Open Access

Open Access

ARTICLE

Improving the Environmental Friendliness of Glued Structures Made of Thermal Wood by Preliminary Low-Temperature Plasma Treatment

Department of Architecture and Design of Wood Products, Kazan National Research Technological University, Kazan, 420015, Russia

* Corresponding Author: Ksenia Saerova. Email:

(This article belongs to the Special Issue: Advances in Eco-friendly Wood-Based Composites: Design, Manufacturing, Properties and Applications – Ⅱ)

Journal of Renewable Materials 2025, 13(9), 1829-1840. https://doi.org/10.32604/jrm.2025.02025-0076

Received 04 April 2025; Accepted 31 July 2025; Issue published 22 September 2025

Abstract

This article presents research focused on developing and scientifically substantiating a technology for producing environmentally friendly glued structures from wood treated through a two-stage process. The methodology involves preliminary thermal modification followed by high-frequency low-temperature plasma treatment. Thermal modification enhances performance characteristics such as resistance to rot, lowers hygroscopicity, and increases dimensional stability. However, it can diminish the adhesive properties of wood, complicating the bonding process. To address this challenge, the study introduces high-frequency low-temperature plasma treatment, which activates the wood surface, improving wettability and adhesion while minimizing glue consumption. Experimental results indicate that plasma treatment reduces the contact angle by 46% and adhesive consumption during bonding by 24%, thereby enhancing the environmental friendliness of the glued structures. Furthermore, this dual treatment process increases the shear strength of adhesive joints by 22.7% and bending strength of glued beams by 66.6%, demonstrating a 30% lower carbon footprint compared to conventional methods. The findings affirm the efficacy of this technology in producing building materials, particularly glued beams for large-span structures.Keywords

Glued wood occupies a significant position in the construction industry due to its superior mechanical properties and ecological advantages. However, despite these merits, it faces several critical challenges, such as high hygroscopicity and low moisture resistance. For example, studies have shown that high hygroscopicity can lead to deformation and the failure of adhesive joints [1,2]. These drawbacks significantly reduce the longevity and reliability of wooden structures.

Existing modification methods, including thermal modification, have their limitations. Thermal modification enhances dimensional stability and resistance to decay by thermally decomposing certain components of the wood [3]. However, it can also diminish the adhesive properties, complicating the bonding processes [4,5]. The use of traditional adhesives, such as phenol-formaldehyde resins, often results in toxic emissions, posing an additional health and environmental concern [6].

In recent decades, researchers have begun exploring alternative modification techniques, including chemical and physical technologies such as plasma treatment. This method offers advantages in activating wood surfaces to enhance adhesion, making them more suitable for use in bonded joints [5]. Plasma treatment can increase the number of functional groups on the wood surface, potentially improving the bond with adhesives [6].

This study proposes an innovative approach that combines thermal modification with high-frequency low-temperature plasma treatment. This unique combination has not been extensively studied in the context of glued wood, underscoring the originality of this approach. This two-step method is designed not only to improve wood characteristics such as decay resistance and reduced hygroscopicity but also to activate the wood surface for enhanced adhesion, leading to stronger joints and reduced adhesive consumption.

The originality of this approach lies in its ability to create a synergistic effect that addresses challenges identified in previous studies. The objectives of this research include evaluating the effectiveness of this two-stage technology, analyzing its impact on the strength characteristics of adhesive joints, and reducing the carbon footprint in the production process.

Thus, this research aims to fill existing gaps in wood modification technology and develop novel, more environmentally friendly approaches that meet contemporary sustainable construction requirements.

As part of an experimental study of the dependence of the wetting angle by the lying drop method on the parameters of the modifying effect, wood samples made of pine, birch and oak species measuring 30 mm × 70 mm × 7 mm were used. The samples were obtained by sawing the raw material and then processing it on a jointing machine.

Taking into account the influence of the modulus of elasticity on the strength characteristics of wood [7,8], an additional study was conducted to determine the dependence of the modulus of elasticity in bending of glued structures perpendicular to the wood fibers on the pretreatment parameters.

For the experiment, 18 three-layer composite samples measuring 150 mm × 30 mm × 10 mm were prepared, divided into three groups of six samples each: the first group consisted of control samples without heat treatment; the second group underwent thermal modification at a temperature of 210°C; the third group was treated similarly to the second group, followed by high-frequency plasma treatment within 10 min. The layers were glued using urea-formaldehyde adhesive manufactured in accordance with GOST 14231-88 [9].

The estimated weight of the binder for creating a three-layer glued composition measuring 30 mm × 70 mm made of birch veneer was 20.16 g of urea-formaldehyde resin and 0.21 g of ammonium chloride.

To study the bending strength, the samples were divided into two categories: dry and moistened. Humidification was carried out in a desiccator with distilled water for 72 h at room temperature, and drying was carried out in a vacuum dryer at 103°C for 24 h. The strength characteristics were evaluated using a universal testing machine, where the samples were placed on supports with a distance of 100 mm between them.

2.2 Equipment for Thermal Modification of Wood Samples

The wood modification process is a comprehensive method that allows purposefully changing both the morphological structure of the material and its chemical composition, which makes it possible to achieve specified functional properties depending on the specifics of the requirements. Within the framework of this study, in order to reduce the hygroscopicity of wood and decrease the swelling pressure, a method of thermal modification of wood by convective blowing through a layer of material was investigated.

The results obtained from experimental studies of thermal modification were subsequently compared with data obtained using an alternative method—high-frequency low-temperature plasma treatment of wood particles.

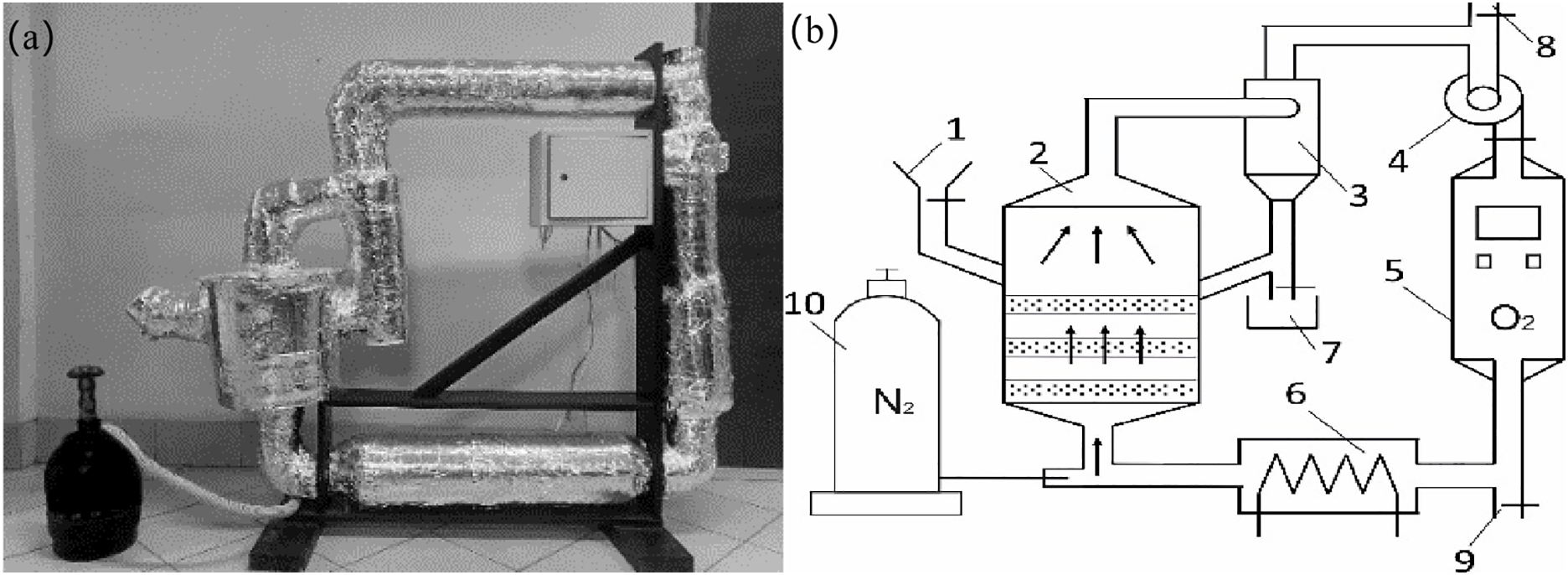

To carry out a detailed analysis of the wood filler, a specialized experimental setup was developed that provides thermal modification by convective blowing through the layer. The design diagram and appearance of this setup are shown in Fig. 1.

Figure 1: Experimental installation of thermal modification by convective blowing through a layer: (a) appearance; (b) scheme: where 1 is the neck; 2 is the hopper; 3 is the cyclone; 4 is the fan; 5 is the oxygen analyzer; 6 is the heating unit; 7 is the storage unit; 8, 9 is the damper; 10 is the gas cylinder (nitrogen)

The presented experimental setup operates on the basis of a cyclic process of thermal heating of a gaseous medium. The heat treatment of wood is carried out due to the thermal energy released by the heating device (6), which is transferred to the processed lumber located in the hopper (2) by convective heat exchange using a gas cylinder (10).

The principle of operation of the setup is as follows: the test material is pre-weighed and loaded into the hopper chamber (2) through the loading funnel (1). After activation of the electric panel, forced air circulation occurs inside the setup, while nitrogen is supplied to create an inert atmosphere. The gas mixture supply is automatically stopped when the oxygen content drops below 10%, which is monitored by a gas analyzer. The gas flow rate is regulated by changing the fan speed (4), which ensures the stability of the process without entraining small particles of the material.

For thermal modification, the set treatment temperature (180°C, 210°C, or 240°C) is established using a heating element. The cyclone (3) is used to collect possible mechanical impurities or wood dust entering the circulating gas stream, which ensures their accumulation in the collector. The heated gas medium circulates in a closed loop, ensuring uniform heating of the material.

Within the framework of the experimental studies, wood particles are heated to the set temperature according to the time interval specified in the experimental plan. Upon completion of the heat treatment, the heating element is deactivated, the gas supply is stopped, and then the hopper door opens for sample extraction and subsequent analysis.

The study employed the following methods:

1. Thermal Modification: treatment of wood at temperatures of 180°C–240°C to reduce hygroscopicity.

2. Plasma Treatment: utilization of low-frequency plasma to activate wood surfaces and enhance adhesion.

3. Experimental Measurements: evaluation of moisture resistance and strength of adhesive joints using standardized methods.

These methods were chosen for a comprehensive assessment of both the physical-mechanical and adhesive properties of wood.

2.4 Equipment for High-Frequency Low-Temperature Plasma Treatment of Thermally Modified Wood Samples

As part of achieving the set goal—to create a composite material with improved performance characteristics—wood samples subjected to preliminary thermal modification were additionally treated with high-frequency plasma modification.

The use of high-frequency plasma treatment of wood provides an increase in its wettability, which improves the adhesive properties of wood particles when interacting with a mineral binder. This phenomenon is a key factor in optimizing the technological processes for the production of wood-based composite materials.

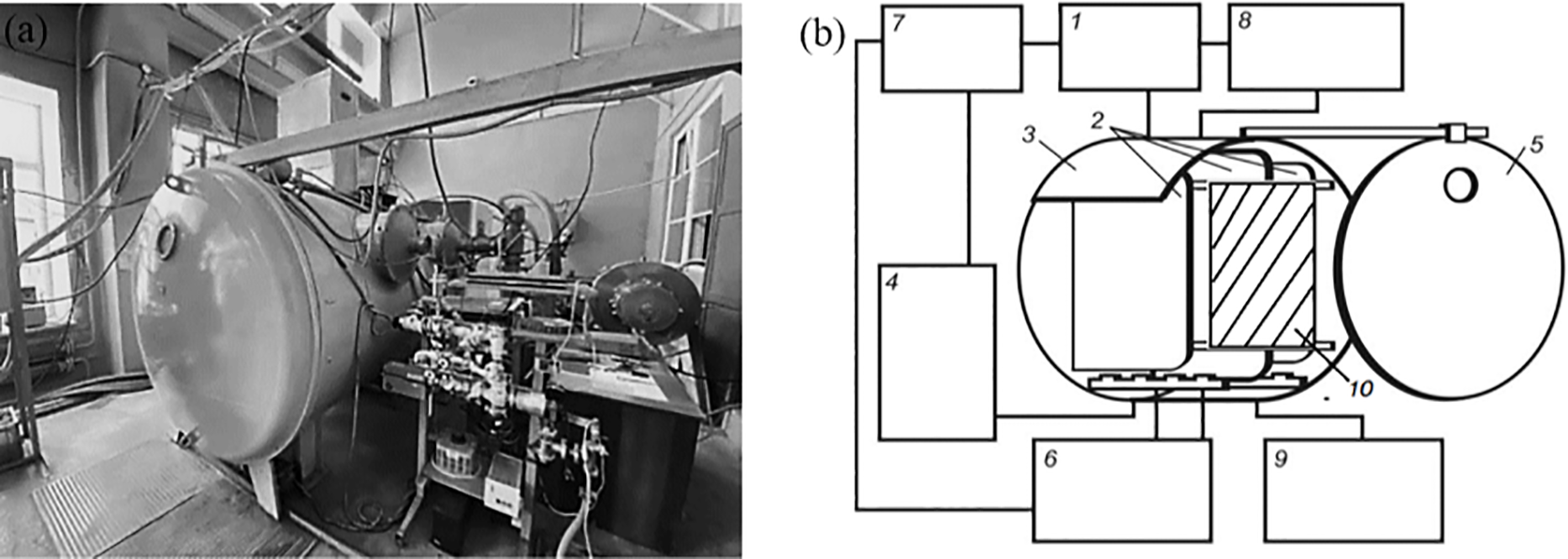

To carry out the plasma modification, a pilot plant for generating a high-frequency capacitive discharge was used, the design scheme and appearance of which are shown in Fig. 2a,b. The generation of a low-pressure high-frequency electron discharge (HF) was performed using an RF generator model VCHG6-80 with a frequency of 13.56 MHz.

Figure 2: Pilot industrial RF plasma installation: (a) appearance of the installation; (b) installation diagram: 1—RF generator; 2—electrodes (RF electrode-1 pc.; grounded electrode-2 pcs.); 3—vacuum chamber; 4—air pumping system with vacuum pumps, valves for creating and maintaining working pressure in the vacuum chamber; 5—the lid of the vacuum chamber; 6—the system for supplying working gases; 7—a control system that ensures the operation of the installation in automatic and manual modes; 8—cooling systems, including a cooling station; 9—diagnostic complex; 10—processed material

The generator’s design includes cabinet doors designed for servicing internal equipment. The doors of the generator unit are equipped with an electromechanical lock to ensure maintenance safety. The system controls are located on the front panel of the doors: control buttons, measuring instruments, an anode voltage regulation potentiometer, selsyns, warning lights, a stabilization unit, and control switches for the drives.

The wood samples were loaded into a UVM-16M type vacuum chamber for high-frequency plasma modification. The electrode system of the plasma torch consisted of three copper electrodes manufactured to ensure the effective generation of a high-frequency capacitive discharge at reduced pressure. For the convenience of loading modified materials and servicing the chamber, an end cap was used.

A special device for securing the processed samples was developed individually and installed between the electrodes, which made it possible to ensure an even distribution of the plasma flow along the entire length of the samples. A special matching unit was used to match the load and stabilize the processing mode in all areas of the chamber.

The plasma-forming gas was supplied and the pressure in the working chamber was automatically regulated through two channels using the RRG-10 regulator in the range of 1.33–133 Pa. The discharge in the chamber was generated using a combined system of vacuum pumps (DVM-1500 and AVZ-180). The pumping system included vacuum valves of types KVP-100, KVP-63, and KVP-25, bellows assemblies with diameters DN-100 and DN-63, as well as corresponding pipelines.

The installation could be controlled both automatically and manually thanks to the controller of the control system. The vacuum parameters were measured using PMT 6-3, PMM-32, and CMR-274 transducers. A water cooling station was used to prevent overheating of the installation components [10,11].

The modification of the wood samples was carried out by placing them in a gap between parallel, vertically positioned electrodes, where they were exposed to a stream of plasma-forming gas. The plasma-forming gas was selected based on an analysis of the results of preliminary studies. The process began with the preliminary evacuation of air from the chamber, followed by the supply of the working gas. The set pressure was adjusted by regulating the valve connecting the vacuum chamber to the vacuum unit.

The plasma stream was formed when a high-frequency voltage was applied to the electrodes, which caused the ionization of the plasma-forming gas. The plasma treatment mode was determined by the following parameters: gas flow (G) in the range of 10–50 g/s, high-frequency discharge power (Wp)—2 kW, pressure in the working chamber (P)—19.3–20.1 Pa, treatment duration (T)—10 and 20 min, process temperature—25°C–32°C. Air was used as the plasma-forming gas.

2.5 Physical Picture of the Process

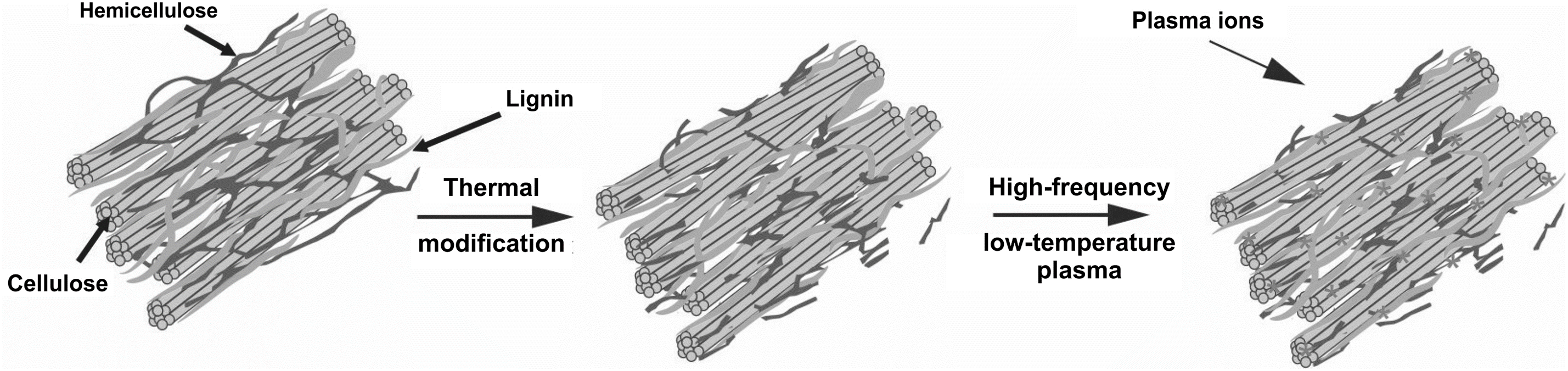

The method of sequential modification of wood, including preliminary heat treatment followed by high-frequency low-temperature plasma treatment, is an advanced approach to changing the physical, mechanical and chemical properties of this natural material. For a deeper understanding of the mechanism of this process, it is necessary to consider its fundamental aspects at the level of the macro- and micro-structure of wood.

The cell wall of wood can be represented as a complex mesh structure consisting of interconnected long-chain cellulose molecules supplemented with hemicellulose and filled with lignin [12]. By analogy with reinforced concrete, cellulose performs the function of a supporting frame, hemicellulose plays the role of a binder, and lignin acts as a binding component.

Cellulose, together with hemicellulose and proteins, forms a complex network, further strengthened by hydrogen bonds between cellulose molecules rich in hydroxyl groups [13,14]. The structural organization of the cell wall of natural wood is schematically shown in Fig. 3.

Figure 3: Scheme of the wood processing process by preliminary thermal modification and subsequent high-frequency low-temperature plasma treatment

As a result of thermal modification, partial thermal decomposition of hemicellulose occurs at temperatures in the range of 160°C–240°C. This process leads to a decrease in the concentration of hydroxyl groups in the volume of the wood, which significantly reduces its hygroscopicity throughout the material. In addition, reducing the hemicellulose content increases the bio-resistance of wood by decreasing the availability of nutrients for microorganisms. However, this transformation also causes changes in the mechanical properties: cell walls become less elastic and more brittle.

After thermal modification, the wood is exposed to high-frequency low-temperature air plasma. The choice of air as a plasma-forming gas is determined by its availability, economic efficiency, and environmental safety. Compared with other plasma-forming gases such as argon, oxygen, and nitrogen, air demonstrates similar functionality: it activates and modifies the wood surface due to the interaction of oxygen ions, which helps reduce the contact angle and improve the adhesive properties of the material.

The plasma treatment process is characterized by the bombardment of the wood surface with a stream of plasma ions, formed by a high-frequency electric discharge. The main purpose of this procedure is to optimize the surface properties of wood in order to increase its adhesion to various coatings and formulations.

Plasma exposure helps to modify the cell walls of wood by removing residual impurities and forming new active functional groups on its surface. This leads to an increase in the reactivity of the material’s surface and, consequently, to an improvement in its adhesive properties.

It is worth noting that the technology of thermal modification of wood is well studied in the literature [15,16], whereas the mechanism of high-frequency plasma treatment requires deeper theoretical analysis and fundamental substantiation. In this regard, a study was conducted on the molecular dynamics of the interaction of low-energy plasma-forming gas ions with wood under conditions of low-pressure high-frequency (HF) plasma.

2.6 Examination of Prepared Samples

Determination of the Contact Angle

An analysis of the properties of modified wood in relation to its wettability has been carried out. The study was conducted by measuring contact angles, which were recorded using microscopic equipment equipped with a special optical protractor [17]. The surface’s wettability reflects a wide range of technological characteristics of heterogeneous structures. Thus, in injection molding systems, this parameter has a key effect on the viscosity properties of the material, and in wood-mineral composite materials, it significantly determines the strength of adhesion between the wood and the binder used.

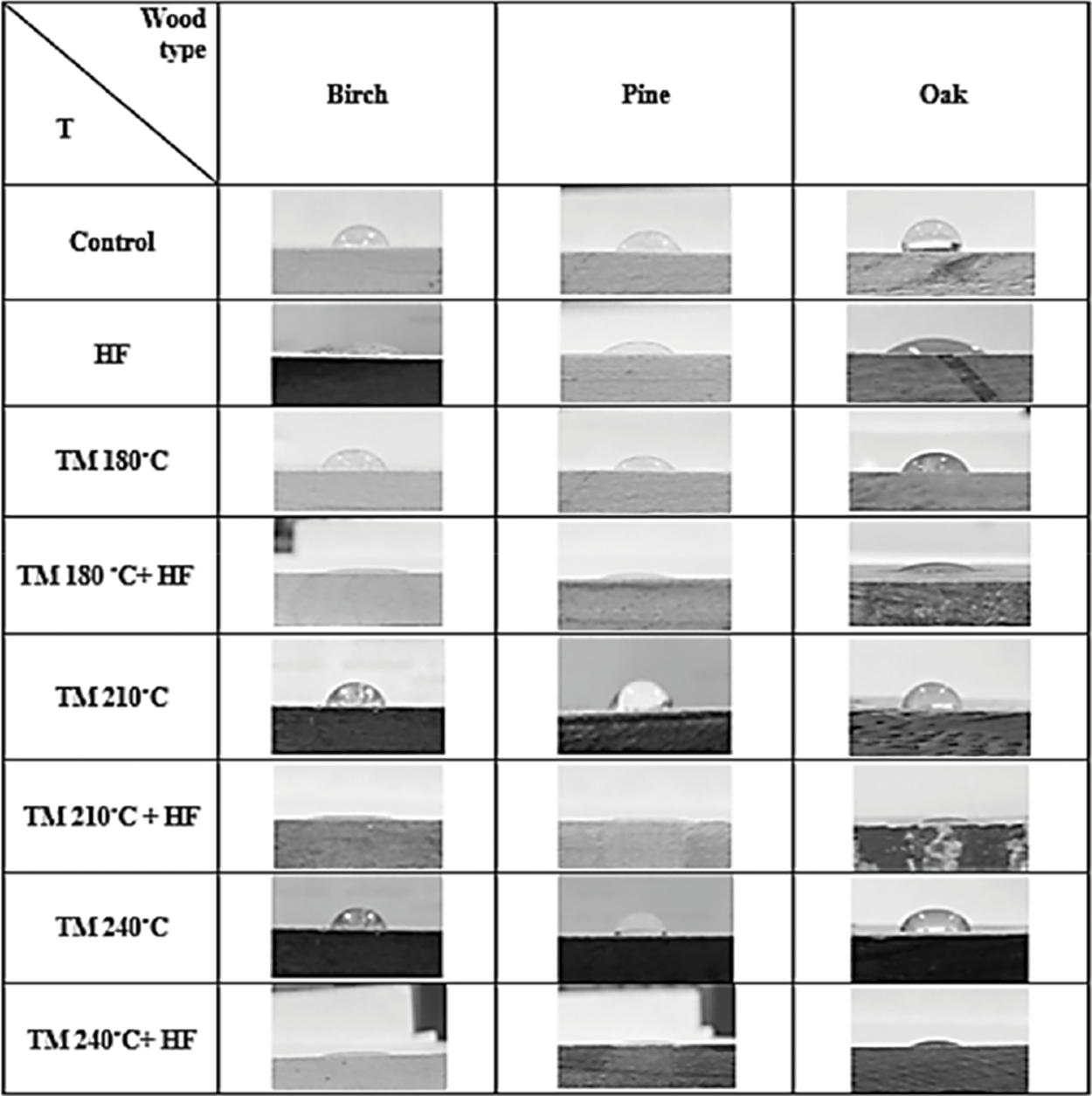

To date, many techniques have been developed for measuring contact angles [18–20]. Within the framework of this study, the sessile drop method was used to practically determine these angles on the surfaces of treated wood (Fig. 4), which was chosen due to its relative simplicity and ease of use.

Figure 4: Determination of the contact angle of processed and untreated wood samples, where TM is thermal modification and HF is high-frequency plasma treatment

The study aims to evaluate the influence of plasma treatment duration and thermal modification temperature on the performance of glued structures. To obtain comprehensive data, we conducted multiple experiments, varying the thermal treatment parameters, specifically focusing on different processing temperatures (180°C, 210°C, and 240°C) and durations of plasma treatment (10 and 20 min).

3.1 Influence of Thermal Modification and Plasma Treatment

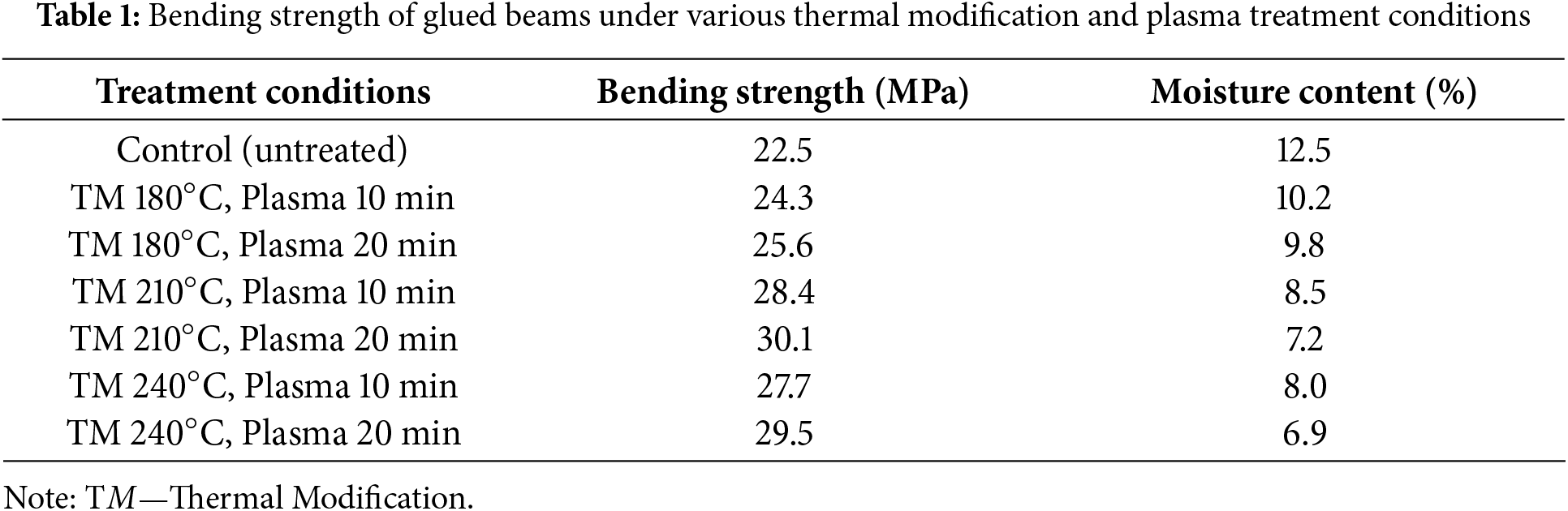

Table 1 summarizes the results of the bending strength tests for glued beams subjected to various thermal modification conditions and plasma treatment.

As shown in Table 1, the bending strength of the glued beams exhibited a clear trend toward improvement with increasing thermal modification temperature and plasma treatment duration what corresponds to the research [21–23]. The beams treated at 210°C with plasma treatment for 20 min showed the highest bending strength (30.1 MPa), indicating that this combination of parameters most effectively enhances the properties of the joints.

Conversely, at lower temperatures like 180°C, even with extended plasma treatment times, lower strength values were observed, suggesting that insufficient thermal processing limits the enhancement of adhesive properties [24,25]. Meanwhile, extreme temperatures, such as 240°C, demonstrate good results but can also lead to strength loss if the plasma treatment time is not optimized.

3.2 Influence of Plasma Treatment on the Wettability of Wood Surfaces

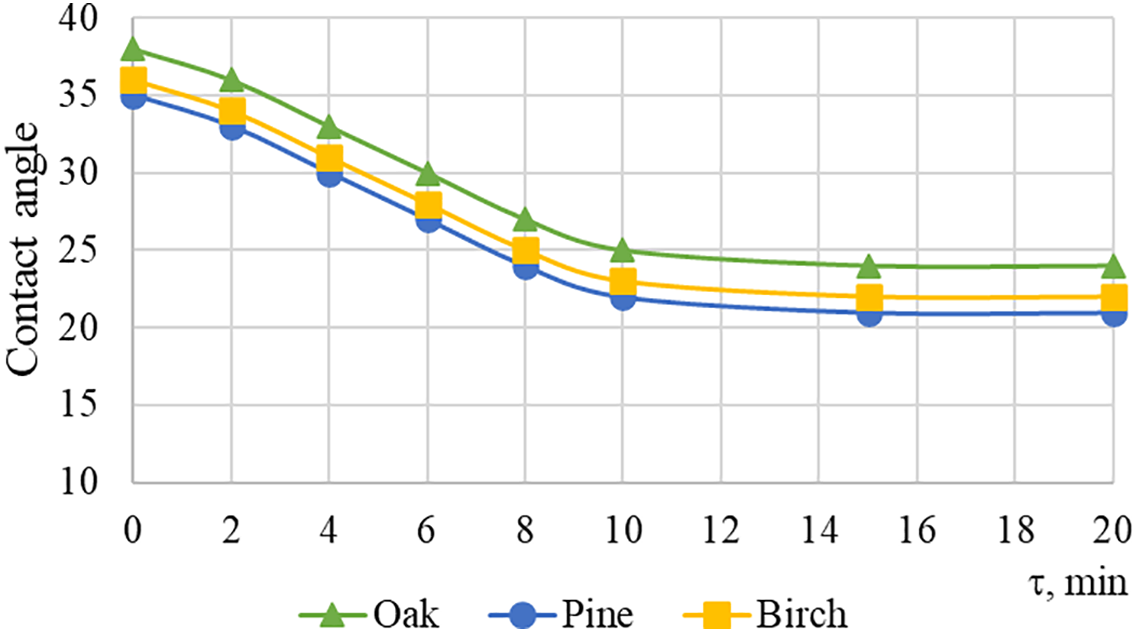

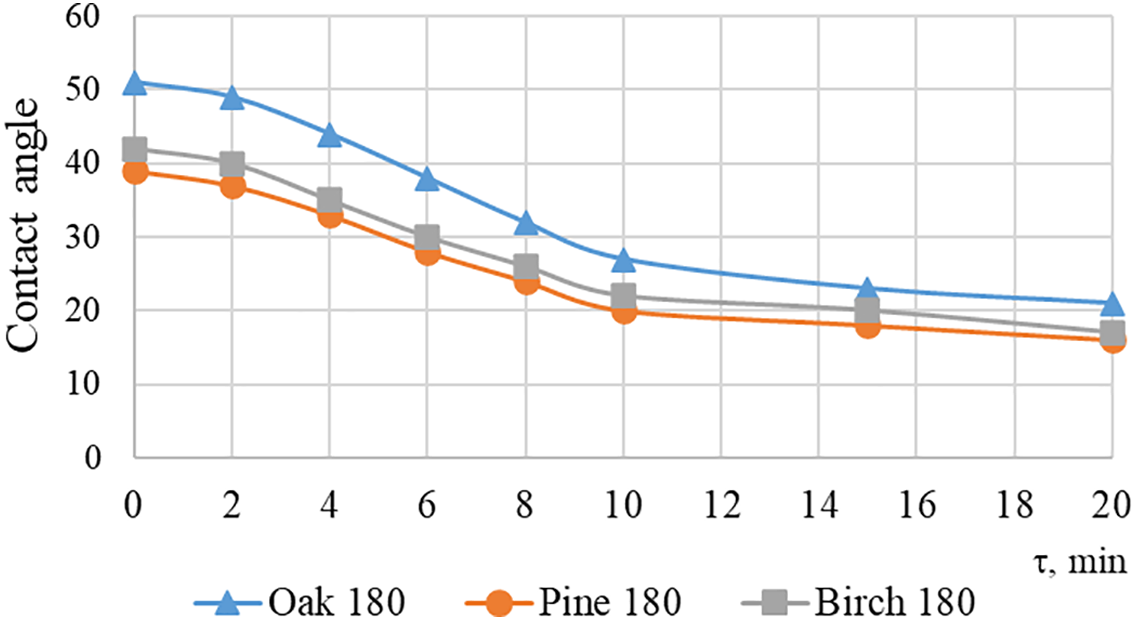

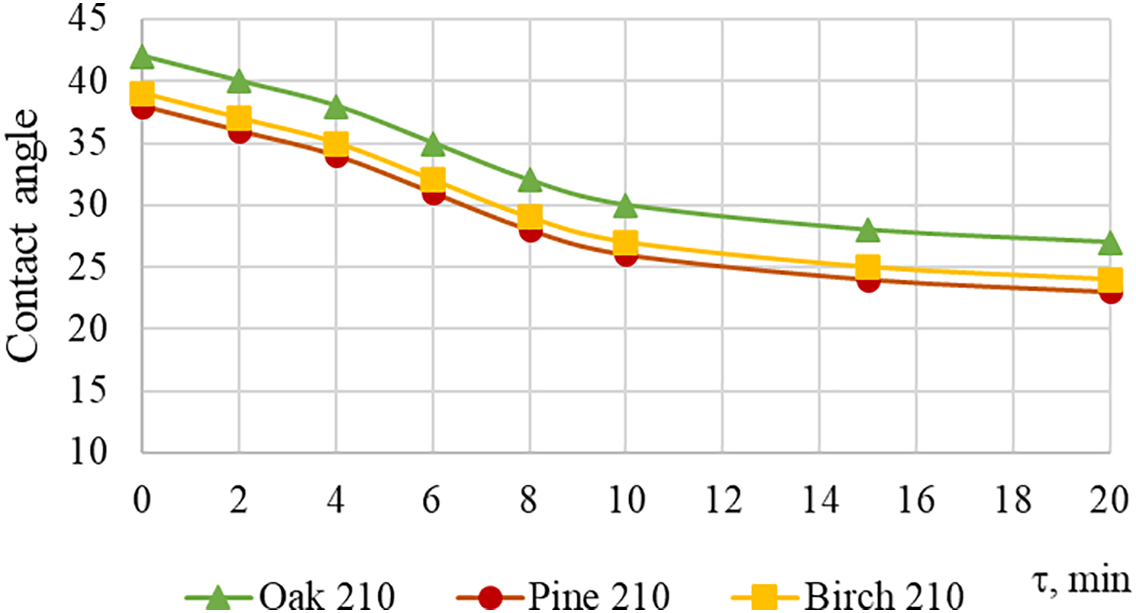

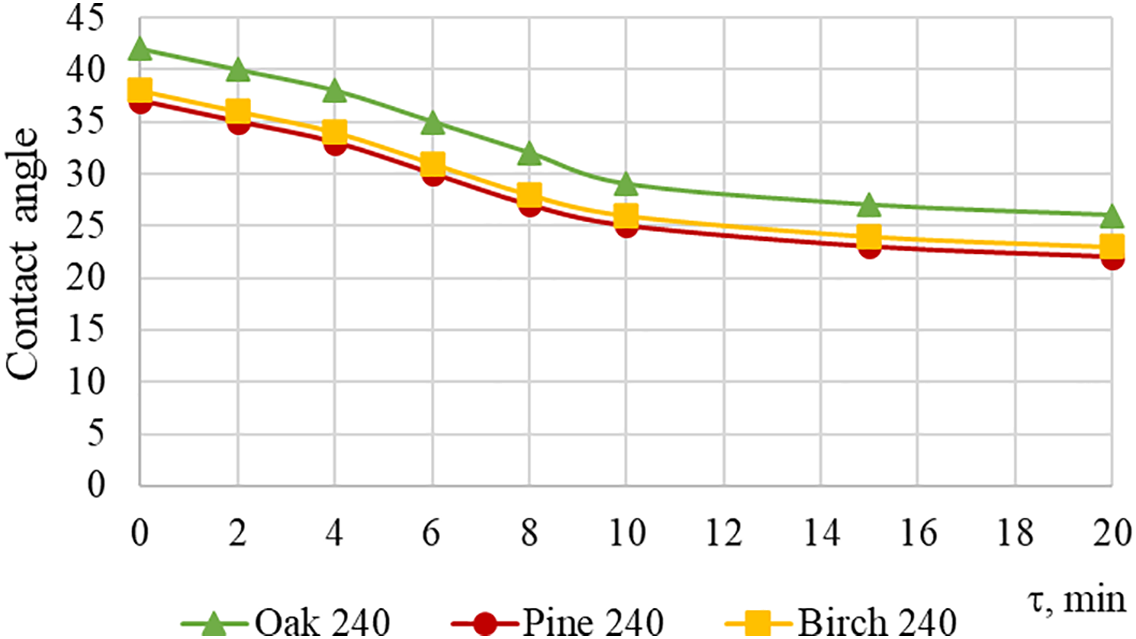

As a result of plasma treatment, a significant reduction in the contact angle of 46% was observed, improving the wettability and adhesion properties of the wood surface, further enhancing the adhesive characteristics. Figs. 5–8 show graphical dependences of the contact angle on the time of high-frequency low-temperature plasma treatment.

Figure 5: The effect of plasma treatment time on the contact angle of the control wood surface

Figure 6: The effect of plasma treatment time on the contact angle of a wood surface that has undergone 180°C thermal modification

Figure 7: The effect of plasma treatment time on the contact angle of the surface of wood that has undergone thermal modification at 210°C

Figure 8: The effect of plasma treatment time on the contact angle of the surface of wood that has undergone a thermal modification of 240°C

Analysis of the presented graphical data shows that, regardless of the wood species and the parameters of thermal modification, a significant decrease in the wetting angle is observed within the first ten minutes.

Thermal modification of wood veneer created hydrophobic surfaces, while plasma treatment caused hydrophilization of the surfaces without inducing morphological changes [18–20]. However, preliminary thermal modification followed by high-frequency low-temperature plasma treatment resulted in the formation of more hydrophilic surfaces than plasma treatment alone. This is due to the enhanced polar properties of the wood surface [26–28]. It is assumed that the improvement in the polar component of surface free energy during plasma treatment is mainly attributed to the formation of carboxyl groups in the lignin network. This corresponds to the high efficiency of plasma treatment of thermally modified wood, which is rich in lignin [29,30].

The developed technology of complex wood modification makes it possible to address key operational issues, namely: reducing hygroscopicity, which minimizes structural deformation; increasing the adhesion of adhesive joints; enhancing the mechanical strength of structural elements; and reducing the need for toxic adhesives.

The practical application of this technology opens up new opportunities for the production of building materials, including beams for large-span structures, sports and public facilities, as well as bridges requiring high reliability with minimal weight.

Thus, it is recommended to use two-stage wood processing when creating glued wooden structures, especially under conditions of high humidity.

The proposed technology addresses key challenges such as reducing hygroscopicity by 60%, improving dimensional stability, decreasing adhesive consumption by 24%, and increasing bending strength by 66.6%, making the resulting structures suitable for use in large-span applications.

Acknowledgement: The study was conducted using the equipment of the Joint Use Center Nanomaterials and Nanotechnologies at Kazan National Research Technological University.

Funding Statement: This research was funded by the Technostart competition, Agreement No. 12-22 (2-22) dated 01 February 2022.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: Ksenia Saerova, Ruslan Safin; data collection: Ksenia Saerova; analysis and interpretation of results: Ksenia Saerova, Ruslan Safin; manuscript draft preparation: Ksenia Saerova. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Data openly available in a public repository.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Wascher R, Kühn C, Avramidis G, Bicke S, Militz H, Ohms G, et al. Plywood made from plasma-treated veneers: melamine uptake, dimensional stability, and mechanical properties. J Wood Sci. 2017;63(4):338–49. doi:10.1007/s10086-017-1632-5. [Google Scholar] [CrossRef]

2. Huang Y, Wang J, Zhan X, Mei C, Li W, Deng Y, et al. Effect of plasma treatment on the surface characteristics and adhesive penetration performance of heat-treated wood. Holzforschung. 2022;76(10):941–53. doi:10.1515/hf-2022-0031. [Google Scholar] [CrossRef]

3. Hill C, Altgen M, Rautkari L. Thermal modification of wood—a review: chemical changes and hygroscopicity. J Mater Sci. 2021;56(11):6581–614. doi:10.1007/s10853-020-05722-z. [Google Scholar] [CrossRef]

4. Ebnesajjad S. Surface treatment of materials for adhesive bonding. Amsterdam, The Netherlands: William Andrew; 2014. doi: 10.1016/C2013-0-12914-5. [Google Scholar] [CrossRef]

5. van Blokland J, Olsson A, Oscarsson J, Daniel G, Adamopoulos S. Crack formation, strain distribution and fracture surfaces around knots in thermally modified timber loaded in static bending. Wood Sci Technol. 2020;54(4):1001–28. doi:10.1007/s00226-020-01190-5. [Google Scholar] [CrossRef]

6. Khasanshin RR, Saerova KV, Galyavetdinov NR, Salimgaraeva RV, Mukhametzyanov SR, Safin RR. The use of low-temperature plasma treatment to improve the mechanical performance of glued structures. Woodwork Ind. 2021;4(8):67–74. (In Russian). doi:10.3390/coatings11080918. [Google Scholar] [CrossRef]

7. Lekobou WP, Englund KR, Laborie MP, Pedrow PD. Influence of atmospheric pressure plasma treatments on the surface properties of ligno-cellulosic substrates. Holzforschung. 2016;70(1):55–61. doi:10.1515/hf-2014-0211. [Google Scholar] [CrossRef]

8. Sun F, Chen K, Tan Y, Peng H, Jiang J, Zhan T, et al. Experimental and numerical assessment of the orthotropic imbibition dynamics of wood. Wood Mater Sci Eng. 2023;18(2):607–17. doi:10.1080/17480272.2022.2057814. [Google Scholar] [CrossRef]

9. GOST 14231-88. Carbamide-formaldehyde resins. Technical specifications. Moscow, Russia: Publishing House of Standards; 1989. (In Russian). [Google Scholar]

10. Saerova KV, Safin RR, Galyavetdinov NR. High frequency low-temperature plasma treatment of thermally modified wood filler and its effect on the properties of filled polymers. Fibre Chem. 2025;56(5):334–9. doi:10.1007/s10692-025-10582-x. [Google Scholar] [CrossRef]

11. Talviste R, Galmiz O, Stupavská M, Ráhel J. Effect of DCSBD plasma treatment distance on surface characteristics of wood and thermally modified wood. Wood Sci Technol. 2020;54(3):651–65. doi:10.1007/s00226-020-01175-4. [Google Scholar] [CrossRef]

12. Girfanov AA, Safin RR, Saerova KV, Safina AV. The influence of methods of pretreatment of the wood surface on the penetrating ability of a flame retardant. Woodwork Ind. 2023;4:11–9. (In Russian). [Google Scholar]

13. Liu Z, Han C, Li Q, Li X, Zhou H, Song X, et al. Study on wood chips modification and its application in wood-cement composites. Case Stud Constr Mater. 2022;17(1):e01350. doi:10.1016/j.cscm.2022.e01350. [Google Scholar] [CrossRef]

14. Peng X, Zhang Z. Research of polypropylene (PP) decorative board surface painting used for wood product decoration and the paint film adhesion improvement by plasma. J Adhes Sci Technol. 2020;34(3):246–62. doi:10.1080/01694243.2019.1667139. [Google Scholar] [CrossRef]

15. Pétrissans A, Lin Y, Nguyen TN, Colin B, Quirino R, Rios-Teixeira P, et al. Influence of the heating rate on the thermodegradation during the mild pyrolysis of the wood. Wood Mater Sci Eng. 2023;18(2):412–21. doi:10.1080/17480272.2022.2039289. [Google Scholar] [CrossRef]

16. Timoshina YA, Voznesensky EF, Teptina AI, Zhelonkin YO. Model of the interaction of reactive gases with polymer materials in low-pressure radio-frequency plasma. High Energy Chem. 2023;57(1):S234–7. doi:10.1134/S0018143923070536. [Google Scholar] [CrossRef]

17. Voznesensky EF, Dresvyannikov AF, Mukhametshin AM. The influence of plasma treatment on the quality of natural leather production processes. Bull Kazan Technol Univ. 2005;2:269–73. (In Russian). [Google Scholar]

18. Callum ASH. Wood modification-chemical, thermal and other processes. Chichester, UK: John Wiley & Sons; 2006. 260 p. [Google Scholar]

19. Altgen D, Altgen M, Kyyrö S, Rautkari L, Mai C. Time-dependent wettability changes on plasma-treated surfaces of unmodified and thermally modified European beech wood. Eur J Wood Wood Prod. 2020;78(2):417–20. doi:10.1007/s00107-020-01505-0. [Google Scholar] [CrossRef]

20. Žigon J, Pavlič M, Kibleur P, Van den Bulcke J, Petrič M, Van Acker J, et al. Treatment of wood with atmospheric plasma discharge: study of the treatment process, dynamic wettability and interactions with a waterborne coating. Holzforschung. 2021;75(7):603–13. doi:10.1515/hf-2020-0182. [Google Scholar] [CrossRef]

21. Wang J, Minami E, Asmadi M, Kawamoto H. Effect of delignification on thermal degradation reactivities of hemicellulose and cellulose in wood cell walls. J Wood Sci. 2021;67(1):19. doi:10.1186/s10086-021-01952-0. [Google Scholar] [CrossRef]

22. Wang J, Minami E, Kawamoto H. Location of uronic acid group in Japanese cedar and Japanese beech wood cell walls as evaluated by the influences of minerals on thermal reactivity. J Wood Sci. 2021;67(1):3. doi:10.1186/s10086-020-01936-6. [Google Scholar] [CrossRef]

23. Hideno A. Thermal-degradation characteristics of mechanically nanofibrillated bleached pulps from hardwood and softwood. BioResources. 2023;18(4):8573–84. doi:10.15376/biores.18.4.8573-8584. [Google Scholar] [CrossRef]

24. Friedrich D. Thermoforming of wood-plastic composites: a compolytics-approach translating combined polymer and policy analyses into industrial design principles. Int J Adv Manuf Technol. 2023;124(10):3533–51. doi:10.1007/s00170-022-10760-9. [Google Scholar] [CrossRef]

25. Hänsel A, Tröger J, Rößler M, Brachhold N, Niemz P. Influence of surface treatment on the bonding quality of wood for load-bearing purposes. Wood Mater Sci Eng. 2023;18(6):2128–39. doi:10.1080/17480272.2023.2269138. [Google Scholar] [CrossRef]

26. Klébert S, Mohai M, Csiszár E. Can plasma surface treatment replace traditional wood modification methods? Coatings. 2022;12(4):487. doi:10.3390/coatings12040487. [Google Scholar] [CrossRef]

27. Capuder M, Bizjak Štrus N, Dahle S, Šega B, Šernek M. Influence of plasma surface treatment on bonding of beech wood with polyurethane adhesive. Les Wood. 2024;73(2):35–48. doi:10.26614/les-wood.2024.v73n02a04. [Google Scholar] [CrossRef]

28. Salehi S, Shokri A, Khani MR, Bigdeli M, Shokri B. Investigating effects of atmospheric-pressure plasma on the process of wound healing. Biointerphases. 2015;10(2):029504. doi:10.1116/1.4914377. [Google Scholar] [PubMed] [CrossRef]

29. Žigon J. Interactions of a waterborne coating with plasma pre-treated densified beech wood. Eur J Wood Wood Prod. 2021;79(6):1383–94. doi:10.1007/s00107-021-01716-z. [Google Scholar] [CrossRef]

30. Žigon J, Saražin J, Šernek M, Kovač J, Dahle S. The effect of ageing on bonding performance of plasma treated beech wood with urea-formaldehyde adhesive. Cellulose. 2021;28(4):2461–78. doi:10.1007/s10570-021-03687-z. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools