Open Access

Open Access

REVIEW

A Comprehensive Review of Natural Fibers: Bio-Based Constituents for Advancing Sustainable Materials Technology

1 Department of Mechanical Engineering, Sandip Institute of Technology and Research Centre, Nashik, 422213, MS, India

2 Department of Mechanical Engineering, St. Vincent Pallotti College of Engineering and Technology, Nagpur, 441108, MS, India

3 Department of Mechanical Engineering, Amrutvahini College of Engineering, Sangamner, 422605, MS, India

* Corresponding Author: Sachin Ghalme. Email:

(This article belongs to the Special Issue: Renewable Materials and Advanced Technologies for Sustainability)

Journal of Renewable Materials 2025, 13(2), 273-295. https://doi.org/10.32604/jrm.2024.056275

Received 18 July 2024; Accepted 28 November 2024; Issue published 20 February 2025

Abstract

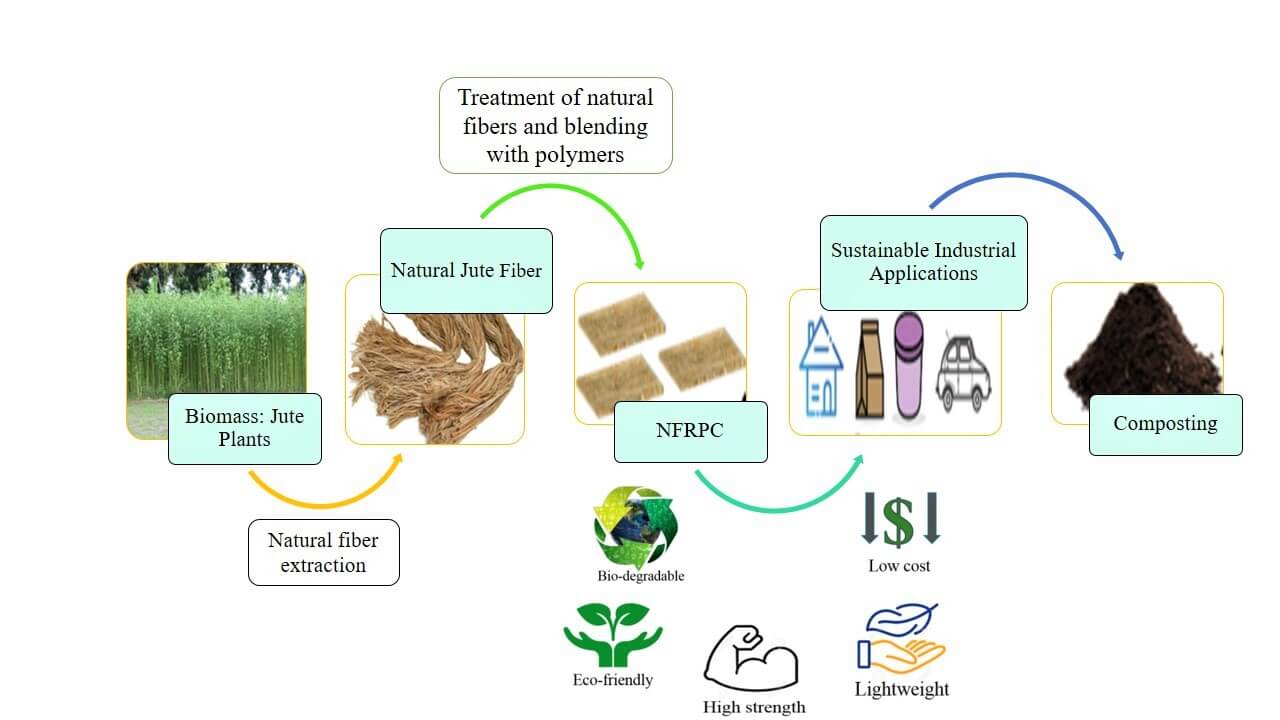

With growing concerns for global warming and environmental issues, the research community has contributed significantly to green technology in the area of material science through the development of natural fiber-reinforced polymer composites (NFRPC). Polymers serve as the matrix in NFRPC, while natural fibers serve as the reinforcing materials. Demand for high-performing materials made with natural resources is growing continuously. Natural fiber-reinforced polymer composites are sustainable biocomposites fabricated with natural fibers embedded with a polymer matrix. They offer a wide range of advantages, including a low weight-to-strength ratio, high flexural strength, damping properties, and resistance to corrosion, wear, and impact. Understanding the basic properties, characteristics, and processing techniques for natural fibers is important to consider their use as raw materials for high-quality biocomposite. Natural fibers come with low density and a high strength-to-weight ratio, allowing them to be a potential reinforcement for low-weight composites. This article attempts to present a comprehensive review of the available natural fibers, their classification, types, structures, physical properties, characteristics, and mechanical properties. Natural fibers are hydrophilic in nature and require physical and chemical treatment prior to their application as reinforcing material. This review will also cover the required physical and chemical treatments of natural fibers for fabricating biocomposites.Graphic Abstract

Keywords

Nomenclature

| FRPC | Fiber-Reinforced Polymer Composite |

| NFRPC | Natural Fiber-Reinforced Polymer Composite |

Composite materials are composed of two or more constituents, one being a base matrix reinforced with different types of fibers. Composite materials are widely preferred in industrial applications due to their capability of weight reduction along with high specific strength, high specific modulus, and strong damping properties [1,2]. The evolution of composites begins with the discovery of plastics in the 1900s. Due to the limitation of the load-bearing capacity of plastics, this promoted the development of composite materials with various types of fiber reinforcement. The first fiber-reinforced polymer composite (FRPC) came into the picture in 1935, with major development during World War II in search of lightweight materials [3]. Fiber reinforcement is a major constituent of FRP with load-bearing capacity; it is a thin, long, and intact structure [4]. Depending upon the source, the fibers are classified as natural fibers, synthetic fibers, and semi-synthetic fibers. Glass, carbon, and aramid fibers are the most commonly used synthetic fibers as reinforcement in polymer composites [5].

Growing concern for the environment and the demand for environment-friendly materials boosted the development of materials from natural sources. The use of petroleum-based plastics harms the environment along with the depletion of environmental resources. FRPCs with natural and environmental materials are substituting FRPCs fabricated with synthetic material with environmental advantage and competitive mechanical properties required for industrial, automobile, aircraft, infrastructure, and structural applications [5]. Growing awareness about the environment and regulations related to industrial pollution is forcing the research community to explore sustainable and environment-friendly alternatives to conventional materials [6]. As we are moving towards the circular economy, it is essential to recycle every product for the conservation of the environment. Fig. 1 below presents the life cycle of non-renewable and renewable products. Renewable and sustainable products follow a circular life cycle with complete decomposition and contribute to environmental protection. They are the major contributors to sustainable development.

Figure 1: Life cycle of non-renewable (a) and renewable products (b)

In the category of renewable materials, the demand for environment-friendly and renewable bio-composite is growing to replace the conventional composites fabricated with synthetic polymers [7,8]. Natural fibers are major constituents used for reinforcing bio-composites satisfying current industrial requirements [9]. The various types of natural fibers extracted from natural resources, including sisal, pineapple, jute, flax, kenaf, hemp, cotton, kapok, coir, elephant grass, etc., are widely used for the preparation of NFRPCs [10,11]. According to one recent survey, the market size for bio-composite is growing at a compound annual growth rate (CAGR) of 11.86% from 2016 to 2024. It is estimated that in 2024, the market size for bio-composite will be $10.89 billion, up from $4.46 billion in 2016. So, the utilization of materials from natural resources will rise from 5% in 2004 to 10% in 2010, 18% in 2020, and 25% in 2023.

While biocomposites are an alternative to non-renewable materials, they are not free from drawbacks, including hydrophilic nature, fiber/matrix incompatibility, and processing level difficulty. In addition to being anisotropic, the properties of natural fibers vary, inherently affecting the durability of biocomposites. Natural fibers contain large amounts of cellulose, hemicellulose, lignin, pectin, etc., resulting in hydrophilic material and poor bonding when embedded with hydrophobic polymers. This results in the loss of mechanical and thermal properties of the composites. With rising demand from the global market, the research community is continuously evaluating bio-composites for their improved properties. It is important to know the properties of fibers and matrices and their processing techniques for better performance [12,13].

This article will present a critical review in the area of development of sustainable bio-composites including various matrix and fibers used for the fabrication of NFRPCs. This review will present the chemical composition, physical and mechanical properties, and extraction of fibers and polymers from natural resources for the fabrication of bio-composites. Surface treatment of fibers, their modification, hybridization, the addition of fillers, and advanced manufacturing techniques are also presented.

2 Natural Fiber-Reinforced Polymer Composites

Fiber–reinforced composites comprise two phases: matrix and reinforcement. So, a natural fiber-reinforced polymer composite consists of natural fibers as reinforcement for biopolymers forming NFRPCs. Since 2800 BC, natural fibers have been grown and used for various household and other day-to-day applications. However, attention to global warming and minimizing dependability on petroleum-based products triggered the utilization of biocomposites with natural fibers for industrial applications also. In 1500 BCE, people used bamboo shoots for reinforcing mud walls and laminated glued wood [13]. We can find natural fiber-based NFRPCs in aircraft applications as early as the 1940s. With increasing public awareness about climate, environment, global warming, and dependency on fossil fuel resources, there is a huge demand for biodegradable composites fabricated with natural and sustainable resources. Reinforcing natural fibers with polymer matrix is advantageous due to their biodegradability and easy availability [14]. The mechanical properties like tensile strength, stiffness, stability, and modulus of elasticity of NFRPCs are found to be comparable to synthetic fiber-reinforced polymer composites with due consideration for fiber treatment and fiber proportion with the matrix. NFRPCs are now considered prime alternatives to non-renewable materials, with their advantages in terms of less toxicity, ease of disposal, less energy consumption, and greenhouse gas emissions [15].

NFRPCs are used extensively in various fields as an alternative to conventional synthetic fiber-reinforced polymer composites [16,17]. The comparative property difference between NFRPCs and synthetic fiber-reinforced composites is due to the poor adhesion between natural fibers and polymer matrix. This comes into the picture due to the hydrophilic nature of plant fibers, leading to debonding between fiber and matrix. With poor adhesion and debonding between fiber and matrix, NFRPCs are inferior to synthetic fiber-reinforced polymer composites. Natural fibers are reactive to moisture content; with time, they lose their properties. Improving the bonding between the natural fibers and matrix along with reducing moisture content is possible with the physical and chemical treatment of natural fibers. Therefore, both natural fiber and matrix require modification, which further improves their adhesion and bonding, resulting in improved mechanical properties [18,19].

Considering origin/source the natural fibers are classified as shown in Fig. 2 below.

Figure 2: Classification of natural fibers

The major contribution of natural fibers comes from plants, followed by animals. Cellulose is a major constituent of plant fibers, and protein is a major constituent of animal fibers. While asbestos is the main mineral-based fiber used in practice, due to its hazardous nature, it is also banned in most countries.

Plant fibers are a major contributor to the field of sustainable fibers. We further divide them into primary and secondary fibers. The fibers like cotton, sisal, jute, kenaf, hemp, etc., which are cultivated mainly for the production, are known as primary fibers, and secondary fibers are obtained as byproducts after their main use, like banana, coir, oil palm, coconut, etc., [20]. Plant fibers are collected from different parts of plants, including leaf fibers collected from plant leaves, seed fibers from plant seeds, bast fibers from skin and bast around the plant stem, grass fibers from various types of grass, wood pulp fibers, and core fibers from the plant stalks. Plant fibers are major constituents of cellulose, hemicellulose, lignin, wax and pectin. Straw fibers have been used since the early years and proved their applicability in improving composite performance [21]. Fig. 3 below shows the structure of plant fiber with three major components. Generally, plant fibers are constituents of cellulose, hemicellulose, and lignin. The combined structure of plant cells is called lignocellulose. The variation in the chemical composition of plant fiber is also observed depending on the geographical conditions and species of the plants. The microfibril angle and its arrangement inside the side wall affect the properties of the plant fibers.

Figure 3: Structure of natural fiber. Adopted with permission from Reference [22], Copyright © 2022, MDPI

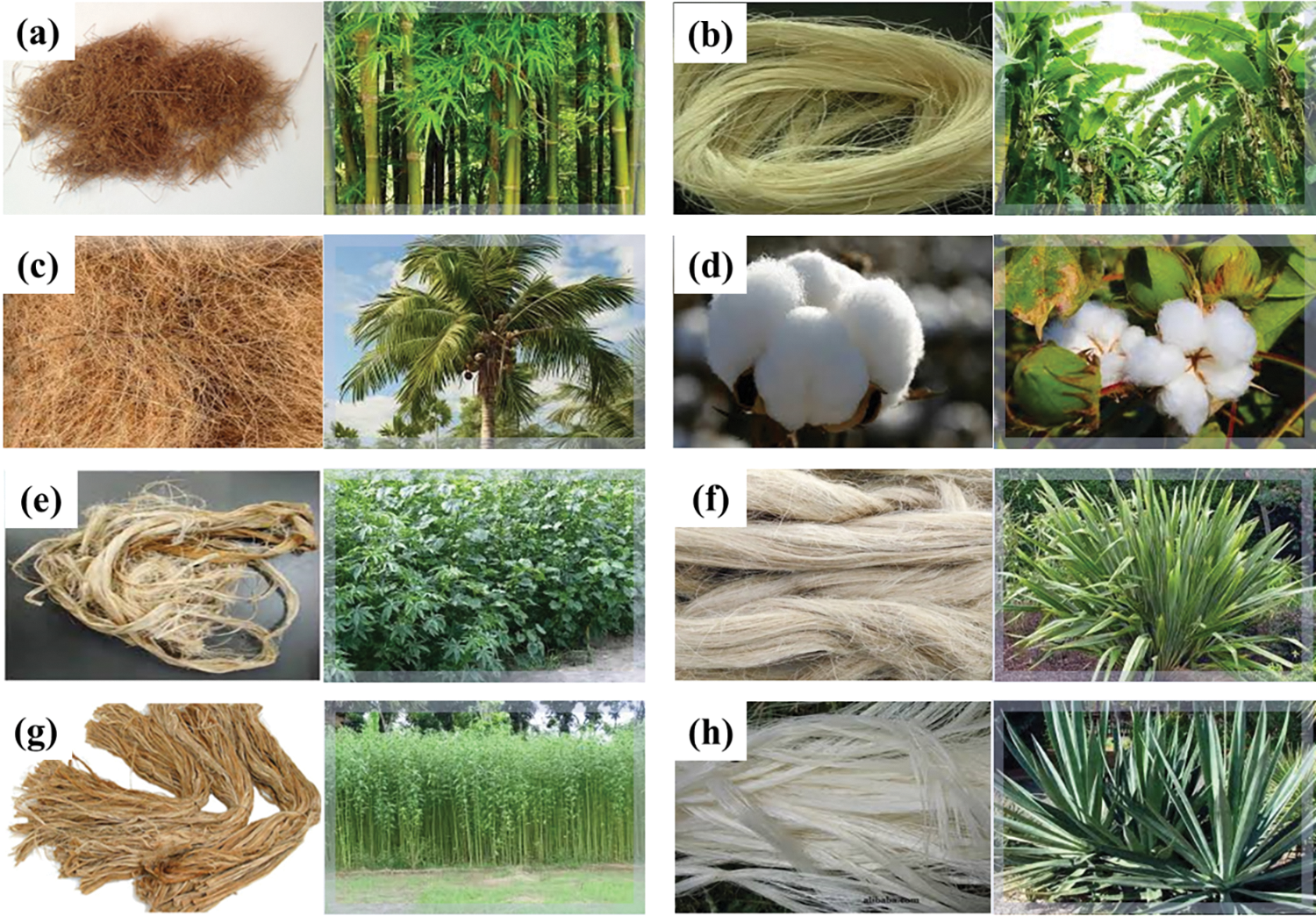

The different mechanical properties of plant fibers are illustrated in Table 1. Fig. 4 depicts the various plants and respective plant-based natural fibers.

Figure 4: Natural plants and their extracted fibers: (a) bamboo (grass fiber type); (b) banana (leaf type fiber); (c) coir (fruit type fiber); (d) cotton (seed type fiber); (e) kenaf (bast type fiber); (f) flax (bast type fiber); (g) jute (bast type fiber); (h) sisal (leaf type fiber)

Apart from this, various plant fibers are explored nowadays. Different plant fibers explored by researchers are Phaseolus vulgaris, Axadirachta indica bark, Carica papaya bark, Pithecellobium dulce, Elettaria cardamomum stem, Albizia amara bark, Eleusine indica grass, Ripe Bulrush, Sterculia urens bark, Leucas aspera stem, Kigelia Africana fruit fiber, Citrullus lanatus climbers, Parthenium hysterophorous [27–31].

Date palm leaves are abundantly available in Middle Eastern countries and North Africa. Date palm leaves have the potential for various applications, including cement reinforcing, the paper industry, energy production, and soil fertilizing [32]. Dhakal et al. [33] evaluated the impact and tensile properties of date palm fiber-reinforced polycaprolactone bio-composite fabricated with an extrusion process. They found that tensile and impact strength increased by 28% and 101.42% for date palm fiber-reinforced biocomposite. The addition of luffa fibers improved the impact energy absorption capacity, and mechanical and acoustic properties of the composite [34,35]. Faheed et al. [36] evaluated the sisal and cotton fibers for fabricating biocomposite for prosthetic applications. Ghalme [37] in his study attempted to optimize the proportion of rice husk and straw fiber to improve the mechanical properties of rice husk and straw fiber-reinforced bio-composite. Various applications of plant fibers are illustrated in Table 2.

With wide applicability has promoted the demand for plant-based natural fibers. Table 3 depicts the worldwide production of plant fibers.

Animal fibers are the second most important and preferable source of natural fibers after plant fibers for biocomposite reinforcement with their promising mechanical and physicochemical properties, easy availability, and non-toxic nature. Animal fibers are obtained from three different sources, namely hair, avian feather, and secretions [60,61].

In the category of wool (hair) fiber is obtained from mammalian hair like sheep, alpaca, goat, camel, llama, etc.; silk (secretion) fiber is obtained from silkworms, butterflies, spiders, etc.; and avian fibers are obtained from bird feathers. Protein is the main constituent for animal fibers formed by combining amino acids with long-chain molecules of polypeptide [62]. Silk fiber consists of fibroin-type protein molecules with 140 nm long and another 70 nm long composed of tyrosine and other side groups. Silk constitutes two fibroins in triangular shape covered with sericin gum, as shown in Fig. 5 [63].

Figure 5: (a) Structural image of silk fiber; (b) longitudinal and cross-sectional image of silk fiber; (c) morphological side view of silk fiber

Hair/wool and feather constituents are mainly α-keratin types of proteins. α-Keratin fiber is structured with an inner part known as the cortex and medulla while the outer layer is known as the cuticle [64,65]. The thickness of the cuticle ranges from 1 to 2 scales for fine wool fibers and 8 to 10 cuticle cells for goat hair coarse fiber. Cuticle contributes to 10% to 20% weight of fiber and provides a protective layer for 80% to 90% of the bulk fiber in the form of spindle-shaped cortical cells. Microfibril embedded in the matrix contributes mainly to the mechanical strength of the wool fiber. Cortical cells in the cortex are polyhedral, spindle-shaped, and 100 nm long. Fig. 6 shows the morphological and chemical structure of wool fiber [66]. The cuticle is again overlapped with the epicuticle, with a few nanometers in thickness. It has protein and high chemical resistance and is important for all surface properties. Epicuticle is again covered with a thin layer of fatty acid and is responsible for the water-repellency of mammal fibers [67].

Figure 6: Morphological and chemical structure of wool fiber

The various mechanical properties of animal fibers are presented in Table 4.

Animal fibers are mainly used in the textile industry for different products like clothes and textile goods. Demand for organic, sustainable, eco-friendly, and lightweight products for the automobile industry is driving the market growth for animal fibers. Bird feathers, human hair, and animal hair/wool are all waste by-products and can be used for the production of sustainable composites for use in various sectors. Huge production of wool and feather fiber is expected in the coming days. On average, a single sheep can produce 4.5 kg of wool, and in 2022 the number of sheeps have risen to 1.296 billion, generating a significant amount of wool [74]. It is estimated that of the total weight of chicken, the 6% weight goes to the feathers [75]. In 2022, about 138.8 million tons of chicken meat were produced, generating 8.32 million tons of chicken feathers as waste by-products [76,77]. 124.6 million tons of pig meat was also produced in 2022, generating waste of pig hairs, which are difficult to decompose, providing an opportunity for the use of pig hair fibers [76]. Human hairs also have protein filaments available naturally and non-biodegradable [78]. It has been expected that the total population will grow up to 2 billion by 2053 from the current population, making the availability of a huge amount of human hair fibers. Manjunatha et al. [70] and Bheel et al. [78] evaluated the applicability of human hairs as reinforcement for construction materials. Human hairs have wide applications including wigs, fertilizer, clay reinforcement, fabric making, artwork, oven lining, cosmetic brushes, etc. [79]. Silk is the oldest fiber known to human beings and has been in use for 5000 years. Silk is recognized for its unique luster, glamour, and unique mechanical properties, along with offering warmth in the cold season and comfort in the warm season [80]. It is produced through the secretion of animals and insects to prepare their cocoons and webs. The textile industry uses silk for commercial purposes produced by silkmoth, mulberry, Bombyx mori, and some other genera [81]. Silk produced by other insects like spiders is used rarely for commercial applications like in weapons and telescope cross-hair [82]. Silk is the lustrous fabric used in the textile and apparel industry, biomedical applications, construction, and silk non-woven fabric preparation [80]. Bird feathers are also found suitable for biomedical and automobile applications [83].

4 Natural Fiber Treatments and Modifications

Natural fibers are considered as reinforcement for polymer matrix, but adhesion and compatibility of fibers with matrix affect the properties of NFRPCs. Bonding between matrix and natural fiber is affected by various factors like chemical compatibility, fiber surface roughness, humidity, and surface treatment. As well, natural fibers are hydrophilic in nature and matrix are generally hydrophobic in nature, resulting in poor adhesion and bonding leading to poor mechanical properties of the reinforced composite. To improve the compatibility and adhesion between natural fiber and matrix, along with reducing the hydrophilicity of natural fibers, the fiber treatment is essential [60,84].

To improve the fiber/matrix adhesion and improve moisture resistance, fibers are chemically treated. Chemical treatment helps to improve the bonding between fiber and matrix.

Alkalization was initially developed in 1844, is still commonly used in textile industries, and is also known as mercerization. In this process, fibers are exposed to a saturated aqueous solution of NaOH. This leads to dilatation and changes in cell structure, size, morphology, and mechanical properties. Alkalization removes the oil, and wax from the surface and lignin and hemicellulose from fibers before its fabrication process [85]. Alkalization improves the surface roughness of fiber, thereby improving the adhesion and bonding between matrix and fiber. Excess alkalization leads to excess removal of lignin and hemicellulose, thereby damaging the cell walls of fiber and affecting mechanical strength [86]. Alkalization also contributes to the thermal stability of fibers. The schematic representation of alkalization is presented in Fig. 7, and the reaction of cellulose with NaOH is presented below reaction [86].

Figure 7: Alkalization treatment and variation in fiber structure

Silane is a coupling agent, and it acts as a mediator between the hydrogen bond of the polymer and the hydroxyl group of the fiber [87–89]. Silane is a multifunctional compound of silicon oxide with a chemical formula of SinH2n+2 and bi-functional group that reacts with fiber and polymer matrix. By means of the siloxane element, silane forms a chemical link between fiber and matrix. Natural fibers undergo three different stages when treated with silane.

a) Hydrolysis: during this stage, silane monomers are released and silanols are formed due to hydrolysis in the presence of moisture and hydrolysable alkoxy groups [89].

b) Self-condensation: during this stage the silanols formed are allowed to be absorbed with hydroxyl groups present with natural fibers.

c) Adsorption: during this stage, silanol monomers are adsorbed with the surface of natural fibers or in the cell walls. The free silanols react with each other and form polysiloxane with a stable bond of -Si-O-Si- [90].

d) Grafting: during this stage, at high temperatures a hydrogen bond between the hydroxyl group of natural fibers and silanol forms a covalent bond of -Si-OC- with the evaporation of water [90].

Aminopropyltriethoxysilane (APS) is the most commonly used silane for natural fiber treatment [90]. A recent investigation of silane-treated NFRPC presented improved mechanical properties in comparison to alkaline-treated NFRPC [91–95].

Acetylation is also known as esterification and is used for the plasticization of natural fibers, which helps to treat the surface of fibers and modify them to be less hydrophilic and thermally stable. The acetyl group reacts with the hydroxyl group of natural fibers and removes existing moisture present with natural fibers. The hydroxyl group (-OH) of natural fibers gets replaced with an acetyl group (CH3CO-), making them hydrophobic in nature and dimensionally stable [96,97]. During acetylation, fibers are soaked with acetic acid and then treated with acetic anhydride for 60–180 min at high temperature. Two chemical reactions with acid and without acid catalysts are presented below:

Acetyl treated fibers show rough surface roughness with improved mechanical properties, thermal stability, and bio-resistance [98–101].

Pretreated natural fibers are again treated with benzoyl chloride, thereby reducing the hydrophilic nature of fibers, improving interfacial adhesion, and thermal stability with improved mechanical properties of NFRPCs. Pretreated fibers with alkaline remove wax and lignin and give more exposure to the hydroxyl group with fiber surface. These pretreated fibers, when treated with benzoyl chloride, lead to the replacement the hydroxyl group from the fiber surface with the benzoyl group, leading to more hydrophobic nature and improving adhesion and bonding between fiber and matrix [102–106].

During this treatment, alkaline-pretreated fibers are immersed with potassium permanganate (KMnO4) and different concentrations of acetone for a duration of 1−3 min [107]. KMnO4 reacts with plant fibers and forms reactive permanganate ions (Mn3+); these ions react with a hydroxyl group to form cellulose permanganate. This cellulose permanganate removes non-cellulose constituents like lignin from the fiber cell wall. Removal of these non-cellulose constituents improves the thermal stability and moisture resistance of natural fiber [31,108–111].

Physical treatment of modification techniques helps to increase the fiber strength, thereby improving the bonding of natural fiber and matrix. These methods modify the fiber’s surface and structure without affecting the chemical composition, leading to improved adhesion between fiber and matrix [112].

Plasma treatment is a widely used physical fiber surface treatment technique in industrial applications specifically used for etching and cleaning the surface of the food processing industry. Plasma treatment helps to remove surface contaminants and improves surface properties like wettability, dyeability, flammability, etc. Due to plasma treatment, surface roughness increases and helps to improve the mechanical bonding between matrix and polymer. Fig. 8 shows a schematic representation of plasma treatment for natural fibers. Due to plasma treatment polar groups are generated with the surface and improve significantly adhesion and hydrophilicity of the fiber surface [113,114]. Plasma-treated fibers show improvement in Young’s modulus, tensile strength, flexural strength, stiffness, and fracture toughness also [115–119].

Figure 8: Plasma surface treatment. Adopted with permission from Reference [120], Copyright © 2019, Elsevier Ltd

Treating natural fiber surface with ozone (O3) or oxygen-fluorine contributes to the improving natural fiber surface. Ozone gas is a powerful oxidizing agent with significant oxidation potential. Ozone treatment helps to improve the surface energy and contact angle between polymer and matrix. Improvements in mechanical properties were observed for jute fiber [121,122] and rice husk fiber [123,124] after ozone treatment.

Corona treatment or electric discharge treatment was found to be effective in reducing fiber surface impurities and increasing surface energy, leading to improved bonding between hydrophilic fiber and hydrophobic matrix [125–127]. Corona treatment activates the surface through oxidation, leading to increasing aldehyde group concentration on the fiber surface and modifying the fiber surface without affecting their properties [128]. During corona treatment, the samples are placed between two electrodes and bombarded with high-speed electrons. These high-energy electrons break the molecule bonding of the substrate surface. This will induce the surface oxidation due to oxidants present during corona discharge. Oxidation will increase the polar groups, leading to improvements in the wettability and adhesion properties of the surface. Corona treatment is very essential in the textile industry. Corona treatment is a low cost process with low energy consumption.

4.2.4 Ultraviolet Irradiation Treatment

UV irradiation is electromagnetic radiation that has an efficient source of energy and the ability to execute photochemical reactions at the molecular level of natural fibers, thereby eliminating surface impurities of the natural fiber surface and improving mechanical properties [129–133]. UV treatment acts as a clean and cost-effective treatment to improve surface properties.

4.3 Evaluation of Natural Fiber Treatment Processes

Chemical and physical treatments for natural fibers improve their compatibility and adhesion between fiber and matrix. Understanding these processes during natural fiber treatment on various criteria is essential. Chemical treatments of natural fibers, such as alkalization, silane, and acetylation, showed 4–54.5, 10–45, and 35%–56% improvement in tensile strength, respectively [134–137]. The tensile strength of banana fiber was found to be increased by 13% and 5%, respectively, after benzoylation and permanganate treatment. These two processes are not effective in comparison to the rest of the chemical treatment processes [138]. Considering the amount of energy consumed per unit of natural fibers during these chemical treatments, silane, acetylation, and alkalization consume about 18, 15, and 10 KW of energy, respectively [139]. Although these figures represent total energy consumption during these processes, the silane and alkaline processes consume more amount of process energy, and the acetylation process consumes more amount of effluent energy due to the additional pretreatment for natural fibers. Whereas, in the case of physical treatments, there is no use of effluents and no valid data available related to energy consumption during these processes. But, in physical treatments, the corona treatment consumes low energy as well it is a low-cost process. The cost of natural fiber treatment also varies depending on the type of fibers, so the data related to cost-wise comparison for these physical and chemical processes is also not available. Overall, the alkaline treatment is simple, eco-friendly, repeatable, and cheap and is extensively applicable for all the natural fibers. In comparison to other processes, silane coupling agents are expensive. Acetic anhydride used during acetylation is a cheap chemical, but at the same time, it is toxic. Acetylation improves the adhesion between fiber and matrix as well as its susceptibility to moisture, thereby improving dimensional stability and resistance to environmental degradation of fibers. The resultant improvement in the mechanical properties of natural fibers and energy consumption during these processes may be considered as a selection parameter.

In consideration of cost, the natural fibers are also cheaper than the synthetic fibers. The synthetic fibers are 3–4000 times more expensive than the natural fibers. Natural fibers are low density, which makes them cheaper in transportation in comparison to synthetic fibers. Reinforcing natural fibers in matrix leads to cheaper natural fiber reinforced polymer composites than synthetic fiber reinforced polymer composites. The cost comparison for natural and synthetic fibers is presented in Table 5.

Fiber-reinforced polymer composites are preferable for various applications due to their lightweight and comparable strength, but growing concerns for environmental issues have suggested an alternative to these FRPCs. Natural fibers derived from natural resources like plants, animals, and minerals are biodegradable, naturally available, low cost, and low weight, making them a fascinating alternative for the fabrication of natural fiber-reinforced polymer composites (NFRPC). The commercialization of NFRPCs is expected to grow on a large scale with growing awareness about the environment among the public. Natural fibers are now widely used in automobile industries, aerospace industries, construction industries, electronic components, sports material, and packaging industries, and even in biomedical fields also due to their advantages:

• Biodegradable, eco-friendly, and minimizing fossil fuel dependency.

• Abundant availability and some fibers are even generated with waste.

• Light in weight, helping to improve the fuel efficiency for automobile and aerospace applications.

• Utilization of agricultural waste creates more job opportunities.

• Comparable acoustic properties for sound absorption.

• Significant mechanical properties.

Along with these advantages, natural fibers come with drawbacks limiting their applicability:

• Limiting capability for water absorption.

• Due to its hydrophilic nature, there is poor adhesion between fiber and matrix.

• Limited resistance to fungi and microorganisms.

• Poor thermal conductivity and poor temperature resistance.

• Crop patterns are responsible for the supply of fibers.

To improve the mechanical performance of NFRPCs through the improved adhesion between fiber and matrix, various chemical and physical techniques are proposed for the treatment of natural fibers. These treatments modify the surface as well as the hydrophilic nature of natural fibers so that they can better adhesion. Moreover, with the growing demand for sustainable materials with improved properties, more research is needed in the area of manufacturing also using these sustainable resources for developing sustainable biocomposites.

Acknowledgement: None.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm contribution to the paper as follows: Study conception and data collection: Mohammad Hayat. Draft manuscript preparation: Sachin Ghalme and Mahesh Harne. Writing final review article: Sachin Ghalme. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Linul E, Lell D, Movahedi N, Codrean C, Fiedler T. Compressive properties of zinc syntactic foams at elevated temperatures. Compos Part B, Eng. 2019;167(8):122–34. doi:10.1016/j.compositesb.2018.12.019. [Google Scholar] [CrossRef]

2. Sherif G, Chukov D, Tcherdyntsev V, Torokhov V. Effect of formation route on the mechanical properties of the polyethersulfone composites reinforced with glass fibers. Polymers. 2019;11(8):1364. doi:10.3390/polym11081364. [Google Scholar] [PubMed] [CrossRef]

3. Tsai Stephen W. Introduction to composite materials. USA: Routledge; 2018. [Google Scholar]

4. Murdiyanto D. Potensi serat alam tanaman Indonesia sebagai bahan fiber-reinforced composite kedokteran gigi. Jurnal Material Kedokteran Gigi. 2017;6(1):14 (In Indonesian). doi:10.32793/jmkg.v6i1.260. [Google Scholar] [CrossRef]

5. Khalid MY, Rashid AA, Arif ZU, Ahmed W, Arshad H, Zaidi AA. Natural fiber-reinforced composites: sustainable materials for emerging applications. Results Eng. 2021;11(6):100263. doi:10.1016/j.rineng.2021.100263. [Google Scholar] [CrossRef]

6. Andrew JJ, Dhakal HN. Sustainable biobased composites for advanced applications: recent trends and future opportunities—a critical review. Compos Part C, Open Access. 2022;7(9):100220. doi:10.1016/j.jcomc.2021.100220. [Google Scholar] [CrossRef]

7. Väisänen T, Das O, Tomppo L. A review on new bio-based constituents for natural fiber-polymer composites. J Clean Prod. 2017;149(6):582–96. doi:10.1016/j.jclepro.2017.02.132. [Google Scholar] [CrossRef]

8. Das S, Das P, Das NC, Das D. A review of emerging bio-based constituents for natural fiber polymer composites. J Text Inst. 2024;115(12):1–27. doi:10.1080/00405000.2023.2300592. [Google Scholar] [CrossRef]

9. Gowda TGY, Sanjay BKS, Madhu P, Senthamaraikannan P, Yogesha B, Pham D. Polymer matrix-natural fiber composites: an overview. Cogent Eng. 2018;5(1):1446667. doi:10.1080/23311916.2018.1446667. [Google Scholar] [CrossRef]

10. Madhu P, Sanjay MR, Senthamaraikannan P, Pradeep S, Saravanakumar SS, Yogesha B. A review on synthesis and characterization of commercially available natural fibers: part II. J Nat Fibers. 2017;16(1):25–36. doi:10.1080/15440478.2017.1379045. [Google Scholar] [CrossRef]

11. Thomas MG, Abraham E, Jyotishkumar P, Maria HJ, Pothen LA, Thomas S. Nanocelluloses from jute fibers and their nanocomposites with natural rubber: preparation and characterization. Int J Biol Macromol. 2017;81(2):768–77. doi:10.1016/j.ijbiomac.2015.08.053. [Google Scholar] [PubMed] [CrossRef]

12. Neto J, Queiroz H, Aguiar R, Lima R, Cavalcanti D, Banea MD. A review of recent advances in hybrid natural fiber reinforced polymer composites. J Renew Mater. 2022;10(3):561–89. doi:10.32604/jrm.2022.017434. [Google Scholar] [CrossRef]

13. Awais H, Nawab Y, Amjad A, Anjang A, Akil HM, Abidin MSZ. Environmental benign natural fibre reinforced thermoplastic composites: a review. Compos Part C, Open Access. 2021;4(5):100082. doi:10.1016/j.jcomc.2020.100082. [Google Scholar] [CrossRef]

14. Pickering KL, Efendy MGA, Le TM. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A, Appl Sci Manuf. 2016;83(10):98–112. doi:10.1016/j.compositesa.2015.08.038. [Google Scholar] [CrossRef]

15. Ramesh M, Deepa C, Kumar LR, Sanjay MR, Siengchin S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: a critical review. J Ind Text. 2020;51(4_suppl):5518S–42S. doi:10.1177/1528083720924730. [Google Scholar] [CrossRef]

16. Akhil UV, Radhika N, Saleh B, Krishna SA, Noble N, Rajeshkumar L. A comprehensive review on plant-based natural fiber reinforced polymer composites: fabrication, properties, and applications. Polym Compos. 2023;44(5):2598–633. doi:10.1002/pc.27274. [Google Scholar] [CrossRef]

17. Khan A, Vijay R, Singaravelu DL, Sanjay MR, Siengchin S, Jawaid M, et al. Extraction and characterization of natural fibers from Citrullus lanatus climber. J Nat Fibers. 2020;19(2):621–9. doi:10.1080/15440478.2020.1758281. [Google Scholar] [CrossRef]

18. Ali A, Shaker K, Nawab Y, Jabbar M, Hussain T, Militky J, et al. Hydrophobic treatment of natural fibers and their composites—a review. J Ind Text. 2016;47(8):2153–83. doi:10.1177/1528083716654468. [Google Scholar] [CrossRef]

19. Karimah A, Ridho MR, Munawar SS, Adi DS, Ismadi N, Damayanti R, et al. A review on natural fibers for development of eco-friendly bio-composite: characteristics, and utilizations. J Mater Res Technol. 2021;13(10):2442–58. doi:10.1016/j.jmrt.2021.06.014. [Google Scholar] [CrossRef]

20. Chen H, Lin Z, Tan C. Classification of different animal fibers by near infrared spectroscopy and chemometric models. Microchem J. 2019;144:489–94. doi:10.1016/j.microc.2018.10.011. [Google Scholar] [CrossRef]

21. Rajeshkumar G, Devnani GL, Maran JP, Sanjay MR, Siengchin S, Al-Dhabi NA, et al. Characterization of novel natural cellulosic fibers from purple bauhinia for potential reinforcement in polymer composites. Cellulose. 2021;28(9):5373–85. doi:10.1007/s10570-021-03919-2. [Google Scholar] [CrossRef]

22. Arumugam S, Kandasamy J, Venkatesan S, Murugan R, Narayanan VL, Sultan MTH, et al. A review on the effect of fabric reinforcement on strength enhancement of natural fiber composites. Materials. 2022;15(9):3025. doi:10.3390/ma15093025. [Google Scholar] [PubMed] [CrossRef]

23. Oushabi A. The pull-out behavior of chemically treated lignocellulosic fibers/polymeric matrix interface (LF/PMa review. Compos B Eng. 2019;174(1):107059. doi:10.1016/j.compositesb.2019.107059. [Google Scholar] [CrossRef]

24. Siva R, Valarmathi TN, Palanikumar K, Samrot AV. Study on a novel natural cellulosic fiber from Kigelia africana fruit: characterization and analysis. Carbohydr Polym. 2020;244(20):116494. doi:10.1016/j.carbpol.2020.116494. [Google Scholar] [PubMed] [CrossRef]

25. Elfaleh I, Abbassi F, Habibi M, Ahmad F, Guedri M, Nasri M, et al. A comprehensive review of natural fibers and their composites: an eco-friendly alternative to conventional materials. Results Eng. 2023;19(3):101271. doi:10.1016/j.rineng.2023.101271. [Google Scholar] [CrossRef]

26. Vijay R, Singaravelu DL, Vinod A, Sanjay MR, Siengchin S, Jawaid M, et al. Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. Int J Biol Macromol. 2019;125(8):99–108. doi:10.1016/j.ijbiomac.2018.12.056. [Google Scholar] [PubMed] [CrossRef]

27. Ramachandran A, Rangappa SM, Kushvaha V, Khan A, Seingchin S, Dhakal HN. Modification of fibers and matrices in natural fiber-reinforced polymer composites: a comprehensive review. Macromol Rapid Commun. 2022;43(17):1. doi:10.1002/marc.202100862. [Google Scholar] [PubMed] [CrossRef]

28. Karimah A, Ridho MR, Munawar SS, Ismadi N, Amin Y, Damayanti R, et al. A comprehensive review on natural fibers: technological and socio-economical aspects. Polymers. 2021;13(24):4280. doi:10.3390/polym13244280. [Google Scholar] [PubMed] [CrossRef]

29. Senthamaraikannan P, Saravanakumar SS. Utilization of Mucuna atropurpurea stem fiber as a reinforcement in fiber-reinforced plastics. Polym Compos. 2022;43(8):4959–78. doi:10.1002/pc.26763. [Google Scholar] [CrossRef]

30. Ahmed MJ, Balaji MS, Saravanakumar S, Sanjay MR, Senthamaraikannan P. Characterization of Areva javanica fiber—a possible replacement for synthetic acrylic fiber in the disc brake pad. J Ind Text. 2018;49(3):294–317. doi:10.1177/1528083718779446. [Google Scholar] [CrossRef]

31. Madhu P, Sanjay MR, Pradeep S, Bhat KS, Yogesha B, Siengchin S. Characterization of cellulosic fibre from Phoenix pusilla leaves as potential reinforcement for polymeric composites. J Mater Res Technol. 2019;8(3):2597–604. doi:10.1016/j.jmrt.2019.03.006. [Google Scholar] [CrossRef]

32. Refaai MRA, Reddy RM, Reddy MI, Khan BSH, Nagaraju V, Kumar SP. Investigation on physical and mechanical characteristics of date palm fiber-reinforced aliphatic epoxy hybrid composites. Adv Polym Technol. 2022;2022(11):1–11. doi:10.1155/2022/4916499. [Google Scholar] [CrossRef]

33. Dhakal H, Bourmaud A, Berzin F, Almansour F, Zhang ZY, Shah DU, et al. Mechanical properties of leaf sheath date palm fibre waste biomass reinforced polycaprolactone (PCL) biocomposites. Ind Crops Prod. 2018;126:394–402. doi:10.1016/j.indcrop.2018.10.044. [Google Scholar] [CrossRef]

34. Alhijazi M, Safaei B, Zeeshan Q, Asmael M, Eyvazian A, Qin Z. Recent developments in luffa natural fiber composites: review. Sustainability. 2020;12(18):7683. doi:10.3390/su12187683. [Google Scholar] [CrossRef]

35. Dharmalingam S, Meenakshisundaram O, Elumalai V, Boopathy RS. An investigation on the interfacial adhesion between amine functionalized luffa fiber and epoxy resin and its effect on thermal and mechanical properties of their composites. J Nat Fibers. 2020;18(12):2254–69. doi:10.1080/15440478.2020.1726238. [Google Scholar] [CrossRef]

36. Faheed NK, Hamad QA, Oleiwi JK. Tensile and stress analysis of hybrid composite prosthetic socket reinforced with natural fibers. J Renew Mater. 2022;10(7):1989–2013. doi:10.32604/jrm.2022.017573. [Google Scholar] [CrossRef]

37. Ghalme S. Improving mechanical properties of rice husk and straw fiber-reinforced polymer composite through reinforcement optimization. Jordan J Mech Ind Eng. 2021;15:411–7. [Google Scholar]

38. Gupta US, Dhamarikar M, Dharkar A, Tiwari S, Namdeo R. Study on the effects of fibre volume percentage on banana-reinforced epoxy composite by finite element method. Adv Compos Hybrid Mater. 2020;3(4):530–40. doi:10.1007/s42114-020-00179-9. [Google Scholar] [CrossRef]

39. Girijappa YGT, Rangappa SM, Parameswaranpillai J. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: a comprehensive review. Front Mater. 2019;6:6. doi:10.3389/fmats.2019.00226. [Google Scholar] [CrossRef]

40. Farzana NM, Maraz NKM, Sonali NSN, Hossain MM, Alom MZ, Khan NRA. Properties and application of jute fiber reinforced polymer-based composites. GSC Adv Res Rev. 2022;11(1):84–94. doi:10.30574/gscarr.2022.11.1.0095. [Google Scholar] [CrossRef]

41. Dhaliwal JS. Natural fibers: applications. IntechOpen eBooks. 2020. doi:10.5772/intechopen.86884. [Google Scholar] [CrossRef]

42. Suparno O. Upaya potensi dan masa depan serat alam Indonesia sebagai bahan baku aneka industri. Jurnal Teknologi Industri Pertanian. 2020;30(2):221–7 (In Indonesian). doi:10.24961/j.tek.ind.pert.2020.30.2.221. [Google Scholar] [CrossRef]

43. Pandit P, Pandey R, Singha K, Shrivastava S, Gupta V, Jose S. Pineapple leaf fibre: cultivation and production. Green Energy Technol. 2020:1–20. doi:10.1007/978-981-15-1416-6. [Google Scholar] [CrossRef]

44. Pramasari DA, Haditjaroko L, Sunarti TC, Hermiati E, Syamsu K. The effectiveness of physical and alkali hydrothermal pretreatment in improving enzyme susceptibility of sweet sorghum bagasse. J Bahan Alam Terbarukan. 2017;6(2):117–31. doi:10.15294/jbat.v6i2.9910. [Google Scholar] [CrossRef]

45. Syamani FA, Ramatia D, Sudarmanto N, Akbar F, Kusumah SS, Hermawan D. Combination of citric acid and maltodextrin as bonding agent in sorghum bagasse particleboard. IOP Conf Ser Mater Sci Eng. 2020;935(1):012058. doi:10.1088/1757-899X/935/1/012058. [Google Scholar] [CrossRef]

46. Dong C. Review of natural fibre-reinforced hybrid composites. J Reinforced Plast Compos. 2017;37(5):331–48. doi:10.1177/0731684417745368. [Google Scholar] [CrossRef]

47. Pantamanatsopa P, Ariyawiriyanan W, Sungsanit K, Ekgasit S. Physicochemical characterization of acid-treated nanocrystal cellulose and amorphous cellulose from bamboo sawdust. J Nat Fibers. 2023;20(2):1. doi:10.1080/15440478.2023.2286323. [Google Scholar] [CrossRef]

48. Khantayanuwong S, Yimlamai P, Chitbanyong K, Wanitpinyo K, Pisutpiched S, Sungkaew S, et al. Fiber morphology, chemical composition, and properties of kraft pulping handsheet made from four Thailand bamboo species. J Nat Fibers. 2022;20(1):20. doi:10.1080/15440478.2022.2150924. [Google Scholar] [CrossRef]

49. Chen C, Li H, Dauletbek A, Shen F, Hui D, Gaff M, et al. Properties and applications of bamboo fiber-a current-state-of-the art. J Renew Mater. 2022;10(3):605–24. doi:10.32604/jrm.2022.018685. [Google Scholar] [CrossRef]

50. Dauletbek A, Li H, Lorenzo R. A review on mechanical behavior of laminated bamboo lumber connections. Compos Struct. 2023;313(1):116898. doi:10.1016/j.compstruct.2023.116898. [Google Scholar] [CrossRef]

51. Chauhan V, Kärki T, Varis J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J Thermoplastic Compos Mater. 2019;35(8):1169–209. doi:10.1177/0892705719889095. [Google Scholar] [CrossRef]

52. Dua S, Khatri H, Naveen J, Jawaid M, Jayakrishna K, Norrrahim MNF, et al. Potential of natural fiber based polymeric composites for cleaner automotive component production—a comprehensive review. J Mater Res Technol. 2023;25(6):1086–104. doi:10.1016/j.jmrt.2023.06.019. [Google Scholar] [CrossRef]

53. Verma D, Sharma S. Green biocomposites: a prospective utilization in automobile industry. Green Energy Technol. 2017;167–91. doi:10.1007/978-3-319-49382-48. [Google Scholar] [CrossRef]

54. Jawaid M, Khalil HPSA. Cellulosic/synthetic fibre reinforced polymer hybrid composites: a review. Carbohydr Polym. 2011;86(1):1–18. doi:10.1016/j.carbpol.2011.04.043. [Google Scholar] [CrossRef]

55. Moshi AAM, Ravindran D, Bharathi SRS, Suganthan V, Singh GKS. Characterization of new natural cellulosic fibers—a comprehensive review. IOP Conf Series Mater Sci Eng. 2019;574(1):012013. doi:10.1088/1757-899x/574/1/012013. [Google Scholar] [CrossRef]

56. Feng NL, Malingam SD, Jenal R, Mustafa Z, Subramonian S. A review of the tensile and fatigue responses of cellulosic fibre-reinforced polymer composites. Mech Adv Mater Struct. 2018;27(8):645–60. doi:10.1080/15376494.2018.1489086. [Google Scholar] [CrossRef]

57. Bisht N, Gope PC, Rani N. Rice husk as a fibre in composites: a review. J Mech Behav Mater. 2020;29(1):147–62. doi:10.1515/jmbm-2020-0015. [Google Scholar] [CrossRef]

58. Halip J, Lee S, Tahir P, Chuan L, Selimin M, Saffian H. A review: chemical treatments of rice husk for polymer composites. Biointerface Res Appl Chem. 2021;11(4):12425–33. doi:10.33263/briac114.1242512433. [Google Scholar] [CrossRef]

59. Asyraf M, Khan T, Syamsir A, Supian A. Synthetic and natural fiber-reinforced polymer matrix composites for advanced applications. Materials. 2022;15(17):6030. doi:10.3390/ma15176030. [Google Scholar] [PubMed] [CrossRef]

60. Bharath KN, Manjunatha GB, Santhosh K. Failure analysis and the optimal toughness design of sheep-wool reinforced epoxy composites. In: Failure analysis in biocomposites, fibre-reinforced composites and hybrid composites. Elsevier B.V.; 2019. p. 97–107. doi:10.1016/b978-0-08-102293-1.00005-x. [Google Scholar] [CrossRef]

61. Gholampour A, Ozbakkaloglu T. A review of natural fiber composites: properties, modification and processing techniques, characterization, applications. J Mater Sci. 2019;55(3):829–92. doi:10.1007/s10853-019-03990-y. [Google Scholar] [CrossRef]

62. Hu J, Jahid Md A, Harish Kumar N, Harun V. Fundamentals of the fibrous materials. In: Handbook of fibrous materials. Wiley eBooks; 2020. p. 1–36, doi: 10.1002/9783527342587.ch1. [Google Scholar] [CrossRef]

63. Babu KM. Silk fibres—structure, properties and applications. In: Handbook of natural fibres (Second Edition). Elsevier B.V.; 2020. vol. 24, no. 6, p. 385–416. doi:10.1016/b978-0-12-818398-4.00013-x. [Google Scholar] [CrossRef]

64. Prahsarn C, Klinsukhon W, Padee S, Suwannamek N, Roungpaisan N, Srisawat N. Hollow segmented-pie PLA/PBS and PLA/PP bicomponent fibers: an investigation on fiber properties and splittability. J Mater Sci. 2016;51(24):10910–6. doi:10.1007/s10853-016-0302-0. [Google Scholar] [CrossRef]

65. Zhang C, Qin Q, Liu Z, Xu X, Lan M, Xie Y, et al. Identification of the key proteins associated with different hair types in sheep and goats. Front Genet. 2022;13:13. doi:10.3389/fgene.2022.993192. [Google Scholar] [PubMed] [CrossRef]

66. Baskan-Bayrak H, Karakas H. Morphology and chemical structure of a wool fiber. In: The wool handbook. Elsevier Ltd.; 2024. p. 181–94. doi:10.1016/b978-0-323-99598-6.00020-7. [Google Scholar] [CrossRef]

67. Szatkowski P, Tadla A, Flis Z, Szatkowska M, Suchorowiec K, Molik E. The potential application of sheep wool as a component of composites. Roczniki Naukowe Polskiego Towarzystwa Zootechnicznego. 2021;17(4):1–8. doi:10.5604/01.3001.0015.5947. [Google Scholar] [CrossRef]

68. Yao D, Wu J, Wang G, Wang P, Zheng J-J, Yan J, et al. Effect of wool fiber addition on the reinforcement of loose sands by microbially induced carbonate precipitation (MICPmechanical property and underlying mechanism. Acta Geotechnica. 2021;16(5):1401–16. doi:10.1007/s11440-020-01112-6. [Google Scholar] [CrossRef]

69. Tesfaye T, Sithole B, Ramjugernath D, Chunilall V. Valorisation of chicken feathers: characterisation of physical properties and morphological structure. J Clean Prod. 2017;149(3):349–65. doi:10.1016/j.jclepro.2017.02.112. [Google Scholar] [CrossRef]

70. Manjunatha M, Kvgd B, Vengala J, Manjunatha LR, Shankara K, Patnaikuni CK. Experimental study on the use of human hair as fiber to enhance the performance of concrete: a novel use to reduce the disposal challenges. Mater Today: Proc. 2021;47:3966–72. doi:10.1016/j.matpr.2021.04.039. [Google Scholar] [CrossRef]

71. Araya-Letelier G, Antico FC, Carrasco M, Rojas P, García-Herrera CM. Effectiveness of new natural fibers on damage-mechanical performance of mortar. Constr Build Mater. 2017;152(1):672–82. doi:10.1016/j.conbuildmat.2017.07.072. [Google Scholar] [CrossRef]

72. Hao LC, Sapuan SM, Hassan MR, Sheltami RM. Natural fiber-reinforced vinyl polymer composites. In: Natural fibre reinforced vinyl ester and vinyl polymer composites. Elsevier Ltd.; 2018. p. 27–70. doi:10.1016/b978-0-08-102160-6.00002-0. [Google Scholar] [CrossRef]

73. Ramamoorthy S, Ramadoss M, Ramasamy R, Thangavel K. Analysis of physical and thermal properties of chiengora fibers. J Nat Fibers. 2018;17(2):246–57. doi:10.1080/15440478.2018.1479996. [Google Scholar] [CrossRef]

74. Murillo M, Sánchez A, Gil A, Araya-Letelier G, Burbano-Garcia C, Silva YF. Use of animal fiber-reinforcement in construction materials: a review. Case Stud Constr Mater. 2024;20:e02812. doi:10.1016/j.cscm.2023.e02812. [Google Scholar] [CrossRef]

75. Araya-Letelier G, Gonzalez-Calderon H, Kunze S, Burbano-Garcia C, Reidel U, Sandoval C, et al. Waste-based natural fiber reinforcement of adobe mixtures: physical, mechanical, damage and durability performance assessment. J Clean Prod. 2020;273:122806. doi:10.1016/j.jclepro.2020.122806. [Google Scholar] [CrossRef]

76. Meat market review emerging trends and outlook 2022. Rome: Food and Agriculture Organization of United Nations; 2022. [Google Scholar]

77. Matiz-Villamil A, Méndez-Carranza KJ, Pascagaza-Pulido AF, Rendón-Rendón T, Noriega-Noriega J, Pulido-Villamarín A. Trends in the management of organic swine farm waste by composting: a systematic review. Heliyon. 2023;9(8):e18208. doi:10.1016/j.heliyon.2023.e18208. [Google Scholar] [PubMed] [CrossRef]

78. Bheel N, Awoyera P, Aluko O, Mahro S, Viloria A, Sierra CAS. Sustainable composite development: novel use of human hair as fiber in concrete. Case Stud Constr Mater. 2020;13(2):e00412. doi:10.1016/j.cscm.2020.e00412. [Google Scholar] [CrossRef]

79. Vitus V, Ibrahim F, Zaman WSWK. Valorization of human hair and its derivatives in tissue engineering: a review. Tissue Eng Part C Methods. 2022;28(10):529–44. doi:10.1089/ten.tec.2021.022333. [Google Scholar] [PubMed] [CrossRef]

80. Colomban P, Silk Jauzein V. 5-Silk: fibers, films, and composites—types, processing, structure, and mechanics. In: Handbook of properties of textile and technical fibres (Second Edition). Elsevier Ltd.; 2018. vol. 24, no. 7295, p. 137–83. doi:10.1016/b978-0-08-101272-7.00005-5. [Google Scholar] [CrossRef]

81. Schmidt T, Puchalla N, Schendzielorz M, Kramell AE. Degumming and characterization of Bombyx mori and non-mulberry silks from Saturniidae silkworms. Sci Rep. 2023;13(1):13. doi:10.1038/s41598-023-46474-5. [Google Scholar] [PubMed] [CrossRef]

82. Dou Y, Wang Z-P, He W, Jia T, Liu Z, Sun P, et al. Artificial spider silk from ion-doped and twisted core-sheath hydrogel fibres. Nat Commun. 2019;10(1):10. doi:10.1038/s41467-019-13257-4. [Google Scholar] [PubMed] [CrossRef]

83. Terrill RS, Shultz AJ. Feather function and the evolution of birds. Biol Rev/Biol Rev Camb Philos Soc. 2022;98(2):540–66. doi:10.1111/brv.12918. [Google Scholar] [PubMed] [CrossRef]

84. Mahir FI, Keya KN, Sarker B, Nahiun KM, Khan RA. A brief review on natural fiber used as a replacement of synthetic fiber in polymer composites. Mater Eng Res. 2019;1(2):88–99. doi:10.25082/mer.2019.02.007. [Google Scholar] [CrossRef]

85. Sullins T, Pillay S, Komus A, Ning H. Hemp fiber-reinforced polypropylene composites: the effects of material treatments. Compos Part B, Eng. 2017;114(6):15–22. doi:10.1016/j.compositesb.2017.02.001. [Google Scholar] [CrossRef]

86. Ismail NF, Radzuan NAM, Sulong AB, Muhamad N, Haron CHC. The effect of alkali treatment on physical, mechanical and thermal properties of kenaf fiber and polymer epoxy composites. Polymers. 2021;13(12):2005. doi:10.3390/polym13122005. [Google Scholar] [PubMed] [CrossRef]

87. Mahesha GT, Shenoy SB, Kini VM, Padmaraja NH. Effect of fiber treatments on mechanical properties of Grewia serrulata bast fiber reinforced polyester composites. Mater Today: Proc. 2018;5(1):138–44. doi:10.1016/j.matpr.2017.11.064. [Google Scholar] [CrossRef]

88. Seisa K, Chinnasamy V, Ude AU. Surface treatments of natural fibres in fibre reinforced composites: a review. Fibres Text East Eur. 2022;30(2):82–9. doi:10.2478/ftee-2022-0011. [Google Scholar] [CrossRef]

89. Nor SSM, Patah MFA, Salleh MM. Surface modification of bio-based composites via silane treatment: a short review. J Adhes Sci Technol. 2022;37(5):801–16. doi:10.1080/01694243.2022.2049087. [Google Scholar] [CrossRef]

90. Vijay R, Manoharan S, Arjun S, Vinod A, Singaravelu DL. Characterization of silane-treated and untreated natural fibers from stem of leucas aspera. J Nat Fibers. 2020;18(12):1957–73. doi:10.1080/15440478.2019.1710651. [Google Scholar] [CrossRef]

91. Barczewski M, Mysiukiewicz O, Andrzejewski J, Piasecki A, Strzemięcka B, Adamek G. The inhibiting effect of basalt powder on crystallization behavior and the structure-property relationship of α-nucleated polypropylene composites. Polym Test. 2021;103(23):107372. doi:10.1016/j.polymertesting.2021.107372. [Google Scholar] [CrossRef]

92. Sumrith N, Techawinyutham L, Sanjay MR, Dangtungee R, Siengchin S. Characterization of alkaline and silane treated fibers of ‘water hyacinth plants’ and reinforcement of ‘water hyacinth fibers’ with bioepoxy to develop fully biobased sustainable ecofriendly composites. J Polym Environ. 2020;28(10):2749–60. doi:10.1007/s10924-020-01810-y. [Google Scholar] [CrossRef]

93. Prakash VRA, Viswanthan R. Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos Part A, Appl Sci Manuf. 2019;118(6):317–26. doi:10.1016/j.compositesa.2019.01.008. [Google Scholar] [CrossRef]

94. Atiqah A, Jawaid M, Sapuan SM, Ishak MR, Ansari MNM, Ilyas RA. Physical and thermal properties of treated sugar palm/glass fibre reinforced thermoplastic polyurethane hybrid composites. J Mater Res Technol. 2019;8(5):3726–32. doi:10.1016/j.jmrt.2019.06.032. [Google Scholar] [CrossRef]

95. Cavalcanti DKK, Banea MD, Neto JSS, Lima RAA, Da Silva LFM, Carbas RJC. Mechanical characterization of intralaminar natural fibre-reinforced hybrid composites. Compos Part B, Eng. 2019;175(1):107149. doi:10.1016/j.compositesb.2019.107149. [Google Scholar] [CrossRef]

96. Manimaran P, Senthamaraikannan P, Sanjay MR, Marichelvam MK, Jawaid M. Study on characterization of furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohydr Polym. 2018;181(3):650–8. doi:10.1016/j.carbpol.2017.11.099. [Google Scholar] [PubMed] [CrossRef]

97. Amiandamhen SO, Meincken M, Tyhoda L. Natural fibre modification and its influence on fibre-matrix interfacial properties in biocomposite materials. Fibers Polym. 2020;21(4):677–89. doi:10.1007/s12221-020-9362-5. [Google Scholar] [CrossRef]

98. Zaman HU, Khan RA. Acetylation used for natural fiber/polymer composites. J Thermoplastic Compos Mater. 2019;34(1):3–23. doi:10.1177/0892705719838000. [Google Scholar] [CrossRef]

99. Chung TJ, Park JW, Lee HJ, Kwon HJ, Kim HJ, Lee YK, et al. The improvement of mechanical properties, thermal stability, and water absorption resistance of an eco-friendly PLA/kenaf biocomposite using acetylation. Appl Sci. 2018;8(3):376. doi:10.3390/app8030376. [Google Scholar] [CrossRef]

100. Loong ML, Cree D. Enhancement of mechanical properties of bio-resin epoxy/flax fiber composites using acetic anhydride. J Polym Environ. 2017;26(1):224–34. doi:10.1007/s10924-017-0943-3. [Google Scholar] [CrossRef]

101. Joffre T, Segerholm K, Persson C, Bardage SL, Hendriks CLL, Isaksson P. Characterization of interfacial stress transfer ability in acetylation-treated wood fibre composites using X-ray microtomography. Ind Crops Prod. 2017;95:43–9. doi:10.1016/j.indcrop.2016.10.009. [Google Scholar] [CrossRef]

102. Vinayagamoorthy R. Influence of fiber surface modifications on the mechanical behavior of Vetiveria zizanioides reinforced polymer composites. J Nat Fibers. 2017;16(2):163–74. doi:10.1080/15440478.2017.1410513. [Google Scholar] [CrossRef]

103. Safri SNA, Sultan MTH, Saba N, Jawaid M. Effect of benzoyl treatment on flexural and compressive properties of sugar palm/glass fibres/epoxy hybrid composites. Polym Test. 2018;71(2):362–9. doi:10.1016/j.polymertesting.2018.09.017. [Google Scholar] [CrossRef]

104. Nayak S, Mohanty JR. Influence of chemical treatment on tensile strength, water absorption, surface morphology, and thermal analysis of areca sheath fibers. J Nat Fibers. 2018;16(4):589–99. doi:10.1080/15440478.2018.1430650. [Google Scholar] [CrossRef]

105. Izwan SM, Sapuan SM, Zuhri MYM, Mohamed AR. Thermal stability and dynamic mechanical analysis of benzoylation treated sugar palm/kenaf fiber-reinforced polypropylene hybrid composites. Polymers. 2021;13(17):2961. doi:10.3390/polym13172961. [Google Scholar] [PubMed] [CrossRef]

106. Mohanta N, Acharya S. Fiber surface treatment: its effect on structural, thermal, and mechanical properties of luffa cylindrica fiber and its composite. J Compos Mater. 2016;50(22):3117–31. doi:10.1177/0021998315615654. [Google Scholar] [CrossRef]

107. Samanth M, Bhat KS. Conventional and unconventional chemical treatment methods of natural fibres for sustainable biocomposites. Sustain Chem Clim Action. 2023;3(3):100034. doi:10.1016/j.scca.2023.100034. [Google Scholar] [CrossRef]

108. Khan JA, Khan MA, Islam R. Effect of potassium permanganate on mechanical, thermal and degradation characteristics of jute fabric-reinforced polypropylene composite. J Reinforced Plast Compos. 2012;31(24):1725–36. doi:10.1177/0731684412458716. [Google Scholar] [CrossRef]

109. Imoisili PE, Jen T-C. Mechanical and water absorption behaviour of potassium permanganate (KMnO4) treated plantain (Musa Paradisiacal) fibre/epoxy bio-composites. J Mater Res Technol. 2020;9(4):8705–13. doi:10.1016/j.jmrt.2020.05.121. [Google Scholar] [CrossRef]

110. Sanjay MR, Siengchin S, Parameswaranpillai J, Jawaid M, Pruncu CI, Khan A. A comprehensive review of techniques for natural fibers as reinforcement in composites: preparation, processing and characterization. Carbohydr Polym. 2019;207(20):108–21. doi:10.1016/j.carbpol.2018.11.083. [Google Scholar] [PubMed] [CrossRef]

111. Li W, Meng L, Ma R. Effect of surface treatment with potassium permanganate on ultra-high molecular weight polyethylene fiber-reinforced natural rubber composites. Polym Test. 2016;55:10–6. doi:10.1016/j.polymertesting.2016.08.006. [Google Scholar] [CrossRef]

112. Khan RA. A review on the properties of natural fibers and manufacturing techniques of fiber reinforced biocomposites. Modern Concepts Mater Sci. 2021;4(4):4. doi:10.33552/mcms.2021.04.000592. [Google Scholar] [CrossRef]

113. Jumaidin R, Diah NA, Ilyas RA, Alamjuri RH, Yusof FAM. Processing and characterisation of banana leaf fibre reinforced thermoplastic cassava starch composites. Polymers. 2021;13(9):1420. doi:10.3390/polym13091420. [Google Scholar] [PubMed] [CrossRef]

114. Fazeli M, Florez JP, Simão RA. Improvement in adhesion of cellulose fibers to the thermoplastic starch matrix by plasma treatment modification. Compos Part B, Eng. 2019;163:207–16. doi:10.1016/j.compositesb.2018.11.048. [Google Scholar] [CrossRef]

115. Nyssanbek M, Kuzina N, Kondrashchenko V, Azimov A. Effects of plasma treatment on biodegradation of natural and synthetic fibers. Npj Mater Degradation. 2024;8(1):8. doi:10.1038/s41529-024-00437-x. [Google Scholar] [CrossRef]

116. Gupta US, Dhamarikar M, Dharkar A, Chaturvedi S, Kumrawat A, Giri N, et al. Plasma modification of natural fiber: a review. Mater Today: Proc. 2021;43(3):451–7. doi:10.1016/j.matpr.2020.11.973. [Google Scholar] [CrossRef]

117. Rachtanapun P, Sawangrat C, Kanthiya T, Thipchai P, Kaewapai K, Suhr J, et al. Effect of plasma treatment on bamboo fiber-reinforced epoxy composites. Polymers. 2024;16(7):938. doi:10.3390/polym16070938. [Google Scholar] [PubMed] [CrossRef]

118. Naebe M, Haque ANMA, Haji A. The effect of plasma treatment on dyeing of natural fibers. In: Rather LJ, Haji A, Shabbir M, editors. Innovative and emerging technologies for textile dyeing and finishing. USA: Scrivener Publishing LLC; 2021. p. 191–212. doi:10.1002/9781119710288.ch7. [Google Scholar] [CrossRef]

119. Mosquera GS, Mariño CA, Luna TP. Effects of dry etching plasma treatments on natural and synthetics fibers: a comparative study. Mater Circular Economy. 2022;4(1):4. doi:10.1007/s42824-021-00048-w. [Google Scholar] [CrossRef]

120. Ferreira DP, Cruz J, Fangueiro R. Surface modification of natural fibers in polymer composites. In: Green composites for automotive applications. Elsevier Ltd.; 2019. vol. 22, p. 3–41. doi:10.1016/b978-0-08-102177-4.00001-x. [Google Scholar] [CrossRef]

121. Pillai RR, Thomas V. Plasma surface engineering of natural and sustainable polymeric derivatives and their potential applications. Polymers. 2023;15(2):400. doi:10.3390/polym15020400. [Google Scholar] [PubMed] [CrossRef]

122. Maqsood HS, Bashir U, Wiener J, Puchalski M, Sztajnowski S, Militky J. Ozone treatment of jute fibers. Cellulose. 2017;24(3):1543–53. doi:10.1007/s10570-016-1164-y. [Google Scholar] [CrossRef]

123. Royan NRR, Sulong AB, Yuhana NY, Chen RS, Ghani MHA, Ahmad S. UV/O3 treatment as a surface modification of rice husk towards preparation of novel biocomposites. PLoS One. 2018;13(5):e0197345. doi:10.1371/journal.pone.0197345. [Google Scholar] [PubMed] [CrossRef]

124. Nishata RRR, Sulong AB, Yuliana NY, Sahrim A. Effect of surface modified rice husk (RH) on the flexural properties of recycled HDPE/RH composite. Adv Mater Process Technol. 2017;3(4):482–9. doi:10.1080/2374068x.2017.1340420. [Google Scholar] [CrossRef]

125. Gassan J, Gutowski VS. Effects of corona discharge and UV treatment on the properties of jute-fibre epoxy composites. Compos Sci Technol. 2000;60(15):2857–63. doi:10.1016/s0266-3538(00)00168-8. [Google Scholar] [CrossRef]

126. Mirmehdi S, Hein PRG, De Luca Sarantópoulos CIG, Dias MV, Tonoli GHD. Cellulose nanofibrils/nanoclay hybrid composite as a paper coating: effects of spray time, nanoclay content and corona discharge on barrier and mechanical properties of the coated papers. Food Packag Shelf Life. 2018;15(4):87–94. doi:10.1016/j.fpsl.2017.11.007. [Google Scholar] [CrossRef]

127. Adekomaya O, Majozi T. Sustainability of surface treatment of natural fibre in composite formation: challenges of environment-friendly option. Int J Adv Manuf Technol. 2019;105(7–8):3183–95. doi:10.1007/s00170-019-04581-6. [Google Scholar] [CrossRef]

128. Campomori JB, Hugen LN, De Andrade Silva F, Filho RDT, Guimarães TC, Bufalino L, et al. Effect of hot water and corona discharge treatments on the bonding behavior of jute fibers in polyester matrix. Discov Mater. 2024;4(1):4. doi:10.1007/s43939-024-00085-7. [Google Scholar] [CrossRef]

129. Nguyen VD, Hao J, Wang W. Ultraviolet weathering performance of high-density polyethylene/wood-flour composites with a basalt-fiber-included shell. Polymers. 2018;10(8):831. doi:10.3390/polym10080831. [Google Scholar] [PubMed] [CrossRef]

130. Ching YC, Gunathilake TU, Ching KY, Chuah CH, Sandu V, Singh R, et al. Effects of high temperature and ultraviolet radiation on polymer composites. In: Durability and life prediction in biocomposites, fibre-reinforced composites and hybrid composites. Elsevier Ltd; 2019. p. 407–26. doi:10.1016/B978-0-08-102290-0.00018-0. [Google Scholar] [CrossRef]

131. Nasri K, Toubal L, Loranger É., Koffi D. Influence of UV irradiation on mechanical properties and drop-weight impact performance of polypropylene biocomposites reinforced with short flax and pine fibers. Compos Part C Open Access. 2022;9:100296. doi:10.1016/j.jcomc.2022.100296. [Google Scholar] [CrossRef]

132. Harikrishnan MP, Vishnu V, Kothakota A, Pandiselvam R, Venkatesh T, Pillai S, et al. Impact of integrated ultra violet-ozone treatment on textural and structural properties of dough made of natural fiber based agro residues. J Nat Fibers. 2023;20(1):20. doi:10.1080/15440478.2022.2161690. [Google Scholar] [CrossRef]

133. Lee S, Kim SH, Jo Y-Y, Ju W-T, Kim H-B, Kweon H. Effects of ultraviolet light irradiation on silk fibroin films prepared under different conditions. Biomolecules. 2021;11(1):70. doi:10.3390/biom11010070. [Google Scholar] [PubMed] [CrossRef]

134. Kim JT, Netravali AN. Mercerization of sisal fibers: effect of tension on mechanical properties of sisal fiber and fiber-reinforced composites. Compos Part A Appl Sci Manuf. 2010;41(9):1245–52. doi:10.1016/j.compositesa.2010.05.007. [Google Scholar] [CrossRef]

135. Huda MS, Drzal LT, Mohanty AK, Misra M. Effect of chemical modifications of the pineapple leaf fiber surfaces on the interfacial and mechanical properties of laminated biocomposites. Compos Interfaces. 2008;15(2–3):169–91. doi:10.1163/156855408783810920. [Google Scholar] [CrossRef]

136. Nam TH, Ogihara S, Tung NH, Kobayashi S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly (butylene succinate) biodegradable composites. Compos B Eng. 2011;42(6):1648–56. doi:10.1016/j.compositesb.2011.04.001. [Google Scholar] [CrossRef]

137. Bachtiar D, Sapuan SM, Hamdan MM. The effect of alkaline treatment on tensile properties of sugar palm fibre reinforced epoxy composites. Mater Des. 2007;29(7):1285–90. doi:10.1016/j.matdes.2007.09.006. [Google Scholar] [CrossRef]

138. Koohestani B, Darban AK, Mokhtari P, Yilmaz E, Darezereshki E. Comparison of different natural fiber treatments: a literature review. Int J Environ Sci Technol. 2018;16(1):629–42. doi:10.1007/s13762-018-1890-9. [Google Scholar] [CrossRef]

139. Aravindh M, Sathish S, Raj RR, Karthick A, Mohanavel V, Patil PP, et al. A review on the effect of various chemical treatments on the mechanical properties of renewable fiber-reinforced composites. Adv Mater Sci Eng. 2022;2022(5):1–24. doi:10.1155/2022/2009691. [Google Scholar] [CrossRef]

140. Shahinur S, Hasan M. Natural fiber and synthetic fiber composites: comparison of properties, performance, cost and environmental benefits. In: Encyclopedia of renewable and sustainable materials. Elsevier Inc.; 2020. p. 794–802. doi:10.1016/B978-0-12-803581-8.10994-4. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools