Open Access

Open Access

ARTICLE

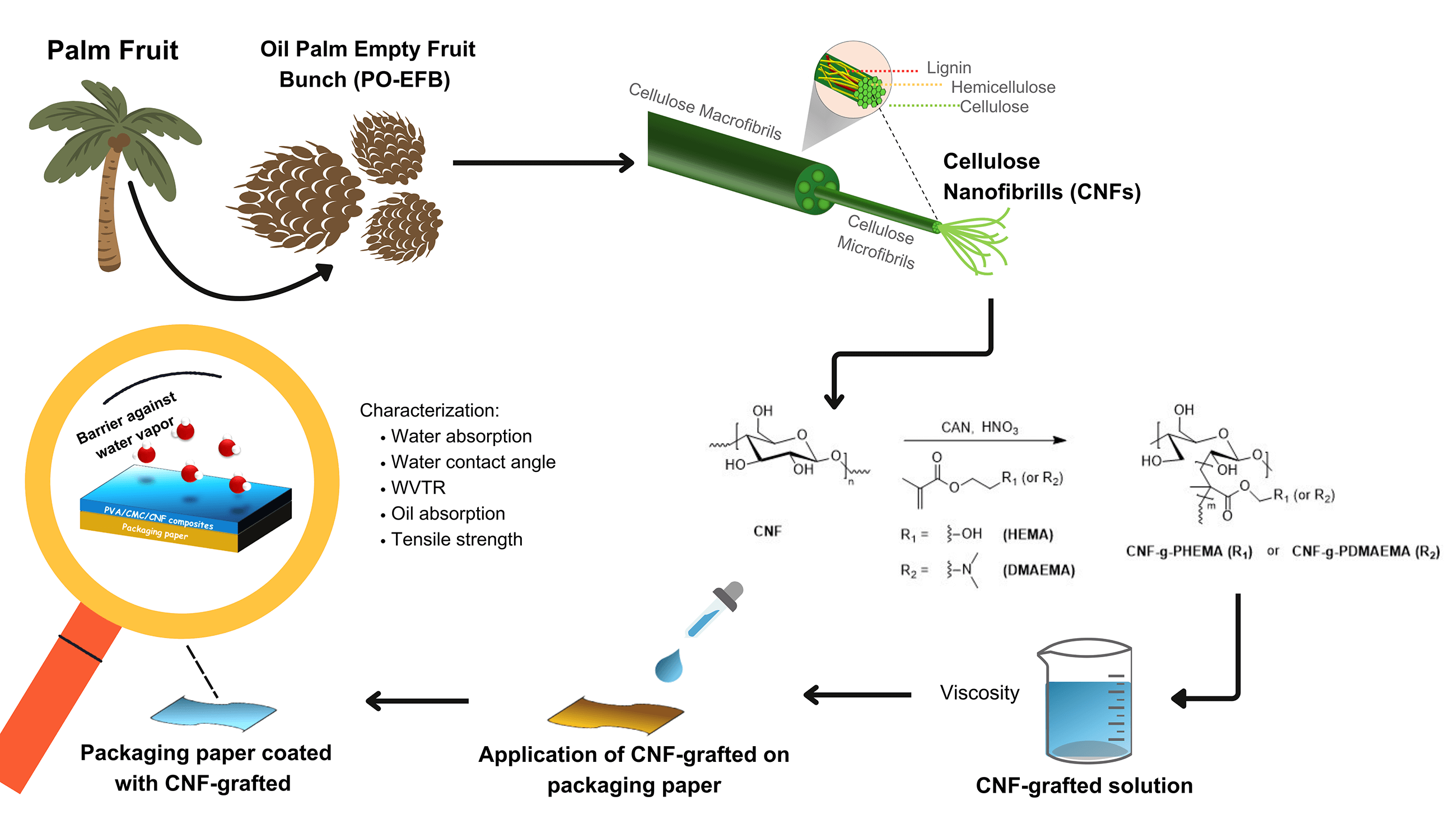

Grafting Modification of Cellulose Nanofibril with 2-(N,N-Dimethylamino) Ethyl Methacrylate and 2-Hydroxyethyl Methacrylate as a Barrier-Improved Coating for Paper-Based Food Packaging

1 Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Indonesia, Depok, 16424, Indonesia

2 Department of Chemical Engineering, Institut Teknologi Indonesia, Tangerang Selatan, 15314, Indonesia

3 Department of Metallurgical and Material Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia

* Corresponding Author: Noverra Mardhatillah Nizardo. Email:

Journal of Renewable Materials 2025, 13(6), 1209-1227. https://doi.org/10.32604/jrm.2025.02024-0068

Received 21 December 2024; Accepted 28 April 2025; Issue published 23 June 2025

Abstract

Food packaging is becoming popular as the consumption of ready-to-eat food products rises. Easy-to-use, non-biodegradable plastic packaging is commonly used in food packaging, contributing to the deteriorating environmental situation. This issue increases the concern for the environment and encourages the usage of alternative materials. Cellulose nanofibrils (CNF) are abundant and biodegradable, which makes them ideal candidates to replace plastic coatings. The ability to form H-bonds between the hydroxyl groups makes coated paper with CNF have good strength, but poor barrier properties. The barrier properties can be improved by grafting DMAEMA or HEMA onto CNF (CNF-g-PDMAEMA and CNF-g-PHEMA, respectively). Thus, the objective of this study was to modify CNF chemically to enhance the barrier properties of the food packaging paper. It was found that paper coated with CNF-g-PDMAEMA and CNF-g-PHEMA exhibited improvements in mechanical and barrier properties while maintaining the desired viscosity for the coating process. The water contact angle increased for paper coated with CNF-g-PHEMA and CNF-g-PDMAEMA, reaching a maximum of 97.51° and 92.58°, respectively with the decreasing Cobb60 values by 49% and 11%. The oil absorption was also reduced for both coated papers compared to the blank paper. Mechanical properties improved, as indicated by a 3% increase in tensile strength for paper coated with CNF-g-PHEMA and a 5% for paper coated with CNF-g-PDMAEMA. The results indicated significant potential for the application of modified CNF in coatings for food packaging paper. Noteworthy, the grafting process should be improved to enhance the mechanical and barrier properties of the coated paper.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools