Open Access

Open Access

ARTICLE

Innovative Biobased Composites from Oil Palm Trunk: Enhancing Mechanical and Flame-Retardant Properties through Optimized Additive Treatments

1 Centre of Excellence in Wood Engineered Products (CeWEP), University of Technology Sarawak, Sibu, 96000, Sarawak, Malaysia

2 Division of Bioresource Technology, School of Industrial Technology, Universiti Sains Malaysia, Gelugor, 11800, Penang, Malaysia

3 School of Engineering and Technology, University of Technology Sarawak, Sibu, 96000, Sarawak, Malaysia

4 School of Postgraduate Studies, University of Technology Sarawak, Sibu, 96000, Sarawak, Malaysia

5 School of Foundation Studies, University of Technology Sarawak, Sibu, 96000, Sarawak, Malaysia

* Corresponding Author: Madihan Yusof. Email:

(This article belongs to the Special Issue: Biomass-based Thermoset and Thermoplastic Polymers for Biomass-based Composites)

Journal of Renewable Materials 2025, 13(10), 2059-2075. https://doi.org/10.32604/jrm.2025.02025-0101

Received 05 August 2025; Accepted 18 August 2025; Issue published 22 October 2025

Abstract

This study investigates the development of an oil palm trunk (OPT) high-performance flame-retardant composite derived from an inexpensive and sustainable biomass source, processed using sodium chloride (NaCl) as a low-cost flame retardant, polyvinyl alcohol (PVA) as an adhesive, and calcium carbonate (CaCO3) as an additive. The work aims to address the inherent flammability of OPT and to enhance its mechanical performance, dimensional stability, and fire resistance in an environmentally friendly and cost-effective manner. Results indicate that a 10% NaCl treatment optimally improves the performance of the composite, increasing bending strength (MOR) from 5.95 to 12.61 MPa and internal bonding strength (IB) from 2.05 to 4.18 MPa. Dimensional stability was significantly enhanced, thickness swelling (TS) and water absorption (WA) being reduced by 43.8% and 51.3%, respectively. Flame retardancy was significantly enhanced, achieving an Underwriters Laboratories (UL-94) V-0 rating and a limiting oxygen index (LOI) value of 33.57%. Higher NaCl concentrations exceeding 10% led to reduced mechanical performance and flame retardancy, likely due to disruption of matrix-fiber interactions or the formation of voids. Compared to halogenated or phosphorus type flame retardants, the NaCl had an advantageous cost, ecology and processing ease, along with the removal of toxic emissions. Synergistic effects of NaCl, PVA, and CaCO3 contributed to reduced water absorption, enhanced dimensional stability, and improved fire resistance, making this composite a viable green product for applications where flame retardation is required. This study provides new insights into the utilization of agricultural waste products to develop eco-friendly flame-retardant composite materials, contributing to environmental sustainability and the production of fire-safe engineered wood products.Graphic Abstract

Keywords

Fire risks represent a significant hazard across various industries, including construction, packaging, and furniture manufacturing, particularly when dealing with lignocellulosic materials such as wood and agricultural waste. It has been reported that combustible products contribute to approximately 30% of building fires, highlighting the urgent need for the development of next-generation flame-retardant (FR) technologies [1].

Oil palm trunk (OPT), a highly renewable biomass material abundant in tropical regions such as Indonesia and Malaysia, holds substantial potential for sustainable product development. Although these compositions are advantageous for mechanical strength, their high cellulose and lignin content make them highly combustible, limiting their usage in flame-retardant applications [2]. While OPT offers clear environmental advantages, its inherent flammability remains a major constraint. Conventional flame-retardant approaches often involve synthetic chemicals, particularly halogenated compounds, which, despite their effectiveness, pose serious environmental and health risks [3,4]. As of this, scientists are now turning more to inorganic and bio-based options to attain fire resistance without disrupting ecological harmony [5].

In contrast, NaCl is a benign, low-cost, and abundant inorganic salt that enhances flame retardancy primarily through char formation and suppression of flammable volatiles [6]. Its simple treatment process, non-toxic nature, and compatibility with bio-based adhesives such as PVA make it a more environmentally responsible alternative. Moreover, the absence of hazardous emissions during thermal degradation positions NaCl as a safer choice in indoor applications or consumer products. This study explores NaCl as a viable substitute for conventional flame retardants in oil palm trunk composites, offering comparative benefits in performance, processability, cost-effectiveness, and ecological impact. Furthermore, while some studies explore borax or boric acid as flame retardants, NaCl offers advantages in terms of availability, cost, and salt-induced charring mechanisms that may be particularly suited to the porosity and cellular structure of OPT. The rationale for selecting NaCl over other agents lies in its benign nature, compatibility with hydrophilic binders, and prior evidence of effective flame-retardant behavior in agricultural fibers [6].

Other components, such as calcium carbonate (CaCO3) and polyvinyl alcohol (PVA) also play critical roles in composite formulation. CaCO3, commonly used in fire-resistant systems, enhances thermal stability by releasing CO2 during decomposition, thereby reducing oxygen availability for combustion [7,8]. PVA, a widely used binder in wood composites, provides excellent interfacial adhesion, though it has limited thermal stability [9]. To address this, researchers have explored the integration of inorganic fillers like boric acid and phosphorus compounds in PVA-based composites to improve fire resistance. Consequently, recent research has increasingly focused on inorganic and bio-based alternatives that achieve fire resistance while maintaining ecological integrity [5].

Conventional flame retardants, particularly halogenated and phosphorus-based compounds, are widely recognized for their high flame-inhibiting efficiency, however, their application raises critical concerns related to toxicity, environmental persistence, and disposal challenges. Halogenated systems can emit corrosive and carcinogenic gases during combustion, while phosphorus-based additives, although less toxic, often require complex synthesis and high production costs [4,5].

Despite these advances, several limitations persist in the existing research. While phosphorus-based intumescent systems have demonstrated efficacy in promoting char formation and reducing heat release rates, research on NaCl-based flame-retardant especially in biomass composite is limited [10]. Additionally, many flame-retardant applications involve complex chemical processes, which increase production costs and introduce environmental concerns [11]. Most existing studies also focus on conventional wood species, whereas the distinctive porosity and lower density of oil palm trunk require targeted research to optimize flame-retardant performance [11].

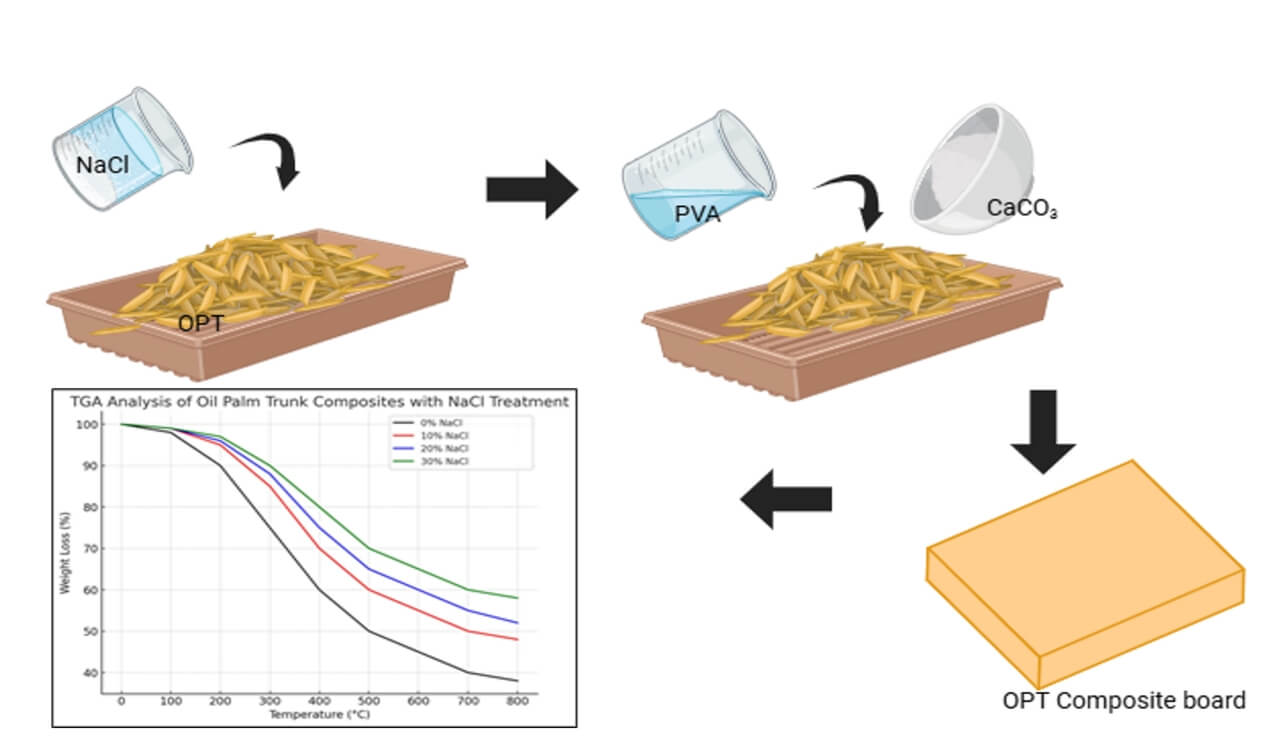

To address these gaps, this study hypothesizes that NaCl-treated oil palm trunk composites, when combined with PVA and CaCO3, will exhibit enhanced fire retardancy and mechanical performance comparable to that of conventional flame-retardant systems, while offering environmental and cost benefits. This study introduces a novel, high-performance flame-retardant composite by applying NaCl treatment to OPT, utilizing PVA as an adhesive and CaCO3 as an additive, and Fig. 1 shows the schematic of the proposed oil palm trunk flame-retardant composite board.

Figure 1: Schematic of the proposed oil palm trunk flame retardant composite boards

NaCl concentrations of 10%, 20%, and 30% were selected to investigate the threshold beyond which performance declines, based on preliminary optimization studies and literature indicating a nonlinear effect of salt loading on composite properties [6,12]. The novelty of this work lies in the optimization of NaCl-based treatment for OPT and the comparative evaluation against synthetic flame-retardant systems in terms of cost, performance, and environmental impact.

The aim is to contribute to sustainability by transforming OPT waste into a value-added product. In contrast to previous studies predominantly centered on synthetic flame retardants, this work proposes an eco-friendly, cost-effective strategy for improving flame resistance using agricultural waste-derived materials. The results are expected to generate new knowledge on sustainable fire-retardant technologies for biomass-derived composites, enhancing fire safety in engineered wood products and supporting the advancement of sustainable material development.

The OPT particles were obtained from Encore Agriculture Industries Sdn. Bhd., Kuala Lumpur, Malaysia, while the rubberwood (RW) was sourced from a plywood factory P. W Plywood in Penang, Malaysia. Both OPT and RW were ground to achieve a fine particle size of approximately 10 mm. CaCO3 and NaCl were procured from ChemAr in Selangor, Malaysia, and QRec in Negeri Sembilan, Malaysia, respectively. PVA and citric acid were supplied by R&M Chemicals from Penang, Malaysia. All the chemicals were used as received and were of analytical grade.

2.2.1 Sample Preparation and Composite Making

The OPT was subsequently screened using a four-level screener to isolate particles ranging from 10 to 20 mm in size. These particles were treated with NaCl by immersion in 10%, 20%, and 30% NaCl solutions for 6 h, following the method described by Das and Sarmah [12]. After treatment, the particles were oven-dried at 105°C to remove excess water. The dried particles were then mixed with 20% PVA and 4% CaCO3. The aqueous PVA solution was prepared by dissolving the PVA powder in deionized water at 80°C under constant stirring until fully dissolved [13]. Subsequently, 10% citric acid was added to the PVA solution to facilitate crosslinking, enhancing its performance as a binder. The crosslinked PVA and CaCO3 were then blended with OPT particles. The size of the composite board was 300 mm × 300 mm × 10 mm, and the target board density was 1 kg/m3. Composite boards were hot-pressed for 10 min at a temperature of 220 ± 2°C [14], achieving a final thickness of 0.5 cm. After pressing, the composite boards were trimmed to the desired dimensions. Fig. 2 shows the process of preparing the composite boards.

Figure 2: Schematic diagram outlining the preparation of oil palm trunk flame-retardant composite boards

2.2.2 Bending Test and Internal Bonding Test

The bending test was conducted using an Instron Universal Testing Machine, model 4204 from Instron Company, Norwood, CT, USA, in accordance with the JIS A 5908-2003 [15]. The test was performed under a concentrated loading rate of 10 mm/min. Specimens for the bending test measured 50 mm × 200 mm, with an effective span of 150 mm. For each particleboard type, four test samples were prepared to determine bending performance.

Internal bonding tests were also carried out following the JIS A 5908-2003 standard [15], using the same Instron 4204 machine employed in the bending test. Each specimen was adhered to a block with dimensions of 50 mm × 50 mm and positioned in the testing machine. A vertical tensile load was applied to the surface of the board at a loading speed at 2 mm/min. The maximum load (P’) at which the perpendicular tensile strength of the board failed was recorded as the internal bonding strength. Four samples were replicates for the internal bonding test.

2.2.3 Dimensional Stability Test

The composite board was evaluated for thickness swelling (TS) and water absorption (WA) by calculating the ratio of its thickness and weight after water immersion to its initial thickness and weight, respectively. The tests were conducted by submerging the composite board in water for 24 h, and subsequent measurements were recorded. All procedures were performed by the JIS A 5908-2003 [15]. Four replicates were done for testing TS and WS, respectively.

2.2.4 Limited Oxygen Index Test (LOI)

The Limited Oxygen Index (LOI) test was conducted to evaluate the flammability of composite boards by determining the minimum oxygen concentration in air required to sustain combustion [16]. The test was performed using Fire Testing Technology LOI equipment, manufactured by Firetesting Technology Company, West Sussex, UK, following the ASTM D 2863-00 standard [17]. All procedures were carried out under controlled environmental conditions in accordance with the specified oxygen index testing protocol. Each specimen measured 8 cm × 1 cm × 0.5 cm, consistent with the ASTM D 2863-00 [17] standard.

The UL 94 flammability test was conducted to assess the flammability characteristics of plastic materials, including flame-retardant composites, commonly used in the electronics and construction industries. This test quantitatively evaluates ignitability and flame propagation in vertically mounted specimens exposed to a small ignition source. The procedure, originally formulated by Underwriters Laboratories Inc., was performed in accordance with ASTM D 635-03 [18].

During testing, the burner was adjusted to produce a blue flame with an inner cone height of 20 mm and a flame power rating of 50. The flame was applied on the bottom edge of each vertically mounted specimen, with the burner positioned approximately 10 mm below the lower rim. Each sample was exposed to the flame for 10 s, repeated five times to ensure consistent combustion assessment. Five replicate specimens were prepared for each flame-retardant composite type, with dimensions of 12.5 cm × 1.3 cm × 0.5 cm.

2.2.6 Thermogravimetric Analysis Test

Thermogravimetric analysis (TGA) was performed using a Shimadzu TGA-50 thermogravimetric analyzer, manufactured by Shimadzu, Nishinokyo, Japan. Sample was heated from ambient temperature to 920°C at a constant rate of 20°C min−1 under a nitrogen atmosphere. The TGA data were recorded as weight percentage loss relative to temperature. The thermal degradation behavior and kinetics were analyzed using the Freeman-Carroll method [19].

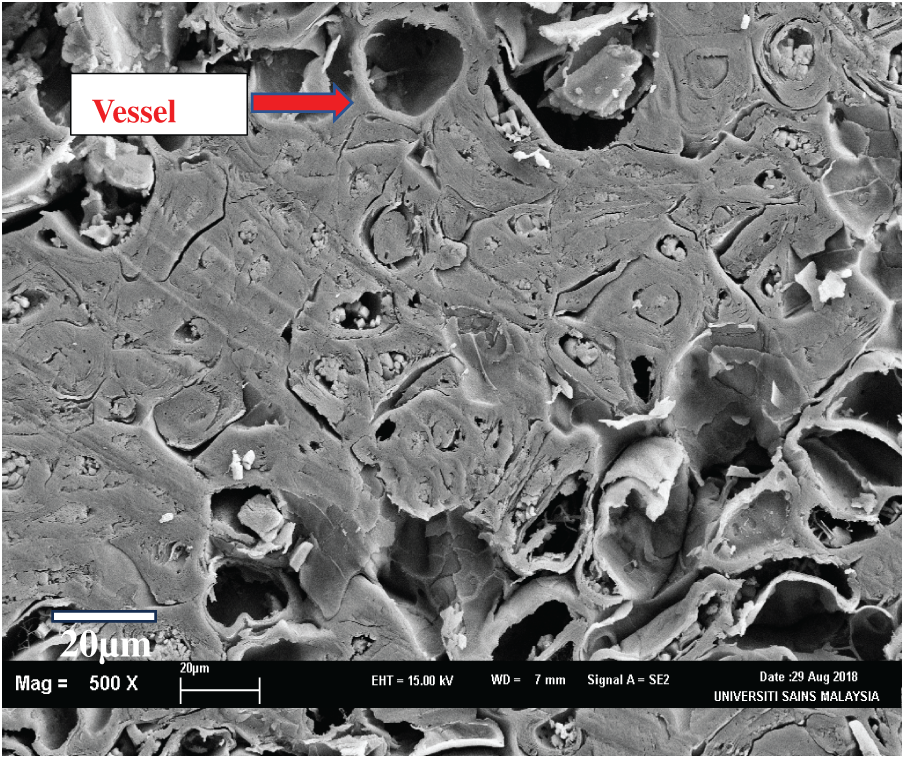

Scanning electron microscopy (SEM) was employed as part of the morphological characterization of the composite samples. Test specimens measuring 1 cm × 1 cm × 1 cm were prepared from the internal bonding strength samples. Before imaging, the specimens were thoroughly cleaned to remove any contaminants and oven-dried at 105°C. To enhance conductivity, the samples were coated with a thin layer of gold (approximately 20 nm in thickness) using a POLARON 515 sputter coater. Imaging was carried out using a LEO Supra 50 variation pressure (VP) scanning electron microscope manufactured by Carl Zeiss, Oberkochen, Germany, which was connected to a computer for image acquisition and processing. SEM images were evaluated based on surface morphology and analyzed from various preferred angles.

2.2.8 Fourier Transform Infrared (FTIR) Analysis

Fourier transform infrared analysis (FTIR) was performed to study the chemical structure of organic molecules, and to detect potential structural changes. Spectra were viewed using a Perkin-Elmer Spectrometer supplied by Perkin Elmer Company from Bridgeport, USA. The spectra of the samples were obtained by averaging 15 scans with a wavenumber range between 4000 cm−1 and 650 cm−1 with a resolution of 2 cm−1. Each piece was mixed with KBr and pressed into a disk with a ratio of 1:100. In infrared spectroscopy, the radiation of infrared light (IR) is passed through the piece.

The IBM SPSS Statistics version 23 (SPSS Inc. Chicago, IL, USA) was used to analyze the data. The data were analyzed by the researchers using a single-factor, completely randomized design. Composite board properties were evaluated through Analysis of variance (ANOVA), as well as Duncan’s multiple range test, with p-values ≤ 0.05 being statistically significant.

3.1 Evaluation of Mechanical Properties and Dimensional Stability

Fig. 2 illustrates the bending strength (MOR) of the bio-based composite board derived from oil palm trunk (OPT), demonstrating a significant improvement as the NaCl content increases from 0% to 10%. The MOR value rises from 5.95 to 12.61 MPa, reflecting a substantial enhancement in mechanical properties through 10% NaCl treatment [20,21]. According to JIS A 5908-2003 [15], widely used in the evaluation of wood-based composites, the minimum MOR of composite board (Type 8) is 8.0 MPa. The standard also offers a span-to-thickness ratio of 15:1 for bending tests. As a result, the board demonstrates potential mechanical performance for non-structural applications such as wall cladding, furniture panel, and interior components. This improvement is attributed to the synergistic effects of NaCl and the inherent structure of OPT particles, which contribute to enhancing structural integrity and resistance to bending stresses. However, beyond this optimal concentration, the MOR begins to decline, falling to 9.57 MPa at 20% NaCl and further to 9.43 MPa at 30% NaCl. These results suggest that while moderate NaCl treatment reinforces the composite, excessive NaCl may disrupt the matrix-fiber interactions or induce void formation, thereby compromising structural integrity [22,23]. The optimal 10% NaCl concentration thus achieves a balance between improved flame retardancy and mechanical performance, underscoring the potential of bio-based materials such as OPT for high-performance applications.

Similarly, Fig. 3 presents the internal bonding (IB) strength of the composite board, following a comparable trend. As the NaCl content increases from 0% to 10%, IB strength rises markedly from 2.05 to 4.18 MPa, indicating enhanced interfacial adhesion and resistance to internal stresses. This enhancement is likely due to the combined effects of NaCl, PVA, and CaCO3, which interact to reinforce the internal structure of the composite. However, as NaCl content exceeds 10%, IB strength decreases slightly to 4.16 MPa at 20% and further to 3.88 MPa at 30%. This decline highlights the necessity of optimizing additive concentrations to avoid weakening adhesion and structural stability. Similar trends have been reported in other bio-based composites, where the addition of flame-retardant or reinforcing agents enhances mechanical properties only up to a certain threshold, beyond which performance deteriorates due to matrix interference [23]. Overall, the results confirm that 10% NaCl represents the optimal concentration for maximizing the internal bonding strength of the OPT-based composite, offering a well-balanced performance in terms of both mechanical strength and fire resistance.

Figure 3: Bending strength and internal bonding strength from oil palm trunk flame retardant composite boards

These findings emphasize the vital role of renewable components such as OPT particles, PVA adhesive, and CaCO3 additive in fabricating high-performance composites. By effectively integrating bio-based resources and optimizing treatment conditions, this study demonstrates a sustainable pathway for improving the mechanical and flame-retardant characteristics of bio-based materials. Such an approach contributes to the broader objective of developing environmentally friendly alternatives to conventional synthetic composites.

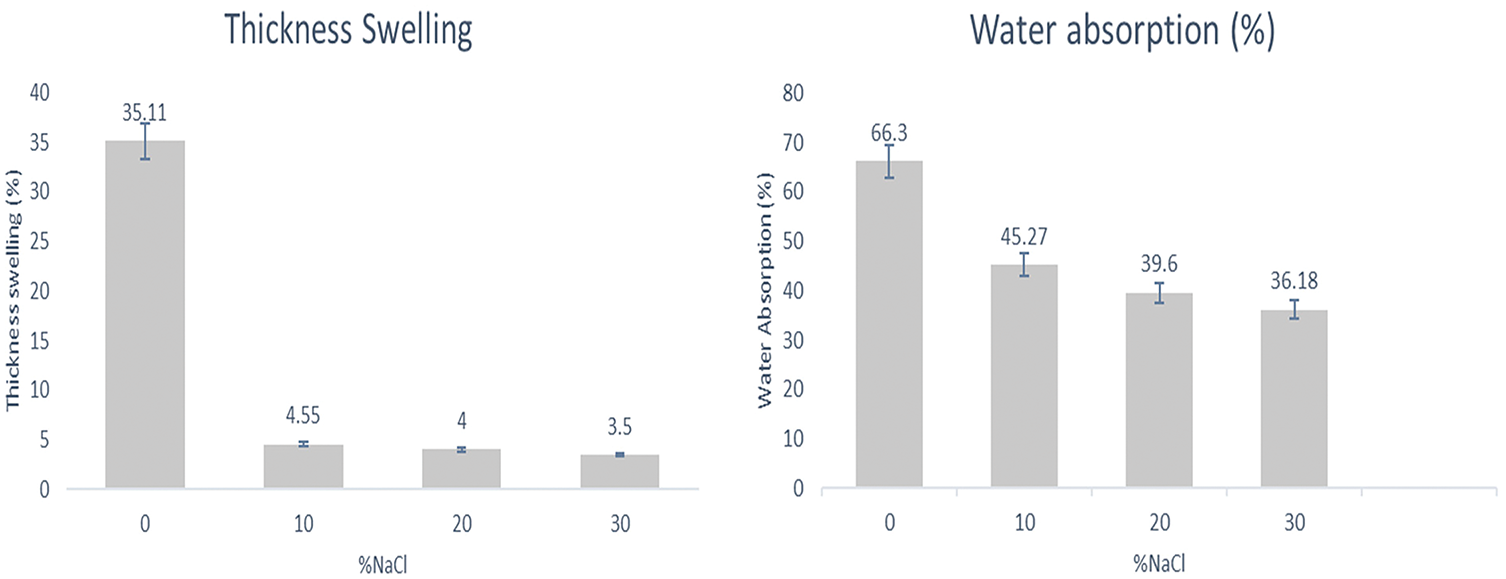

Fig. 4 presents the physical properties of the OPT composite board, focusing on TS and WA, which are the key indicators of dimensional stability and moisture resistance in bio-based products. The TS values show a substantial reduction with increasing NaCl concentration from 0% to 10%, with values decreasing from 35.11% to 4.55%. This marked improvement highlights the efficacy of NaCl treatment in enhancing the dimensional stability of OPT-based composites. These results align with prior studies on bio-based materials, in which inorganic salt treatments reduced swelling and improved composite integrity. For example, Lòpez et al. [24] demonstrated that the incorporation of NaCl into thermoplastic-reinforced wood particleboards significantly reduced swelling, while Song et al. [25] found that salt-based treatments improved dimensional stability of lignocellulosic composites. Similarly, Hafidz et al. [26] reported that alkaline treatments on oil palm fibers led to micropore contraction and capillary collapse, reducing both thickness swelling and water uptake.

Figure 4: Thickness swelling and water absorption from oil palm trunk flame-retardant composite boards

WA results further substantiate the benefits of NaCl treatment in enhancing the performance of OPT composites. As NaCl content increases from 0% and 30%, WA significantly decreases from 66.3% to 36.18%. This trend can be attributed to the synergistic interaction among the OPT particles, PVA adhesive, and CaCO3 additive. NaCl likely alters the composite’s internal structure and surface chemistry, acting as a cross-linking agent that reduces hydrophilicity and inhibits water uptake [22]. The reduction in WA becomes more pronounced at higher NaCl concentrations, confirming NaCl’s crucial role in enhancing water resistance [20,21]. Additionally, PVA, a bio-based adhesive, further contributes through its strong film-forming ability, which acts as a moisture barrier [27]. The synergistic effect between NaCl and PVA enhances this barrier function, resulting in lower water absorption. Moreover, CaCO3, a naturally occurring mineral, decreases porosity and improves mechanical cohesion, further restricting pathways for water infiltration [28].

Collectively, the interaction of NaCl, PVA, and CaCO3 represents a clear expression of individual and synergistic contributions to reducing moisture uptake and improving dimensional stability. By leveraging agricultural waste such as OPT and incorporating sustainable additives, this study presents a promising approach to developing high-performance, eco-friendly composites. These results not only validate the potential of agricultural waste-derived materials but also demonstrate their applicability in industries requiring moisture-resistant and dimensionally stable bio-based composites.

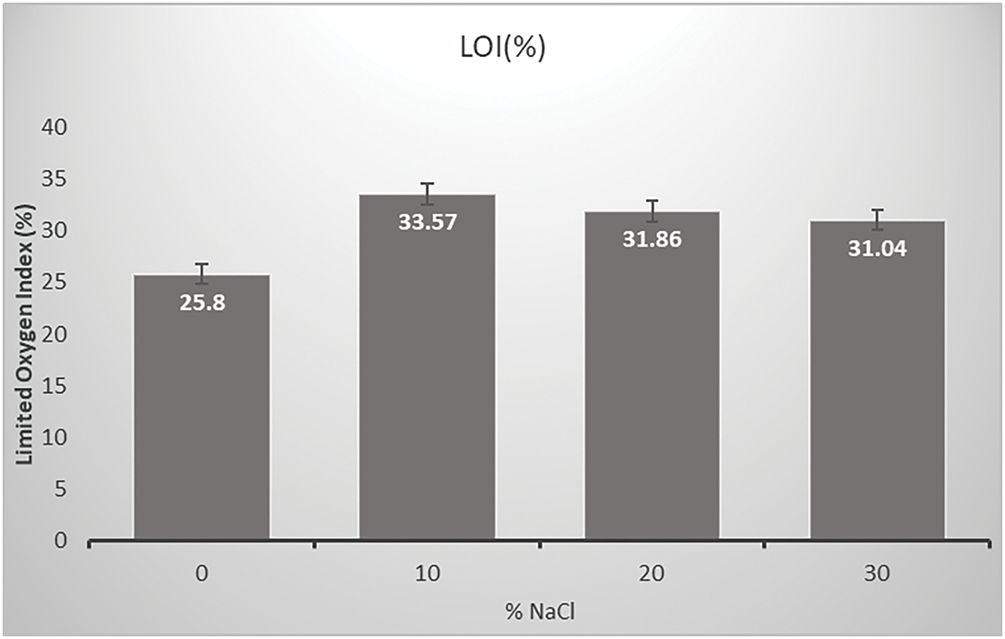

3.2 Evaluation on Limited Oxygen Index

Table 1 presents the classification of materials based on their flammability, where substances requiring oxygen concentrations below 20.95% are categorized as highly flammable, while those with LOI values of 28% or higher are considered to possess strong flame-retardant characteristics. Fig. 5 illustrates the LOI results for OPT flame-retardant composite boards treated with varying concentrations of NaCl. The LOI measures the minimum oxygen concentration required to sustain combustion, with higher values indicating superior flame retardant performance.

Figure 5: LOI from oil palm trunk flame retardant composite boards

A significant increase in LOI is observed as the NaCl content increases from 0% to 10%, rising from 25.8% to 33.57%. This notable improvement underscores the efficacy of NaCl in enhancing the flame retardancy of bio-based OPT composites [21]. The enhancement is likely attributed to the role of NaCl as a flame inhibitor, which promotes char formation, facilitates the release of non-combustible gases during thermal decomposition, and contributes to the formation of a protective barrier that insulates the substrate from heat and oxygen exposure [29].

However, beyond the 10% NaCl threshold, a decline in LOI is observed, with values decreasing to 31.86% at 20% NaCl and further to 31.04% at 30% NaCl. This reduction suggests that while moderate NaCl incorporation enhances fire resistance, excessive concentrations may negatively impact composite performance. The decline is likely due to the disruption of matrix-fiber interactions or the formation of microvoids within the composite, which may undermine its structural coherence and thermal barrier effect [30]. These findings indicate that a 10% NaCl concentration provides the optimal balance between flame retardancy and mechanical integrity in OPT-based composites. This trend is consistent with observations in other bio-based systems, where flame-retardant effects are enhanced up to a critical concentration, beyond which material performance may deteriorate due to structural instability [31].

The contribution of bio-based components such as OPT particles, PVA, and CaCO3 is also critical to the observed flame-retardant performance. PVA, a bio-derived adhesive, improves interfacial bonding and film formation, while CaCO3 enhances thermal stability and reduces porosity, further contributing to the flame-retardant properties of the composite [27,28]. By utilizing renewable resources and optimizing additive formulations, this study offers a sustainable strategy for enhancing fire safety in bio-based materials. These findings support the development of eco-friendly alternatives to synthetic composites and demonstrate the potential of agricultural waste-derived materials in applications requiring reliable flame retardancy.

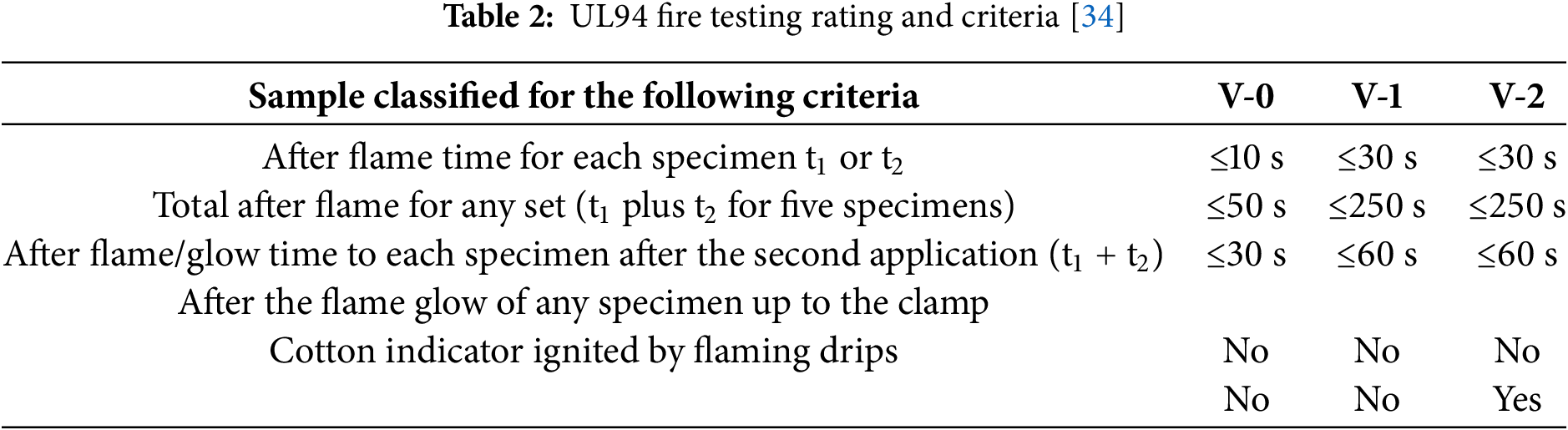

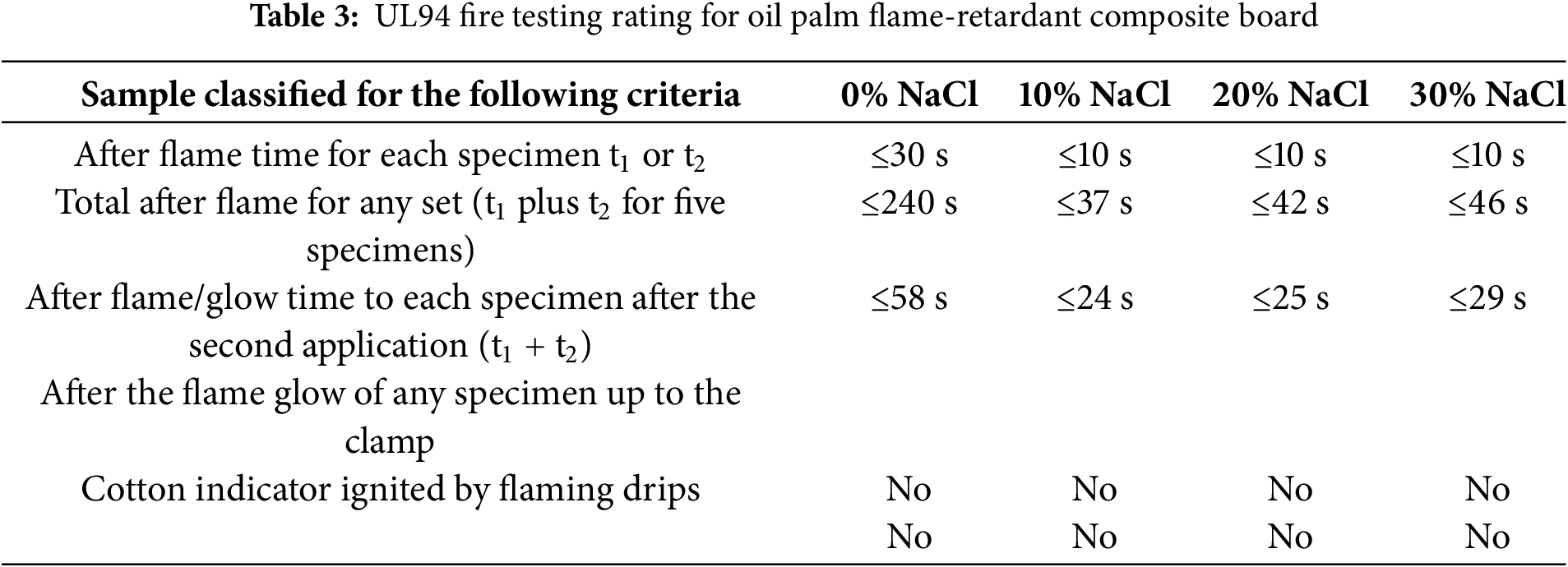

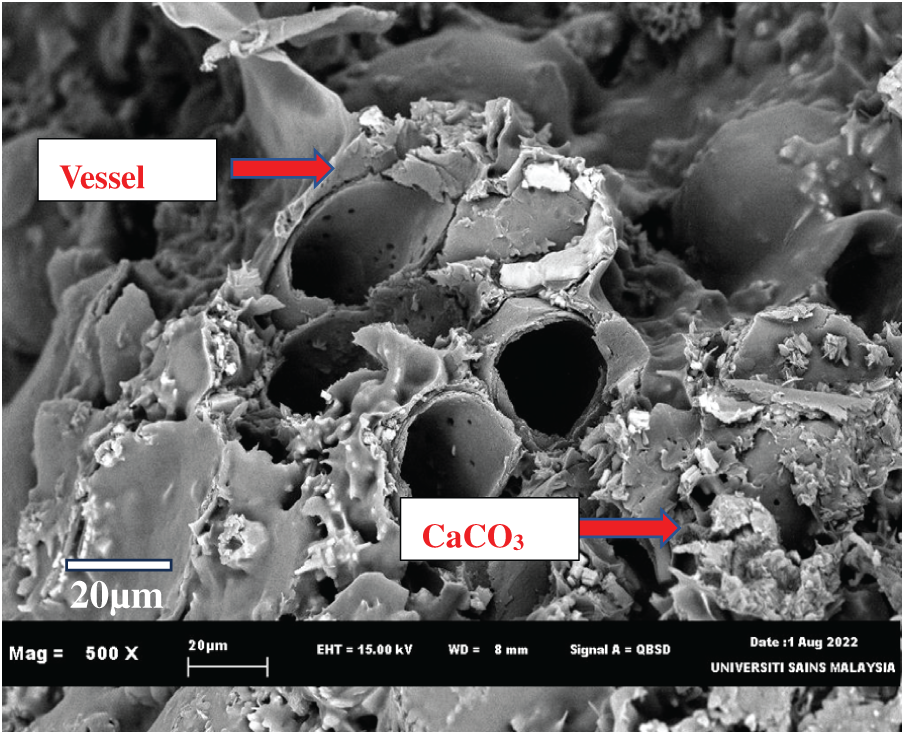

The categorization of flammability in the UL-94 vertical burning test is defined by the V-0, V-1, and V-2 classifications, as outlined in Table 2. The corresponding results presented in Tables 3 and 4 demonstrate a clear enhancement in flame-retardant performance with the increasing concentrations of NaCl in the OPT composite. At 0% NaCl, the composite achieves a V-1 rating, indicating that it self-extinguishes within 30 s but may emit flaming droplets during combustion.

In contrast, the addition of NaCl at 10%, 20%, and 30% consistently enables the composite to attain a V-0 rating, which is the highest classification in the UL-94 standard. A V-0 rating indicates that the material self-extinguishes within 10 s and does not produce flaming drips, reflecting excellent flame-retardant behaviour. This improvement can be attributed to the role of NaCl as both a char-forming agent and flame inhibitor. During thermal decomposition, NaCl likely facilitates the release of non-combustible gases that dilute flammable volatiles and interrupt the combustion process. Simultaneously, it contributes to the formation of a thermally stable protective barrier that limits oxygen and heat access to the composite substrate [29]. Previous studies have similarly reported the efficacy of inorganic salts such as NaCl in improving flame retardancy in natural fiber composites by enhancing thermal stability and suppressing flame spread [32]. The consistent achievement of V-0 with NaCl loadings as low as 10% emphasizes the efficiency of NaCl in delivering high flame retardant performance. These findings are consistent with earlier research on the role of inorganic flame retardants in augmenting the fire resistance of lignocellulosic products [33]. In general, these findings underscore the critical function of NaCl in enhancing the fire safety of OPT composites, validating their potential in environments where stringent flame retardant standards are required.

3.4 Evaluation of Thermal Stability of Composite

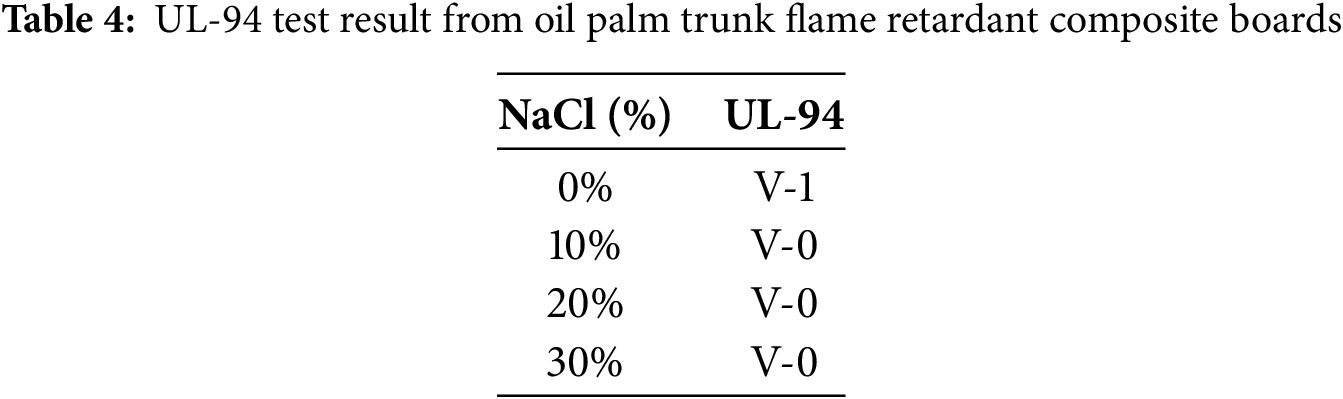

Thermogravimetric analysis (TGA) was employed to assess the thermal stability and decomposition behaviour of OPT composite boards treated with varying concentrations of NaCl. Fig. 6 presents the weight loss (%) as a function of temperature for the different NaCl-treated samples. The data indicate that increasing NaCl concentration enhances the thermal stability of the composites. The untreated sample (0% NaCl) exhibits the highest weight loss at lower temperatures, indicating early onset of thermal degradation and poor thermal resistance. In contrast, the composite treated with 10% NaCl demonstrates improved thermal stability, characterised by delayed degradation and a higher residual mass at elevated temperatures. Samples treated with 20% and 30% NaCl exhibit further enhancement in thermal resistance, consistent with findings from previous studies on salt-treated lignocellulosic composites [27].

Figure 6: TGA and DTG of oil palm trunk flame retardant composite boards

The derivative thermogravimetric (DTG) curve shows distinct thermal degradation profiles with a prominent peak between approximately 300°C to 400°C corresponding to the decomposition of major lignocellulosic components, hemicellulose and cellulose [27]. The most significant rate of weight loss was observed in the 0% NaCl, which proves that lower thermal stability than the treated sample. Increasing the NaCl content, especially at 20% and 30%, resulted in less intense DTG peaks that slightly shifted towards higher temperatures, interfering with a slowing down of the thermal decomposition process. This can be attributed to the flame-retardant nature of NaCl, which would facilitate the formation of a protective char layer during thermal degradation and halt volatile emission. Typically, the 30% NaCl sample had the lowest derivative weight loss, confirming enhanced thermal stability. In general, DTG curves demonstrate that the thermal resistance of oil palm trunk composite boards is improved by the NaCl treatment to be more suitable for applications where thermal durability and fire resistance are required. The improved thermal performance is attributed to the role of NaCl in reducing the evolution of volatile organic compounds, promoting the formation of a protective barrier over the lignocellulosic matrix, and enhancing char development during decomposition. Salts such as NaCl are known to facilitate the formation of carbonaceous char, which serves as an insulating layer that retards heat transfer and minimizes combustion [35].

3.5 Evaluation of Morphological

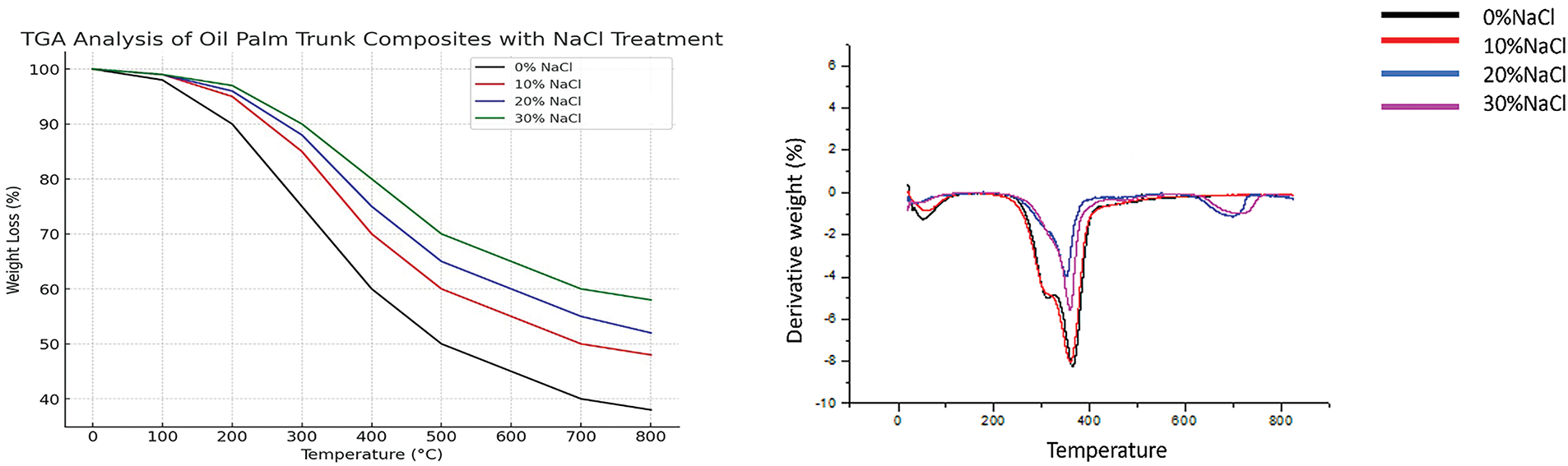

The scanning electron microscopy (SEM) micrographs offer detailed insights into the microstructural differences between OPT composite treated with 10% NaCl and those left untreated. As shown in Fig. 6, the NaCl-treated composite exhibits a denser and smoother surface morphology compared to the untreated sample. NaCl treatment appears to reduce surface porosity and improve the overall structural integrity of the composite. This is evident from the reduced presence of voids and the enhanced surface smoothess in the treated sample. The increased compactness likely contributes to the improvements in mechanical strength and reduced water absorption previously reported (Fig. 7) [20].

Figure 7: SEM from OPT with 10% NaCl with 500× magnification

In contrast, Fig. 8 illustrates the untreated OPT composite, which displays a rougher surface with a higher degree of porosity. The abundance of voids and surface irregularities indicates weak interfacial bonding and poor structural cohesion, which can negatively affect both mechanical performance and dimensional stability. These microstructural deficiencies correspond with the lower bending strength (MOR) and IB values observed in untreated composites. The smoother and more homogenous surface of the NaCl sample, on the other hand, suggests improved adhesion between the matrix and the fibers, contributing to superior resistance against both bending and internal stresses [22].

Figure 8: SEM from OPT with 0% NaCl with 500× magnification

Additionally, the SEM observations align with the results of the WA and TS tests. The reduced porosity in the 10% NaCl-treated composite limits the pathway for water ingress, resulting in enhanced dimensional stability. This suggests that NaCl may alter both the inner structure and surface properties of the OPT particles, potentially acting as a crosslinking agent that decreases hydrophilicity while enhancing flame resistance [27]. The synergistic interaction among NaCl, PVA adhesive, and CaCO3 is further validated by the superior performance in flame retardancy tests. Specifically, the 10% NaCl-treated composites achieved the highest LOI value and consistent V-0 ratings in the UL-94 test [29,32].

Overall, the SEM micrographs visually confirm the beneficial effects of NaCl treatment on the microstructure of OPT composites, which underlie the observed enhancement in mechanical, dimensional, and flame-retardant properties. These findings are consistent with prior research demonstrating how inorganic fillers such as NaCl and CaCO3 can significantly improve the structural and functional performance of lignocellulosic composites [33]. The 10% NaCl treatment is identified as the optimal formulation, offering an effective balance between flame retardancy and mechanical performance, and thus presents a promising strategy for the development of high-performance, sustainable OPT-based composites.

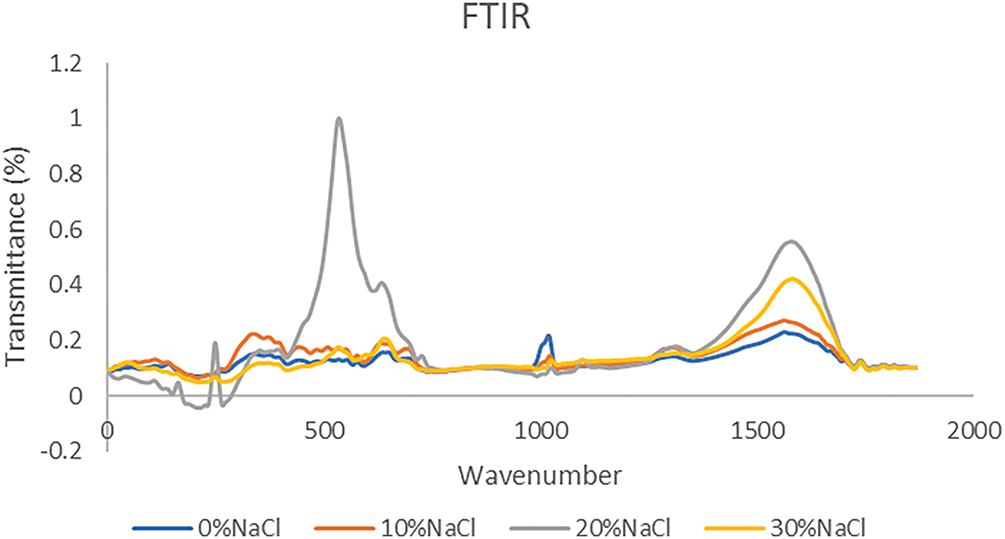

The FTIR analysis of composite boards of oil palm trunk treated with different concentrations reveals the chemical modification presented in Fig. 9. Characteristic lignocellulosic peaks were observrd in all samples, such a broad absorption band 3300 cm−¹ (O–H stretching), 2900 cm−¹ (C–H stretching), and peaks at around 1730 and 1600 cm−¹ corresponding to C=O stretching in hemicellulose and aromatic skeletal vibrations in lignin, respectively. Notably, the 20% NaCl-treated sample displayed significantly higher transmittance intensities across the fingerprint region (400–1500 cm−¹), particularly at ~500 and ~1500 cm−¹, indicating deeper chemical interactions or structural reorganization. This can be taken to imply partial crystallization of the NaCl-induced reorganization of the polymeric network that enhances the rigidity or thermal response of the composite. The changes also indicate potential alterations in hydrogen bonding and NaCl biopolymer interactions, supporting improvements in fire resistance and thermal stability as observed in DTG analysis. The findings are consistent with current studies on the role of inorganic salts in modifying the physicochemical structure and flame retardancy of lignocellulosic composites [27,34,36]. The inclusion of NaCl not only alters the chemical environment but can also enhance composite durability for thermal and structural applications.

Figure 9: FTIR spectra of oil palm trunk composite boards

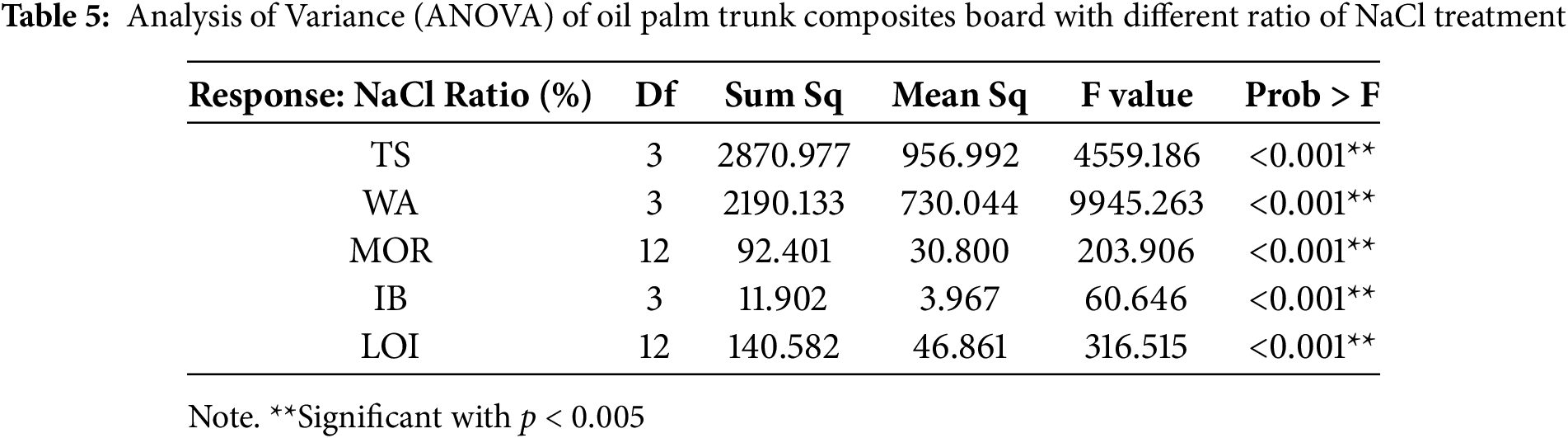

3.7 Statistical Analysis of ANOVA

The ANOVA results in Table 5 clearly show that different NaCl treatment ratios significantly affected all properties of the oil palm trunk composite board, including TS, WA, MOR, IB, and LOI. For all response variables, the p-values are less than 0.001, indicating statistically significant differences among the treatment groups at the 0.005 significance level. For TS, ANOVA shows a very high F-value, demonstrating a strong impact of NaCl treatment ratio on the dimensional stability of the composite board. Similarly, for WA, a higher F-value confirms that NaCl treatment plays a significant role in reducing moisture absorption within the composite structure.

The mechanical properties for MOR and IB also showed significant variation with NaCl treatments. This indicates that the NaCl content affects bending strength and internal bonding in the composite. This may be either by changing fiber-matrix interaction or reinforcement of the fiber due to NaCl, depending upon concentration. While for LOI showed a highly significant treatment effect with F-value of 316.515. It means that the flammability characteristics of the composite are altered by the addition of NaCl. Overall, ANOVA results confirm that the variation of NaCl ratio significantly affects the physical, mechanical and flame retardant properties of oil palm trunk composite boards. The finding emphasize the importance of optimizing NaCl concentration to enhance the performance characteristics of bio-based composite for panelling or structural applications.

3.8 Aging Behaviour and Environmental Durability

Although this study demonstrates enhancements in flame retardancy, mechanical properties, and dimensional stability of the treated OPT composite with NaCl at different concentrations, there remains a genuine concern over long-term durability under environmental stress conditions for real-world applications. Exposure to cyclic humidity, UV radiation, and thermal cycling can lead to structural degradation and loss of fire resistance. The hydrophilicity of NaCl and PVA may result in salt leaching or binder degradation over time, causing interfacial bonding loss and weakening of composite integrity. UV exposure can also cause polymer chain scission or surface degradation with a negative influence on appearance, as well as mechanical stability. Accelerated aging tests like moisture absorption-desorption, thermal aging, and UV exposure, therefore, ought to be incorporated in future investigations to evaluate the long-term performance of the material. In particular, prolonged moisture contact can alter salt distribution and reduce adhesion between OPT fibers and PVA–CaCO3 matrix. These works are essential to confirm environmental reliability and functional durability of the composite, particularly in exterior building or outdoor furnishing use. Such durability experiments integrated into the paper will provide more in-depth insight into lifecycle performance and guide the material’s industrial-scale usage.

3.9 Limitations and Future Work

While this study presents encouraging results in enhancing OPT composites using NaCl, PVA, and CaCO3, several limitations warrant attention for future development. The current evaluation was confined to initial mechanical, physical, and flame-retardant properties, without assessing long-term durability under environmental aging conditions such as UV exposure, humidity cycling, or thermal fluctuations. These factors are essential for predicting the composite’s real-world performance, particularly in outdoor or semi-exposed applications. Industrial scalability also poses significant challenges. The NaCl immersion process, while effective at the laboratory scale, may be inefficient for large-scale production due to extended drying times, high water consumption, and the risk of uneven salt distribution. Furthermore, although PVA enhances adhesion and environmental compatibility, its relatively high cost may limit feasibility for mass production. Uniform dispersion of CaCO3 and consistent matrix-fiber interaction across large panels also require further process optimization. To ensure commercial viability, future research should focus on pilot-scale production trials, automation of the treatment and forming steps, and comprehensive life cycle and techno-economic assessments. Environmental impact studies, particularly concerning NaCl leaching and end-of-life disposal, are also necessary to support the material’s sustainability claims and industrial adoption. To ensure responsible material development, future studies should incorporate comprehensive life-cycle assessments (LCA) to quantify the environmental footprint of the composite, from raw material extraction to end-of-life management. This includes evaluating salt leaching behavior, eco-toxicity thresholds, and potential impacts under various disposal and recycling pathways. Incorporating such analyses will be essential for validating the composite’s sustainability and aligning its application with environmental regulations and circular economy principles.

The fabrication of flame-retardant OPT composites with NaCl, PVA, and CaCO3 exemplifies a green and sustainable alternative to conventional petroleum-based composites. By optimizing the NaCl treatment conditions, this study successfully enhances the mechanical, thermal, and flame-retardant properties of OPT-based composites, while simultaneously addressing the environmental concerns associated with synthetic flame retardants. The results underscore the significance of advanced treatment strategies and processing techniques in improving the compatibility of biomass-derived reinforcements with polymer matrices. The synergistic interactions among NaCl, PVA, and CaCO3 are shown to improve structural integrity, dimensional stability, and flame resistance, validating the approach of integrating bio-based additives for performance enhancement. Moreover, the investigation of interfacial bonding and microstructural features highlights the critical role of material design in the development of high-performance bio-composites. This research makes a valuable contribution to the growing field of hybrid composites based on lignocellulosic materials and biopolymers, supporting the advancement of sustainable material technologies. As industries increasingly prioritize environmental responsibility, the findings provide a foundational framework for the development of next-generation biomass-based thermoset and thermoplastic composites and offering cost-effective, high-performance, eco-friendly alternatives for diverse industrial applications.

Acknowledgement: The authors are grateful to the University of Technology Sarawak (UTS) and Universiti Sains Malaysia (USM) for providing access to their research facilities and laboratories, which were required for conducting and analyzing various aspects of this study.

Funding Statement: The authors are grateful for the support from research grants YSRG/1/2022/02, 1001/PTEKIND/8014083, and the Science and Technology Research Partnership for Sustainable Development (SATREPS) (203.PTEKIND.67811002).

Author Contributions: The authors confirm contribution to the paper as follows: Conceptualization, methodology, writing original: Madihan Yusof; writing—review and editing: Ros Syazmini Mohd Ghani; visualization: Mohamad Saiful Sulaiman; interpretation of data: Sofiyah Mohd Razali. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Not applicable.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Rybiński P, Mirkhodjaev UZ, Żukowski W, Bradło D, Gawlik A, Zamachowski J, et al. Effect of hybrid filler, carbon black lignocellulose, on fire hazard reduction, including PAHs and PCDDs/Fs of natural rubber composites. Polymers. 2023;15(8):1975. doi:10.3390/polym15081975. [Google Scholar] [PubMed] [CrossRef]

2. Yusof M, Lamaming J, Hashim R, Yhaya MF, Sulaiman O, Selamat ME. Flame retardancy of particleboards made from oil palm trunk-poly(vinyl) alcohol with citric acid and calcium carbonate as additives. Constr Build Mater. 2020;263(4):120906. doi:10.1016/j.conbuildmat.2020.120906. [Google Scholar] [CrossRef]

3. Chukwunwike S, Chukwunwike SA, Okafor KJ. A review on some selected bio-based (Green) flame retardants. J Eng Technol. 2019;8(1):38–43. [Google Scholar]

4. Wang M, Yin GZ, Yang Y, Fu W, Díaz Palencia JL, Zhao J, et al. Bio-based flame retardants to polymers: a review. Adv Indust Eng Poly Res. 2023;6(2):132–55. doi:10.1016/j.aiepr.2022.07.003. [Google Scholar] [CrossRef]

5. Samanta P, Samanta A, Montanari C, Li Y, Maddalena L, Carosio F, et al. Fire-retardant and transparent wood biocomposite based on commercial thermoset. Compos Part A Appl Sci Manufact. 2022;156(26):106863. doi:10.1016/j.compositesa.2022.106863. [Google Scholar] [CrossRef]

6. Tan BK, Ching YC, Poh SC, Abdullah LC, Gan SN. A review of natural fiber reinforced poly(vinyl alcohol) based composites: application and opportunity. Polymers. 2015;7(11):2205–22. doi:10.3390/polym7111509. [Google Scholar] [CrossRef]

7. Assaedi H, Alomayri T, Kaze CR, Jindal BB, Subaer S, Shaikh F, et al. Characterization and properties of geopolymer nanocomposites with different contents of nano-CaCO3. Constr Build Mater. 2020;252(2014):119137. doi:10.1016/j.conbuildmat.2020.119137. [Google Scholar] [CrossRef]

8. Astari L, Belleville B, Umemura K, Filkov A, Ozarska B, Crawford RH. Determination of physical, mechanical and fire retardancy properties of innovative particleboard made from corn stalk (Zea mays L.) particles. J Renew Mater. 2024;12(10):1729–56. doi:10.32604/jrm.2024.054786. [Google Scholar] [CrossRef]

9. Yu J, Wang N, Wang MH, Zhang JR, Hou D. Recyclable rubber-cement composites produced by interfacial strengthened strategy from polyvinyl alcohol. Constr Build Mater. 2020;264(13):120541. doi:10.1016/j.conbuildmat.2020.120541. [Google Scholar] [CrossRef]

10. Hofmann M, Shahid AT, Machado M, Garrido M, Bordado JC, Correia JR. GFRP biocomposites produced with a novel high-performance bio-based unsaturated polyester resin. Compos Part A Appl Sci Manufact. 2022;161:107098. doi:10.1016/j.compositesa.2022.107098. [Google Scholar] [CrossRef]

11. Han S, Li S, Zhang X, Liu D, Guo S, Wang B, et al. Enhancing the protective performance of anti-impact, corrosion resistant and flame retardant polyurea coatings using bio-based supramolecular decorated montmorillonite. Constr Build Mater. 2024;435(1):136721. doi:10.1016/j.conbuildmat.2024.136721. [Google Scholar] [CrossRef]

12. Das O, Sarmah AK. Mechanism of waste biomass pyrolysis: effect of physical and chemical pre-treatments. Sci Total Environ. 2015;537(2):323–34. doi:10.1016/j.scitotenv.2015.07.076. [Google Scholar] [PubMed] [CrossRef]

13. Ngadiman NHA, Noordin MY, Kurniawan D, Idris A, Shakir ASA. Influence of polyvinyl alcohol molecular weight on the electrospun nanofiber mechanical properties. Procedia Manuf. 2015;2:568–72. doi:10.1016/j.promfg.2015.07.098. [Google Scholar] [CrossRef]

14. Najm SS. Effect of additive of copper nanoparticles on the electrical properties of polyvinyl-alcohol films. Mater Today Proc. 2022. doi:10.1016/j.matpr.2021.03.732. [Google Scholar] [CrossRef]

15. JIS A 5908-2003. Particleboards. In: Japanese industrial standard practice board JIS A 5908. Tokyo, Japan: Japanese Standard Association 2003; 2003. [Google Scholar]

16. Korobeinichev OP, Sosnin EA, Shaklein AA, Karpov AI, Sagitov AR, Trubachev SA, et al. The effect of flame-retardant additives DDM-DOPO and graphene on flame propagation over glass-fiber-reinforced epoxy resin under the influence of external thermal radiation. Molecules. 2023;28(13):5162. doi:10.3390/molecules28135162. [Google Scholar] [PubMed] [CrossRef]

17. ASTM D 2863-00. Standard test method for measuring the minimum oxygen concentration to support candlelike combustion of plastics (oxygen index). In: International Standard Worldwide. West Conshohocken, PA, USA: American Society for Testing and Materials; 2000. [Google Scholar]

18. ASTM D 635-03. Standard test method for rate of burning and/or extent and time of burning of plastic in a horizontal position. In: International Standard Worldwide. West Conshohocken, PA, USA: American Society for Testing and Materials; 2000. [Google Scholar]

19. Hatakayama T, Quinn FX. Thermal analysis: fundamental and applications to polymer science. 2nd ed. Chichester, NY, USA: John Wiley & Sons Ltd.; 1999. [Google Scholar]

20. Setyayunita T, Widyorini R, Marsoem SN, Irawati D. Study on the characteristics of NaCl treated kenaf fiber epoxy composite board. IOP Conf Ser Earth Environ Sci. 2021;891(1):012006. doi:10.1088/1755-1315/891/1/012006. [Google Scholar] [CrossRef]

21. Yang SQ, Hong WX, Wang JG, Ranjith PG, Wang XL. Experimental investigation on the influence of NaCl concentration on triaxial mechanical behaviors of a low-clay shale. Int J Rock Mech Min Sci. 2024;176(6):105716. doi:10.1016/j.ijrmms.2024.105716. [Google Scholar] [CrossRef]

22. Setyayunita T, Widyorini R, Marsoem SN, Irawati D. Effect of different conditions of sodium chloride treatment on the characteristics of kenaf fiber bundles. J Korean Wood Sci Technol. 2022;50(6):392–403. doi:10.5658/WOOD.2022.50.6.392. [Google Scholar] [CrossRef]

23. Cha MS, Yoon SJ, Kwon JH, Byeon HS, Park HM. Mechanical properties of cork composite boards reinforced with metal, glass fiber, and carbon fiber. J Korean Wood Sci Technol. 2022;50(6):427–35. doi:10.5658/WOOD.2022.50.6.427. [Google Scholar] [CrossRef]

24. López YM, Paes JB, Rodríguez EM, Gustave D, Gonçalves FG. Wood particleboards reinforced with thermoplastics to improve thickness swelling and mechanical properties. Cerne. 2018;24(4):369–78. doi:10.1590/01047760201824042582. [Google Scholar] [CrossRef]

25. Song F, Xu X, Jiang P, Chen Z, Jia H, Yu W, et al. Preparation of wood scrimber with low hygroscopicity and high flame retardancy through impregnation of silicon-boron inorganic salt. Constr Build Mater. 2025;467(2):140384. doi:10.1016/j.conbuildmat.2025.140384. [Google Scholar] [CrossRef]

26. Hafidz NSBM, Rehan MSBM, Mokhtar HB. Effect of alkaline treatment on water absorption and thickness swelling of natural fibre reinforced unsaturated polyester composites. Mater Today Proc. 2021;48(5):720–7. doi:10.1016/j.matpr.2021.02.209. [Google Scholar] [CrossRef]

27. Liu B, Zhang J, Guo H. Research progress of polyvinyl alcohol water-resistant film materials. Membranes. 2022;12(3):347. doi:10.3390/membranes12030347. [Google Scholar] [PubMed] [CrossRef]

28. Johari AN, Ishak MR, Leman Z, Yusoff MZM, Asyraf MRM. Influence of CaCO3 in pultruded glass fiber/unsaturated polyester resin composite on flexural creep behavior using conventional and time-temperature superposition principle methods. Polimery/Polymers. 2020;65(11–12):792–800. doi:10.14314/polimery.2020.11.6. [Google Scholar] [CrossRef]

29. Shi XH, Li XL, Li YM, Li Z, Wang DY. Flame-retardant strategy and mechanism of fiber reinforced polymeric composite: a review. Compos Part B Eng. 2022;233(11):109663. doi:10.1016/j.compositesb.2022.109663. [Google Scholar] [CrossRef]

30. Mapossa AB, dos Anjos EGR, Sundararaj U. Boosting flame retardancy of polypropylene/calcium carbonate composites with inorganic flame retardants. Materials. 2024;17(18):4553. doi:10.3390/ma17184553. [Google Scholar] [PubMed] [CrossRef]

31. Bazan P, Salasińska K, Kuciel S. Flame retardant polypropylene reinforced with natural additives. Ind Crops Prod. 2021;164(4):113356. doi:10.1016/j.indcrop.2021.113356. [Google Scholar] [CrossRef]

32. Hiremath VS, Reddy DM, Reddy Mutra R, Sanjeev A, Dhilipkumar T, Naveen J. Thermal degradation and fire retardant behaviour of natural fibre reinforced polymeric composites—a comprehensive review. J Mater Res Technol. 2024;30(9):4053–63. doi:10.1016/j.jmrt.2024.04.085. [Google Scholar] [CrossRef]

33. Yin K, Liu M, Shao Z, Chen C, Wu W, Tan Y, et al. Enhancing flame retardancy and smoke suppression of lignocellulose through modification with green aqueous flame retardants. Ind Crops Prod. 2025;225:120493. doi:10.1016/j.indcrop.2025.120493. [Google Scholar] [CrossRef]

34. Mngomezulu ME, John MJ, Jacobs V, Luyt AS. Review on flammability of biofibres and biocomposites. Carbohyd Poly. 2014;111(2):149–82. doi:10.1016/j.carbpol.2014.03.071. [Google Scholar] [PubMed] [CrossRef]

35. Bachtiar EV, Kurkowiak K, Yan L, Kasal B, Kolb T. Thermal stability, fire performance, and mechanical properties of natural fibre fabric-reinforced polymer composites with different fire retardants. Polymers. 2019;11(4):699. doi:10.3390/polym11040699. [Google Scholar] [PubMed] [CrossRef]

36. Sulistyo AB, Wirawan WA, Muslimin M. Evaluation of mechanical and morphological properties composite of agel leaf fiber (Alf)-epoxy modified with carbon powder. EUREKA Phys Eng. 2024;2024(1):144–53. doi:10.21303/2461-4262.2024.002974. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools