Open Access

Open Access

REVIEW

Thermomechanical Energy Converters for Harvesting Thermal Energy: A Review

V. Lashkaryov Institute of Semiconductor Physics, NAS of Ukraine, Kyiv, 03028, Ukraine

* Corresponding Author: Oleg P. Dimitriev. Email:

Journal of Renewable Materials 2023, 11(4), 1555-1600. https://doi.org/10.32604/jrm.2023.024772

Received 08 June 2022; Accepted 02 August 2022; Issue published 01 December 2022

Abstract

Thermal energy, i.e., the electromagnetic energy in the infrared range that originates from the direct solar radiation, outgoing terrestrial radiation, waste heat from combustion of fuels, heat-emitting electrical devices, decay of radioactive isotopes, organic putrefaction and fermentation, human body heat, and so on, constitutes a huge energy flux circulating on the earth surface. However, most energy converters designed for the conversion of electromagnetic energy into electricity, such as photovoltaic cells, are mainly focused on using a narrow part of the solar energy lying in the visible spectrum, while thermomechanical engines that are fueled by heat in the broad energy range and then convert it into mechanical work or store it as mechanical deformation, are paid less attention. Although the efficiency of thermomechanical devices is relatively low, they can be applied to collect waste heat which otherwise contributes to negative climate changes. In this review, operational principles of thermomechanical energy converters and a description of basic devices and materials that utilize thermal energy are given. In addition to conventional macroscopic engines, based on thermoacoustic, thermomagnetic, thermoelastic, hydride heat converters, and shape memory alloys, the emergent devices are described which are classified as smart actuators, breathing frameworks, thermoacoustic micro-transducers, nanomechanical resonators, plasmomechanical systems, and optothermal walkers. The performance of the different types of thermomechanical energy converters is described and compared.Graphic Abstract

Keywords

Abbreviations

| AB | azobenzene |

| BMMPA | broadband metamaterial perfect absorber |

| C | chair |

| CNT | carbon nanotubes |

| DBCOD | dibenzocyclooctadiene |

| GNR | graphene nanoribbon |

| GO | graphene oxide |

| EC | ethylene cellulose |

| HTMH | high-temperature metal hydride |

| IR | infrared |

| LCE | liquid crystal elastomer |

| LCN | liquid crystal network |

| LTMH | low-temperature metal hydride |

| MOF | metal-organic framework |

| NTE | negative thermal expansion |

| NIR | near infrared |

| NP | nanoparticle |

| PCE | power conversion efficiency |

| PEO | poly(ethylene oxide) |

| PNIPAM | poly(N-isopropylacrylamide) |

| rGO | reduced graphene oxide |

| SMA | shape memory alloy |

| SME | shape memory effect |

| SMP | shape memory polymers |

| SMPC | shape memory polymer composite |

| SCO | spin crossover |

| STF | solar thermal fuel |

| ss-PCM | solid−solid phase-change material |

| SSPT | solid-to-solid phase transitions |

| SWCNT | single-wall carbon nanotube |

| TEG | thermoelectric generator |

| TMG | thermomagnetic generators |

| TB | twist-boat |

| UV | ultraviolet |

Low-grade thermal energy in the form of the waste heat produced by either industrial or natural processes constitutes an enormous energy reserve that remains currently almost unexploited. Thermal energy, whose electromagnetic spectrum covers a broad infrared (IR) range, can originate from different sources, such as direct solar radiation, outgoing terrestrial radiation, waste heat due to combustion of fuels, heat-emitting electrical and electronic devices, decay of radioactive isotopes, human body heat, heat from organic putrefaction and fermentation, etc.; these energy sources give rise to a huge energy flux circulating on the Earth surface. For example, almost half of the solar radiation reaching the earth surface belongs to the IR region and even a larger amount of IR energy is re-emitted from the earth surface in the form of terrestrial radiation of the planet, which is a black body with an average temperature of TEarth = 288 K. The power of this thermal energy is huge and constitutes about ∼1017 W; i.e., this is comparable with the power of direct solar radiation. Furthermore, the total amount of waste heat constitutes up to 72% of all electrical energy produced in 2016 [1].

However, harvesting low-grade heat is a challenging issue because of the low Carnot efficiency. Different methods aimed at harvesting thermal energy, which can be conventionally divided into photonic (photoelectric) and thermal devices, suffer from low efficiency and other drawbacks as well. Photonic methods are based on electronic excitation as a result of absorption of the IR radiation, by picking up an electron from the ground state or valence band to the excited state or conduction band of molecules or crystals. Since the energy of IR photons is relatively low, less than 1.6 eV, narrow-gap materials are needed to harvest IR radiation. For this purpose, narrow-gap inorganic semiconductors and semimetals (such as HgxCd1–xTe, Ge:Cu, Ge:Zn, Si:As, etc.), inorganic quantum wells and quantum dots, superlattices, and some organic compounds can be employed [2]. However, the energy of electronic excitations in the low-energy IR range is comparable to the thermal energy at room temperature (∼26 meV); therefore, the vibrational excitations affect the operation of such photonic devices and relevant efforts should be undertaken to reduce the thermal noise by cooling the absorber. The longer the wavelength of the IR absorption, the deeper the cooling temperature should be. Although the peak quantum efficiency of the best photoelectric converters exceeds 80% [3], the required low-operation temperatures remain the greatest disadvantage of the photonic systems for harvesting thermal energy, since these systems require additional energy for cooling too. Also, the power conversion efficiency (PCE) of photonic devices in the IR is low. For example, the best IR photovoltaic cells based on colloidal quantum dots demonstrate PCE of 4.2% [4].

Thermal engines usually operate owing to the available temperature gradients and/or heat flows. For example, the temperature gradient in thermoelectric generators (TEGs) leads to the diffusion of charge carriers, where the different mobility of electrons and holes gives rise to the net flow of charged carriers between the hot and cold sides of the device, which in turn creates a voltage difference. The typical efficiency of TEGs is around 5%–8% [5]. The other drawback of materials used in both photonic and thermal devices that convert electromagnetic energy to electricity is their cost, which is rather high.

On the other hand, thermomechanical energy converters that can be used for conversion of thermal energy directly into mechanical work or store it as mechanical deformation are paid less attention. Although efficiency of such thermomechanical devices is relatively low, their cost is relatively cheap and they can be applied to collect waste heat that otherwise contributes to the negative climate changes. Therefore, these can be used as a reasonable alternative to photonic and thermal devices which convert thermal energy to electricity.

This review just appeals to the above type of devices as relatively cheap and simple devices which can be made of renewable materials as well and which can operate in the low-energy domain where conventional solar cells are silent. In this review, operational principles of thermomechanical energy converters and description of basic devices and materials that are fed by thermal energy are collected. After a brief overview of traditional thermomechanical devices which include thermoacoustic, thermomagnetic, thermoelastic, shape memory alloy, and hydride heat converters, description of emergent devices, such as smart actuators, breathing frameworks, thermoacoustic transducers, nanomechanical resonators, plasmomechanical systems and optothermal walkers are given. Performance of the different types of thermomechanical energy converters is discussed and compared as well.

2 Trends in Development of Thermomechanical Energy Converters

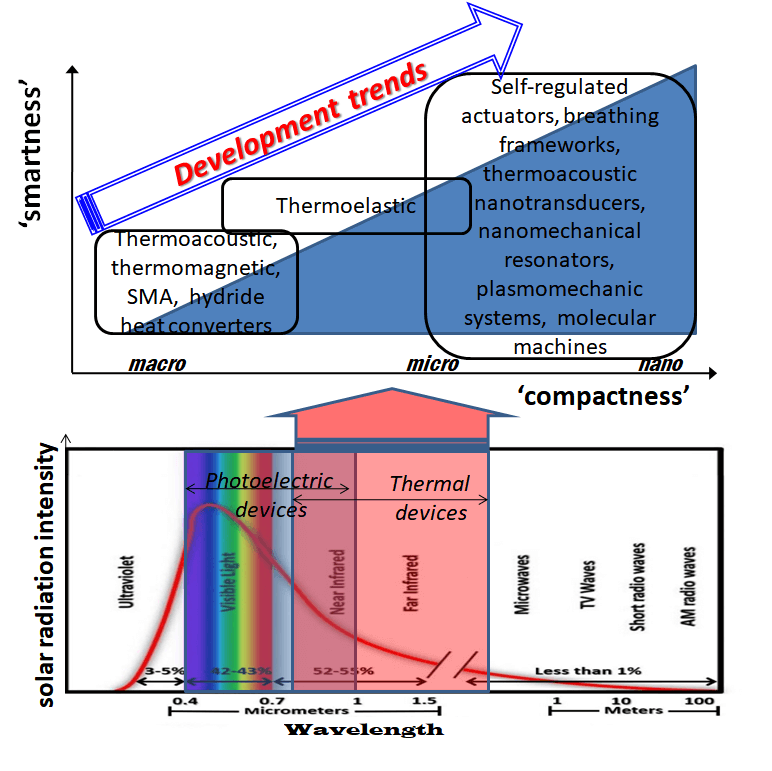

Development of thermomechanical actuators for harvesting thermal energy during the last decades follows a two-fold trend (Fig. 1). The first trend corresponds to the miniaturization of the thermomechanical actuators from macro- to micro- and nano-scale, i.e., the trend to manufacture ever smaller mechanical products and devices. Although the miniaturization of a device in some cases can be accompanied by worsening its performance due to the loss of coupling efficiency at small scales, complex manufacturing processes, and increasing power consumption [6], overall, this trend looks reasonable for this field, as specific operation of thermomechanical energy converters occurs due to conversion of thermal energy into mechanical one; therefore, they do not require wires or batteries, electrical or chemical stimuli for their mechanical mobility, which could otherwise restrict this trend. This trend offers exciting perspective of development of emergent fields such as (i) health control where nano-actuators can be deployed inside the human body and self-controlled either by body temperature or remotely controlled over the Internet by an external user such as a healthcare provider [7]; (ii) design of nano-scale robotics and nanotools able, for example, to manipulate with nano-objects (nanotubes, bio-nanoparticles, etc.) by using nanotweezers, such as bimetallic composites based on Ti2NiCu alloy with shape memory effect [8,9]; (iii) surface nano-patterning in the form of the surface relief grating by photo-isomerization of azopolymer being on the surface of some nano-objects such as microspheres, wires, or thin films at temperatures well below the glass transition temperature of the azopolymer [10]; (iv) design of nano-sensory devices able for the ultrasensitive detection of zeptogram masses [11], nanoscale temperature mapping [12] or nano-antenna radiation detecting [13] with a resolution exceeding the diffraction limit. In this direction, a complete understanding of the mechanical behavior of nano-actuators is crucial for the design of nanodevices and nanosystems. Therefore, the flexural, stability and vibration analysis of various nano-actuators in the form of nanobeams, nanoplates, nanowires, nanotubes, graphene sheets and nanoshells, etc., has received a great attention in the recent years [14].

Figure 1: Overview of the different groups of thermomechanical devices in terms of a two-dimensional scheme of their development trends

The second trend in development of thermomechanical energy converters is the use of smart, programmable, self-regulated actuators able to mimic natural processes. For example, one of the most ambitious challenges is the creation of smart soft robotics with the design of actuators closely resembling the skeletal muscle actuation system and capable of reaching performances comparable to the skeletal muscles [15]. Smart actuators are usually manipulated by a feedback control, communication capabilities, position control, and fault detection, which can be achieved by application of multiple or qualitatively different stimuli (such as light, heat, electricity, magnetism, humidity, pH, etc.), by programmable logic, and/or by integration of functionally different multiple segments in the same device [16]. For example, a flexible graphene-based Janus film composed of two components, a graphene oxide (GO) layer and a reduced GO (rGO) layer, can roll up on the short-side in response to moisture stimulation due to the hygroscopic expansion of the GO layer, while the film rolls up in the opposite direction under the thermal stimulation, which occurs due to the negative thermal expansion of the rGO layer [17]. In this way, the GO/rGO Janus film can be triggered by a sweaty or warm hand with an improved sensitive response capacity, demonstrating an intelligent actuating behavior. Also, smart actuators can integrate energy harvesters (which are thermomechanical engines themselves) and side transducers, or these can be self-powered by combining the cable-driven actuation with soft triboelectric nanogenerators, which makes them self-sustainable systems, which can be considered for implantable and wearable diagnostic, therapeutic and treatment applications as well [18,19].

Taking into account the above trends, the known thermomechanical actuators able for thermal energy conversion will be roughly divided into three groups (Fig. 1). The first group comprises conventional macroscopic devices whose construction and/or functioning requires a sizeable amount of material. These include thermoacoustic, thermomagnetic, hydride heat converters, and shape memory alloys. The other group is related to emergent devices whose construction and/or operation principles are realized on the micro- or nano-scale. The driving forces in these devices are due to nanoscale processes such as molecular switch, change in interatomic distances, etc. This group of devices includes smart nano-actuators, breathing frameworks, thermoacoustic micro/nanotransducers, nanomechanical resonators, plasmomechanical systems, and molecular machines or nano-walkers. Finally, thermoelastic devices comprised of elastic materials such as polymers and elastomers can be referred to as a separate, intermediate group. These are usually hybrid devices that can integrate switchable molecules and a polymer matrix. The operation of these devices therefore can be based due to switches on the molecular level, but these also require a sizeable amount of material to realize their elastic properties. The above three groups of devices are reviewed in more detail below.

3 Conventional Thermomechanical Energy Converters

3.1 Thermoacoustic Heat Engines

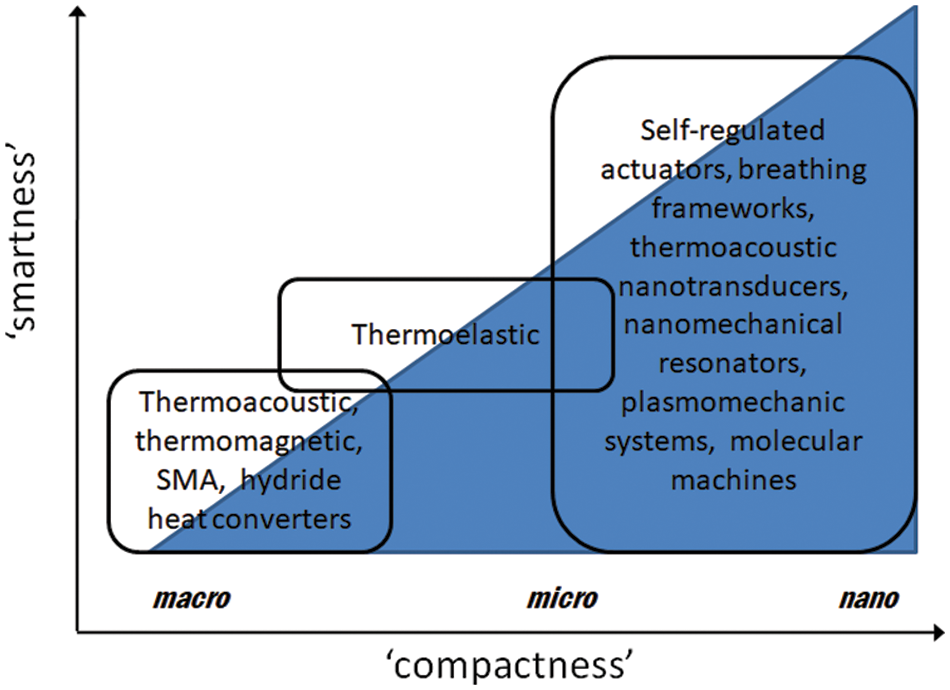

A basic thermoacoustic heat engine converts heat into acoustic wave energy. The major elements of such a device are two heat exchangers near the closed end of a resonant tube, with a regenerator stack situated between them in the form of a porous material producing an acoustic wave as gas flows between the two exchangers due to the temperature gradient which causes the gas to periodically expand and contract (Fig. 2). These oscillations lead to the generation of acoustic waves escaping the open end of the tube; the mechanical waves can be further converted into electrical energy by using a transducer [20]. In terms of the produced cycles, the thermoacoustic engine operates similar to a standard heat engine, possessing a compression, heating, expansion, and cooling cycle [21]. Thermoacoustic engines can be designed either as travelling wave devices which are better described by the Stirling cycle [22,23], or as standing wave devices which correspond to the Brayton cycle [24]. In the Brayton cycle, gas heated from the hot side of engine experiences the expansion through the regenerator stack that promotes the volume of gas to expand to the cold side, which reduces the gas temperature. Then, the local cool temperature of the wall forces the gas to contract and to reduce its pressure, completing the cycle. This cycle produces a corresponding standing wave in the tube, where the acoustic wavelength is defined by the tube dimensions (Fig. 2). If necessary, the acoustic energy can be further converted to electricity using a diaphragm or piezoelectric transducer at the open end of the thermoacoustic tube.

Figure 2: Scheme of a standing wave thermoacoustic heat engine

In the Stirling cycle, a travelling wave pressure is required, and the device must be tuned so that the energy is always added in phase with the input travelling wave, thereby amplifying the wave. The engine operates by moving the working fluid from the cold to the hot end, thus amplifying an acoustic pressure wave travelling from the cold to the hot side of the device. The increasing temperature of the gas, when flowing towards the hot end, causes the gas pressure to increase, followed by a pressure drop as the gas expands and flows back to the cool side.

The ideal Stirling cycle, being used in the traveling wave devices, is inherently more efficient than the ideal Brayton cycle that operates in the standing wave devices [24,25]. However, whereas in a standing wave stack deliberately imperfect thermal contact is sufficient, a travelling wave device requires narrower pores to provide good thermal contact with the fluid, which gives rise to greater frictional losses, reducing practical efficiency. The most efficient Stirling-based device has performance near 40% of the Carnot limit, with a record reported efficiency being 49% of the Carnot limit (for the most efficient operating point corresponding to the drive ratio of 8.14% and engine temperature of 580°C), which corresponds to the neat PCE of 32% [25].

The advantage of the thermoacoustic engines is due to their environmental friendliness, potentially high reliability owing to simple structure and minimal number of moving parts, and reasonable efficiency. However, the need of large temperature gradients is their mere disadvantage. Application of modest temperature gradients on practice leads to low efficiency of such engines. For example, a temperature gradient of about 100 degrees by Celsius in a small-scale standing-wave thermoacoustic engine generates sound with the acoustic power of ∼100 mW and estimated thermoacoustic energy conversion efficiency of 5%–6% [26].

The reverse process, i.e., the conversion of mechanical energy into a thermal difference, can be also fulfilled, which is used in thermoacoustic refrigerators, where the gas adiabatically and alternatively compresses and expands, accompanied by the simultaneous change in gas pressure and temperature, where the pressure reaches a maximum or minimum along with corresponding changes in the temperature [27]. Application of the reverse process for gas liquefaction [28], medical storage with minimum reached temperature up to −19.7°C [29], etc., have been reported, which showed an exergy efficiency of 24% and cooling power of 2.1 kW achieved at 130 K [30].

3.2 Heat Engines Based on Shape Memory Materials

Materials that are able to recover their original shape after their deformation due to heating/cooling or by strain/stress are referred to as shape memory materials [31]. Historically, the shape memory property was first observed long time ago in metal alloys, such as gold–cadmium, copper–zinc, and nickel–titanium (NiTi) [32,33]; nevertheless, the shape memory alloy (SMA) materials have been receiving increasingly more attention and study in recent years as well. A SMA material possesses two different phases, i.e., austenite and martensite, between which a temperature-induced solid-state phase transition occurs, called also a martensitic phase transformation, which is accompanied by the shape memory effect (SME). The transformation between the conventional low-temperature and low-strength martensite phase and the high-temperature and high-strength austenite state usually occurs as a displacitive, lattice-distortive, first-order diffusionless athermal transformation, for example, the transformation from the high-temperature, body-centered cubic lattice austenitic phase to the low temperature, face-centered tetragonal lattice without atomic diffusion, which sometimes goes through an intermediate phase corresponding to a rhombohedral crystal structure in NiTi alloys that contain a surplus of nickel or nickel partly replaced with a third element [34]. Remembering a specific state of the alloy is achieved through forming and constraining the SMA in a desired shape and annealing it at a prescribed temperature, which represents a ‘training’ process. This process rearranges the dislocations present in the SMA in the way that allows the material to take on a new shape without internal stresses, which allows the SMA to be pliable at low temperatures [35]. The strain of the SMA material exhibits a hysteresis as a function of temperature, where the cycle begins from the martensite start temperature (Ms) to the martensite finish temperature (Mf), and the recovery, i.e., the reverse transformation that occurs on heating, beginning from the austenite start temperature (As), and ending at the austenite finish temperature (Af). Due to the hysteresis, some of the mechanical energy is lost in this process, and the austenite form generally possesses a higher strength than the martensite form [36].

Performance of SMA engines varies depending on their composition and construction features. Today, SMAs based on nickel–titanium (e.g., NiTi, NiTiCu, NiTiFe, etc.), iron (FePt, FeNiC, etc.), copper (CuSn, CuZn, etc.), silver (AgCd, etc.), gold (AuCd, etc.), and cobalt (CoNiAl, etc.) are commercially available, with the NiTi SMA to be the most popular and effective as it possesses better mechanical and thermomechanical properties compared to the other SMAs such as iron or copper-based alloys [37]. Usually, SMA materials produce work density of the order of 10 J/g and have efficiency of several percents [38]. However, a record efficiency for a crankshaft Nitinol (NiTi) SMA heat engine has been recently reported, which produced the highest power output value of 4 watt, with 11.3% of engine efficiency [39].

Besides SMAs, shape memory polymers (SMPs) have been attracted increasing attention and research interest in the recent years [40–42]. SMPs have certain advantages before SMAs, due to their relatively high strain of 400%–800% (while SMAs reach only ∼8%), easy and fast shape training, low cost, bio-compatibility and degradability, and because these can be processed at much lower temperatures and pressure and have higher efficiency compared to SMAs [43].

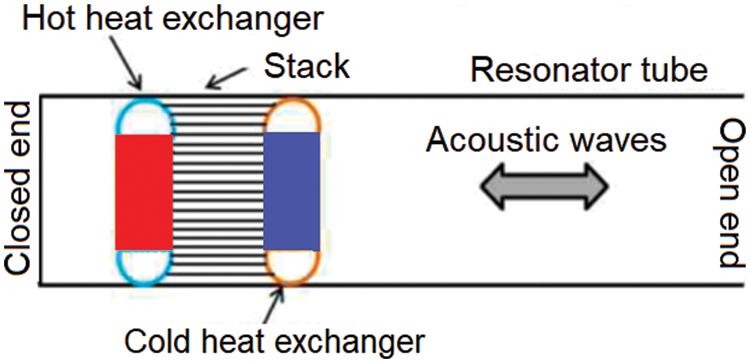

The entropic elasticity of polymers is the core mechanism of the SME in polymers [44]. The equilibrium entropy of an amorphous polymer phase is largely determined by chain-chain interactions, leading to strong coiled conformation of the polymer chain. Applied stress results in elongation of the random polymer coils along the stress direction; thereby, the number of chain-chain interactions becomes reduced, which also reduces the entropy [45]. A subsequent release of the stress causes the polymers to return back to their original coiled state with high entropy again. In this way, a “memory” about the polymer initial, undeformed state is persisted. But a long-time application of the stress (hours rather than seconds) can result in slippage of the polymer chains that yields irreversible non-elastic changes, which serves to erase the polymer “memory” concerning its original shape [46]. To prevent the slippage effect, SPMs are prepared by using interchain cross-linking, where chemical or physical cross-links fix the polymer in its most thermodynamically favorable shape, also called a permanent shape. However, in addition to cross-links, which restrain shape-fixing of the permanent shape and provide so-called “hard” regions, “soft” regions are also needed to facilitate transition of the polymer chains into a less coiled shape, called a temporary state [47]. The availability of the “soft” and “hard” regions of the polymer enables to lock and unlock its temporary shape. When a suitable trigger is applied, the cross-linking of the temporary shape is undone, resulting in “unfreezing” the polymer chains and allowing for a recovery of the permanent shape. The temporary shape can be generated by polymer training or programming [48], i.e., the process of shaping and fixing the polymer in its temporary shape via two processing steps (Fig. 3a). During the first processing step, the permanent shape is fixed by means of chemical or physical cross-linking. In the second step, the applied stress deforms the permanent shape into a temporary shape and, along with application of a suitable trigger assisting in “freezing” the shape-fixing regions, this leads to sustaining the temporary shape in the form of deformation. Therefore, when the stress is released, the polymer will maintain its temporary shape, while recovery of the permanent shape can be achieved by applying another trigger to the polymer to undo the cross-links introduced during the first step. Low and high temperatures can serve as corresponding triggers that provide the cycle of the polymer shape transformations (Fig. 3b).

Figure 3: (a) Illustration of the thermally induced shape-memory effect via programming steps. Reprinted with permission from [60] Copyright 2020, John Wiley and Sons. (b) Reversible shape memory effect of polyolefin thermoplastic elastomer. Reprinted with permission from [61] Copyright 2019, American Chemical Society

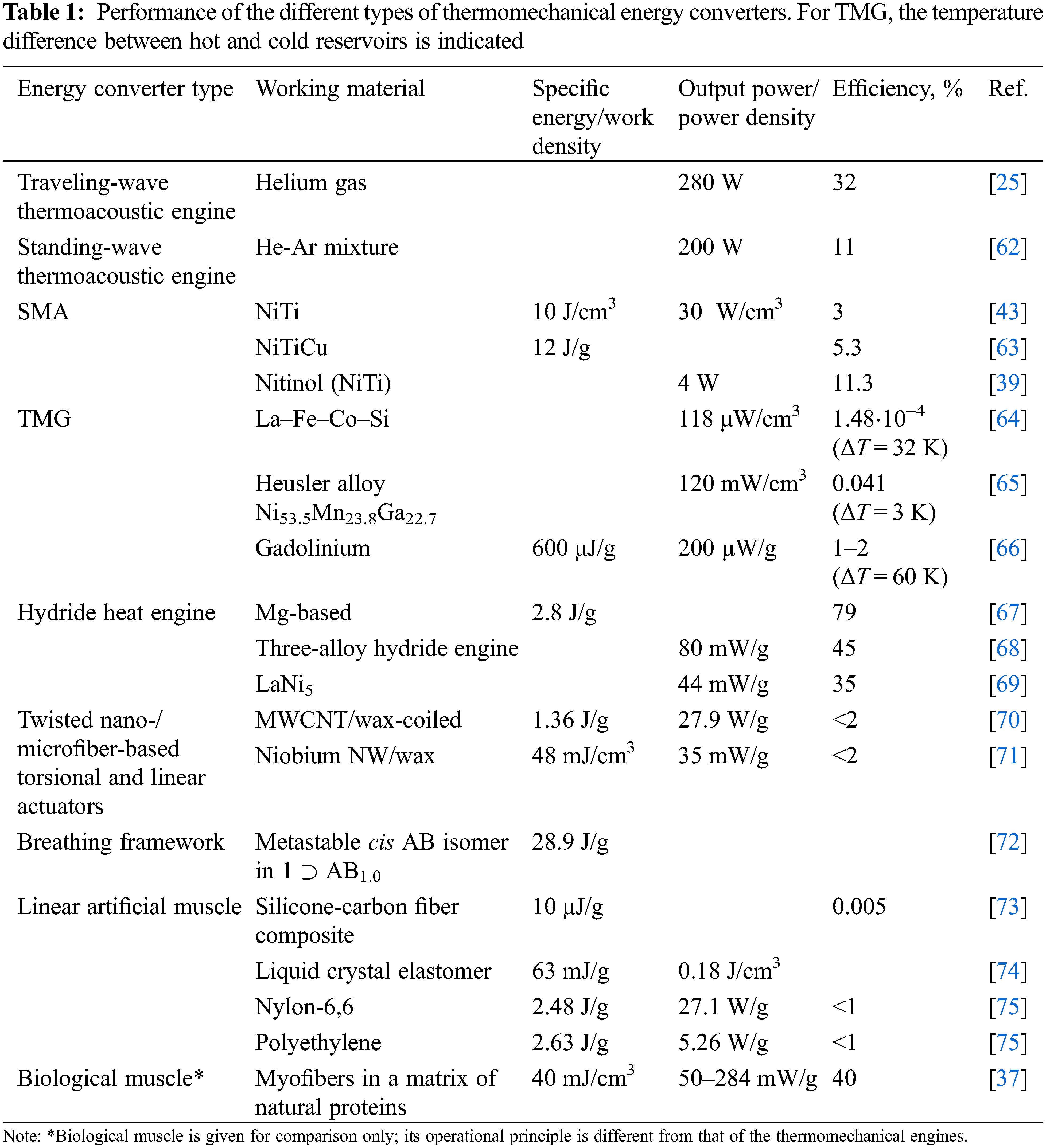

In order to facilitate shape memory effect in SMPs induced by electromagnetic radiation, different fillers can be added to the polymer network, which results in formation of shape memory polymer composites (SMPCs) or shape memory hybrids. The fillers assist in absorption of heat, where different materials can be employed for that. For example, gold nanoparticles were used as fillers in poly(ethylene oxide) (PEO) [49] and poly(d,l-lactic acid) [50] networks, where the SME was actuated by the increase in temperature assisted by photothermal conversion of the Au particles. Silver nanoparticles grafted on cellulose nanocrystal were shown to promote a rapid IR response of the obtained SMPC [51]. Incorporation of the organic rare-earth complex, namely, Yb(TTA)3Phen and Nd(TTA)3Phen, into poly[ethylene-ran-(vinyl acetate)] (PEVA) matrix yielded a selective photothermal conversion effect under the near-infrared (NIR) light at 980 and 808 nm, respectively [52]. Carbon-based materials that effectively transform light absorption into the heat, such as carbon nanotubes and carbon nanodots, were also used as SME triggers in different shape memory hybrids. Wu et al. synthesized polyvinyl alcohol–carbon dots composite which demonstrated SME under the ultraviolet (UV) light irradiation [53]. Polymer–carbon nanotube [54] and polymer–Fe3O4 nanoparticle [55] thermo-responsive composites were shown to display SME under microwave radiation. By incorporating gold nanoparticle/reduced graphene oxide (AuNP-rGO) hybrids into the cross-linked poly(ε-caprolactone). Li et al. [56] showed a synergistic effect of AuNP-RGO on the light-actuated shape recovery speed of this SMPC. Natural sunlight-actuated SMPC with reversible shape change and self-healing abilities based on conductive polymer composite, i.e., chlorinated poly(propylene carbonate) filled with carbon nanotubes, was fabricated by Cui et al. [57]. The composite could lift 550 times their own weigh triggered by IR light and the shape recovery time of the composite triggered by natural sunlight was only 39 s. A novel SMP hybrid able to respond to both UV and NIR light and to make contraction and bending motions was demonstrated by Zhou et al. via loading W18O49 nanowires (NWs) modified by oligo(ethylene glycol) (OEG) into cross-linked polymer matrices of polyethylene glycol diacrylate (cPEGDA) [58]. The cPEGDA/W18O49 NW hybrid actuators exhibited stable helical deformation (right-handed and left-handed) by utilizing oriented chain segments of the crystalline polymer and vector sum of shape recovery forces. Qi et al. demonstrated shape memory triggered at body temperature (Ttrans = 36.6°C) in bio-based Eucommia ulmoides gum/silica hybrids, which restored the permanent shape within 60 s at 37°C with a shape fixity ratio of 99% and shape recovery ratio near 100% [59]. However, the main drawback of SMPs remains their low mechanical strength and stiffness and also their recovery is accompanied by small forces. Therefore, among shape-memory materials, SMAs demonstrate the best performance today (Table 1).

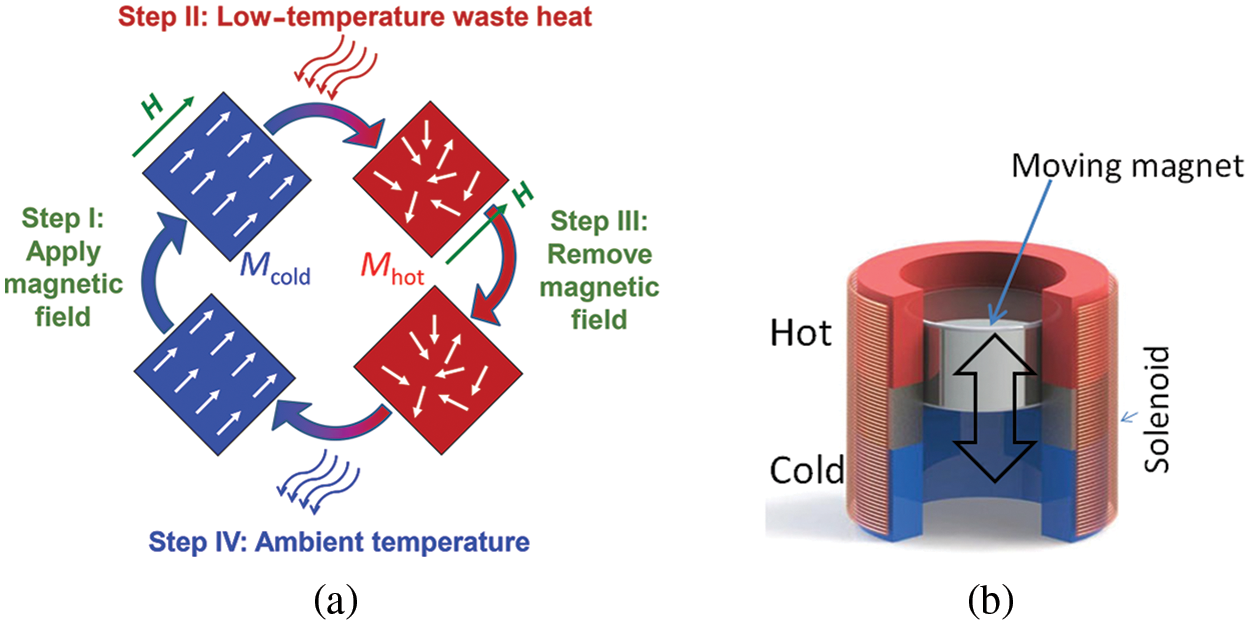

Among various thermal energy harvesting devices available for capturing low-grade heat with temperature less than 100°C, the engines based on thermomagnetic effect can find niche applications. Thermomagnetic generators (TMGs) rely on the varying magnetization of a soft magnet that occurs upon change in its temperature. The magnet itself is being under applied magnetic field which renders a force to the magnet when it has nonzero magnetization available only at low temperature. In operation, a TMG alternately heats and cools the magnet by bringing it into contact with thermal reservoirs possessing different temperatures. The resulting change in the magnetization is accompanied by a mechanical work performed by the magnetized material, or can produce currents in nearby conductive materials creating an electrical circuit, resulting in a net conversion of energy from thermal to electromagnetic (Fig. 4). Technically, design of TMGs is based on the use of ferromagnetic materials at temperatures close to the Curie point in order to facilitate the loss in material’s magnetization upon heating. In this region, the internal magnetization of a magnet experiences large change at small temperature difference, causing high thermal-to-magnetic conversion efficiency.

Figure 4: (a) Illustration of a thermomagnetic cycle and (b) basic design of a TMG using active magnet actuation. Part (a) reprinted with permission from [83] under Creative Commons Attribution (CC BY) license. Copyright 2021, Author(s)

Operation of TMGs can be realized via an active or passive mode. The movement between the hot and cold reservoirs in the passive mode occurs due to the change in the material magnetization. The movement to the hot reservoir is realized by magnetic force attraction between the magnet and the magnetic pole of the hot reservoir, whereas the restoring force between the magnet and the cold non-magnetic reservoir is realized by a spring or other means. Being in contact with the hot reservoir, the magnet is heated up and loses its magnetization; thus, the magnetic attraction decreases below the level of the restoring force. Under the force of the spring, the magnet returns to the cold reservoir. Being in contact with the cold reservoir, the magnet cools down; this is accompanied by the increase in its magnetization. That yields a strong enough magnetic force able to overcome the restoring force, resulting in movement of the magnet to the hot reservoir, completing the cycle [76].

In the active mode, instead of the magnetized hot reservoir an external force in the form of a cycling external magnetic field using electromagnets is applied to move the magnet between the reservoirs. That is, an external magnetic field is applied when cooling a magnet and increasing its magnetization, moving it to the hot reservoir; then the magnetic field is removed upon magnet heating [77]. The energy can then be harvested via induction.

The energy harvesting by TMG can be evaluated as thermodynamic efficiency which is defined as a fraction of usable output energy vs. thermal input energy Qin during each cycle, where the upper limit of the output energy for the TMG is the magnetic energy Em. The TMG efficiency is then given according to the formula

where μ0 is the magnetic field constant, M the magnetization and H the magnetic field.

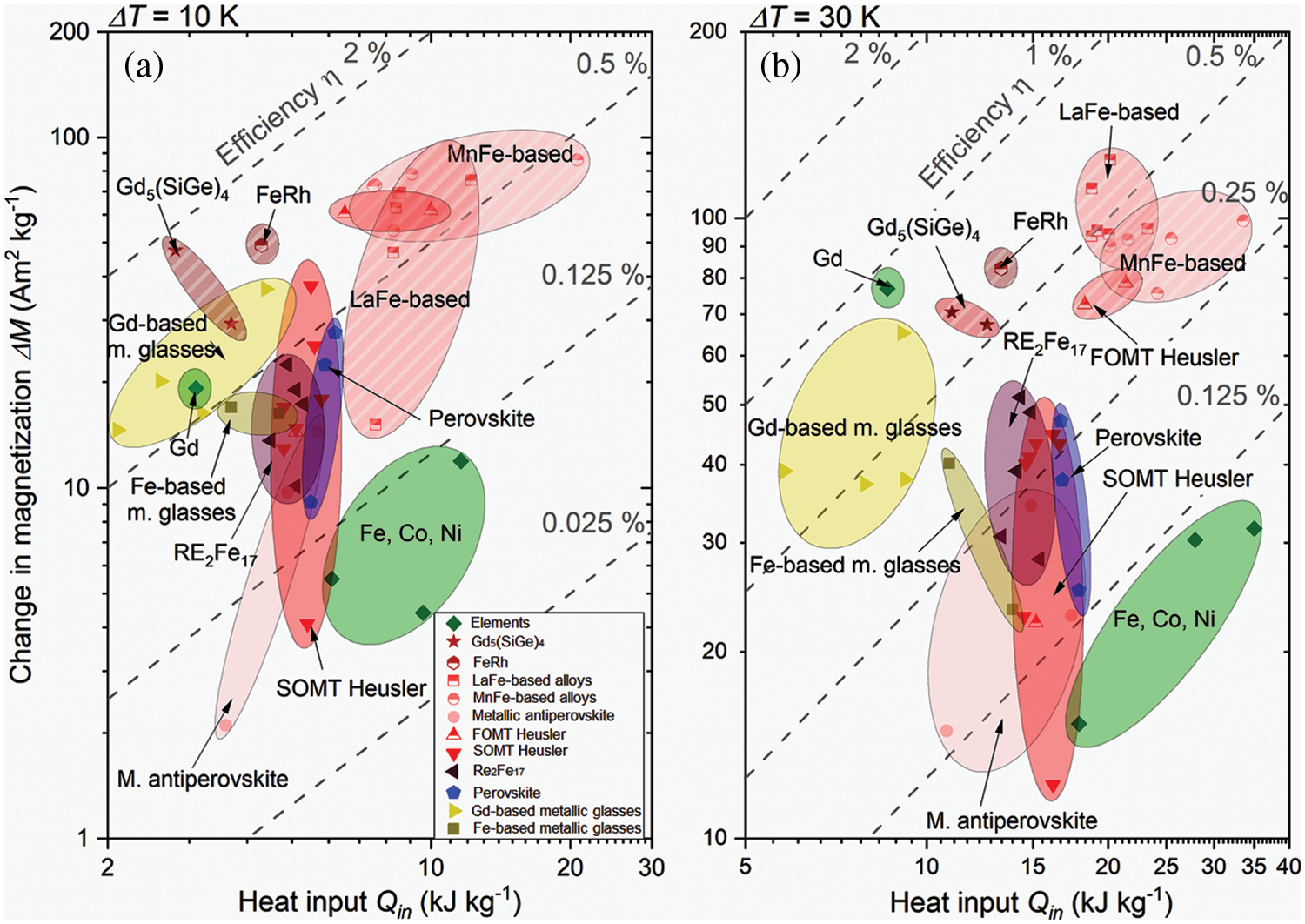

In the early works, the theoretical limit for the TMG efficiency was evaluated to be below 1% [78]. However, recent efforts demonstrated that the gadolinium based TMGs can exhibit efficiency as high as 20.5% of the Carnot efficiency for the near room temperature operating condition with a temperature gradient of only 5 K and magnetic field up to 3000 Oe, which was realized using neodymium based permanent magnets [79]; this corresponds to the neat efficiency for the Gd-based TMG to be 1.46% due to its smaller Qin and larger ΔM [80] in Eq. (1). It should be noted that TMG performance is dependent on temperature difference of the hot and cold reservoirs and for the optimal difference of 10 K the efficiency can further approach 2% for TMG based on Gd5(SiGe)4 compounds [81] (Fig. 5).

Figure 5: Thermodynamic efficiencies η of different thermomagnetic materials. To reach high η, a large change in magnetization ΔM is beneficial, as well as a low heat input Qin. The gray dashed lines represent a constant efficiency η = μ0ΔMH/Qin. Accordingly, the most efficient materials are located in the top left corner, where η approaches 2%. Material properties were evaluated for two different temperature spans in Ashby-type plots: (a) at ΔT = 10 K, materials exhibiting a first order transition (half solid symbols) reach the highest efficiencies; (b) at ΔT = 30 K, materials with a second order transition (solid symbols) become competitive. Metallic materials are displayed in shades of red, ceramics in blue, metallic glasses in shades of yellow, and elements in green. Reprinted with permission from [83] under Creative Commons Attribution (CC BY) license. Copyright 2021, Author(s)

Recently, TMGs based on Heusler alloy films have been successfully developed with an increasing electrical power per footprint by a factor of 3.4; i.e., the electrical power per footprint reached 50 μW/cm2 at a temperature change of only 3 K [65]. TMG performance can be increased via resonant actuation of freely movable thin-film devices based on the Heusler alloy Ni–Mn–Ga, which showed unprecedented power density of 118 mW/cm3 with a periodic temperature change of only 3 K required for operation and the duration of thermomagnetic duty cycle of about 12 ms; this efficiency compares favorably with that of the best thermoelectric generators [82]. Gueltig et al. reported the TMG gadolinium prototype which exhibited an oscillation frequency of 0.33 Hz, a work output of 0.6 J/kg per cycle, and a power density of 0.2 W/kg under the temperature difference of 60 K [82].

The hydride heat engine is based on the property of some metals and metal alloys, such as LaNi5, La0.8Ce0.2Ni5, Mg2Ni, TiMn2, TiFe, Pd, etc., to store hydrogen within their crystalline lattice through formation of a metal hydride. Hydration and dehydration processes are described by the reaction:

where M is the metal used, MH the metal hydride, and Q the quantity of the reaction heat. The reaction (2) includes the following steps [84]: (i) physisorption of hydrogen molecules on the metal surface; (ii) dissociation of hydrogen molecules; (iii) penetration of hydrogen atoms from the surface into the crystal lattice; (iv) hydride formation by nucleation and growth; (v) diffusion of hydrogen atoms through the hydride layer, involving interstitial and/or vacancy mechanism.

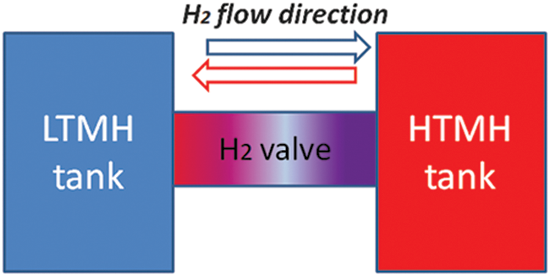

The amount of hydrogen accumulated by metal hydride lattices is dependent on the temperature of the metal hydride; low temperatures facilitate hydrogen storing while high temperatures promote its desorption from the metal hydride. Their different storage capacity at different temperatures can be used to generate a hydrogen flow between two metal hydride storage media, i.e., a high-temperature metal hydride (HTMH) and a low-temperature metal hydride (LTMH), that are attached to each other through a hollow, sealed tube filled with hydrogen, where one medium desorbs hydrogen, while the other absorbs it (Fig. 6). The flow of hydrogen then can be converted into mechanical work of a pneumatic motor inserted into the closed-tube system; this work then can be converted to electrical energy through an electromagnetic generator. In this construction, each storage medium must be alternately heated and cooled to allow the hydrogen to circulate between the two media and to produce a cyclic motion of the generator, respectively, which is a particular disadvantage of this type of the heat engines [35].

Figure 6: Scheme of the hydride heat engine in the form of the coupled HTMH and LTMH tanks by a hydrogen connection

Metal hydrides can offer several advantages over other thermochemical hydrogen storing materials (salt hydrates, metal hydroxides, oxides, and carbonates) due to the higher energy storage capacity and power density. The relatively high efficiency and reasonably low temperature difference between HTMH and LTMH yield the advantages of the metal hydride heat engines (Table 1). However, performance of metal hydride heat engines varies and is generally limited by reactor configuration, design, optimization and selection of appropriate thermochemical materials. Ham and coauthors improved thermal energy conversion via synchronous motion of the thermal waves and the heat source (or sink) inside paired porous media channels, which accompanied the phase transition in the succession of unit metal-hydride heat pumps [84]. For the best hydride pair of LaNi4Al and TiV0.62Mn1.5 coefficient of performance was calculated to be near 60%. Lototskyy et al. proposed combination of latent heat and thermochemical heat storage system based on two-tank metal hydrides [85]. The systems consisted of two metal hydride tanks coupled and equipped with a phase change material (PCM) jacket. The heat charging process activated desorption of hydrogen from HTMH, followed by its storing in LTMH. At the same time, the heat that originates from the hydrogen absorption in the LTMH tank was stored as latent heat in a PCM jacket surrounding the LTMH tank, which can be reused during the heat discharging.

4 Thermoelastic Engines (Artificial Muscles)

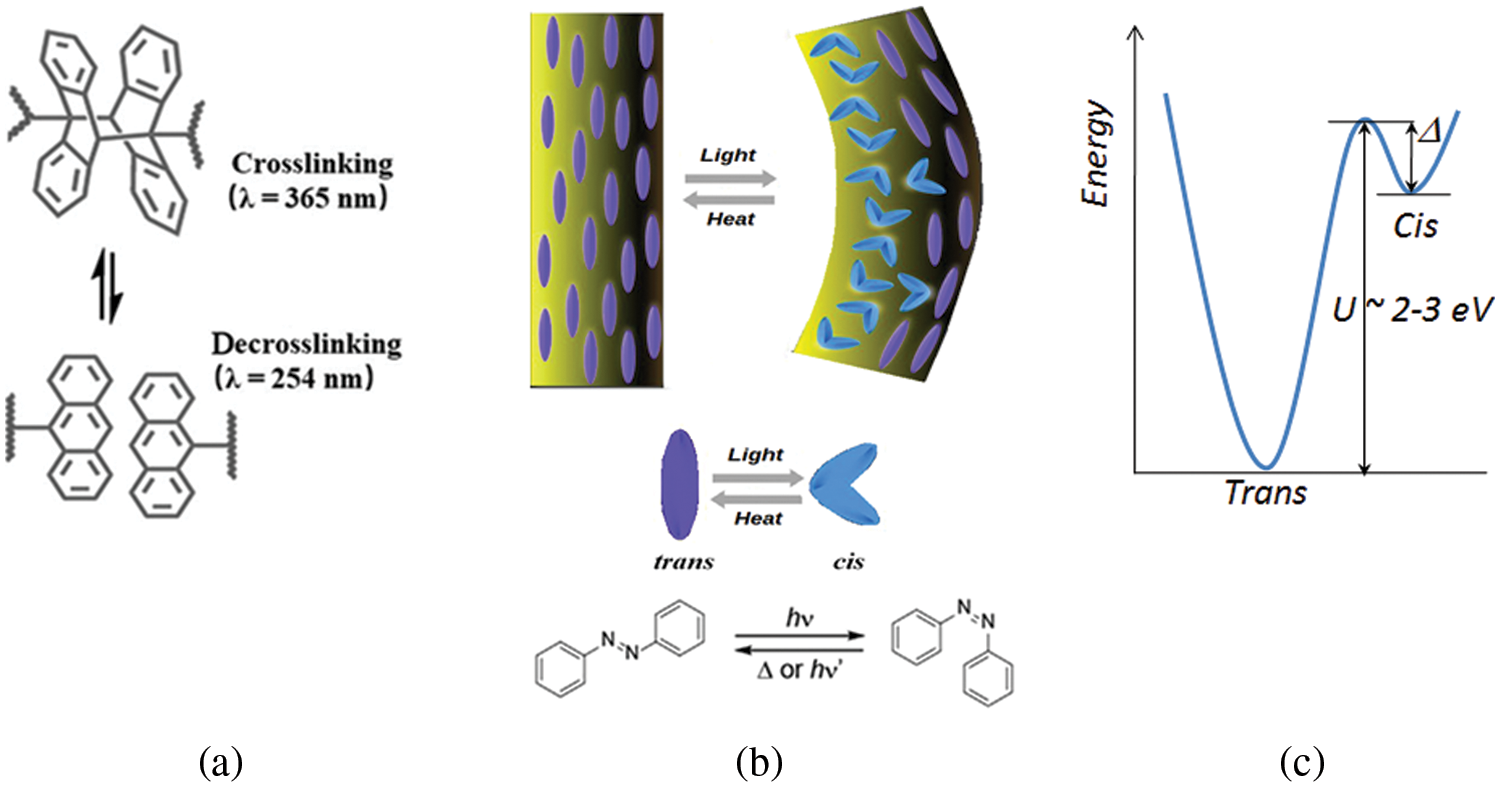

Thermoelastic engines operate owing to specific molecular mechanisms in elastic materials such as polymers, leading to change in the polymer volume, i.e., its contraction or expansion, in response to electromagnetic irradiation of the material. The mechanisms of this change include molecular isomerization, conformational changes, cross-linking or disruption of intermolecular bonding, packing rearrangement, changes in chain segments mobility as well. The above processes can occur under irradiation of the material by different wavelengths; however, one should distinguish the processes induced either by light quanta of high energy, i.e., in the UV or visible region, or due to absorption of IR photons, i.e., heat [2]. In the first case, there is a relatively high barrier that corresponds to the energy gap of the π−π* or n−π* transition, where electronic excitation triggers molecular isomerization or cross-linking (Fig. 7). These processes are referred to as reversible photochromic or photochemical ones [86,87], where photoisomerization involves one-bond-flip or hula-twist mechanism, although no chemical bonds are broken, but the molecule only changes its shape, while cross-linking does break chemical bonds. The devices based on such processes will be referred to as photonic devices.

Figure 7: Illustration of photochemical mechanisms leading to elastomer deformation due to (a) crosslinking/decrosslinking and (b) isomerization mechanisms. (c) Potential energy profile of a photosensitive isomer showing relative potential barriers for the cis and trans configurations

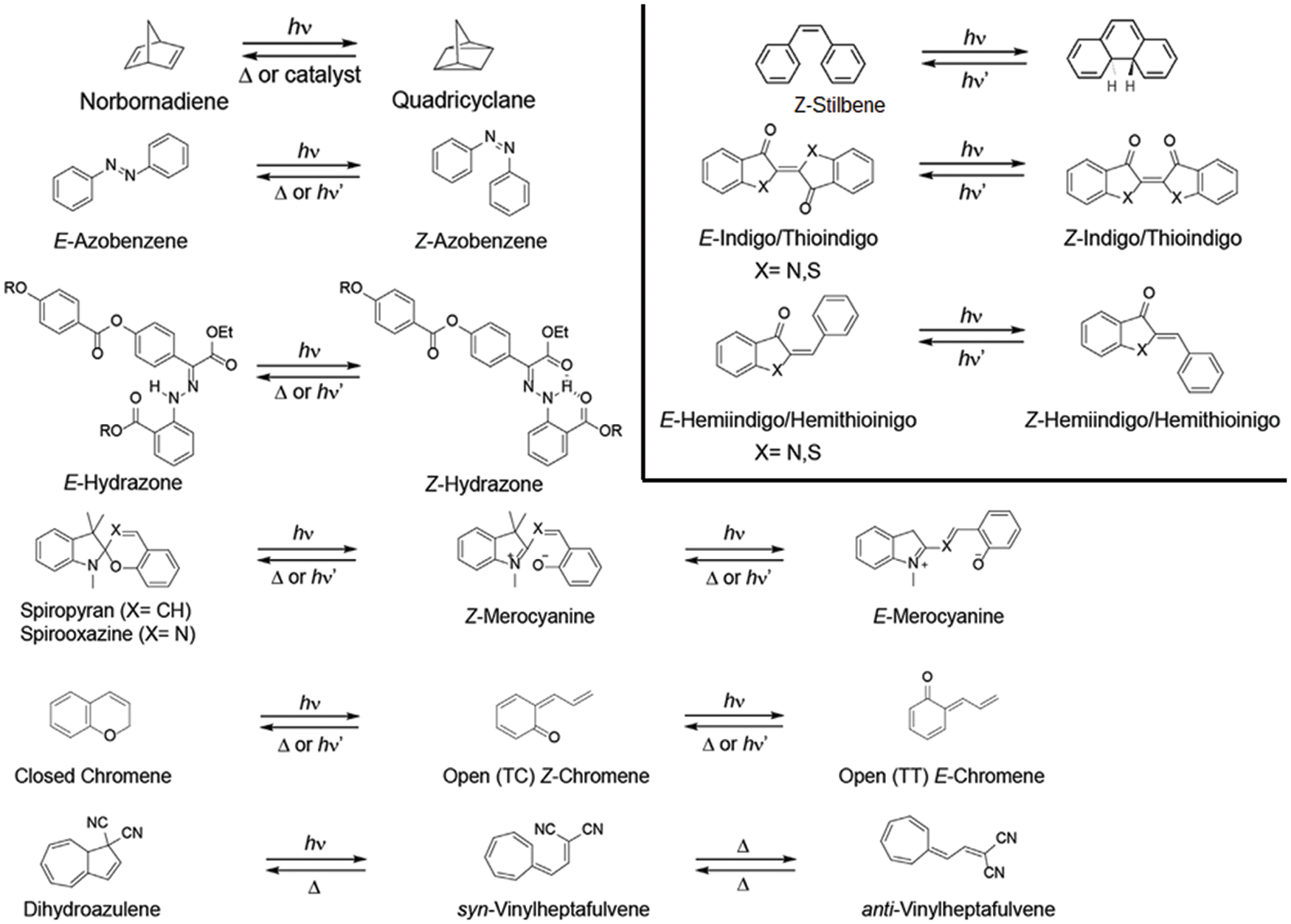

In the second case, the energy is dispersed over molecular vibrations, and isomerization or other molecular processes are vibronic-induced; this will be referred to as thermal devices. The typical molecules employed in the above two processes are shown in Scheme 1.

Scheme 1: Examples of isomerization processes for different molecules. The right upper corner indicates processes induced by UV-Vis light only, whereas for the others both light and heat can trigger isomerization

Although the above photonic devices cannot be literally referred to as thermomechanical engines, their operational principle due to conversion of electromagnetic radiation to mechanical energy is very similar to the thermal devices (Fig. 7b); therefore, we consider them first.

4.1 Actuation via Light-Driven Photochemical Mechanisms

Photonic devices based on light-responsive materials have been of great interest as they can be used in different applications such as optical memory [88–90], energy harvesting [91], light-driven robotics [92,93], micro-electromechanical systems and actuators [94]. The majority of photonic devices operate due to photochemical switch between cis and trans isomers of specific molecules [95] (see Scheme 1). Such molecules often constitute of azobenzene moieties which possess good thermal stability, well separated absorbance bands of the trans and cis isomers, a relatively rapid reversible thermal cis–trans conversion as well. In this moiety, bearing two phenylamines, whose nitrogen atoms are linked together by a double bond forming an axle, the optical excitation induces a clockwise rotation of a photoisomerizable group around the molecular axle, triggering a thermally stable elongated trans configuration towards a meta-stable bent cis form [96]. The thermal activation step then converts the unstable cis isomer back to the stable trans-isomer form.

Fine details of azobenzene photoisomerization have been disclosed recently. This process was described as an “inversion-assisted torsion” along a torsional coordinate around the central C−N=N−C moiety, which is assisted by C−N=N bending modes [97]. During the isomerization, the phenyl rings remain roughly stationary, while the central C−N=N−C moiety rotates and moves between them in a pedal-type motion, while the phenyl rings also follow this motion, but on a much slower timescale compared to the central moiety. As a result, the rings remain still out of plane when the central CNNC dihedral angle has reached 180°, but they continue to twist after the main isomerization event has finished [98].

Besides cis/trans isomerization mechanism, photo-crosslinking (photodimerization) and decrosslinking (photocleavage) can be responsible for the photoinduced actuation in some materials as well (Fig. 7). Jiang et al. demonstrated this process on the example of an anthracene-containing liquid crystal polymer, where the anthracene pendant groups were responsible for reversible photodimerization and dimer photocleavage under exposure at two different wavelengths in the UV range, which yielded reversible deformation of the polymer, respectively [99].

Recently, a number of small photochromic molecular switches responsible for a photoinduced motion have been demonstrated (see Scheme 1) [100–108]. Besides, more complex photochromic moieties have been proposed as well. For example, Kajiya et al. designed photoresponsive inorganic–organic hybrid molecules consisting of diarylethene and polyhedral oligomeric silsesquioxane linked by amide bonds, which showed an enhanced conversion ratio from the open- to the closed-ring isomers upon UV irradiation in a solution [109]. Synthesis of photoactive block copolymer containing 1-(2-hydroxyethyl)−3,3-dimethylindoline- 6-nitrobenzopyran (SP) as a photochromic agent and ZnS nanoparticles (NPs) as a mediator for photo-optical switch of the SP derivative to the open form due to the interaction with the NP surface was reported by Pizarro et al. [110].

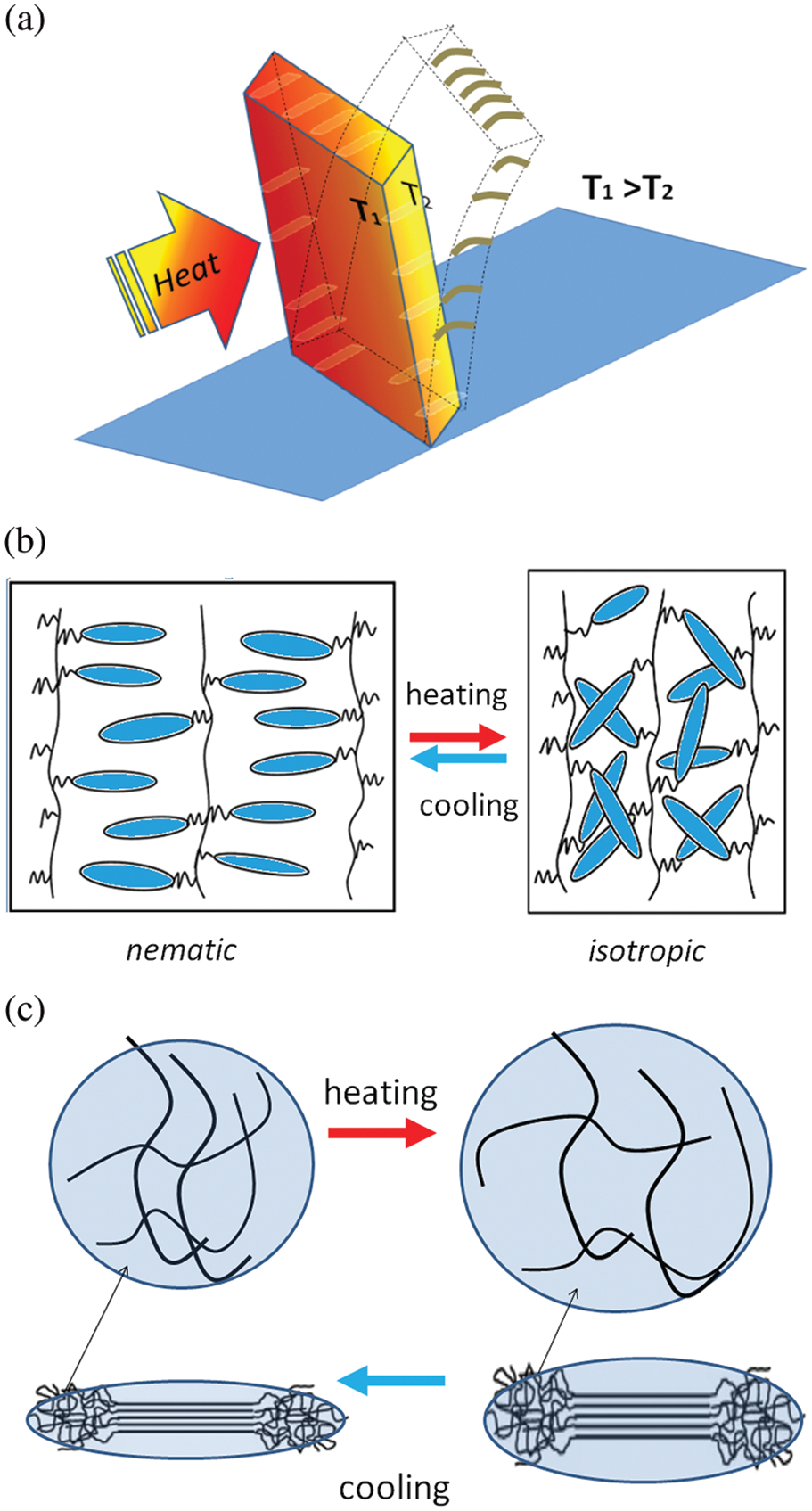

The nanoscopic structural movement of isomerizing molecules can be translated to macroscopic motions of organic crystals and amorphous materials that comprise the photochromic compounds [111–117]. For example, Morimoto et al. demonstrated macroscopic mechanical work through the photoinduced movement of a light-driven actuator in the form of a millimeter-sized two-component cocrystal composed of diarylethene derivatives [118]. However, to perform macroscopic mechanical work, for example, in the form of mimicking human muscle-like motion by artificial actuators, the material should be soft and deformable in response to external stimuli, such as temperature and light. Polymer, liquid crystal elastomer (LCE) and liquid crystal network (LCN) materials satisfy this requirement and can serve as a matrix for photo-switchable molecules [119]. LCEs and LCNs have additional advantage due to their inherent anisotropy which amplifies the mechanical properties and can serve as a trigger for reversible mechanical deformations through order parameter reduction or reorientation of the network [120]. LCEs exhibit good thermoelastic properties. Particularly, when heated above the nematic–isotropic phase transition, LCEs contract along the alignment direction of their mesogens, but expand by cooling below the phase transition temperature (Fig. 8). By combining the thermoelastic properties of LCEs with photoinduced changes in the molecular volume of incorporated photochromic molecules such as spyropyranes, azobenzenes, stilbenes, fulgides, diarylethylenes, the light-induced deformation of the LCE composite material is highly feasible [121]. Finkelmann et al. demonstrated that an azobenzene containing LCE that has a polysiloxane main chain, experiences contraction as much as 20% upon exposure to UV light due to the trans–cis isomerization of the azobenzene moiety [122].

Figure 8: (a) Illustration of mechanical changes upon inhomogeneous heating of an elastomer strip with molecular mechanisms indicated for (b) liquid crystal elastomers with negative thermal expansion (redrawn from [138]) and (c) polymers with positive thermal expansion. In (c), both crystalline and amorphous regions are indicated

The introduction of photochromic molecules into LCNs yields novel composite materials (such as azo-LCN) that have found various applications where light input is converted into mechanical output [123–127]. Application of azo-LCN as a photodriven polymer oscillator with a frequency as high as a hummingbird wing beat (20–80 Hz) was reported by White et al., where the demonstrated polymer cantilever consisted of a monodomain azobenzene containing LCN [128]. The oscillation of the azo-LCN cantilever could be turned on and off by switching the polarization direction of the driving laser beam, and it has been considered to be prospective for application in light energy harvesting devices [129]. Yue et al. [130] exploited a “photomelting” azobenzene monomer cross-linked into the LCNs to fabricate photoresponsive polymer films that were able for photomechanical actuations and demonstrated reversible photoswitchable glass transition temperatures (Tg) in response to the UV/visible light exposure. The Tg of the polymer network was higher than room temperature in the trans-form and lower than room temperature in the cis-form; thus, the bending mechanism operated via the photoswitchable Tg. Gelebart et al. by achieving fast cis-to-trans thermal relaxation of modified azobenzene moiety incorporated into azo-LCNs demonstrated generation of continuous, directional, and macroscopic mechanical waves under constant light illumination, with a feedback loop that was driven by self-shadowing; this was proposed for potential application in light-driven locomotion and surfaces self-cleaning [131]. Other applications of azo-materials include their exploiting as photomechanical light harvesters that operate at relatively high frequencies [132], soft robotic relays of LCE/PEDOT:PSS photomechanical conductive bilayers [133], mesoscale photomechanical optical fibers [134], transduction of photomechanical deformation into piezoelectric signal for the generation of electrical energy [135], photomechanical pendulum that produces electric current in a coil wrapped around its end when allowed to oscillate in a static magnetic field [136], surface engineering and lithography (light-induced directional mass migration) [95], capture of CO2 by light-responsive ionic liquids through reversible trans–cis isomerization [137], etc.

4.2 Actuation via Thermally Induced Isomerization

There are different examples of materials, where a low-grade heat can induce molecular isomerization via specific processes such as thermally-induced isomerization in non-conjugated linoleic and α-linolenic acids [139,140], trilinolein and trilinoelaidin at 250°C [141], carbon disulfide dimer anions [142], (E/Z)-isomerization of retro-carotenoid rhodoxanthin [143], water-assisted linear-to-cyclic isomerization of donor-acceptor Stenhouse adducts [144], thermally-induced isomerization between all E- and Z-isomer-rich xanthophylls [145], and even isomerization of CdS magic-size clusters which have identical cluster masses but slightly different structures, whose interconversions follow first-order unimolecular reaction kinetics [146]. In most cases, trans-isomer is considered to be stable; however, stable cis- coordination complexes, such as (cis-L)ZnCl2 and (cis-L2)MIICl2 [M = Fe, Co, Ni] have been recently reported also, which are converted to their trans-1,2-bis(1-R-benzo[d]imidazol-2-yl)ethene (R = H or R = CH3) ligands using high-energy UV light, whereas the trans-to-cis isomerization is induced thermally [147].

Thermally induced cis-to-trans isomerization kinetics for azo-compounds is usually slow, having the time constants from minutes to days; however, this kinetics can be greatly accelerated by attaching specific substituents to the azo-dyes structures [148]. By minimal modifications of the arylazoindole core via methylation, Simeth et al. were able to dramatically change the Z-to-E thermal isomerization rate from days to a nanosecond time scale [149]. They also showed fine-tuning of the Z-to-E lifetimes through choosing a proper dimethyl sulfoxide–water (or buffered water) solvent mixture. Azo dyes that possess a strong push–pull configuration and provide an azo–hydrazone tautomeric equilibrium were shown as promising chromophores that demonstrate fast thermal cis-to-trans isomerization kinetics at room temperature. Garcia-Amoros et al. reported a synthesis of a new highly biocompatible pyrimidine-based azophenol that exhibited nanosecond thermal-relaxation times of cis-to-trans isomerization at 298 K, i.e., at temperatures close to physiological conditions, which gives a clear perspective for its biological and medical applications [150]. Poutanen et al. [151] showed acceleration of the thermal cis–trans isomerization rate through hydrogen bonding of the azobenzenes, which makes this effect applicable for high sensitive humidity sensor with quick response to relative humidity changes. It was reported that thermal decay of the metastable cis isomers of the other photochromes, mono-arylated indigo derivatives, can be greatly accelerated by a factor of 300 by using a small amount of water [152]. Another elegant approach to accelerate cis-to-trans isomerization rate is coupling of molecular switches and metal nanoparticles. Titov et al. found that the interaction of the azobenzene-containing molecules with gold nanoparticles leads to decreasing thermal lifetimes of the cis isomer by up to 3 orders of magnitude in comparison to the lifetime of the free molecules separated from Au nanoparticles [153]. This effect was explained by lowering activation barriers for azobenzene-containing molecules due to either electron injection or withdrawal, which promotes a dramatic increase in the thermal isomerization rate.

Depending on the photochrome used, the back-conversion cis-trans reaction can release heat energy via triggering by different processes, including catalytic and electrocatalytic ones [154,155]. A high-energy metastable state in photo-isomers can be considered as energy storage, where up to 21% of the solar energy can be stored as chemical energy for the later heat production [156]. Recently, Wang et al. demonstrated a combination of solution- and neat-film azobenzene-based molecular solar thermal systems, where solar energy can be stored as chemical energy for as long as one month and released as heat, with a solar energy storage efficiency of 0.5% and with power output up to 0.1 nW (with a power output per unit volume up to 1.3 W/m3) [157].

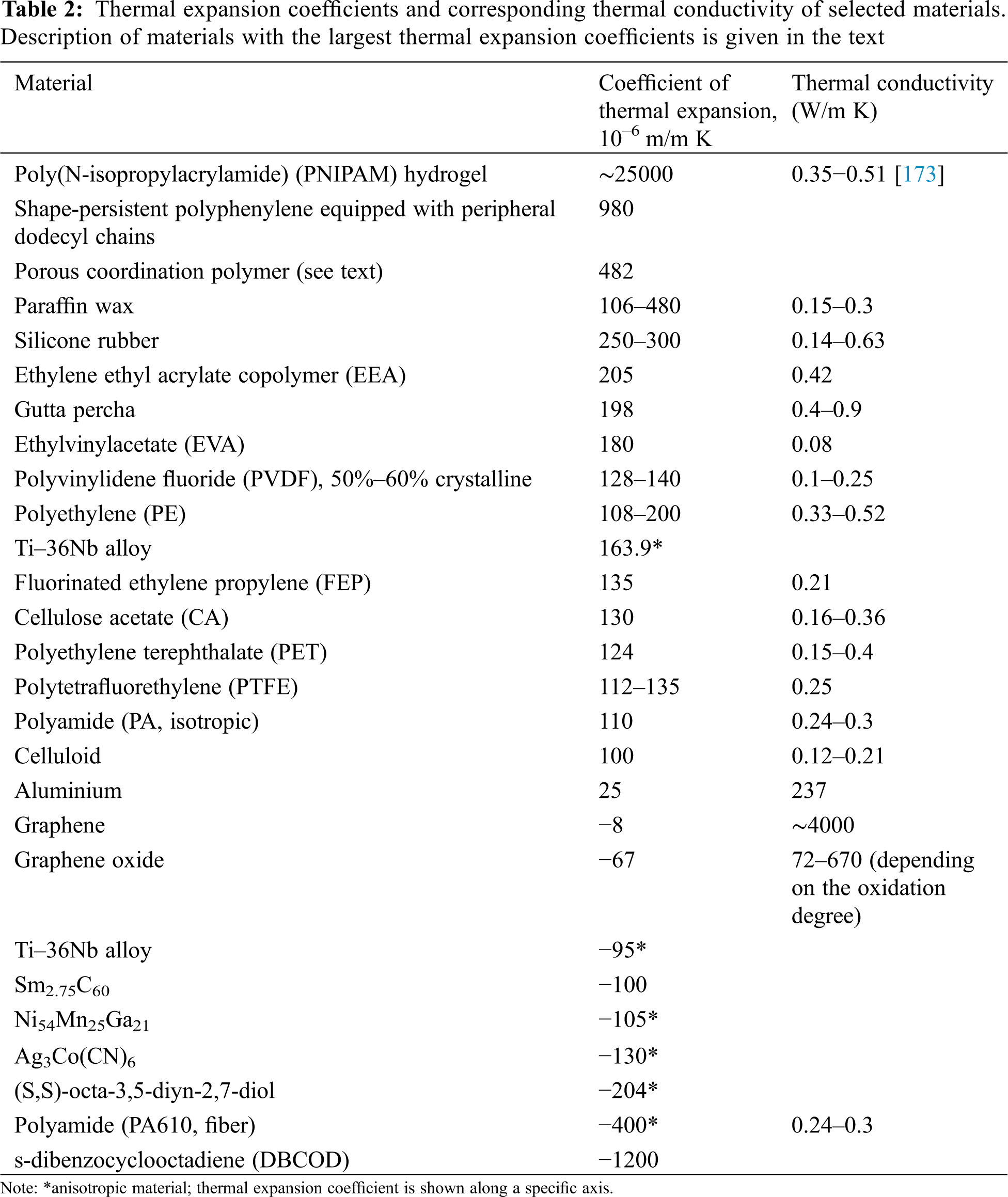

4.3 Thermally Induced Actuation with Positive Thermal Expansion

Thermally induced reversible process of the material expansion due to the changes in molecular mobility leading to repulsion between molecules and packing rearrangement upon heating can be used for harvesting and storing IR energy in the form of mechanical energy of deformation. In order to realize this idea the heat absorber must be a deformable material that possesses a high thermal expansion coefficient. Best materials for this purpose are polymers and elastomers, whose thermal expansion coefficients are one order of magnitude larger and their thermal conductivity is 2–3 orders of magnitude lower than that of metals (Table 2). The only exception can be found for some metal alloys whose thermal expansion coefficients are comparable with that of polymers [158] (Table 2). Owing to the low thermal conductivity, polymer material can be heated inhomogeneously, when one side of the material is exposed to heat, while the other side remains relatively cold. Thus, a free polymer strip, when exposed to heat/IR energy from one side, tends to bend due to the poor equalizing of temperature across the sample and therefore different expansion of the material at the opposite sides of the strip (Fig. 8a). The dominant physical mechanism of this thermomechanical effect is due to producing a temperature gradient across the strip thickness that causes strip bending as a result of uneven thermal expansion distribution across the strip. Layers closest to the front side of the strip expand more than layers of the rear side, causing bending. Thus, polymer materials can transduce thermal energy into mechanical stress by the macroscopic deformation of the sample, i.e., thermomechanical effect. Many polymers and elastomers with positive thermal expansion coefficients possess additional advantageous properties, such as high processability, flexibility, easy fabrication characteristics, large deformation and power density, low manufacturing costs, which are required for fabrication of artificial muscles [159–162].

Nylon-made coiled actuators representing specific type twisted polymeric fibers were reported to have excellent thermo-mechanical characteristics, such as hysteresis, repeatability, predictability, high stored elastic energy, large deformations when heated, together with promising performance in terms of energy and power densities [163]. Particularly, the maximum elastic energy density up to 2.1 kJ/kg, can be stored in nylon coils, which is much higher than that in steel springs (up to 0.9 kJ/kg). Haines et al. discovered a new class of thermo-mechanical actuators based on drawn polymeric fibers (mostly nylon), commonly employed as fishing lines and sewing threads [164]. Specifically, Haines and coauthors demonstrated the relationship between temperature-induced deformations and twisted/coiled configuration of these fibers, which showed outstanding performances with energy densities as high as 2.63 kJ/kg and power densities over 5.3 kW/kg (Table 1), and strokes up to 50%, which can be employed both in linear and rotational actuators. Chou and coauthors showed that the coiled polyethylene-terephthalate (PET) artificial muscles exhibit stress softening and their nominal activation energies represent linearly decreasing functions of the training load [165].

Many actuators, however, are based on multifunctional materials, where mechanical actuation in response to the thermal energy input is provided by synergetic action of two components. Combination of nickel-titanium alloys and polymers represents the well-known hybrid thermo-mechanical SMA actuators which recover their deformation when heated above a certain temperature [166]. Such a shape-memory effect combines a thermoelastic martensite-austenite phase transition in the Ni-Ti alloy and a variation of conformational entropy in the shape memory polymer [47].

On the other hand, different fillers that assist effective heating of the polymer matrix were also actively used. For example, absorbers such as carbon nanotubes (CNTs), silver, gold and magnetic Fe3O4 nanoparticles, etc., were exploited as nano-heaters [167–169]. Specific action of magnetic NPs dispersed in the polymer matrix facilitates nanocomposite heating, thus triggering its shape recovery, when being undergone by an applied oscillating magnetic field or radio frequency (RF)-microwave radiation. In contrast to CNTs and other strongly adsorbing species, the temperature dependence of magnetic susceptibility of magnetic NPs effectively creates a self-limiting processing that fundamentally restricts the maximum temperature above which magnetization ceases [170]. Carbon fibers added to the silicone matrix in an ordered manner serve as specific filler which renders a dual effect of promoting heating as well as controlling polymer deformation; the latter is strongly dependent on the fiber orientation in the sample [73]. Jia et al. observed that a photo-thermal effect of CNTs incorporated to the polyurethane matrix is accompanied by a self-healing effect in this flexible matrix, which can find corresponding application in electronics [171], because the self-healing of the above nanocomposite could be induced precisely, remotely and efficiently under irradiation by NIR laser without influencing the undamaged areas. The healing efficiency of the composite containing 3 wt% CNTs was shown to reach 90.1% [171]. In addition, the conductive layer coated onto the nanocomposite surface could also be recovered under irradiation. Dai et al. fabricated a self-healable hybrid yarn based on the silicone elastomer as a guest material, where improved material’s environmental adaptability and a work capacity of 0.49 J/g, which is 12.7 times that of the natural muscle, were demonstrated [172].

4.4 Thermally Induced Actuation with Negative Thermal Expansion

There are several processes that induce negative thermal expansion (NTE) of materials. First, these include transverse vibrations of atoms in complex structures such as zeolites, metal organic frameworks (MOFs), porous coordination polymers, etc. Here, a central linking atom in the chain

The second factor leading to NTE is geometric flexibility of the material structure. For example, LCE materials possess crystalline ordered network and structural transformability, which is bistable or multistable; therefore, heating can induce change from the ordered structure, for example, nematic structure with distance-tolerant position of mesogenic units, to isotropic disorder, where these units do not obey the above distance and where the material displays dynamic framework deformation [138]. Here, the existence of large pores in the LCE structure provides extra space for the thermal motion caused by geometry deformation (Fig. 8b).

Third, host-quest materials are able to display the NTE behavior as well. These materials are complex systems constructed by two or more molecules or ions that are held together through noncovalent interactions, where the existence of guest molecules in the pores may largely influence the thermal expansion behavior. The examples include ZnPt(CN)6 with guest water molecules, Cd(CN)2 with different occupancies of CCl4 guests, intercalation of Li+ into Sc0.9Fe0.1F3, etc. [174]. In these materials, heating results in desorption of the guest molecules, which yields shrinkage of the lattice framework, respectively.

Spin crossover (SCO), also known as spin transition, is the fourth factor able to induce the NTE. This phenomenon usually takes place in materials containing 3d4∼3d7 transition metal complexes, where the spin state can switch between low spin and high spin under external stimuli including temperature [177]. The variation of 3d electron configurations leads to the changes of bond length and unusual volume changes in SCO systems, respectively. Examples of SCO materials include Fe[Au(CN)2]2, which possesses hinge like motif with iron(ɪɪ) as the screw, where the spin state changes of Fe(ɪɪ) largely influence the conformation of the framework [178].

NTE that occurs via molecular rearrangement is caused owing to weak intermolecular interactions in molecular systems, coupled by van der Waals forces, π…π interactions, halogen-halogen interactions, as well as hydrogen bonds [179,180]. These weak bonds compared to the covalent bonds, are sensitive to temperature changes, leading to large structural rearrangements. A relevant example can be taken from the ice structure, where disruption of weak hydrogen bonds upon heating results in liberation of water molecules which then occupy inter-site space, thus leading to contraction of the volume. A similar behavior was found in the dumbbell shaped molecules of (S, S)-octa-3,5-diyn-2,7-diol stacked in columns along c-axis and connected through hydrogen bonds in their 3D network structures (Table 2). This structure has a considerable sheath of empty space around each molecule, so that heating leads to a rare biaxial NTE behavior [181]. Unusual anisotropy in thermal expansion behavior was observed in liquid crystal cobalt octakis(ndecylthio) porphyrazine thin films (CoS10) which exhibited 2D NTE in the transverse plane, but positive thermal expansion along the column axis [182]. This was explained by the tilting of the porphyrazine cores and contraction of side chains which together provide the 2D NTE, whereas the increasing cofacial distance and tilting of core yields the 1D positive thermal expansion along the column. Similar thermal expansion anisotropy was observed in nylon fibers, which demonstrated the negative expansion along the fiber axes but positive radial expansion [183].

Conformational change is another mechanism leading to NTE behavior. The most known thermo-responsive polymer with NTE is poly(N-isopropylacrylamide) (PNIPAM). This polymer is hydrophilic below 32°C, but it is hydrophobic when the temperature is higher than 32°C. The hydrophilic chains exist as single chains with expanded coil conformation, while the hydrophobic PNIPAM chains transform into single chain globules or multichain aggregates accompanied with a large thermal contraction [184]. Recently, specific conformational changes of dibenzocyclooctadiene (DBCOD) derivatives, responsible for the NTE properties, were found. In DBCOD, the conformations occur between chair (C) and twist-boat (TB) forms, leading to thermal contraction of DBCOD when the TB conformation is able to turn into C conformation with temperature increase, and when the volume of C conformation is smaller than the volume of TB conformation [185].

It was claimed that introducing molecular asymmetry can reduce crystallinity significantly and consequently facilitates the kinetics of the conformational change which leads to the large NTE. Shen et al. revealed a giant negative thermal expansion coefficient of ∼−1200 ppm K−1 at ambient or near ambient temperatures for a polyarylamide film containing DBCOD. This film revealed unconventional and completely reversible thermal contraction under low-energy stimulation, which exceeded that for any known negative-thermal-expansion materials under similar operating conditions [186]. The origin of the above abnormal thermal shrinkage was assigned due to the conformational change of the DBCOD moiety, which occurs from the thermodynamic global energy minimum in the TB to a local minimum in the C conformation. Even a larger NTE was measured for the DBCOD-based polymer systems, which was in the range from −1140 to −2350 ppm K−1 [187]. This effect was claimed to open a new pathway for creating NIR-based macromolecular switches and motors, as well as devices for ambient thermal energy conversion and storage.

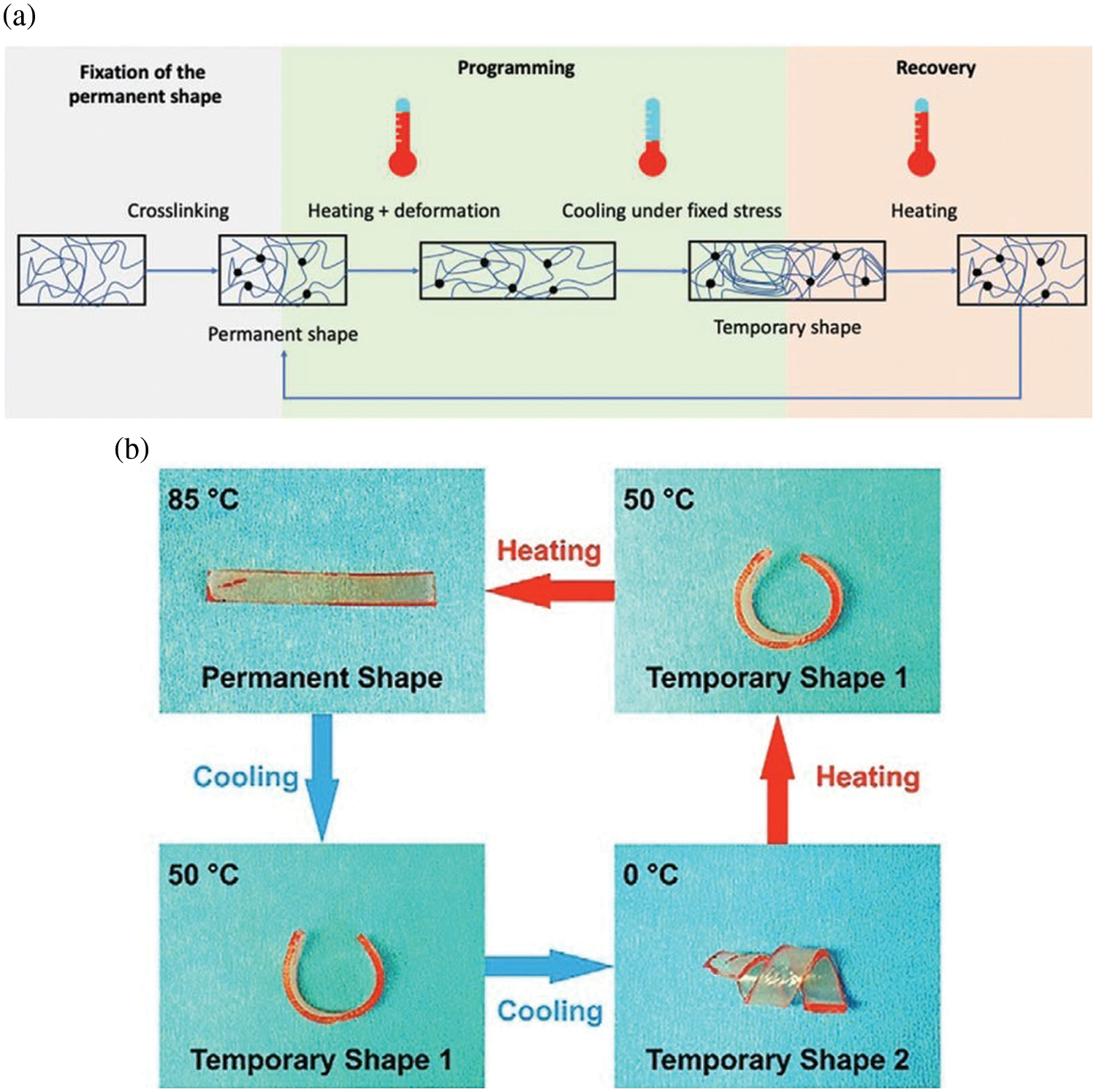

5 Emergent Thermomechanical Devices

5.1 Shape-Programmable Actuators

The concept of shape programming exploits the difference in thermal expansion coefficients of different components in a multicomponent actuator possessing multiple degrees of freedom and thus provides its programmable shape control according to its differential design architecture upon exposure to light or heat. Gao et al. exploited the humidity-dependent nonlinear coefficient of thermal expansion of GO in fabricated graphene oxide/ethylene cellulose (GO/EC) bilayers that indicated a rapid temperature-dependent photothermal actuation and a programmable 3D origami shape control (Fig. 9a). In the above bilayer structure, GO served as a NIR-active layer with negative thermal expansion coefficient, whereas EC as a layer with positive thermal expansion when exposed to heat. The developed strategy allowed the authors to construct complex systems with the remote control of their 3D shapes, such as a rapid blooming rate in bionic flowers, which in fact represented mechanical metamaterials with auxetic behavior [188].

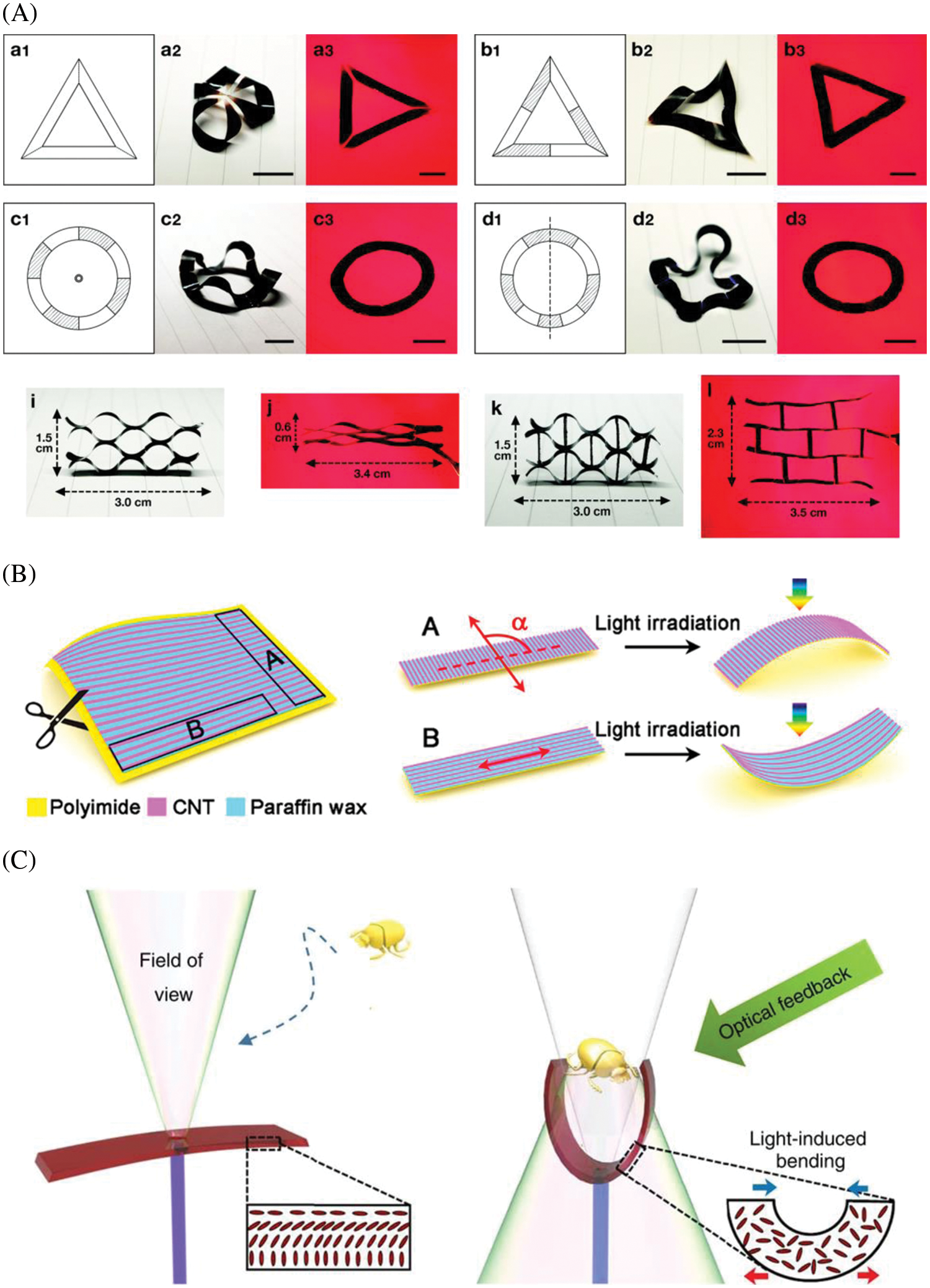

Figure 9: (A) Various shape programmable 3D architectures derived from 2D layouts. (a–d) Graphic designs, room temperature stable 3D modes and high temperature planar states of (a) an equilateral triangular ring encoded with only positive curvature; (b) an equilateral triangular ring encoded with alternating positive and negative curvatures; (c) an annulus programmed with central symmetry; and (d) an annulus programmed with axial symmetry; scale bars is 1 cm. (i–l) 3D-PTA enabled mechanical metamaterials including (i and j) an assembly strategy for ultra-positive Poisson’s ratio and (k and l) an assembly strategy for negative Poisson’s ratio. The length direction of the stripe is regarded as the axial direction for Poisson’s ratio calculation. All demonstrations shown above were fabricated with 10 μm GO and 30 μm EC. Reversible actuations were performed under the 200 mW cm−2 NIR irradiation. Reprinted with permission from [188]. Copyright 2020, Royal Society of Chemistry. (B) Schematic illustration of the apheliotropic and phototropic bending of the composite strips with different aligned directions of carbon nanotubes. Reprinted with permission from [191]. Copyright 2016, American Chemical Society. (C) Left: Schematic drawing of the light-triggered artificial flytrap at its open stage, when no object has entered its field of view. No light is back-reflected to the LCE actuator, which remains in the open stage. Right: The flytrap closes when an object enters its field of view and causes optical feedback to the LCE actuator. Light-induced bending of the LCE leads to closure action, thus capturing the object. The insets show the schematic molecular orientation in LCE actuator at the open and closed stages. Reprinted with permission from [192] under the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/). Copyright 2017 by the Author(s)

Motion that depends on the direction of the triggering stimulus and that autonomously and self-sufficiently reacts to changing environmental stimuli in a direction-dependent manner is the core of smart biomimetric actuators [189]. Artificial heliotropic devices with no additional mechatronic components and resultant energy consumption, which are able to follow sunlight and which can be used for increased light interception, have been demonstrated by Li et al. [190]. The heliotropic devices were constructed from a novel reversible photo-thermomechanical LCE–single-wall carbon nanotube (SWCNT) nanocomposite that was able to be directly driven by natural sunlight and that possessed strong actuation capability. When such an actuator faced the sun, it contracted, leading to tilting an attached solar cell towards the sun, thus demonstrating an artificial heliotropism. Using the LCE nanocomposite actuators, the artificial heliotropic devices showed full-range heliotropism in both laboratory and in-field tests. As a result, significant improvement in the photocurrent output from the solar cells attached to the artificial heliotropic devices was observed.

Deng et al. presented a general strategy effective for fabricating visible-light-responsive actuators with diverse and tunable deformations by embedding aligned CNTs in the paraffin wax on a polyimide substrate [191]. The synergy of the above two components made it possible mimicking plant operation, where aligned CNTs functioned as cellulose fibrils, and the paraffin wax resembled the soft cells/tissues of a plant. It was demonstrated that various motions of photomechanical actuations, i.e., phototropic/apheliotropic bending to three-dimensional helical buckling can be controlled by tuning the CNT alignment direction (Fig. 9b). An additional benefit of using the CNTs was their ability to absorb infrared and visible light, endowing the resultant actuators with rapid responsiveness. The reported photomechanical actuators also demonstrated controlling a mechanical arm and functioning in an energy harvesting system to execute complex but well-controlled motions.

An autonomous soft self-regulated actuator that is able to mimic the action of a flytrap plant when exposed to light and that uses optical feedback to trigger photomechanical actuation was demonstrated by Wani et al. [192]. The flytrap was designed using a light-responsive LCE, fabricated onto the tip of an optical fiber, which acted as a power source and served as a contactless probe that senses the environment. Mimicking natural flytraps, this artificial flytrap was capable of autonomous closure and object recognition (Fig. 9c). It enabled self-regulated actuation within the fiber-sized architecture, thus opening up avenues towards soft, autonomous, and small-scale devices.

An alternative to thermoelastic thermal expansion is a large reversible volumetric change or material “breathing” that is thermally induced by solid-to-solid phase transitions (SSPTs). The SSPT process does not change the state of matter, but it usually occurs as a change in the material symmetry via relatively large internal shifts, leading to significant, up to several percents, volumetric changes, whereas thermoelastic expansion yields much smaller volumetric changes of the order of 10−2% at best (see Table 1). For example, SSPT in silicate group materials, such as olivine Mg2SiO4, being abundant in the Earth’s crust, under the pressure gives rise to the other denser polymorph, i.e., spinel. The solid transformation from olivine to spinel produces an appreciable change in volume (∼8%), which is regarded as the cause of deep-focus earthquakes [193].

Recently, some metal-organic frameworks revealed large volumetric changes via SSPT. MOFs represent an exciting new class of nanoporous crystalline solids constituting metal ions/clusters combined with multifunctional organic linkages, which self-assemble at molecular level and generate a variety of ordered 3D structures. Bailey and Tezcan demonstrated protein–metal–organic frameworks (protein-MOFs) in the form of chemically designed protein crystals, composed of ferritin nodes predictably assembled into 3D lattices through coordination of various metal ions and ditopic, hydroxamate-based linkers [194]. The designed protein-MOFs possess extremely sparse lattice connectivity owing to their unique tripartite construction, leading to unusual thermomechanical properties, particularly, highly cooperative crystal-to-crystal transformation with a large volumetric change. Bailey et al. demonstrated reversible cycling of fdh-Ni-ferritin lattice expansion/contraction near-room temperature, with a 4% volumetric change within only 1°C and a hysteresis window of ∼10°C. This highly cooperative crystal-to-crystal transformation, which occurs due to the soft crystallinity of ferritin-MOFs, was proposed to provide the advantage of modular construction strategies that assist in discovering novel materials with tunable properties [194].

Maspoch et al. designed an open-framework Cu3(PTMTC)2(py)6(CH3CH2OH)2(H2O) structure, called MOROF-1, which combines very large pores with size of 2.8–3.1 nm and a bulk magnetic ordering [195]. MOROF-1 showed a reversible and highly selective solvent-induced ‘shrinking–breathing’ process accompanied by the large volumetric changes (25%–35%) and also the changes in magnetic properties.

Smets et al. reported thermally induced SSPT occurring in enantiotropically related polymorphs of molecular crystals composed of linear-chain amino acid racemates [196]. It was shown that shorter (quasi)racemates possessed larger (absolute) volume changes, which was assigned to the disorder change in the crystal structures. The maximum transition volume changes of ∼12 Å3 per unit cell was found for (quasi)racemates with five carbon atoms per molecule. Different mechanisms of the SSPT were proposed, i.e., the torsional changes that occur in a molecule-by-molecule fashion and cooperative motion of multiple molecules at the same time without torsional changes. The latter is different from the classical first-order transition and occurs via motion of layers with respect to each other without changing the layer structure itself, which is enabled by the strong hydrogen bonding within the layers and the weak van der Waals interactions between them.

Recent strategies were also directed towards synthesis of hyper-expandable porous materials with remarkable framework flexibility and record thermal expansion coefficients [197]. Zhou et al. [198] synthesized guest-controlled multimode porous polymer framework based on dinuclear Cd2(RCOO)4(Lpy)4 (Lpy = pyridyl group) unit, which interconnected with eight neighbors through four 34pba− and four 44pba− ligands, resulting in a 3D coordination network with a uninodal 8-connected bcu topology. Due to the 3D hinge-like framework and quasi-discrete ultramicropores, this flexible porous coordination polymer exhibited both drastic guest-modulation effect and anisotropic expansion with record positive/negative thermal expansion coefficients of +482/−218 × 10−6 K−1 (Table 2). This enormous effect was assigned due to the jack-like motion of the guest supramolecular dimers, being analogous to the anisotropic thermal expansion of bulk van der Waals solids, which is crucial for changing the flexibility mode and thermal expansion behavior of the crystal.

Scherb et al. [199] reported exceptionally large thermal expansion in supramolecular polymer network assembled into an organized order, where the flexible organic architecture with high adjustability and weak intermolecular interaction exists in assemblies. This architecture represented a 2D supramolecular network on Au(111), consisting of shape-persistent polyphenylene molecules equipped with peripheral dodecyl chains, and this polymer system showed a giant thermal expansion coefficient of 980 ± 110 × 10−6 K−1 (Table 2).

Kim et al. [200] developed a PNIPAM hydrogel with a layered structure consisting of cofacially oriented electrolyte TiNS nanosheets. In the PNIPAM hydrogel, in the absence of substantial water uptake and release, the distance between the nanosheets increases and decreases rapidly on heating and cooling, respectively, leading to significant expansion and contraction of the hydrogel; this represents a unidirectionally proceeding actuator that operates without the need for external physical biases. As a result, the hydrogel revealed unprecedentedly large, rapid, and anisotropic thermal expansion up to ∼25000 × 10−6 K−1 due to the electrostatic repulsion between TiNS nanosheets (Table 2).

MOFs are ideally suited to host photoswitchable guest molecules, because the MOF inherent porous structures provide enough space where photoswitchable molecules can isomerize. Furthermore, due to the structural “breathing” of SSPT frameworks, the space within the pores undergoes significant changes, which can be exploited to facilitate or to trigger isomerization of guest molecules, where significant changes in molecular geometry are required. Griffiths et al. demonstrated a specific MOF with quest azobenzene (AB) photoswitches in the MOF pores with four different AB loading, specified as 1 ⊃ AB0.3, 1 ⊃ AB0.5, 1 ⊃ AB0.9, and 1 ⊃ AB1.0, respectively. This structure could work as a hybrid solar thermal fuel (STF) and solid−solid phase-change material (ss-PCM) [72]. Upon irradiation with 365 nm light, 40% of the AB guests converted from the trans to the higher-energy cis isomeric form in 1 ⊃ AB1.0, whereas the stored energy could be released upon heating the metastable cis isomers while balancing the endotherm associated with the phase transition. A net energy release over a full heating−cooling cycle was obtained with the maximum energy density of 28.9 J/g for the fully loaded 1 ⊃ AB1.0 composite, which is much better compared with energy density produced by traditional thermomechanical engines (see Table 1). The MOF composite with cis-AB guests showed also negligible thermal reconversion during 4 months at ambient temperature, which corresponded to an estimated energy storage half-life of 4.5 years, which is suitable for potential application of this composite MOF in STF. As a result of AB loading, the orthorhombic to tetragonal SSPT gave rise to volumetric changes of this “breathing” MOF up to ∼11%, with cis isomer of the guest molecules being stable when contracting the pores. In addition to the guest loading effect, the thermally induced reversible phase transition was observed for the 1 ⊃ ABx, systems, characterized them as ss-PCMs that store and release energy via crystallographic structure/order−disorder transformations [72].

Thermally induced SSPT via mechanical molecular motion can mediate intermolecular interaction of chromophores that serve as a visual indication of the process. Wight et al. described colorimetric switching between two differently colored polymorph forms of monoalkoxynaphthalene-naphthalimide donor-acceptor dyads [201]. Upon heating, the orange form of alkyl chain layers became disordered, which facilitated lateral diffusion of dyads within the layer and corresponding dyad exchange from a head-to-head stacking geometry (orange) to a head-to-tail stacking geometry (yellow). This transition involved a nucleation and growth due to a faster cooperative wavefront mechanism during the transition. The fastest moving of the wavefronts corresponded to a non-conventional

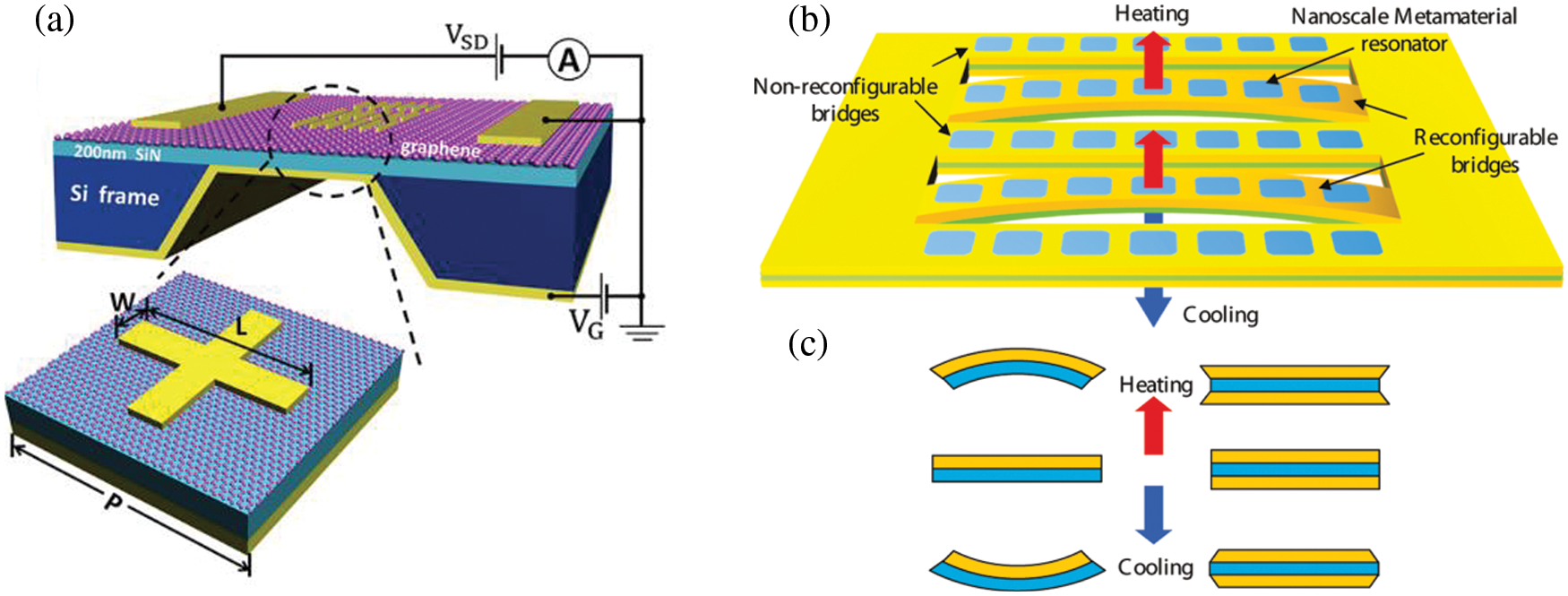

5.3 Thermoacoustic Micro-Transducers and Nanomechanical Resonators