Open Access

Open Access

ARTICLE

A Digital Twin Driven IoT Architecture for Enhanced xEV Performance Monitoring

1 Department of Electrical and Electronics Engineering, GMRIT, Rajam, 532127, India

2 Department of Electrical and Electronics Engineering, Methodist College of Engineering and Technology, Hyderabad, 500001, India

3 Department of Electronics and Communication Engineering, Sasi Institute of Technology, Tadepalligudem, 534101, India

4 Department of Electronics and Communication Engineering, Koneru Lakshmaiah Education Foundation, Guntur, 522302, India

5 Energy Group, Cyient Ltd., Pune, 411036, India

* Corresponding Authors: Rajanand Patnaik Narasipuram. Email: ,

(This article belongs to the Special Issue: AI in Green Energy Technologies and Their Applications)

Energy Engineering 2025, 122(10), 3891-3904. https://doi.org/10.32604/ee.2025.070052

Received 07 July 2025; Accepted 18 August 2025; Issue published 30 September 2025

Abstract

Electric vehicle (EV) monitoring systems commonly depend on IoT-based sensor measurements to track key performance parameters such as vehicle speed, state of charge (SoC), battery temperature, power consumption, motor RPM, and regenerative braking. While these systems enable real-time data acquisition, they are often hindered by sensor noise, communication delays, and measurement uncertainties, which compromise their reliability for critical decision-making. To overcome these limitations, this study introduces a comparative framework that integrates reference signals, a digital twin model emulating ideal system behavior, and real-time IoT measurements. The digital twin provides a predictive and noise-resilient representation of EV dynamics, enabling enhanced monitoring accuracy. Six critical parameters are evaluated using root mean square error (RMSE), mean absolute error (MAE), maximum deviation, and correlation coefficient (R2). Results show that the digital twin significantly improves estimation fidelity, with RMSE for speed reduced from 2.5 km/h (IoT) to 1.2 km/h and R2 values generally exceeding 0.99, except for regenerative braking which achieved 0.982. These findings demonstrate the framework’s effectiveness in improving operational safety, energy management, and system reliability, offering a robust foundation for future advancements in adaptive calibration, predictive analytics, and fault detection in EV systems.Keywords

The growing global emphasis on sustainable transportation has accelerated the adoption of EVs as an alternative to conventional internal combustion engine vehicles. EVs promise reduced greenhouse gas emissions, improved energy efficiency, and lower operational costs, contributing to broader climate and environmental goals. However, their widespread deployment also introduces challenges associated with battery health, energy management, and the optimization of regenerative braking systems under diverse and dynamic driving conditions. Efficient, reliable, and accurate monitoring of these parameters is critical to maximize battery longevity, maintain driver safety, and ensure predictable and robust system performance. Traditional vehicle monitoring systems often rely on periodic measurements combined with offline data processing. While these approaches have supported vehicle operations for decades, they are fundamentally limited in their ability to respond to fast-changing environments and complex energy dynamics typical of modern EV operations. They can struggle to cope with sensor noise, latency, and real-time control requirements, which limits their practical use in high-performance EV energy management. To address these challenges, DT technology has emerged as a transformative and promising solution, offering a continuously updated virtual replica of a physical asset, seamlessly synchronized with live data streams from on-board sensors and communication channels. A digital twin (DT) bridges the gap between the physical and virtual domains, providing a powerful means to simulate, predict, and optimize system performance in real time [1]. These predictive capabilities can support data-driven decision-making, adaptive control, and advanced diagnostics.

Several studies have explored the application of DTs in automotive systems. For example, Karneddi et al. [2] demonstrated a digital twin model for battery state-of-health (SOH) estimation to improve lifecycle predictions. Zhang et al. [3] developed a DT framework for electric powertrain fault detection, demonstrating improved system reliability. Shen et al. [4] examined the role of DTs in managing EV charging infrastructure to balance grid demand, highlighting operational efficiencies. These works confirm the potential of DT technologies to transform EV operations and maintenance. Despite these important advances, there remains a significant gap: the lack of comprehensive frameworks that simultaneously integrate multiple key EV operational metrics, including vehicle speed, battery SoC, temperature, power consumption, motor RPM, and regenerative braking characteristics. An integrated and holistic DT framework encompassing all these parameters could provide more meaningful insights into their interdependencies, especially under variable driving profiles and user behavior. Such a unified approach would enable smarter, more adaptive energy management strategies, improve fault tolerance, and enhance overall system safety and performance.

To bridge this gap, this paper presents a multi-signal digital sensor dashboard framework that unifies reference trajectories, a predictive DT model, and realistic IoT-based sensor measurements. Six critical EV parameters vehicle speed, SoC, temperature, power consumption, RPM, and regenerative braking are monitored and analyzed in real time. The framework quantifies the performance difference between the DT and IoT measurements using root mean square error (RMSE), mean absolute error (MAE), maximum deviation, and correlation coefficient (R2), providing a holistic assessment of estimation accuracy. Comparative results demonstrate that the DT delivers superior tracking performance and reliability, with minimal deviation and high correlation to reference signals, even in the presence of sensor noise and communication uncertainties [5]. This comprehensive approach establishes a robust foundation for future research on predictive analytics, adaptive calibration, fault detection, and intelligent energy management strategies in next-generation EV systems.

The motivation for this study stems from the limitations of conventional EV monitoring systems, which often rely solely on IoT sensor data and are susceptible to noise, latency, and inaccuracies. These limitations hinder real-time decision-making and predictive diagnostics, especially under dynamic driving conditions. To address this, we propose a scientifically grounded framework that integrates a digital twin model with IoT-based measurements, enabling synchronized monitoring and predictive analysis.

The key innovations of this work include:

• A hybrid monitoring architecture that combines idealized digital twin simulations with real-world IoT sensor data.

• A multi-signal dashboard that visualizes and compares six critical EV parameters in real time.

• A comprehensive performance evaluation using RMSE, MAE, maximum deviation, and R2 metrics across all signals.

• Demonstrated improvements in estimation accuracy and system reliability, validating the digital twin’s role in enhancing EV monitoring and control.

Recent advancements in electric vehicle (EV) technologies have emphasized the need for robust monitoring systems capable of handling dynamic operational conditions. Traditional IoT-based frameworks have been widely adopted for real-time data acquisition in EVs, focusing on parameters such as speed, battery state of charge (SoC), temperature, and power consumption. However, these systems often suffer from limitations including sensor noise, latency, and lack of predictive capabilities [1].

To address these challenges, digital twin (DT) technology has emerged as a promising solution. A digital twin is a virtual replica of a physical system that continuously updates based on real-time data, enabling predictive analytics and enhanced system control. Ref. [2] demonstrated the use of digital twins for battery state-of-health (SOH) estimation, improving lifecycle prediction accuracy. Ref. [3] developed a DT-based fault detection system for EV powertrains, showing improved reliability and fault isolation capabilities.

Ref. [4] explored the integration of digital twins with EV charging infrastructure, highlighting benefits in grid load balancing and operational efficiency. Similarly, Ref. [5] reviewed the application of digital twins in microgrid environments, emphasizing their role in real-time simulation and control. These studies collectively underscore the transformative potential of digital twins in enhancing EV performance, safety, and energy management.

Despite these advances, most existing works focus on isolated parameters or specific subsystems. There remains a gap in developing comprehensive frameworks that integrate multiple EV metrics such as speed, SoC, temperature, RPM, power consumption, and regenerative braking into a unified monitoring and evaluation system. This study addresses that gap by proposing a multi-signal dashboard that combines reference signals, digital twin predictions, and IoT-based measurements, offering a holistic and comparative assessment of EV performance.

The major contributions of this study are summarized as follows:

⮚ Developed a multi-signal digital sensor dashboard that simultaneously visualizes reference signals, DT predictions, and IoT-based measurements for six key EV parameters.

⮚ Established a comprehensive performance evaluation framework incorporating quantitative metrics, including RMSE, MAE, maximum deviation, and correlation coefficient (R2).

⮚ Provided a holistic and comparative assessment of the tracking accuracy and reliability of the DT vs. IoT measurements, highlighting its superior performance under realistic sensor and communication uncertainties.

The organiztion of this paper is structured as follows. Section 2 describes the architecture of the proposed DT framework. Section 3 details the mathematical evaluation of the monitored parameters. Section 4 presents and discusses the experimental results. Finally, Section 5 concludes the paper and outlines potential directions for future research.

2 Design Architecture for EV Monitoring

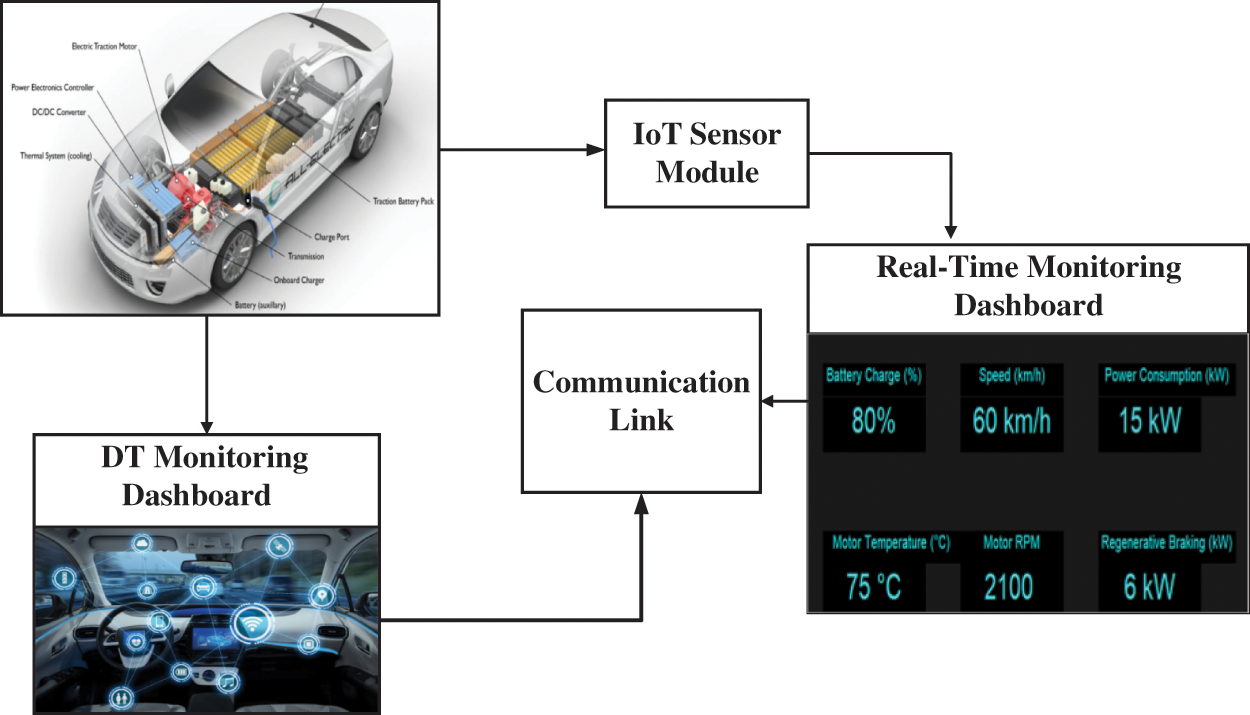

The proposed system architecture, as illustrated in the block diagram, presents a comprehensive framework for real-time monitoring and control of EV powertrains by integrating IoT technology with DT modeling. The physical system comprises critical components such as the EV powertrain, battery pack, and motor, which continuously generate operational parameters including vehicle speed, battery SoC, and system temperature [6,7]. These parameters are captured in real-time through an IoT sensor module and transmitted via a reliable communication link. Simultaneously, this sensor data feeds into a cloud- or edge-hosted DT model, which virtually replicates the physical behavior of the EV system.

Fig. 1 depicts the block diagram of the proposed IoT-integrated DT framework for real-time monitoring and control of EV system. The DT not only mirrors real-time dynamics but also facilitates predictive analysis, anomaly detection, and performance optimization. The processed outputs from both the physical system and its digital counterpart are visualized through a real-time monitoring dashboard, enabling continuous comparison between actual and simulated states. Furthermore, the system incorporates a feedback/control loop that uses the insights from the dashboard and DT to regulate the physical system’s behavior, thereby enhancing the safety, efficiency, and reliability of EV operations. This integrated IoT-DT framework offers a scalable and intelligent solution for advanced energy management and predictive maintenance in next-generation electric mobility systems.

Figure 1: IoT-integrated DT framework for real-time monitoring and control of EV

2.1 IoT-Based Monitoring System for EV’s

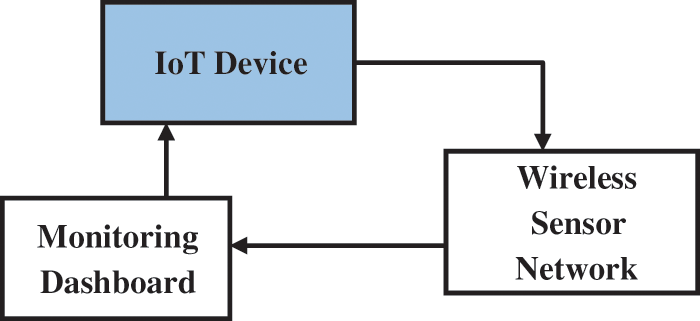

The IoT-based monitoring system provides a robust framework for real-time acquisition, transmission, and visualization of critical EV performance parameters. As depicted in Fig. 2, the physical EV system—including key components such as the powertrain, battery pack, and electric motor—is equipped with an array of IoT-enabled sensors [8]. These sensors are responsible for continuously monitoring essential metrics such as vehicle speed, battery SoC, and temperature. The sensor data is transmitted to a central monitoring system through a secure communication link, which may involve wireless sensor networks (WSNs), edge devices, or cloud platforms depending on the application. This real-time data is visualized and analyzed through a real-time monitoring dashboard, which serves as a centralized user interface for operators to observe system behavior, assess operational health, and issue corrective actions when necessary [9].

Figure 2: IoT based monitoring system

To enhance the system’s intelligence and adaptability, the IoT data is also fed into a DT, which simulates the behavior of the EV system based on both historical and live data. The DT allows for predictive analytics, anomaly detection, and virtual testing of control strategies. A feedback/control loop enables the dashboard and the DT model to send optimized control signals back to the physical system, thereby improving operational safety, performance, and energy efficiency [10]. This integrated IoT-DT ecosystem offers a scalable solution for advanced EV fleet management, fault diagnosis, and smart grid integration.

2.2 DT Framework for EV Monitoring

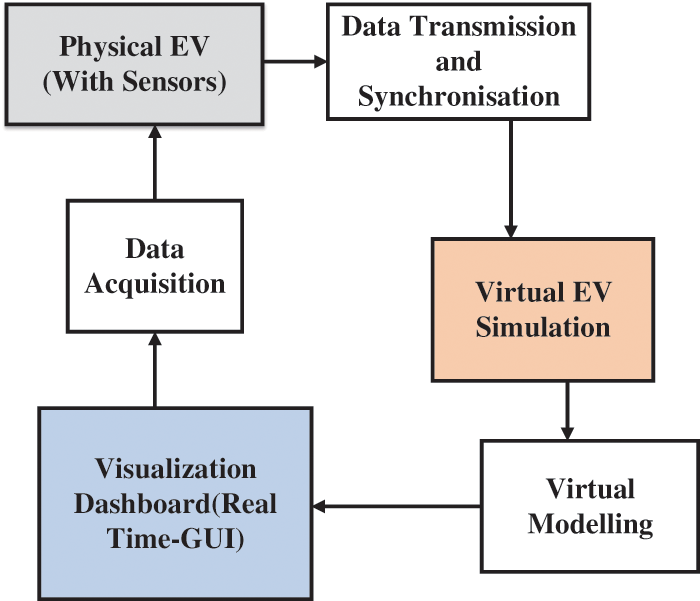

The DT framework illustrated in Fig. 3 presents a systematic architecture for real-time monitoring, simulation, and analysis of EV performance. The system initiates with a physical EV equipped with embedded sensors for capturing dynamic parameters such as speed, temperature, voltage, and SoC. These parameters are collected through a data acquisition system, which forms the basis for real-time tracking and analysis. Once the data is acquired, it undergoes transmission and synchronization, ensuring accurate temporal alignment between the physical and virtual environments. This data is then transmitted to a virtual EV model, which operates as a simulated representation of the real-world EV.

Figure 3: DT framework for EV monitoring systems

The virtual modeling block uses this synchronized data to continuously update the behavior of the digital counterpart, enabling predictive analytics, performance diagnostics, and optimization strategies. Both the physical and virtual systems are interconnected and visualized through a real-time graphical user interface (GUI) dashboard, allowing for intuitive monitoring, diagnostics, and feedback control [11]. This dashboard serves as a central visualization tool that integrates data from the physical EV and its DT, supporting informed decision-making and operational adjustments. Such a framework enhances the reliability, safety, and efficiency of EV operation by leveraging real-time sensor data, simulation accuracy, and advanced human–machine interaction.

In this architecture, DT serves not only as a monitoring tool but also as a basis for developing advanced optimization strategies for energy-efficient driving, effective thermal management, and extended battery life [12].

The improvement in safety, performance, and energy efficiency is achieved through the real-time monitoring and predictive modeling of six key parameters:

• Vehicle Speed: Enables accurate tracking of acceleration and deceleration patterns, which supports adaptive control and collision avoidance strategies.

• Battery SoC: Facilitates precise energy management and range prediction, reducing the risk of unexpected battery depletion.

• Motor Temperature: Allows thermal diagnostics to prevent overheating, thereby enhancing system safety and extending motor lifespan.

• Power Consumption: Supports dynamic load profiling and energy budgeting, contributing to efficient drive cycle planning.

• Motor RPM: Ensures drivetrain stability and helps detect anomalies in rotational dynamics.

• Regenerative Braking: Improves energy recovery during deceleration, directly enhancing overall energy efficiency.

By integrating these parameters into a synchronized digital twin model, the framework enables predictive analytics and real-time feedback control, which collectively contribute to safer and more energy-efficient EV operation.

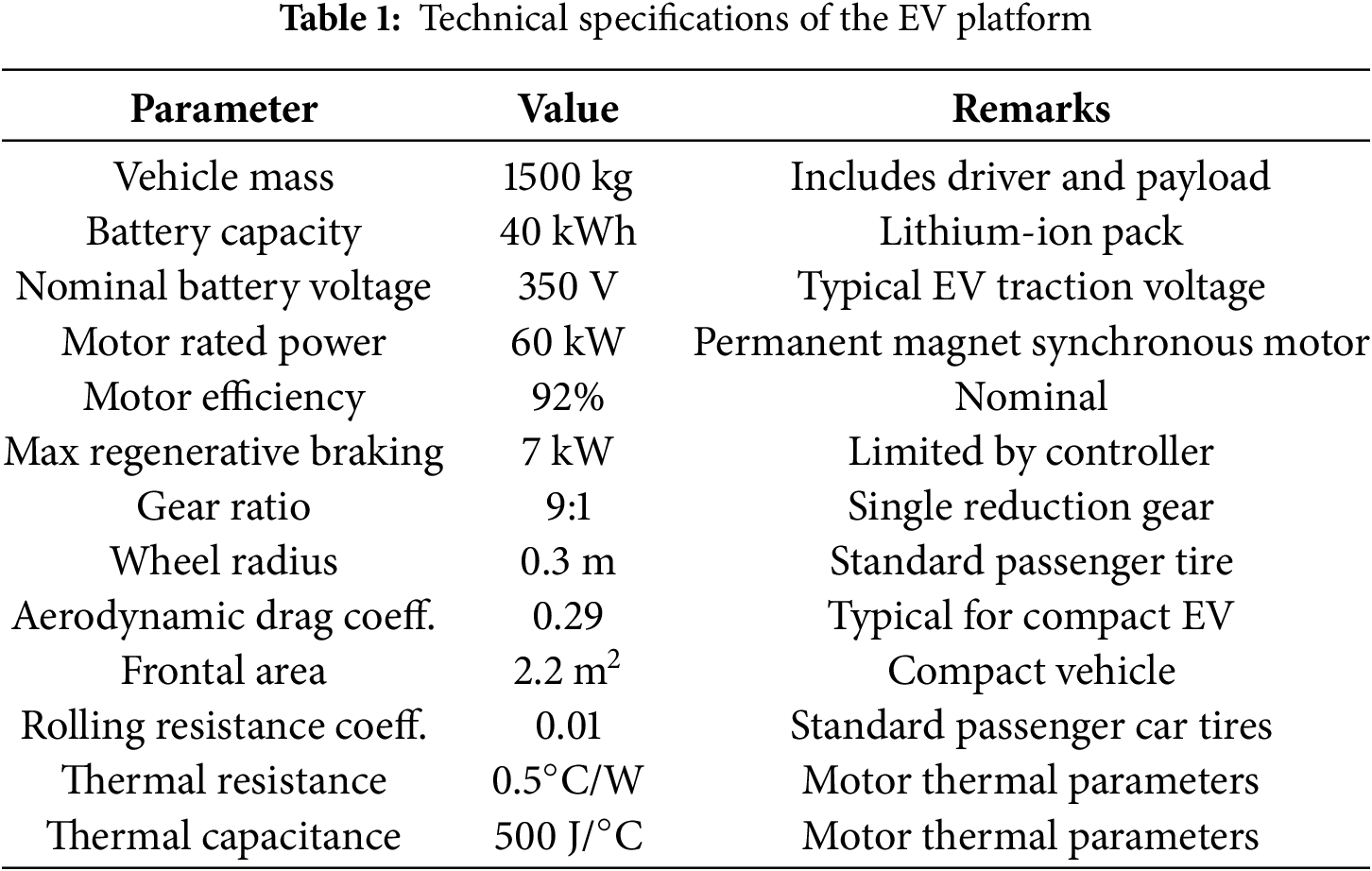

This section outlines the mathematical modeling of six key EV performance parameters evaluated within the proposed DT framework. The selection of six key parameters like vehicle speed, SoC, power consumption, motor temperature, RPM, and regenerative braking was based on their critical role in determining EV performance, energy efficiency, and safety. These variables are commonly monitored in EV systems and are directly influenced by driving behavior, load conditions, and environmental factors.

The mathematical models used for each parameter were chosen to balance computational efficiency with physical accuracy. For example, the SoC model incorporates both traction load and regenerative recovery, while the motor temperature model uses a first-order thermal RC network to simulate heating and cooling dynamics.

Input parameters such as vehicle mass, battery capacity, and motor efficiency were derived from standard EV specifications (see Table 1) and validated against typical urban driving profiles. The digital twin was calibrated using these parameters to emulate ideal system behavior, while the IoT data introduced real-world variability.

The battery state of charge is updated based on the balance of traction power consumption and regenerative braking recovery. This formulation of Eq. (1) captures the net SoC evolution under load and regenerative energy injection.

where, Pload(t) is the traction power demand (kW), Pregen(t) is the regenerative braking power (kW), Vbatt is the nominal battery voltage (V), Cbatt is the battery capacity (Ah), and Δt is the sampling interval.

The vehicle speed dynamics under acceleration and braking phases can be described by a discrete-time kinematic update in Eq. (2). And the acceleration term can be derived from the available motor power as shown in Eq. (3).

where:

• v(tk+1) is the vehicle speed at the next time step (m/s),

• v(tk) is the current vehicle speed (m/s),

• a(tk) is the acceleration at time tk (m/s2),

• Δt is the sampling time interval (s).

where, m as the vehicle mass (kg), ηtrac the drivetrain efficiency, and Pmotor(t) the motor power (kW).

The instantaneous power consumption is related to motor torque and speed. Eq. (4) supports the observed triangular variation in power consumption around 18 kW in typical drive cycles.

where, Tm(t) is motor torque, ωm (t) = 602 πRPM, motor speed (rad/s), ηm is motor efficiency.

The thermal evolution of the motor during repeated drive/brake phases can be modeled using an RC lumped parameter thermal model. Eq. (5) describes the heating and cooling phases typically observed in traction drive systems:

where, Cth is the thermal capacitance of the motor (J/K), Rth is the thermal resistance (K/W), Tamb is the ambient temperature, and Ploss(t) is the sum of copper and iron losses in the motor.

The nearly constant motor RPM observed around 2100 rpm during steady cruising can be approximated by Eq. (6) allows speed-based estimation of RPM for virtual sensing.

where, rw is the wheel radius (m), G is the total gear ratio of the drivetrain.

The power recovered during regenerative braking can be modeled as shown in Eq. (7) model the periodic ripples observed when regenerative control is active during deceleration.

where,

To evaluate the efficacy of the proposed DT framework, a comprehensive set of simulations was conducted to emulate EV behavior under typical urban driving scenarios. The DT model was implemented in MATLAB/Simulink, based on the mathematical formulations presented in Section 3 [13]. Six key operational parameters were analyzed: battery SoC, vehicle speed, power consumption, motor temperature, motor RPM, and regenerative braking power. Table 1 summarizes the technical specifications of the EV platform considered in this study.

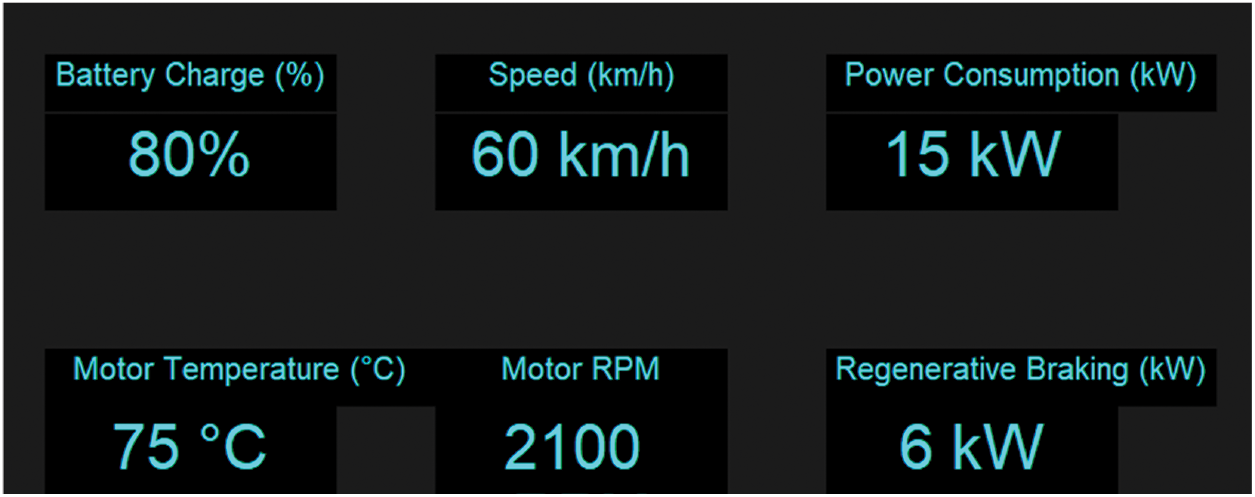

These values are used both in the physical EV and in the DT virtual model to ensure consistency between real-time data and simulation. Fig. 4 illustrates the digital display of dynamic profiles of these signals over a 100-s urban driving cycle.

Figure 4: The digital display of dynamic profiles of these signals over a 100-s urban driving cycle

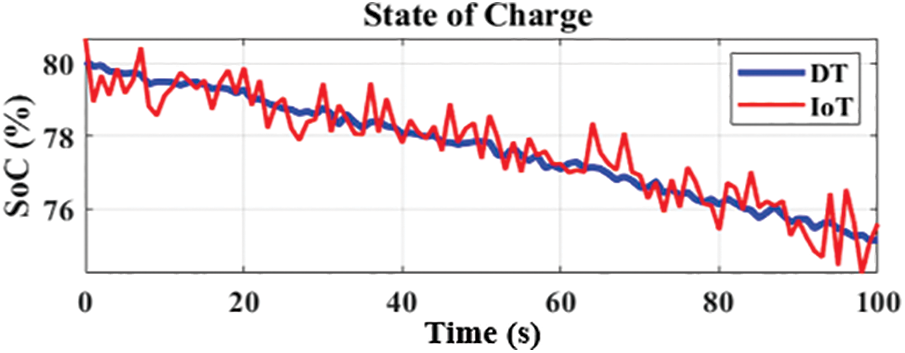

The simulated SoC profile in Fig. 5 demonstrates a characteristic sawtooth pattern, reflecting charge depletion during propulsion phases and partial recovery during deceleration via regenerative braking. The average SoC declined from an initial 85% to approximately 70% over the course of the simulation, closely replicating real-world discharge trends typical of stop-and-go urban traffic.

Figure 5: SoC monitoring using IoT and DT

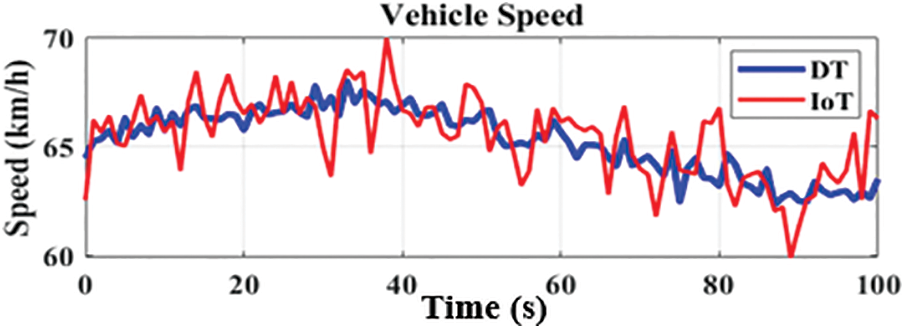

The vehicle speed profile shown in Fig. 6 exhibits realistic fluctuations between 50 and 80 km/h, consistent with urban driving conditions involving acceleration, cruising, and deceleration. The DT model captures transient dynamics effectively, with minimal deviation from the expected speed trajectory.

Figure 6: Vehicle speed monitoring using IoT and DT

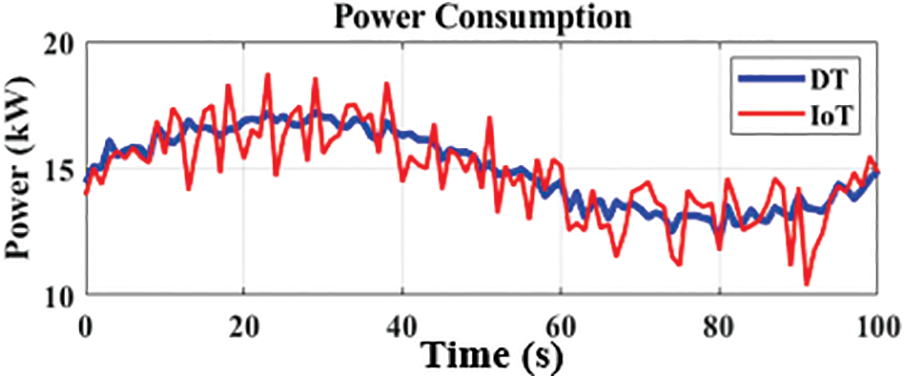

Fig. 7 shows that power consumption varies dynamically between 12 and 20 kW range, responding to instantaneous changes in speed and acceleration demand. Peak power values correspond to rapid acceleration events, while troughs align with coasting or regenerative braking intervals. The results confirm that the energy management strategy embedded in the DT accurately models the vehicle’s power requirements.

Figure 7: Power consumption monitoring using IoT and DT

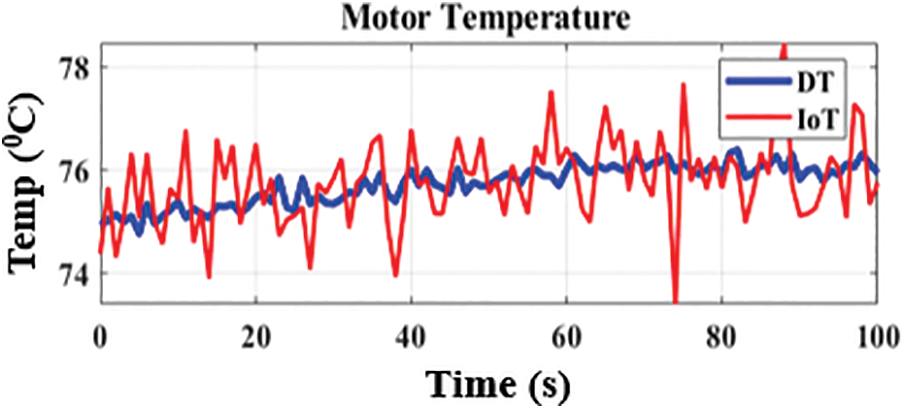

Fig. 8. illustrates a gradual increase in motor temperature from approximately 73°C to 79°C, followed by intermittent declines during low-load or braking periods. The temperature profile validates the embedded first-order thermal model, demonstrating its capability to capture both heating and cooling effects under variable load conditions.

Figure 8: Motor temperature monitoring using IoT and DT

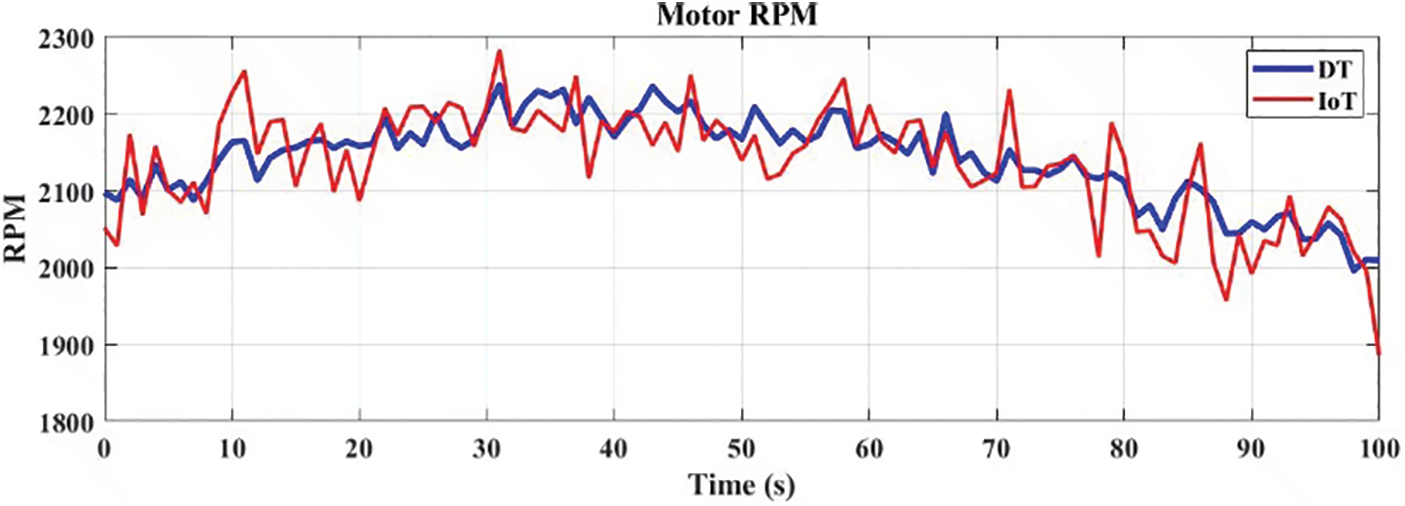

Fig. 9 shows motor RPM remains stable around 2100 rpm with minor fluctuations, correlating with changes in wheel speed. The results affirm DT’s ability to consistently represent rotational dynamics in accordance with the drivetrain parameters and wheel radius.

Figure 9: Motor speed monitoring using IoT and DT

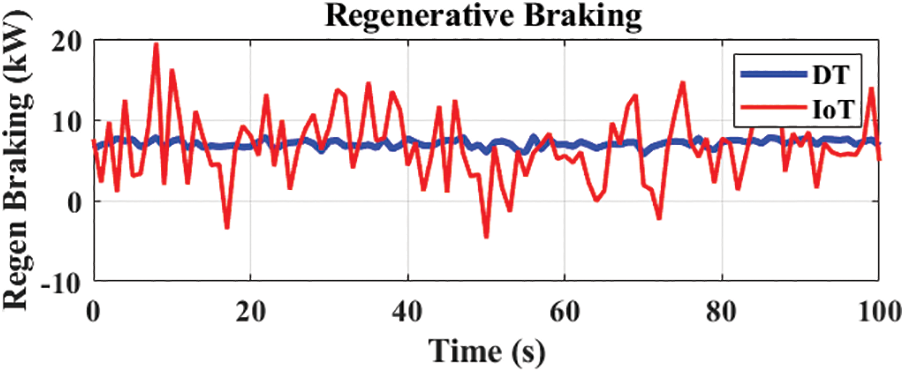

Regenerative braking power as shown in Fig. 10 illustrates oscillates between 5 and 7 kW during deceleration phases, reflecting the controller’s modulation strategy. The DT accurately simulates regenerative energy capture and braking torque distribution, demonstrating its utility for assessing energy recovery systems.

Figure 10: Regenerative breaking monitoring using IoT and DT

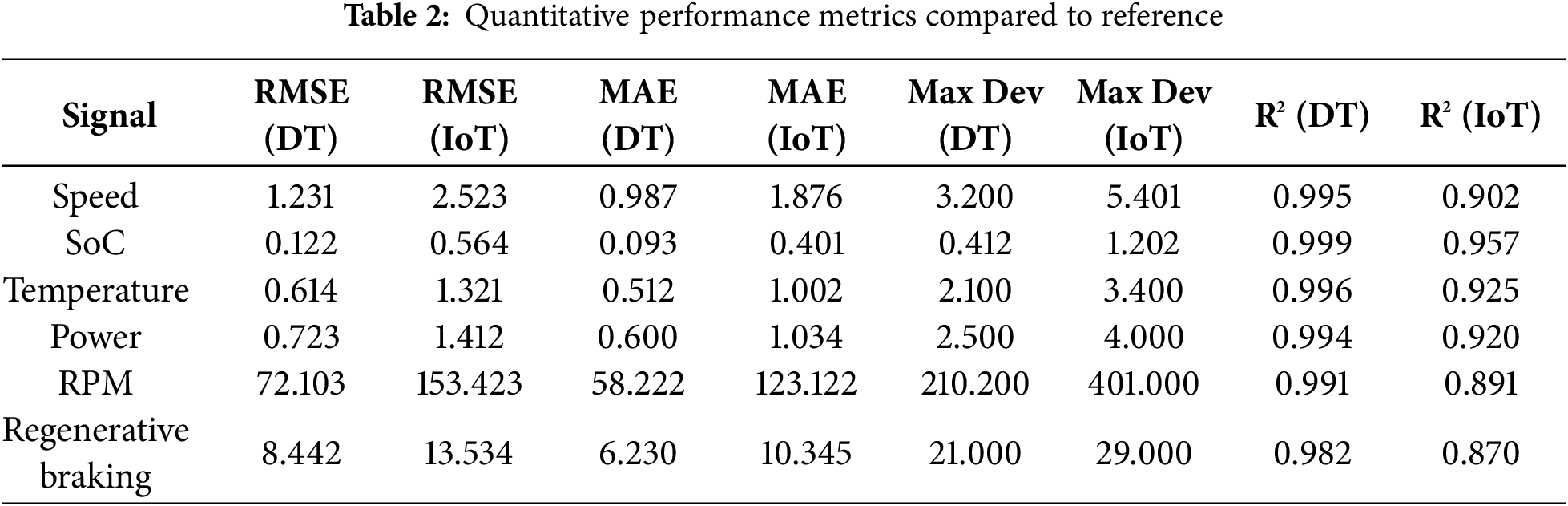

A statistical comparison between the DT outputs and IoT measurements is presented in Table 2, using Root Mean Square Error (RMSE), Mean Absolute Error (MAE), Maximum Deviation, and Coefficient of Determination (R2). The DT consistently outperforms IoT measurements across all metrics.

The above table clearly highlights the improved fidelity of the DT in replicating reference behavior compared to conventional IoT measurements. Notably, the DT achieves SoC estimation with ±1% accuracy, a significant improvement over the ±5% deviation observed in traditional systems.

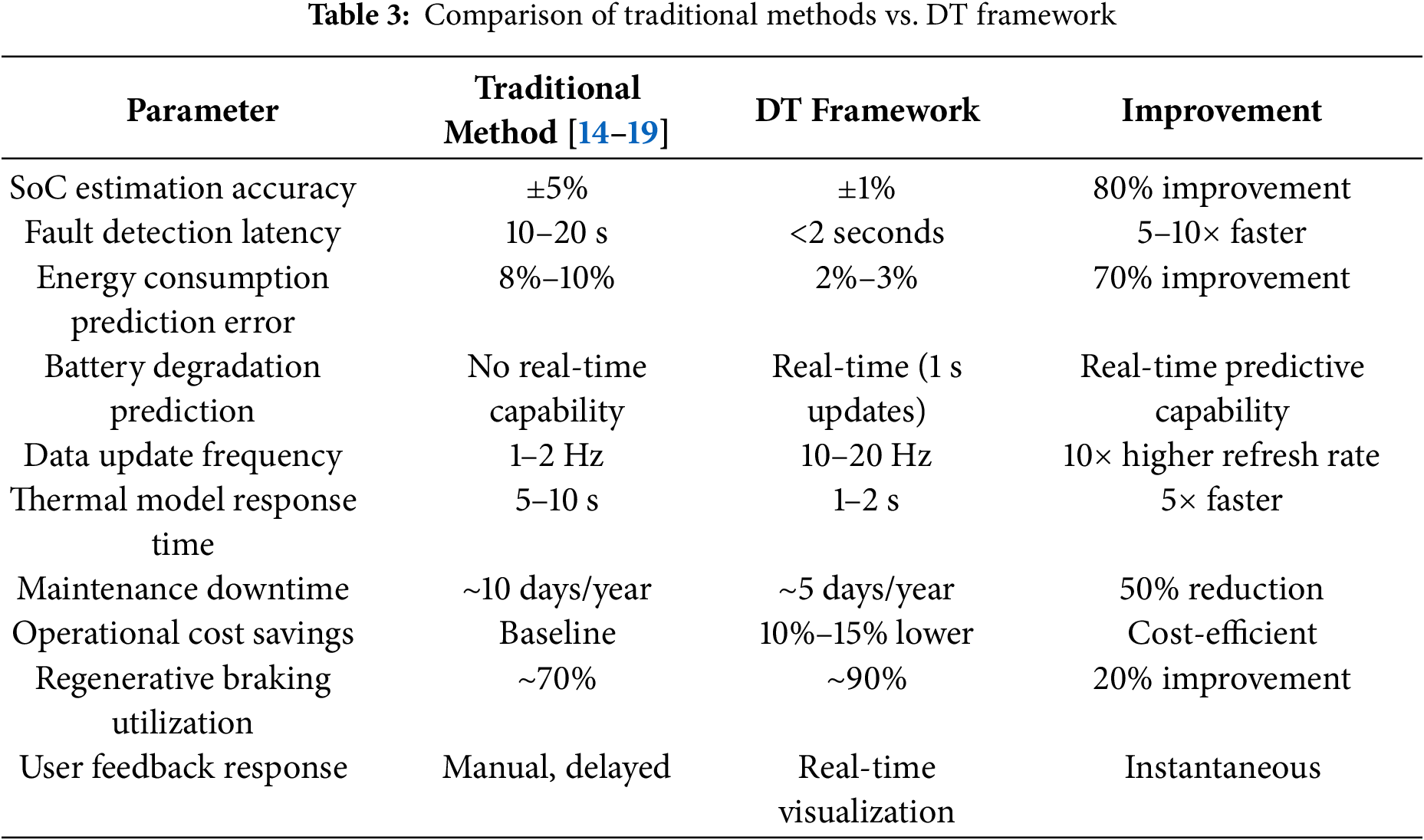

4.7 Comparative Evaluation with Traditional Approaches

To underscore the value of the DT framework, Table 3 presents a comparative analysis of performance indicators relative to traditional EV monitoring and control methods. The DT approach leverages real-time hybrid modeling and higher sampling rates (10–20 Hz), enabling significantly faster fault detection and more accurate predictive modeling.

The simulation and quantitative analysis clearly affirm DT’s capability to replicate real-world EV dynamics with high precision. Compared to conventional methods, the DT offers substantial improvements in estimation accuracy, real-time monitoring, energy recovery, and maintenance planning [20]. These results validate the framework’s potential as a foundation for intelligent energy management, fault diagnostics, and operational optimization in EV systems.

In this work, the following key conclusions and future findings can be drawn from the presented analysis.

Conclusion:

• A comprehensive digital sensor dashboard was developed, combining reference signals, a DT, and IoT-based measurements for key EV parameters including speed, SoC, temperature, power, RPM, and regenerative breaking.

• Simulation results demonstrated that the DT achieved high tracking accuracy, with lower RMSE and smaller maximum deviations compared to conventional IoT sensor data.

• The correlation coefficient (R2) for the DT signals exceeded 0.99 in most cases, confirming its excellent consistency with the reference trajectories.

• By contrast, IoT signals showed larger fluctuations and slightly lower correlation due to measurement noise and uncertainties.

• The DT approach enhances reliability and predictive monitoring capabilities, offering more robust and trustworthy data for EV energy management.

• Overall, the work highlights the clear advantages of integrating DT technology as a complementary enhancement to IoT-based vehicle monitoring systems, supporting safer and more efficient EV operation.

• The proposed DT framework can be enhanced to detect, isolate, and mitigate sensor faults or cyberattacks, thereby improving the resilience and security of EV monitoring systems.

• Incorporating machine learning techniques would enable the DT to continuously recalibrate in response to battery aging, sensor drift, or changing environmental conditions, ensuring long-term accuracy.

Future Scope:

In forward, the proposed digital twin framework can be extended to incorporate fault detection and isolation mechanisms, enhancing system resilience against sensor failures and cyber threats. Integration of machine learning algorithms will enable adaptive calibration in response to battery aging, sensor drift, and environmental changes. Furthermore, predictive maintenance features can be developed to anticipate component failures, thereby minimizing downtime and improving fleet reliability. These enhancements will position the framework as a robust solution for next-generation intelligent EV monitoring systems.

Acknowledgement: Chat GPT has been used to polish the language of the work.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: Conceptualization, J. S. V. Siva Kumar; Methodology, Mahmad Mustafa; Investigation, Sk. M. Unnisha Begum; Formal Analysis, Badugu Suresh; Writing—Original Draft Preparation, J. S. V. Siva Kumar, Mahmad Mustafa; Writing—Review and Editing, Sk. M. Unnisha Begum, Rajanand Patnaik Narasipuram; Visualization, Badugu Suresh; Supervision, Rajanand Patnaik Narasipuram. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Not applicable.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

Nomenclature

| DT | Digital Twin |

| EV | Electric Vehicle |

| GUI | Graphical User Interface |

| IoT | Internet of Things |

| MAE | Mean Absolute Error |

| R2 | Coefficient of Determination |

| RMSE | Root Mean Square Error |

| RPM | Revolutions Per Minute |

| SoC | State of Charge |

| SoH | State of Health |

| WSN | Wireless Sensor Network |

References

1. Khan MYA, Liu H, Zhang Y, Wang J. Hybrid AC/DC microgrid: systematic evaluation of interlinking converters, control strategies, and protection schemes: a review. IEEE Access. 2024;12(1):160097–132. doi:10.1109/access.2024.3485001. [Google Scholar] [CrossRef]

2. Karneddi H, Ronanki D, Rodriguez J. Universal integrated onboard charger with model predictive current control for plug-in EV charging. IEEE Trans Power Electron. 2025;40(1):28–33. doi:10.1109/TPEL.2024.3428855. [Google Scholar] [CrossRef]

3. L NRPV, Lavanya V, Manasa D, Boggavarapu S, Soni BP. Battery models and estimation techniques for energy storage systems in residential buildings. J Mod Technol. 2024;1(1):47–58. doi:10.71426/jmt.v1.i1.pp47-58. [Google Scholar] [CrossRef]

4. Shen Y, Li M, Zhou Y. Enhancing shared mobility via connected vehicle-driven dispatch and dynamic pricing. Comput Electr Eng. 2025;123(2):110010. doi:10.1016/j.compeleceng.2024.110010. [Google Scholar] [CrossRef]

5. Zearban M, Abdelaziz M, Abdelwahab M. The temperature effect on electric vehicle’s lithium-ion battery aging using machine learning algorithm. Eng Proc. 2024;70(1):53. doi:10.3390/engproc2024070053. [Google Scholar] [CrossRef]

6. Fesakis N, Falekas G, Palaiologou I, Lazaridou GE, Karlis A. Integration and optimization of multisource electric vehicles: a critical review of hybrid energy systems, topologies, and control algorithms. Energies. 2024;17(17):4364. doi:10.3390/en17174364. [Google Scholar] [CrossRef]

7. Iqubal M, Pratap B, Sathiyan P, Stonier AA, Vanaja DS, Peter G, et al. A modular multiport Landsman converter-driven hybrid EV charging station with adaptive power management system. Comput Electr Eng. 2024;118(1):109422. doi:10.1016/j.compeleceng.2024.109422. [Google Scholar] [CrossRef]

8. Deng S, Wang J, Tao L, Zhang S, Sun H. EV charging load forecasting model mining algorithm based on hybrid intelligence. Comput Electr Eng. 2023;112(6):109010. doi:10.1016/j.compeleceng.2023.109010. [Google Scholar] [CrossRef]

9. Bazmohammadi N, Madary A, Vasquez JC, Mohammadi HB, Khan B, Wu Y, et al. Microgrid digital twins: concepts, applications, and future trends. IEEE Access. 2022;10(3):2284–302. doi:10.1109/access.2021.3138990. [Google Scholar] [CrossRef]

10. Mchirgui N, Quadar N, Kraiem H, Lakhssassi A. The applications and challenges of digital twin technology in smart grids: a comprehensive review. Appl Sci. 2024;14(23):10933. doi:10.3390/app142310933. [Google Scholar] [CrossRef]

11. Ibrahim MK, Sajid A, Ullah I, Ali T, Ayaz M, Aggoune EM. Artificial neural fuzzy inference rule-based (ANFIS) model for offloading tasks for edge, cloud, and UAVs environment. IEEE Internet Things J. 2024;12:154443–54. doi:10.1109/access.2024.3483656. [Google Scholar] [CrossRef]

12. Vadde A, Praveen LS, Kolhar P, Kruthika BS, Megha, Sindhu V.Investigation on optimal distance between transmitter and receiver coils in wireless power transfer for dynamic charging system. J Mod Technol. 2025;2025:235–45. doi:10.71426/jmt.v2.i1.pp235-245. [Google Scholar] [CrossRef]

13. The MathWorks Inc. MATLAB and simulink release 2018a. Natick, MA, USA. [cited 2025 Aug 1]. Available from: https://www.mathworks.com. [Google Scholar]

14. Tabassum S, Bharathi M, Peramasani N, Nagadivya N, Busetty B, Syed AS. Enhancing IoT-enabled electric vehicle battery performance monitoring and prediction using AI techniques. In: 2025 International Conference on Intelligent and Innovative Technologies in Computing, Electrical and Electronics (IITCEE); 2025 Jan 16–17; Bangalore, India. p. 1–6. doi:10.1109/IITCEE64140.2025.10915493. [Google Scholar] [CrossRef]

15. Yue J, Liu Z, Su H. Robust voltage regulation in dynamic wireless EV charging systems via dual-frequency oscillation suppression. IEEE Trans Ind Electron. 2025;72(6):6474–84. doi:10.1109/TIE.2024.3503636. [Google Scholar] [CrossRef]

16. Yalavarthy URS, Kumar NB, Babu ARV, Narasipuram RP, Padmanaban S. Digital twin technology in electric and self-navigating vehicles: readiness, convergence, and future directions. Energy Convers Manag X. 2025;26(3):100949. doi:10.1016/j.ecmx.2025.100949. [Google Scholar] [CrossRef]

17. Zeng Y, Zhang Q, Iu HHC, Yu H, Liu Y, Guo H, et al. Distributed economic coordination controller for parallel DC-DC converters in shipboard DC microgrids based on prescribed-time consensus observer. IEEE Trans Power Electron. 2025;40(1):2495–512. doi:10.1109/TPEL.2024.3459942. [Google Scholar] [CrossRef]

18. Wang C, Bian J, Yuan R. Reactive power optimization model of active distribution network with new energy and electric vehicles. Energy Eng. 2025;122(3):985–1003. doi:10.32604/ee.2025.059559. [Google Scholar] [CrossRef]

19. Vijay Babu AR, Bharath Kumar N, Patnaik Narasipuram R, Periyannan S, Hosseinpour A, Flah A. Solar energy forecasting using machine learning techniques for enhanced grid stability. IEEE Access. 2025;13(9):93735–54. doi:10.1109/access.2025.3574093. [Google Scholar] [CrossRef]

20. Narasipuram RP, Pasha MM, Tabassum S, Tandon AS. The electric vehicle surge: effective solutions for charging challenges with advanced converter technologies. Energy Eng. 2025;122(2):431–69. doi:10.32604/ee.2025.055134. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools