Open Access

Open Access

REVIEW

The Evolution and Environmental Prospects of Renewable Bioplastics: Types, Production Methods, and Sustainability

1 Department of Aerospace Engineering, Faculty of Engineering, Universiti Putra Malaysia, Serdang, 43400, Malaysia

2 Laboratory of Biocomposite Technology, Institute of Tropical Forestry and Forest Products (INTROP), Universiti Putra Malaysia, Serdang, 43400, Malaysia

3 Aerospace Malaysia Innovation Centre [944751-A], Prime Minister’s Department, MIGHT Partnership Hub, Jalan Impact, Cyberjaya, 63600, Malaysia

* Corresponding Author: Mohamed Thariq Hameed Sultan. Email:

Journal of Renewable Materials 2025, 13(6), 1071-1101. https://doi.org/10.32604/jrm.2024.02024-0011

Received 10 October 2024; Accepted 10 December 2024; Issue published 23 June 2025

Abstract

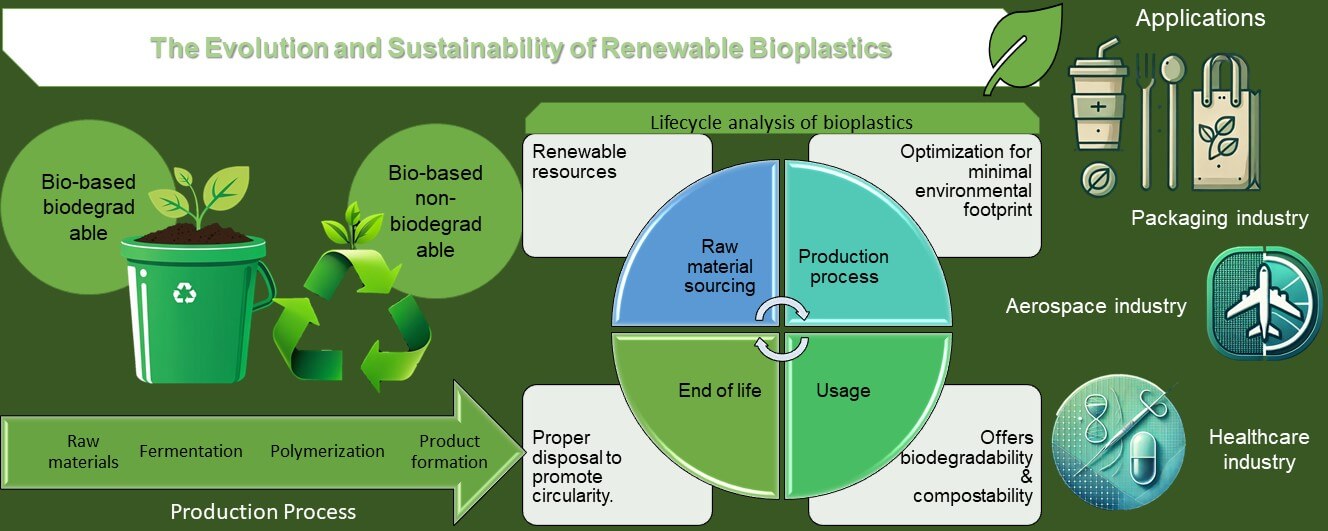

In this comprehensive review, the evolution and progress of bioplastics are examined, with an emphasis on their types, production methods, environmental impact, and biodegradability. In light of the increasing global efforts to address environmental degradation, bioplastics have emerged as a highly potential substitute for conventional petroleum-based plastics. This review classifies various categories of bioplastics, encompassing both biodegradable and bio-based variations, and assesses their environmental consequences using life cycle evaluations and biodegradability calculations. This paper analyzes the technological advancements that have enhanced the mechanical and thermal characteristics of bioplastics, hence increasing their feasibility for extensive commercial applications in diverse sectors. This review critically examines the possible uses of bioplastics in important industries including packaging, aerospace, and healthcare, emphasizing both achievements and current obstacles. In addition, the assessment addresses the economic and technical obstacles to expanding bioplastic manufacturing, namely concerns about cost, material efficiency, and waste disposal. Moreover, the article forecasts the future potential of bioplastics in furthering a sustainable circular economy and suggests methods to address existing constraints, such as improvements in recycling technology and the establishment of more economically efficient manufacturing methods. The findings are intended to educate policymakers, industry stakeholders, and researchers on the crucial contribution of bioplastics in attaining sustainability objectives and promoting innovation in the field of material science.Graphic Abstract

Keywords

Bioplastics represent a transformative shift in materials science, driven by the increasing need for sustainable alternatives to traditional petroleum-based plastics. Defined broadly as plastics derived from renewable biological sources or designed to be biodegradable, bioplastics have gained prominence due to their potential to address environmental concerns associated with conventional plastics. Unlike their petrochemical counterparts, which are typically non-renewable and persist in the environment for hundreds of years, bioplastics offer the promise of reducing dependency on fossil fuels and mitigating plastic pollution. The evolution of bioplastics is rooted in their dual focus: on the one hand, they aim to be derived from renewable resources, such as plant starch, cellulose, or algal biomass, and on the other hand, they seek to enhance environmental sustainability through biodegradability [1]. This dual approach is aligned with the principles of a circular economy, where the emphasis is on designing products that minimize waste and make efficient use of resources [2]. In this context, bioplastics are not only seen as a substitute for traditional plastics but also as a critical component of strategies aimed at creating more sustainable product life cycles.

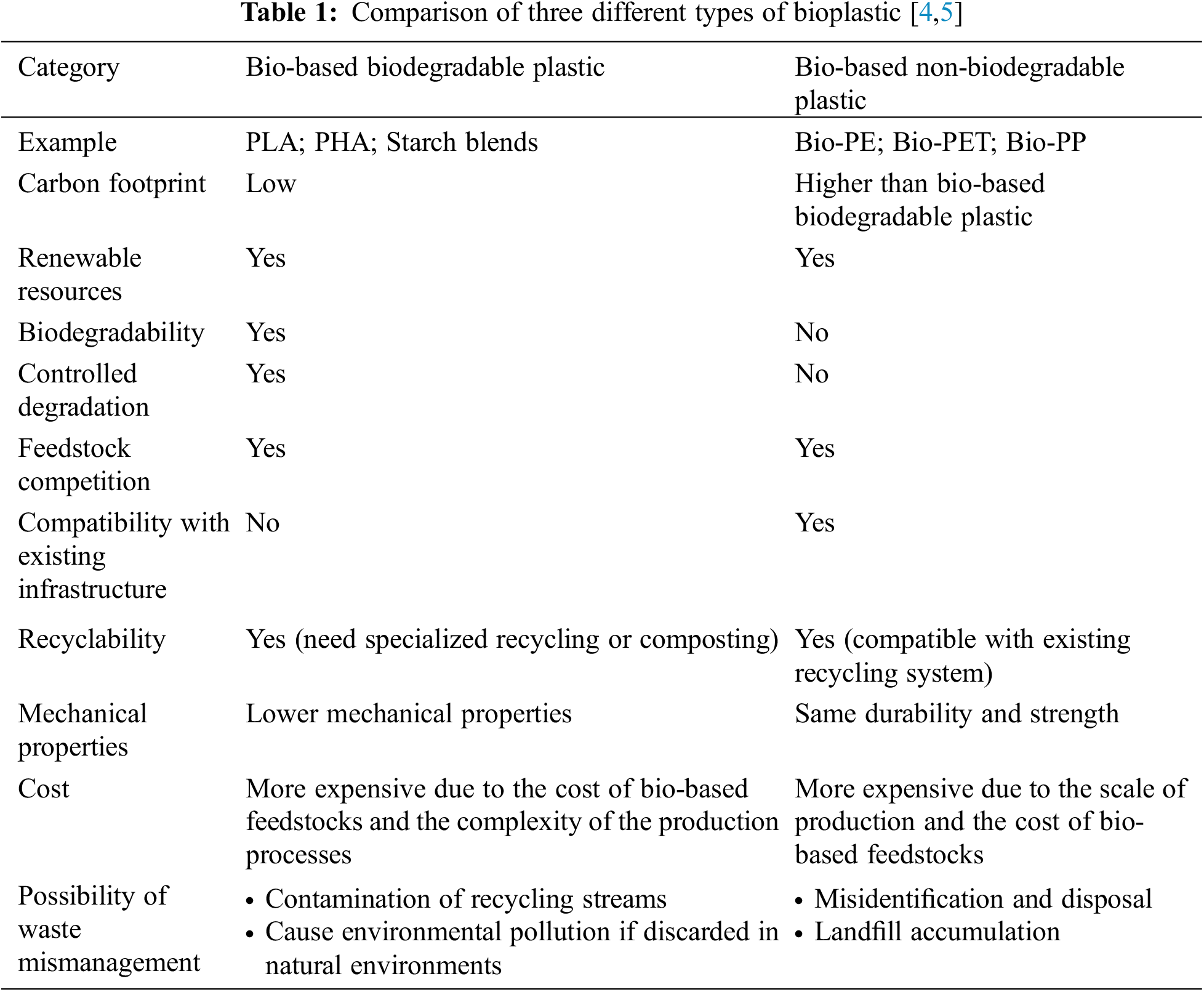

Bioplastics can be classified into three main types based on their source and properties which are bio-based non-biodegradable plastics, bio-based bio-degradable plastics, and fossil-based biodegradable plastics [3]. However, only bio-based non-biodegradable plastics and bio-based bio-degradable plastics are made from renewable materials. For example, Polyethylene (PE) is produced from fermented biomass, such as sugarcane or corn, and is well known for its resistivity towards degradation, while polylactic acid (PLA) is produced from fermented plant sugars and is known for its compostability. In this review, renewable bioplastics that are sourced from renewable materials are discussed. Bio-based biodegradable plastics and bio-based non-biodegradable plastics differ significantly in terms of environmental impact, biodegradability, and mechanical properties, which affects their compatibility with existing recycling infrastructure. Bio-based biodegradable plastics, such as PLA and PHA, are sourced from renewable materials and can decompose into natural elements under specific conditions, offering a solution to plastic pollution and reducing environmental impact. However, their biodegradability can complicate recycling, as they are not always compatible with traditional plastic recycling streams and often require separate processing. On the other hand, bio-based non-biodegradable plastics, like bio-PE or bio-PET, are made from renewable resources but exhibit similar durability and mechanical properties to their fossil-based counterparts. These non-biodegradable plastics are fully recyclable within conventional recycling systems, making them more easily integrated into existing infrastructure. Table 1 shows the benefits and limitations of each category of renewable bioplastic.

The production methods and raw material choices for bioplastics play a crucial role in determining their cost, scalability, and environmental benefits compared to traditional petroleum-based plastics. Bioplastics are typically sourced from renewable resources like corn, sugarcane, or agricultural waste, offering reduced carbon emissions and lower dependency on fossil fuels. However, these materials often require more complex production processes, such as fermentation or microbial cultivation, which can drive up costs and limit large-scale production. Additionally, fluctuations in crop availability and potential competition with food resources can affect the scalability of bioplastics. In contrast, petroleum-based plastics are derived from readily available fossil resources and benefit from established, large-scale production systems that make them more cost-efficient. However, bioplastics offer long-term environmental benefits, such as lower carbon footprints and biodegradability, positioning them as a more sustainable option despite current economic and scalability challenges. Moreover, the biodegradability and compostability of bioplastics are critical aspects of their environmental performance. Biodegradation mechanisms vary among different types of bioplastics, and achieving complete biodegradability presents significant challenges [6]. Understanding these mechanisms and addressing the limitations associated with biodegradability are essential for enhancing the effectiveness of bioplastics in reducing environmental impact and improving waste management practices.

The biodegradability and compostability of bioplastics face several challenges, primarily due to the specific conditions required for them to decompose efficiently. Many bioplastics, such as PLA (Polylactic Acid), need high temperatures, controlled moisture levels, and the presence of certain microorganisms to break down, which are typically only found in industrial composting facilities. In natural environments, such as landfills, oceans, or home composting systems, these conditions are often absent, leading to the persistence of bioplastics and contributing to plastic pollution, contrary to popular belief that they break down everywhere [7,8]. Additionally, the lack of clear labeling and public understanding about the proper disposal of biodegradable plastics often results in them being mixed with traditional plastics in recycling streams, where they can cause contamination and reduce recycling efficiency. To address these challenges, advancements are needed in creating bioplastics that can degrade under more common environmental conditions, like home composting or even marine settings [9,10]. Simultaneously, expanding composting infrastructure and improving waste management systems to handle bioplastics effectively, along with public education on correct disposal methods, would enhance the role of bioplastics in tackling global plastic pollution and improving waste management practices.

In summary, the evolution and future prospects of bioplastics encompass a broad spectrum of factors, including their types, production methods, environmental impacts, and biodegradability. As the world seeks more sustainable solutions to plastic pollution and resource depletion, bioplastics offer a promising avenue for innovation and improvement in materials technology. Thus, this review aims to provide a thorough exploration of these aspects, offering insights into the current state of bioplastic technology and its potential to shape a more sustainable future. The scope of this review encompasses a broad examination of bioplastics, including the different types available, their environmental impact, and the technological innovations driving their development. This review will also analyze the prospects of bioplastics in the context of sustainability and highlight key areas such as the biodegradability of bioplastics, their applications across industries, and the challenges they face in achieving widespread adoption.

The novelty of this review lies in its comprehensive approach to evaluating the evolution of bioplastics, integrating technological, environmental, and industrial perspectives. Unlike previous studies, which often focus on isolated aspects such as biodegradability or specific applications, this review synthesizes advancements across production methods, life cycle assessments, and practical applications in sectors like packaging, aerospace, and healthcare. It offers a detailed analysis of bioplastics’ role in advancing a circular economy, providing innovative insights into emerging trends like AI-driven material optimization and nanotechnology-enhanced biopolymers. This holistic evaluation not only bridges knowledge gaps but also sets a foundation for future interdisciplinary research and sustainable industrial practices.

2 Bioplastics as an Alternative to Traditional Plastics

2.1 Definitions, Differences, and Production Method

Renewable bio-based plastics are derived from renewable biological resources, such as plants or microorganisms, and are produced from feedstocks like corn starch, sugarcane, or algae [11]. Examples of bio-based plastics include bio-based PET, PLA, and PHA (polyhydroxyalkanoates). These plastics emphasize the use of renewable resources for their production, aiming to reduce reliance on fossil fuels and potentially lower the carbon footprint during manufacturing. However, bio-based plastics are not necessarily biodegradable and can persist in the environment if they are not specifically designed to degrade.

When comparing the raw materials used in bioplastic production, there are significant differences between renewable and non-renewable resources. Renewable resources are derived from biological sources that can be naturally replenished, such as agricultural products like corn, sugarcane, and algae. Utilizing renewable resources in bioplastic production generally reduces dependence on fossil fuels and lowers the carbon footprint. For example, corn starch, sugarcane, or cassava are used to produce PLA [12]. PLA is one of the most widely used bioplastics, valued for its biodegradability and versatility. The primary production process for PLA involves the fermentation of carbohydrate-rich feedstocks to produce lactic acid. This is achieved through microbial fermentation, commonly using strains like Lactobacillus species. Lactic acid will then undergo polymerization through two main pathways: direct condensation polymerization or ring-opening polymerization of lactide. The latter is the preferred industrial method, as it produces PLA with a higher molecular weight and superior mechanical properties. Using renewable agricultural resources, PLA reduces dependency on fossil fuels, but there are sustainability concerns related to crop-based substrates, including competition with food resources and the environmental impact of intensive agriculture. Research is ongoing to identify alternative, non-food substrates such as agricultural waste (e.g., corn stover) and cellulosic feedstocks, which have a lower environmental impact but require further advancements in technology for commercial feasibility.

PHA is another important bioplastic, known for its complete biodegradability under various environmental conditions. PHAs are synthesized using a variety of carbon-rich substrates, often including industrial waste streams (glycerol from biodiesel production, wastewater sludge, and food waste), plant oils and fatty acids (palm oil, soybean oil, etc.), and molasses/other agricultural byproducts (e.g., byproducts from sugar processing). Microorganisms such as Cupriavidus necator and Pseudomonas putida are cultivated in fermenters with controlled conditions to promote PHA accumulation within the cells. These bacteria convert carbon sources into PHA granules stored within the cell, which are later harvested and purified. The ability to use waste-derived carbon sources makes PHA production highly sustainable and less dependent on agricultural resources, reducing its carbon footprint. Current research focuses on improving the cost efficiency and scalability of PHA production, as well as on developing microbial strains that can efficiently utilize complex waste substrates.

Bio-based polyethylene (Bio-PE) is chemically identical to conventional polyethylene but is derived from bio-based feedstocks, primarily ethanol produced from sugarcane. Ethanol from sugarcane undergoes dehydration to produce ethylene, which is then polymerized into polyethylene using conventional polymerization methods. The final product is chemically identical to fossil-based PE, making it compatible with existing recycling streams and infrastructure. Bio-PE offers the advantage of being fully recyclable within conventional recycling systems, contributing to a circular economy. Sugarcane production, however, can have significant environmental impacts, including deforestation, high water usage, and fertilizer runoff. Sustainable sourcing practices, such as certified sugarcane, can mitigate these issues.

In addition to traditional crops, researchers are exploring a variety of alternative substrates to improve the sustainability of bioplastic production such as algal biomass (algae), agricultural and food waste (crop residues, fruit peels, etc.), and lignocellulosic biomass (non-edible plants). In contrast, non-renewable resources are obtained from fossil fuels, including petroleum and natural gas. Although some bioplastics made from fossil fuels can be designed to be biodegradable, their production contributes to environmental issues such as greenhouse gas emissions and resource depletion. This shows that the choice of raw materials in bioplastic production impacts both the sustainability of the products and their environmental effects.

The most basic production methods for bioplastics are mainly fermentation and polymerization. Fermentation is where microorganisms are used to convert renewable feedstocks, such as sugars or starches, into bioplastics. For instance, corn starch can be fermented into lactic acid, which is then polymerized to produce polylactic acid (PLA) [13]. Similarly, polyhydroxyalkanoates (PHA) are created through the bacterial fermentation of organic substrates. On another note, polymerization is a process where monomers undergo chemical reactions to form polymers. This can be achieved through methods such as condensation or addition polymerization and is used to create both bio-based and fossil-based polymers, such as bio-based PET.

From the basic production of bioplastics, it can be further tailored to the specific type of shape needed to be manufactured. For example, extrusion is an important production method, where bioplastic materials are melted and forced through a die to create various shapes, such as films, sheets, or fibers. This technique is commonly used for producing packaging materials like PLA films. Injection molding involves injecting molten bioplastic into molds to create specific shapes and products, making it suitable for complex, high-precision items, such as bioplastic components for automotive parts. Blow molding, on the other hand, is used to produce hollow bioplastic products by inflating molten plastic inside a mold, which is often employed for making bioplastic bottles and containers.

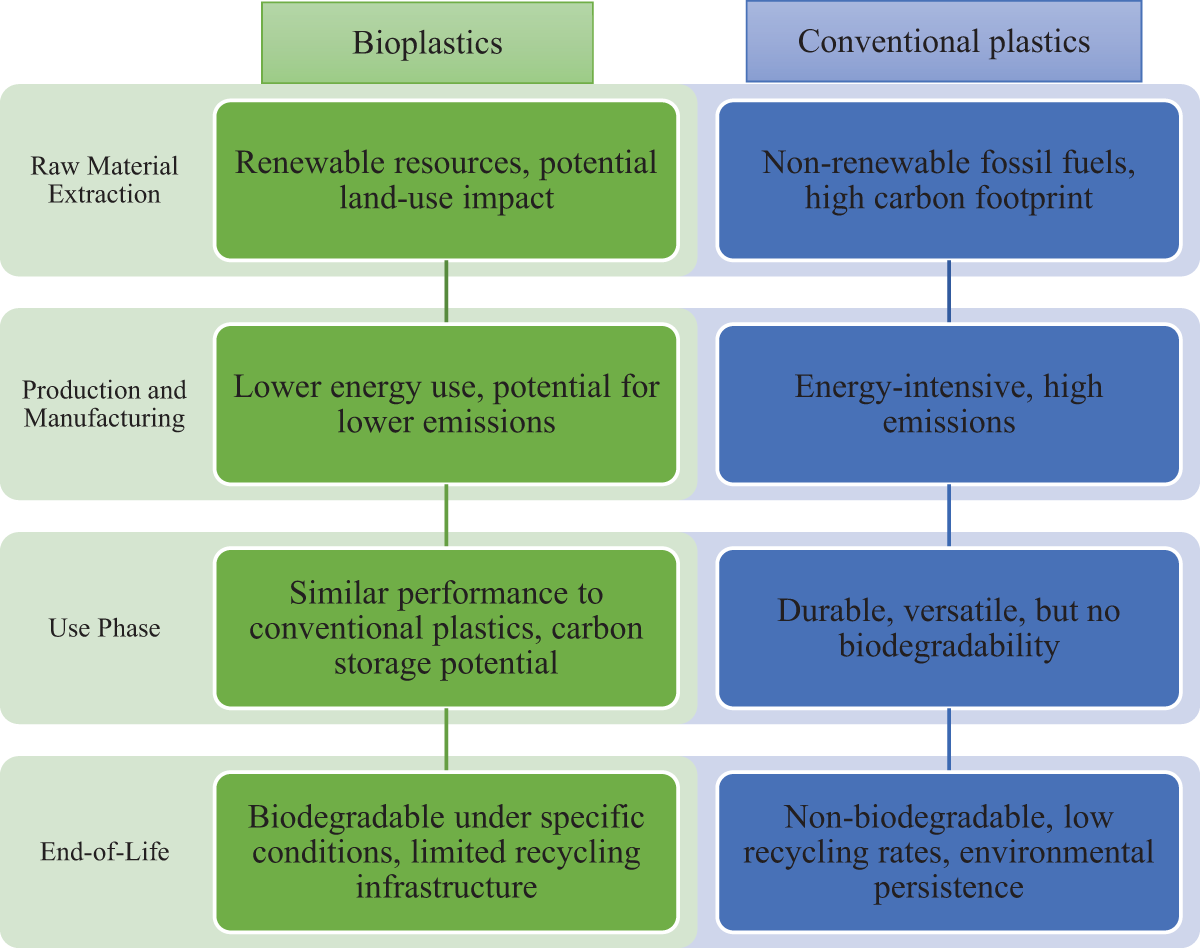

Renewable bioplastic has gained attention as a sustainable alternative to traditional petroleum-based plastics, driven by the pressing need to address the environmental impacts associated with plastic waste, resource depletion, and climate change. While bioplastics offer potential environmental benefits, a comprehensive understanding of their impact requires a detailed life cycle assessment (LCA). Life cycle assessment is a systematic method for evaluating the environmental impacts of a product throughout its life cycle. For bioplastics, LCA typically begins with the extraction of feedstocks, such as crops or algae, followed by the production and manufacturing process, use phase, and end-of-life scenarios, including disposal or recycling [14].

LCA evaluates the environmental impact of bioplastics by considering all stages of their lifecycle, including feedstock cultivation, manufacturing, usage, and end-of-life disposal. Modern LCAs utilize comprehensive datasets and advanced modeling software to analyze metrics like carbon footprint, energy consumption, and waste generation. For bioplastics, LCAs often highlight not only reduced greenhouse gas emissions but also potential trade-offs such as water and fertilizer use during feedstock production. LCAs reveal that while bioplastics typically have a lower carbon footprint than traditional plastics, their environmental performance depends significantly on the feedstock and production processes used. For instance, growing crops like corn or sugarcane for bioplastic production may lead to deforestation and biodiversity loss if not managed sustainably. On the other hand, bioplastics derived from agricultural byproducts can mitigate such impacts by utilizing waste streams that would otherwise contribute to environmental burdens.

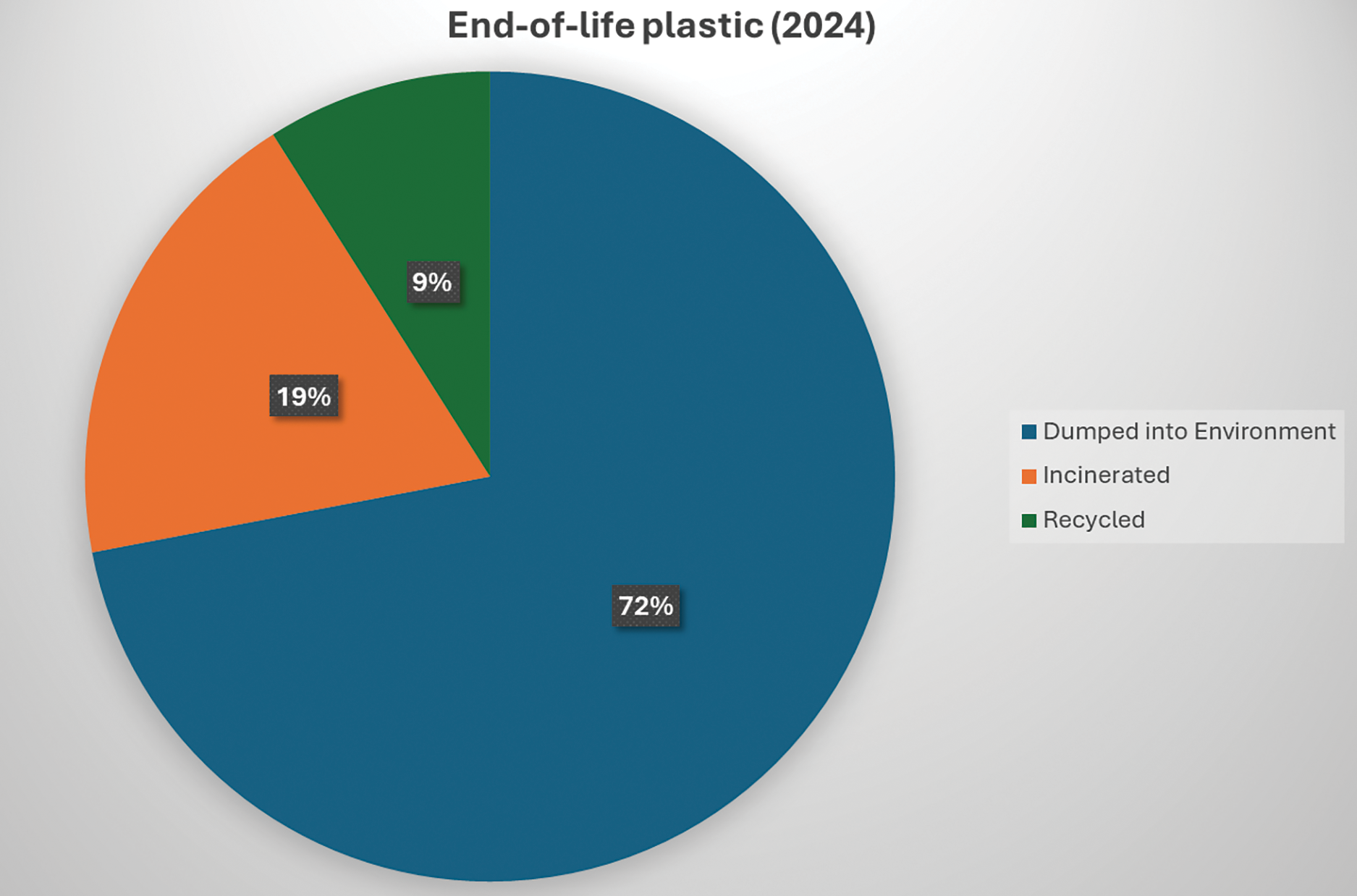

Fig. 1 shows that End-of-life management is a critical factor influencing the overall sustainability of bioplastics. According to recent reports from the Organisation for Economic Co-operation and Development, approximately 72% of plastic waste in 2024 was improperly managed, leading to environmental contamination in natural habitats such as oceans and forests. Only about 9% of plastic waste was recycled, and 19% was incinerated for energy recovery [15–17]. These figures underline the urgent need for developing comprehensive waste management solutions to prevent bioplastics from contributing to similar disposal issues. The biodegradability of bioplastics, such as PHA, makes them more favorable in natural settings where they can decompose efficiently. However, bioplastics like PLA often require industrial composting facilities for effective degradation, which may not be readily available, potentially leading to persistence in landfills similar to conventional plastics. To maximize the environmental benefits of bioplastics, investments in infrastructure, such as expanding industrial composting facilities and improving recycling processes, are essential. Public education on proper disposal practices is also crucial to ensure that biodegradable plastics are correctly handled and do not contaminate traditional recycling streams.

Figure 1: End-of-life plastic in 2024 [15–17]

The raw material stage for bioplastics involves the cultivation of renewable resources. For instance, PLA is derived from fermenting plant sugars, while PHA is produced by microorganisms. This contrasts with conventional plastics, which are derived from non-renewable fossil fuels. Bioplastics generally exhibit lower carbon footprints during this stage due to their renewable origins. However, the agricultural inputs required for bioplastic feedstocks can pose environmental challenges. Cultivation of crops such as corn or sugarcane for PLA production necessitates significant water, fertilizers, and pesticides, potentially leading to land-use changes, deforestation, and biodiversity loss. This can counterbalance some of the environmental benefits of using renewable resources. A significant factor impacting the scalability and economic viability of bioplastics is the choice of raw materials. Using primary crops like corn and sugarcane as feedstocks can contribute to higher production costs and raise concerns about food resource competition. To address these issues, utilizing agricultural residues such as corn stover, wheat straw, and sugarcane bagasse offers a cost-effective and sustainable alternative. These substrates are byproducts of existing agricultural operations and do not compete with food production, thus aligning with circular economy principles. Research indicates that using such non-food-based feedstocks can substantially lower raw material costs and reduce the overall environmental footprint of bioplastic production. Additionally, developing efficient fermentation processes and enhancing the use of these residues can contribute to more sustainable and economically viable bioplastic manufacturing.

The manufacturing phase involves converting raw materials into final products. Bioplastics often require different processing conditions compared to conventional plastics. While some bioplastics have lower energy requirements during production, others, like PLA, may require high-temperature processing, which can offset their environmental benefits. Conventional plastics, derived from petroleum, typically have established and energy-efficient production processes. The use phase of bioplastics generally mirrors that of conventional plastics. Both types of plastics are used in a wide range of applications, from packaging to consumer goods. The environmental impact during use is often similar, though bioplastics may offer advantages in specific contexts, such as reduced emissions during disposal.

Finally, one of the most critical aspects of the life cycle of bioplastics is their end-of-life management. Conventional plastics often face challenges related to disposal, with a significant portion ending up in landfills or the environment, where they can persist for hundreds of years [18]. In contrast, bioplastics are often designed to be biodegradable or compostable, theoretically reducing their impact on waste management systems [19]. However, the actual environmental benefit depends on proper disposal conditions. Many bioplastics require industrial composting facilities with specific temperature and humidity conditions to degrade effectively. In the absence of such facilities, bioplastics may not break down any faster than conventional plastics, leading to potential environmental pollution. Furthermore, the composting process itself must be managed carefully to avoid generating greenhouse gases or other pollutants. Fig. 2 shows the general LCA of both bioplastics and conventional plastics.

Figure 2: Life cycle assessment (LCA) of bioplastics vs. conventional plastics

Despite their advantages, bioplastics present several challenges when evaluated through life cycle assessments. The cultivation of feedstocks for bioplastics requires significant agricultural inputs, including water, fertilizers, and pesticides. This can lead to land-use changes, deforestation, and biodiversity loss. LCAs often reveal that the environmental impact of bioplastic feedstock cultivation can be substantial, sometimes offsetting the benefits gained from reduced carbon emissions during production [20]. The biodegradability of bioplastics is highly dependent on specific environmental conditions. Many bioplastics require industrial composting facilities to degrade effectively, which are not always available. Life cycle assessments may show that, under typical landfill or natural conditions, some bioplastics do not decompose efficiently and can contribute to waste accumulation similar to conventional plastics. This challenge highlights the need for better waste management systems to realize the full benefits of bioplastics.

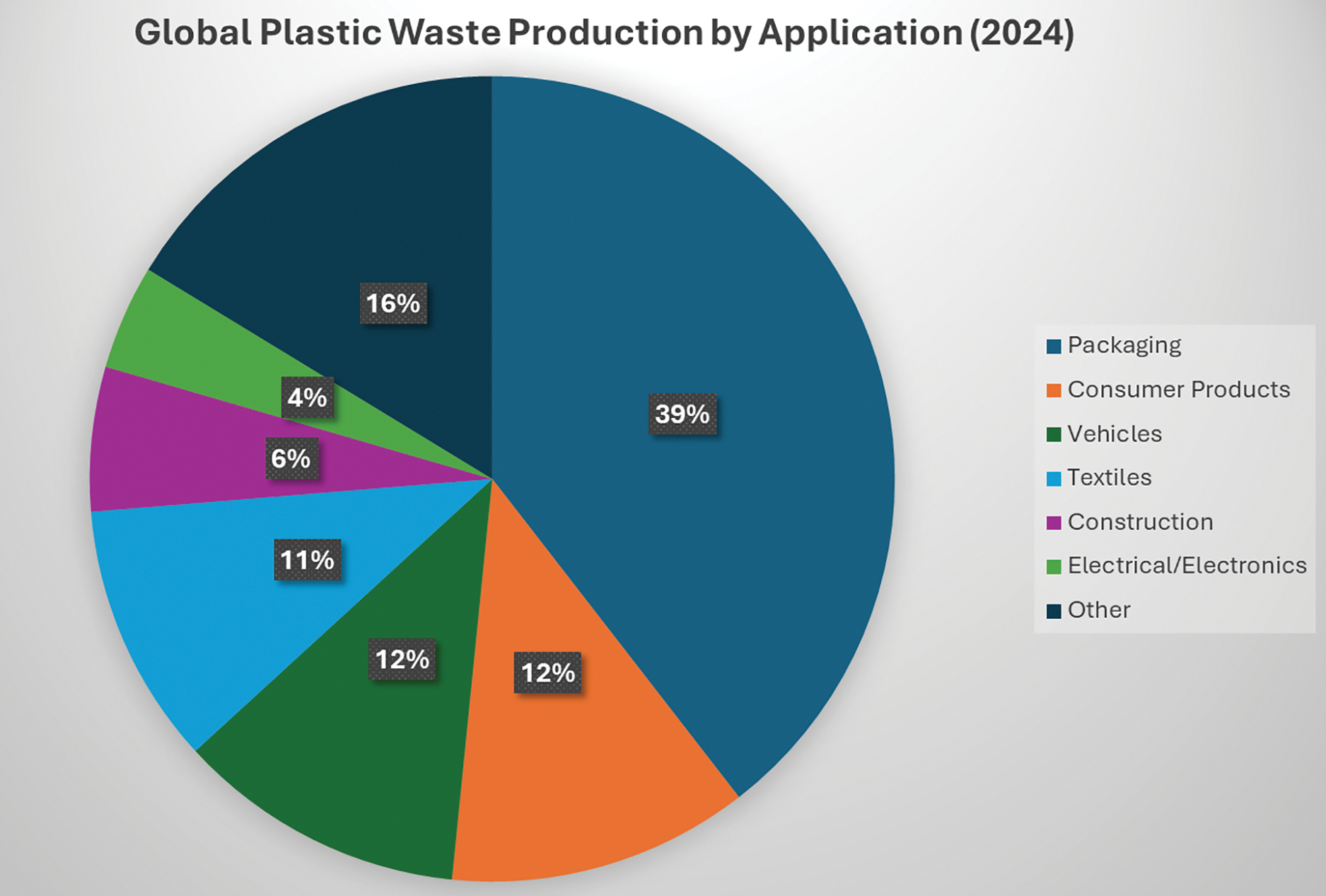

Additionally, while bioplastics may reduce greenhouse gas emissions during production, their overall environmental impact includes factors such as resource use, energy consumption, and waste management [21]. For example, some bioplastics require high energy inputs for synthesis and processing, which can diminish their environmental benefits. Life cycle assessments often indicate that the production and processing of bioplastics can have a comparable or even higher energy footprint than traditional plastics, particularly when considering the full life cycle from raw material extraction to disposal. Fig. 3 illustrates the distribution of plastic waste production by application. Packaging is the primary source of plastic waste, followed by consumer products, vehicles, and textiles.

Figure 3: Global plastic waste production by application in 2024 [22]

To enhance the sustainability of bioplastics and align them with the principles of a circular economy, several strategies are essential. One of the strategies is to improve feedstock efficiency. Innovations in crop selection and agricultural practices can help minimize the environmental impact of bioplastic production. Advances in biotechnology may also lead to the development of more efficient and less resource-intensive bioplastics. Another way is to enhance end-of-life management. Expanding industrial composting infrastructure and improving recycling technologies are critical for ensuring that bioplastics achieve their intended environmental benefits. Encouraging proper disposal and increasing consumer awareness are also vital. Finally, by integrating circular principles. Designing bioplastic products with recyclability in mind and promoting systems for closed-loop recycling can help mitigate the environmental impacts associated with their disposal.

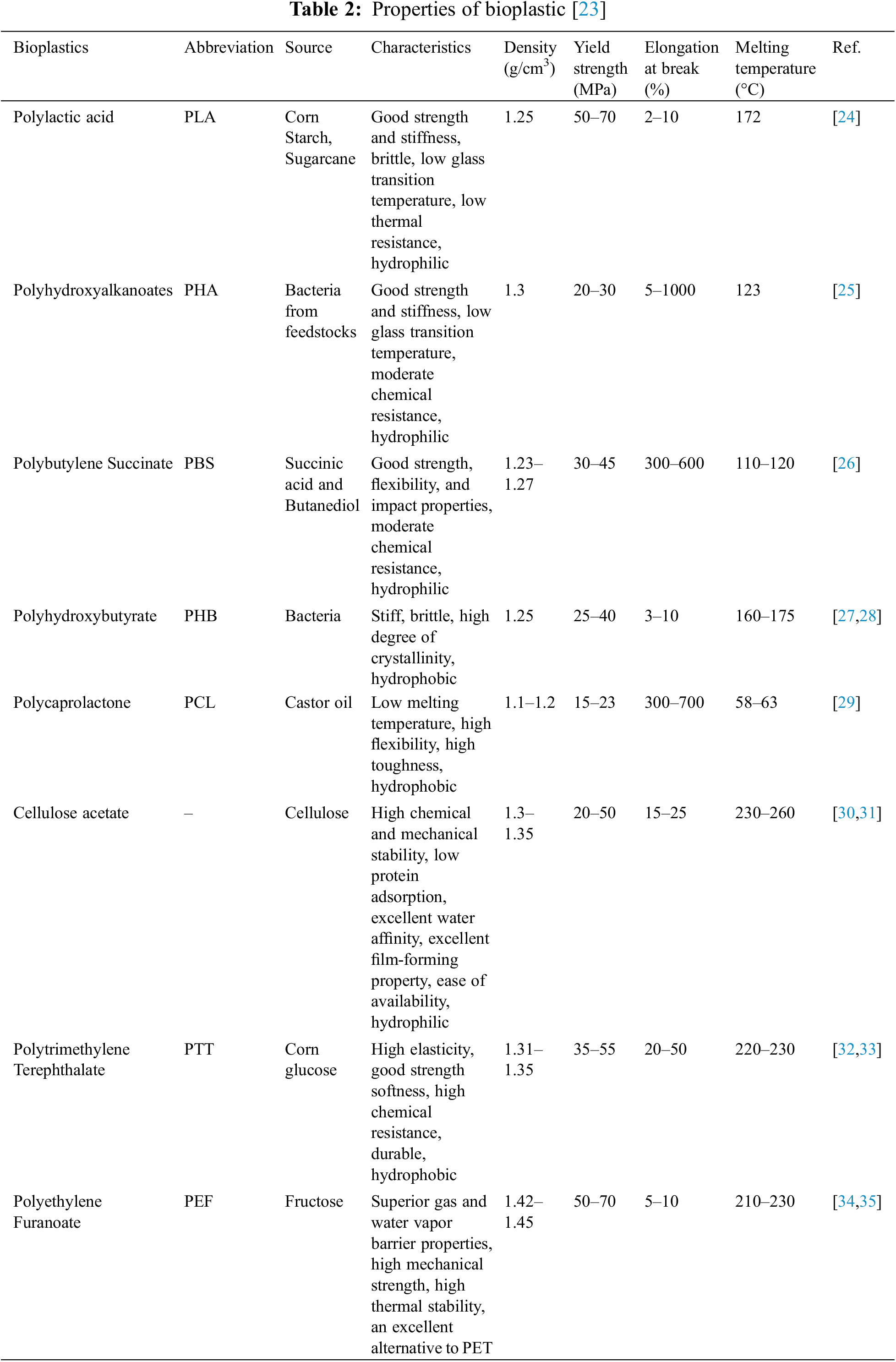

Technological advancements in bioplastics are crucial for enhancing their performance, broadening their applications, and making them viable alternatives to conventional plastics. Many new techniques in biopolymer synthesis and processing are currently being explored aimed at improving the properties of bioplastics, and material engineering advancements. Table 2 shows some of the common bioplastics made from renewable sources available in the market.

2.3.1 Advancement in Bioplastic Production

In biopolymer synthesis and processing, recent breakthroughs have focused on refining how bioplastics are produced [36]. One notable development is in fermentation technologies, which have revolutionized the production of biopolymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) [37]. PLA and PHA are some of the most commonly used bioplastics. PLA is widely used due to its cost-effectiveness and versatility, particularly in disposable packaging, cutlery, and compostable bags. Its base components are typically derived from corn and sugarcane, making it both bio-based and biodegradable, though industrial composting facilities are needed for full degradation. PHA, another widely used bioplastic, is favored for applications in both medical and single-use packaging due to its ability to biodegrade in various environments, including marine settings. However, PHA is considerably more expensive than PLA, which limits its broader adoption [38,39]. Advances in microbial fermentation have led to more efficient production processes, with engineered microbial strains achieving higher yields and reduced production costs. This has been further complemented by improvements in enzymatic polymerization, where enzymes are utilized to synthesize biopolymers with high precision and lower energy inputs. This method offers a more sustainable approach by minimizing the use of harmful chemicals and reducing the overall environmental impact.

One of the most recent studies conducted by Abdelrahman et al. uses enzymatic polymerization on the bioconversion of agro-industrial wastes into polyhydroxybutyrate (PHB) using a novel strain of Salinicola salarius ES021 [40]. PHB is a biodegradable bioplastic, which serves as an eco-friendly alternative to traditional plastics. The research explored the genetic and fermentation process of PHB production, identifying the genes responsible for its synthesis. PHB is synthesized via microbial fermentation and the Salinicola salarius strain utilized agro-industrial wastes like salted whey and sugarcane molasses, demonstrating a sustainable and cost-effective fermentation process. Enzymes such as 3-ketoacyl-CoA thiolase, acetoacetyl-CoA reductase, and PHB synthase are involved in the PHB synthesis pathway, catalyzing key reactions from acetyl-CoA to PHB. This fermentation technology, combined with the use of low-cost carbon sources, offers a promising approach to producing biodegradable bioplastics like PHB in a circular economy. Their study also highlights the potential of fermentation and enzymatic polymerization technologies for the production of bioplastics from renewable resources, addressing both sustainability and environmental concerns.

Processing innovations have also played a crucial role in enhancing the sustainability and functionality of bioplastics. The use of green solvents and methods has become more prevalent, with technologies like supercritical CO2 being employed to process bioplastics in a more environmentally friendly manner. As an example, the study conducted by Lenti et al. explores the use of supercritical CO2 (scCO2) as a green solvent in the benzoylation of starch [41]. This process chemically modifies starch to enhance its hydrophobicity while maintaining biodegradability, thus presenting a more sustainable route compared to traditional methods that rely on toxic chemicals. Supercritical CO2 offers advantages such as non-toxicity, ease of removal from the reaction mixture, and low operational costs. The starch was modified using vinyl benzoate through a base-catalyzed transesterification process, resulting in varying degrees of substitution, from 0.01 to 3.00. The result shows that the materials have enhanced hydrophobicity and improved thermal stability. The hydrophobicity of starch, with contact angle measurements, could reach values as high as 99°, compared to the much lower values of 40–60° typical for unmodified starch. This indicates a considerable increase in water resistance. Whereas for thermal stability, the temperature of maximum weight loss rate for the benzoylated starches increased to as much as 361°C for higher degrees of substitution samples, compared to 315°C for native starch. The use of scCO2 as a green solvent allows for reduced environmental impact compared to organic solvents typically employed in starch modifications. In relation to bioplastics, this method aligns with the goal of developing biodegradable polymers processed using sustainable approaches. By using scCO2, the method reduces reliance on toxic solvents, positioning it as an eco-friendly alternative for producing bioplastics with enhanced functionality, such as water resistance and durability. Thus, this green method of processing starch could be highly relevant in the development of bioplastics that are not only biodegradable but also produced through environmentally responsible techniques. However, the cost of using supercritical carbon dioxide (scCO2) in processing varies based on the scale, purity, and specific technology required for extraction or polymerization applications. ScCO2 is generally considered a cost-effective solvent in sustainable manufacturing because it can replace toxic organic solvents and is easily recycled within the process. However, actual costs can depend on the specific process setup and associated maintenance of high-pressure systems required for scCO2, making it challenging to estimate a universal price [42].

Additionally, advances in additive manufacturing, or 3D printing, have enabled the precise fabrication of bioplastic components. This technique allows for the creation of complex geometries and customized products, expanding the potential applications of bioplastics and demonstrating their versatility [43,44]. The integration of additive manufacturing, particularly 3D printing, enhances the customization and application potential of bioplastics by allowing precise, on-demand fabrication of complex shapes and structures with minimal waste [45]. This technology enables the production of sustainable, lightweight, and high-performance components for industries like aerospace, automotive, and healthcare. For example, PLA, a commonly used bioplastic in 3D printing, is popular for creating biodegradable prototypes and consumer products. Another advancement is in the use of biocomposite filaments (e.g., PLA reinforced with natural fibers), which improve mechanical properties while maintaining biodegradability, offering a sustainable alternative for high-strength applications. These innovations highlight the potential of 3D printing to drive sustainable manufacturing and expand the practical use of bioplastics across industries.

In 3D printing, PLA is extensively used due to its ease of printing, biodegradability, and relative affordability. However, 3D printing accounts for only a portion of PLA’s applications. A significant share of PLA is utilized in the packaging industry—an estimated 40% of bioplastics go into packaging, with PLA being the most prominent type used for short-life packaging materials like disposable cutlery, food trays, and other thermoformed products. As a result, while PLA has become popular in 3D printing, its largest demand remains in packaging and other short-use applications, driven by high-volume disposable product markets [46].

The study by Smith et al. highlights the advanced capabilities of additive manufacturing when applied to bioplastics, particularly in achieving precision, complexity, and customization [47]. The use of methacrylated bovine serum albumin (MA-BSA) in 3D printing demonstrates how bioplastics can be adapted for specific mechanical and physical properties, further expanding their applications. The optimization of resin viscosity, critical for printability, shows the level of control achievable with additive manufacturing, ensuring smoother printing processes even with complex geometries. This level of customization and material engineering is essential for expanding the use of bioplastics in various industries. By using techniques like vat photopolymerization and thermal curing, the mechanical performance of bioplastics can be significantly enhanced. For instance, increasing the compressive modulus up to 638 MPa indicates that these bioplastic materials can possess strength comparable to conventional plastics. The decrease in swelling ratio which is 2.64 (lower than uncured materials) through thermal curing is also key in making bioplastics more suitable for environments where water uptake would otherwise limit their use. This opens doors for bioplastics to replace traditional polymers in applications where mechanical stability and resistance to environmental factors are crucial. Therefore, the ability to fine-tune properties like viscosity, mechanical strength, and water absorption through additive manufacturing processes suggests that bioplastics can be manufactured to meet the demands of specific applications. This increases their prospects in industries ranging from healthcare to packaging, automotive, and beyond. The synergy between bioplastics and additive manufacturing positions them as sustainable alternatives, with customizable properties that rival those of conventional synthetic materials.

The series of recent advancements made in bioplastics production shows that bioplastics hold tremendous potential as sustainable alternatives to conventional plastics, offering both environmental and functional benefits. Recent breakthroughs in biopolymer synthesis, particularly through fermentation technologies and enzymatic polymerization, have improved production efficiency while lowering costs and environmental impact. The innovative use of microbial strains like Salinicola salarius ES021 for polyhydroxybutyrate (PHB) production exemplifies the shift toward more sustainable feedstocks, such as agro-industrial wastes, in bioplastic production. Processing advancements, including the use of green solvents like supercritical CO2, have further enhanced bioplastics by improving their physical properties while minimizing harmful byproducts. Moreover, the integration of additive manufacturing has expanded the possibilities for bioplastics by enabling highly customized, complex geometries with fine-tuned mechanical and physical properties. This convergence of bioplastic production and 3D printing not only enhances their versatility but also opens new applications in industries like healthcare, aerospace, and packaging. As sustainability becomes more critical, bioplastics are poised to replace traditional polymers, aligning with the goals of a circular economy. Their ability to offer comparable strength, water resistance, and durability to conventional plastics while being biodegradable ensures that bioplastics can play a key role in reducing environmental pollution and supporting greener technologies.

The field of material engineering has seen notable progress, particularly in blending and copolymerization techniques. Blending different biopolymers or combining bioplastics with conventional polymers can improve the performance and functionality of the final material. For instance, blending PLA with polybutylene succinate (PBS) can enhance PLA’s thermal and mechanical properties, thereby expanding its range of applications. Tangnorawich et al.’s study investigates the impact of PBS content on PLA/PBS composite fibers [48]. Differential scanning calorimetry analysis (DSC) revealed that the crystallization temperature of the PLA sheet decreased with increasing PBS addition levels down to 91.7°C at 10 wt% PBS. This suggests that the addition of PBS may affect PLA crystallization, which is consistent with X-ray diffraction analysis that revealed that the crystallinity of PLA (19.2%) increased with increasing PBS addition up to 28.1% at 10 wt% PBS. Moreover, adding PBS increased the tensile properties while the % elongation at break was significantly decreased. The study highlights the potential of nonwoven melt-blown technology to produce biodegradable wound dressings, reducing environmental impact and potentially benefiting patient healing.

Additionally, the incorporation of functional fillers, such as natural fibers or mineral additives, into bioplastic blends can enhance properties like strength and thermal stability, while also contributing to the material’s sustainability [49,50]. The study conducted by Ozhyhar et al. used alkenyl succinic anhydride (ASA)-surface-treated calcium carbonate as a functional mineral additive in Wood Fiber (WF) reinforced PLA composites. The study focuses on the tensile properties, modulus of elasticity (MOE), ultimate tensile strength (UTS), elongation at break, and Charpy impact strength (IS) of cellulose-enabled polylactic acid (PLA) composite [51]. The researchers used measurements on six samples for the tensile properties, five samples for the MFR and impact strength properties, and three individual samples for contact angle measurements for each composite variant. They also studied WF-reinforced PLA composites with 40 wt% fiber reinforcement and 0% mineral addition, 10% untreated mineral addition, 10% ASA-treated mineral addition, 20% ASA-treated mineral addition, and 30% ASA-treated mineral addition. The study found that the MOE and UTS for WF-reinforced PLA as affected by mineral additives were significantly higher than those for other composites. The researchers also found that the composites had better mechanical properties than those of other composites.

Copolymerization techniques have also advanced, allowing for the creation of bioplastics with tailored properties. Block copolymers, which involve combining different polymer segments, can produce materials with unique characteristics, such as a balance between rigidity and flexibility. As an example, a study conducted by Rahman et al. focuses on the characterization of rosin-based A−B−A triblock and A−B−A−B−A pentablock copolymers to enhance their mechanical properties [52]. The mechanical properties of these copolymers depend on their molecular weight, compositions, morphology, and chain architectures. The mechanical properties of block copolymers, including tri- and pentablock copolymers, were compared using uniaxial tensile tests using dog-bone specimens. Rosin-containing homopolymers with lower molecular weight are brittle and cannot form free-standing films. However, rosin-containing tri- and pentablock copolymers showed higher yield points, necking, and greater toughness compared to homopolymers with comparable molecular weight. The promising toughening properties of pentablock copolymers are likely due to the presence of rosin-containing middle blockchains, which act as bridging chains between neighboring polynorbornene domains, increasing the energy needed for crack propagation through the rosin-containing matrix. The microphase-separated polymeric architecture plays an important role in mechanical properties, with pentablock copolymers showing remarkable toughening properties compared to tri- and homopolymers. This study provides a strategy to innovate biomass-containing sustainable polymers with superior performance via the control of macromolecular architectures. The integration of renewable cellulose and rosin into block copolymers has the potential to revolutionize the production of sustainable polymers and plastics.

Similarly, graft copolymers, which involve attaching polymer branches to a main chain, can enhance compatibility and performance by improving interactions between bioplastics and other materials. The study by Akay et al. conducted in vitro biodegradation of LCC and LCC-g-PCL samples in both hydrolytic and enzymatic environments over 35 days [53]. The LCC sample showed degradation of 2.1% and 12.9, while LCC-g-PCL showed degradation of 6.7% and 23.5 in hydrolytic and enzymatic conditions, respectively. The presence of the PCL segment, which degrades rapidly, increased biodegradation in both media. The results also show that the incorporation of PCL groups on LCC provides increasing hydrophobicity. The degradation behavior of the LCC-g-PCL copolymer is found to be more prominent under enzymatic medium than hydrolytic conditions. The study found that cellulose, the main structural component in plants, is abundant and can be used as an additional feature-providing component in composite materials or directly modified by its functional groups. The graft copolymer with LCC and PCL is versatile, has engineering potential for various bio-applications, and is anticipated to be a potential eco-friendly material, particularly in the bioplastic industry.

The development of advanced bioplastic composites has opened up new possibilities for their application. Biofiber-reinforced composites, which incorporate natural fibers such as hemp, flax, or jute, offer improved mechanical properties and environmental benefits. These composites are lighter and can replace conventional materials in sectors like automotive, aerospace, and construction. Furthermore, bioplastic-based nanocomposites, which combine bioplastics with nanomaterials, provide enhanced strength, barrier properties, and thermal stability, making them suitable for applications in packaging, electronics, and medical devices.

2.4 Applications of Bioplastics

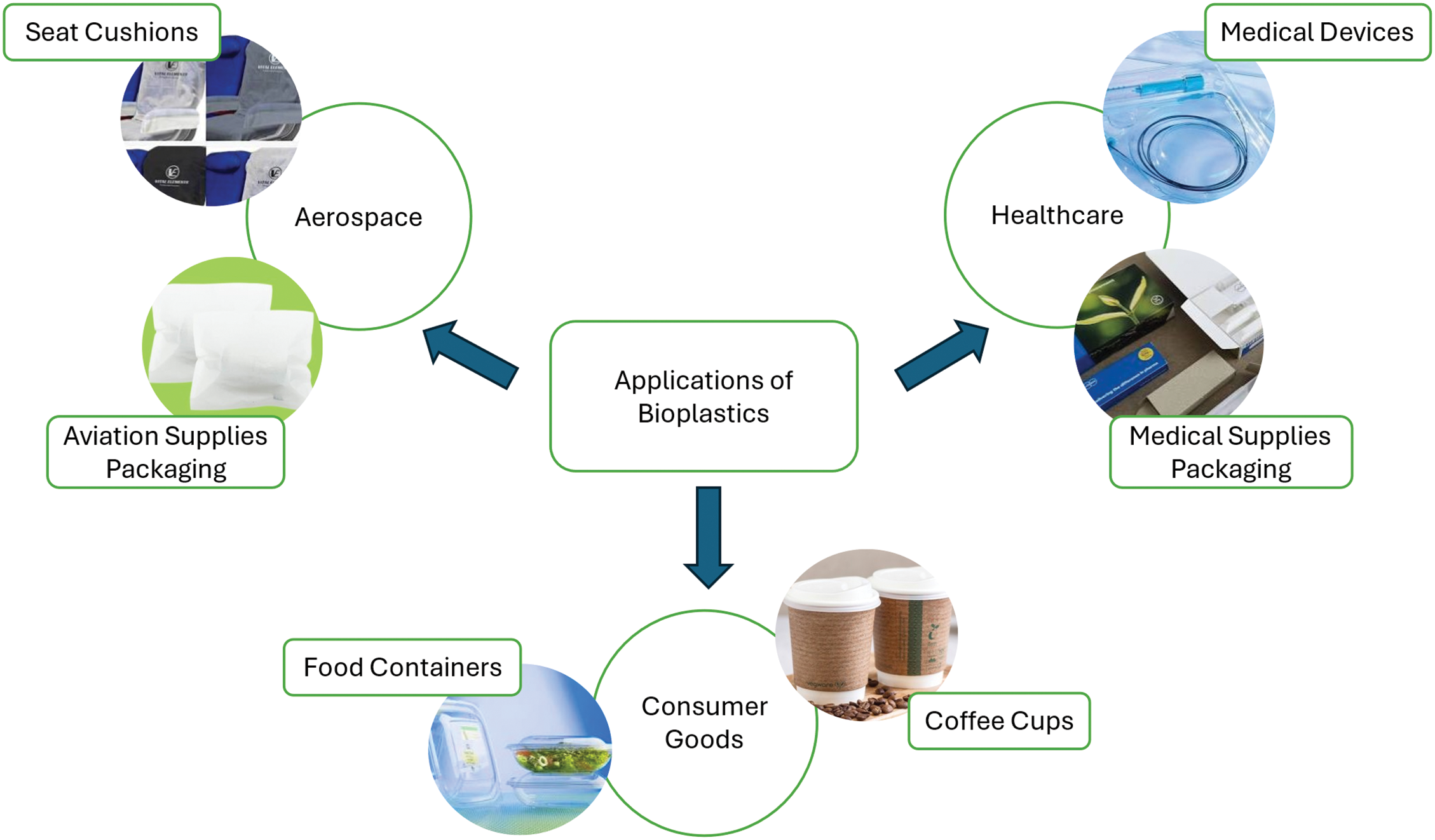

Bioplastics, with their evolving properties and improved production methods, are increasingly being integrated into various applications. Their versatility allows them to be used across multiple sectors, offering both environmental and functional benefits. Fig. 4 shows some of the bioplastics applications in different industries.

Figure 4: Applications of bioplastics [54–58]

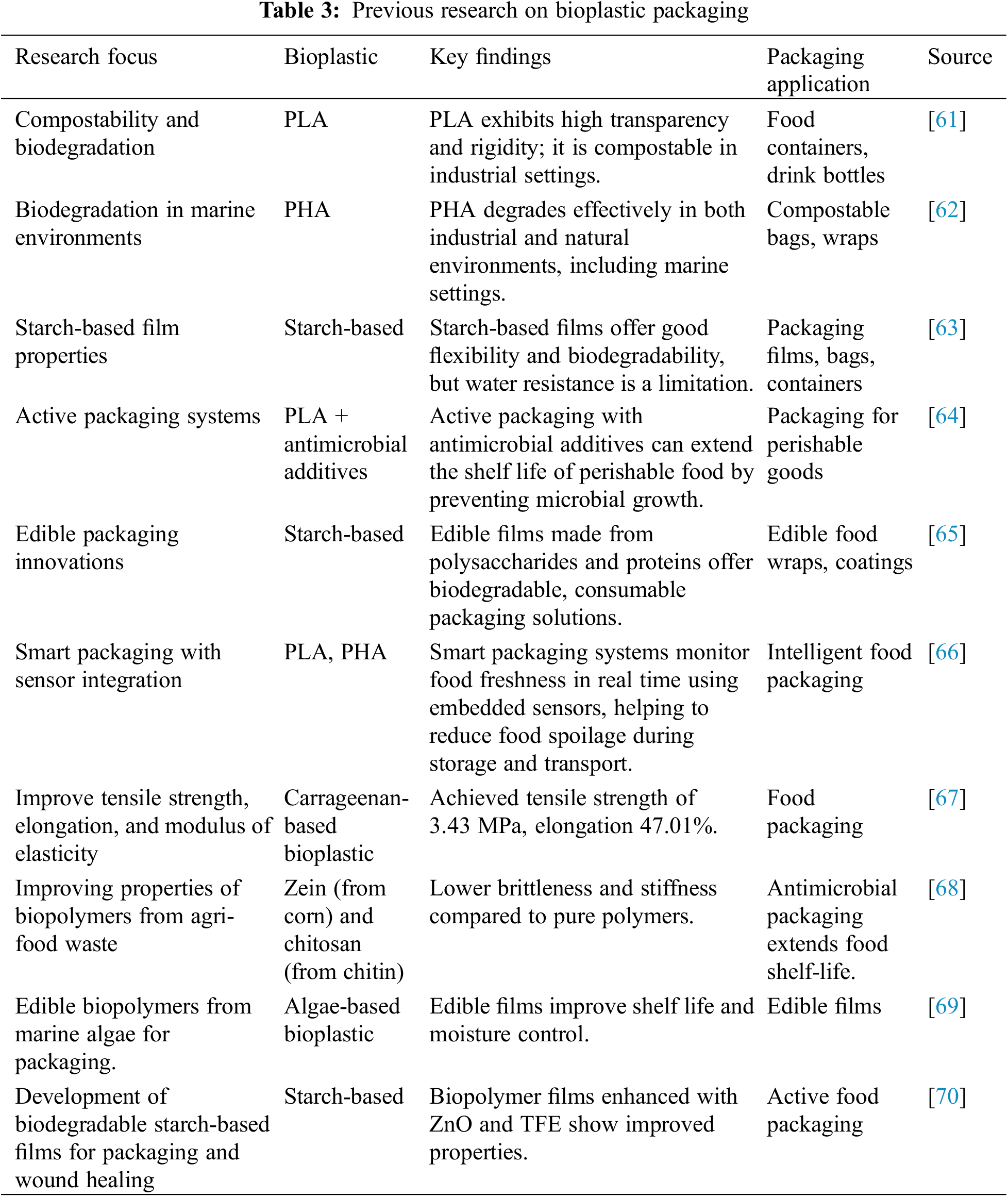

The packaging industry is one of the largest consumers of plastic materials, which has led to a growing interest in bioplastics as a more sustainable alternative. Bioplastics, derived from renewable resources, offer several benefits in packaging applications, including reduced environmental footprint, improved biodegradability, and potential for recycling. In packaging, bioplastics like Polylactic Acid (PLA) and Polyhydroxyalkanoates (PHA) are increasingly used for single-use items, food containers, and films due to their biodegradability and compostability, which help reduce plastic waste and environmental impact [59,60]. Their strength, lightweight nature, and ability to be produced from renewable resources make them appealing options for manufacturers looking to enhance sustainability while maintaining product integrity.

Among the various types of bioplastics, PLA stands out for its widespread use in packaging applications. Derived from fermented plant sugars, PLA is commonly utilized in products such as food containers, drink bottles, and disposable cutlery [61]. Its clarity and rigidity make it suitable for transparent packaging, while its compostability under industrial conditions provides an eco-friendly alternative to traditional plastics, reducing landfill waste.

Another significant bioplastic in packaging is PHA, which is produced through microbial fermentation of organic substrates [62]. PHAs are particularly valued for their ability to degrade in both industrial composting facilities and natural environments. This makes them suitable for applications like compostable bags and wraps, offering a practical solution for reducing environmental impact.

Starch-based bioplastics, derived from corn, potatoes, or other starch-rich plants, are also making their mark in the packaging industry [63]. These bioplastics are often used to create films, bags, and containers. Their biodegradable nature allows them to decompose more easily than conventional plastics, making them versatile for various packaging needs.

Innovative applications of bioplastics are also emerging in the packaging industry. Active packaging systems that incorporate bioplastics can extend the shelf life of products through antimicrobial properties or other preservation features [64]. Edible packaging, which can be consumed along with the product, represents a novel approach to reducing waste [65]. Additionally, the integration of bioplastics with smart technologies, such as sensors or indicators, is paving the way for advancements in packaging that provide real-time information about product conditions [66]. Table 3 shows some of the research conducted on bioplastic for packaging applications.

Bioplastics are gradually finding applications in the aerospace industry, an area traditionally dominated by high-performance, synthetic materials. The use of bioplastics in aerospace is driven by the industry’s increasing focus on sustainability, fuel efficiency, and reduced environmental impact. Table 4 shows some of the research focus on bioplastic development in the aerospace industry.

Several aerospace companies and research organizations are beginning to experiment with bioplastics for non-primary, interior components and secondary structures. One of the examples is Airbus. Airbus is actively investigating bioplastics for interior cabin components such as tray tables, seat back shells, and storage compartments. These bioplastics reduce weight and emissions during production and help minimize waste over the aircraft’s lifecycle. Boeing has also conducted research into biocomposites and bioplastics, particularly for aircraft interiors, aiming to integrate sustainable materials into future designs and improve the sustainability profile of their products. Other than that, NASA has explored bioplastics for use in non-structural parts of space missions. Materials like PLA are being tested for 3D printing small parts and tools, leveraging both the lightweight and biodegradable nature of bioplastics. While bioplastics are not yet prevalent in primary structures, they are gaining traction for use in secondary structures and interior components within the aerospace industry. These developments are primarily driven by sustainability initiatives and the need for lightweight, eco-friendly materials that align with a circular economy approach.

In the aerospace industry, bioplastics are being utilized in a variety of ways to enhance the sustainability of aircraft and spacecraft. One notable application is in the development of lightweight components. The aerospace sector places a strong emphasis on reducing the weight of aircraft and spacecraft to improve fuel efficiency and performance. Bioplastics, with their potential for high strength-to-weight ratios, are being explored as materials for components such as interior panels, seat cushions, and structural elements. For instance, bioplastic composites that incorporate natural fibers, such as flax or hemp, are being tested for use in cabin interiors and other non-structural components [73]. These composites offer a promising combination of low weight and enhanced mechanical properties, contributing to overall weight reduction and fuel savings.

Another application of bioplastics in aerospace is in the production of insulation materials. Bioplastics can be used to create thermal and acoustic insulation materials that meet the rigorous requirements of the aerospace industry. These materials help manage temperature and noise levels within aircraft cabins and spacecraft, contributing to passenger comfort and operational efficiency. Additionally, the use of bioplastics for insulation can lead to reduced environmental impact compared to conventional synthetic materials.

Research and development efforts are focused on enhancing the performance and safety of bioplastics for aerospace applications. Engineers and material scientists are working to improve the thermal stability, fire resistance, and overall durability of bioplastics to ensure they meet the stringent safety standards required for aerospace materials. For example, advancements in bioplastic composites are aimed at achieving the high-performance characteristics needed for aerospace applications, such as resistance to extreme temperatures and mechanical stresses [74]. Table 5 shows the comparison between bioplastics and traditional materials.

The integration of bioplastics into aerospace design and manufacturing processes also presents opportunities for reducing the industry’s reliance on fossil fuels and lowering greenhouse gas emissions. By incorporating renewable and biodegradable materials into aircraft and spacecraft, the aerospace industry can contribute to a more sustainable future while maintaining high performance and safety standards.

In the healthcare industry, bioplastic offers a range of benefits from sustainability to enhanced functionality. Their applications span various aspects of healthcare, including medical devices, packaging, and tissue engineering [78,79]. One prominent application is in the production of biodegradable sutures and surgical meshes [80]. Traditional sutures and meshes are often made from non-degradable materials, which can lead to complications and require additional procedures for removal. Bioplastics offer the advantage of being biodegradable, thus eliminating the need for surgical removal and reducing the risk of long-term complications. These bioplastics can safely degrade within the body over time, leaving no harmful residues.

Another significant application of bioplastics in healthcare is in the creation of drug delivery systems. Biodegradable bioplastics are used to develop drug-delivery devices that can release medication in a controlled manner over an extended period. This approach improves patient compliance by reducing the frequency of dosage and enhances the efficacy of the medication by targeting specific areas within the body. For example, bioplastic-based implants can gradually release antibiotics or other therapeutic agents, minimizing the risk of infections and promoting faster healing [81].

Bioplastics are also making their way into the realm of tissue engineering and regenerative medicine. In this field, bioplastics are used to create scaffolds that support the growth of new tissues and organs. These scaffolds provide a temporary framework for cells to grow and form new tissues, which can then be used to repair or replace damaged body parts. Bioplastics such as PLA and PCL are chosen for their biocompatibility and ability to degrade at a controlled rate, allowing the scaffolds to gradually dissolve as new tissue forms [81].

Moreover, bioplastics are being explored for their potential in creating improved wound dressings and bandages [82]. Advanced bioplastics can be designed to have antimicrobial properties, which help prevent infections and promote faster wound healing. These bioplastic-based dressings can provide a protective barrier while allowing for moisture management and oxygen permeability, essential for effective wound care. Table 6 shows some of the current research on bioplastics in the healthcare industry.

Despite the promising applications, the use of bioplastics in healthcare also comes with challenges. Ensuring that bioplastics meet the stringent safety and performance standards required for medical applications is crucial [89]. Bioplastics must undergo rigorous testing to confirm their biocompatibility, durability, and effectiveness. Additionally, the cost of bioplastic materials and production processes can be higher than conventional plastics, which may impact their widespread adoption.

3 Challenges and Future Prospects of Bioplastics

3.1 Challenges in the Adoption of Bioplastics

The adoption of bioplastics, which are derived from renewable resources and offer potential environmental benefits over traditional petroleum-based plastics, faces several significant challenges. Despite their promising attributes, including reduced reliance on fossil fuels and enhanced sustainability, bioplastics encounter hurdles related to scalability and production costs, material performance, and waste management. These challenges need to be addressed to facilitate broader adoption and maximize the environmental advantages of bioplastics.

Scalability and production costs are primary concerns, as the current economic viability of bioplastics is hindered by high production expenses compared to conventional plastics. Additionally, the performance characteristics of bioplastics, such as their mechanical and thermal properties, often fall short of those of traditional materials, which can limit their applications. Furthermore, effective waste management and end-of-life options for bioplastics are crucial for ensuring that their environmental benefits are realized, yet infrastructure and practices for recycling and composting are not always adequate.

In terms of scalability and production costs, the economic challenges in large-scale bioplastic production are substantial. For instance, according to recent data, the production cost of PLA, a widely used bioplastic, is approximately 1.5 to 2 times higher than that of conventional petroleum-based plastics. A study by Kumari et al. highlights that the cost of PLA production can be 2 to 4 times more than petroleum-based plastics like polyethylene [90]. This cost disparity is primarily due to the higher price of raw materials and the complexities involved in the bioplastic production process. Strategies to reduce production costs are actively being explored. For example, advancements in fermentation technology and the use of more cost-effective feedstocks could potentially lower costs. Research by Wellenreuther et al. demonstrated that using agricultural residues, such as corn stover, as feedstocks could reduce the cost of PLA significantly compared to using food-grade corn [91]. Scaling up production facilities also plays a role in cost reduction; increasing the production scale can leverage economies of scale, thus lowering the per-unit cost of bioplastics.

On another note, in terms of material performance, bioplastics often face limitations in mechanical and thermal properties compared to traditional plastics. For instance, PLA has a tensile strength of approximately 62.1 MPa, which is lower than that of conventional polyethylene, which has a tensile strength of around 72.4 MPa [92]. Similarly, PLA has a relatively low thermal stability with a glass transition temperature of about 54.85°C, which limits its use in high-temperature applications [92]. Ongoing research is focused on addressing these limitations. A study by Jonoobi et al. explored the incorporation of cellulose nanofibers into PLA, resulting in a significant improvement in tensile strength, increasing it to 71.2 MPa, which brings it closer to the performance of traditional plastics [93]. Additionally, researchers are investigating new biopolymer blends and composite materials to enhance the thermal stability and mechanical properties of bioplastics.

As an example, the development of PLA/PHA blends by Burzic et al. has shown improved impact resistance, making them suitable for a wider range of applications [94]. The study focuses on enhancing the impact toughness of PLA by incorporating biobased PHA copolymers, specifically targeting improvements without compromising PLA’s biodegradability and compostability. PLA is recognized for its environmental benefits but has limitations in impact strength, which restrict its applications. The research investigates the blending of PLA with two types of amorphous PHA copolymers at loading levels of 10–20 wt%. The findings reveal that the addition of PHA significantly improves the impact performance of PLA. Notably, the PLA/PHA2 blend demonstrated remarkable results, with notched Charpy impact strength increasing from 4.5 to 13 kJ/m2 after an annealing process at 100°C for one hour, representing a more than 300% enhancement. The study also highlights that the crystallinity of the blends was positively affected by the incorporation of PHA, achieving a crystallinity of 37% for the PLA/PHA2 blend at an 80/20 ratio. Thermal analysis indicated that blending with PHA not only improved the mechanical properties but also facilitated a more stable crystalline structure in PLA during processing. The annealing treatment further enhanced both tensile and impact properties, making this modified PLA/PHA blend suitable for broader applications, particularly in packaging and biomedical fields. Overall, this research presents a promising strategy for improving PLA’s performance while maintaining its environmentally friendly characteristics.

While bioplastics are promoted as sustainable alternatives, their human safety and environmental profiles are equally critical. Medical-grade bioplastics like PLA and PHA have demonstrated biocompatibility, minimizing risks of adverse reactions in medical applications through rigorous cytotoxicity and histocompatibility testing. Materials such as PLA and PHA have been widely studied for their safe application in medical devices and implants due to their non-toxic and biocompatible properties. For example, PLA has been approved by regulatory agencies for use in sutures and orthopedic implants because it degrades into lactic acid, a naturally occurring compound in the human body, minimizing inflammation and adverse responses. Extensive cytotoxicity and histocompatibility tests are performed on medical-grade bioplastics to ensure they do not provoke immune responses or cytotoxic effects. This includes examining their degradation products to ensure they do not accumulate or cause harm over time.

In terms of environmental safety, bioplastics exhibit variable biodegradability. While PHA can naturally decompose in environments like oceans and soil, PLA often requires specific industrial composting conditions. The environmental benefits are further nuanced by LCAs that evaluate water use, fertilizer impact, and potential eco-toxicity during degradation, especially if stabilizers are present. While bioplastics like PHA degrade in natural settings such as soil and marine environments, PLA requires specific conditions found only in industrial composting facilities. This disparity can lead to confusion in waste management and potential pollution if PLA is improperly disposed of. LCAs show that while bioplastics often have a lower carbon footprint compared to conventional plastics, environmental stressors like water consumption, fertilizer use, and land competition can offset these benefits. For example, growing crops for biopolymer production can lead to deforestation and biodiversity loss if not managed sustainably. Some bioplastics might introduce eco-toxic elements during their degradation if additives or stabilizers are used in their formulation. Ensuring that the complete breakdown products are non-toxic is crucial for environmental safety.

Finally, in terms of waste management and end-of-life options, effective waste management for bioplastics is crucial for realizing their environmental benefits. Current recycling and composting infrastructures face significant limitations in handling bioplastics, which can undermine their environmental benefits. One major issue is that many bioplastics, like PLA, are not compatible with traditional recycling systems, leading to contamination in recycling streams when they are improperly disposed of alongside conventional plastics. Additionally, existing composting facilities often lack the required conditions for effectively decomposing bioplastics, as many require industrial composting environments with specific temperature and moisture levels, which are not achievable in typical home compost setups. As a result, bioplastics may persist in landfills or the environment, contributing to plastic pollution rather than alleviating it.

To address these challenges, advancements such as improved home composting solutions are being developed. For example, researchers are working on formulating bioplastics that can degrade in a wider range of conditions, including home compost systems, by enhancing their microbial compatibility and reducing the temperature thresholds required for decomposition. Additionally, the development of compostable bioplastics that break down more readily in various environmental conditions is gaining traction. While bioplastics like PLA and PHA are designed to be biodegradable, their end-of-life management often faces challenges. For instance, PLA requires industrial composting facilities with specific temperature and humidity conditions to degrade effectively. Strategies to improve recyclability and disposal include developing bioplastics that can be composted under a broader range of conditions or better integrated into existing recycling systems. Understanding the safety and impact of bioplastics from a lifecycle and biodegradation perspective is essential to maximizing their sustainability potential and guiding responsible usage and disposal.

Research by Mayekar et al. has shown promising results in creating bioplastics with enhanced degradability in home composting conditions, addressing some of the limitations of industrial composting [95]. They explore the enhancement of PLA biodegradation through the incorporation of thermoplastic starch (TPS). In this research, the authors developed a PLA-g-TPS blend using a twin screw extrusion process, which involved adding a chemical modifier and peroxide radicals to facilitate the blending. The biodegradation of the resultant films was assessed over 180 days in simulated compost conditions at two temperatures, 37°C and 58°C, by measuring CO2 evolution and monitoring changes in molecular weight through size exclusion chromatography. The findings indicate that TPS significantly accelerates the degradation of PLA by enhancing its hydrophilicity and providing essential nutrients for microbial activity. This interaction promotes microbial hydrolysis of PLA, particularly during the initial stages of degradation, thereby improving its overall compostability. The study emphasizes that blending PLA with TPS can lead to complete biodegradation without leaving harmful microplastics, as both components decompose into benign substances like lactic acid and glucose. This research contributes valuable insights into improving PLA’s compostability in both industrial and home composting environments, addressing concerns related to plastic waste, and promoting sustainable waste management practices. The incorporation of TPS not only enhances the biodegradation rate of PLA but also aligns with environmental goals by reducing reliance on fossil-based plastics.

While bioplastics offer significant environmental benefits, their widespread adoption faces several challenges. Addressing scalability and production costs, improving material performance, and enhancing waste management and end-of-life options are critical for advancing the use of bioplastics. Ongoing research, technological advancements, and investments in infrastructure are essential for overcoming these challenges and realizing the full potential of bioplastics in creating a more sustainable future. Table 7 summarizes some of the challenges in bioplastic applications and their potential solutions.

As bioplastics continue to evolve, their prospects are shaped by emerging trends and innovations, industry-specific developments, and strategies to overcome current limitations. Looking ahead, several advancements in bioplastic technology are poised to revolutionize the field. One of the key areas of focus is the development of new biopolymers with enhanced properties. Innovations in bioplastic materials are expected to include improvements in mechanical strength, thermal stability, and functionality. For instance, advancements in polymer chemistry and material engineering are likely to produce bioplastics with performance characteristics that rival or exceed those of conventional plastics. Market trends favoring sustainability and regulatory pressures aimed at reducing plastic pollution drive the adoption of bioplastics, but advancements in production efficiency, cost reduction, and enhanced material properties are essential to enhance their competitiveness with conventional plastics. The integration of nanotechnology is anticipated to play a significant role in this evolution. Nanomaterials can enhance the mechanical and barrier properties of bioplastics, making them suitable for more demanding applications [96]. Nanotechnology enables the enhancement of bioplastic properties by incorporating nanomaterials, such as nanoclays or carbon nanotubes, which can improve strength, thermal stability, and barrier properties without significantly increasing weight [97,98]. This can lead to more robust applications in sectors like packaging and automotive, where performance is critical.

Additionally, artificial intelligence (AI) is becoming increasingly important in material science, including the development of bioplastics. AI algorithms can accelerate the discovery of new materials by predicting their properties and optimizing production processes. Machine learning models are being used to analyze vast datasets and identify patterns that lead to the development of high-performance bioplastics [99]. AI algorithms can analyze vast datasets to identify potential bio-based feedstocks and predict their suitability for specific bioplastic formulations. Machine learning models can also streamline the material design process by simulating how various compositions will perform under different conditions, thereby reducing the time and costs associated with traditional trial-and-error methods [100,101]. Furthermore, AI can optimize production processes by analyzing operational data in real-time, leading to improvements in efficiency, energy consumption, and waste reduction. Collectively, these technologies will not only enhance the performance and sustainability of bioplastics but also foster innovation in developing novel materials that meet the evolving demands of various industries.

Furthermore, the adoption of bioplastics is projected to grow across various industries, driven by increasing consumer demand for sustainable products and regulatory pressures. In the packaging industry, bioplastics are expected to see a rise in use as companies seek to reduce their environmental footprint. The food and beverage sector are major area of growth due to the demand for eco-friendly packaging solutions. Market analysts suggest that the global bioplastics market for packaging is projected to reach $30.9 billion by 2033, reflecting a compound annual growth rate (CAGR) of 10.3% [102]. In the automotive and aerospace industries, bioplastics are anticipated to become more prevalent as these sectors strive for weight reduction and improved sustainability. The development of high-performance bioplastic composites could lead to their increased use in structural components, contributing to fuel efficiency and reduced emissions. Moreover, the healthcare industry is likely to see expanded applications of bioplastics in medical devices and drug delivery systems, driven by advancements in material science and growing awareness of the benefits of biodegradable options.

To address the challenges currently faced by bioplastics, several strategies are being proposed. Enhancing scalability and cost-effectiveness is crucial for broader adoption. This can be achieved through advancements in production technologies, such as improved fermentation processes and the use of more cost-effective raw materials. Additionally, increasing production capacities and investing in infrastructure can help reduce unit costs and make bioplastics more competitive with traditional plastics. Improving the biodegradability and recyclability of bioplastics is another key focus. Research is ongoing to develop bioplastics that can degrade more effectively in various environmental conditions, including home composting setups. Moreover, creating bioplastics that can be easily integrated into existing recycling systems will enhance their end-of-life management and reduce environmental impact.

The prospects for bioplastics are promising, with emerging trends in technology and growing industry adoption paving the way for significant advancements. By addressing current limitations through strategic innovations and supportive policies, bioplastic has the potential to play a transformative role in creating a more sustainable and environmentally friendly future.

In conclusion, this comprehensive review has provided an in-depth examination of the evolution and progress of bioplastics, highlighting their sustainability, diverse applications, and challenges in the context of a circular economy. The increasing awareness of environmental issues and the need for sustainable solutions have driven the development of bioplastics as a viable alternative to traditional fossil-fuel-based plastics. While bioplastics offer several advantages, including biodegradability, renewable resource utilization, and reduced greenhouse gas emissions, their widespread adoption is hindered by challenges such as high production costs, limited scalability, and infrastructure constraints. Nevertheless, the prospects of bioplastics appear promising, with ongoing research and development focused on improving their properties, reducing costs, and enhancing their sustainability. As the world transitions towards a circular economy, bioplastics are poised to play a significant role in reducing plastic waste, mitigating the environmental impacts of traditional plastics, and promoting a more sustainable future.

Acknowledgement: The authors would like to thank the Department of Aerospace Engineering, Faculty of Engineering, Universiti Putra Malaysia, and Laboratory of Biocomposite Technology, Institute of Tropical Forestry and Forest Products (INTROP), Universiti Putra Malaysia, for the close collaboration in this research.

Funding Statement: The authors are grateful for the financial support given by the Ministry of Higher Education Malaysia (MOHE) under the Higher Institution Centre of Excellence (HICOE2.0/5210004) at the Institute of Tropical Forestry and Forest Products.

Author Contributions: Farah Syazwani Shahar was responsible for conceptualization, data curation, formal analysis, investigation, project administration, visualization, and the original draft preparation of the manuscript. Thinesh Sharma Balakrishnan contributed to the conceptualization, data curation, investigation, methodology, visualization, and review and editing of the manuscript. Mohamed Thariq Hameed Sultan was involved in the conceptualization, funding acquisition, supervision, and review and editing of the manuscript. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The authors confirm that the data supporting the findings of this study are available within the article.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Chauhan K, Kaur R, Chauhan I. Sustainable bioplastic: a comprehensive review on sources, methods, advantages, and applications of bioplastics. Polymer-Plastics Technol Mater. 2024 May 23;63(8):913–38. doi:10.1080/25740881.2024.2307369. [Google Scholar] [CrossRef]

2. Gong L, Passari AK, Yin C, Kumar Thakur V, Newbold J, Clark W, et al. Sustainable utilization of fruit and vegetable waste bioresources for bioplastics production. Crit Rev Biotechnol. 2024;44(2):236–54. doi:10.1080/07388551.2022.2157241. [Google Scholar] [PubMed] [CrossRef]

3. Jayarathna S, Andersson M, Andersson R. Recent advances in starch-based blends and composites for bioplastics applications. Polymers. 2022;14(21):1–24. doi:10.3390/polym14214557. [Google Scholar] [PubMed] [CrossRef]

4. Filho WL, Salvia AL, Bonoli A, Saari UA, Voronova V, Klõga M, et al. An assessment of attitudes towards plastics and bioplastics in Europe. Sci Total Environ. 2021 Feb 10;755:142732. doi:10.1016/j.scitotenv.2020.142732. [Google Scholar] [PubMed] [CrossRef]

5. Bishop G, Styles D, Lens PNL. Environmental performance comparison of bioplastics and petrochemical plastics: a review of life cycle assessment (LCA) methodological decisions. Resour Conserv Recycl. 2021 May 1;168:105451. doi:10.1016/j.resconrec.2021.105451. [Google Scholar] [CrossRef]

6. Sathiaseelan JJ, Afifah NMR, Abdullah AAA, Ramakrishna S, Vigneswari S, Bhubalan K. Exploring the advantages and limitations of degradation for various biodegradable micro-bioplastic in aquatic environments. J Environ Manage. 2024 Aug 1;366(2):121777. doi:10.1016/j.jenvman.2024.121777. [Google Scholar] [PubMed] [CrossRef]

7. Phosri S, Kunjiek T, Mukkhakang C, Suebthep S, Sinsup W, Phornsirigarn S, Charoeythornkhajhornchai P. Biodegradability of bioplastic blown film in a marine environment. Front Mar Sci. 2022 Aug 16;9:917397. doi:10.3389/fmars.2022.917397. [Google Scholar] [CrossRef]

8. Venâncio C, Lopes I, Oliveira M. Bioplastics: known effects and potential consequences to marine and estuarine ecosystem services. Chemosphere. 2022 Dec 1;309(9):136810. doi:10.1016/j.chemosphere.2022.136810. [Google Scholar] [PubMed] [CrossRef]

9. Palit S, Hussain CM. Bioplastics in marine environment—the insightful road to scientific wisdom. Bioplastics for Sustainability: Manufact, Technol, Environ. 2024 Jan 1;387–406. doi:10.1016/B978-0-323-95199-9.00017-2. [Google Scholar] [CrossRef]

10. Eronen-Rasimus EL, Näkki PP, Kaartokallio HP. Degradation rates and bacterial community compositions vary among commonly used bioplastic materials in a brackish marine environment. Environ Sci Technol. 2022 Nov 15;56(22):15760–9. doi:10.1021/acs.est.2c06280. [Google Scholar] [PubMed] [CrossRef]

11. Hossain MT, Shahid MA, Akter S, Ferdous J, Afroz K, Refat KRI, et al. Cellulose and starch-based bioplastics: a review of advances and challenges for sustainability. Polymer-Plastics Technol Mater. 2024;63(10):1329–49. doi:10.1080/25740881.2024.2329980. [Google Scholar] [CrossRef]

12. Li J, Wang Y, Xu C, Liu S, Dai J, Lan K. Bioplastic derived from corn stover: life cycle assessment and artificial intelligence-based analysis of uncertainty and variability. Sci Total Environ. 2024 Oct 10;946:174349. doi:10.1016/j.scitotenv.2024.174349. [Google Scholar] [PubMed] [CrossRef]

13. Ahmad A, Banat F, Alsafar H, Hasan SW. An overview of biodegradable poly (lactic acid) production from fermentative lactic acid for biomedical and bioplastic applications. Biomass Convers Biorefinery. 2022;14(3):3057–76. doi:10.1007/s13399-022-02581-3. [Google Scholar] [CrossRef]

14. Tecorralco-Bobadilla AL, Vázquez-Morillas A, González-Cardoso G, Sotelo-Navarro PX. Life cycle assessment (LCA) of bioplastics. In: Toxic effects of micro- and nanoplastics: environment, food and human health. Beverly, MA, USA: Scrivener Publishing LLC; 2024 Jan 1. p. 21–59. doi:10.1002/9781394238163.ch2. [Google Scholar] [CrossRef]

15. Main D. Think that your plastic is being recycled? Think again. | MIT Technology Review. 2023. Available from: https://www.technologyreview.com/2023/10/12/1081129/plastic-recycling-climate-change-microplastics/. [Accessed 2024]. [Google Scholar]

16. United Nations Development Programme. Why aren’t we recycling more plastic? by United Nations Development Programme—United Nations Development Programme | UNDP-Exposure. 2023. Available from: https://stories.undp.org/why-arent-we-recycling-more-plastic. [Accessed 2024]. [Google Scholar]

17. Karasik R, Lauer NE, Baker AE, Lisi NE, Somarelli JA, Eward WC, et al. Inequitable distribution of plastic benefits and burdens on economies and public health. Front Mar Sci. 2023 Jan 10;9. doi:10.3389/fmars.2022.1017247. [Google Scholar] [CrossRef]

18. Jiao H, Ali SS, Alsharbaty MHM, Elsamahy T, Abdelkarim E, Schagerl M, et al. A critical review on plastic waste life cycle assessment and management: challenges, research gaps, and future perspectives. Ecotoxicol Environ Saf. 2024 Feb 1;271:115942. doi:10.1016/j.ecoenv.2024.115942. [Google Scholar] [PubMed] [CrossRef]