Open Access

Open Access

ARTICLE

Innovative Biobased Composites from Oil Palm Trunk: Enhancing Mechanical and Flame-Retardant Properties through Optimized Additive Treatments

1 Centre of Excellence in Wood Engineered Products (CeWEP), University of Technology Sarawak, Sibu, 96000, Sarawak, Malaysia

2 Division of Bioresource Technology, School of Industrial Technology, Universiti Sains Malaysia, Gelugor, 11800, Penang, Malaysia

3 School of Engineering and Technology, University of Technology Sarawak, Sibu, 96000, Sarawak, Malaysia

4 School of Postgraduate Studies, University of Technology Sarawak, Sibu, 96000, Sarawak, Malaysia

5 School of Foundation Studies, University of Technology Sarawak, Sibu, 96000, Sarawak, Malaysia

* Corresponding Author: Madihan Yusof. Email:

(This article belongs to the Special Issue: Biomass-based Thermoset and Thermoplastic Polymers for Biomass-based Composites)

Journal of Renewable Materials 2025, 13(10), 2059-2075. https://doi.org/10.32604/jrm.2025.02025-0101

Received 05 August 2025; Accepted 18 August 2025; Issue published 22 October 2025

Abstract

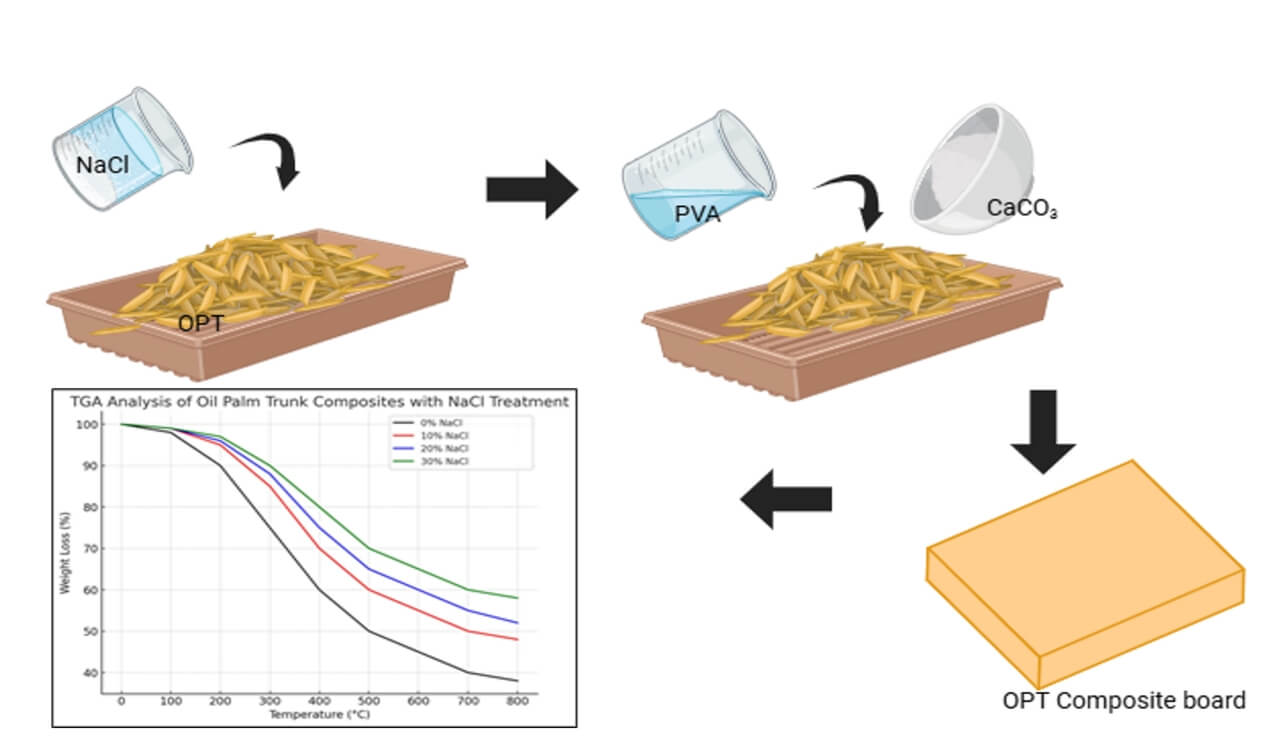

This study investigates the development of an oil palm trunk (OPT) high-performance flame-retardant composite derived from an inexpensive and sustainable biomass source, processed using sodium chloride (NaCl) as a low-cost flame retardant, polyvinyl alcohol (PVA) as an adhesive, and calcium carbonate (CaCO3) as an additive. The work aims to address the inherent flammability of OPT and to enhance its mechanical performance, dimensional stability, and fire resistance in an environmentally friendly and cost-effective manner. Results indicate that a 10% NaCl treatment optimally improves the performance of the composite, increasing bending strength (MOR) from 5.95 to 12.61 MPa and internal bonding strength (IB) from 2.05 to 4.18 MPa. Dimensional stability was significantly enhanced, thickness swelling (TS) and water absorption (WA) being reduced by 43.8% and 51.3%, respectively. Flame retardancy was significantly enhanced, achieving an Underwriters Laboratories (UL-94) V-0 rating and a limiting oxygen index (LOI) value of 33.57%. Higher NaCl concentrations exceeding 10% led to reduced mechanical performance and flame retardancy, likely due to disruption of matrix-fiber interactions or the formation of voids. Compared to halogenated or phosphorus type flame retardants, the NaCl had an advantageous cost, ecology and processing ease, along with the removal of toxic emissions. Synergistic effects of NaCl, PVA, and CaCO3 contributed to reduced water absorption, enhanced dimensional stability, and improved fire resistance, making this composite a viable green product for applications where flame retardation is required. This study provides new insights into the utilization of agricultural waste products to develop eco-friendly flame-retardant composite materials, contributing to environmental sustainability and the production of fire-safe engineered wood products.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools