Open Access

Open Access

REVIEW

A Comprehensive Review of Natural Rubber Composites: Properties, Compounding Aspects, and Renewable Practices with Natural Fibre Reinforcement

1 Department of Chemical Engineering and Sustainability, Kulliyyah of Engineering, International Islamic University Malaysia, Kuala Lumpur, 50728, Malaysia

2 Faculty of Chemical Engineering, Universiti Teknologi MARA (UiTM), Shah Alam, 40450, Malaysia

3 Department of Construction Management, Faculty of Built Environment, Tunku Abdul Rahman University of Management and Technology, Kuala Lumpur, 53300, Malaysia

4 Department of Bioprocess and Polymer Engineering, Faculty of Chemical and Energy Engineering, Universiti Teknologi Malaysia, Johor Bahru, 81310, Malaysia

5 Department of Chemical Engineering, Sunchon National University, Suncheon, 57922, Republic of Korea

* Corresponding Author: Fathilah Ali. Email:

(This article belongs to the Special Issue: Recent Advances on Renewable Materials)

Journal of Renewable Materials 2025, 13(3), 497-538. https://doi.org/10.32604/jrm.2024.057248

Received 12 August 2024; Accepted 08 November 2024; Issue published 20 March 2025

Abstract

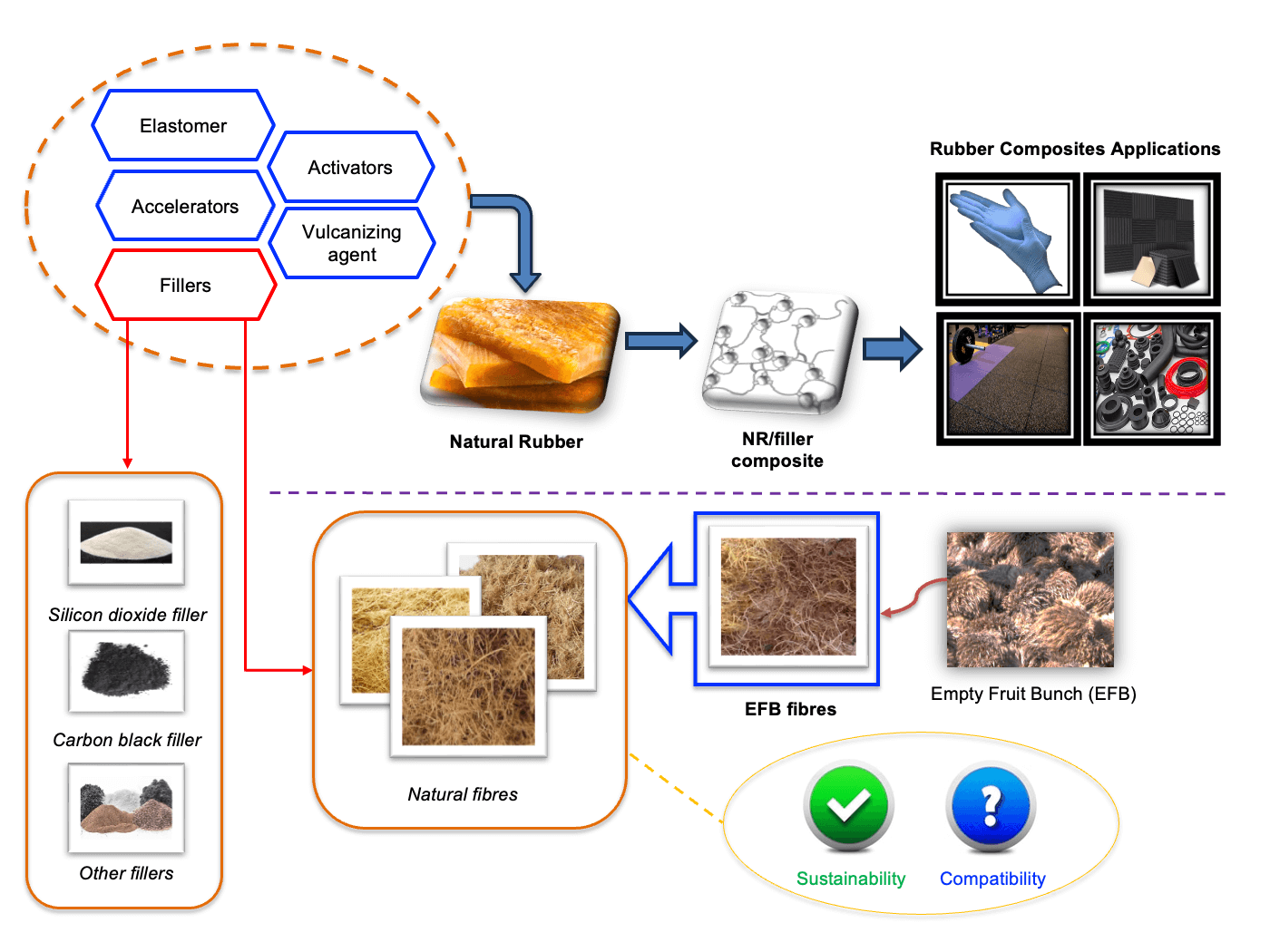

This review provides a comprehensive overview of natural rubber (NR) composites, focusing on their properties, compounding aspects, and renewable practices involving natural fibre reinforcement. The properties of NR are influenced by the compounding process, which incorporates ingredients such as elastomers, vulcanizing agents, accelerators, activators, and fillers like carbon black and silica. While effective in enhancing properties, these fillers lack biodegradability, prompting the exploration of sustainable alternatives. The potential of natural fibres as renewable reinforcements in NR composites is thoroughly covered in this review, highlighting both their advantages, such as improved sustainability, and the challenges they present, such as compatibility with the rubber matrix. Surface treatment methods, including alkali and silane treatments, are also discussed as solutions to improve fibre-matrix adhesion and mitigate these challenges. Additionally, the review highlights the potential of oil palm empty fruit bunch (EFB) fibres as a natural fibre reinforcement. The abundance of EFB fibres and their alignment with sustainable practices make them promising substitutes for conventional fillers, contributing to valuable knowledge and supporting the broader move towards renewable reinforcement to improve sustainability without compromising the key properties of rubber composites.Graphic Abstract

Keywords

Nomenclature

| NR | Natural Rubber |

| EFB | Empty Fruit Bunch |

| SMR | Standard Malaysia Rubber |

| phr (unit) | Parts per hundred rubber |

| MPa (unit) | MegaPascal |

1 Introduction to Natural Rubber

Today, latex-producing plants and trees have grown naturally in many regions of the world. The raw material (rubber) is typically extracted or tapped from Hevea brasiliensis, the Brazilian rubber tree particularly native to the Amazon, the largest socio-geographic region in Brazil, encompassing all nine states of the Amazon basin. In the last 1800s, the forests of these trees were raided by the Brazilians who converted the latex into rubber, allowing Brazil to dominate the world market for natural rubber and Amazonia to reach a production of 42,000 tons per year. During this time, rubber was collected by the enterprising indigenous community near the lower Amazon and processed the rubber into goods such as shoes and other products, which were then sold and shipped to traders or to the United States. Gradually, collecting rubber became the main occupation of the Brazilian natives in the northeast. Since the world was experiencing a period of discovery and prosperity at the time, the rapid growth of the Industrial Revolution led to the opening of new markets with higher demand than supply in industrial sectors such as automobiles, streetcars, telephones, electric lights, and others [1].

Several species rubber-producing plants were identified, as shown in Table 1, properties were studied and compared. However, the comparison showed that the Hevea brasiliensis tree is the best candidate for high latex production rate. Remarkably, this tree has a smooth, thick bark and possesses an efficient latex vascular system. It features good bark renewal, a high growth rate after latex harvesting begins, and demonstrates tolerance to severe diseases and strong winds. Additionally, it has a higher rubber content, ranging from 30% to 40%, compared to other trees. These attributes ensure that it can produce a substantial rubber yield to meet the growing demand [2,3].

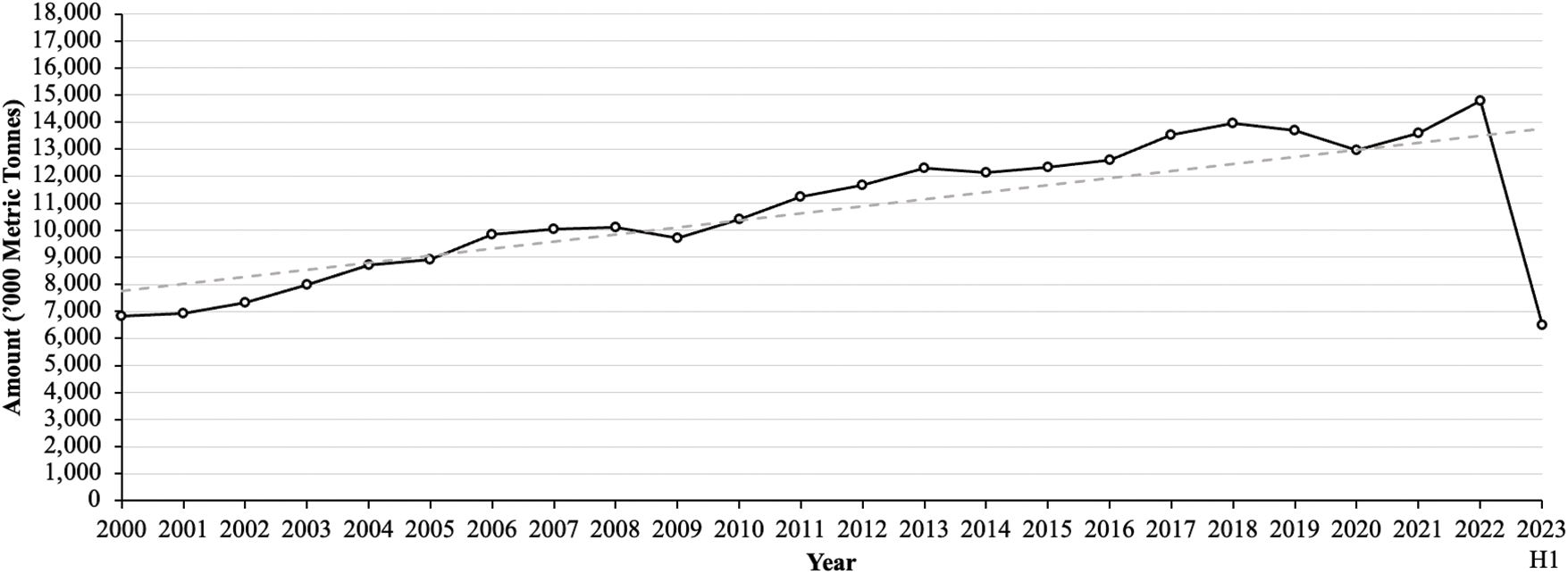

So far, increasing development has been observed, especially in rubber production, from the year 2000 to mid of the year 2023. As summarized in Fig. 1, global rubber production has gradually increased over the years, indicating the high demand for rubber goods worldwide. This growth can be attributed to the enormous potential uses of rubber in various industries, where natural rubber continues to play an essential role due to its versatility and numerous applications. Specifically, natural rubber is crucial for tyre production for vehicles, conveyor belts, and medical products such as surgical gloves, catheters, and elastic bands.

Figure 1: Annual global natural rubber production from 2000 to the first half of 2023. Own elaboration with adaptation from [4]. Copyright © Statista 2024

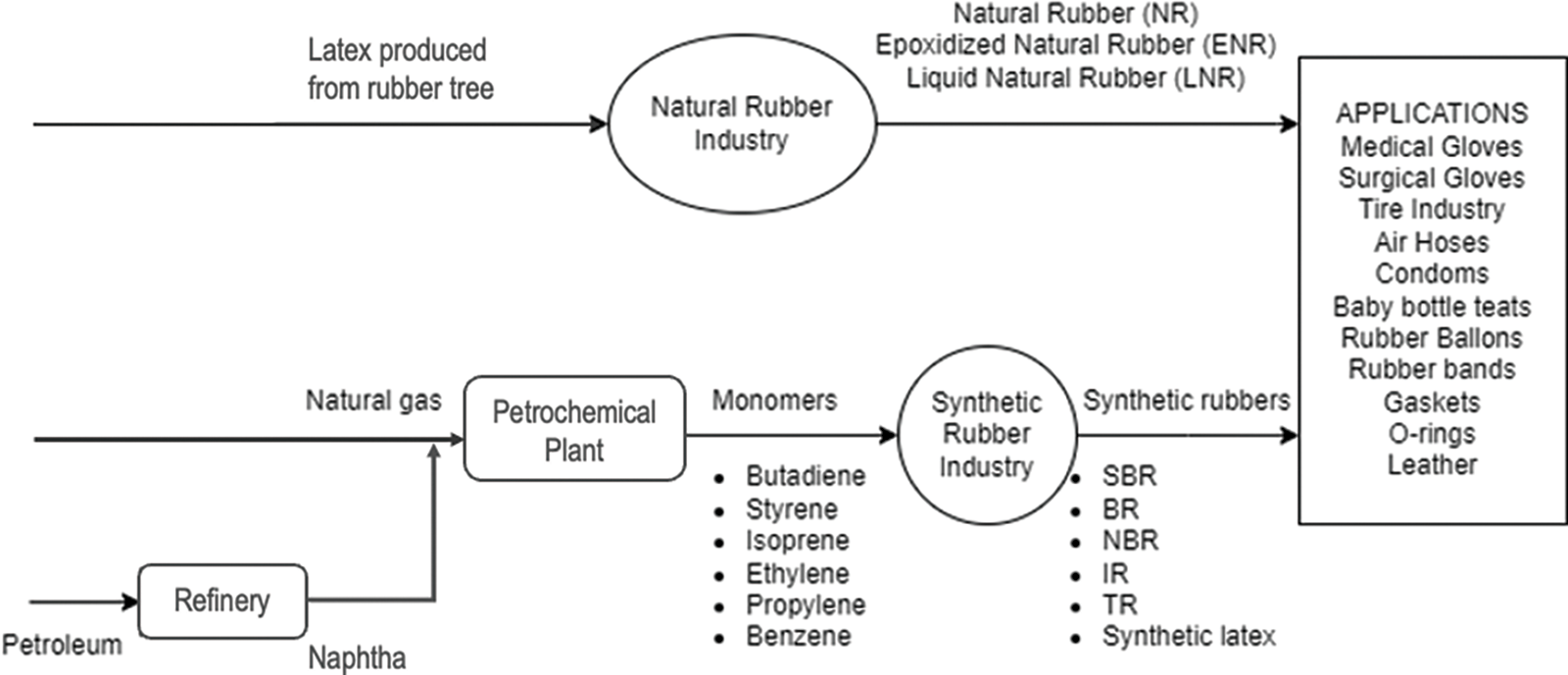

However, synthetic rubbers, which have been developed since the 20th century, are now also widely used in similar applications, such as car tyres, footwear, balloons, adhesives, protective gloves, hoses, rubber bands, and gaskets, due to their enhanced material properties [5]. As illustrated in Fig. 2, these two types of rubber materials differ significantly in their production processes, which impact their overall properties and suitability for different industrial uses.

Figure 2: Production system for natural rubber and synthetic rubber

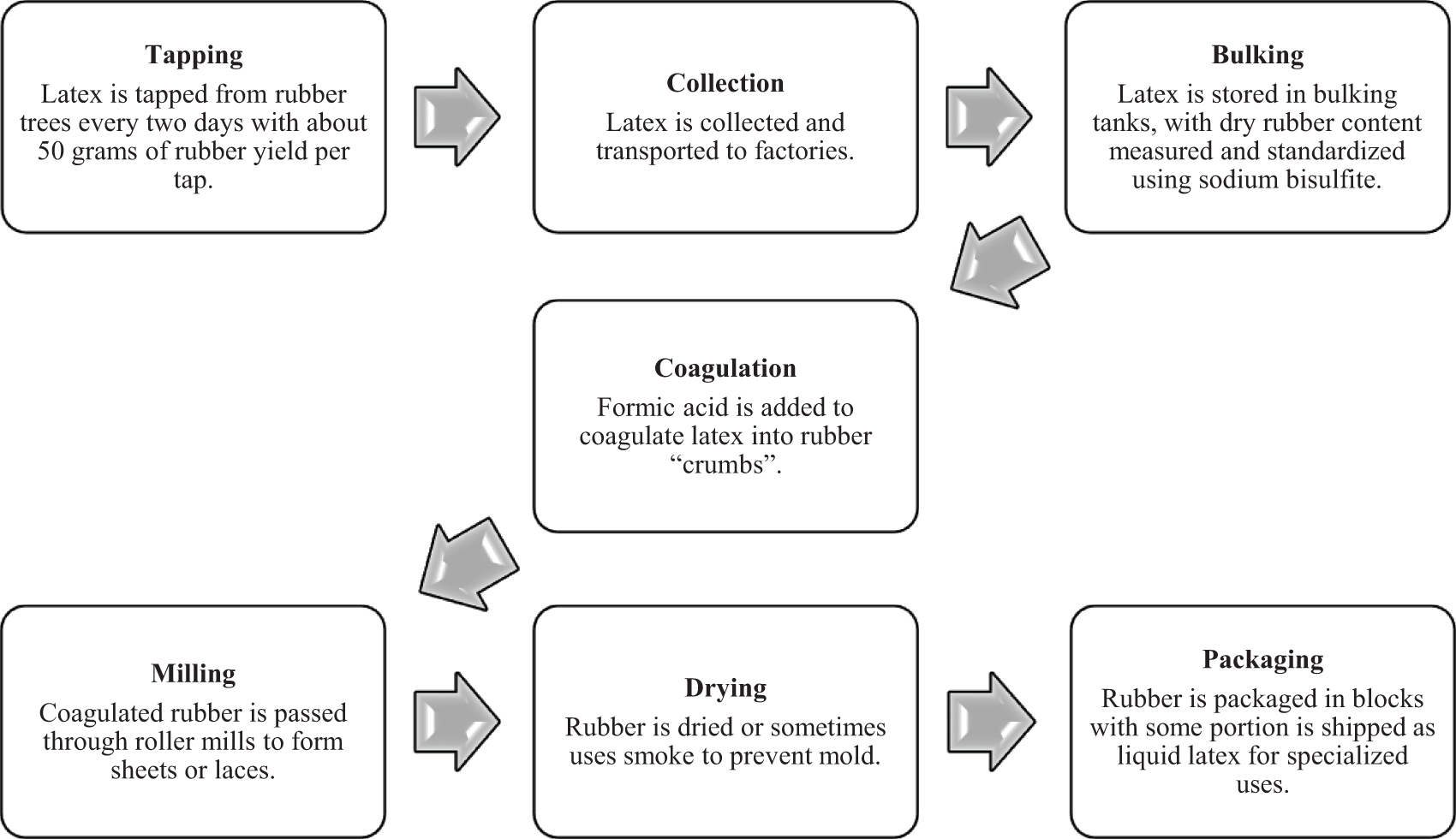

Fig. 3 illustrates the step-by-step process involved in the forming of natural rubber from latex, starting from the tapping of rubber trees to the final packaging for shipment. The formation of natural rubber begins with the tapping of rubber trees, a process usually carried out every two days. During this process, an angled cut is made on the bark to extract latex, which contains about 50 g of solid rubber per tapping. Rubber trees can be tapped once they reach 5 or 6 years of age and can continue producing latex for over 20 years. The latex is collected and transported to factories, where it is stored in bulking tanks. The dry rubber content (typically about 30%–40%) is measured using a hydrometer, and sodium bisulfite and water are added to standardize the latex and prevent spoilage. Once collected, the latex undergoes coagulation to separate the rubber from the liquid. This is typically done by adding formic acid, resulting in the formation of rubber “crumbs” that resemble curds of milk. The coagulated rubber is then washed, passed through roller mills to form thin sheets or laces, and thoroughly dried over a period of three to four days. In some cases, rubber is dried over smoky wood fires, which imparts a characteristic amber colour and protects the rubber from mold. The rubber sheets or blocks are then trimmed and packaged in most cases of 25-kg bulk, or into larger blocks measuring 67 by 33 by 18 cm and weighing 33.3 kg before shipment. In addition, about 10% of natural rubber can be shipped in liquid latex form for some particular uses, such as surgical gloves and toys, among others [6,7].

Figure 3: Flow diagram of natural rubber formation from latex

In contrast, polymerization of monomers is the method used in producing synthetic rubbers as illustrated in Fig. 2. First, naphtha is produced by refining petroleum, coal, and other hydrocarbons. The naphtha is then combined with natural gas in petrochemical plants to produce monomers. Typically, monomers such as butadiene, styrene, isoprene, chloroprene, acrylonitrile, ethylene, or propylene are used as starting chemicals, which in turn are treated in the synthetic rubber industry by polymerization using catalyst and process steam to form polymer chains. Finally, rubber materials are manufactured and processed into rubber products using vulcanization processes [5].

Apart from differences in production systems, natural and synthetic rubbers also vary significantly in their properties. Natural rubber is known for its high wear resistance, elasticity, tensile strength, and good resilience, making it an ideal material for applications requiring flexibility and durability. It also performs well at low temperatures. However, natural rubber has limitations, such as poor aging properties, limited chemical and oil resistance, and low resistance to elevated temperatures. In contrast, synthetic rubbers generally offer better resistance to chemicals, oils, ozone, and weathering and greater stability over a wide temperature range. However, while synthetic rubber hardens over time, natural rubber retains its flexibility, though it has inferior aging and abrasion resistance compared to many synthetic alternatives [8,9].

In some applications, natural and synthetic rubbers are blended to overcome the limitations of individual properties by combining their strengths for optimal performance. For example, natural rubber, which excels in elasticity, can be blended with nitrile butadiene rubber (NBR) to enhance its chemical and oil resistance. However, blending different rubbers often leads to challenges due to differences in molecular weight, viscosity, and polarity, which can result in phase separation during processing. The resulting morphology, including co-continuous phases or a dispersed phase, greatly influences the performance of the rubber blend [10]. Nonetheless, blending is widely used in various industries such as the tyre, footwear, and belting industries to achieve an optimal balance of properties for specific applications. Optimizing the morphology of rubber blends, ensuring uniform dispersion, and minimizing phase separation are critical steps in maintaining the consistency and quality of these materials. The complementary use of natural and synthetic rubbers helps address individual limitations, thereby achieving both cost-efficiency and high performance [11].

Despite these differences and rubber combinations, natural rubber remains undeniably crucial in today’s market due to its unique combination of elasticity, strength, and resilience, which synthetic alternatives alone cannot fully replicate. Its widespread use in industries reflects its ongoing significance, with growing demand in regions where natural production capacity expands. The increasing global production trend of natural rubber also demonstrates its continued relevance and essential role in meeting the high demand for rubber goods worldwide.

2 Properties of Natural Rubber

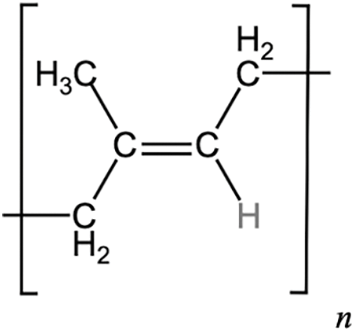

NR is a polymer consisting of repeating cis-1,4-isoprene units, with some amounts of lipids, proteins and other components as presented in Table 2 and its general chemical structure is shown in Fig. 4.

Figure 4: Chemical structure of NR (own elaboration)

Apart from that, NR is also a flexible polymer chain with a molecular weight of over 106 g/mol and a high elasticity that allows it to stretch without breaking or failing. In addition, one of the characteristics of NR is its high elasticity—it can be stretched without breakage/failure. The material returns to its original length after the stretching force is released. The elasticity is because all rubbers consist of long and flexible molecules (linear high polymer). To make the properties of the rubber flexible and strong, the long-chain molecules must be cross-linked together through vulcanization [8,13].

Malaysia produces rubber in various grades of Standard Malaysia Rubber (SMR). SMR L (latex grade) is made from acid-coagulated latex and is the highest quality. SMR 10 and SMR 20 are produced from cup lump, and the numerals refer to the dirt content. The SMR 10 and SMR 20 grades of rubber are used to make products such as tyres for automobiles [14]. The introduction of technically specified SMR products has changed the production process and enabled better cleaning and automation of the process. As more natural rubber producers entered the market, natural rubber of comparable quality was produced in Thailand and Indonesia. Table 3 below shows the specifications of various types of SMR according to Mech Chem Laboratory [15].

SMR L is highly recommended for its light colour and exceptional cleanliness. To prevent enzymatic darkening during the latex stage, 0.05% sodium metabisulfite is added as a preservative. This rubber is primarily used in coloured compounds, especially those requiring vivid or light hues, as its cleanliness reduces the amount of dye needed and improves colour consistency between batches. Additionally, the minimal contamination ensures excellent physical properties. Although SMR 5 is more affordable and cleaner, it has a less attractive colour. However, when SMR L meets all requirements, there is little reason to use two different types of the same product [16]. It is also worth noting that other rubber-producing countries, such as Thailand and Indonesia, have also produced natural rubber of comparable quality.

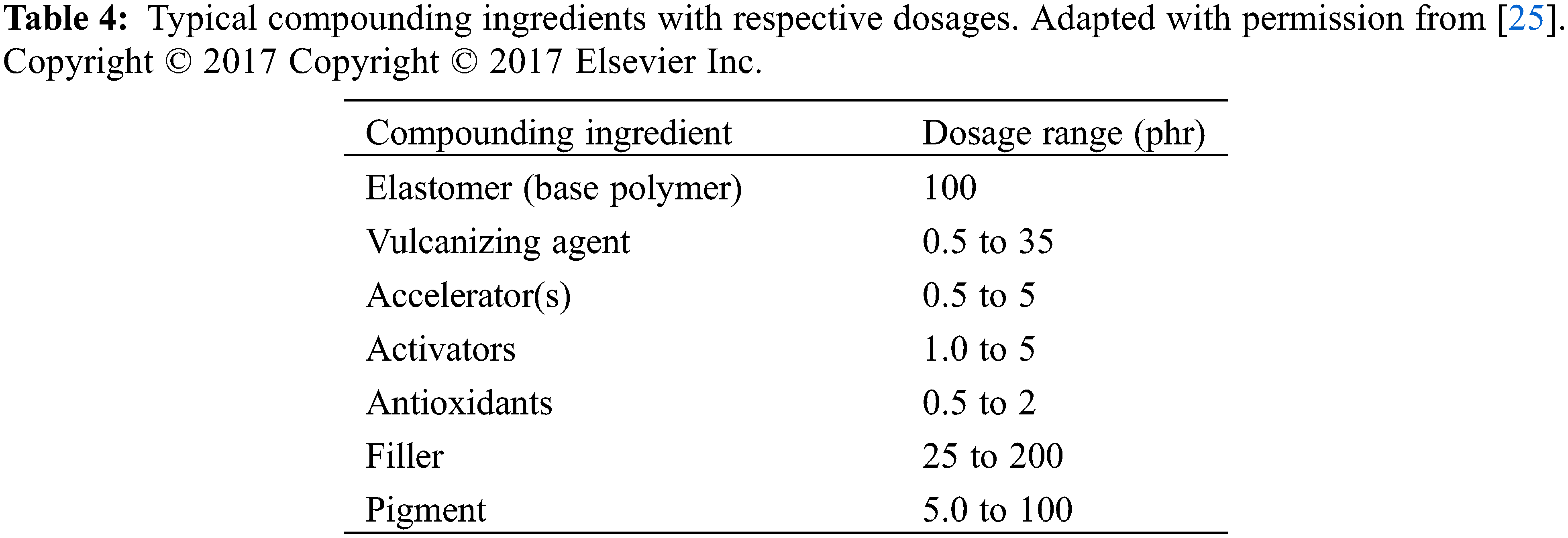

Rubber compounding is an essential aspect of rubber technology. It is a process in which various compounds such as elastomers, vulcanizing agents, accelerators, activators, fillers, and other additives are mixed to produce rubber composites with specific mechanical properties. Elastomers, which serve as the base polymer matrix, form the basis of the composite material, giving it strength and flexibility. In addition, vulcanizing agents improve the durability and elasticity of the rubber composite, and the use of accelerators speeds up the vulcanization process of the rubber composite. Activators on the other hand increase the effectiveness of the accelerators during the curing of the rubber composite. Fillers such as carbon black or silica are commonly used to reinforce the composite material and improve the mechanical strength and wear resistance of the rubber composites [17].

Various technologies have been employed to form these rubber composites. These methods include latex compounding [18], in-situ polymerization process [19], compression moulding [20], as well as melt-blending and two-roll milling [21]. Among these techniques, the combination of compression moulding and two-roll milling has become prevalent and extensively used in the rubber industry. This is because these combined processes are considerably more environmentally friendly as they do not involve organic solvents in the application. Additionally, the combined processes provide relatively high compatibility with the existing industrial system, which consequently makes them a direct and practical technique for rubber composite production [22–24]. The mixing process involves determining the specific ratio of materials or additives and the vulcanization process to produce the rubber composite. The typical ingredients used in rubber compounding for the production of rubber composites are presented in Table 4 below. Additionally, one critical aspect of these technological processes is vulcanization, where various factors, including but not limited to temperature, curing time, sulphur-to-accelerator ratio, and the type of accelerators and activators, significantly impact the final product’s properties. For example, higher curing temperatures can result in shorter cross-links, improving heat resistance but potentially decreasing flexibility. On the other hand, adjusting the sulphur-to-accelerator ratio can control the mechanical strength, modulus, and elongation of the rubber composite. These factors must be carefully monitored and optimized to ensure the rubber composite achieves desirable qualities such as durability, abrasion resistance, and elasticity. A detailed discussion of vulcanization and its impact on product quality is outlined in the subsequent sections of this review. As a result, the rubber composite produced from the rubber compounding will usually have a unique and outstanding combination of properties that make it suitable for various industrial applications.

Rubber composites are widely used in the automotive industry for the production of key components. Since the base material is an elastomer, these composites are safe, reliable, effective, robust, and durable. These are the most important properties required in the automotive industry, e.g., for car and bicycle components. Rubber composites are also used in the aerospace industry to produce seals, hoses, and vibration-isolating mounts. In the construction industry, rubber composites are used extensively for seals, gaskets and vibration dampers. Rubber composites are also used in the production of conveyor belts, hoses, and industrial seals [17,26]. Developments in the rubber compounding process are continuously being investigated. Researchers are currently focusing on producing environmentally friendly compounds to meet the growing demand for green materials. Researchers are currently exploring the use of bio-based materials such as natural rubber and fillers, as well as recycled rubber to reduce the carbon footprint. Bio-based material and recycled rubber can replace synthetic rubber, which will lead to a reduction in the consumption of synthetic rubber derived from petroleum-based raw materials [27]. In addition, there is some research on self-healing elastomers that can lead to an improvement in the use of rubber materials in the automotive industry. One example is self-healing tyres, which are able to heal or seal damage caused by punctures or cracks themselves, thus extending the service life of the materials and reducing the consumption of raw materials [26].

Elastomers are materials known for their elasticity, flexibility, toughness, and durability, and they are also impermeable to water and air. These materials are made up of long polymer chains held together by weak intermolecular forces, which allow them to stretch and deform but still return to their original shape. Elastomers generally consist of natural or synthetic rubber. Common types include silicone elastomers, natural rubber, polyurethane, neoprene, and polybutadiene. It is worth to note that the term “elastomer” is rephrased from “elastic polymer”, and is often used as a broad designation for a group of polymers that share common properties, including high elasticity, viscoelasticity, and a glass transition temperature well below room temperature. While rubber is frequently referred to as an elastomer due to its exceptional elasticity, the terms should not be considered synonymous in a narrow sense. The term elastomer encompasses all polymeric materials with high elasticity, including rubber, but not exclusively. However, in a broader sense and common usage, the word “rubber” is often used interchangeably with “elastomer.” In this context, and throughout this discussion, the terms can be considered interchangeable, as “rubber” typically refers to the general concept rather than the more technical, narrow definition [26]. It is known that elastomers are economically significant and find widespread use across industries such as manufacturing, healthcare, power lines, and information technology. Their versatility allows them to be used in a wide range of products, from rubber balloons to seals for industrial machinery [28].

Natural rubber, which is known for its excellent abrasion resistance, high and low temperature tolerance, enhanced tensile strength and high resilience, remains a crucial industrial polymer. The latex derived from various plant species shows significant variability in its characteristics. As presented in Table 1, latex from Hevea brasiliensis is known for its high rubber content, making it the primary source for commercial rubber production, with molecular weight averaging 1.31 MDa and annual production reaching 12,760,000 tons. In comparison, guayule and Russian dandelion are emerging sources of latex, with guayule producing brown/green high-protein latex, while Russian dandelion produces a milky liquid rich in high-quality rubber, both of which offer potential as alternative sources for natural rubber. Other plants, such as the fig tree, banyan fig, and prickly lettuce, produce latex with lower rubber content. For example, prickly lettuce yields milky latex with rubber content ranging between 2%–8%, while sunflower stems contain a latex-like substance but with minimal rubber yield (0.1%–1%). While not yet commercially significant in rubber production, these plants offer insight into the diverse natural sources of latex and their potential applications. Other plants, such as the fig tree, banyan fig, and prickly lettuce, produce latex with lower rubber content. For example, prickly lettuce yields milky latex with rubber content ranging between 2%–8%, while sunflower stems contain a latex-like substance but with minimal rubber yield (0.1%–1%).

Natural rubber remains a vital industrial polymer despite competition from synthetic elastomers like styrene-butadiene rubber and polybutadiene derived from petroleum by-products. While synthetic alternatives have gained popularity, over half of the world’s rubber production is still dedicated to automobile tyres, with the remainder used in mechanical components (e.g., mountings, gaskets, belts, and hoses) and a variety of consumer products such as shoes, furniture, and toys. One key feature of natural rubber is its lightly cross-linked structure, which allows for the full extension of polymer chains. These cross-links, however, prevent the molecules from sliding past each other, ensuring that even significant deformations are reversible. Its low glass transition temperature further contributes to its flexibility across a broad range of environmental conditions, making it suitable for diverse applications. Thus, despite some advantages offered by synthetic elastomers, natural rubber’s unique combination of elasticity, biodegradability, and renewability ensures its ongoing importance in both industrial and consumer markets [29].

Vulcanizing agents are important chemicals in the rubber compounding that trigger chemical reactions such as the cross-linking of elastomer molecules. They transform raw rubber into a durable material that can withstand environmental stresses. Combined with accelerators and activators at elevated temperatures, they form stable covalent carbon-carbon double bonds in the rubber matrix. Sulphur is a commonly used vulcanizing agent but must meet purity standards of 99.5% with a minimum ash content of 0.5%. Other chemicals such as selenium, tellurium, thiuram disulphides, peroxides, metal oxides, and quinone dioximes also improve rubber performance [30,31]. Adding these vulcanizing agents in combination with accelerators and activators at elevated temperatures initiates the crosslinking process in motion. This cross-linking strengthens the rubber and increases its resistance to environmental stresses such as heat, cold, chemicals, and mechanical forces. The resulting vulcanized rubber has improved tensile strength, tear resistance, abrasion resistance, and dimensional stability, making it suitable for a wide range of applications, including tyres, seals, hoses, and gaskets.

Adhesives based on epoxidized natural rubber (ENR) were produced with two-roll mills using ENR25 with two crosslinking systems: Diamine/bisphenol A and anhydride/imidazole, and adhesive resin PX1150 (terpene polymer) as tackifying resin. It was found that the adhesive made from sulphur-cured ENR25 had higher tensile strength than that made from anhydride-cured ENR25 due to better crosslinking efficiency. In addition, the tensile strength and tensile modulus of the sulphur-cured ENR25 adhesive were improved by the addition of tackifying resin [32].

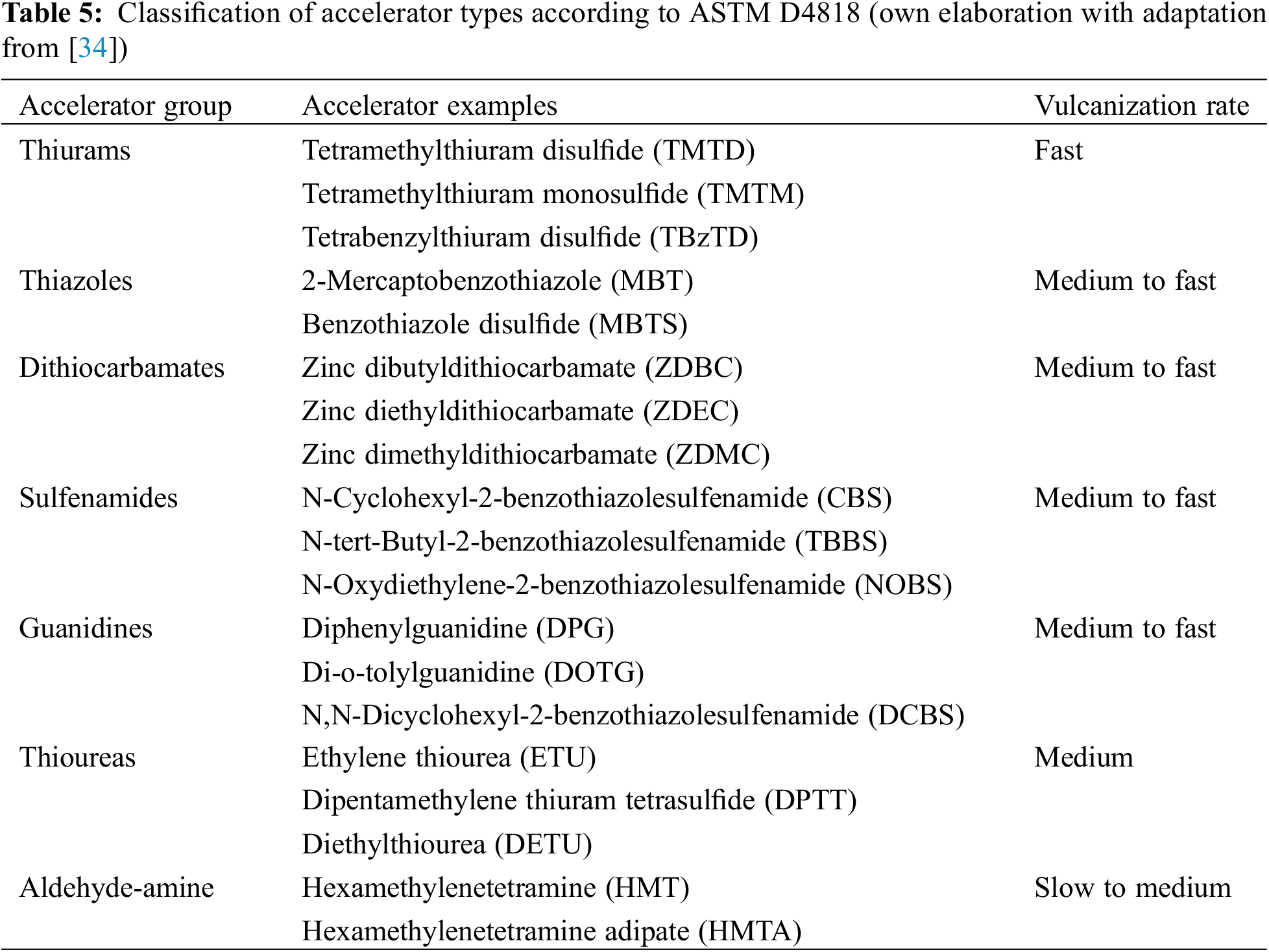

Accelerators are used in chemical compounding to increase the speed of rubber vulcanization. They are categorized into groups such as sulphonamides, thiazoles, guanidines, dithiocarbamates, and thiurams. These accelerators promote chemical reactions between rubber molecules and crosslinking agents, thereby improving the mechanical strength, elasticity, and durability of the material. They can be used as single, binary, or multiple accelerators in the rubber vulcanization system. Each group has unique properties, such as thiazoles, which provide a balanced combination of scorch safety and vulcanization rate, sulphonamides, which provide good vulcanization rates and compatibility with various elastomers, thiurams for rapid vulcanization, dithiocarbamates, which provide moderate to fast vulcanization rates, guanidines, which provide medium to fast vulcanization rates, thioureas, which improve performance, and aldehyde amines, which provide slow to medium vulcanization rates [17,33]. A summary of typical accelerator groups is listed in Table 5, along with examples and corresponding vulcanization rates.

Activators such as amines, stearic acid, and zinc oxide (ZnO) are commonly-used activators, and are essential in rubber compounding to enhance the effectiveness of accelerators. Stearic acid is the predominant organic activator, while zinc oxide is the predominant inorganic activator. Depending on the particle size, 3%–5% zinc oxide is usually required to activate the vulcanization fully. Zinc oxide forms complexes with the sulphur accelerator, which increases the curing speed by 3%–5% depending on the particle size. These Zn2+ based complexes enable the curing of sulphur and accelerators and improve the effectiveness of the rubber compounding [35,36]. The chemical interaction between zinc oxide and fatty acid to form Zn2+ ions, as shown in the Eq. (1) below:

Heideman et al. investigated the effect of adding zinc oxide (ZnO) as an activator for the sulphur vulcanization of solution styrene-butadiene rubber and ethylene–propylene–diene rubber. They found that the addition of ZnO enhanced the vulcanization efficiency and vulcanizate properties and shortened the vulcanization time of the two rubbers [35]. However, it has been reported that the excessive use of zinc oxide in the rubber compounding disturbs the ecological balance [37]. To address this problem, researchers have explored other alternatives, such as magnesium oxide (MgO), that can replace zinc oxide while retaining the required vulcanization properties [33].

Alam et al. [33] found that the use of binary activators combining ZnO and MgO in rubber composites can significantly minimize the ZnO content in the rubber compounding while improving the vulcanization rate from 0.3 to 0.85 Nm/min when a 3:2 ratio of MgO to ZnO is used as a vulcanization activator, compared to the use of 5 phr ZnO alone. The use of 60 MgO as a cure activator can improve the mechanical properties, resulting in 7.5% higher M100 (modulus at 100% elongation) (0.58 MPa from 0.54 MPa), 20% higher tensile strength (23.7 MPa from 19.5 MPa), 15% higher elongation at break (1455% from 1270%) and 68% higher fracture toughness (126 MJ/m3 from 75 MJ/m3). Similar to the mechanical properties, the thermal stability of the rubber composite is also significantly improved by the combination of both vulcanization activators in the rubber [33].

The mechanical, thermal, and other properties of rubber composites can be improved by the addition of fillers, which can strengthen the rubber composite, increase the efficiency of the process, and facilitate processing. When combined with compatibilizers and elastomers, fillers can improve the properties of the rubber composite, such as tensile strength, hardness, modulus, elongation, tear, and abrasion resistance. The choice of fillers is very important along with elastomer and vulcanizing agent type as it significantly influences the physical and processing properties of rubber composites. Plus, the degree of reinforcement provided by fillers correlates inversely with their particle size, with finer particles providing better reinforcement. However, finer filler particles require higher energy consumption during processing to achieve proper dispersion within the polymer matrix, making them more difficult to process. Consequently, the particle size of fillers has a great influence on the tensile properties, especially the tensile strength, of the polymer compound.

Organic and inorganic fillers are two types of fillers generally used in rubber compounding. Organic fillers, typically sourced from natural fibres such as rice husk, coconut fibre, kenaf, and oil palm biomass, provide high electrical resistance, thermal insulation, fracture resistance, and strength. On the other hand, synthetic or inorganic fillers, such as glass, carbon, or polymer fibres, can be used along with thermoplastic or thermoset resins, but may have the poor reinforcing ability, so chemical modification is required [38]. A more detailed discussion on fillers, including their role in vulcanization and sustainable alternatives, is outlined in the subsequent sections.

In general, rubber often is challenging to be used in its pure form in making of another elastomer product, so additives must be compounded together with NR to create new rubber composites. This is because conventional NR is inherently soft and sticky as when unvulcanized—hence the vulcanization process is required to bond polymer chains together. Vulcanization is generally a process of chemically creating a network “bridge” by introducing cross-links between polymer chains. A cross-link can be a group of sulphur atoms in a short chain, a single sulphur atom, a carbon-carbon bond, a polyvalent organic radical, an ionic cluster, or a polyvalent metal ion. Due to its unsaturated double bond on the main polymeric chain, NR generally has low resistance to chemicals, aromatic oils, and environmental factors. However, vulcanized NR significantly improves properties like tensile strength, hardness, and abrasion resistance [8,39–41].

4.1 Factors Affecting Vulcanization

Variables that affect vulcanization kinetics include cure temperature, accelerator type, and accelerator-sulphur ratio. Vulcanization affects the crosslink length and density, which, unlike thermoplastics, has a direct effect on the mechanical properties of rubber elastomers. These factors influence the resulting rubber elastomer.

Increasing the vulcanization temperature results in a significant decrease in the maximum density of chemical crosslinks within the network, which accelerates the subsequent decrease in crosslink density. Higher curing temperatures lead to the creation of shorter sulphidic bonds (mono- and di-sulphidic bonds), reducing the poly-sulphidic bridges and promoting the distribution of di- and mono-sulphidic bridges in NR during accelerated sulphur vulcanization. On the other hand, lower curing temperatures favours the formation of longer sulphidic bonds (poly-sulphidic bonds) with lower stability. Additionally, high curing temperatures may trigger devulcanization to take place [42–44].

The curing time during vulcanization is one factor that directly influences the crosslink density and, consequently, the mechanical properties and service life of rubber composites. As the curing time increases, crosslinking between the polymer chains is progressively established, leading to enhanced durability and performance. However, beyond a certain optimal point, over-curing can cause degradation in properties. According to Yilmaz et al. [45], natural rubber composites used in the automotive industry require an optimized curing time to ensure safe performance. In an investigation, rubber samples were vulcanized for 3, 5, 10, and 15 min at a constant temperature of 160°C. The study found that the sample vulcanized for 10 min showed the maximum crosslink density and the best mechanical properties, including the lowest permanent compression set values at various temperatures. This sample also demonstrated a predicted service life of 2282 h at 70°C [45], showing that finding the correct curing time is able to ensure the longevity and performance of rubber products, especially under elevated temperature conditions. Similarly, another study focused on pre-vulcanized natural rubber latex prepared at 55°C for different time periods (2 to 10 h) showed that curing time significantly affects the latex’s colloidal stability and physical properties. As the vulcanization time increased, mechanical stability improved, and tensile strength peaked after 20 days of storage [46]. This shows that curing time not only affects immediate properties but also has a long-term impact on the product’s performance during storage.

Curing pressure is another factor affecting vulcanization which directly influencing the mechanical properties and structural integrity of rubber composites. Optimal curing pressure ensures the formation of strong interfacial bonds, appropriate cross-link density, and minimal product defects. Various studies highlight the significant role curing pressure plays in determining the final performance of rubber materials. In producing natural rubber/ethylene propylene diene monomer (NR/EPDM) composites, it has been proven that lower curing pressures result in poor interfacial adhesion, leading to compromised mechanical properties. Conversely, excessively high curing pressures can cause deformation or breakage of the rubber that negatively impacts the material’s structure. Optimal pressure during curing is essential to improve tensile strength and reduce geometric inaccuracies, ensuring high-quality rubber products [47].

Similarly, research on silicone rubber used in polymer electrolyte membrane fuel cell (PEMFC) gaskets showed that a curing pressure of 10 MPa yielded the best results. At this pressure, the material exhibited superior tensile strength, compression properties, and stress relaxation resistance. The pressure also minimized the compression set rate, which is crucial for long-term durability under compression. Apparently, pressures higher than 10 MPa did not provide additional benefits and, in some cases, reduced performance [48]. Thus, optimizing curing pressure is necessary to achieve the desired mechanical and physical properties in rubber composites, making it one of the key factors in the vulcanization process.

Accelerators have a significant impact on the rate and effectiveness of rubber vulcanization. There are several types of accelerators used, and each has unique characteristics and impacts on vulcanization. The type of accelerator chosen is determined by several factors, including the required end-use, processing conditions, and desired vulcanization rate. According to their chemical composition and mode of action, accelerators are categorized into various groups as previously discussed and presented in Table 5.

4.1.5 Sulphur/Accelerators Ratio

The sulphur/accelerator ratio in the vulcanization of rubber is a decisive factor that influences the mechanical properties, the vulcanization systems, and the formation of cross-links [44]. It influences conventional (CV), efficient (EV) and semi-EV vulcanization systems. The ratio has a significant influence on the type of crosslinks formed during the vulcanization process. CV systems have a low sulphur/accelerator ratio (0.1–0.6), resulting in a high percentage (95%) of poly-sulphidic crosslinks and only 5% mono- and di-sulfidic crosslinks. This provides high mechanical strength and flexibility, but with a low modulus and low heat resistance. In contrast, EV systems use a high sulphur/accelerator ratio (2.5–12), leading to predominantly mono- and di-sulfidic crosslinks (90%) with only 10% poly-sulphidic crosslinks. EV vulcanization has low mechanical strength and flexibility but features a high modulus and high heat resistance. Semi-EV system lies between the two extremes, with a sulphur/accelerator ratio of 0.8–1.2, resulting in a balanced mixture of poly-sulphidic (50%) and mono- and di-sulfidic crosslinks (50%). It provides medium mechanical strength, flexibility, modulus, and heat resistance, thereby offering a balanced combination of properties between CV and EV systems. It is reported that CV and EV systems were used on different types of NR latex, including concentrated NR (CNR), deproteinized NR (DPNR), and small rubber particle NR (SRP), resulting in varied mechanical properties. The CV system enhanced tensile strength and elongation at break in CNR films despite lower crosslink density, while DPNR films showed a more uniform Young’s modulus distribution correlating with superior mechanical strength. In contrast, SRP films exhibited rigidity due to accelerated vulcanization rates, leading to excessive network structures that hampered interparticle crosslinking [49].

In principle, a high sulphur/accelerator ratio in rubber leads to an abundance of polysulphidic bonds, which correspond to the original sulphur content in the form of S8 molecules. However, these bonds decrease with a longer cure time due to thermal instability. Initially, only small amounts of mono- and di-sulphidic bonds are present, gradually increasing with longer cure time. A low sulphur/accelerator ratio leads to a predominance of monosulphide bonds, which increase initially but decrease over time. Poly-sulphidic and di-sulphidic bonds decrease over time. In CV systems, the primary cross-linking occurs through poly-sulphidic linkages, while in EV systems, mono-sulphidic bonds predominate [50,51]. The selection of a suitable curing system is crucial for meeting the thermal stability requirements.

4.2 Unfilled and Filled Rubber Composites

The effectiveness of rubber composites is determined mainly by their stiffness and strength, which cannot typically be enhanced by chemical modification alone, as is the case with most polymers. Rubber, by itself, tends to exhibit lower strength and modulus. However, these properties can be significantly improved by adding fillers, which reinforce the material, making it both stronger and stiffer. By adding fillers, rubber composites can improve not only their mechanical properties but also flexibility and abrasion resistance, while also reducing the overall cost of vulcanized rubber [52,53].

Rubber compounds are generally classified into unfilled and filled rubber. Unfilled rubber, which contains no fillers, is typically used in applications such as food-grade gaskets, medical devices, and automotive components. On the other hand, filled rubber refers to rubber composites that incorporate various types of fillers to enhance their properties. The concentration of fillers plays a critical role in determining the mechanical properties of rubber composites, and therefore, the interfacial bonding between the filler and the matrix is another key factor that must be considered for optimal performance. Furthermore, rubber composites can be categorized based on the type of filler or reinforcing material. They are typically divided into continuous fibre composites, short fibre composites, and particle-filled composites. For each type of filler, different properties are required to achieve optimal reinforcement. For example, in particle-based composites, important factors influencing performance include particle size, surface area, surface activity, aggregate structure, filler concentration, dispersion, and filler-matrix interactions. Similarly, the properties of fibrous fillers are influenced by factors such as aspect ratio, concentration, dispersion, and orientation of the fibres, along with the interaction between the fibre and the matrix [54–60].

4.3 Particle Filler Reinforcement

Carbon black, silica, and fibres are the most commonly used reinforcing materials in polymer composites. Silica is reported to provide a particular combination of tensile strength, aging resistance, and great adhesion strength. Carbon black is often used as a reinforcing material in rubber to improve the thermal and mechanical properties of rubber composites. However, it is also known for its negative impact on the environment and the appearance of a black colour. When fillers are added to the natural rubber, the morphological and mechanical properties improved. However, the lack of compatibility at the interface between rubber and filler can reduce the stress transfer between rubber and filler. Therefore, the filler and the matrix should have good compatibility to obtain rubber composites with excellent bonding properties [61].

4.3.1 Carbon Black Reinforcement

Carbon black is a widely researched filler in rubber that can enhance the mechanical properties of rubber composites, such as tensile and tear strength [62–64]. It is an inorganic material obtained from the incomplete combustion of petroleum products and is considered the most effective filler due to its ability to increase hardness and viscosity. Carbon black is used as a reinforcing material and as a diluent to reduce the cost of rubber products. Over 90% of carbon black consists of pure elemental carbon, forming aggregates representing the smallest functional dispersible unit in the rubber matrix. The structure of carbon black is characterized by its graphitic structure, with larger particle sizes resulting in a more graphitic structure [65]. The structure of carbon black can be summarized as partially graphitic onion-like.

The structure of carbon black can vary in different grades. Carbon black-filled rubber consists of three phases, A, B, and C, with the C phase acting as the ‘skeleton’. The physical adsorption of carbon black and chemical bonding contribute to the development of these phases [66]. Carbon black strengthens rubber through van der Waals interactions, chemical bonds, and mechanical interlocking. Van der Waals forces promote adhesion and dispersion within the rubber matrix, while chemical bonding improves interfacial interactions and the overall integrity of the composite material. Mechanical interlocking creates a network of physical bridges that increase tensile strength, tear strength, modulus, and abrasion resistance. The reinforcing mechanism of carbon black on rubber is a complex interplay of physical, chemical, and mechanical interactions that improves the performance and reliability of rubber materials in various industrial applications [67,68].

Carbon black, a widely used reinforcing filler in the rubber industry, is produced at 15 million tons annually. Approximately 93% of this is used in rubber applications, the remaining 7% in paints, coatings, printing inks and plastic compounds. Studies have investigated how carbon black improves the mechanical performance of rubber composites. Rattanasom et al. [69] investigated the effects of the addition of reinforcing fillers (silica, carbon black and clay) on the mechanical properties, heat aging resistance, cut growth behaviour and morphology in natural rubber composites. Carbon black exhibited better mechanical properties (hardness, 300% modulus, tensile strength and tear strength) compared to silica, which was attributed to higher carbon black dispersion in the matrix, as evidenced by the morphological analysis. The carbon black-filled composites had a smoother surface with uniformly dispersed filler particles compared to the silica-filled composites. On the other hand, a higher silica concentration was required to achieve the same hardness as the clay- and carbon black-based composites. Clay achieved competitive, appealing properties with a lower percentage than silica and carbon black.

Carbon black has been used for years in the manufacture of rubber compounds. However, poor dispersion of carbon black in rubber composites can significantly affect the production of high-performance carbon black-filled rubber composites. Therefore, various methods have been developed to improve carbon black dispersion, including surface modification, incorporation of coupling agents, functionalization of the polymer matrix and incorporation of various nanofillers. One approach to enhancing carbon black dispersion is to modify the surface of rubber. Fang et al. [70] utilized TAD click chemistry to produce a range of natural rubber grafts with varying content of urazole groups. This reactive urazole group can promote interfacial interactions in carbon black/natural rubber composites, enhancing carbon black dispersion and composite performance. This observation was demonstrated from the SEM morphology. SEM morphology showed non-uniform dispersion and notable aggregations of carbon black in the rubber matrix. However, as the amount of the urazole group increases, the dispersion of the carbon black becomes more uniform and the agglomeration decreases. This demonstrates that urazole increases the interaction between NR chains and CB, reducing the self-aggregation of CB. In addition, the covalent interaction of TAD-modified NR chains with CB can inhibit the thermodynamically advantageous re-aggregation of CB during vulcanization.

Sattayanurak et al. [71] have investigated the synergistic effect of the combination of carbon black and silica on the properties of natural rubber composites. In this study, the ratio between carbon black and silica was varied, with the carbon black content varying between 0 and 36 by weight percentage. They found that an optimum carbon black content of 18 by weight percentage led to an improvement in the bonded rubber content, mechanical properties, and abrasion resistance of the rubber composites.

However, manufacturing carbon black results in a significant carbon footprint, leading to a focus on researching environmentally friendly fillers for rubber reinforcement, focusing on natural resources, waste materials, and industrial or agricultural by-products [72]. One sustainable solution is to use used tyres and recycle or convert them into gaseous, liquid, and carbon-rich solid fractions (RCB) through pyrolysis processes. RCB has a high potential to replace conventional carbon black and can address many environmental problems, such as pollution. Dwivedi et al. [73] investigated the use of RCB as an alternative and environmentally friendly reinforcement for natural rubber composites. They found that the use of RCB can improve the processing parameters, such as shortening the curing and scorch time compared to pure natural rubber. In addition, the tensile strength and elongation at break increased, while the tensile modulus, compressive strength, and tear strength were reduced due to the poor interaction of the RCB particles with the rubber compounds [73]. Similar findings were also reported by Urrego-Yepes et al. [74], who found that RCB improves the properties of natural rubber itself and can be a sustainable solution. However, compared to pure carbon black, RCB offers lower reinforcement properties due to its higher volatile matter and ash content, higher apparent PSD, lower presence of acidic functional groups, and lower SBET. Masa et al. [75] studied the effect of using recycled nitrile glove waste as a blending component in natural rubber and epoxidized natural rubber. They found that increasing recycled nitrile glove waste led to increased tensile properties and elongation at break and increased the decomposition temperature.

Silica, also known as silicon dioxide (SiO2), is a common compound found in plants and grains and is widely distributed throughout the earth’s crust in the form of silicate minerals. Silicon dioxide nanoparticles (SiNPs) are inorganic materials containing silanol groups (Si–OH), characterized by a large surface area, uniform pore size, and controllable particle size. As a result, they exhibit exceptional biocompatibility and have a wide range of industrial applications due to their beneficial physical properties [76,77]. Specifically, it has a chemical formula of SiO2 and a molar mass of 60.08 g/mol. Its density differs depending on the structure, being 2.648 g/cm³ for α-quartz and 2.196 g/cm³ for the amorphous form. Amorphous silicon dioxide has a melting point of 1713°C, while the boiling point is 2950°C. Furthermore, silicon dioxide has a magnetic susceptibility of −29.6 × 10−6 cm³/mol, indicating its diamagnetic nature [78].

Moreover, silica is a hydrophilic and highly polar reinforcing filler with a structure that consists of agglomerates, aggregates, and primary particles [78]. The size of agglomerates ranges from 1 to 40 µm and is formed by hydrogen bonds and Van der Waals forces. Primary particles, typically 5 to 45 nm in size, are linked during the dehydration process by siloxane bonds at the nanoscale, forming a siloxane-silanol surface.

Historically, silica has long been used as a reinforcement in rubber, initially as a white filler in coloured rubber products like shoe soles. Recently, advances have led to the complete replacement of carbon black with silica, particularly in car tyre treads, owing to the multiple benefits of silica-filled rubber. These benefits include reduced hysteresis, lower rolling resistance, improved wet-slip resistance, good mechanical properties, and lower fuel consumption and CO2 emissions [79]. However, the abundance of polar hydroxyl groups on the silica surface causes compatibility issues with non-polar rubber, resulting in problems during feeding and dispersion [80]. To overcome these challenges, surface modification with silane coupling agents has been implemented, reducing hydroxyl groups and increasing rubber affinity, thereby enhancing bonding at the inorganic-organic interfaces. Silane coupling agents function as a bridge, forming Si–O–Si bonds with the hydroxyl groups on silica and linking reactive groups with polymers, ultimately improving the compatibility and performance of silica-filled rubber composites.

Silica rubber technology uses a combination of rubber polymer, specialized silica, an effective coupling agent, and an appropriate mixing technique to create tyre technology that balances rolling resistance, traction, and wear. In particular, bifunctional organosilanes, such as bis(triethoxysilylpropyl)tetrasulfide (TESPT), serve as coupling agents to enhance compatibility between silica and rubber. This process involves several chemical reactions during rubber processing, including silanization, silane-rubber coupling, and crosslinking. The silanol groups play a critical role in affecting the dispersion behaviour, dynamic stiffness, and curing rate of the rubber [78].

Additionally, Khan et al. [81] investigated the effect of silica as a filler on the mechanical properties of a natural-based adhesive with coumarone-indene resin as the tackifying resin. They observed that increasing the silica content enhanced peel strength up to 40 phr for both ENR50 and ENR25, due to stronger molecular interactions between silica and rubber, which led to improved wettability of the adhesive. However, when the silica content exceeded 40 phr, peel strength decreased due to increased viscosity, restricting chain mobility. Furthermore, other adhesion improvers, such as xyloglucan (XG), rice flour (RF), calcium carbonate (CaCO3), and silica (SiO2), are used to enhance the bonding of natural rubber-based pressure-sensitive adhesives (NR-based PSAs) [82]. The adhesive properties of NR-based PSA were enhanced by these fillers, as evidenced by increased shear strength and peel strength. Specifically, NR-based PSA with CaCO3 achieved maximum peel strength, while NR-based PSA with XG showed the best performance as a tack enhancer, maintaining higher peel strength and greater efficiency in preventing hardening during storage.

Due to concerns about the environmental impact of conventional fillers such as silica, the rubber industry has recently shifted towards sustainability. Natural fibres, which are renewable, biodegradable, and less harmful to the environment than synthetic fillers such as silica, are becoming popular alternatives [83]. This change reflects a greater commitment to environmentally conscious practices and sustainability in the rubber industry, as the industry favours more environmentally friendly manufacturing processes.

4.3.3 Other Filler Reinforcement

As mentioned in the previous subtopics, there are many studies investigating other alternatives such as nanocellulose due to the concerns about environmental issues. Other possibilities are the use of bio-fillers in the rubber matrix, as bio-fillers are sustainable and environmentally friendly reinforcement. Biofillers such as lignocellulose, chitosan, and others are being intensively researched by researchers. Kazemi et al. [84] investigated the effects of using lignin, cellulose, and carbon black from black spruce cellulosic pulps on the mechanical properties of natural rubber composites. Bio-based materials are chemically extracted from black spruce sawdust and used as a partial substitute for carbon black (CB) in NR composites. The results showed that a higher L/C ratio led to better tensile strength and elongation at break, while a lower ratio resulted in a higher tensile modulus and hardness [84]. Similar findings were also reported by Dominic et al. [85] who replaced carbon black with rice husk-derived type 1 nanocellulose (RHNC) in natural rubber composites. They reported that the composite containing 25 wt. % carbon black and 5 wt. % RHNC exhibited comparable mechanical properties to the composite containing 30 wt. % carbon black, suggesting that RHNC is suitable to replace carbon black in tyre applications. Sanusi et al. [86] incorporated cellulose derived from cucumber pomace into the natural rubber latex and investigated the tensile properties and the swelling behaviour of natural rubber latex/cellulose. They found that cellulose content increased, so did tensile strength and swelling percentage. The increment of both properties was related to the reinforcement effect by cellulose derived from cucumber pomace in the natural rubber latex.

However, carbon black and silica are still widely used in the production of natural rubber with the addition of other fillers such as graphite, graphene oxide, nanocellulose, mica, carbon nanotubes, and other fillers due to their unique properties. For example, Yan et al. [87] incorporated potassium oleate modified wollastonite into the natural rubber and investigated the effects on the contact angle and the mechanical properties of natural rubber. They found that the polarity of the modified wollastonite was weaker, and the Payne effect and rolling resistance were reduced with increasing tensile strength of the natural rubber composites. Shahamatifard et al. [88] investigated the synergistic effect of carbon black/multiwall carbon nanotubes (MWCNTs) on the mechanical properties of natural rubber composites. They found that the scorch time and optimum curing time of composite natural rubber with a higher MWCNT content improved due to the adsorption of curing agents and the shape difference between carbon black and MWCNTs. The thermal conductivity and mechanical properties of natural rubber composites were significantly improved. For example, the rubber composites with carbon black/MWNCT had a thermal conductivity of 0.602 W/m·k with an increase of over 80%. Similar to the modulus, the rubber composites achieved an increase of 72% with a 20% reduction in elongation at break.

Rajan et al. [89] studied the effects of using graphene as a reinforcing filler on the properties of natural rubber composites. They found that the incorporation of 2.5 phr of graphene into the rubber composites led to better properties of the rubber composites, such as higher elongation at break and higher bonded rubber content. This result was supported by the enhanced distribution of the fillers in the rubber matrix. Similar results have been reported. In addition, organo-modified halloysite (OHNT) was incorporated into ENR50 to optimize the properties of the rubber adhesives for potential use in flame retardant adhesives [90]. OHNT is known as an efficient flame retardant because its tubular shape can help trap flammable volatiles. The thermal analysis showed that the maximum decomposition temperature of the adhesive increased with the increasing amount of OHNT. The limiting oxygen index (LOI) value also increased from 21 up to 72% with the maximum addition of OHNT (5:1 weight ratio of OHNT: ENR50), and these adhesives can be categorized as self-extinguishing materials that may be suitable for fire-resistant coating applications. Varol et al. [91] introduced silver-coated copper as conductive fillers into the epoxy matrix. The electrical conductivity of the epoxy matrix was improved by the presence of Ag/Cu. Morphology analysis showed that the silver coatings were compact and continuous. These observations indicate that these silver coatings can be used for the fabrication of ECAs.

Habep et al. [92] investigated the effect of the incorporation of nanoalumina on the structural, electrical, morphological, and thermal properties of PMMA/ENR-50-based film. They found that the ionic conductivity, electrical conductivity, decomposition temperatures increased with the increase of nanoalumina content due to better the PMMA-filler interactions within the polymer matrix.

The most commonly used reinforcing materials in the composites industry are synthetic and natural fibres. The most commonly used synthetic fibres in fibre-reinforced composites are glass, carbon, aramid, and boron. The use of E-glass fibre as a reinforcement in NR composites demonstrated enhanced flexural, tensile, and impact properties, particularly when combined with liquid epoxidized natural rubber. The addition of liquid epoxidized natural rubber further improved the flexibility and toughness of the composite, although poor adhesion between the untreated glass fibres and the NR matrix was observed [93]. Aramid fibre, on the other hand, displayed slightly better reinforcement efficiency at lower fibre contents (2–5 phr) and temperatures below the glass transition temperature of NR, although its effectiveness decreased at higher temperatures and fibre contents. However, aramid fibre remains a key contender for enhancing the mechanical properties of NR due to its superior modulus and tensile strength [94]. Additionally, carbon fibre extracted from periwinkle shells was studied as a low-cost alternative for reinforcing NR [95]. The incorporation of carbon fibre significantly increased the tensile strength of NR composites, making it a promising material for applications requiring improved vibration isolation. On the thermal front, hexagonal boron nitride (BN) platelets were investigated as a filler to enhance the thermal conductivity of NR composites [96]. Functionalizing BN platelets improved their compatibility with NR, resulting in a 5.4-fold increase in thermal conductivity and a significant improvement in mechanical properties, particularly in tensile strength, making it a potential material for advanced electronic devices.

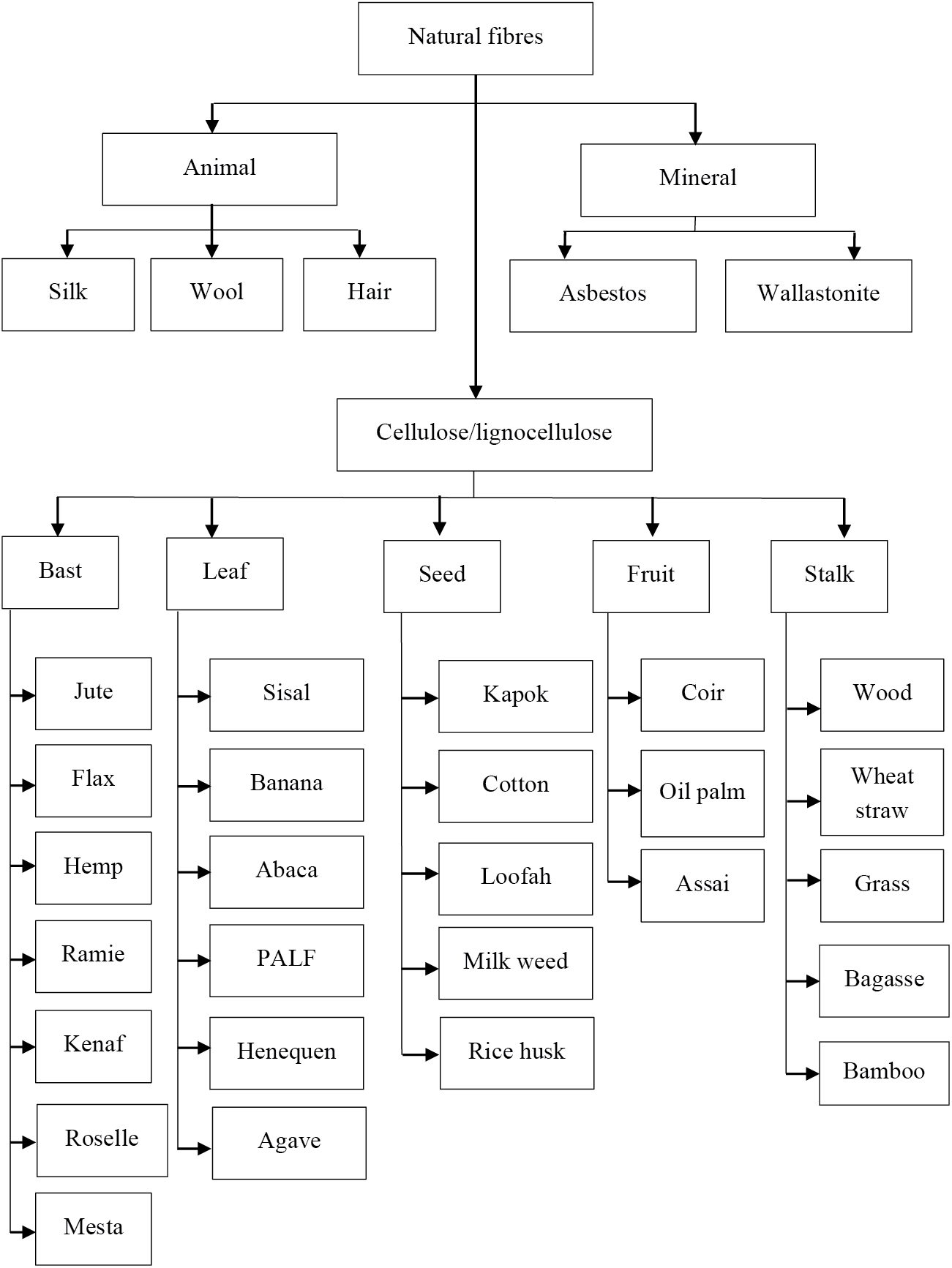

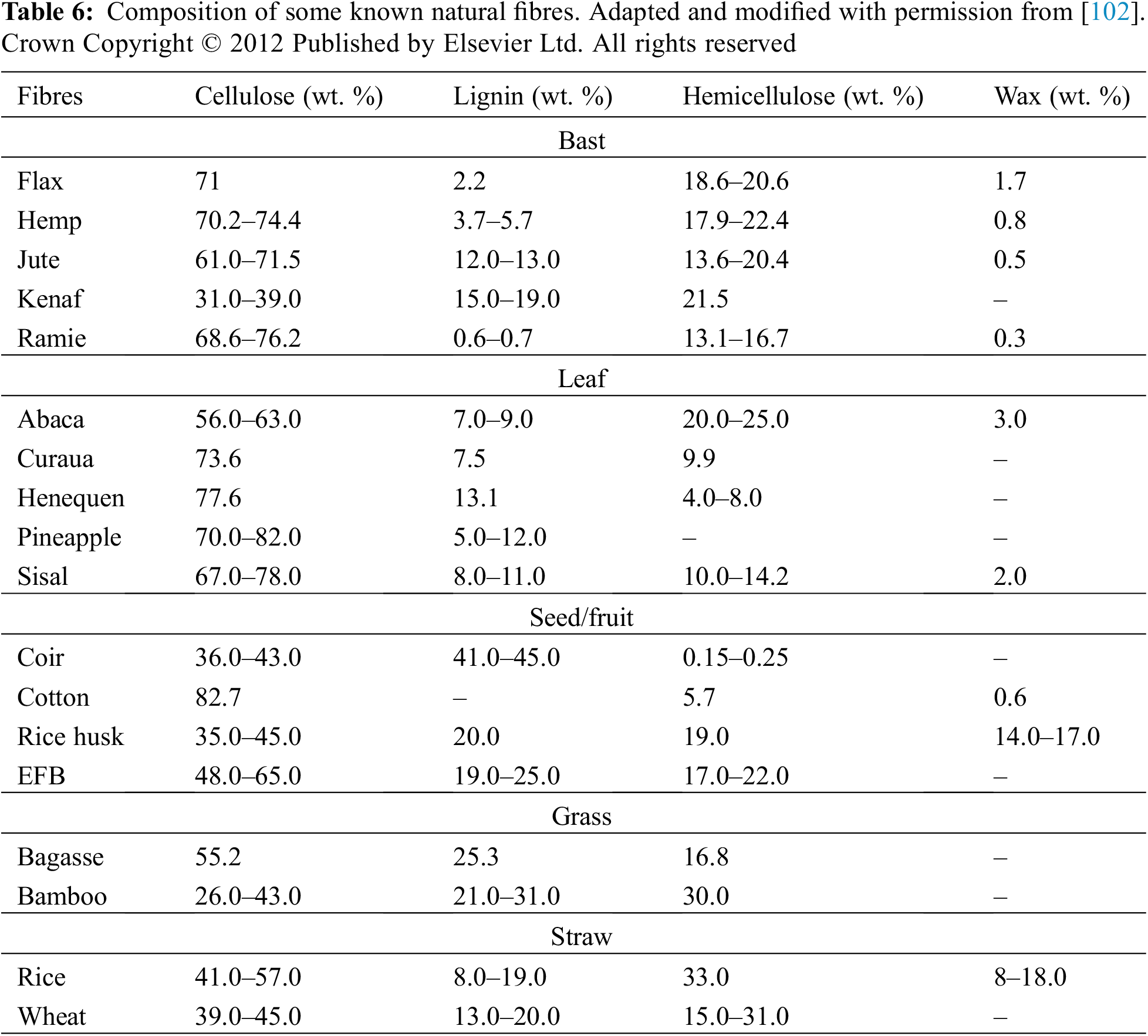

Nevertheless, the demand for sustainable materials has led to a shift towards natural fibres or natural fillers as alternatives to traditional synthetic fillers. These fibres, which come from renewable sources such as plants and animals, are biodegradable, renewable, and have a low environmental impact. They also have promising specific strength properties. As the industry prioritizes sustainability, the use of natural fibres as fillers in composite materials such as rubber reinforcements is an important step towards greener manufacturing processes. Fig. 5 illustrates the classification of natural fibres, where they can be categorised based on their origin: plant, animal, or mineral. Animal fibres such as silk, wool, and hair have not been widely used as reinforcements while plant fibre such as kenaf, jute and hemp fibre have been widely used in composite fields for applications such as construction, packaging, automotive, and marine. Mineral-based fibres are rarely used due to their negative health effects, as they are considered carcinogenic [97].

Figure 5: Natural fibre classification. Adapted with permission from [101]. Copyright © 2021 Elsevier Ltd. All rights reserved

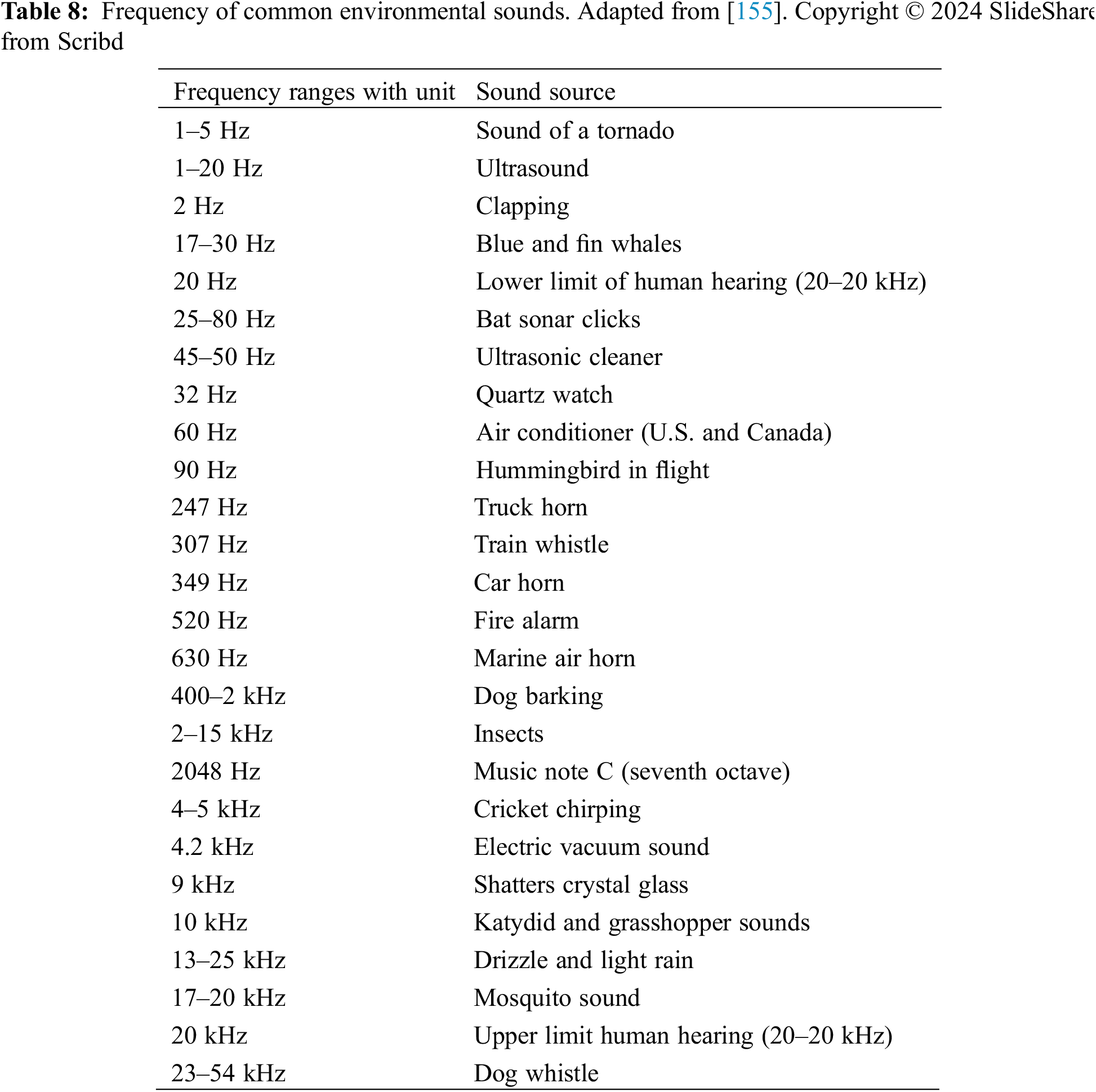

Generally, all animal fibres contain protein as their major structural component, while plant fibres consist of cellulose. Plant fibres, on the other hand, possess higher strengths and stiffness compared to animal fibres, except for silk fibre. Lignocellulosic fibres are natural fibres obtained from plants and consist mainly of cellulose, hemicelluloses, lignin, pectin, and waxes. They contain fewer inorganic substances such as ash and organic extracts. Their crystalline structure combines cellulose with hemicellulose and lignin and forms the main framework [98]. The amount of cellulose, hemicellulose, and lignin varies according to plant, origin, and climate and also varies in different parts of the same plant. Inorganic components enhance the fibre’s abrasion properties, while organic extracts help it resist colour, odour and decay [99,100]. These basic components make up the physical properties of the fibres. These polymers are unevenly distributed in the plant cell wall, making it difficult to determine the exact composition and properties of fibres without further testing and characterization such as Fourier-Transform Infrared Spectroscopy (FTIR), Nuclear Magnetic Resonance (NMR), and X-Ray Diffraction (XRD) [99,100]. Table 6 shows the average chemical composition of some plant fibres. Coconut fibres have the highest percentage of lignin, while cotton fibres have the highest percentage of cellulose.

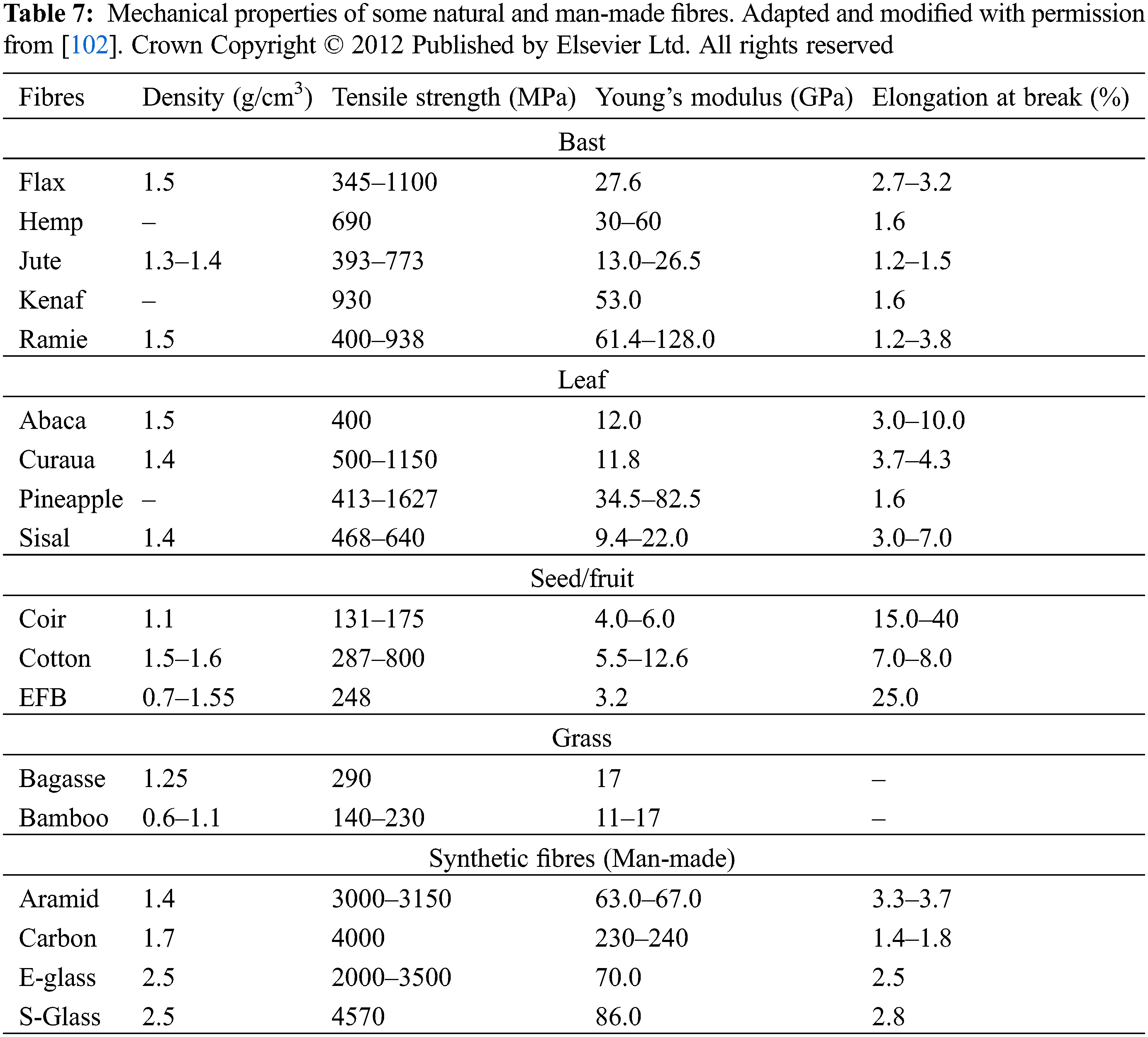

Conceptually, natural fibres consist of a cell wall and a lumen that serves as a transport channel. The main cell wall, which contains lignin, hemicellulose, and wax, reflects cell growth. Long-chain cellulose microfibrils arranged in a helical structure are present in the secondary cell wall [103]. The strength of a natural fibre stems from its lumen core, which is surrounded by layers of cell walls. These layers each have unique orientations of microfibrils, which increase the fibre’s resistance to different types of stress. The tensile properties of natural fibres are largely determined by the microfibrillar angle, which is the angle formed by the cellulose helix structure and the fibre axis. In particular, when microfibrils align along the fibre direction, natural fibre-reinforced polymer composites potentially exhibit a higher tensile modulus, which optimizes strength under tensile loading. In addition, microfibrils have crystalline and amorphous regions; the former determines the strength of the fibre, while the latter ensures flexibility through asymmetrical molecular chains [104]. The properties of various plant fibres are listed in Table 7 and compared with those of man-made fibres.

From Table 7, natural fibres such as flax, jute, kenaf, and sisal vary significantly in properties such as density, tensile strength, Young’s modulus, and elongation at break. For instance, flax possesses a tensile strength range of 345–1100 MPa and a Young’s modulus of 27.6 GPa, making it a strong, lightweight material. Hemp, with a tensile strength of 690 MPa, provides a higher Young’s modulus (30–60 GPa), while jute has moderate strength (393–773 MPa) but lower stiffness compared to flax. Among leaf fibres, pineapple leaf fibre (PALF) stands out with a tensile strength of 413–1627 MPa, higher than many other natural fibres, and a considerable modulus of 34.5–82.5 GPa. Abaca and curaua also demonstrate significant tensile strength (400 and 500–1150 MPa, respectively), showing their potential in various applications requiring strong yet flexible reinforcement. In contrast, synthetic fibres like aramid, carbon, and glass fibres exhibit far superior mechanical properties. Carbon fibre offers exceptional tensile strength (4000 MPa) and an Young’s modulus of up to 240 GPa, making it highly suitable for high-performance applications. Aramid fibre also shows a high tensile strength (3000–3150 MPa) and modulus (63–67 GPa), which is significantly higher than that of natural fibres.

The diversity of properties across both natural and synthetic fibres enables their use in different engineering and industrial applications depending on the specific performance requirements, with synthetic fibres generally offering higher strength and modulus but at the cost of being non-biodegradable.

5 Enhancing Interfacial Stress-Transfer in NR/Fibre Composite

Rubber/fibre composites aim to improve mechanical properties and performance characteristics by incorporating reinforcing fibres into the rubber matrix. However, natural fibres have polar and hydrophilic properties, while most commercial polymers have non-polar properties. This incompatibility often hinders optimal performance, resulting in less efficient stress transfer between the two phases. Researchers are focusing on enhancing the interfacial strength between the rubber matrix and reinforcing fibres, modifying the surface of the fibres to promote adhesion with the rubber matrix. Dry bonding agents and incompatible rubbers like epoxidized natural rubber (ENR), malleated NR (MNR), and NBR have been used as compatibilizers to improve interfacial adhesion. Alkali and silane treatments aim to modify the chemical composition of the fibre surface, creating reactive sites for bonding with the rubber matrix. This approach leads to improvements in tensile strength, modulus, and toughness, expanding the potential of NR/fibre composites [105].

5.1 Alkali Treatment of Fibres

Alkaline treatment is one of the most important methods for enhancing the interfacial adhesion between the fibres and the polymer matrix in polymer composites. It can modify the chemical composition and surface morphology, which can remove some of the hemicellulose, lignin, wax, and oils covering the outer surface of the fibres. Since this hemicellulose, lignin, wax and oils have been removed, the cellulose chains are less dense and rigid and can arrange themselves in tighter packing. This can improve mechanical properties such as tensile strength. Sodium hydroxide (NaOH) has been used for alkaline treatment for many years. However, if the optimum concentration is exceeded, the cellulose structure can be damaged, and the mechanical properties can deteriorate. The general alkaline treatment reaction mechanism of the fibre with NaOH is shown in the Eq. (2) below:

The concentration of the alkali solution and the soaking time significantly influence the surface modification and the properties of the treated fibres. Lower NaOH concentrations and shorter soaking times are preferred to minimize fibre degradation while achieving adequate surface modification. Typically, concentrations of 1%–10% NaOH and soaking times of a few minutes to several hours are used. Studies have shown that a NaOH concentration of 5% and a soaking time of 2 h are optimal for the partial removal of silica bodies in EFB [106–108].

Mat Nasir et al. [109] studied the effects of alkaline treatment on the mechanical properties of Lemba fibres (LeLefs). The LeLeFs were alkaline treated with 6, 8 and 10 wt. % NaOH concentration and it was found that the tensile strength, elongation and modulus increased with higher NaOH concentration. The chemical resistance of LeLeF was also improved compared to untreated LeleF. These observations were attributed to the fact that a higher NaOH concentration removes more surface impurities, hemicellulose, and wax, resulting in tighter packing of the cellulose chains and thus improving mechanical properties and chemical resistance. Norul Izani et al. [110] studied the effect of using untreated and NaOH-treated EFB fibres at a concentration of 2%. The study showed that the alkali treatment significantly improved the surface properties and chemical composition of the fibres, resulting in increased roughness and porosity. This treatment also exposes more hydroxyl groups, which increases their polarity and creates more reactive sites for bonding with polymer matrices. This enhances wetting and adhesion properties, interfacial strength, and mechanical properties in composites [110]. Researchers can explore different concentration ranges and soaking times to tailor the treatment to specific applications and fibre types.

Dominic et al. [111] studied the effect of alkaline treatment of cellulose nanofibres from Cuscuta reflexa and evaluated its reinforcing efficiency towards the mechanical and thermal properties of natural rubber composites. They found that as the fibre content and the alkaline treatment increased, the tensile strength and tear strength increased, with the optimum value at 2 phr of alkali-treated fibre content. Murugesan et al. [112] investigated the effect of the incorporation of untreated and alkali treated Sanseveria cylindrica on the mechanical properties of natural rubber composites. The incorporation of Sansevieria cylindrica fibres into the natural rubber significantly improved the mechanical properties of the natural rubber and, in particular, the composite with treated fibres exhibited significantly higher tensile strength. This was attributed to the improved regularity of the fibre cells, in which the Sansevieria cylindrica fibres were arranged hierarchically and provided good adhesion to the rubber matrix. It was demonstrated that the increase in tensile value, tear value, and Shore A hardness of composites with alkali-treated Sansevieria cylindrica fibres compared to those with raw Sansevieria cylindrica fibres was 10.5, 6.25, and 6.10 wt. %, respectively.

In addition, alkali treatment increases the cellulose content of the fibres, resulting in higher purity and crystallinity. This improves the mechanical performance and dimensional stability of composites [113]. However, excessive treatment time or high NaOH concentrations can deteriorate the mechanical properties of the fibres. To optimize the applicability of natural fibre-reinforced polymer composites, factors such as the ideal alkali concentration, soaking time, fibre loading, and potential treatments must be considered [114]. Despite these considerations, alkali treatment remains an effective method for enhancing the properties of composites in various industrial applications.

5.2 Silane Treatment of Fibres

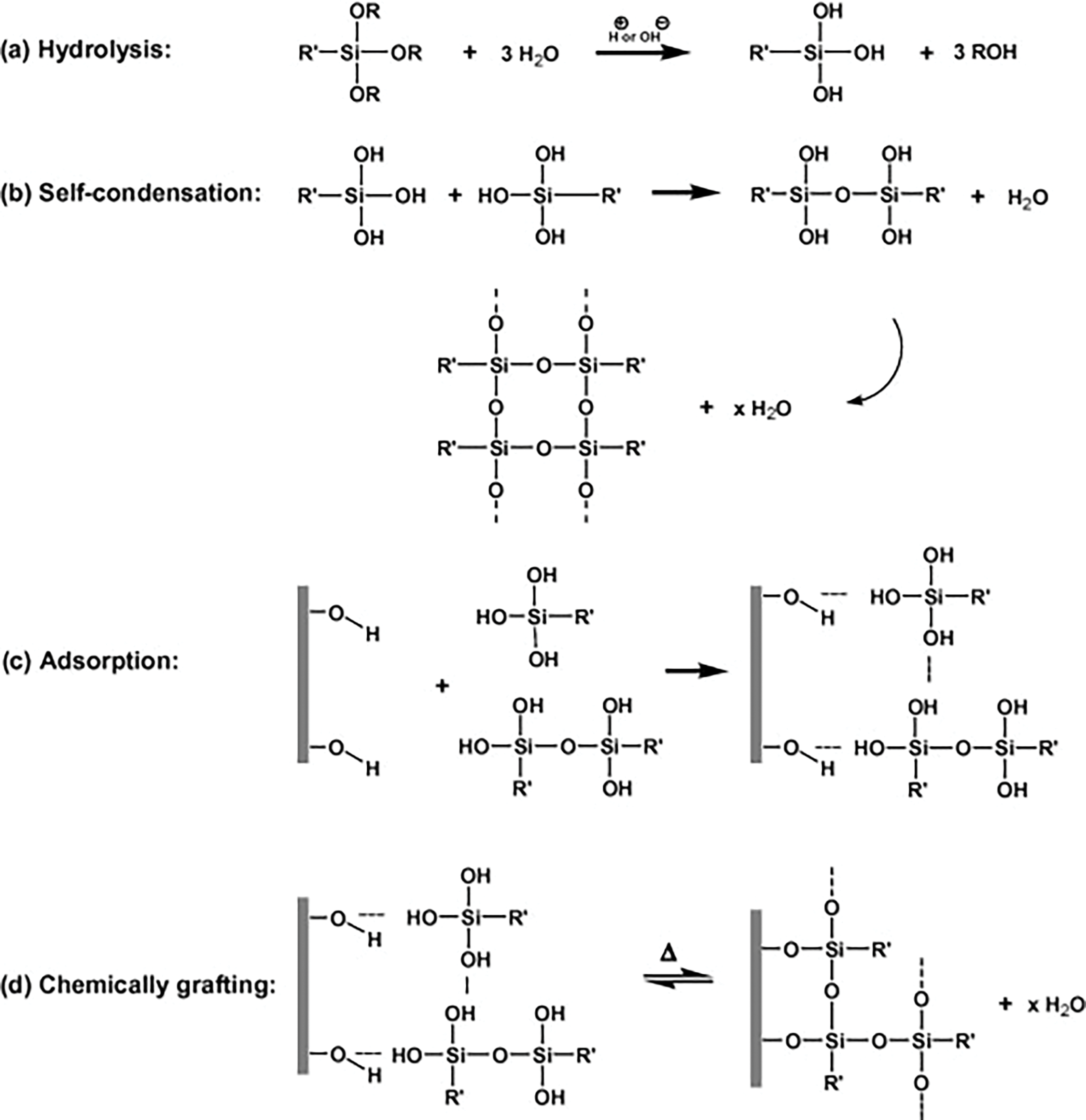

Silanes are a cost-effective method for surface modification of plant fibres compared to other treatments such as phosphorus or benzoyl [115,116]. These hydrophilic compounds with the formula SinH2n+2, in which various groups are bonded to silicon, interact with hydrophilic inorganic minerals or fibres and a hydrophobic organic matrix. They form a strong interfacial adhesion between the components and create a composite phase. The use of silanes has been extensively studied for its potential applications [117,118].

The organofunctional silane compounds contain two distinct reactive parts: (1) an alkyl group for the body and an end group that represents a reactive site for coupling with the polymer, such as amino, methacryloxy, sulphide, or epoxy, and (2) a tail with alkoxy groups (–OR) that can be hydrolysed at the fibre surface, such as methoxy (–OCH3), acetoxy (–OCOCH3), and ethoxy (–OC2H5). The choice of silanes depends on the particular matrix system. The general structure of silane is represented as (RO)3–Si–R–X. In addition, various factors, such as temperature, pH, duration of the hydrolysis reaction and functionality, influence the infiltration of silanes [118]. The mechanism of silane action involves four stages as shown below [117,118] and in Fig. 6:

(i) Hydrolysis: silane monomers are hydrolysed in the presence of water and a catalyst (acid or base), releasing alcohol and forming reactive silanol groups.

(ii) Self-condensation: At this stage, condensation must be minimized to ensure that the silanols remain free for absorption onto hydroxyl groups in natural fibres.

(iii) Adsorption: Reactive silanol monomers or oligomers are physically adsorbed on the surfaces of the fibres (surface coating) and/or within the cell walls (cell wall swelling) via hydrogen bonds with the hydroxyl groups of the natural fibres. Free silanols also react with each other and form a rigid polysiloxane structure with a stable Si–O–Si bond.

(iv) Grafting: At elevated temperatures, hydrogen bonds formed between silanol and hydroxyl groups of the fibres can transform into strong chains Si–OC–, releasing water (condensation). At very high temperatures, a hydrogen bond between silanol and hydroxyl groups in the fibres can form a covalent bond (Si–OC–) with the evaporation of water.

Figure 6: Mechanism steps of fibre modification by silane treatment. Adapted with permission from [119]. Crown Copyright © 2010 Published by Elsevier Ltd. All rights reserved

The silane treatment process begins with the mercerization of natural fibres to clean the surface of various impurities such as lignin, hemicellulose, and pectin. The treated fibres are then subjected to hydrolysis, self-condensation, and adsorption. Due to the lower reactivity of the hydroxyl groups in natural fibres, the hydrolysable groups (trialkoxy groups) are converted into more active silanols by hydrolysis in the presence of atmospheric moisture. During condensation, the silanols formed during hydrolysis condense to form a 3D Si–O–Si (siloxane) structure. Hydrogen bonding with the fibre surface is achieved by adsorption and subsequent heating (curing). Acids or bases can be used to catalyse the hydrolysis and condensation reactions.

Research on rubber/filler composites has shown promising results in improving the interfacial adhesion and mechanical performance of rubber composites. However, there is a significant research gap in exploring optimal treatment methods using different types of silane coupling agents, especially for natural fibre-reinforced (NR) composites. The modification of silica surfaces with bifunctional organosilanes such as bis(triethoxysilyilpropyl)disulfide (TESPT) and bis(triethoxysilyilpropyl)tetrasulfide (TESPD) has been reported to play an important role in the dispersion of silica agglomerates in rubber chains [120]. This modification alters the network of the rubber matrix through chemical interactions between silica, silane, and rubber. In particular, the hydroxyl groups on the surface of the silica chemically react with the hydroxyl groups of the hydrolysed silane via condensation reactions and form a 3D network structure with the rubber chains. In addition, functional sulphur groups chemically bond with the double bonds of the natural rubber, further enhancing the 3D network structure between silica and rubber. Accelerators control the degree and rate of cross-linking reactions during this process, while zinc ions significantly reinforce the 3D network structure.

Two methods are generally used for incorporating silane to improve the mechanical properties of composites materials. Firstly, silane can be incorporated directly during mixing, which facilitates processing but offers limited effectiveness as a compatibilizer. Alternatively, silane can be used to treat the surface of the filler before mixing with the rubber. This requires an additional processing step but results in stronger bonding to the filler surface and better mechanical properties. Silane is normally incorporated directly into NR/silica composites due to the large surface area of silica. It is reported that the incorporation of different silanes into SBR/BR and silica tyre tread compounds to improve the interfacial adhesion between rubber and silica resulted in TESPT significantly improving the interfacial adhesion and thus increasing the modulus of the composites [121]. It has thus been proven that TESPT is remarkably effective as a bonding agent or “adhesion promoter” for silica-reinforced elastomers.

Wan Busu et al. [122] investigated the effect of using kenaf and silane-treated short glass fibres towards the mechanical properties of thermoplastic natural rubber composites. The incorporation of the treated or untreated fibres into TPNR led to an increase in flexural modulus and impact strength of almost 100% compared to the TPNR matrix. However, the maximum elongation decreased with increasing fibre content. The optimum composition for the hybrid composite was at the fibre content of 30% kenaf fibres and 70% glass fibres. The SEM images showed that the composite with a coupling agent or compatibilizer promoted better fibre-matrix interaction. Surajarusarn et al. [94] studied the effect of the addition of untreated and silane-treated of pineapple fibre and aramid fibres toward the mechanical properties of natural rubber. They found that the silane-treated fibres provided better reinforcing efficiency in the natural rubber composites. Similar findings were reported by Somseemee et al. [123]. Both untreated and silane treated of cellulose nanofibres from Napier Grass were used as a reinforcing agent in the natural rubber composites, and the effect towards the mechanical properties were investigated. They found that the modulus, hardness, and tensile strength were improved with increasing fibre loading with the most prominent effect observed on the silane-treated fibre due to the enhanced interfacial adhesion between fibre and the natural rubber matrix, and therefore, improve the mechanical properties of natural rubber composites.

Nevertheless, research on the influence of silane coupling agents on natural fibres is still limited. This is probably due to the fact that the treatment of natural fibres is more complex compared to silica, mainly due to their lower surface area and surface contamination. Instead of direct incorporation during blending, surface treatment methods have been explored to achieve optimal conditions for improving the interaction between natural fibres and the coupling agent.

5.3 Combination of Alkali and Silane Treatment of Fibres

Interestingly, there are also some studies showing that a combined alkali-silane treatment method for fibres is able to show a synergetic effect towards the mechanical properties of the resulting composites. In a study on the effects of different treatments on modified pineapple leaf and kenaf fibre composites, including 2% silane, 6% NaOH, and a combination of both, it was found that the 2% silane treatment showed a remarkable improvement of 105% for pineapple leaf fibres and 175% for kenaf fibres compared to other treatments. Notably, the shear stress at the interface was significantly improved by the 2% silane treatment, reaching about 400% in the case of kenaf fibres [124]. This suggests that silane treatment alone can lead to significant improvements in certain fibres that exceed the effects of NaOH treatment or a combination of NaOH and silane.