Open Access

Open Access

ARTICLE

Development of Filter Composites Based on Eucalyptus Cellulosic Nanofibers, Sugarcane Bagasse Fibers and Soybean Hulls Applied in Biodiesel Purification

1 Institute of Chemistry, Federal University of Uberlândia, Uberlândia, 38400-902, Brazil

2 Institute of Exact and Natural Sciences of Pontal, Federal University of Uberlândia, Ituiutaba, 38304-402, Brazil

3 Exact Sciences, Natural and Education Institute, Federal University of Triângulo Mineiro, Uberaba, 38064-200, Brazil

* Corresponding Authors: Daniel Pasquini. Email: ; Luís Carlos de Morais. Email:

Journal of Renewable Materials 2025, 13(5), 957-980. https://doi.org/10.32604/jrm.2025.02024-0014

Received 11 October 2024; Accepted 31 December 2024; Issue published 20 May 2025

Abstract

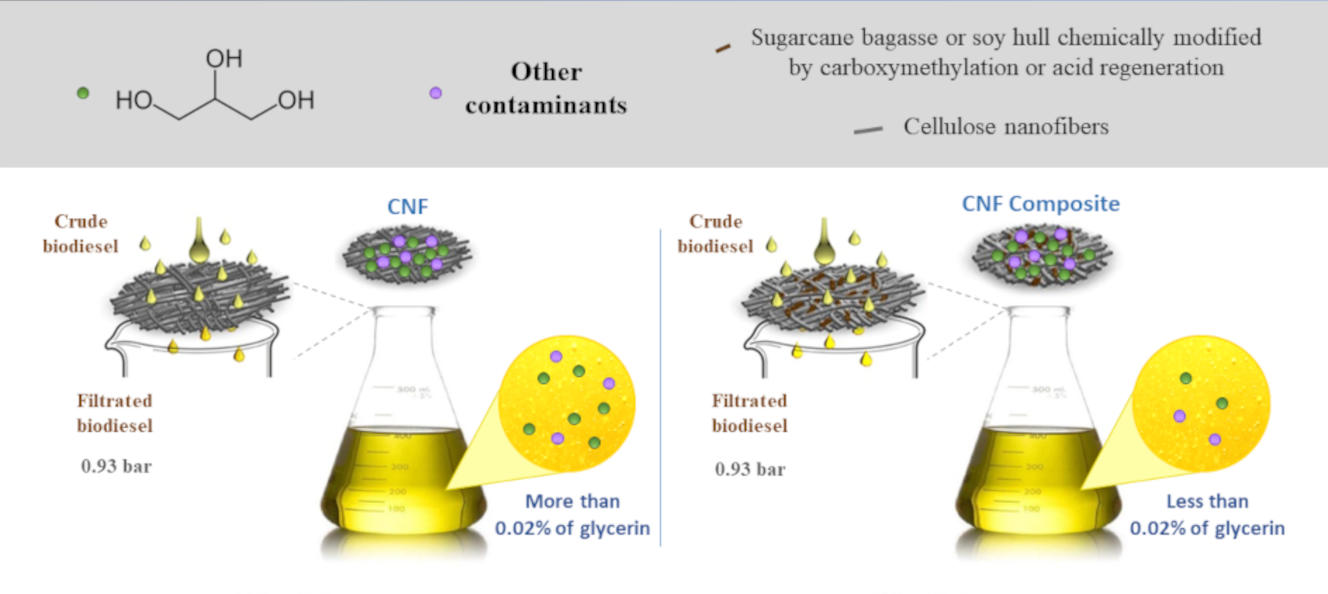

Alternative methods for biodiesel purification that focus on ease of operation, cost reduction, and elimination of contaminated residues or that are easier to treat have received more attention. The dry wash route was used as an alternative to the wet route in biodiesel production. Filter membranes were developed based on cellulose nanofibers as the matrix and sugarcane bagasse fibers or soy hulls, as reinforcement to the matrix, before and after two chemical treatments (carboxymethylation and regeneration with sulfuric acid). The filters were characterized by permeability capacity, morphology, wettability, porosity, SEM and mechanical properties. The filtered biodiesel was also completely characterized. One of the major impacts of dry purification of biodiesel was the glycerin content after filtration. The filters CNFBR 20–28, CNFSR 5–28, CNFSR 5–35, and CNFBC 5–28 produced purified biodiesel with glycerin content below 0.02% (200 mg/L). Another relevant fact is related to the best results for acidity index, combined alkalinity, and glycerin content, obtained by the regenerated filter CNFBR 20–28, which presented a considerable permeate flow rate value above 4145 L h−1 m−2, which can be related to compacted lamellar layers observed by SEM. The produced filters were applied to biodiesel purification using a low-pressure filtration system and a simple vacuum pump, which resulted in an appreciable reduction in cost. The produced filter with sugarcane bagasse fiber carboxymethylated at 28 mesh of granulometry was efficient for biodiesel purification, including the efficient removal of free glycerin, in agreement with the standards defined by the national controlling agencies.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools