Open Access

Open Access

ARTICLE

Analysis of the Relationship between Mechanical Properties and Pore Structure of MSW Incineration Bottom Ash Fine Aggregate Concrete after Freeze-Thaw Cycles Based on the Gray Theory

1 School of Civil Engineering, Inner Mongolia University of Technology, Hohhot, 010000, China

2 Xingtai Construction Group Co., Ltd., Hohhot, 010000, China

3 Inner Mongolia Electric Power (Group) Company Limited Mengdian Project Construction and Management Branch, Hohhot, 010000, China

* Corresponding Author: Dongsheng Shi. Email:

(This article belongs to the Special Issue: Sustainable Concrete with Recyclable Materials)

Journal of Renewable Materials 2023, 11(2), 669-688. https://doi.org/10.32604/jrm.2022.022192

Received 25 February 2022; Accepted 04 May 2022; Issue published 22 September 2022

Abstract

The destruction of concrete building materials in severely cold regions of the north is more severely affected by freeze-thaw cycles, and the relationship between the mechanical properties and pore structure of concrete with fine aggregate from municipal solid waste (MSW) incineration bottom ash after freeze-thaw cycles is analyzed under the degree of freeze-thaw hazard variation. In this paper, the gray correlation method is used to calculate the correlation between the relative dynamic elastic modulus, compressive strength, and microscopic porosity parameters to speculate on the most important factors affecting their changes. The GM (1,1) model was established based on the compressive strength of the waste incineration ash aggregate concrete, the relative error between the simulated and actual values in the model was less than 5%, and the accuracy of the model was level 1, indicating that the GM (1,1) model can well reflect the change in the compressive strength of the MSW incineration bottom ash aggregate concrete during freeze-thaw cycles. Using the gray correlation method, the correlation between the relative dynamic elastic modulus, compressive strength, air content, specific surface area, pore spacing coefficient, and pore average chord length was calculated, and the pore spacing coefficient and pore average chord length were determined to be highly correlated with each other. This determination can help analyze and infer the deterioration mechanism of concrete subject to freeze-thaw cycles. These results can provide a theoretical basis for guiding the engineering practice of concrete with fine aggregates of household bottom ash in the northern cold region.Keywords

With the widespread adoption of municipal waste incineration, the amount of bottom ash generated by incineration is also increasing [1–3]. The common methods implemented for MSW management are land-filling, composting, and incineration [4]. Use of municipal solid waste inert as a powerful replacement of fine aggregate in mortar cube [5]. Mortar made from concrete slurry waste (CSW) and municipal solid waste incineration bottom ash (MSWIBA) could be recycled into cold bonded lightweight aggregates (CBLA) [6]. The amount of domestic waste removed in 2020 was 235 million tons [7], the amount of MSW incinerated harmlessly in 2020 was approximately 146 million tons [8], and the percentage of MSW treated by incineration was approximately 62.1%. At present, the resource utilization of MSW incineration bottom ash in the field of construction engineering mainly includes the following aspects: replacing pavement base material [9]; foam glass with good performance was prepared by using MSW incineration bottom ash as the main raw material [10], etc. Currently, our team has studied the carbonation and resistance to chloride-ion penetration of fine aggregate concrete from MSW incineration and has tested the mechanical properties simulated by engineering members made from MSW incineration ash concrete under simulated construction conditions [11,12]. The test results have shown that the radioactivity of the test ash is within the safe range and can be used for the preparation of construction materials without any restriction and without any impact on environmental safety [13]. The results of the solid toxic substances leaching tests from MSW incineration bottom ash meet the relevant regulations and can be used as concrete aggregates [14]. To study the relationship between the mechanical properties and porosity characteristics of the material and to reasonably match the distribution of the solid phase and porosity, it is urgent to prepare porous materials with high porosity and high strength [15].

In 1982, Chinese scholar Professor Deng Julong developed gray systems theory, which is a new approach to studying uncertainty in systems with little data and poor information [16,17]. Information incompleteness, as the main feature of an uncertain system, has the following characteristics. a) Incomplete element information, b) incomplete structural information, c) incomplete boundary information, and d) incomplete operational behavior information [18]. Gray system theory uses the gray system method and modeling technology, through the analysis of a small amount of “known information”, to identify the key information and relationships in the system and to predict the future development trend of the system [19,20]. GM has differences and compatibility, GM structure has elasticity and diversity, GM is a constant coefficient in nature, and its parameter distribution is gray [21]. As a very active branch of gray system theory, gray correlation analysis is mainly based on the similarity of the series curve geometry to determine whether the connection between different series is strong or not, and the closer the geometry is, the greater the correlation.

As one of the three major factors of concrete damage, freeze-thaw action plays an important role in the research field of concrete durability [22]. In Northern China, the freeze-thaw cycle is the main factor for the decline in structural durability [23]. In the United States, freeze-thaw has become the cause of reinforced concrete structures in cold regions such as North Dakota main factor of deterioration of mechanical properties [24].

This paper focuses on the prediction of the compressive strength of household waste incineration ash aggregate concrete and normal concrete (control group) using the mean GM (1,1) model with the gray theory system and the decay of the compressive strength with an increase in the number of freeze-thaw cycles to predict the compressive strength values in the future. From the microscopic point of view, the pore parameters, such as air content, specific surface area, pore spacing coefficient, and average pores chord length, were analyzed by the gray correlation method to determine the correlation and influence on the compressive strength and relative dynamic elastic modulus of concrete after freeze-thaw cycles to determine the most influential factors on the freezing performance of concrete and to guide engineering practice.

2 Experimental Overview and Results

2.1 Test Material and Concrete Mix Ratio

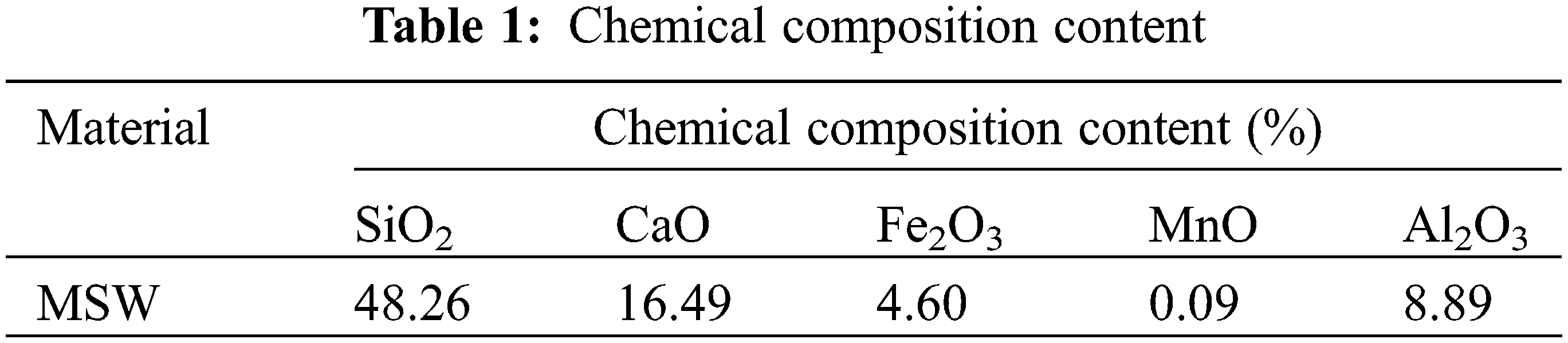

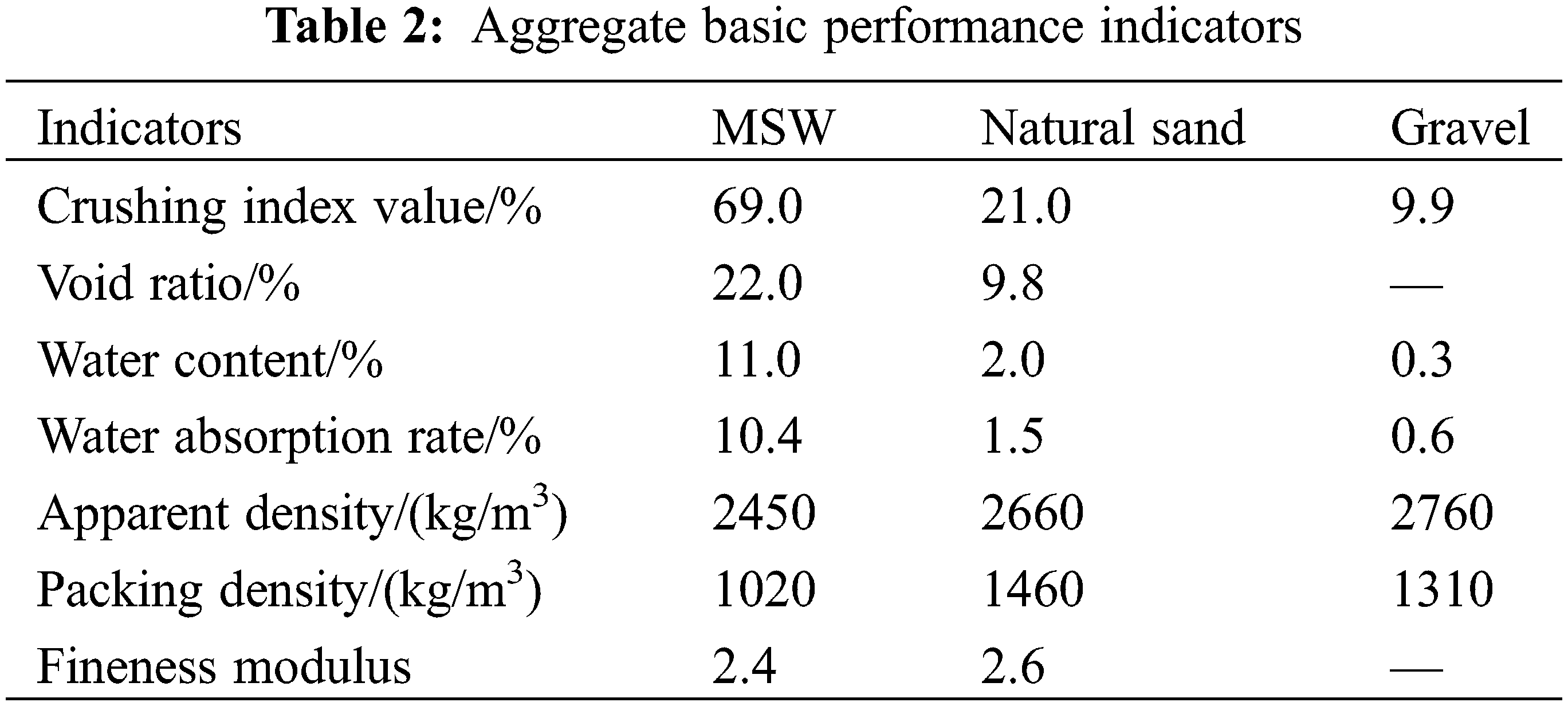

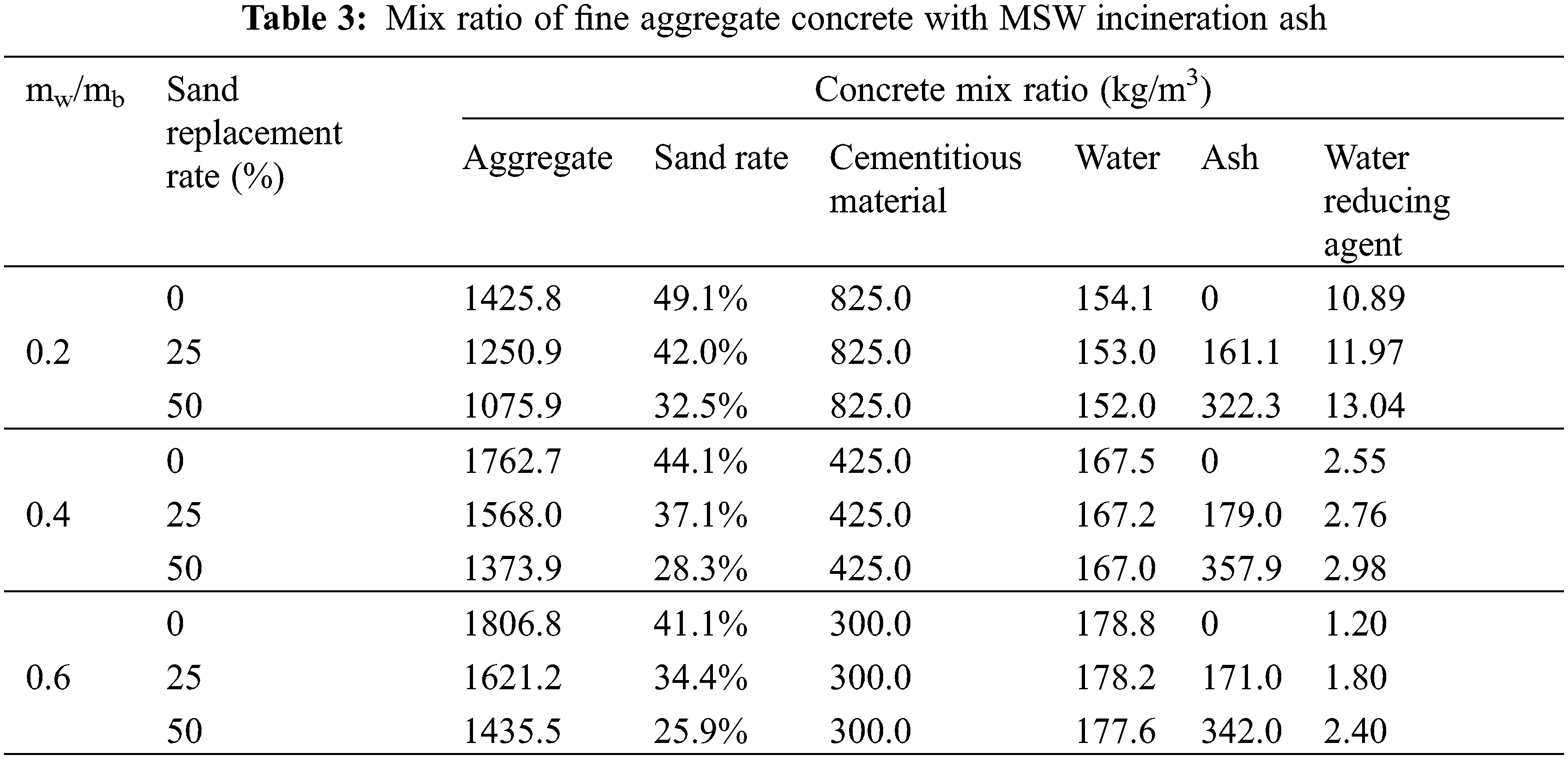

The proportions used in this test were designed by the volumetric method, and the composition of the concrete is outlined below. The MSW incineration bottom ash was from a waste treatment plant in Hohhot, Inner Mongolia, and had a chemical composition similar to that of natural sand, consisting of some oxides. The main chemical composition of the ash from MSW is listed in Table 1. The sand was natural washed sand from the Dahei River in Hohhot, Inner Mongolia. The gravel was first grade crushed granite from Daqing Mountain, Hohhot, Inner Mongolia, with a particle size of 5∼20 mm. The basic performance indicators of aggregates are listed in Table 2. The cement was P⋅O 42.5 grade ordinary silicate cement produced by Jidong Cement Plant in Hohhot. The silica fume was from Lingshou County, Shijiazhuang. The water-reducing agent was polycarboxylic acid high-efficiency water reducing agent, which has the characteristics of low admixture and a high water reducing rate, and the water reducing rate was more than 35% when the admixture was approximately 1%. The tested compounds are listed in Table 3. Three water-cement ratios of 0.2, 0.4, and 0.6 were selected to cover high strength, medium strength, and ordinary strength concrete, and three sand replacement rates (Srr) of 0%, 25%, and 50% were set under each water-cement ratio.

(1) Freeze-thaw test method

The test was by the “Standard for long-term performance and durability of ordinary concrete test methods” (GB/T 50082-2009) using a rapid freeze-thaw method. Specifically, the cube specimen of 100 × 100 × 100 mm3 was used to measure the freezing and thawing times that the concrete can withstand. The relative dynamic modulus of elasticity of MSW incineration bottom ash fine aggregate concrete was measured after every 25 freeze-thaw cycles and the compressive strength of the specimens was measured after 0, 25, 50, 75, 100, 200, and 300 freeze-thaw cycles to analyze and evaluate the freezing resistance of the concrete with ash from MSW incineration. The relative dynamic modulus of elasticity and the mass loss rate is nondestructive methods, so the damage to the concrete specimens can be observed and evaluated in overall freeze-thaw cycles.

(2) Mechanical properties test method

The test was carried out according to the requirements of the “Standard for Mechanical Properties of General Concrete” (GB/T 50081-2002). The cube specimen with the size of 100 × 100 × 100 mm3 is made to test the compressive strength of concrete. The final cube compressive strength of the test is the average value of the pressure measured by the three specimens, and the test data is accurate to 0.1 Mpa. Since the specimen used in the test is a non-standard cube specimen, the cube compressive strength value obtained according to the standard requirement needs to be multiplied by a size conversion coefficient of 0.95.

(3) Optical method of measuring the pore structure

This test uses the optical method to measure the pore structure of the concrete with fine aggregate from MSW incineration. The test instrument was Rapid Air 457. The Rapid Air 457 concrete pore structure analyzer is manufactured by Concrete Experts International in Denmark. The Rapid Air 457 includes an automated analysis system, a computer control unit (PC) and a color monitor, a camera lens and a microscope objective mounted on a mobile bench, a user-friendly analysis software running under Microsoft Windows. a pore structure analyzer for hardened concrete, which can quickly analyze the pore surface area, air content, bubble spacing coefficient, bubble average chord length, and other parameters and can be used to evaluate the frost resistance of concrete from the side by the bubbles and pores [25]. After the number of freeze-thaw cycles of MSW incineration ash fine aggregate concrete is reached, the cube test block of 100 × 100 × 100 mm3 is cut by a cutting machine, and the test block is cut into 100 × 100 × 10 mm3 thin slices. In the grinding process, 320 mesh, 600 mesh, 800 mesh, 1200 mesh silicon carbide, and water 1:1 were used to prepare the solution. The solution was poured into the disc regularly according to the amount of mesh from low to high, and the time interval was about 10 min until the surface of the specimen was smooth and smooth. After grinding, clean and mark the specimen. Melt Vaseline into liquid and white zinc oxide powder according to the proportion of 1:1 to the viscous solution, use knife evenly spread on the surface of the test piece (black side of the surface). Then a knife is used to gently scrape the mixed solution on the surface of the test piece, and a layer of mineral oil is smeared on the surface of the test piece. Finally, the mineral oil is wiped clean and the preparation of the test piece is completed. Subsequently, the micro-pore structure was tested.

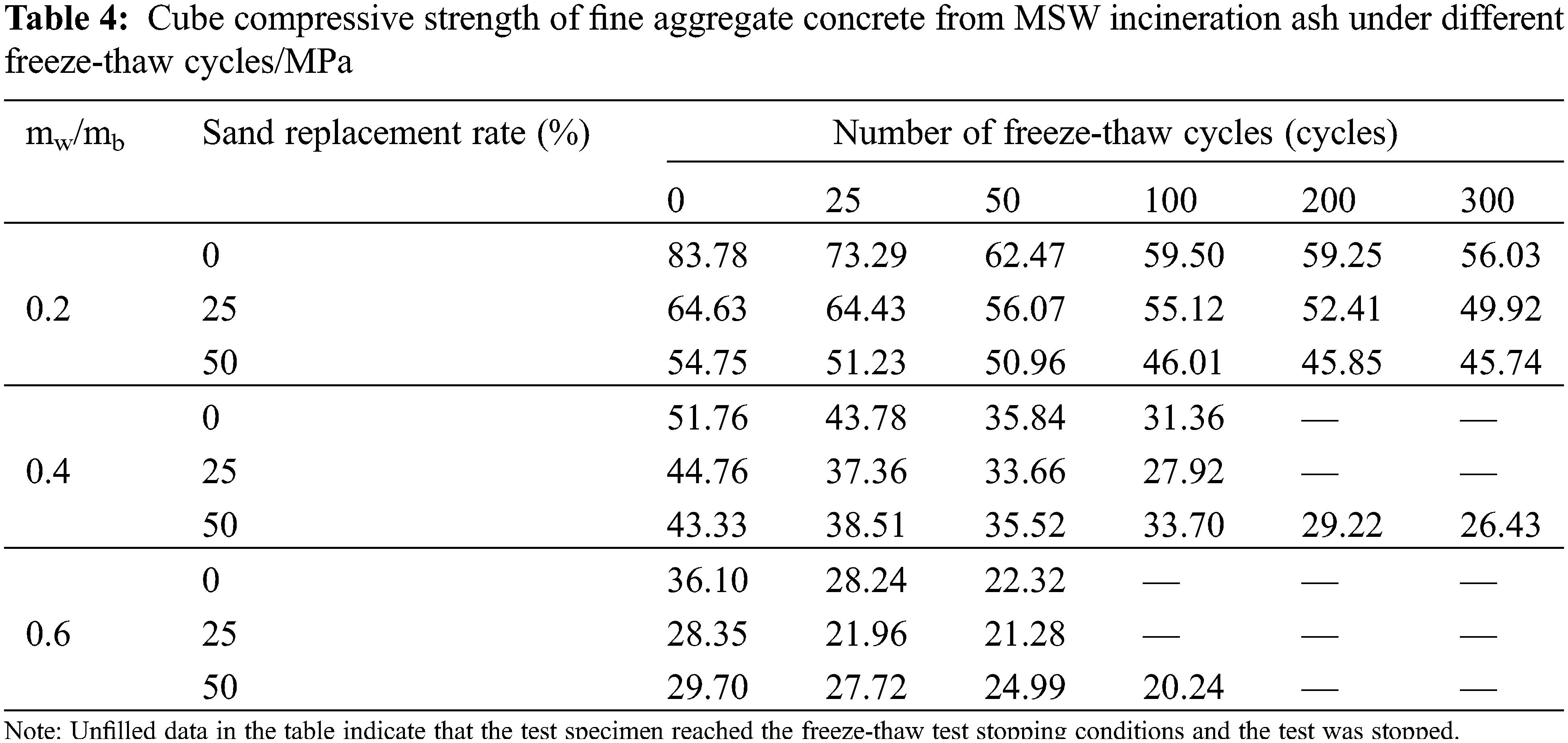

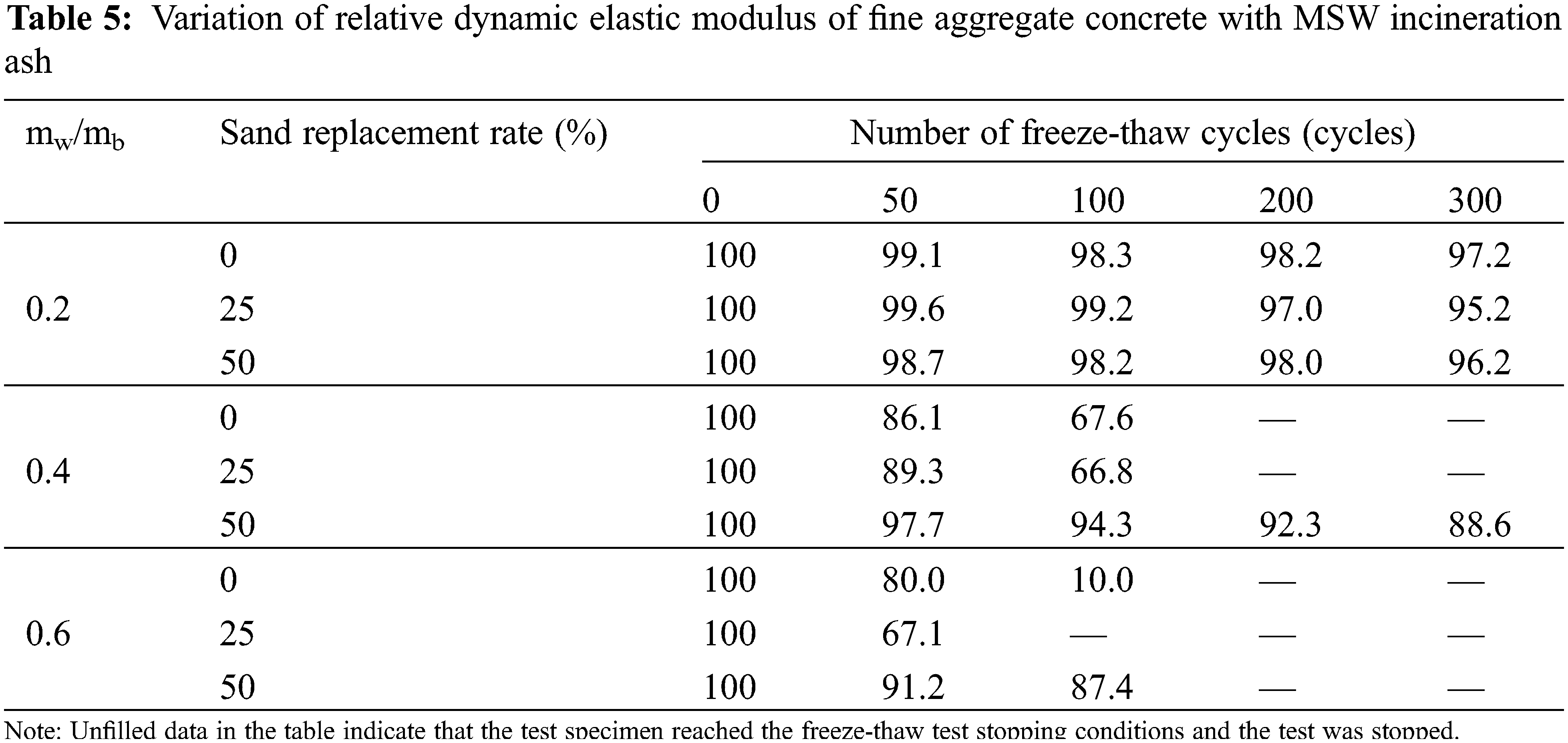

The compressive strength values of the concrete with fine aggregates from MSW incineration bottom ash for different numbers of freeze-thaw cycles are listed in Table 4. The values of the relative dynamic elastic modulus of concrete with fine aggregates from MSW incineration are listed in Table 5. The microscopic pore structure characteristic parameters of concrete with fine aggregates from MSW incineration are listed in Table 6.

3 Gray Theory of Strength under Freeze-Thaw Cycles

Many prediction models are using gray system theory, and since the GM (1, N) model considers many factors, there is also a correlation between each factor. Therefore, it is difficult for the analyst to strip out the most direct factors affecting the test from the model. After many studies, a better effect was found using the single-factor model GM (1,1), meaning a first-order, one-variable gray model, and this model is a basic and comprehensive prediction model [26]. According to the compressive strength values of concrete with fine aggregates from MSW incineration bottom ash, the GM (1,1) model was established to predict the change in the compressive strength with the increase in the number of freeze-thaw cycles and to analyze and evaluate the frost resistance of concrete.

3.1 Establishing the GM (1,1) Model

Set sequence

where x(0)(k) ≥ 0, k = 1,2,…,n. X(1) is the 1-AGO sequence of X(0), i.e., the accumulation of (1) yields the generating series.

where,

where,

The mean value form of the GM (1,1) model is obtained:

Derivation of Eq. (4) with respect to time t yields the whitening equation for the GM (1,1) model:

The parameter vector

where

The solution of the whitening equation of the GM (1,1) model, i.e., the time response equation, is obtained as

Then, the simulated values of the original data are

where a and b are unknown parameters, −a is the development coefficient, which reflects the development trend of

Model residuals

Means and variances of the original series

Means and variances of the residual series

Mean-variance ratio

The small error probability p

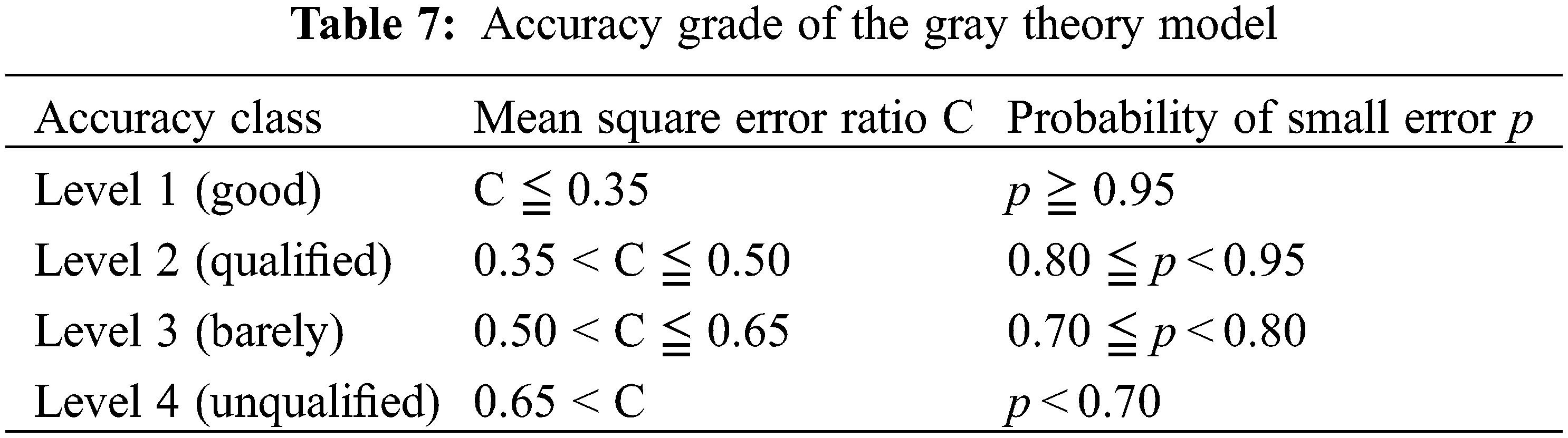

The smaller the C-value is, the better the model; in general, the C-value should be less than 0.35, and the maximum should not exceed 0.65. Another index is needed to evaluate the accuracy of the model: the larger the small error probability p value is, the higher the accuracy of the model; in general, the p value should be greater than 0.95, and the minimum should not be less than 0.70. According to the above conditions, the model prediction accuracy is divided into four levels, as see Table 7.

3.3 Compressive Strength Prediction and Analysis

In this prediction, the compressive strength of MSW incineration bottom ash fine aggregate concrete and ordinary concrete at 0, 25, 50, 100, 200, and 300 freeze-thaw cycles are the original series X(0), and the GM (1,1) prediction model is established according to the method described in 3.1, and the calculation steps are as follows:

(1) The measured compressive strength values of each group of specimens after freeze-thaw cycles were accumulated and processed to obtain the 1-AGO series, as listed in Table 8.

Using Eqs. (4) and (6), based on the principle of least squares, the development coefficient a and the gray effect b were calculated to obtain the solution (time response series) of the whitening equation given by Eqs. (2)–(5), i.e., the gray prediction model, as listed in Table 9.

Using the gray prediction model for forecasting, the obtained results are listed in Fig. 1.

Figure 1: Calculation results of the GM (1,1) model

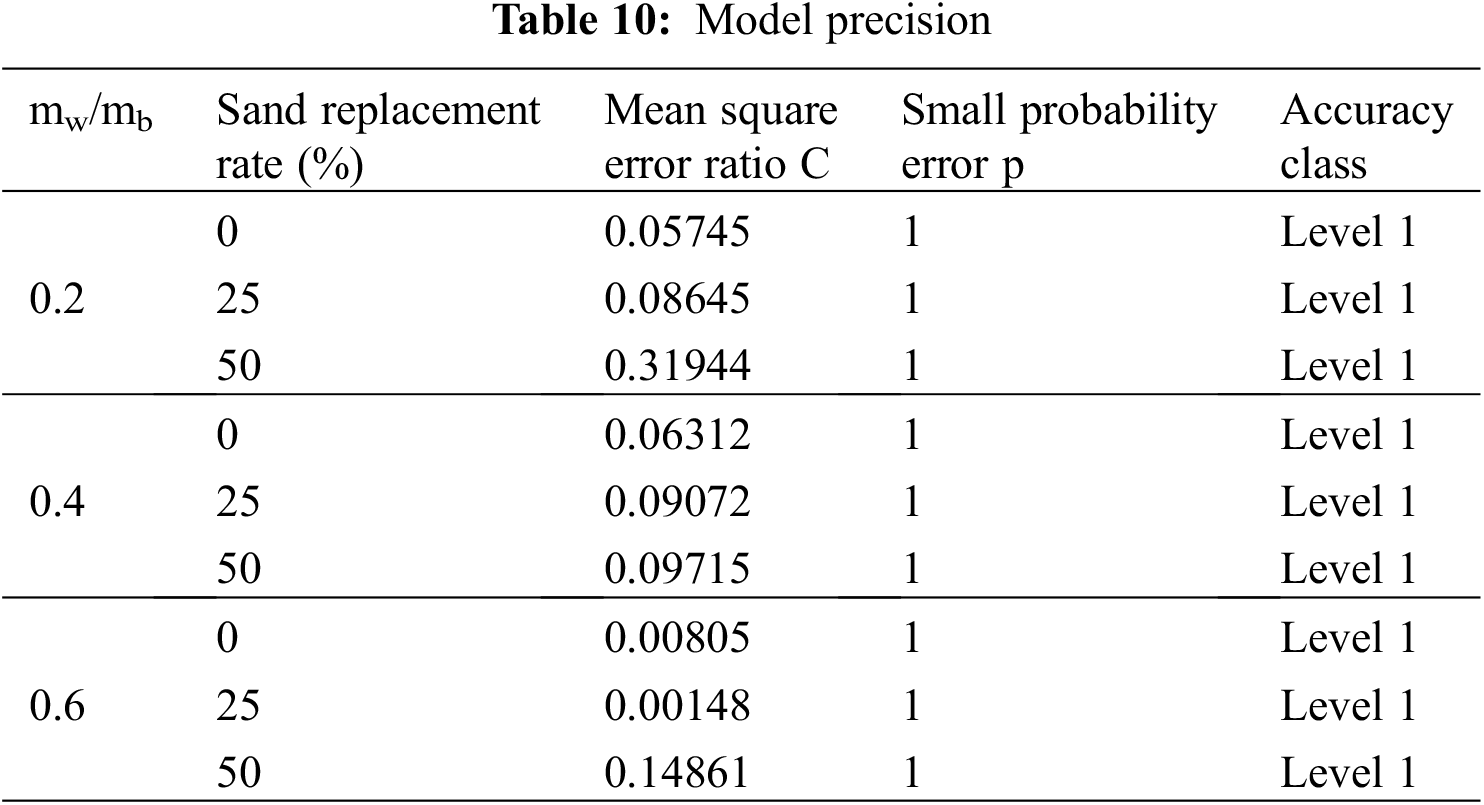

After obtaining the prediction results of the GM (1,1) model, the accuracy of the model was tested according to the method described in Section 2.2, and the results obtained are listed in Table 10.

Fig. 1 shows that the model predicts the compressive strength of concrete with fine aggregate from MSW incineration after freeze-thaw cycles using the GM (1,1) model, regardless of whether it is mixed with MSW incineration bottom ash. The model predictions are better, and the relative errors are less than 5% when comparing the test values with the simulated values, which means that the model can predict the compressive strength values of concrete after freeze-thaw cycles well. As seen in Table 13, the mean squared error ratio C obtained from the actual and predicted values of each group of tests is less than 0.35, the small probability error is 1, which is greater than 0.95, and the prediction accuracy of each group of models is first class, which indicates that the compressive strength of concrete with fine aggregate from MSW incineration bottom ash in freeze-thaw cycles can be effectively predicted using the mean GM (1,1) model, which can accurately reflect the frost resistance of concrete in freeze-thaw cycles.

4 Analysis of the Relationship between Pore Structure and Macroscopic Performance Based on Gray Correlation

The test results show that with the increasing number of freeze-thaw cycles, the relative dynamic modulus of elasticity of concrete with fine aggregate from MSW incineration gradually decreases, and the compressive strength also gradually decreases with the increasing number of freeze-thaw cycles; through the determination of the microscopic pore structure of concrete, it is found that the pore parameters also change with the process of freeze-thaw cycles. Therefore, in this section, the effects of air content, specific surface area, pore spacing coefficient, and average chord length on the macroscopic properties of concrete are analyzed by using the gray correlation method, and the factors that have the greatest influence on the macroscopic properties of concrete are obtained so that the macroscopic properties of concrete can be evaluated more comprehensively. In this way, the allows the macroscopic properties of the concrete to be evaluated more comprehensively.

4.1 Gray Correlation Analysis Method

Let the system behavior sequence be the following:

For ξ ∈ (0, 1), let

where ξ is the discrimination coefficient, and γ(x0, xi) is called the gray correlation between X0 and Xi.

The gray correlation is calculated as follows:

(1) Find the initial value of each sequence. Let

(2) Find the absolute value sequence of the difference between the initial values of X0 and Xi like the corresponding components, and write

(3) Find

The maximum and minimum values, respectively, are denoted as

(4) Calculate of the number of links

(5) Finally, the average of the correlation coefficients is found, i.e., the correlation degree

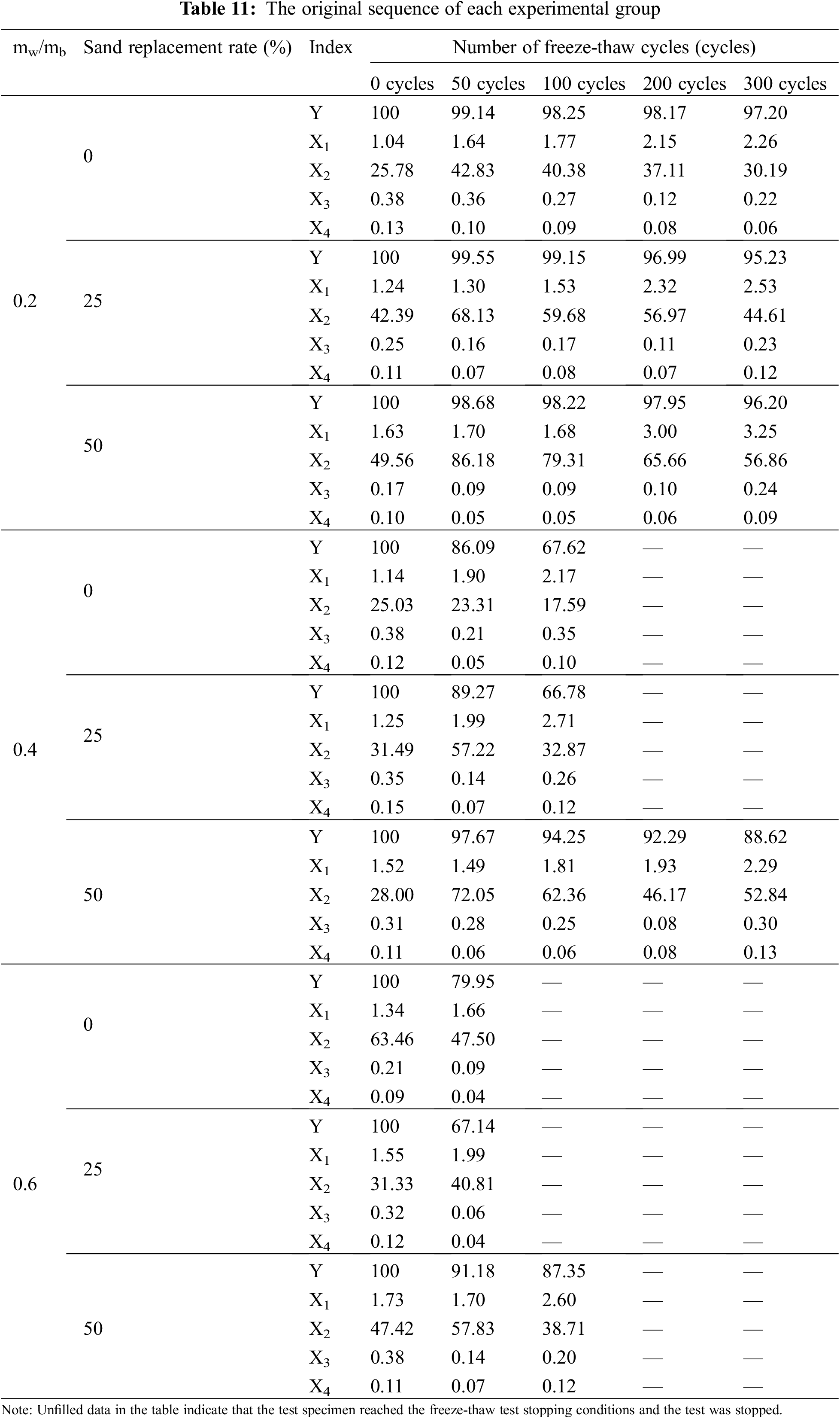

4.2 Relative Dynamic Modulus of Elasticity and Porosity Parameters

According to the above gray correlation method, the relative dynamic modulus of elasticity of concrete with fine aggregate from MSW incineration during freeze-thaw cycles was used as the reference column (Y), and the air content, specific surface area, pore spacing coefficient, and average chord length of pores were used as the comparison columns (X1, X2, X3, and X4) to investigate the degree of correlation between the relative dynamic modulus of elasticity and the pore parameters. The original series are listed in Table 11 below.

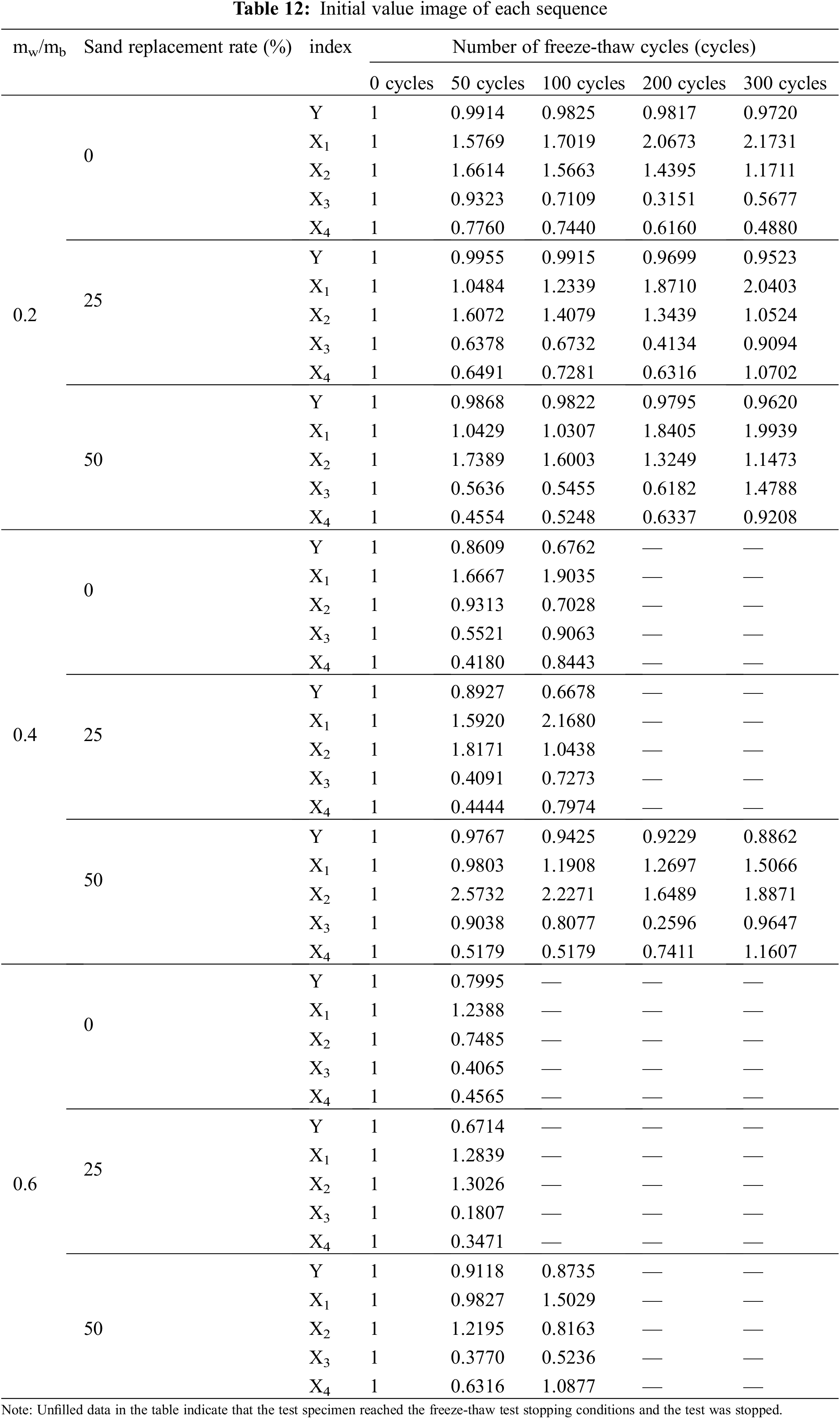

The original sequences of each test group in Table 11 were initialized to obtain Table 12. The original sequences of each test group in Table 11 were subjected to the different operations with the initial values of each sequence in Table 12, the absolute values were taken to obtain the absolute value sequences, and the correlation coefficients and correlation degrees were calculated, which are listed in Table 13 and Fig. 2.

Figure 2: Correlation between the relative dynamic elastic modulus and stomatal parameters

As seen from Fig. 2, the pore parameters that have the greatest correlation with the relative dynamic modulus of the concrete with fine aggregates from MSW incineration are different for different ratios, The correlation between pore spacing coefficient and average pore chord length is high and relatively stable, and the correlation between air content and specific surface area is low and relatively unstable. The quantitative and qualitative analysis of the relative dynamic modulus of elasticity of the concrete is not comprehensive because, during the freeze-thaw cycle, the concrete undergoes complex structural changes, small pores gradually become large pores, cracks are created, and penetrated, and new pores are created.

4.3 Correlation Analysis of the Compressive Strength and Pore Structure

According to the above gray correlation method, the compressive strength of the concrete with fine aggregate from MSW incineration under freeze-thaw cycles was used as the reference column (Y), and the air content, specific surface area, pore spacing coefficient, and average chord length of pores were used as the comparison columns (X1, X2, X3, X4) to investigate the degree of correlation between the compressive strength and pore parameters. The correlation between the compressive strength and stomatal parameters was obtained using the same method as above.

The compressive strength decreases with increasing total pore volume and average pore diameter and increases with increasing specific surface area [27]. As seen in Fig. 3, the best correlation with the compressive strength value of concrete with fine aggregate from domestic waste incineration is the coefficient of pore spacing coefficient and the average pores chord length, and the relationship is similar to the relationship with the relative dynamic modulus of elasticity and pore parameters, indicating that for the compressive strength of the concrete, the size and number of pores have a greater degree of influence. When there are larger and more pores, the internal structure of concrete is looser, and the compressive strength will be reduced to a greater degree.

Figure 3: Correlation between the compressive strength and stomatal parameters

1. Based on the compressive strength of the fine aggregate concrete of MSW incineration bottom ash after freeze-thaw cycles, the gray mean GM (1,1) model was established to simulate the freeze-thaw process, and the simulated values were close to the actual values with relative errors less than 5%, and the accuracy of each group of models was one level, indicating that the mean GM (1,1) model can be well applied to the compressive strength of the fine aggregate concrete of MSW incineration bottom ash and can reflect its variation pattern more accurately.

2. Using the gray correlation method, the compressive strength and relative dynamic elastic modulus of the fine aggregate concrete from MSW incineration were correlated with the air content, specific surface area, pore spacing coefficient, and average pore chord length, and the compressive strength and relative dynamic elastic modulus were correlated with the pore spacing coefficient and average pore chord length. This indicates that the stomatal spacing coefficient and the average chord length of stomata are the main factors affecting the variations.

Funding Statement: This work is supported by the National Natural Science Foundation of China Project 51868058 and 52068058, Inner Mongolia Natural Science Foundation 2018MS05011, Inner Mongolia “Grassland Talent” CYYC5039.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Sawell, S. E., Chandler, A. J., Eighmy, T. T., Hartlén, J., Hjelmar, O. et al. (1995). An international perspective on the characterisation and management of residues from MSW incinerators. Biomass and Bioenergy, 9(1), 377–386. DOI 10.1016/0961-9534(95)00105-0. [Google Scholar] [CrossRef]

2. Holbert, C., Lighty, J. S. (1998). Trace metals behavior during the thermal treatment of paper-mill sludge. Waste Management, 18(6), 423–431. DOI 10.1016/S0956-053X(98)00126-3. [Google Scholar] [CrossRef]

3. Chen, J. C., Wey, M. Y., Lin, Y. C. (1998). The adsorption of heavy metals by different sorbents under various incineration conditions. Chemosphere, 37(13), 2617–2625. DOI 10.1016/S0045-6535(98)00161-1. [Google Scholar] [CrossRef]

4. Rka, B., Hk, A., Sk, C., Svma, B. (2020). Hydrothermal liquefaction of biogenic municipal solid waste under reduced H2 atmosphere in biorefinery format-sciencedirect. Bioresource Technology, 310, 123369–123377. DOI 10.1016/j.biortech.2020.123369. [Google Scholar] [CrossRef]

5. Velusamy, S., Subbaiyyan, A., Ramasamy, K., Shanmugamoorthi, M., Vellingiri, V. et al. (2022). Use of municipal solid waste inert as a powerful replacement of fine aggregate in mortar cube. Materials Today: Proceedings, Tamil Nadu, India. [Google Scholar]

6. Yly, A., Jxl, A., Xiao, C. B., Ps, A., Haa, A. et al. (2022). Characteristics and production of semi-dry lightweight concrete with cold bonded aggregates made from recycling concrete slurry waste (CSW) and municipal solid waste incineration bottom ash (MSWIBA). Journal of Building Engineering, 45, 103434–103445. DOI 10.1016/j.jobe.2021.103434. [Google Scholar] [CrossRef]

7. National Bureau of Statistics (2020). 2020 China national bureau of statistics data domestic waste removal volume. https://data.stats.gov.cn/easyquery.htm?cn=C01&zb=A0B09&sj=2020. [Google Scholar]

8. National Bureau of Statistics (2020). 2020 China national bureau of statistics data waste incineration harmless treatment volume. https://data.stats.gov.cn/easyquery.htm?cn=C01&zb=A0C06&sj=2020. [Google Scholar]

9. Cao, X. G. (2009). Research on application of municipal solid waste combustion residues for freeway pavement base (Master Thesis). Nanjing University of Aeronautics and Astronautics, China. [Google Scholar]

10. Qian, S., Lin, J., Tang, B. S. (2014). Preparation of glass foams from vitrified municipal solid waste incinerator ash. Journal of the Chinese Ceramic Society, 42(1), 108–112. [Google Scholar]

11. Lin, S. Y. (2021). Experimental study on carbonation and chloride ion penetration of fine aggregate concrete from municipal solid waste incineration ash (Master Thesis). Inner Mongolia University of Technology, China. [Google Scholar]

12. Huang, Y. (2021). The study on mechanical properties of simulating component of concrete project with MSWI as fine aggregate (Master Thesis). Inner Mongolia University of Technology, China. [Google Scholar]

13. Xu, K. D., Wang, J. N., Chen, J. L., Li, Z. X., Niu, J. S. et al. (2019). Judge of properties of household waste incineration ash residue and its risk of environmental safety. Non-Metallic Mines, 42(6), 90–93. [Google Scholar]

14. Shi, D. S., Liu, S. J., Song, J. Z. (2021). Experiment of mix design and mechanical properties about concrete using MSW bottom slag as fine aggregate. Concrete, 2021(3), 145–8 + 52. [Google Scholar]

15. Song, Y. F., Deng, C. J., Zhu, H. X., Ding, J., Zhang, X. J. (2016). Correlation between porosity characteristics and cold crushing strength of forsterite porous materials based on grey system theory. Journal of Silicates, 44(6), 896–900. [Google Scholar]

16. Deng, J. L. (1990). A tutorial on gray systems theory. China: Huazhong University of Science and Technology Press. [Google Scholar]

17. Liu, S. F. (2010). Gray system theory and its applications. China: Science Press. [Google Scholar]

18. Guo, Z. Q., Zhao, K., Xie, L., Xiao, H. P. (2012). Grey prediction of dynamic modulus of elasticity of concrete under complex environment. Railway Engineering, 2012(10), 150–153. [Google Scholar]

19. Li, B. X., Cai, L. H., Zhu, W. Z. (2018). Predicting service life of concrete structure exposed to sulfuric acid environment by gray system theory. International Journal of Civil Engineering, 16(9), 1017–1027. DOI 10.1007/s40999-017-0251-2. [Google Scholar] [CrossRef]

20. Li, B., Cai, L., Wang, K., Zhang, Y. (2016). Prediction of the residual strength for durability failure of concrete structure in acidic environments. Journal of Wuhan University of Technology-Mater Science Edition. 31(2), 340–344. DOI 10.1007/s11595-016-1373-0. [Google Scholar] [CrossRef]

21. Yin, Y., Fan, Y., Ning, W. (2018). Research on the prediction of mechanical response to concrete under sulfate corrosion based on the gray theory. IOP Conference Series: Earth and Environmental Science, 153(2). Guang Xi, China. [Google Scholar]

22. Mehta, P. K. (1991). Concrete durability-fifty years progress. Proceedings of 2nd International Conference on Concrete Durability, pp. 1–32. Montreal, Canada. [Google Scholar]

23. Xu, J. N., Liu, Z. X., Liu, H. X. (2018). Experimental study on bond strength of fiber recycled concrete and BFRP Bar under freeze-thaw cycles. Bulletin of the Chinese Ceramic Society, 37(10), 3355–3360. [Google Scholar]

24. Yazdani, F. (2015). Damage assessment, characterization, and modeling for enhanced design of concrete bridge decks in cold regions (Master Thesis). North Dakota State University, USA. [Google Scholar]

25. Zhao, Y. R., Liu, F. F., Wang, L., Guo, Z. L. (2020). Modeling of the compressive strength of basalt fiber concrete based on pore structure under single-side freeze-thaw condition. Materials Reports, 34(12), 12064–12069. [Google Scholar]

26. Chu, H. Q., Jiang, L. H., Zhang, Y. (2010). Forecast of carbonation of concrete after electrodeposition treatment based on grey theory. Journal of Hohai University (Natural Sciences), 38(2), 170–175. [Google Scholar]

27. Luo, B. B., Bi, Q. W. (2012). Experimental study on the influence of pore structure of hybrid fibers self-compacting concrete on compressive strength. Bulletin of the Chinese Ceramic Society, 31(3), 626–630. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools