscous modulus, confirming the system’s exceptional stability and resilience. Furthermore, core damage tests indicated that the VES foam caused only 4.42% formation damage, highlighting its potential for efficient and low-damage stimulation of tight reservoirs. Overall, the findings demonstrate that this low-liquid-content VES foam provides a highly effective, environmentally considerate alternative for hydraulic fracturing in unconventional formations, combining superior proppant transport, rheological stability, and minimal reservoir impairment.Keywords

With the continuous development of the global economy, the demand for petroleum has been steadily increasing, particularly in the exploration and development of unconventional oil and gas resources. The urgency to exploit these unconventional resources has become increasingly prominent. To meet the ever-growing energy demand, improving the efficiency of unconventional oil and gas extraction has emerged as a central research focus in the petroleum industry. However, traditional hydraulic fracturing technology faces considerable limitations when applied to unconventional reservoirs. Firstly, hydraulic fracturing requires substantial water consumption, which is especially problematic in water-scarce regions. Secondly, conventional hydraulic fracturing can cause significant damage to the reservoir, leading to poor post-fracturing oil and gas recovery and reducing the overall effectiveness of the operation. Consequently, under the growing pressure of environmental protection and the global pursuit of green development, the shortcomings of traditional hydraulic fracturing technology are becoming increasingly evident.

In recent years, foam fracturing technology has garnered considerable attention and has become a focus of intensive research. As an emerging fracturing fluid system, foam fracturing fluids have demonstrated distinct advantages in oil and gas development. Compared with conventional hydraulic fracturing fluids, foam-based systems offer several significant benefits. Firstly, they can substantially reduce water consumption, thereby minimizing reliance on freshwater resources—an advantage particularly critical in arid and water-scarce regions. Secondly, foam fracturing fluids exhibit excellent proppant-carrying capacity, efficiently transporting sand particles to deeper rock formations to enhance fracture propagation and effectiveness. Additionally, foam fluids possess low fluid loss, which helps minimize formation damage. Moreover, they exhibit favorable flowback properties, facilitating rapid fluid recovery after fracturing and reducing the risk of reservoir contamination [1,2,3]. As a result, foam fracturing fluids, with their high efficiency and low formation damage, are increasingly recognized as a promising alternative for unconventional oil and gas reservoir stimulation.

However, as a thermodynamically unstable system, foam fracturing fluids still face considerable challenges in maintaining stability. Foam stability is highly sensitive to factors such as temperature, pressure, and the surrounding fluid environment. These factors can easily lead to the collapse of the foam structure during field operations. Studies have shown that foam stability progressively deteriorates over time, with the degradation being particularly pronounced under high-temperature and high-salinity conditions [4,5,6,7]. Therefore, the development of foam fracturing fluids with enhanced resistance to elevated temperatures and salinity has become a critical research focus in the field.

The foaming ability and stability of foam are strongly correlated with the properties of surfactants, which not only govern foam generation but also play a critical role in maintaining its stability. Commonly used surfactants include anionic, cationic, and amphoteric surfactants. Anionic surfactants are widely applied due to their strong foaming ability, low cost, and broad availability [8,9]. Cationic surfactants, characterized by low toxicity and mildness, are suitable for specific environments where reduced irritation is required [10,11]. Amphoteric surfactants are particularly valued for their exceptional salt tolerance, making them ideal candidates for foam systems operating in high-salinity environments [12,13,14,15]. Therefore, the careful selection of both surfactant type and concentration is essential for enhancing foam stability and ensuring the long-term effectiveness of the fracturing fluid system. In addition to surfactants, foam stability is also closely influenced by the choice of stabilizers. Stabilizers function by extending foam half-life and preventing premature foam collapse, thereby further improving stability. By optimizing the type and concentration of stabilizers, the temperature resistance and salt tolerance of foam systems can be significantly enhanced.

In recent years, extensive research has focused on the development of various foam fracturing fluid systems to enhance their stability and adaptability under complex reservoir conditions. Ju et al. [16] formulated a foam fracturing fluid suitable for coalbed methane (CBM) production by employing hydroxypropyl guar (HPG) as the foam stabilizer and sodium dodecyl sulfate (SDS) and cetyltrimethylammonium bromide (CTAB) as foaming agents, demonstrating promising application potential for coal seam exploitation. Zhao et al. [17] proposed the novel use of natural psyllium seed gum (PG) as a CO2 foam stabilizer. Comparative analyses with polyacrylamide and xanthan gum confirmed that PG not only effectively enhanced foam performance but also elucidated its stabilization mechanism. Under high-temperature (110°C) and high-salinity (105 mg/L) conditions, PG exhibited the highest drainage energy barrier (45.13 kJ/mol) and the lowest coarsening rate (8.61 × 103 μm3/min), significantly improving CO2 foam stability and presenting great potential as a novel foam stabilizer for fracturing fluids. Ishii et al. [18] developed cellulose nanofiber (CNF)-based foams and found that their stability under high temperature and high pressure largely depended on the type of surfactant used. When the CNF concentration exceeded 0.10 wt%, foam stability decreased with increasing temperature but improved with higher pressure, with the formation of CNF aggregates induced by interactions with salt cations, thereby significantly enhancing foam stability. Alalawi et al. [19] evaluated the high-temperature performance of nanocomposite-stabilized foams synthesized from graphene oxide and zwitterionic surfactants (GO/SURF). The irreversible adsorption of the nanocomposites markedly reinforced the mechanical strength of the foams, making them suitable for foam fracturing in high-temperature reservoirs. Zheng et al. [20] constructed a supercritical CO2 foam fracturing fluid system stabilized by wormlike micelles using pseudo-Gemini surfactants. The synergistic interaction between oleylamidopropyl betaine (OAB) and alpha-olefin sulfonate (AOS) effectively enhanced foam stability, while the formation damage caused by this system was significantly lower than that of conventional guar gum-based fracturing fluids.

Compared with conventional surfactant-based foams, these novel foam systems each offer distinct advantages. Polymer foams can enhance foam viscosity and elasticity [21,22,23,24], but they tend to leave high levels of residue. Nanoparticle-stabilized foams significantly improve foam stability [25], yet require precise control of particle dispersion and risk pore blockage due to particle sedimentation under harsh conditions. In contrast, viscoelastic surfactant (VES) foams exhibit excellent thermal and salinity resistance without causing excessive viscosity increases, demonstrating strong application potential in the development of unconventional oil and gas reservoirs. Over the past decade, numerous VES-based foam systems have been reported. Common formulations include quaternary ammonium surfactants (e.g., CTAB), zwitterionic surfactants (e.g., erucamidopropyl betaine), or pseudo-gemini structures, often combined with nanoparticles or co-surfactants to enhance foam stability. For example, Gu and Mohanty [21] demonstrated the shear-thinning behavior and low damage of polymer-free VES foams. Zhao et al. [17] enhanced VES-CO2 foam stability using psyllium gum, while Li et al. [26] reported a pH-responsive VES system with switchable wormlike micelles exceeding 90,000 mPa·s in viscosity. However, conventional VES foams still suffer from several limitations, such as [27,28]: Short foam half-life under high total dissolved solids (TDS) conditions (>60 g/L); Instability in the presence of divalent ions (e.g., Ca2+, Mg2+); Limited sand-carrying capacity at high proppant concentrations; High cost due to surfactant concentration requirements; Incomplete foam regeneration in field environments. Although recent advances—including the use of spacer-modified surfactants, pseudogemini amphiphiles, and nanomaterial crosslinking—have attempted to address these issues, many of them remain at the laboratory stage with limited field application data. Therefore, further research is needed to optimize VES foam systems by tailoring surfactant–stabilizer ratios, enhancing thermal and salinity resistance, and improving proppant suspension properties under high-stress conditions. In this context, the present study proposes a novel VES foam fracturing fluid with enhanced performance for tight reservoirs, aiming to bridge the gap between laboratory feasibility and practical application.

The primary objective of this study is to select appropriate foaming agents and stabilizers based on the comprehensive performance of foam fracturing fluids and to optimize their mixing ratios to develop a viscoelastic surfactant (VES) foam fracturing fluid system tailored to the demands of unconventional oil and gas reservoirs. To achieve this goal, a series of experiments will be conducted to compare different foaming agents, stabilizers, and their combinations, with the aim of enhancing foam stability and proppant-carrying capacity, thereby improving the adaptability of foam fracturing fluids under high-temperature and high-salinity conditions. Through systematic evaluation of key performance parameters—including foaming ability, stability, rheological properties, sand-carrying capacity, and fluid loss characteristics—the most suitable foam fracturing fluid system will be identified for application in target reservoirs, providing reliable technical support for the efficient and sustainable development of unconventional oil and gas resources.

This study utilizes three types of foaming agents and two types of stabilizers (Table 1 and Table 2), along with deionized water and five different salts (Table 3). The experimental apparatus includes a 500 mL graduated cylinder, 15 mL sample vials, a Waring blender high-speed stirrer, a German IKA T10 basic disperser, a visual constant-temperature water bath, a pipette, a stopwatch, and an analytical balance.

Table 1: Foaming agent for constructing VES foam system.

| Surfactant Type | Name | Code | Brand |

|---|---|---|---|

| Cationic | Tetradecyltrimethylammonium bromide | TTAB | Aladdin |

| Cationic | Cetyltrimethylammonium bromide | CTAB | Aladdin |

| Cationic | Octadecyltrimethylammonium bromide | STAB | Aladdin |

| Anionic | Fatty alcohol polyoxyethylene ether sulfate sodium | AES | Macklin |

| Anionic | Sodium dodecyl sulfate | SDS | Macklin |

| Anionic | Sodium alpha-olefin sulfonate | AOS | Aladdin |

| Amphoteric | Cocamidopropyl betaine | CAB | Aladdin |

| Amphoteric | Lauryl betaine | CAS | Aladdin |

Table 2: Foam stabilizer for constructing VES foam system.

| Surfactant Type | Name | Code | Brand |

|---|---|---|---|

| Amphoteric | Erucamidopropyl betaine | EAPB | Macklin |

| Amphoteric | Erucamidopropyl hydroxysultaine | EHSB | Macklin |

Table 3: Types of inorganic salts.

| Chemical Formula | Name | Specification | Brand |

|---|---|---|---|

| Na2SO4 | Sodium sulfate | Analytical Reagent | Aladdin |

| NaHCO3 | Sodium bicarbonate | Analytical Reagent | Aladdin |

| NaCl | Sodium chloride | Analytical Reagent | Aladdin |

| CaCl2 | Calcium chloride | Analytical Reagent | Aladdin |

| MgCl2 | Magnesium chloride | Analytical Reagent | Aladdin |

2.2.1 Construction of the VES Foam Fracturing Fluid System

The key to the construction of the VES foam fracturing fluid system lies in the use of foaming agents and stabilizers. The foam comprehensive value (F) is calculated using Eq. (1) [29], and this value is employed to screen the optimal formulation.

Using deionized water as the base fluid, eight foaming agents with the same concentration (0.2%) were compounded with the same stabilizer at a fixed ratio. A 2 mL aliquot of the compounded base fluid was placed in a 15 mL sample vial and stirred for 1 min at 14,000 rpm using the IKA disperser to obtain the VES foam fracturing fluid. The optimal foaming agent was selected by comparing the foam volume of the three foaming agents in the sample vials under the same temperature and salinity conditions.

The selected foaming agents were compounded with water as the base fluid and two stabilizers from the table below at a fixed ratio. The same procedure was followed, and after stirring for 1 min, the timer was started. The time t1/2 was recorded when the foam’s liquid phase volume reached 1 mL. By comparing the half-life of the two stabilizers under the same temperature and salinity conditions, the optimal stabilizer was selected. Once the optimal stabilizer was identified, base fluids with stabilizer concentrations of 1%, 2%, and 3% were prepared to select the best stabilizer concentration.

2.2.2 Performance Evaluation of VES Foam Fracturing Fluid

- (1)Static sand suspension

- A specified amount of 40/70 mesh quartz sand was added to a beaker containing 100 mL of the prepared base fluid. The mixture was thoroughly stirred to ensure uniform dispersion of the quartz sand within the foam fracturing fluid. Subsequently, the mixture was transferred into a 500 mL graduated cylinder, and the sedimentation behavior of the quartz sand was recorded. The experiments were conducted at two sand concentrations: 33.3% and 50%. Each set of experiments was repeated three times to ensure the accuracy of the measurements.

- (2)Dynamic sand carrying capacity

- In the dynamic sand carrying capacity test, a visual dynamic sand carrying device (see Fig. 1) is used. The foam base fluid is mixed with the same quartz sand as mentioned above and foamed. The mixture is injected from the left end of a plate and flows out from the right end. The experiment is conducted with a sand concentration of 10%. Each set of experiments was repeated three times to ensure the accuracy of the measurements.

Figure 1: Visualized dynamic sand-carrying device.

Rheological Properties of the Fracturing Fluid

The rheological properties of the fracturing fluid are one of its most important characteristics, as they determine the working efficiency of the fluid. At a constant temperature of 70°C, the rheological properties of the VES foam fracturing fluid are measured using a Haake MARS III rotational rheometer. The tests include shear resistance and viscoelasticity tests. For the shear resistance test, the shear rate is set to 170 s−1, and the shear time is 120 min. For the viscoelasticity test, the scanning frequency ranges from 0.01 to 10 Hz.

The damage caused by fracturing fluids to the reservoir is also one of the key factors determining production enhancement. In this study, two natural rock cores from the Lingxing Block were selected. Using an unconventional core evaluation device and following the SYT 5107-2016 performance evaluation method for water-based fracturing fluids, the changes in core permeability before and after the treatment with different fracturing fluids were measured. This allows for an analysis of the impact of fracturing fluids on reservoir damage. The core damage experiments were conducted using two natural sandstone cores from the LX Block, with porosity ranging from 8.81% to 15.23% and initial permeability ranging from 6.56 to 13.21 mD. X-ray diffraction (XRD) analysis showed that the mineral composition was dominated by quartz (62.3%), followed by feldspar (18.7%) and clay minerals (19.0%, mainly kaolinite and illite).

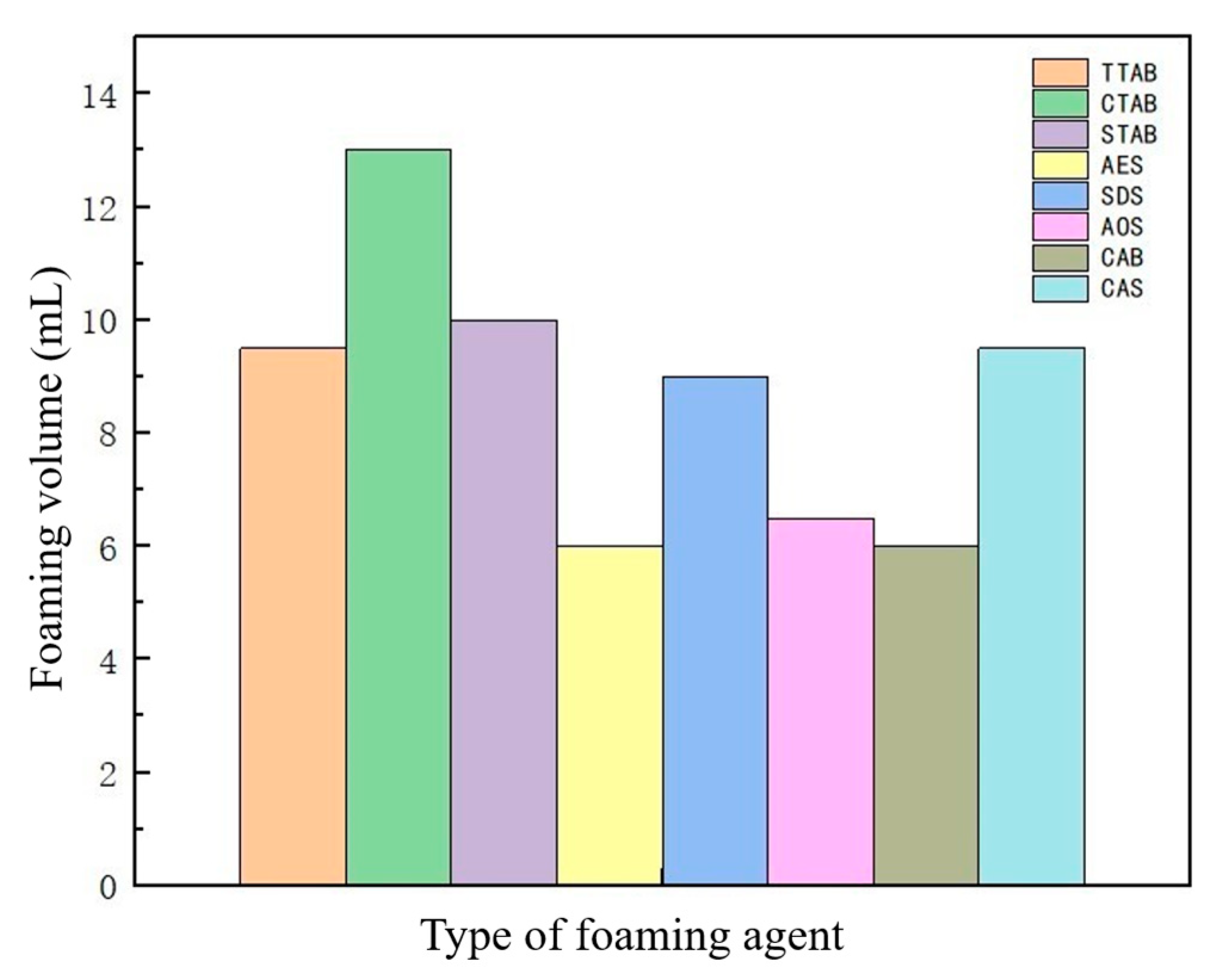

3.1.1 Optimization of Foaming Agent

To identify a suitable foaming agent, we conducted screening experiments at 70°C and a salinity of 30 g/L, which represent typical reservoir conditions in terms of formation temperature and produced water mineralization. The results demonstrated that cationic surfactants exhibited significantly better foaming performance compared to anionic counterparts under high-salinity conditions.

This performance disparity is primarily attributed to the distinct electrostatic and interfacial behaviors of the two surfactant types in saline environments. In particular, anionic surfactants with negatively charged head groups (e.g., -SO3−, -COO−) are prone to electrostatic neutralization and precipitation when exposed to divalent cations (Ca2+, Mg2+), leading to reduced solubility and poor gas–liquid interfacial adsorption. As a result, foams generated by anionic surfactants collapse rapidly due to weak film strength and low stability.

In contrast, cationic surfactants such as cetyltrimethylammonium bromide (CTAB), which carry positively charged head groups, show enhanced compatibility with high-salinity environments. They maintain good solubility and interfacial activity, while also forming more robust foam films that resist coalescence and drainage. This leads to prolonged foam life and improved overall stability.

Therefore, based on the comparative analysis, CTAB was selected as the optimal foaming agent for subsequent experiments due to its superior performance in high-salinity brine, as illustrated in Fig. 2.

Figure 2: Comparison of foam height with different foaming agents.

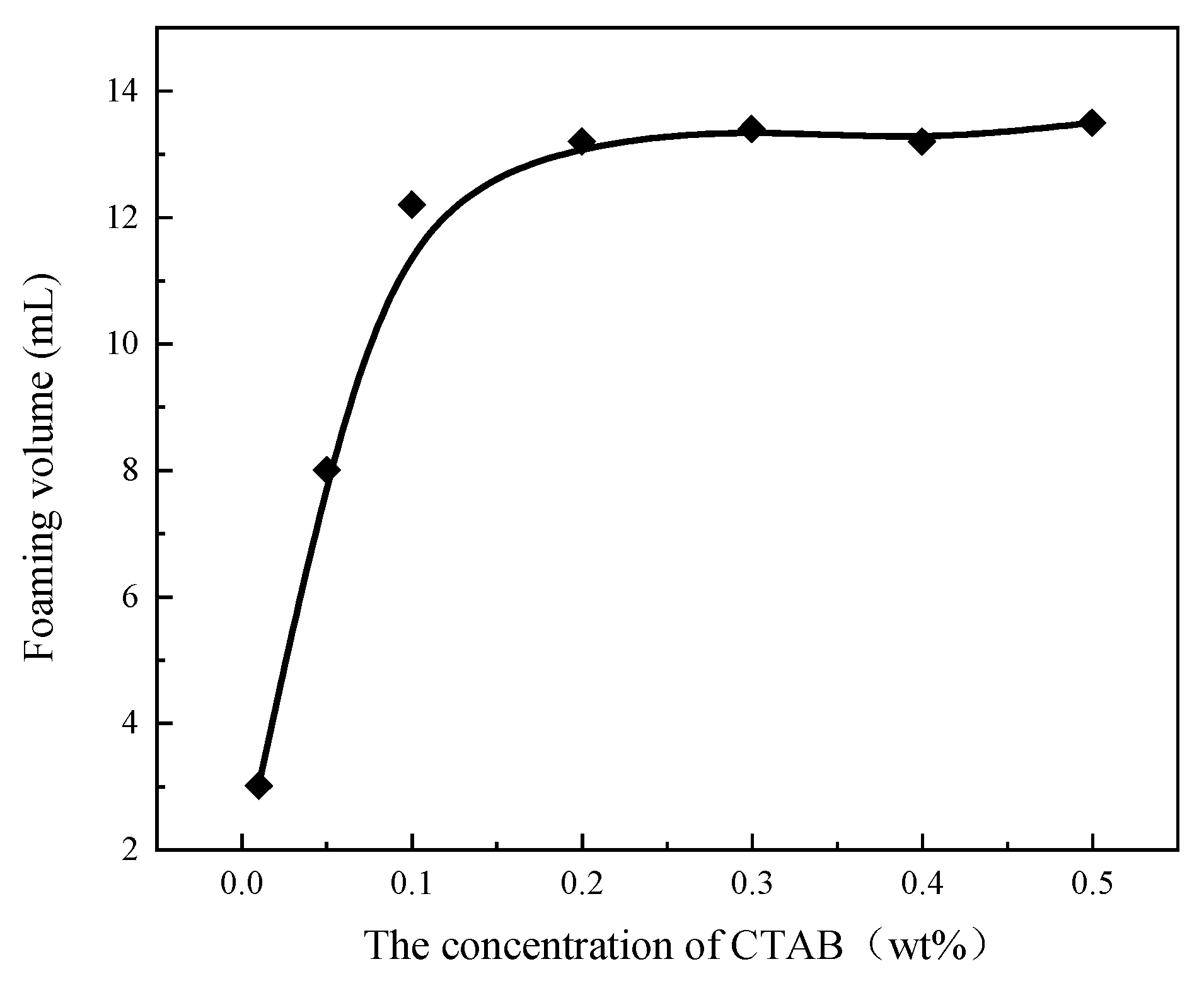

After identifying CTAB as the optimal foaming agent, it is necessary to further optimize its concentration to achieve the most effective dosage. As shown in Fig. 3, the foaming volume of CTAB increases with the rising concentration and then reaches a plateau. When the concentration of CTAB reaches 0.2 wt%, the foaming volume essentially attains its maximum value. Since further increasing the surfactant concentration does not lead to a noticeable enhancement in foaming volume, the optimal concentration of CTAB is determined to be 0.2 wt%.

Figure 3: Optimization of the optimal concentration of foaming agent.

3.1.2 Selection of Foam Stabilizer

Long-chain betaines offer significant advantages over other surfactants in forming wormlike micelles (WLMs), primarily due to their excellent rheological properties, environmental adaptability, controllability, and broad application potential. Firstly, the incorporation of long-chain amide groups enhances hydrophobic interactions, resulting in more stable wormlike micelles, increased solution viscosity, and pronounced shear-thinning behavior. These characteristics improve the fluid’s thickening capacity and proppant-carrying performance, making it highly advantageous for applications such as hydraulic fracturing and enhanced oil recovery (EOR). In addition, the presence of the betaine functional group imparts amphoteric properties to the system, enabling it to maintain favorable rheological behavior under high-temperature, high-salinity, and high-mineralization conditions. This confers superior salt and thermal resistance compared to conventional cationic or anionic surfactants, making long-chain betaines particularly suitable for high-temperature reservoir environments. Compared with traditional quaternary ammonium surfactants or dodecyl betaines, long-chain betaines exhibit greater micellar stability under elevated temperatures and high-shear conditions, effectively preventing micelle dissociation and ensuring the consistent rheological performance of fracturing fluids in extreme conditions. Furthermore, owing to the presence of the betaine group, these surfactants demonstrate superior environmental compatibility, including high biodegradability and low toxicity, aligning well with the principles of green and sustainable development. Notably, wormlike micelle systems formed by long-chain betaines can be intelligently tuned by adjusting external factors such as pH, salt concentration, and shear rate, thereby further broadening their applicability in oilfield chemistry. Therefore, commonly used long-chain betaines, including EHSB and EAPB, were selected as foam stabilizers for the viscoelastic surfactant (VES) fracturing fluid system.

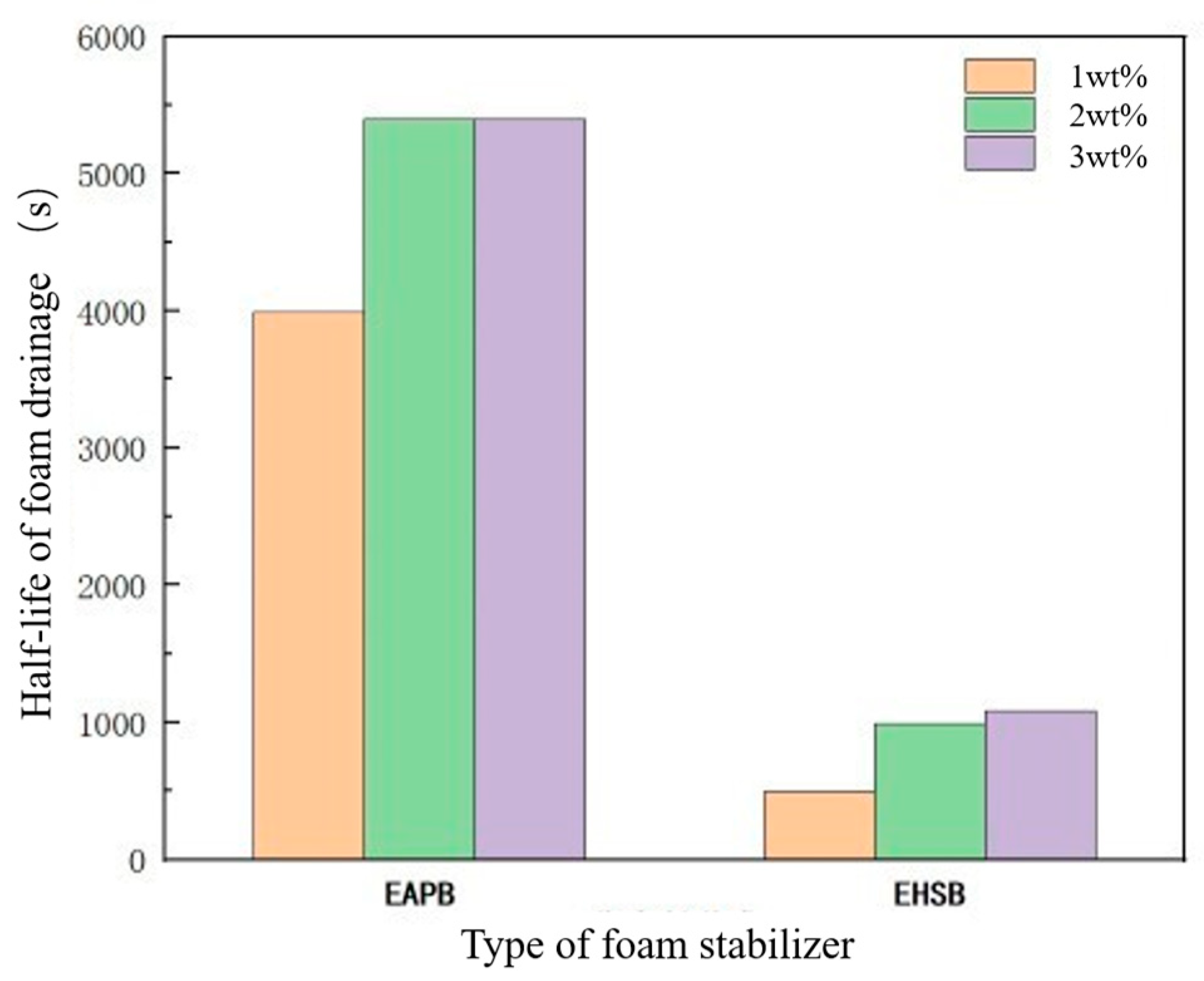

To select the most suitable betaine-based foam stabilizer compatible with the foaming agent, experiments were conducted at 70°C and a salinity of 30 g/L. Two different stabilizers at concentrations of 1%, 2%, and 3% were blended with the previously selected optimal foaming agent to determine the best stabilizer type and concentration. As shown in Fig. 4, erucamidopropyl betaine (EAPB) exhibited significantly better foam stability than Erucamidopropyl hydroxysultaine (EHSB), with a foam drainage half-life of up to 5400 s, making EAPB the optimal foam stabilizer. Although the molecular structures of the two betaines are similar, the key difference lies in the presence of hydroxyl and sulfonate groups in EHSB. However, their foam stabilization performance differs significantly. This discrepancy arises because the strong electrostatic interactions between EHSB and CTAB lead to excessive molecular association or precipitation, weakening interfacial adsorption. Additionally, the larger steric hindrance and higher hydrophilicity of EHSB further reduce interfacial packing efficiency. In contrast, the interactions between EAPB and CTAB are more balanced, resulting in tighter and more dynamic molecular packing, which contributes to superior foaming performance. This phenomenon highlights the delicate balance between “synergistic effects” and “excessive association” in surfactant blending. Furthermore, experimental results showed that at EAPB concentrations of 2 wt% and 3 wt%, the foam drainage half-life remained similar. Therefore, considering economic efficiency, 2 wt% was selected as the optimal foam stabilizer concentration.

Figure 4: Comparison of half-life for water separation with stabilizing agents at different concentrations.

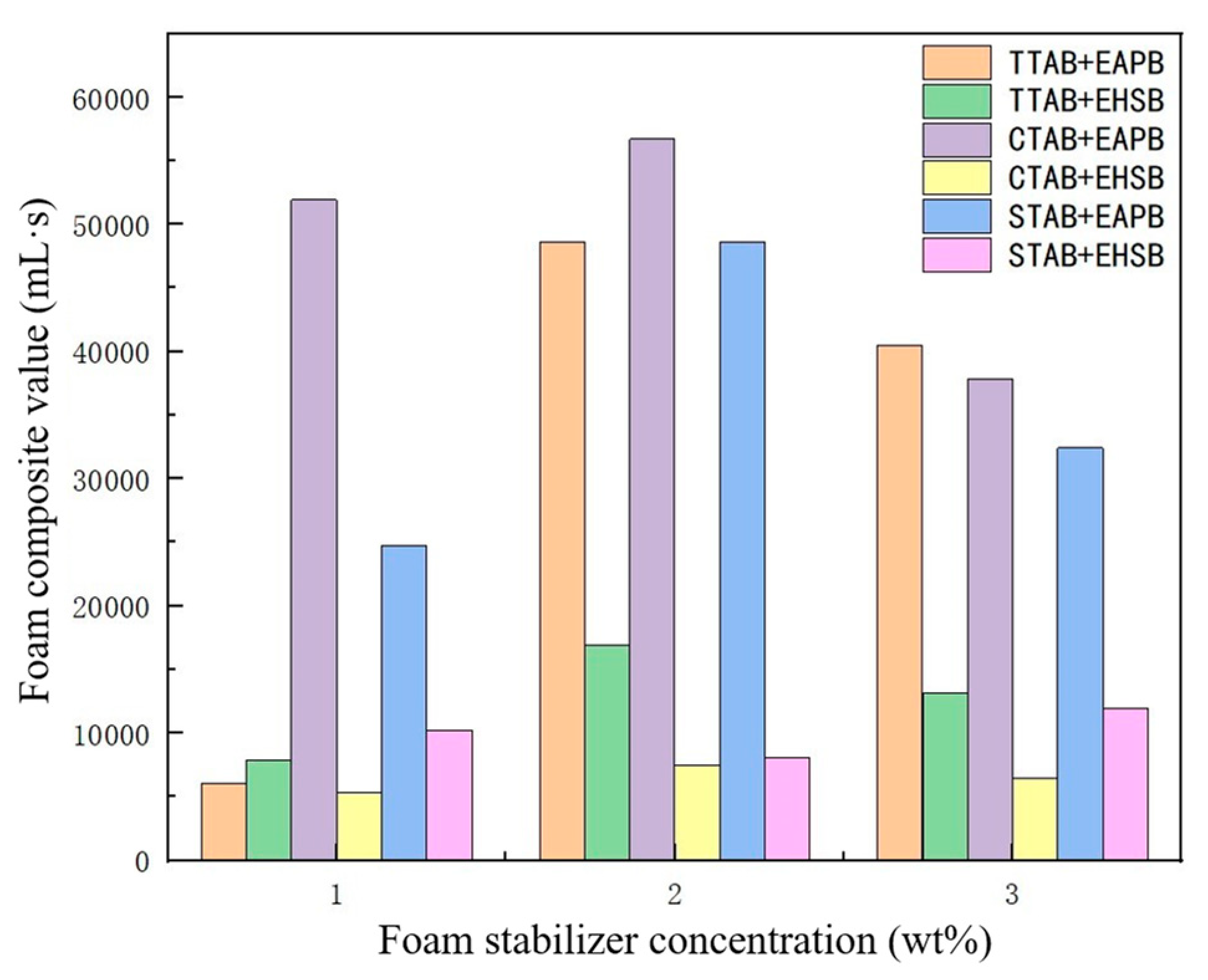

3.1.3 Optimization of Blended System and Mixing Ratio

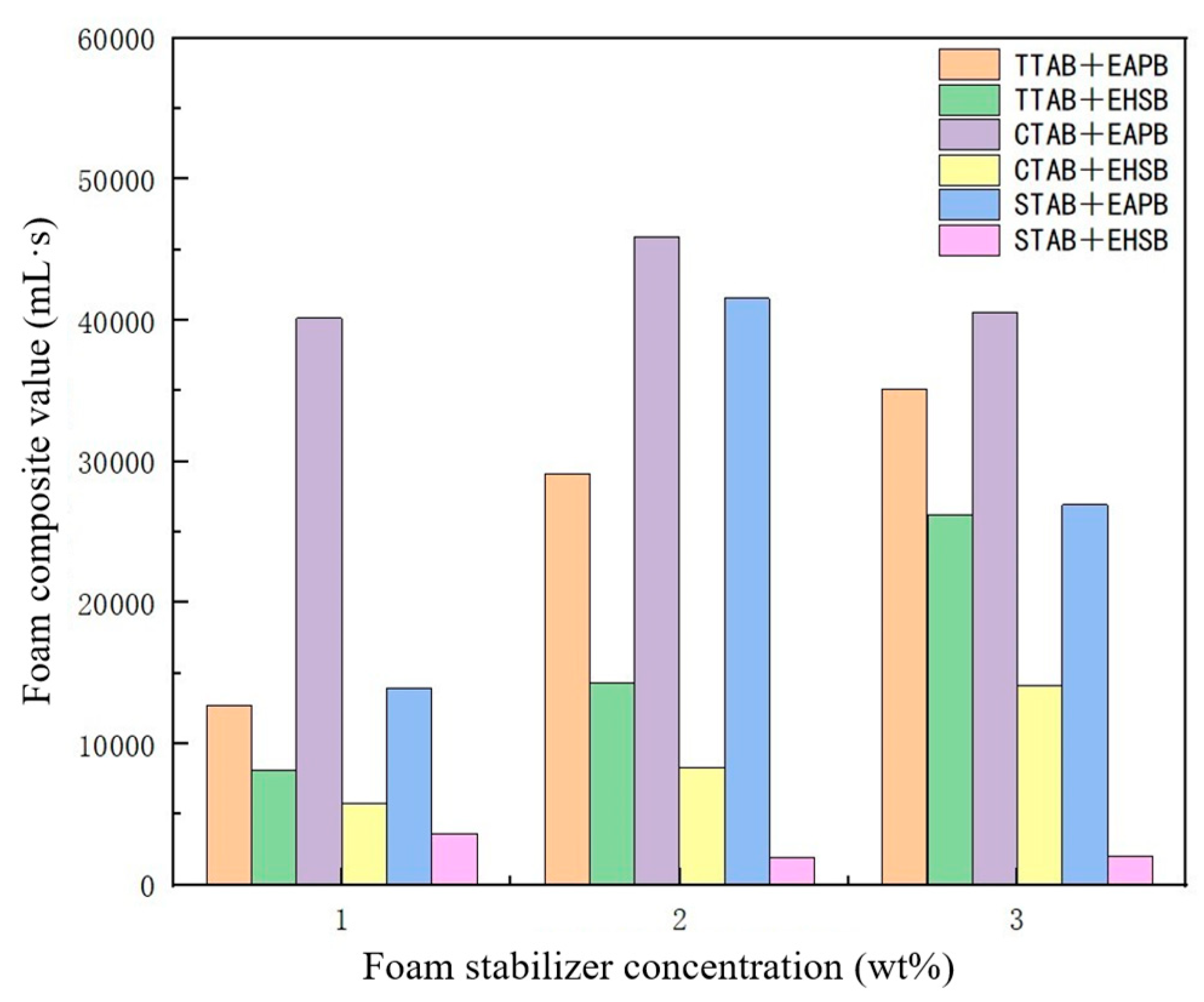

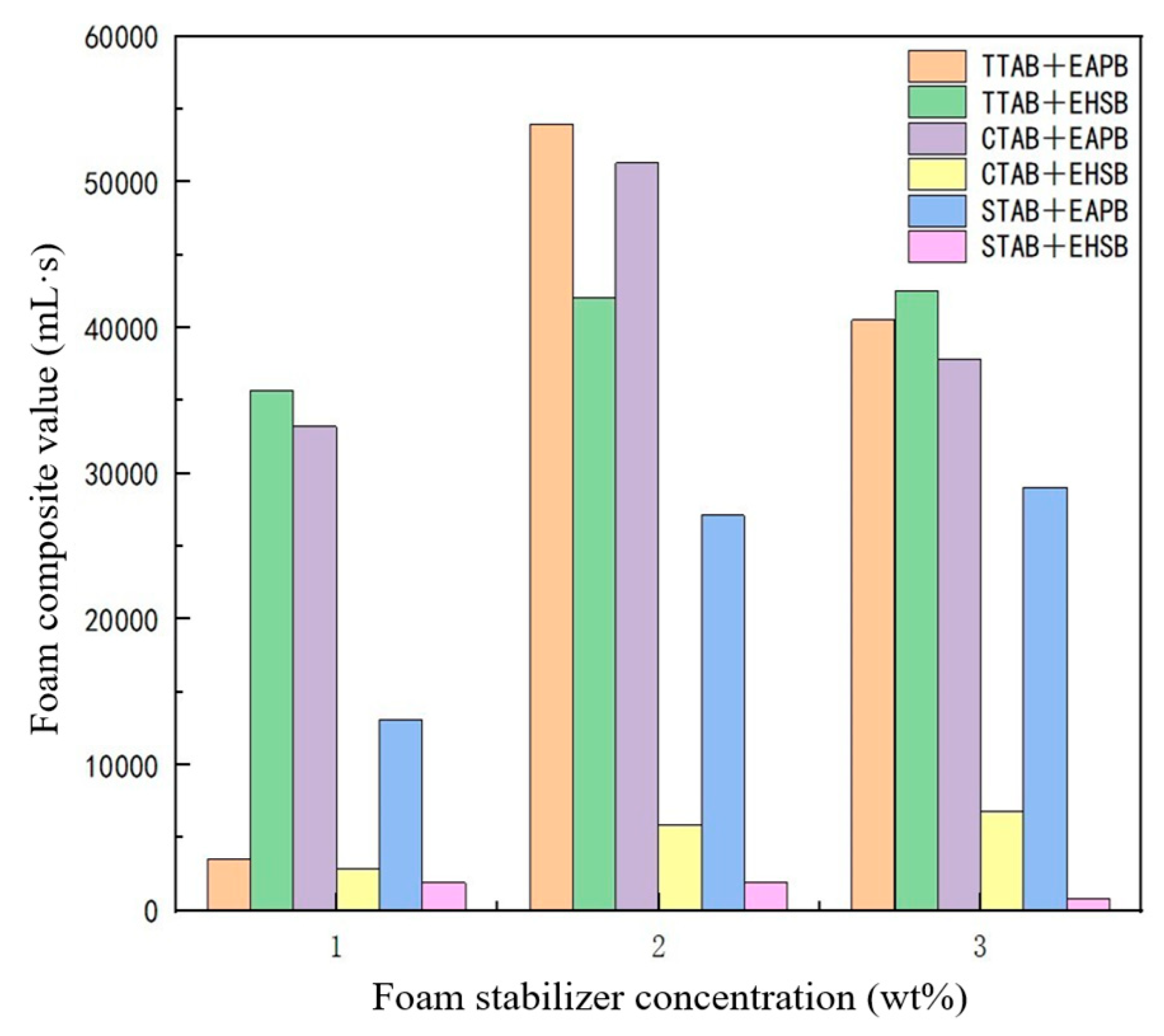

The results obtained from single-factor experiments alone are not sufficient to fully demonstrate that the selected foam stabilizer and foaming agent are optimal. Multiple factors need to be considered, including the salinity of the water sample, external temperature, and the blending ratio of the foam stabilizer and foaming agent, all of which influence foam stability. Based on the foaming agent selection results, cationic surfactants exhibit superior foaming performance compared to anionic and amphoteric surfactants. Therefore, three cationic surfactants were paired with two foam stabilizers in all possible combinations. The experimental results of the six VES foam systems are shown in Fig. 5 and Fig. 6.

Figure 5: Comprehensive foam value at 70°C with 30 g/L mineralization level.

Figure 6: Comprehensive foam value at 70°C with 60 g/L mineralization level.

As shown in Fig. 7, under fixed temperature and salinity conditions, the foam performance index of the blended system exhibits distinct trends depending on the type of foaming agent employed. When the mass fraction of EAPB increases from 1% to 3%, the foam performance index initially increases and then decreases. In contrast, for EHSB, the foam performance index consistently increases as its mass fraction rises from 1% to 3%. These differences can be attributed to the varying aggregation behaviors of VES foam stabilizers with different molecular structures when combined with foaming agents possessing different hydrophobic chain lengths at different concentrations. Such variations influence the degree of spatial network formation and the structural strength of the system, ultimately affecting foam stability and performance.

Figure 7: Comprehensive foam value at 70°C with 90 g/L mineralization level.

The effect of salinity on the foam performance index of the VES system also varies. A moderate increase in salinity can enhance the foam performance index, whereas excessive salinity leads to a decreasing trend. This can be attributed to the dual role of salt in foam stability. The addition of salt ions induces an electrostatic shielding effect, compressing the double electric layer structure of the original micelles, thereby reducing electrostatic repulsion between micelles and promoting micellization in the solution, which increases system viscosity. However, when the salt ion concentration becomes excessively high, wormlike micelles undergo branching, leading to stress relaxation, which results in a decrease in system viscosity and, consequently, a reduction in foam stability. In summary, at low salt concentrations, salt ions enhance solution viscosity and improve foam stability. However, at high concentrations, they disrupt the micellar structure, reduce solution viscosity, and weaken foam stability.

Based on the experimental results, it was observed that at different salinity levels, a formulation containing 2% EAPB and 0.2% CTAB consistently exhibited the highest foam performance index, with a peak value of 56,700 mL·s. Therefore, the optimal formulation was determined to be 0.2% CTAB + 2% EAPB.

3.2.1 Proppant-Carrying Capacity

Static Sand Suspension Capability

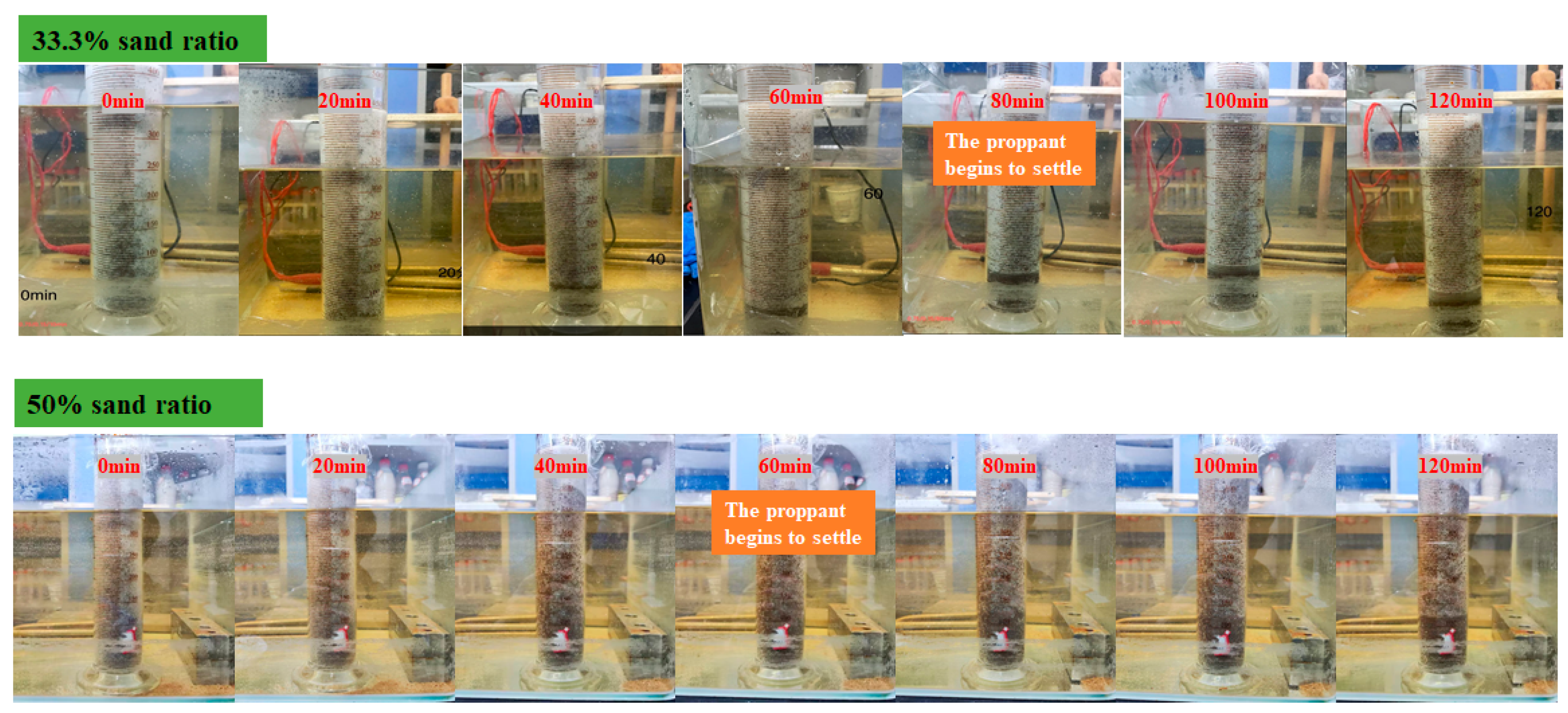

The suspension capability of fracturing fluid for proppants plays a decisive role in proppant placement. Based on the optimized system, we set the sand ratios at 33.3% and 50%, respectively, and tested the settling behavior of 20/40 mesh ceramic proppants in VES foam fracturing fluid. The results are shown in Fig. 8. Due to its unique structure, the foam fracturing fluid exhibits excellent proppant-carrying capability. Even under high sand ratio conditions (33.3% and 50%), it demonstrates outstanding suspension performance. At a sand ratio of 50%, the ceramic proppants began to settle at 60 min, whereas at a sand ratio of 33.3%, settling occurred at 80 min. Moreover, in both cases, the proppants had not completely settled even after 120 min. Quantitatively, the sedimentation ratio within 120 min was approximately 12% for the 33.3% sand ratio and about 18% for the 50% sand ratio, indicating that the majority of proppants remained well suspended. These findings confirm that the optimized VES foam fracturing fluid system possesses excellent proppant suspension performance, even under high proppant loading.

Figure 8: Sedimentation of proppant in foam fracturing fluid.

Moreover, the static proppant suspension capability of foam fracturing fluid varies under different sand ratio conditions. This is primarily attributed to the formation of liquid drainage channels on the proppant surface, which accelerates foam drainage and reduces foam stability. Due to the hydrophilic nature of the ceramic proppant surface, a thin water film forms on it. This water film facilitates the downward movement of liquid along the proppant surface, further accelerating foam drainage, thereby weakening foam stability and proppant-carrying capacity. This explains why the proppant settling rate increases under the 50% sand ratio condition.

Dynamic Sand-Carrying Capacity Test

Dynamic sand-carrying capacity and static sand-suspension capability are equally crucial in hydraulic fracturing operations. As a key parameter characterizing foam’s ability to transport proppants, the dynamic sand-carrying capacity directly determines critical performance metrics including the migration distance of proppants within fractures and their spatial distribution patterns. Superior dynamic carrying performance enables precise placement of proppants at predetermined geological locations through optimized fluid viscosity, velocity control, and stable foam structures. This ensures the formation of highly conductive support networks within fracture systems. Meanwhile, the static suspension capability maintains uniform particle distribution during operational pauses, preventing gravitational settling. Only through the synergistic combination of robust dynamic transportation and effective static suspension can engineers achieve comprehensive proppant placement control, creating optimal permeability channels that significantly enhance reservoir stimulation effectiveness and long-term production sustainability.

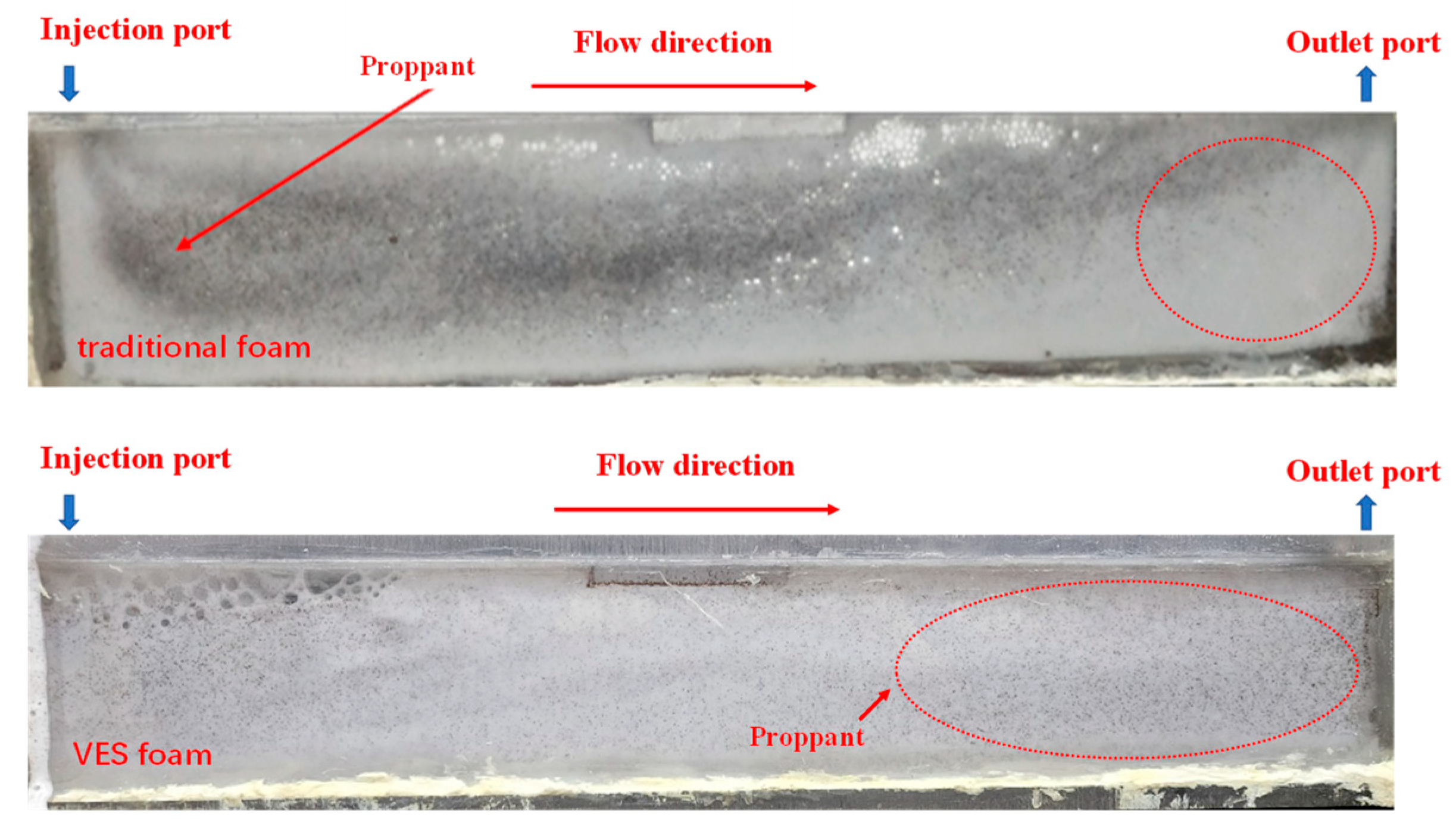

Fig. 9 compares the dynamic sand-carrying performance of the optimized VES foam and the conventional VES foam system (formulated with sodium salicylate and cetyltrimethylammonium bromide) under identical injection rates and a sand concentration of 20%. It can be observed that throughout the injection process, the optimized VES foam maintains a uniform proppant distribution within the observation plate. Notably, uniform dispersion is still observed at the outlet end of the plate, indicating excellent sand-carrying capacity during injection. No noticeable settling of proppants occurs during transport, demonstrating superior dynamic sand-carrying performance. In contrast, the conventional VES foam exhibits an evidently uneven proppant distribution, with a significantly higher concentration near the inlet and visible sedimentation occurring early in the injection. This suggests a markedly lower dynamic transport capability. Furthermore, the non-uniform distribution at the outlet end implies that although the conventional foam can deliver proppants to the far end of the fracture, settling occurs during migration, leading to discontinuous proppant placement, reduced fracture conductivity, and insufficient effective propped length. These shortcomings ultimately compromise the effectiveness of the fracturing operation and the long-term enhancement of production performance. The underlying reasons for such performance differences can be analyzed from both interfacial and bulk-phase perspectives. From an interfacial standpoint, the EAPB + CTAB system, due to the long-chain erucic acid structure and zwitterionic nature of EAPB, forms a denser and more stable foam film at the gas–liquid interface. This densely packed structure significantly reduces interfacial tension while imparting higher elasticity and mechanical strength to the foam film, making it more resistant to rupture under shear stress. Consequently, the foam exhibits longer lifespan and enhanced load-bearing capacity for proppants. In contrast, sodium salicylate (NaSal), a small aromatic carboxylate, can indeed induce ion pair formation with CTAB to generate linear micelles, but it provides limited reinforcement to the foam film. The resulting films tend to be thinner and more brittle, prone to liquid drainage and collapse, thereby limiting the foam’s sand-carrying efficiency. From a bulk-phase perspective, the EAPB + CTAB system forms ultra-long wormlike micelles, which entangle to construct a three-dimensional elastic network. This structure significantly enhances the viscoelasticity and shear-recovery capability of the system. Even under high shear rates or elevated proppant concentrations, the network retains its stability, contributing to excellent particle suspension performance. In contrast, the NaSal + CTAB system forms relatively short micelles with weak entanglement, and its microstructure is highly sensitive to salinity and temperature, leading to poor bulk viscoelasticity and inadequate proppant suspension over extended periods. Additionally, the anionic segment of EAPB synergistically interacts with CTAB to form pseudo-gemini structures, which further improve micellar flexibility and resistance to external perturbations.

Figure 9: Sand carrying conditions during the injection process of VES foam fracturing fluid.

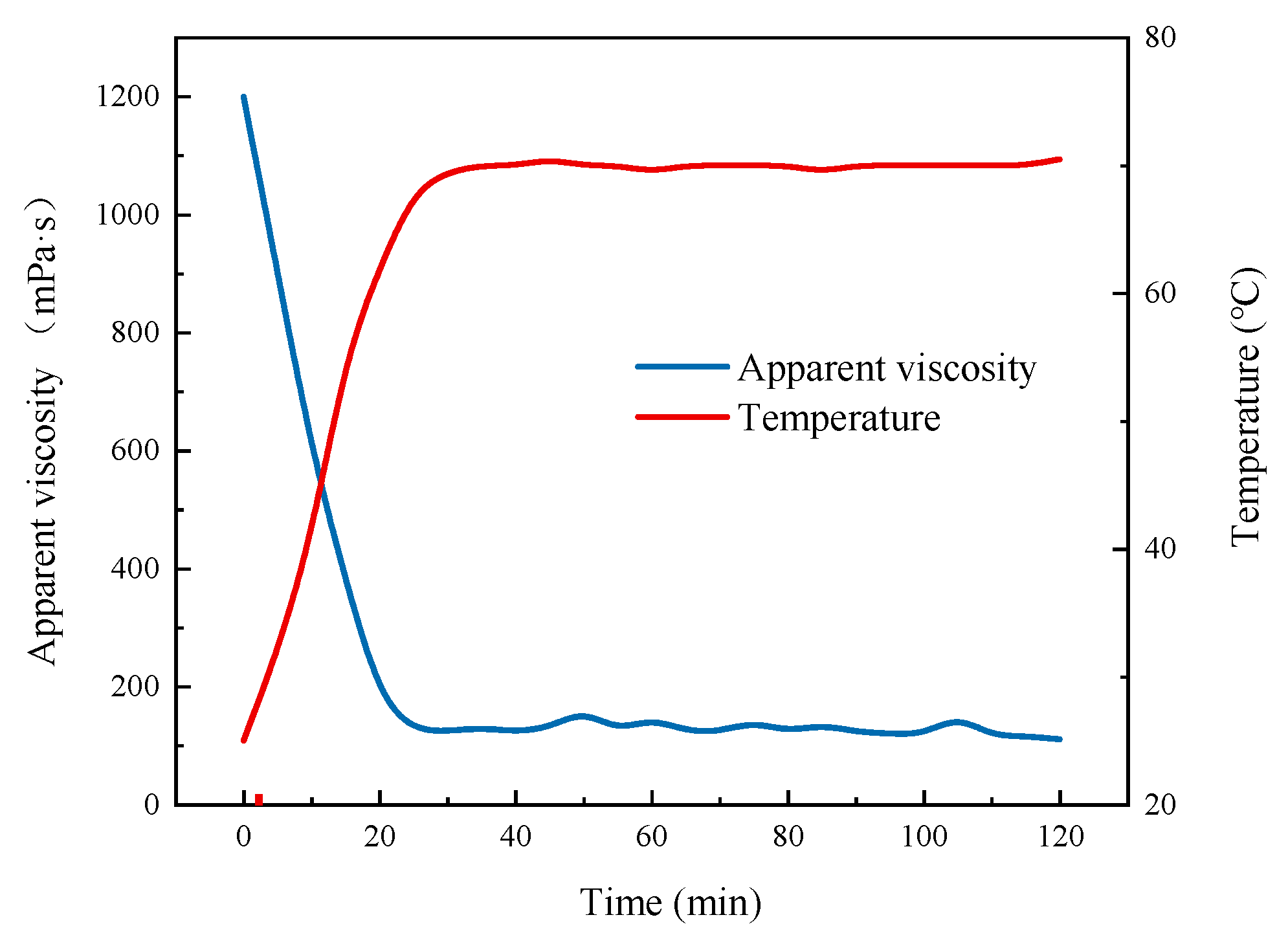

We tested the temperature and shear resistance of the foam fracturing fluid at 70°C, and its variation curve is shown in the Fig. 10 below. It can be observed that after shearing for 120 min at 70°C and 170 s−1, the apparent viscosity of the foam system remained at 120 mPa·s. This indicates that during the injection process of the fracturing fluid, when the shear rate reaches its maximum value (170 s−1), the system still maintains a viscosity above 120 mPa·s, effectively preventing the settling of proppant in the fracturing fluid. This also indirectly validates the accuracy of the proppant transportability test.

Figure 10: Shear resistance test results of VES foam.

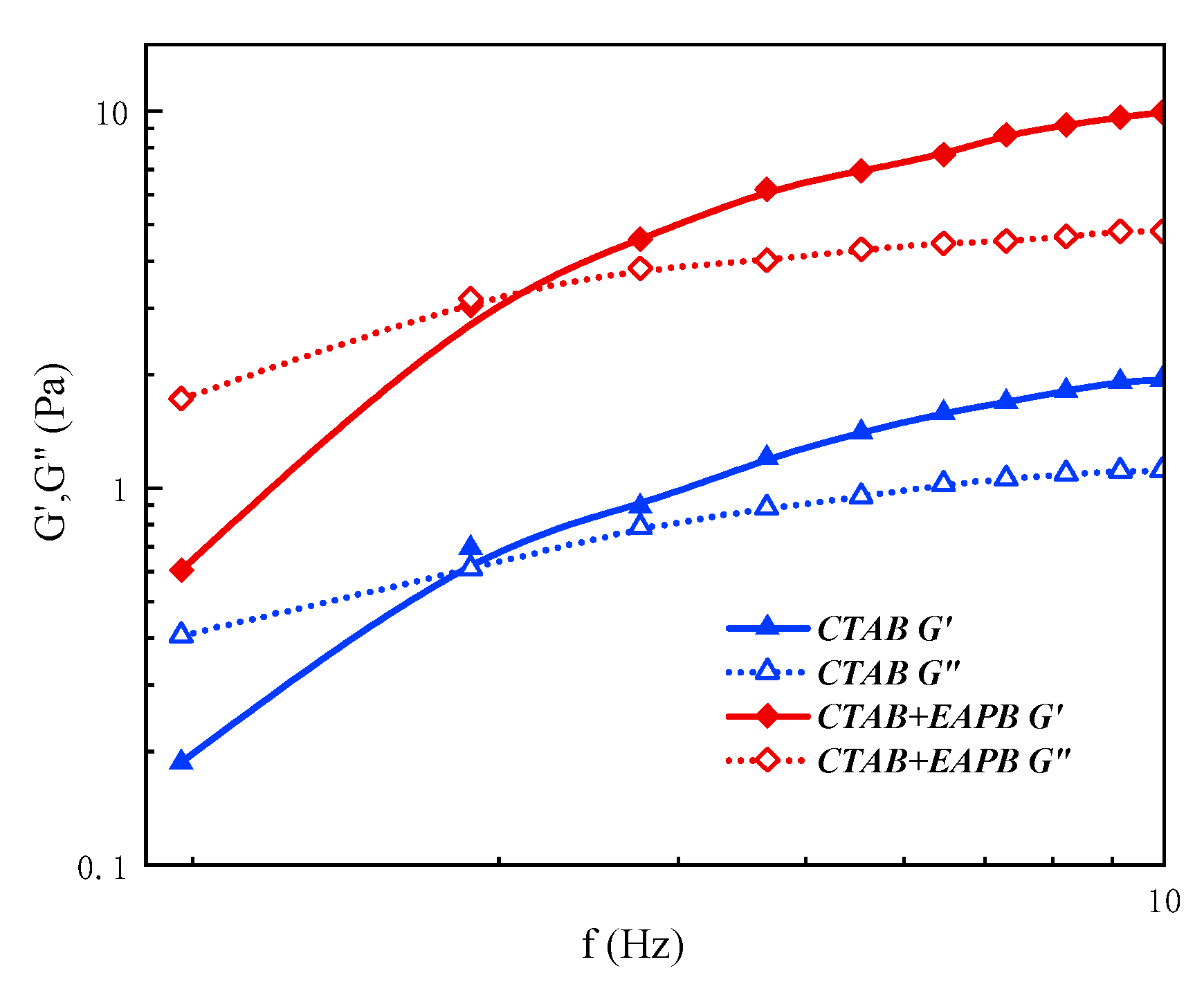

Meanwhile, the viscoelasticity of foam is also an important indicator for evaluating the performance of a foam system. The viscoelasticity test results of the foam fracturing fluid are shown in Fig. 11, where the elastic modulus (G′) and viscous modulus (G″) are measured as functions of frequency. By comparing the elastic modulus of the VES foam system with that of a single surfactant foaming system, it is evident that the elastic modulus of the VES foam is significantly higher than that of the single surfactant foam. Moreover, as the frequency increases, the difference between the two elastic moduli gradually widens, indicating that the VES system exhibits superior elastic properties. This enhancement in elasticity substantially improves the strength of the VES foam, making it less susceptible to external disturbances and degradation.

Additionally, the excellent elasticity of the VES foam system contributes to its superior proppant-carrying capability. When proppant particles act on the foam, the foam deforms to counteract the gravitational force of the proppant. Once the deformation reaches a certain extent, the proppant remains suspended in the foam. The strong elasticity of the VES foam ensures that it maintains its strength even after deformation, which prevents proppant settling even under high proppant concentration conditions. The right figure illustrates the variation of the viscous modulus with oscillation frequency for both the enhanced VES foam system and the single surfactant foam system. The results show that with increasing frequency, the viscous modulus of both systems increases. However, the viscous modulus of the VES foam remains consistently higher than that of the single surfactant foam, indicating that the VES foam system retains better viscosity. In foam systems, higher viscosity effectively slows liquid drainage and reduces the diffusion of gas molecules within the liquid film, significantly improving foam stability. The excellent viscoelasticity of the VES foam system confirms its strong proppant-carrying ability and enhanced foam stability, further corroborating the findings of the previous experimental studies.

Figure 11: The variation of elastic modulus and viscous modulus with scanning frequency.

Using core samples from a tight sandstone reservoir, the cores were first dried and then tested using an unconventional core evaluation device to measure the permeability before damage. Subsequently, experiments were conducted with both the VES system and conventional fracturing fluid to determine the permeability after damage, with the results presented in Table 4. As shown in Table 4, the original damage rate of the VES fracturing fluid is 4.42%, which is significantly lower than that of the guar gum system (20%–35%). This indicates that the VES fracturing fluid is highly suitable for enhancing production in low-permeability tight reservoirs.

Table 4: Damage to core samples caused by VES foam fracturing fluid and guar gum-based fracturing fluid.

| Fracturing Fluid Type | Permeability mD | Damage Rate/% | |

|---|---|---|---|

| Before Damage | After Damage | ||

| VES | 13.03 | 12.42 | 4.42 |

| Guar gum | 12.14 | 9.40 | 22.57 |

In this study, single-factor experiments were first conducted to screen eight different types of foaming agents and two different types of foam stabilizers at varying concentrations. The results showed that cationic foaming agents exhibited significantly superior foaming performance compared to anionic and amphoteric foaming agents. Experimental findings identified cetyltrimethylammonium bromide (CTAB) as the optimal foaming agent, achieving a maximum foam height of 13 mL, while erucamidopropyl betaine (EAPB) was selected as the optimal foam stabilizer, exhibiting a water separation half-life of up to 5400 s. Subsequently, the selected foaming agent and stabilizer were combined for formulation optimization, and the optimal composition was determined to be 0.2% CTAB + 2% EAPB. Experimental results further revealed that increasing the salinity within a certain range enhanced the comprehensive foam performance and stability of the system. Under conditions of 70°C and a salinity of 90 g/L, the VES foam fracturing fluid achieved a comprehensive foam value of 56,700 mL·s, indicating good thermal and salinity resistance and highlighting its great potential for field applications.

The performance evaluation of the VES system further confirmed its effectiveness. The sand-carrying performance tests demonstrated that at sand concentrations of 33% and 50%, the volume of the foam–sand mixture remained nearly constant over 120 min, effectively ensuring the uniform distribution of proppants within fractures. Rheological evaluation revealed that the apparent viscosity of the system increased over time, and both the elastic modulus (G′) and viscous modulus (G″) of the optimized VES system were higher than those of the single-foaming-agent system. Furthermore, the difference between the elastic modulus and viscous modulus widened with increasing frequency, indicating enhanced elasticity at higher shear rates. The excellent viscoelastic properties of the VES system ensured structural integrity and foam stability after deformation. In addition, formation damage evaluation showed that the VES system caused significantly lower damage compared to conventional guar gum fracturing fluids (20%–35%), with the damage rate reduced to only 4.42%.

Therefore, the VES foam system developed in this study demonstrated outstanding performance, providing a more cost-effective and environmentally friendly fracturing fluid system for future oilfield fracturing operations. Since the VES foam system is a low-water system, its widespread application in unconventional oil and gas development is of great significance for water resource conservation and environmental protection.

Acknowledgement:

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: Jie Bian, Liang Zhang; data collection: Xuesong Feng, Jiachen Hu; analysis and interpretation of results: Ji Yu, Chao Zhou; draft manuscript preparation: Tian Lan, Yu Li. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Wanniarachchi WAM , Ranjith PG , Perera MSA . Shale gas fracturing using foam-based fracturing fluid: a review. Environ Earth Sci. 2017; 76: 1– 15. doi:10.1007/s12665-017-6399-x. [Google Scholar] [CrossRef]

2. Qin Q , Zhou K , Wei B , Du Q , Liu Y , Li X , et al. Experimental and simulation study on deep reservoir fracturing technology: a review and future perspectives. Geoenergy Sci Eng. 2024; 242: 13209. doi:10.1016/j.geoen.2024.213209. [Google Scholar] [CrossRef]

3. Agarwal M , Kudapa VK . Foam based fracking in unconventional shale reservoir. Mater Today Proc. 2023; 72: 2785– 90. doi:10.1016/j.matpr.2022.06.419. [Google Scholar] [CrossRef]

4. Zhu J , Zheng N , Yang Z , Li X , Lei T . Experimental study on the foam-stabilizing advantages and foam stabilization mechanism of novel microbial polysaccharides. J Mol Liq. 2023; 385: 122428. doi:10.1016/j.molliq.2023.122428. [Google Scholar] [CrossRef]

5. Creatto EJ , Alvarenga BG , de Moura PG . Viscosity-driven stabilization of CO2-in-brine foams using mixtures of cocamidopropyl hydroxysultaine and sodium dodecyl sulfate. J Mol Liq. 2021; 329: 115614. doi:10.1016/j.molliq.2021.115614. [Google Scholar] [CrossRef]

6. Bello A , Ivanova A , Cheremisin A . Enhancing N2 and CO2 foam stability by surfactants and nanoparticles at high temperature and various salinities. J Petrol Sci Eng. 2022; 215: 110720. doi:10.1016/j.petrol.2022.110720. [Google Scholar] [CrossRef]

7. Zhu J , Yang Z , Li X , Hou L , Xie S . Experimental study on the microscopic characteristics of foams stabilized by viscoelastic surfactant and nanoparticles. Colloid Surf A. 2019; 572: 88– 96. doi:10.1016/j.colsurfa.2019.03.087. [Google Scholar] [CrossRef]

8. Cserháti T , Forgács E , Oros G . Biological activity and environmental impact of anionic surfactants. Environ Int. 2002; 28( 5): 337– 48. doi:10.1016/S0160-4120(02)00032-6. [Google Scholar] [CrossRef]

9. Kume G , Gallotti M , Nunes G . Review on anionic/cationic surfactant mixtures. J Surfactants Deterg. 2008; 11( 1): 1– 11. doi:10.1007/s11743-007-1047-1. [Google Scholar] [CrossRef]

10. Lémery E , Briançon S , Chevalier Y . Skin toxicity of surfactants: Structure/toxicity relationships. Colloids Surface A. 2015; 469: 166– 79. doi:10.1016/j.colsurfa.2015.01.019. [Google Scholar] [CrossRef]

11. Boethling RS . Environmental aspects of cationic surfactants. In: Cationic surfactants. Boca Raton, FL, USA: CRC Press; 2019. p. 95– 136. doi:10.1201/9780429270376-6. [Google Scholar] [CrossRef]

12. Sarkar R , Pal A , Rakshit A . Properties and applications of amphoteric surfactant: a concise review. J Surfactants Deterg. 2021; 24( 5): 709– 30. doi:10.1002/jsde.12542. [Google Scholar] [CrossRef]

13. Sun YQ , Zhang YP , Liu QW , Fan ZZ , Li N , Wei AQ . Research progress on new highly efficient foam drainage agents for gas wells (a review). Pet Chem. 2023; 63( 9): 1119– 31. doi:10.1134/S0965544123080029. [Google Scholar] [CrossRef]

14. Chowdhury S , Rakshit A , Acharjee A , Saha B . Novel amphiphiles and their applications for different purposes with special emphasis on polymeric surfactants. ChemistrySelect. 2019; 4( 23): 6978– 95. doi:10.1002/slct.201901160. [Google Scholar] [CrossRef]

15. Hou J , Huang T , Alotaibi M , Abdulkareem A . Long-term thermal stability of ionic surfactants for improving oil production at high-salinity high-temperature conditions. ACS omega. 2024; 9( 10): 11976– 86. doi:10.1021/acsomega.3c09734. [Google Scholar] [CrossRef]

16. Ju S , Huang Q , Wang G , Li J , Wang E , Qin C , et al. Rheological and morphological characteristics of foam fluid using hydroxypropyl guar and surfactant. J Petrol Sci Eng. 2022; 211: 110124. doi:10.1016/j.petrol.2022.110124. [Google Scholar] [CrossRef]

17. Zhao J , Yu Y , Wu K , Liu Y , Zhu Y , Lu H , et al. A novel CO2 foam stabilizer based on natural polysaccharide psyllium seed gum: experimental and molecular dynamics analysis. Carbohydr Polym. 2025; 123972. doi:10.1016/j.carbpol.2025.123972. [Google Scholar] [CrossRef]

18. Ishii M , Murata S , Ishitsuka K , Liu W . Stability of novel cellulose-nanofiber-containing foam as environmentally friendly fracturing fluid. J Petrol Scie Eng. 2022; 208: 109512. doi:10.1016/j.petrol.2021.109512. [Google Scholar] [CrossRef]

19. Alarawi A , Busaleh A , Saleh TA , Alharbi B . High thermal stability of foams stabilized by graphene oxide and zwitterionic surfactant nanocomposites for fracturing applications. Fuel. 2023; 332: 126156. doi:10.1016/j.fuel.2022.126156. [Google Scholar] [CrossRef]

20. Zheng N , Zhu J , Yang Z , Jiang Z , Li X , Zhang J , et al. Study on the key performance and stabilization mechanism of viscoelastic scCO2 foams: the formation of pseudo-gemini surfactants. J Mol Liq. 2024; 399: 124477. doi:10.1016/j.molliq.2024.124477. [Google Scholar] [CrossRef]

21. Gu M , Mohanty KK . Rheology of polymer-free foam fracturing fluids. J Petrol Sci Eng. 2015; 134: 87– 96. doi:10.1016/j.petrol.2015.07.018. [Google Scholar] [CrossRef]

22. Ahmed S , Elraies KA , Hashmet MR . Viscosity models for polymer free CO2 foam fracturing fluid with the effect of surfactant concentration, salinity and shear rate. Energies. 2017; 10( 12): 1970. doi:10.3390/en10121970. [Google Scholar] [CrossRef]

23. Khan JA , Padmanabhan E , Haq IU , Nurudeen Y . Experimental assessment of fracture initiation and wettability in low and high brittle shales by CO2 foam fracturing fluids. Energy Fuels. 2022; 36( 15): 8288– 300. doi:10.1021/acs.energyfuels.2c00310. [Google Scholar] [CrossRef]

24. Hanamertani AS , Mohamed AI , Saraji S , Piri M . Foam-assisted hydrocarbon gas injection in oil-wet fractured carbonate: in situ investigation of fracture–matrix interactions. Transp Porous Media. 2024; 151( 10): 2081– 117. doi:10.1007/s11242-024-02107-7. [Google Scholar] [CrossRef]

25. Aboahmed AK , Youssif MI , Piri M , Lamia G . Nanofluid-based foam for enhanced oil recovery in fractured carbonates. Energy Fuels. 2023; 37( 23): 18772– 84. doi:10.1021/acs.energyfuels.3c02816. [Google Scholar] [CrossRef]

26. Li X , Zhang X , Wang L . Self-assembled viscoelastic surfactant micelles with pH-responsive behavior: a new fracturing-displacement integrated working fluid for unconventional reservoirs. ACS omega. 2024; 9( 21): 22691– 702. doi:10.1021/acsomega.4c00459. [Google Scholar] [CrossRef]

27. Fu C , Liu N . Study of the synergistic effect of the nanoparticle-surfactant-polymer system on CO2 foam apparent viscosity and stability at high pressure and temperature. Energy Fuels. 2020; 34( 11): 13707– 16. doi:10.1021/acs.energyfuels.0c02435. [Google Scholar] [CrossRef]

28. Wei P , Guo K , Xie Y , Huang X . Liquid foam stabilized by a CO2-responsive surfactant and similarly charged cellulose nanofibers for reversibly plugging in porous media. ACS Appl Mater Interfaces. 2022; 14( 32): 37134– 48. doi:10.1021/acsami.2c08986. [Google Scholar] [CrossRef]

29. Qajar A , Xue Z , Worthen AJ , Johnston KP , Chun H , Bryant S , et al. Modeling fracture propagation and cleanup for dry nanoparticle-stabilized-foam fracturing fluids. J Petrol Sci Eng. 2016; 146: 210– 21. doi:10.1016/j.petrol.2016.04.008. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools