Open Access

Open Access

ARTICLE

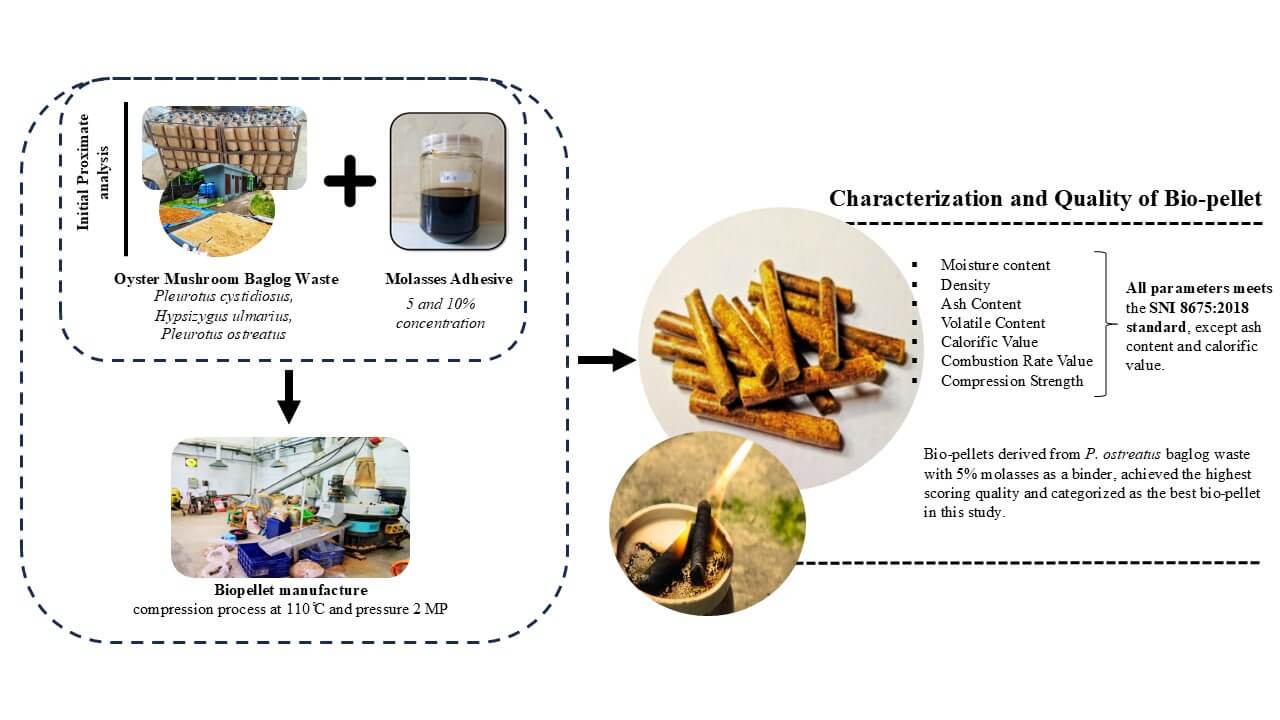

Molasses Adhesive Boosts Bio-Pellet Potential: A Study on Oyster Mushroom Baglog Waste

1 Research Center for Biomass and Bioproducts, National Research and Innovation Agency, Cibinong, 16911, Indonesia

2 Faculty of Biology, Universitas Jenderal Soedirman, Purwokerto, 53122, Indonesia

3 Research Center for Advance Material, National Research and Innovation Agency, Serpong, 15314, Indonesia

4 Research Center for Nanotechnology System, National Research and Innovation Agency, Serpong, 15314, Indonesia

* Corresponding Author: Sukma Surya Kusumah. Email:

(This article belongs to the Special Issue: Renewable and Biosourced Adhesives-2023)

Journal of Renewable Materials 2025, 13(9), 1765-1781. https://doi.org/10.32604/jrm.2025.02025-0014

Received 16 January 2025; Accepted 11 April 2025; Issue published 22 September 2025

Abstract

The increasing demand for renewable energy sources has driven the exploration of innovative materials for biofuel production. This study investigates bio-pellet characteristics derived from several oyster mushroom baglog wastes with varying concentrations of molasses as an adhesive. The process began with sun-drying the baglog waste for three days, followed by oven drying at 80°C for 24 h. Bio-pellets were produced by blending baglog waste with molasses at concentrations of 5% and 10% (w/v), then subsequently fed into a pellet mill. The bio-pellets were left to rest for one hour before analysis. The quality of bio-pellets was determined by evaluating moisture content, ash content, volatile matter, calorific value, combustion rate, density, and compressive strength following SNI 8675:2018 standards. Results indicate that adding molasses as a binder significantly affected the bio-pellet quality. The optimal molasses concentration for balanced performance was found at 5%, providing a lower moisture content (6.8%), volatile matter (68.42%), and density (1.55 g·cm−3). In addition, the bio-pellet has a slightly higher calorific value (approximately 3614 cal·g−1), compressive strength (40.68 N·mm−2), and ash content (18.59%). All of the parameters for the bio-pellet containing 5% molasses satisfied the standard except for ash content and calorific value.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools